Patents

Literature

161 results about "Gas processor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

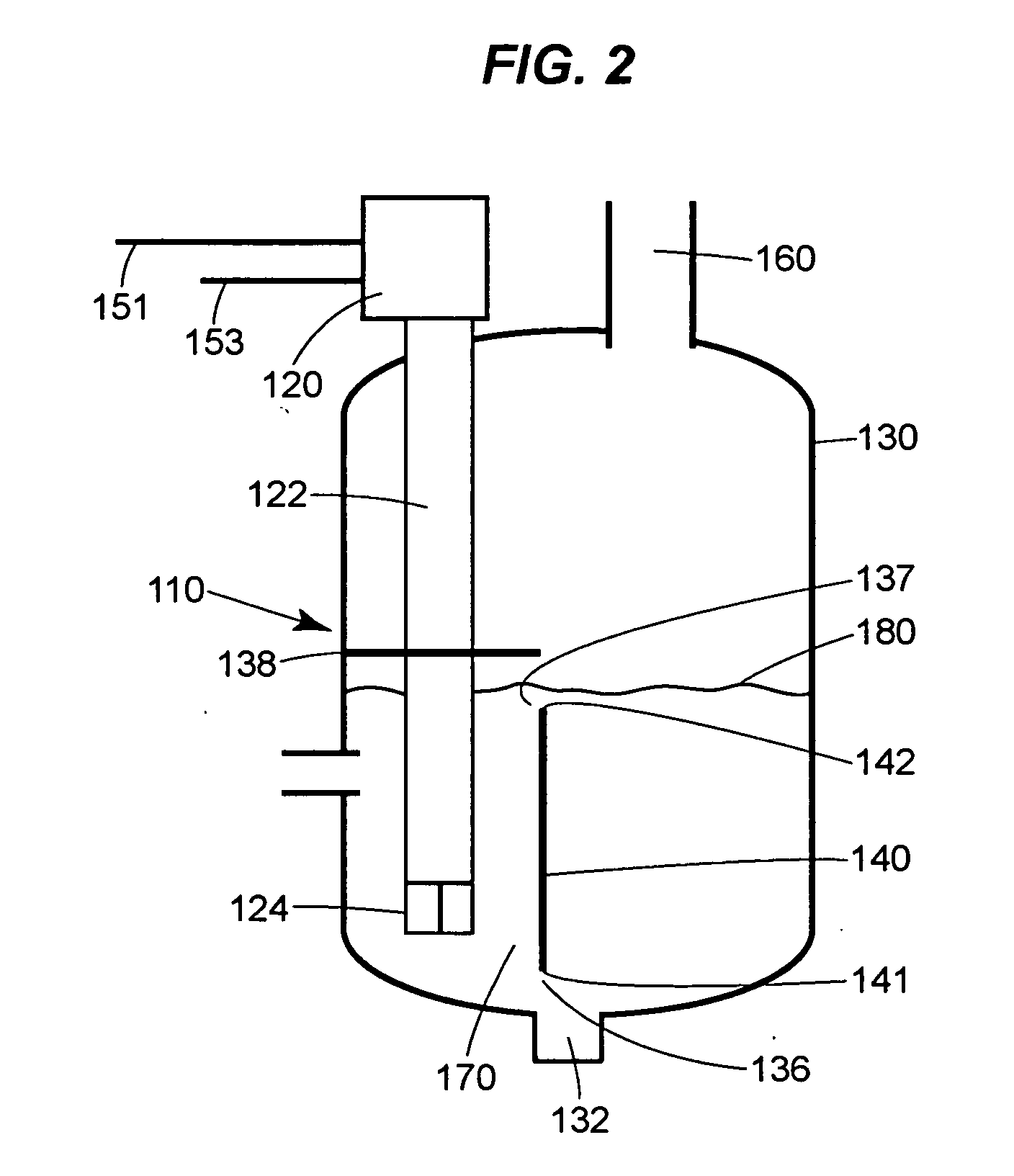

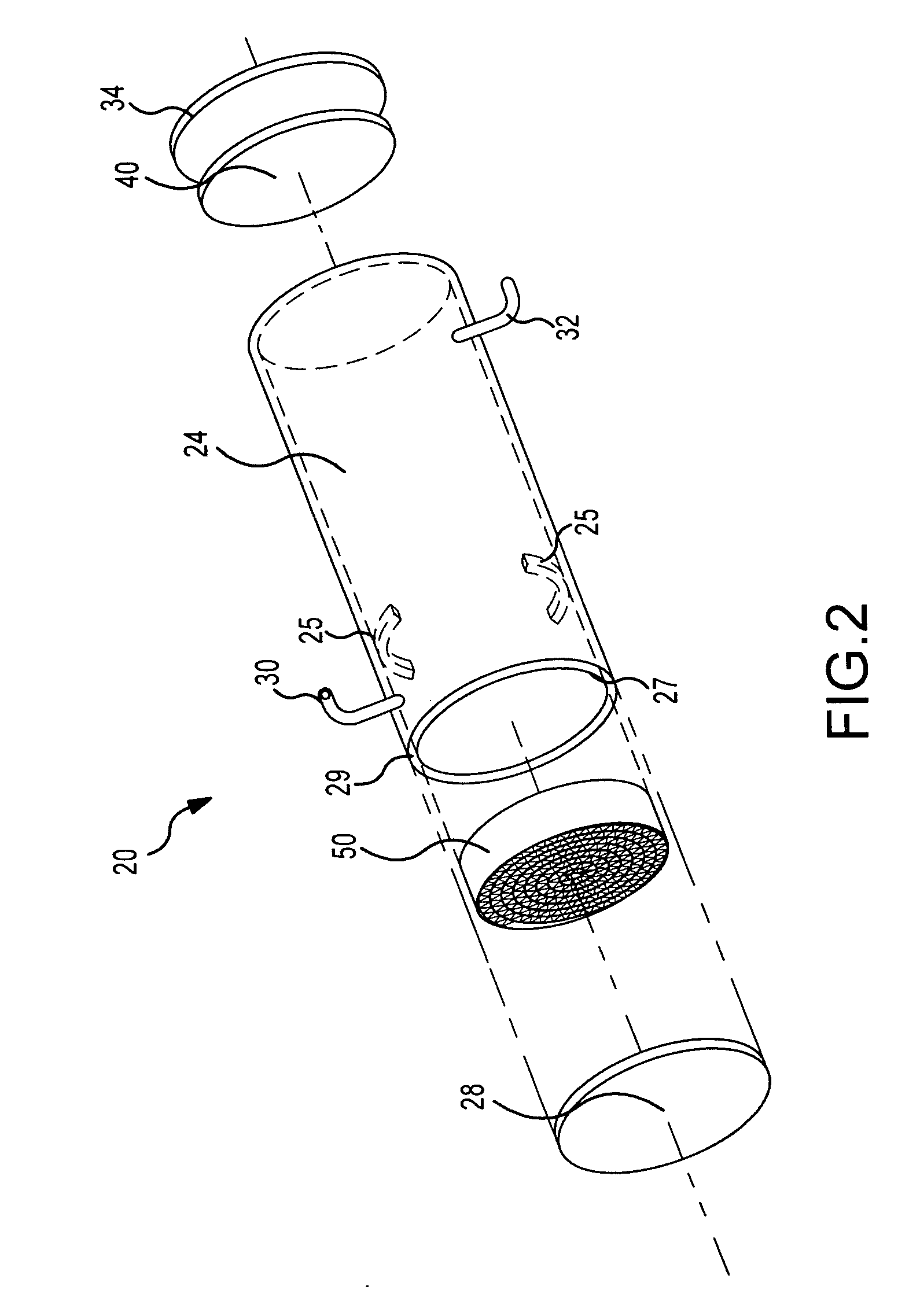

Submerged gas evaporators and reactors

ActiveUS7416172B2Increased turbulenceEnhanced mixing processCarburetting airUsing liquid separation agentChemical reactionHigh rate

