Apparatus for preparing low-tar fuel gas through combining gasification and dry distillation

A technology of combined gasification and gas equipment, which is applied in the manufacture of combustible gas, gasification process, special form of dry distillation, etc., can solve the problems of unreasonable utilization of gas sensible heat, high coke and dust content of gas, and low thermal efficiency of the system , to achieve the effect suitable for large-scale production and easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

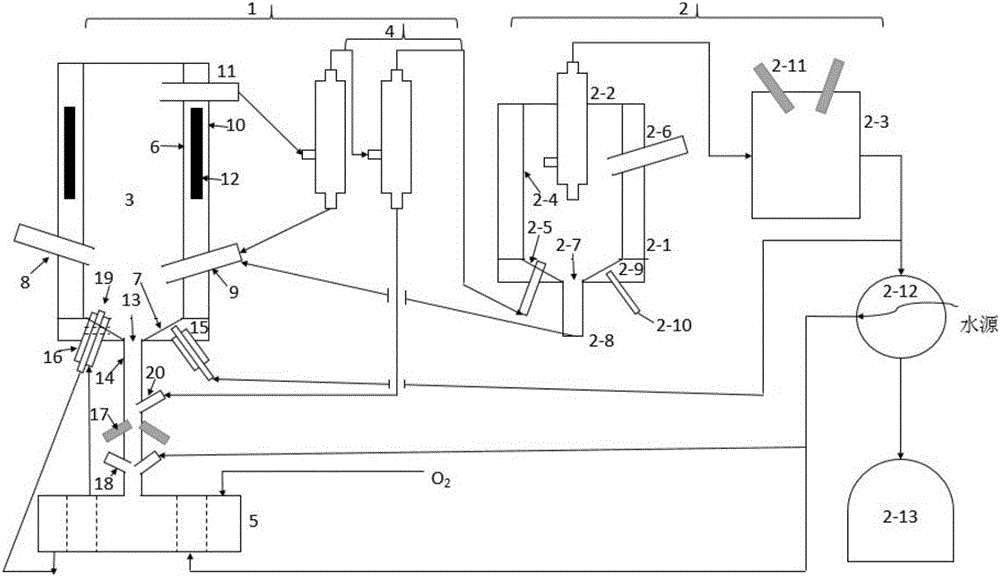

[0032]Embodiment 1: Raw coal (brown coal, anthracite or long-flame coal) moisture content is 6-10wt% after drying treatment, and the raw coal after dehydration is through pulverizing, sieves and separates the pulverized coal A that is greater than 10mm and is less than 16mm and 4- 10mm crushed coal B, mixed with a catalyst to form a mixed coal C, wherein the catalyst is an alkali metal or alkaline earth metal catalyst, the mass ratio of the crushed coal B to the catalyst is 80-200:1, and the mixed coal C passes through the fluidized bed The coal material inlet 8 of the gasification furnace 3 is sent into the fluidized bed gasifier, and the preheated gasification agent (oxygen and steam) passes through the gasification agent inlet pipe 16 and passes through the conical distribution below the coal material inlet 8 in the furnace. The pores on the plate 7 and the nozzles 19 penetrating through the conical distribution plate 7 are fed into the hearth of the fluidized bed gasifier 3...

Embodiment 2

[0033] Embodiment 2: The method for preparing low-tar fuel gas by combined gasification and dry distillation in this embodiment is the same as the method used in Embodiment 1. The difference is that the crushed coal B is directly passed through the coal material of the fluidized bed gasifier 3 The inlet 8 is sent into the fluidized bed gasifier for non-catalytic gasification, and the gasification temperature is controlled at 830-1150°C. After testing, the carbon content in the slag collection device 5 is less than 3.85wt%, the tar content of the gas that has not been treated by the synthesis gas gas processor 2-3 is greater than 1378ppm, and the tar content of the gas in the gas buffer storage tank (2-13) is less than 4.8 ppm, the dust content of solid particles is less than 7.8mg / Nm 3 , the coal processing capacity is greater than 180 tons / d, the thermal efficiency of the system is greater than 82%, and the system has not shut down due to tar blocking the filter element for 2...

Embodiment 3

[0034] Example 3: The method for preparing low-tar fuel gas by combined gasification and carbonization in this example is different from the method used in Example 1. The difference is that the gas-solid separator 2- 2 External, that is, connected to the top gas outlet of the fluidized bed retort furnace through a pipeline, the length of the connecting pipeline is 0.3-0.6m; other process parameters are the same as in Example 1, and the system has been running continuously for 13 months due to tar blockage of the filter element. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com