Method and system for comprehensive utilization of copper tailings and converter coarse dust ash

A technology for coarse dust removal and copper tailings, applied in the field of metallurgy, can solve problems such as increased energy consumption, increased slag volume, and reduced iron content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

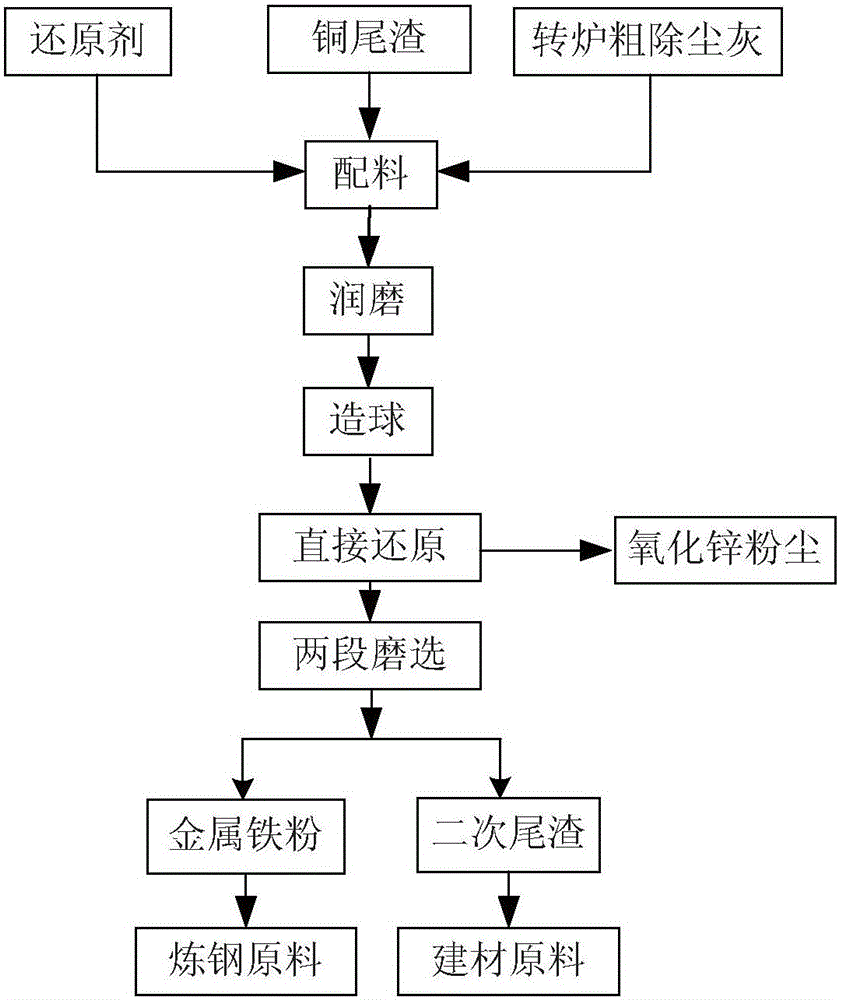

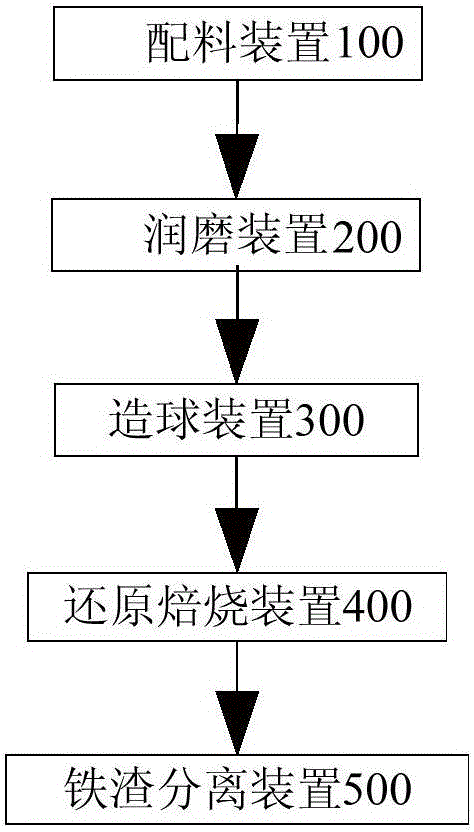

[0070] refer to figure 1 and 2 19wt% of the coarse dust removal of the converter, 19wt% of the coarse dust removal of the coal powder, 18wt% of the coal dust, and the balance of copper tailings are mixed uniformly in proportion in the batching device 100 to form a mixture, and the wet grinding device 200 Wetting and milling for 3 minutes, the particle size of the mixture is 0.074 mm or less, accounting for 91 wt%, and then it is made into pellets through the pelletizing device 300, and dried for later use. The pellets are evenly distributed into the reduction roasting device 400, the temperature in the furnace is 1200-1240°C, and the reduction time is 39 minutes to obtain metallized pellets and zinc oxide dust; then the obtained roasted products are crushed and subjected to two-stage grinding and Two-stage magnetic separation (the proportion of the first-stage grinding fineness below 0.074mm accounts for 70-75wt%, the magnetic field strength of the first-stage magnetic separa...

Embodiment 2

[0072] refer to figure 1 and 2 22wt% of the rough dust removal of the converter, copper tailings, semi-coke, 18wt% of the coarse dust removal of the converter, and 18wt% of the semi-coke, and the balance is that the copper tailings are mixed uniformly in proportion in the batching device 100 to form a mixture, and the wet grinding device 200 Wetting and milling for 5 minutes, the particle size of the mixture is below 0.074mm, accounting for 93%, and then pelletizing device 300 is used to make pellets, and dried for later use. Evenly distribute the pellets into the reduction roasting device 400, the temperature in the furnace is 1200-1250°C, and the reduction time is 42 minutes to obtain metallized pellets and zinc oxide dust; then the obtained roasted products are crushed and then subjected to two-stage grinding and Two-stage magnetic separation (the proportion of the first-stage grinding fineness below 0.074mm accounts for 70-75wt%, the magnetic field strength of the first-s...

Embodiment 3

[0074] refer to figure 1 and 2 , the mixture of pulverized coal and semi-coke mass ratio of 1: 1, coarse dust removal of converter, copper tailings, 16wt% of the mixture of pulverized coal and semi-coke mass ratio of 1: 1, coarse dust removal of converter 25wt%, remaining The amount is that the copper tailings are uniformly mixed in proportion in the batching device 100 to form a mixture, and the grinding device 200 is used to moisten and grind for 7 minutes. The particle size of the mixture is 0.074 mm or less, accounting for 95 wt%, and then the pelletizing device 300 is made into pellets. Dry and set aside. Evenly distribute the pellets into the reduction roasting device 400, the temperature in the furnace is 1210-1260°C, and the reduction time is 40 minutes to obtain metallized pellets and zinc oxide dust; then the obtained roasted products are crushed and then subjected to two-stage grinding and Two-stage magnetic separation (the proportion of the first-stage grinding f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com