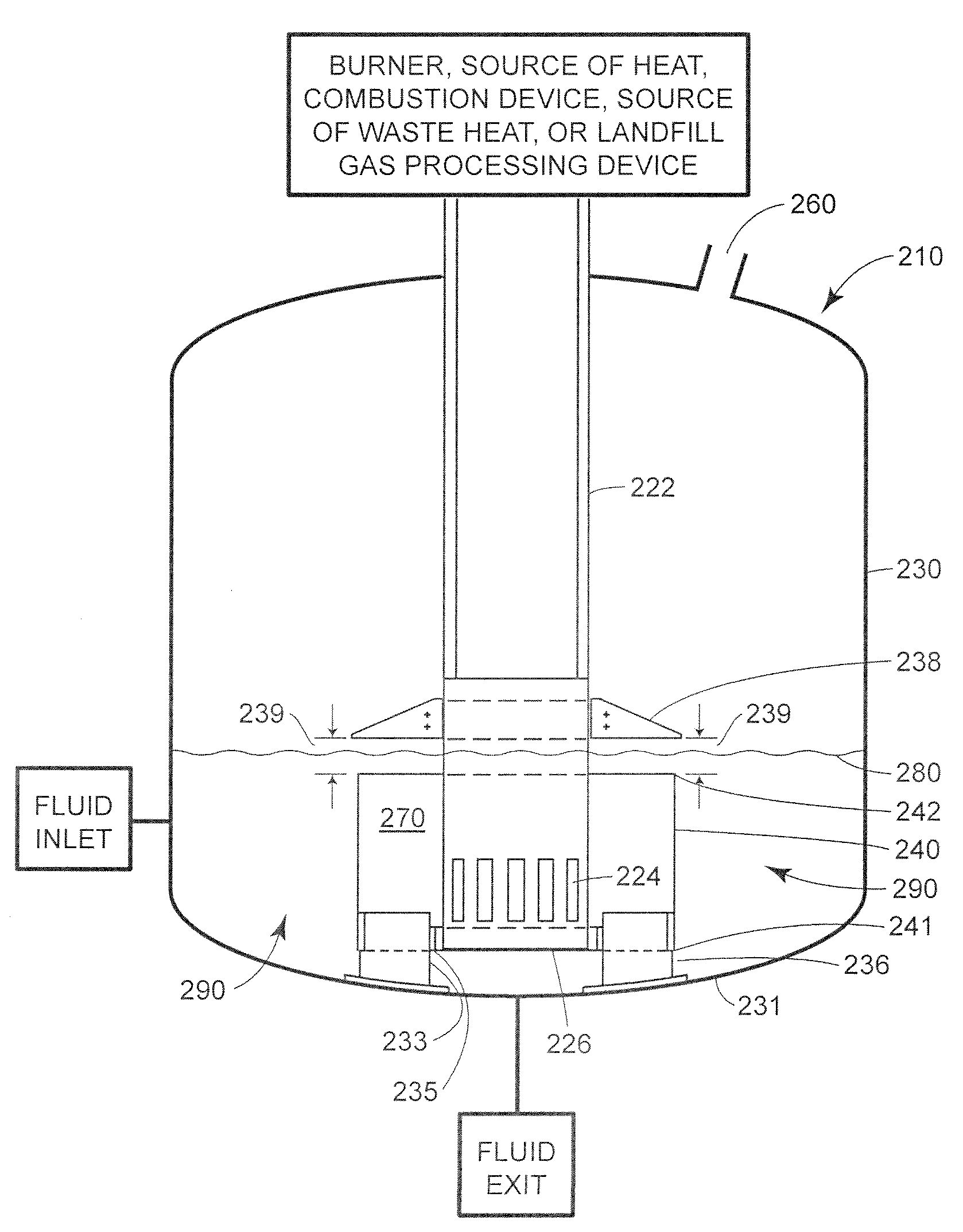

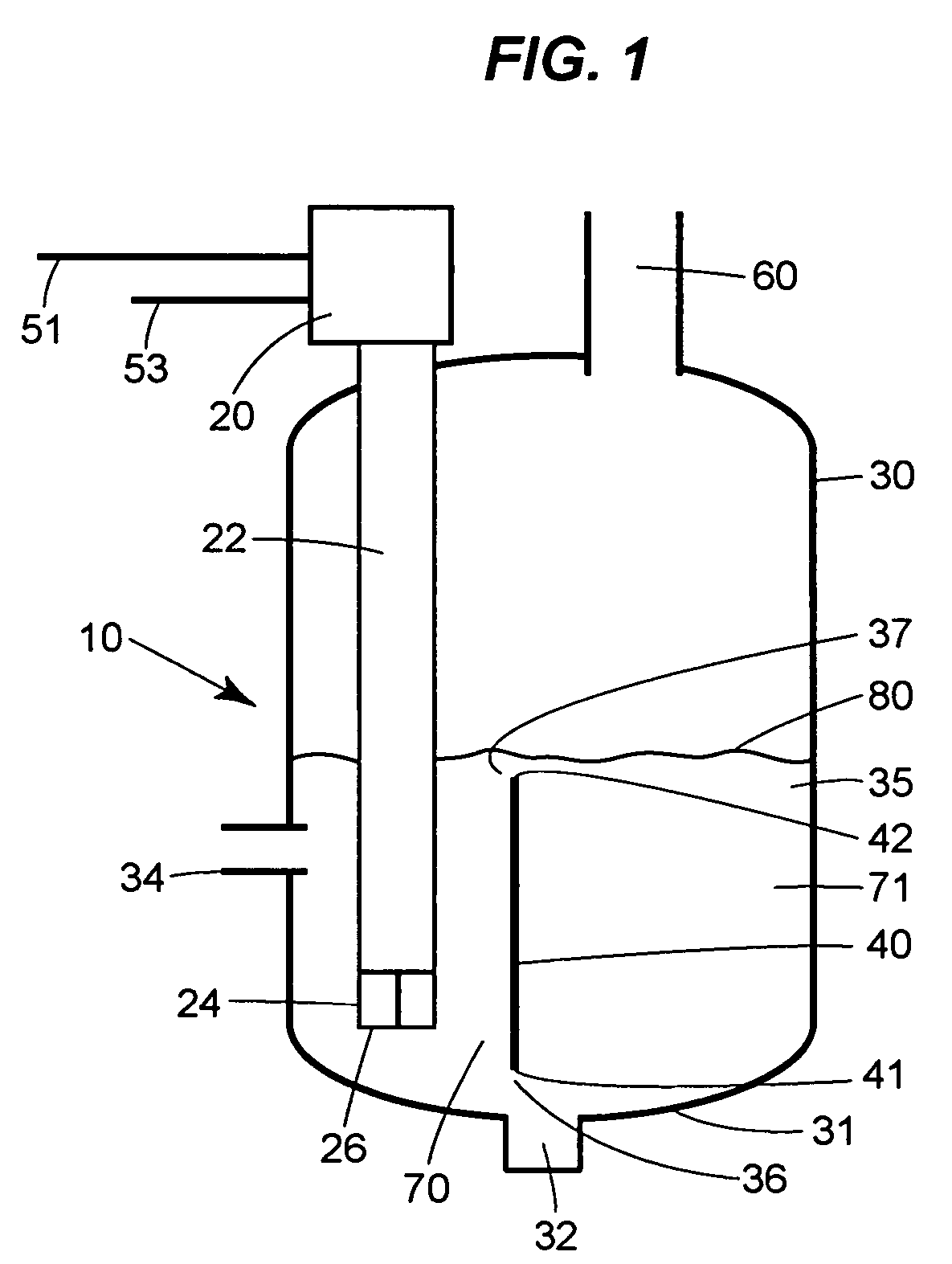

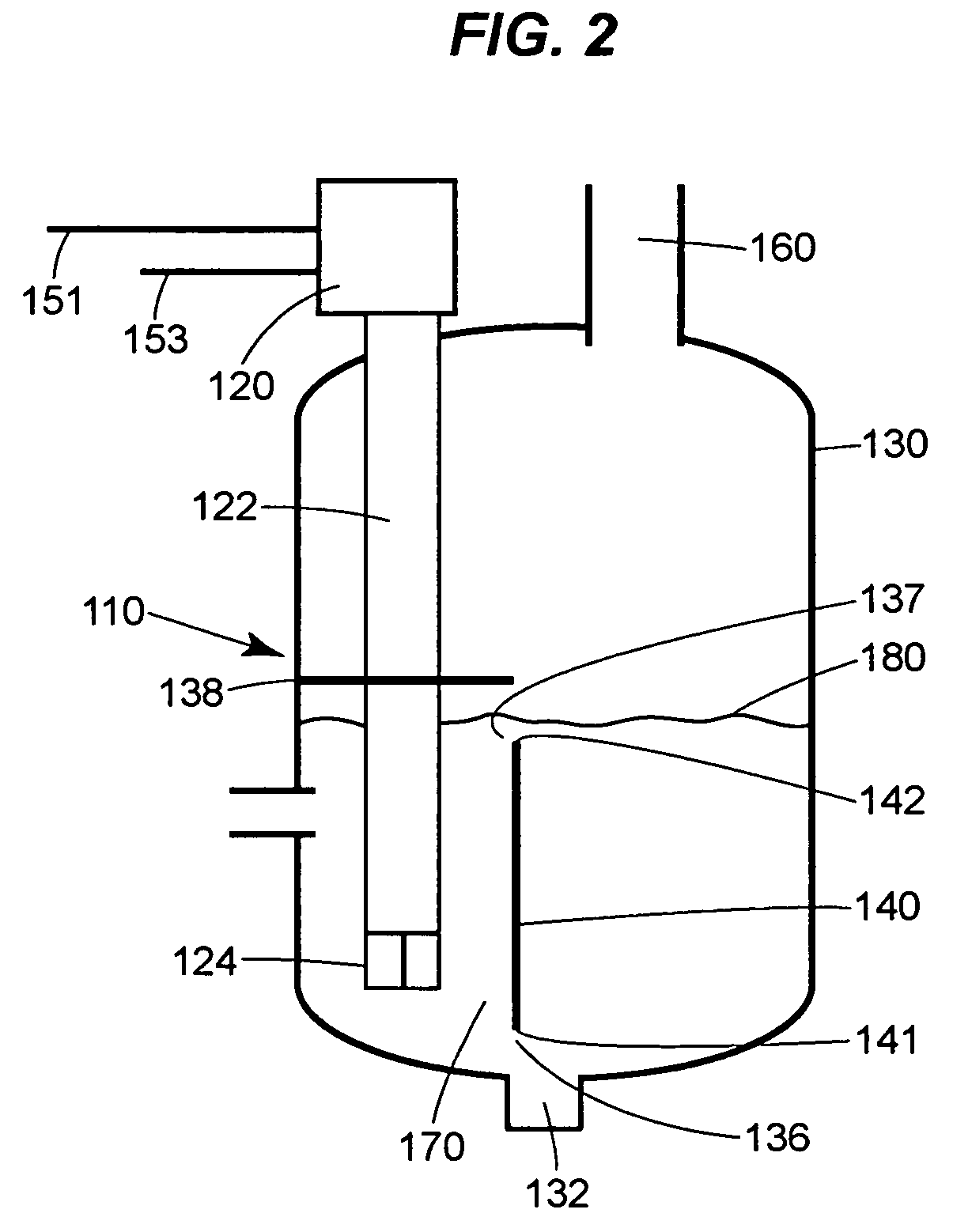

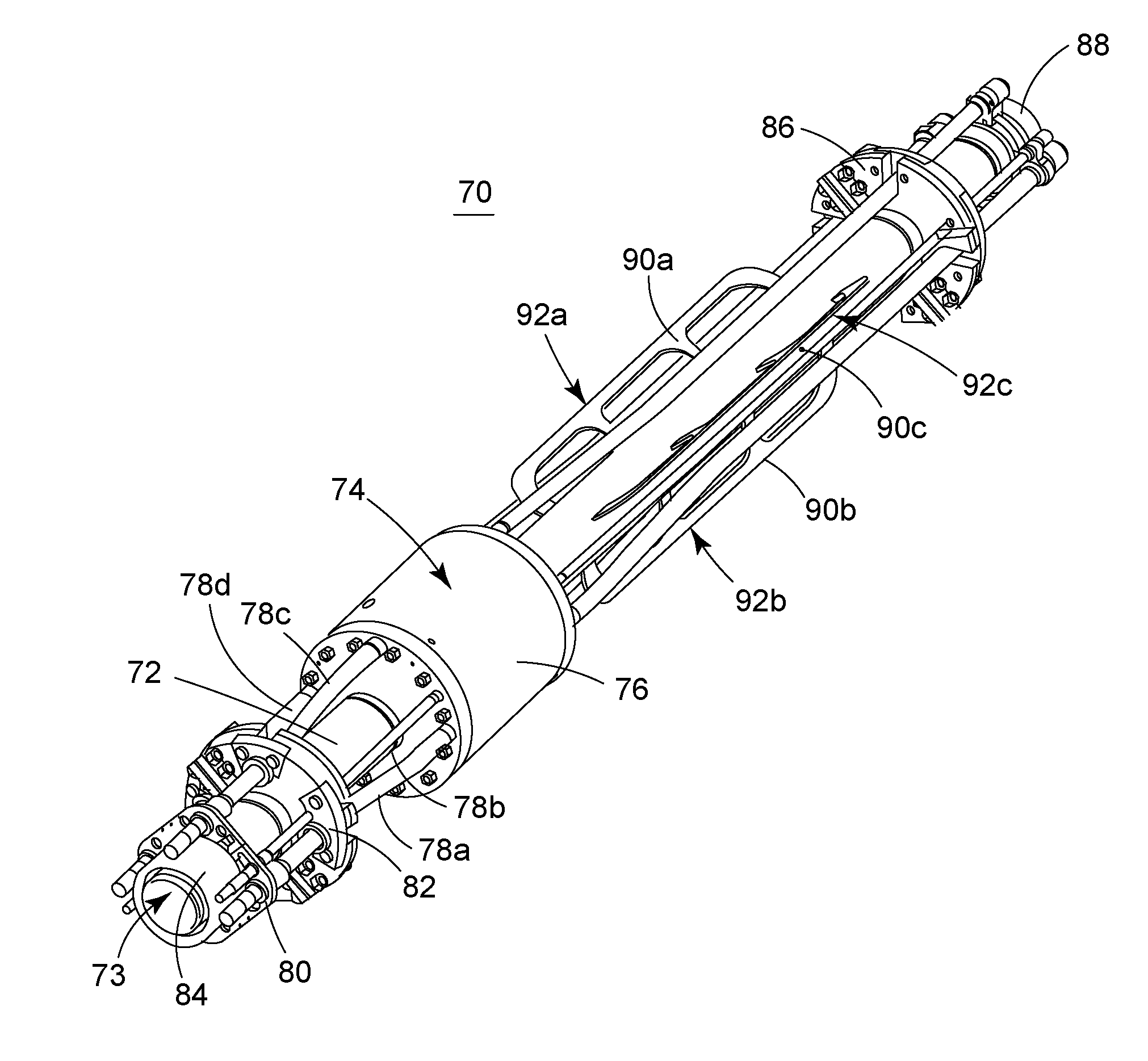

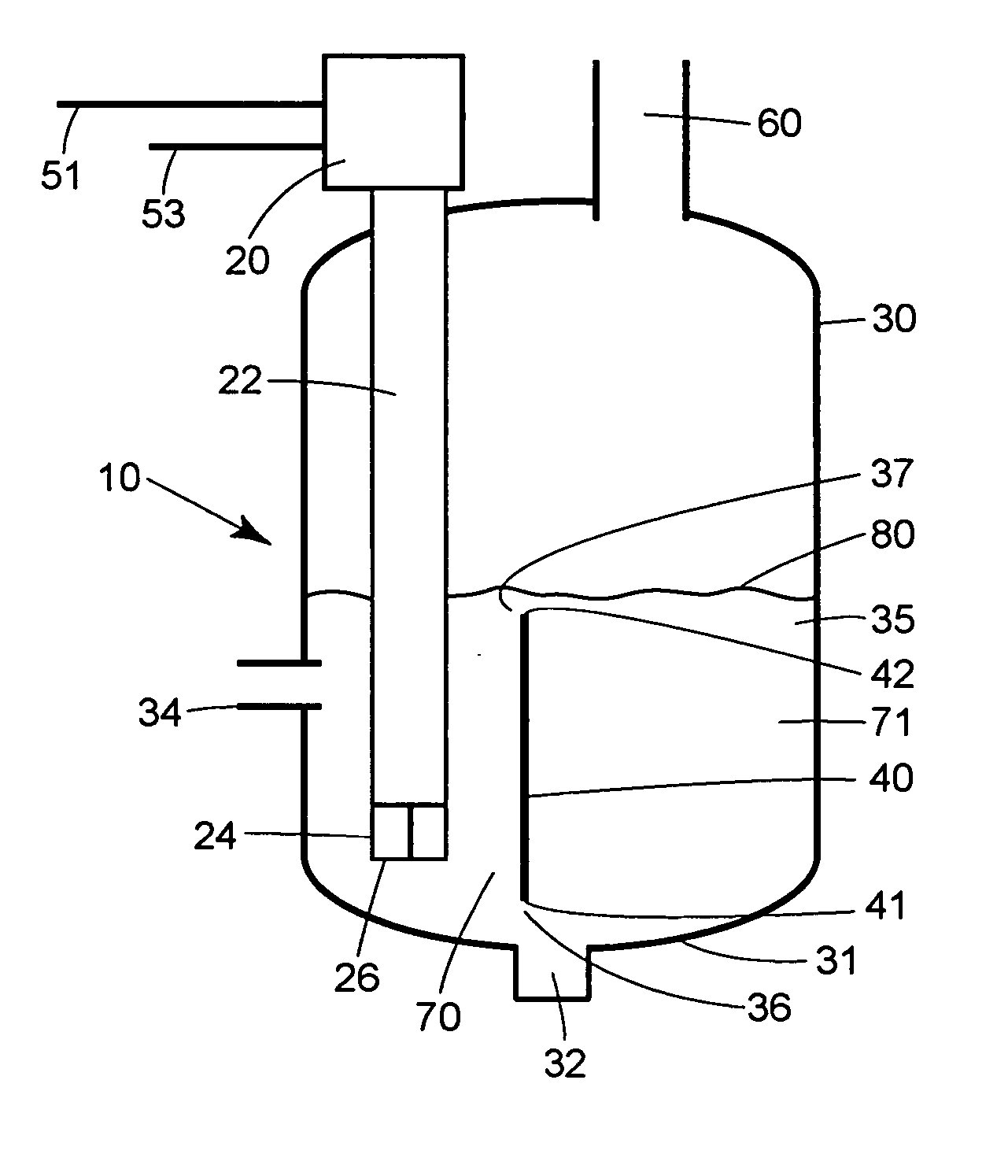

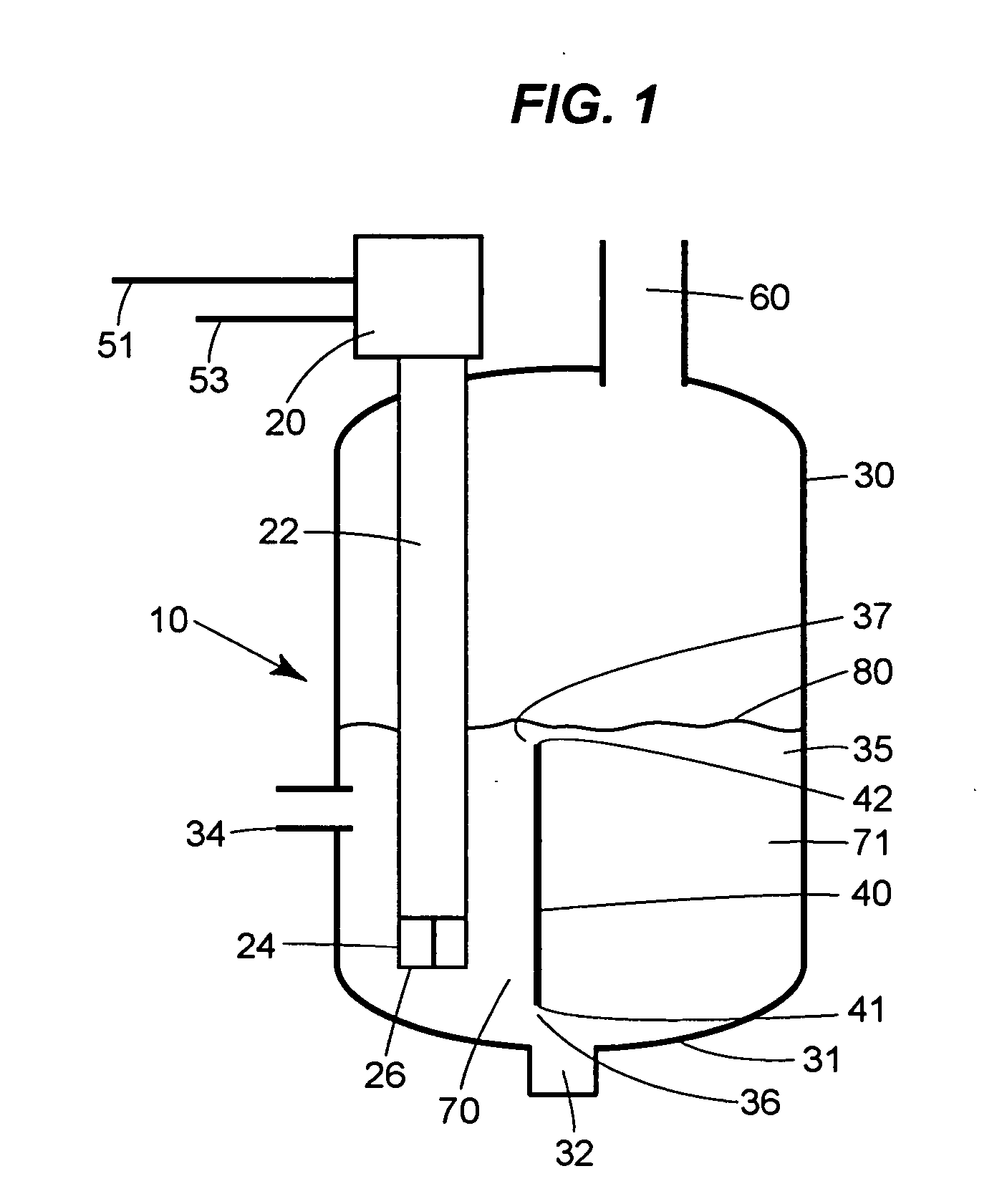

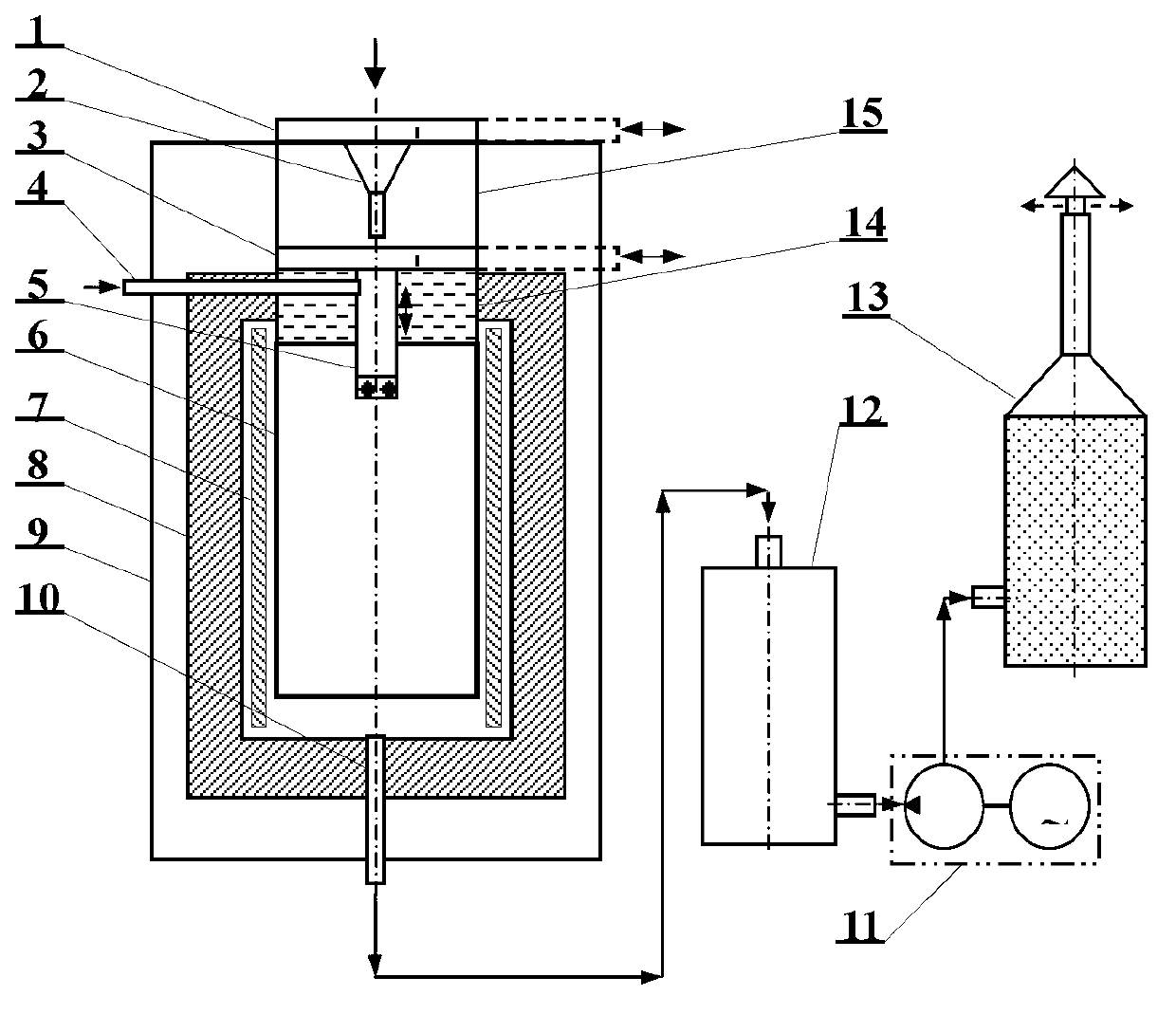

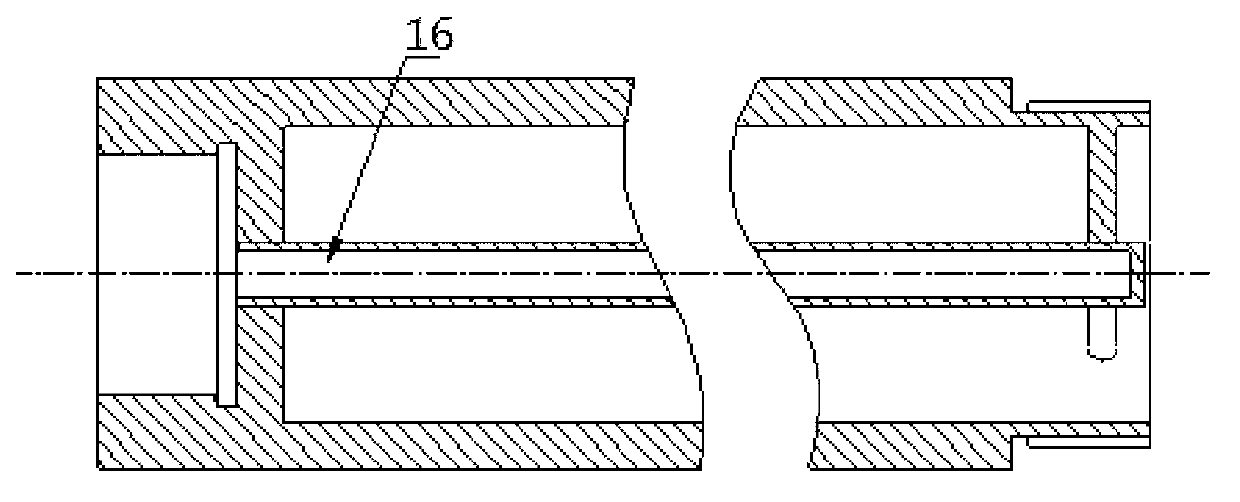

A submerged gas processor in the form of an evaporator or a submerged gas reactor includes a vessel, a gas delivery tube partially disposed within the vessel to deliver a gas into the vessel and a process fluid inlet that provides a process fluid to the vessel at a rate sufficient to maintain a controlled constant level of fluid within the vessel. A weir is disposed within the vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the vessel and a second fluid circulation path between a second weir end and an upper end of the vessel. During operation, gas introduced through the tube mixes with the process fluid and the combined gas and fluid flow at a high rate with a high degree of turbulence along the first and second circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the process fluid. This turbulent flow develops a significant amount of interfacial surface area between the gas and the process fluid resulting in a reduction of the required residence time of the gas within the process fluid to; achieve thermal equilibrium and / or to drive chemical reactions to completion, all of which leads to a more efficient and complete evaporation, chemical reaction, or combined evaporation and chemical reaction process.

Owner:SHAW INTPROP HLDG INC

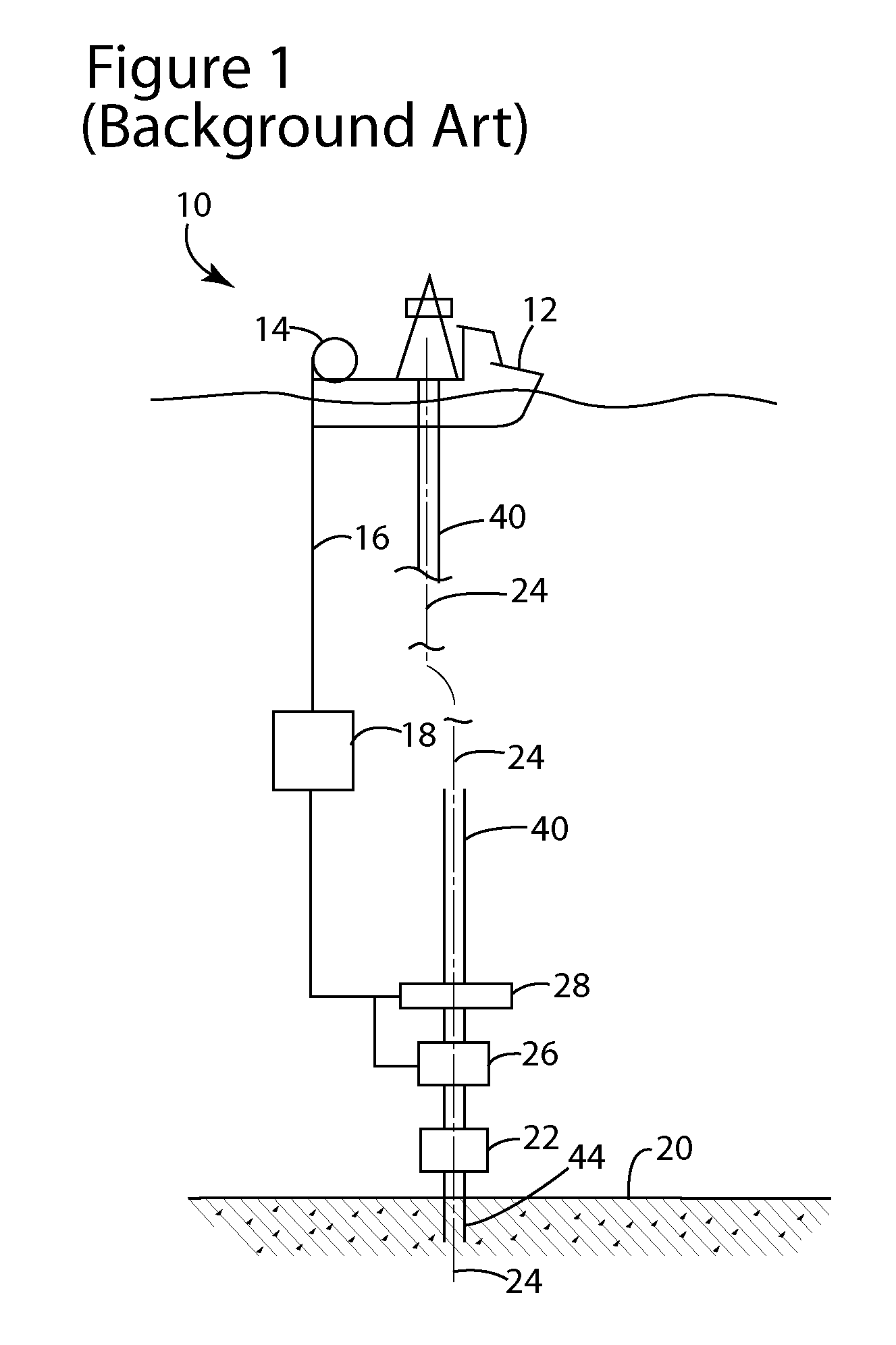

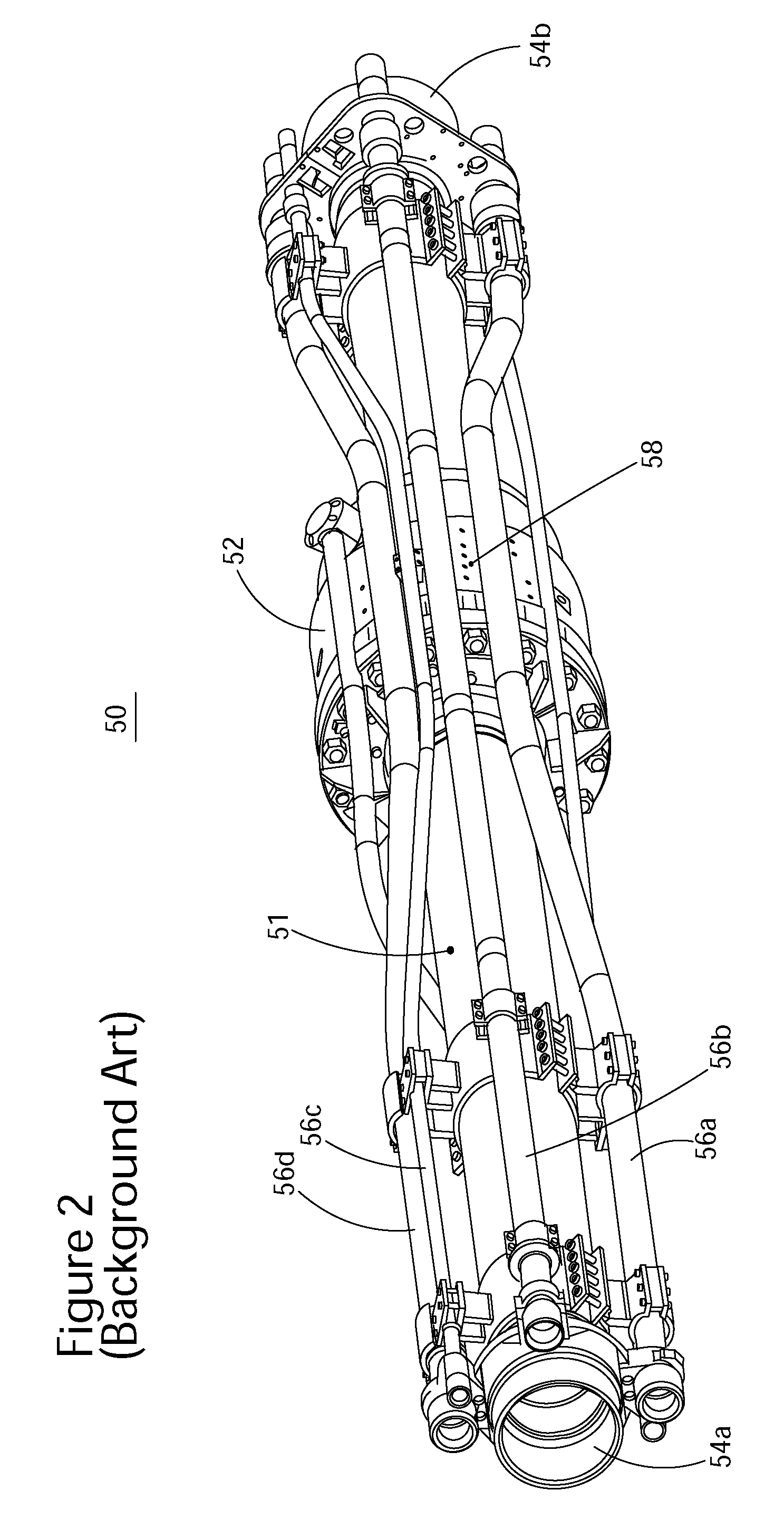

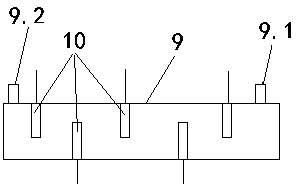

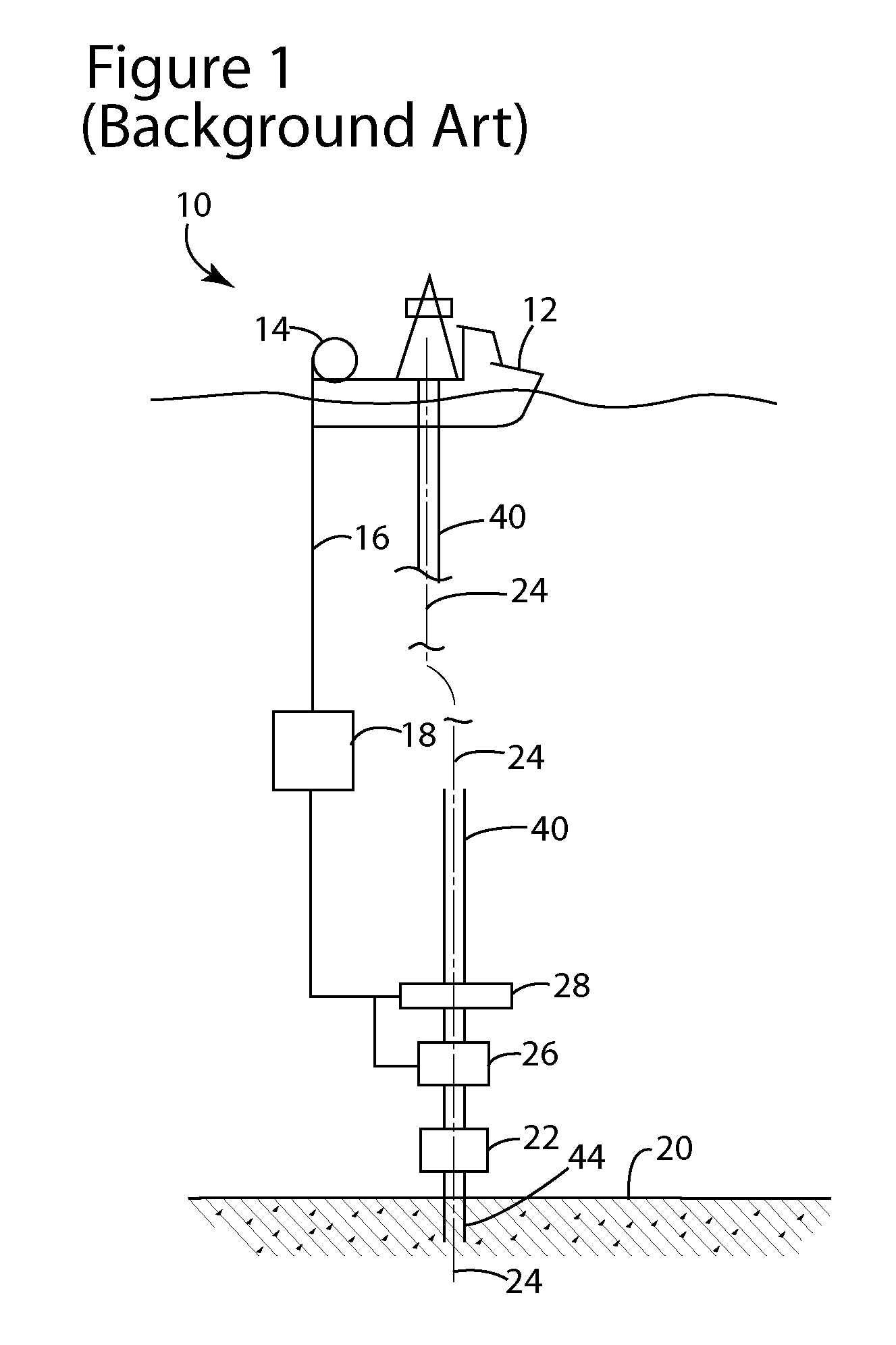

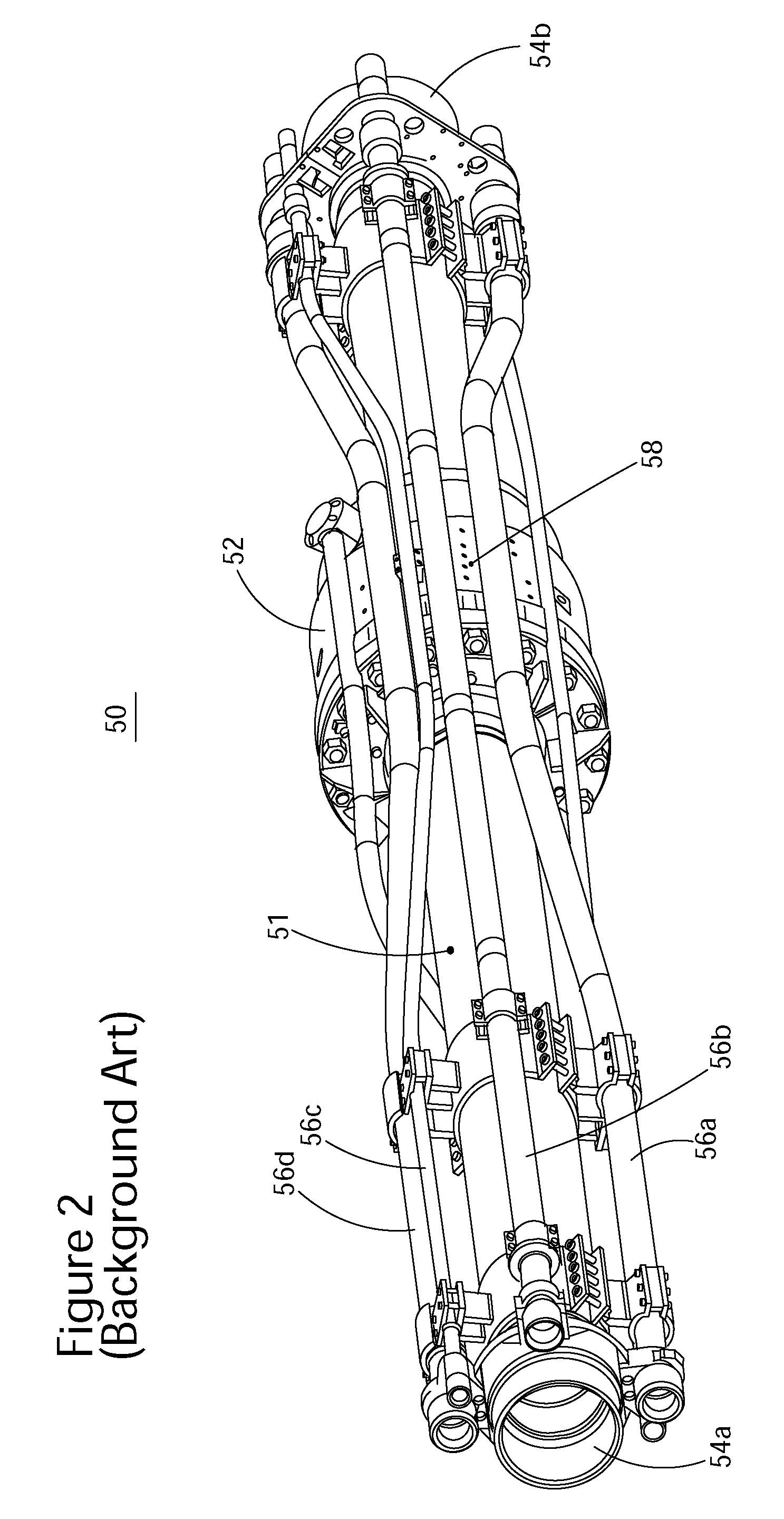

Gas handler, riser assembly, and method

Method, riser assembly and gas handler for diverting gas from a riser. The riser assembly includes a riser having a first end and a second end and a conduit extending from the first end to the second end; a gas handler connected to the riser and provided between the first end and the second end, the gas handler having an external casing; plural pipes attached to an outside of the riser such that at least one pipe of the plural pipes enters through the external casing; and a gas vent pipe configured to start at the gas handler and extend towards the second end of the riser and the gas vent pipe is further configured to divert a gas from the gas handler through the outside of the riser.

Owner:HYDRIL USA DISTRIBUTION LLC

Submerged gas evaporators and reactors

ActiveUS20070114683A1Increased turbulenceEnhanced mixing processCarburetting airMixing methodsChemical reactionHigh rate

A submerged gas processor in the form of an evaporator or a submerged gas reactor includes a vessel, a gas delivery tube partially disposed within the vessel to deliver a gas into the vessel and a process fluid inlet that provides a process fluid to the vessel at a rate sufficient to maintain a controlled constant level of fluid within the vessel. A weir is disposed within the vessel adjacent the gas delivery tube to form a first fluid circulation path between a first weir end and a wall of the vessel and a second fluid circulation path between a second weir end and an upper end of the vessel. During operation, gas introduced through the tube mixes with the process fluid and the combined gas and fluid flow at a high rate with a high degree of turbulence along the first and second circulation paths defined around the weir, thereby promoting vigorous mixing and intimate contact between the gas and the process fluid. This turbulent flow develops a significant amount of interfacial surface area between the gas and the process fluid resulting in a reduction of the required residence time of the gas within the process fluid to; achieve thermal equilibrium and / or to drive chemical reactions to completion, all of which leads to a more efficient and complete evaporation, chemical reaction, or combined evaporation and chemical reaction process.

Owner:SHAW INTPROP HLDG INC

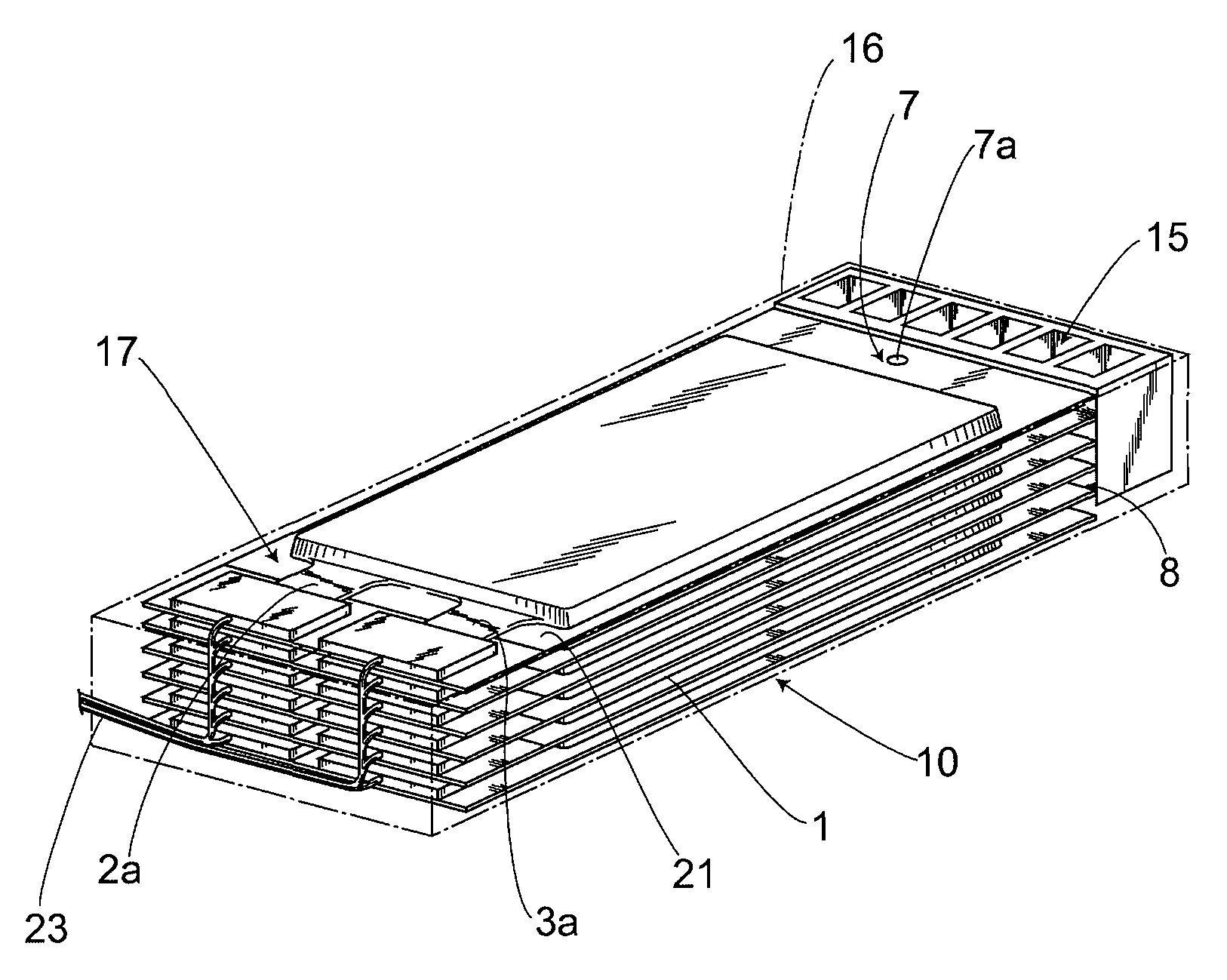

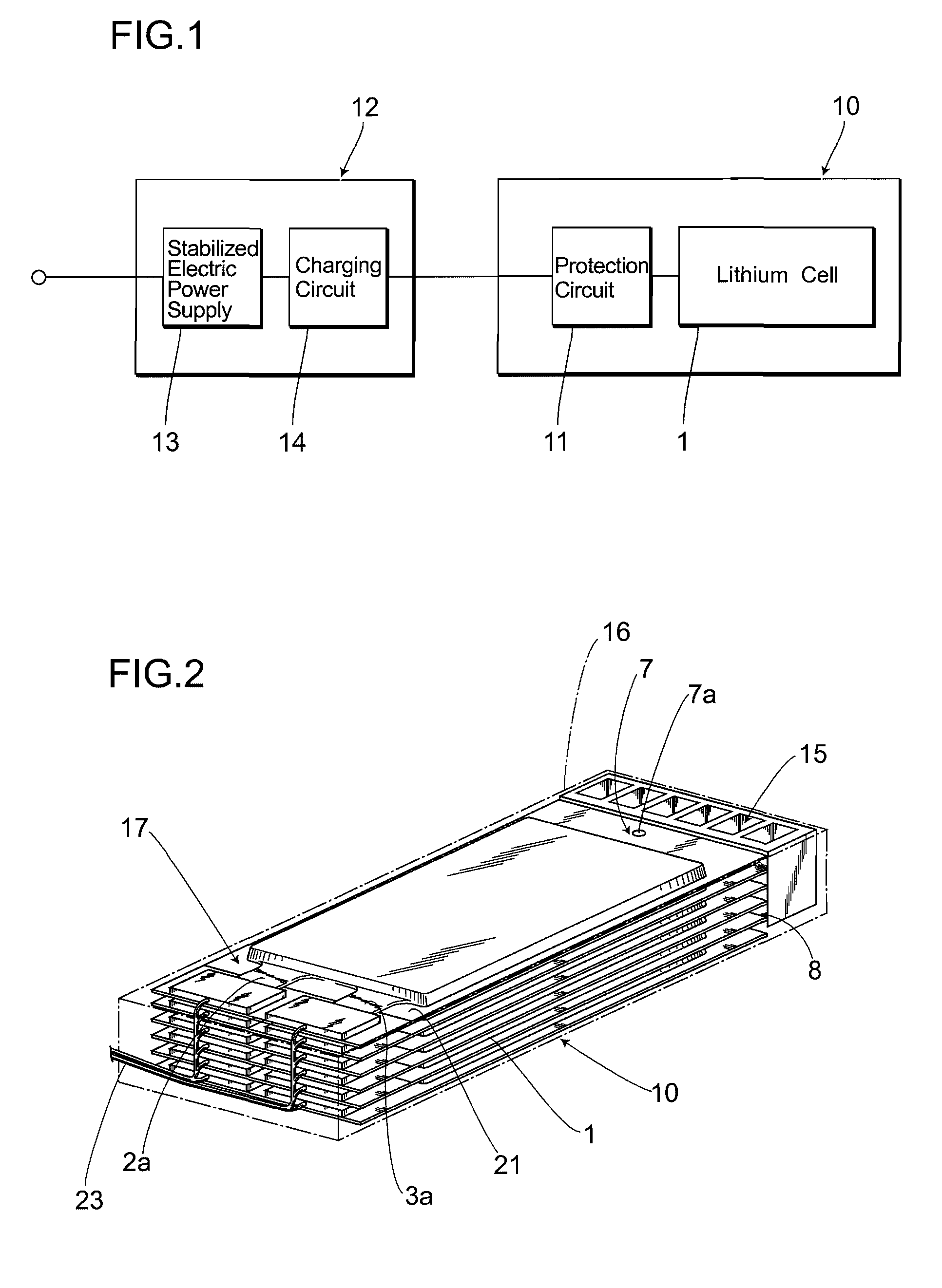

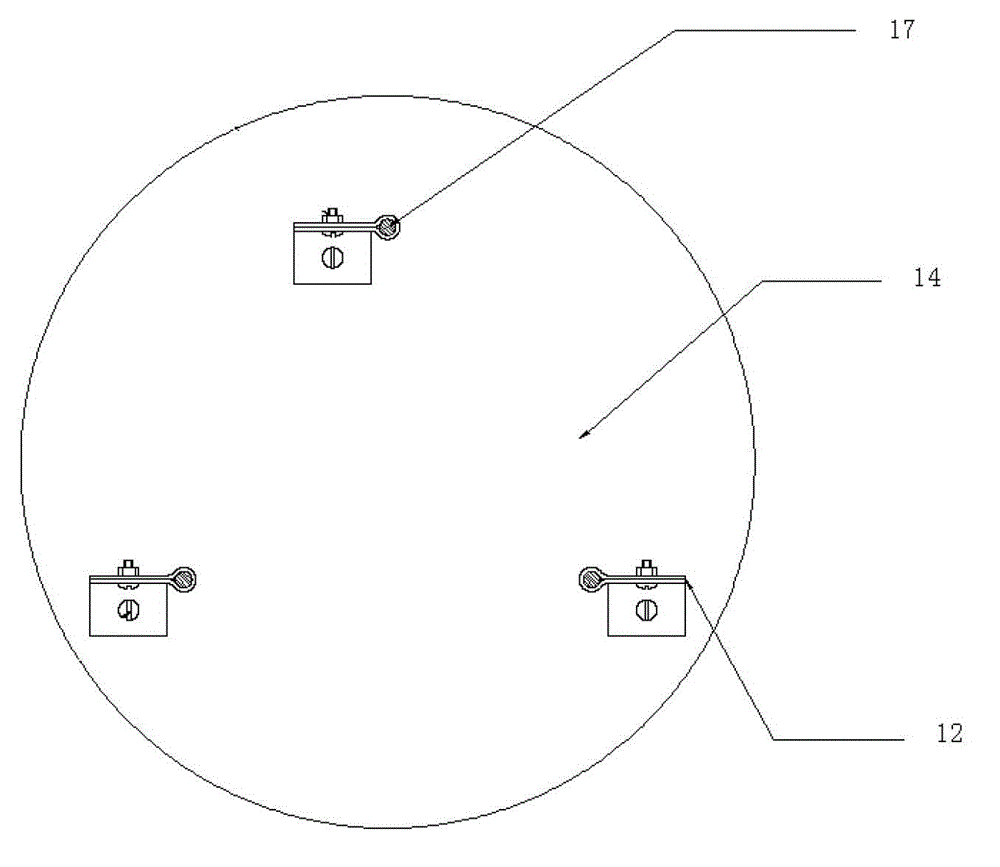

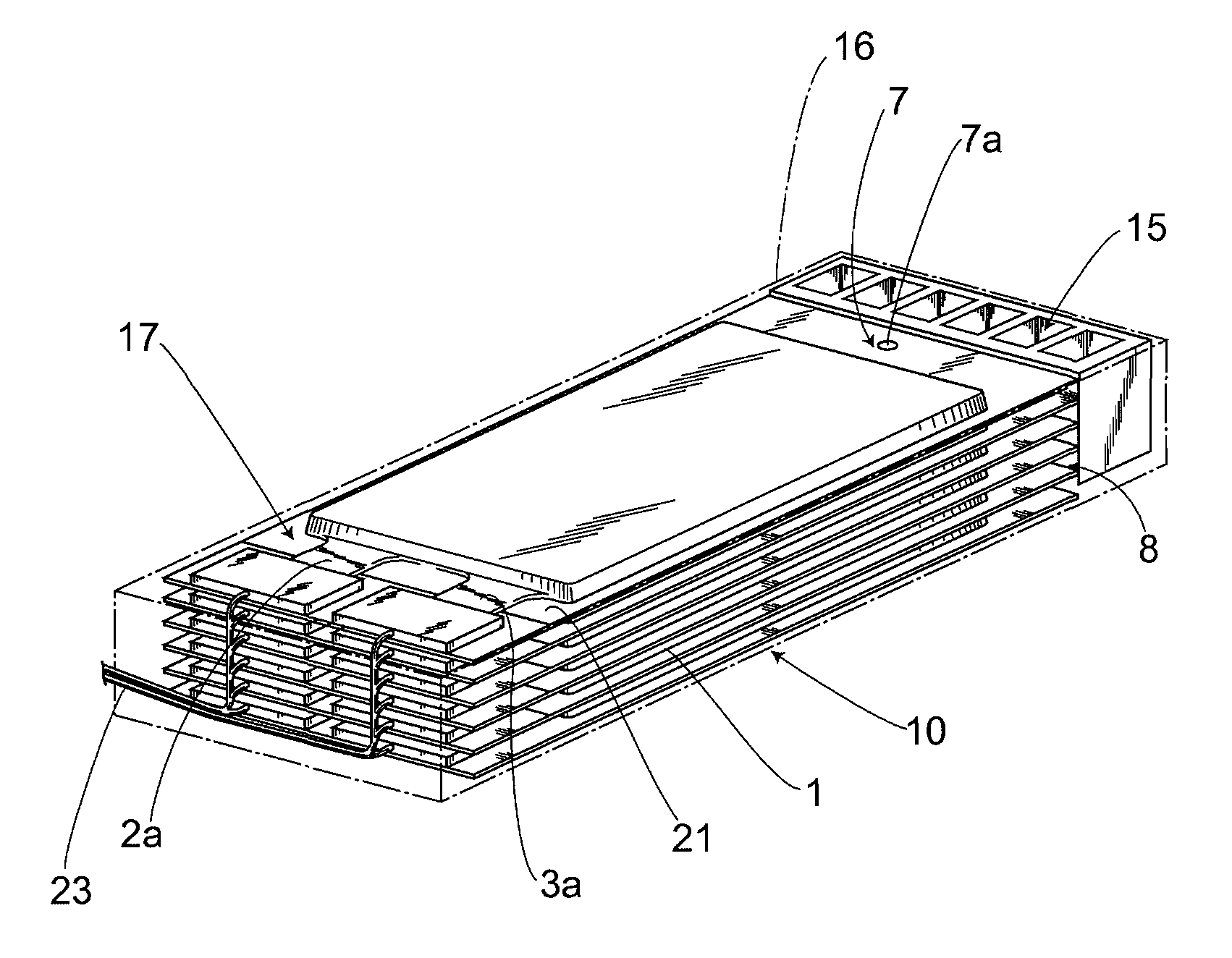

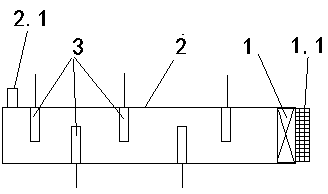

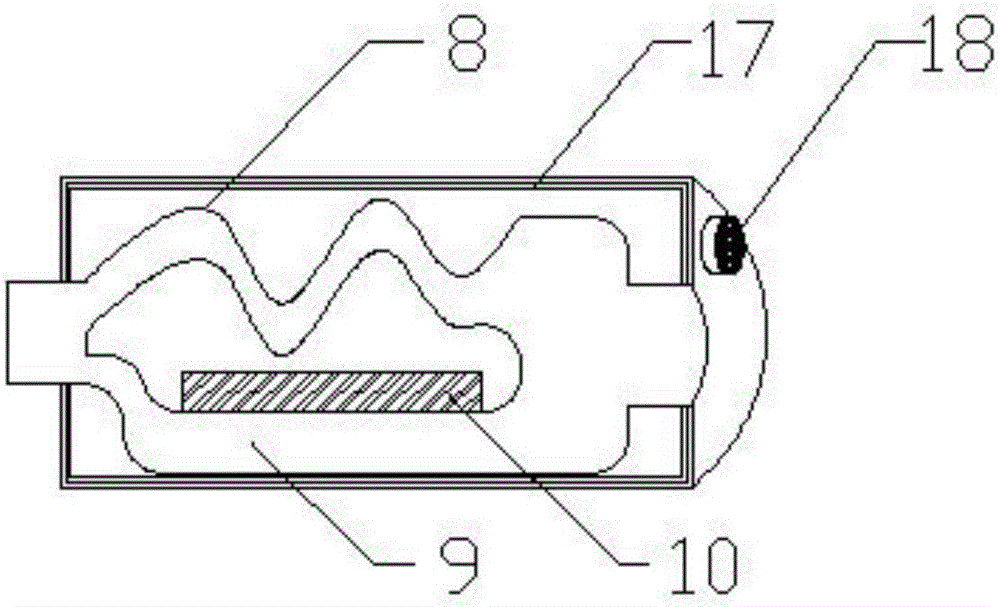

Battery pack

InactiveUS20090220851A1Easy to useFree from riskBattery isolationVent arrangementsOvervoltageBattery cell

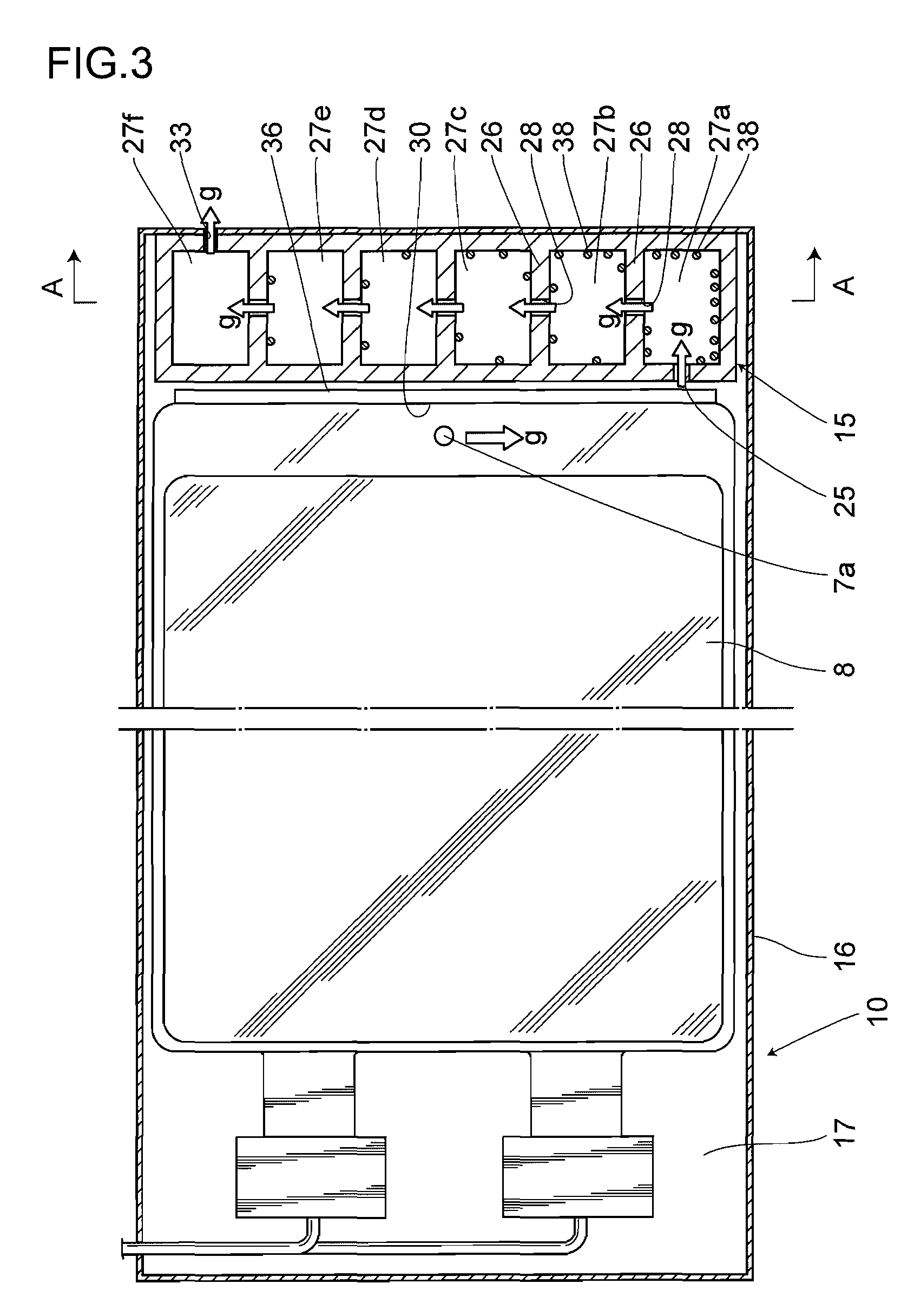

There is provided a risk-free and easy-to-use battery pack using battery cells 1 as a secondary battery, in which internal gases evaporated by applying overvoltage or the like thereto are processed inside a case to be prevented from leaking to the outside of the case and thereby even if the case has been led to rise in pressure due to a thermorunaway of the battery, the case is free from breaking. To realize this performance, the battery pack 10 is provided with a battery cell housing 17 for housing lithium cells 1 and a gas processor 15 for liquefying the internal gases g generated from the lithium cells 1.

Owner:TDK LAMBDA CORP

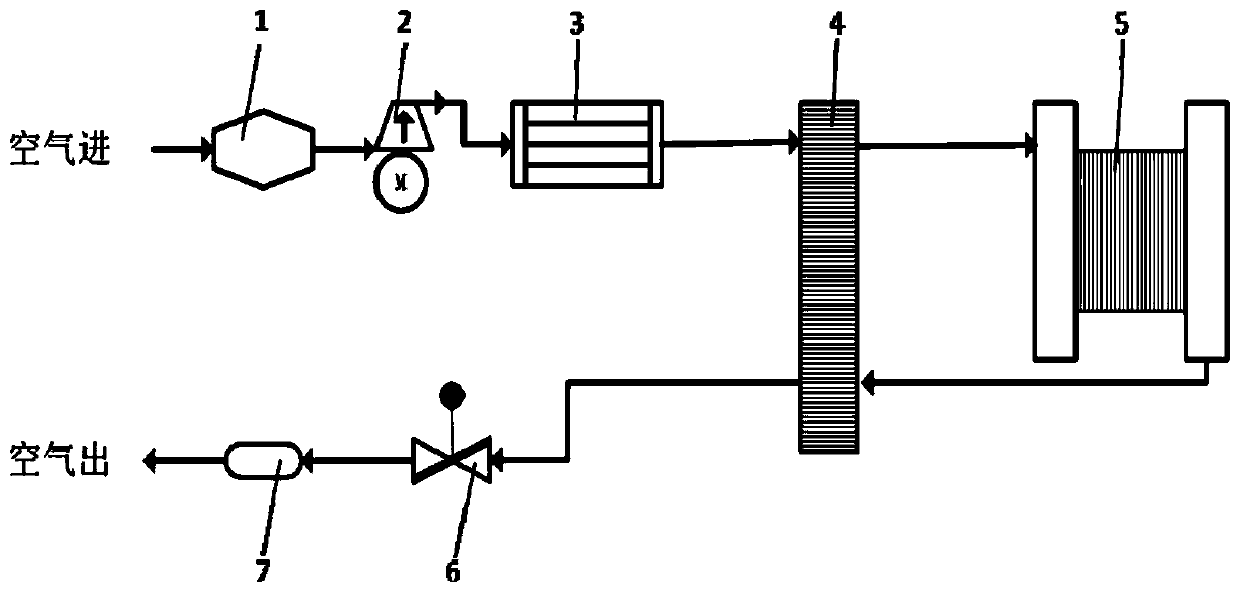

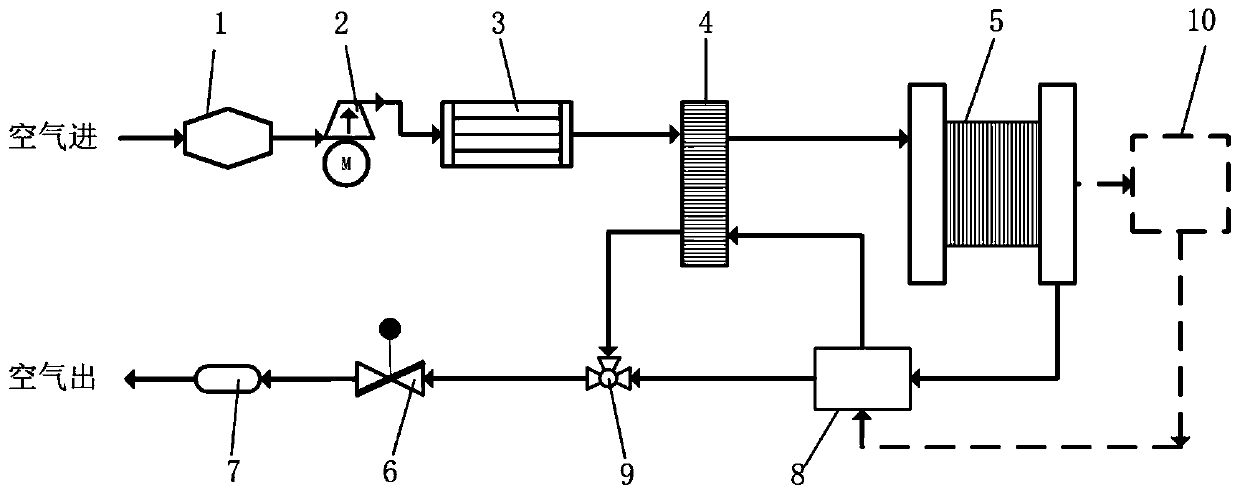

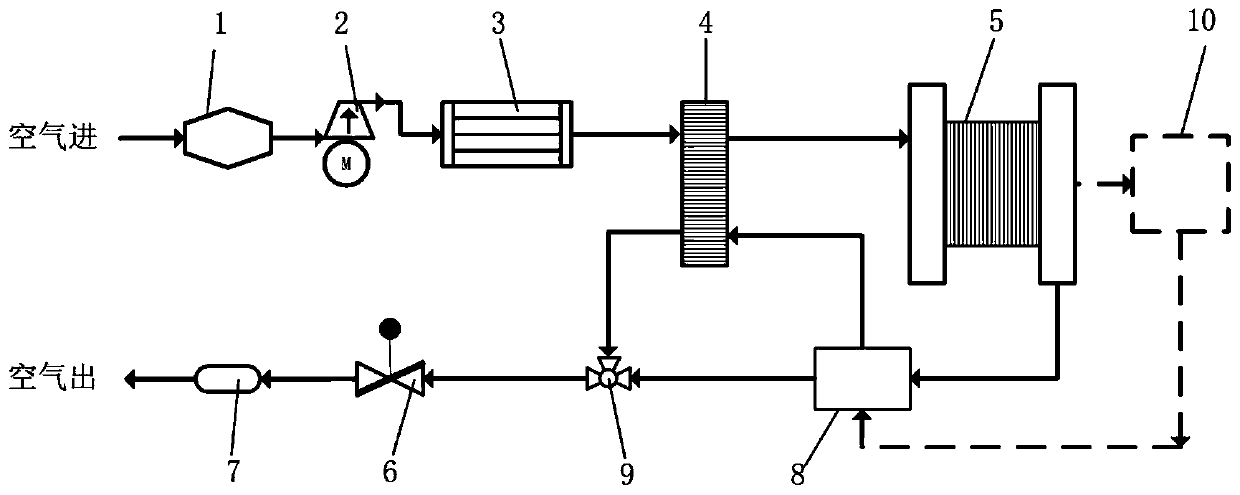

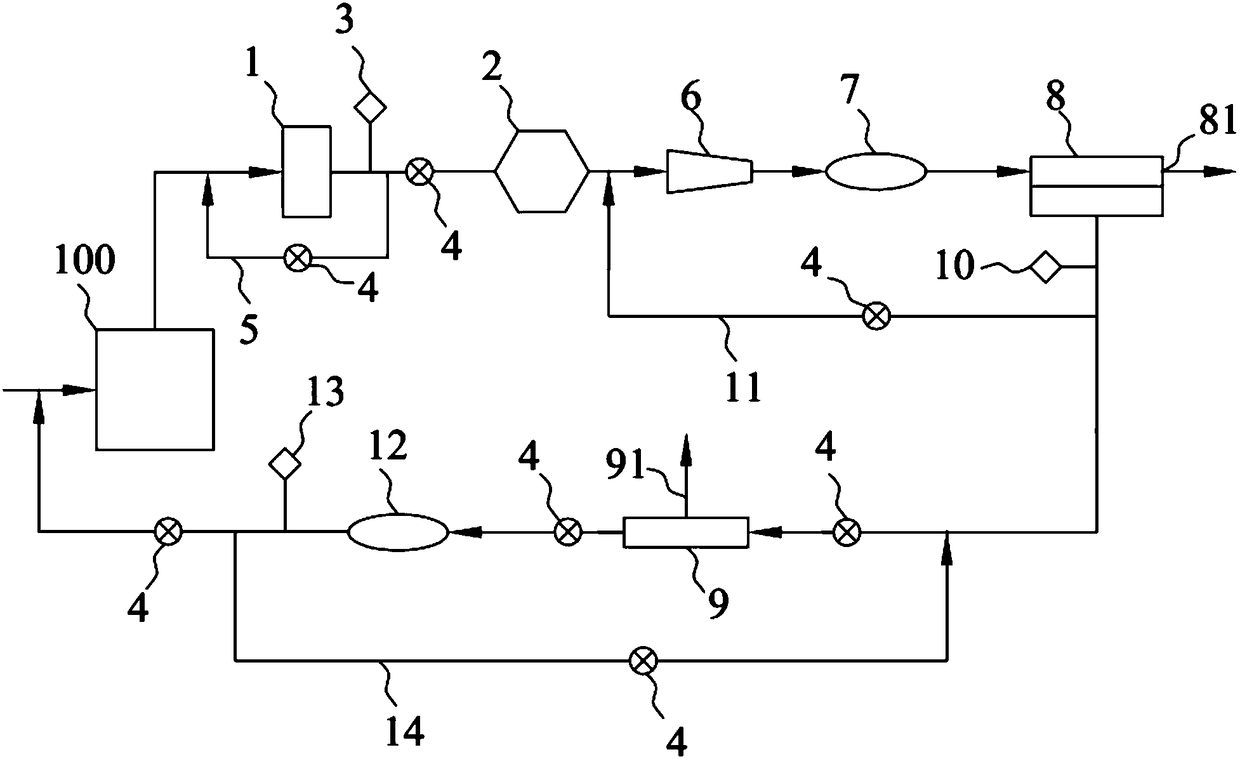

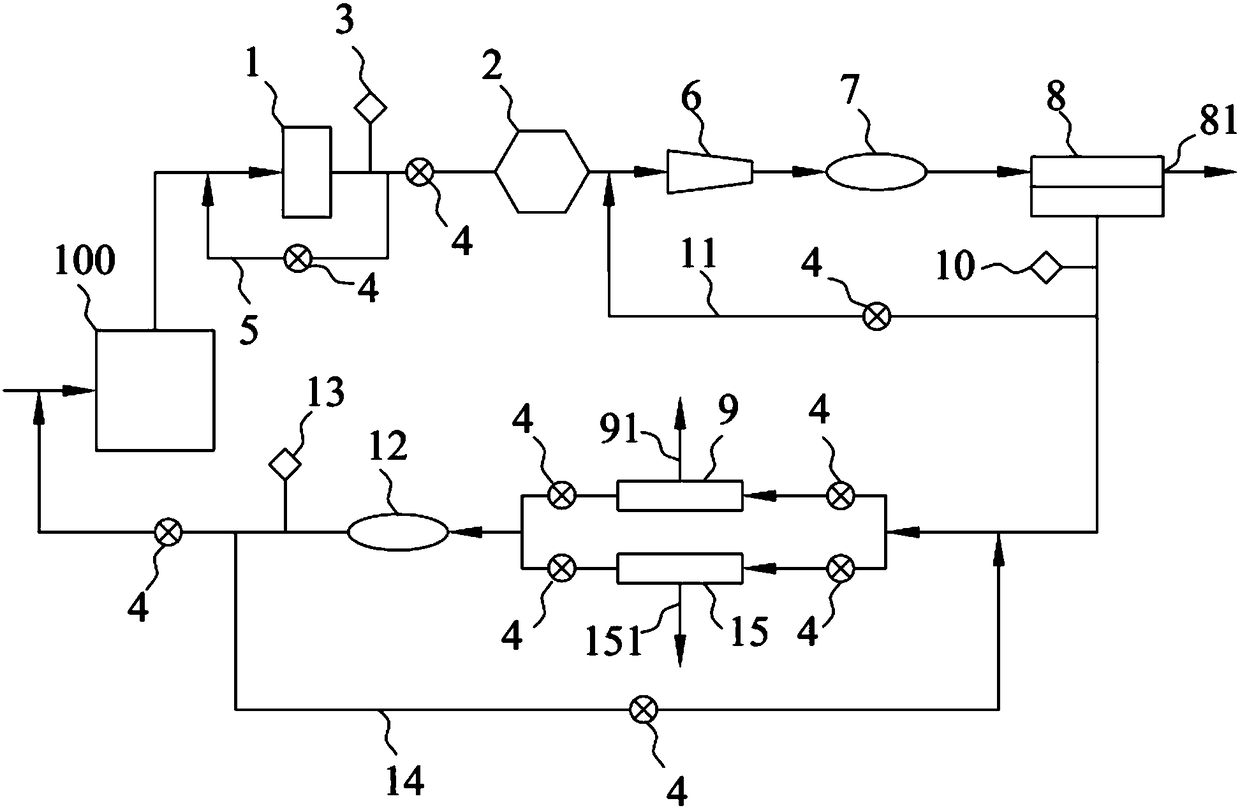

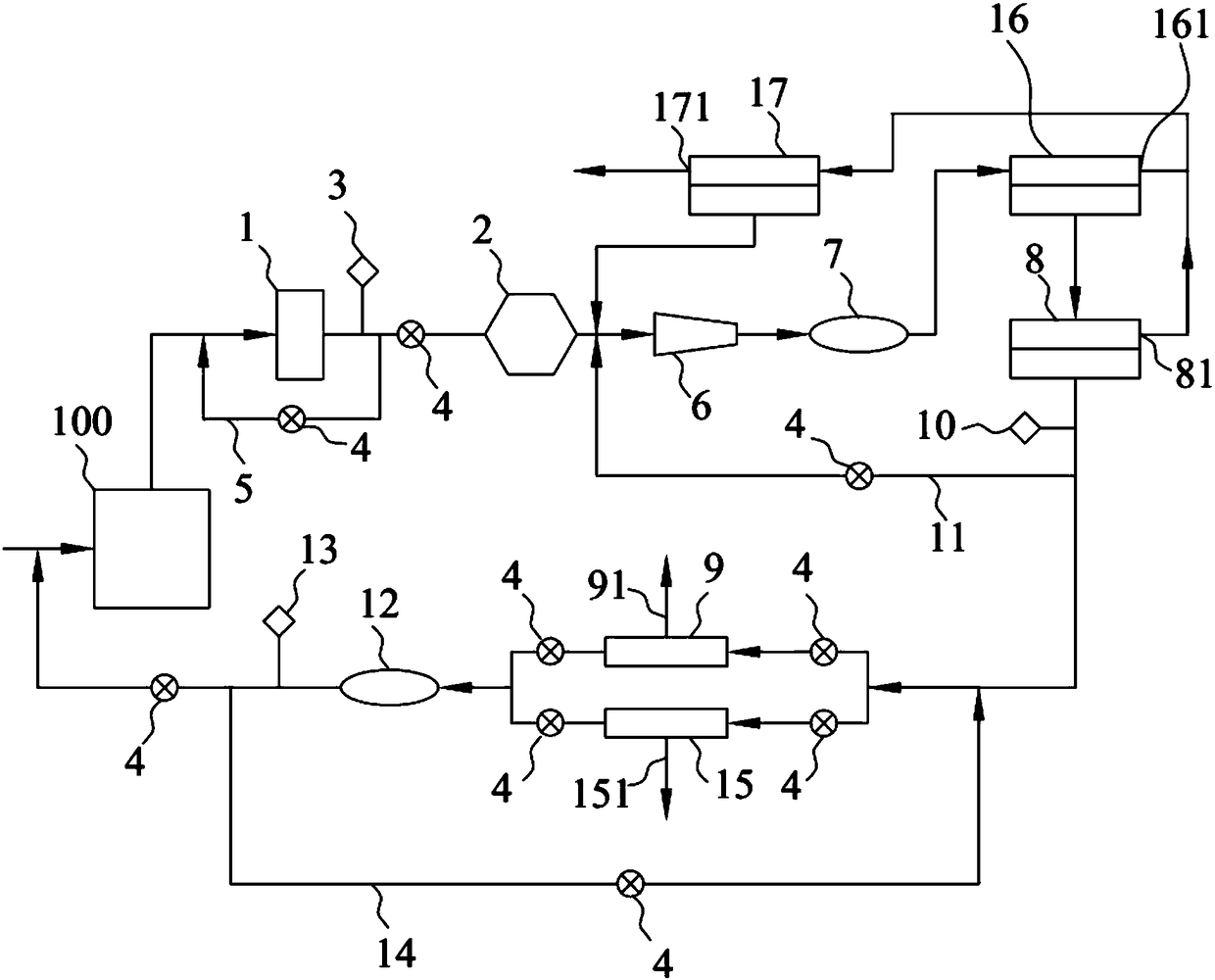

Cathode side gas humidity adjusting system and method for proton exchange membrane fuel cell

InactiveCN109860664AImprove output performanceGuaranteed running stabilityFuel cellsAir filterIntercooler

The invention relates to a cathode side gas humidity adjusting system and method for a proton exchange membrane fuel cell, and the system comprises an air filter, an air compressor, an intercooler, anair humidifier, a fuel cell stack, an exhaust back pressure valve, a tail gas processor, a humidity regulator, a three-way valve, and a fuel cell control unit. An outlet of the fuel cell stack is connected with an inlet of the humidity regulator, and the humidity regulator is connected with the air humidifier. The air humidifier is connected with the three-way valve, and the fuel cell control unit is connected with a water content sensor and a humidity regulator in the fuel cell stack. The humidity of air entering the fuel cell stack can be automatically adjusted according to the actual working requirements of the fuel cell stack, the phenomenon that the interior of the stack is too dry or too wet is avoided, the water balance in the stack is maintained, the output performance of the fuelcell is effectively improved, the operation stability of the fuel cell is guaranteed, and the reliability and durability of the stack are improved.

Owner:FAW JIEFANG AUTOMOTIVE CO

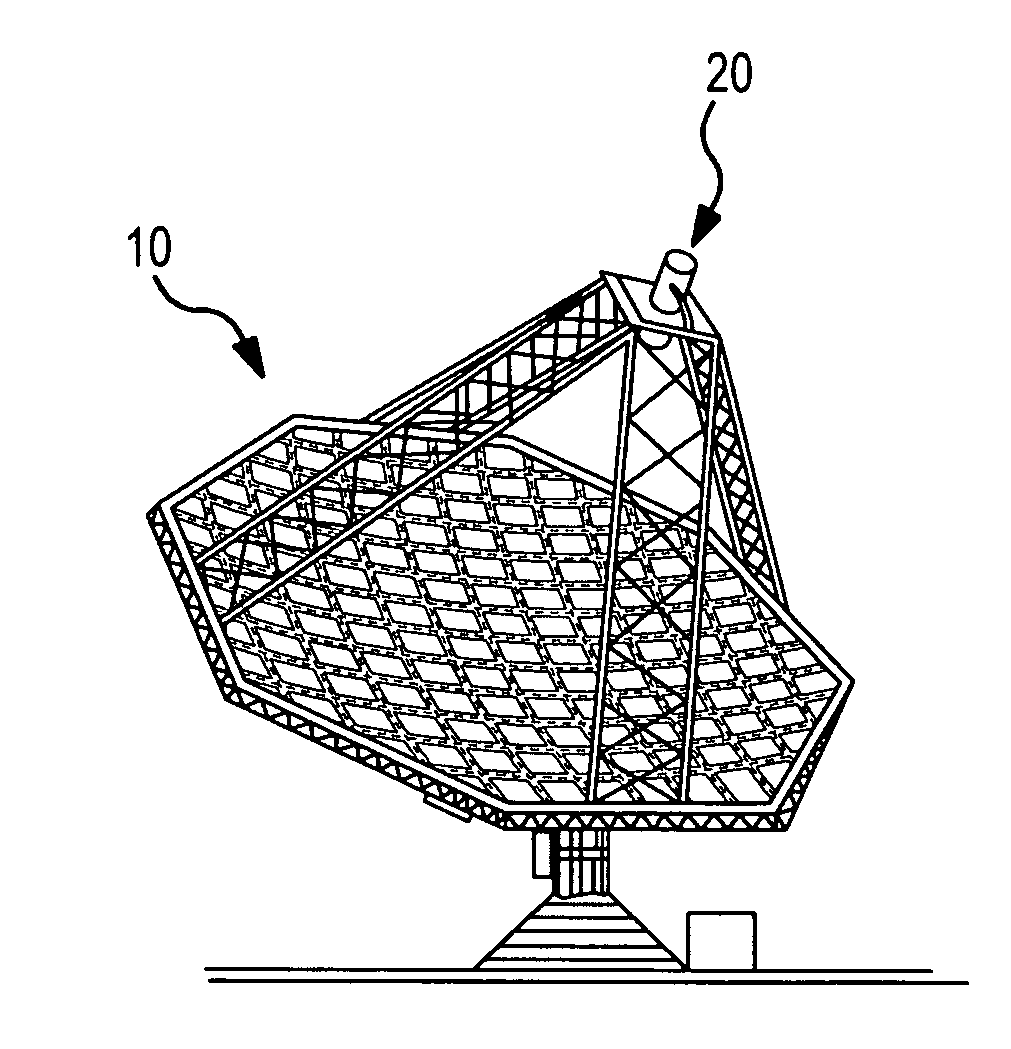

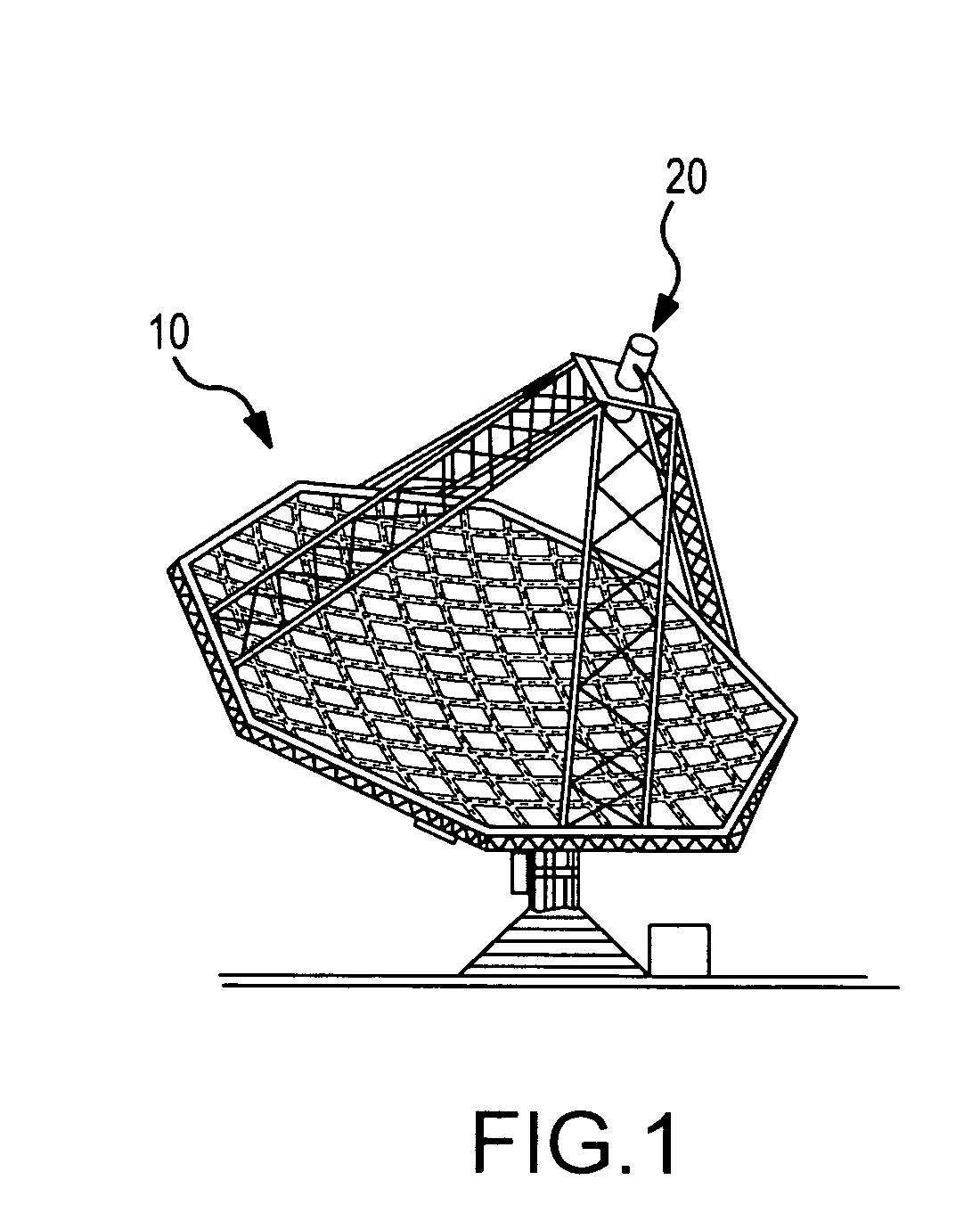

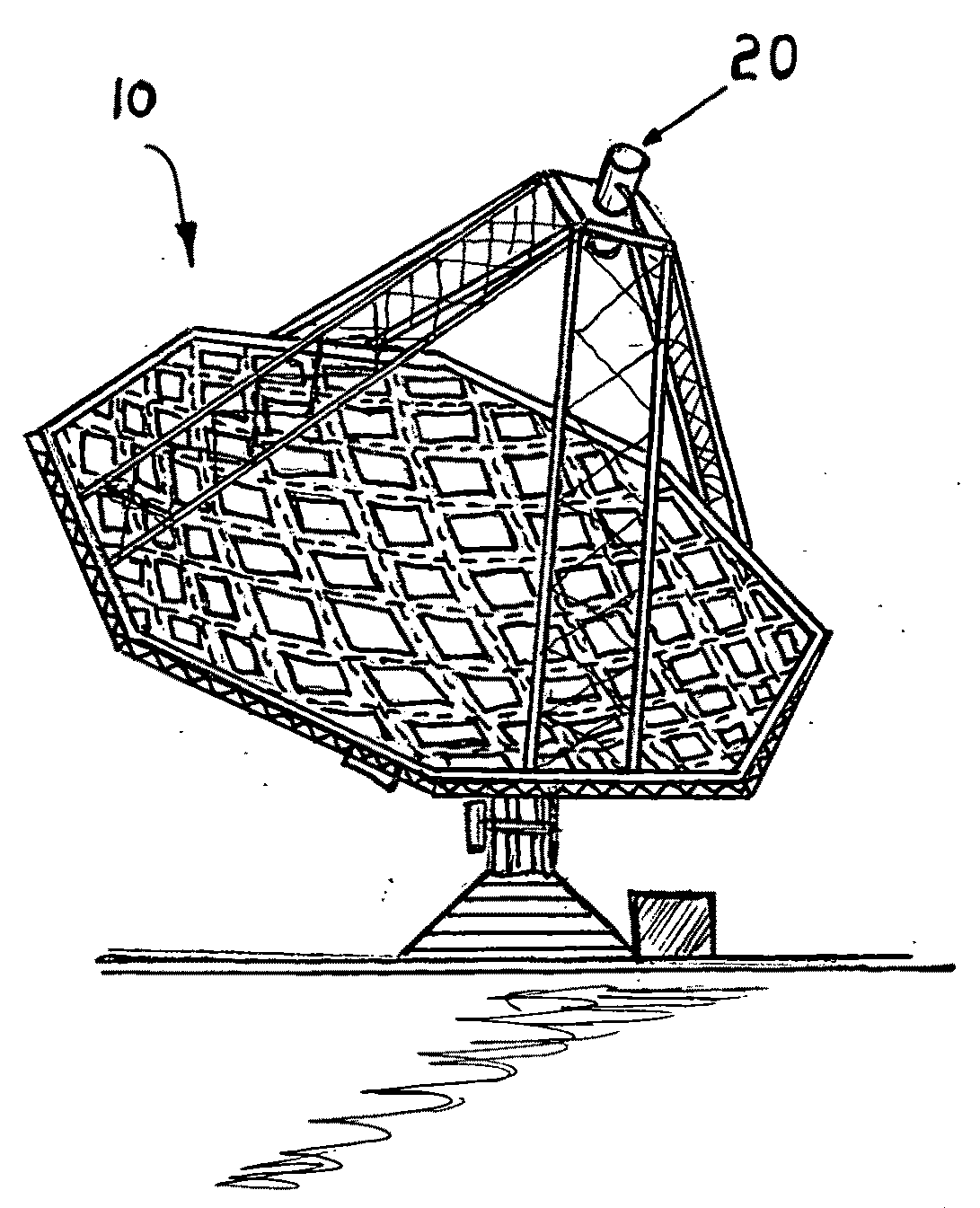

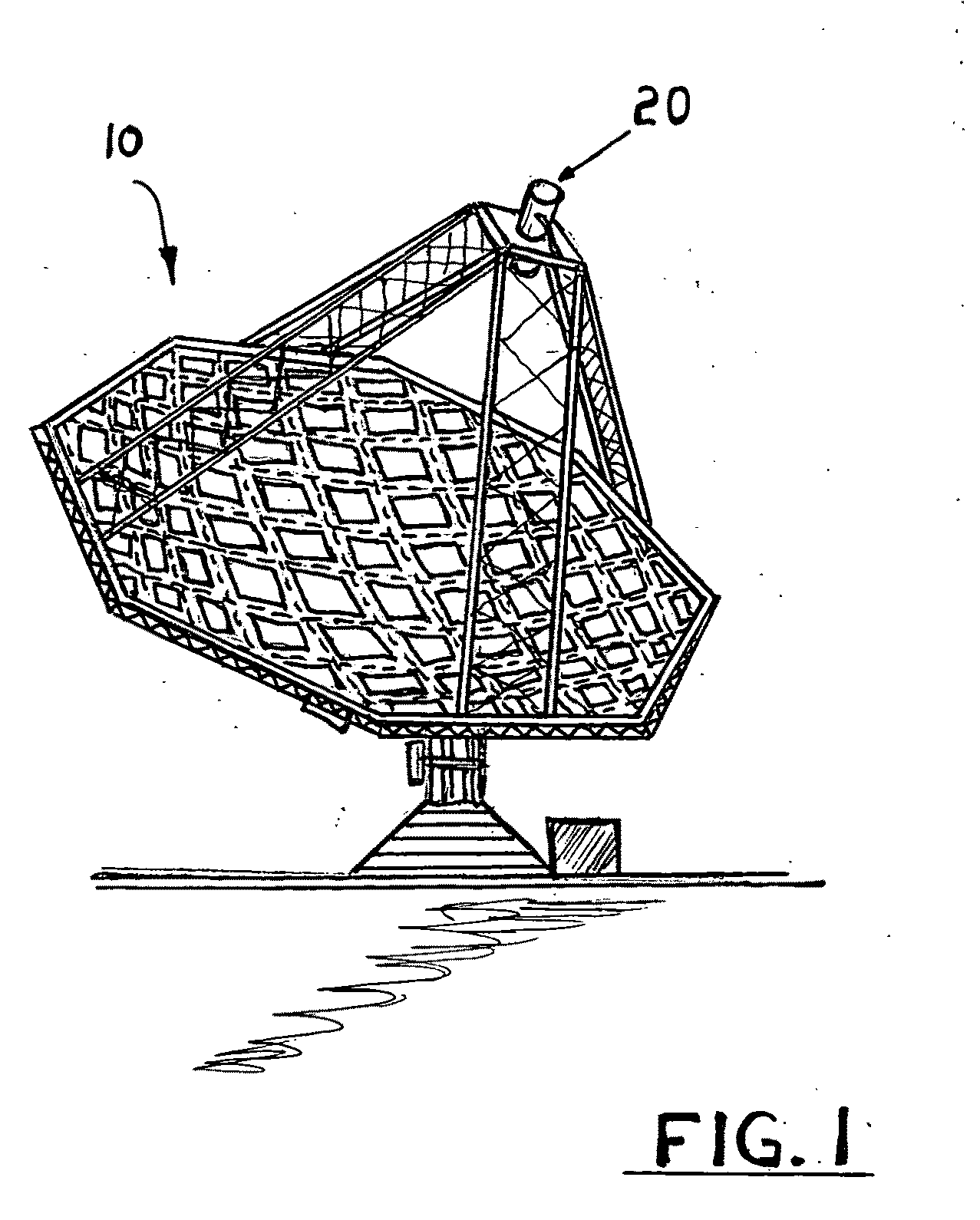

Low entropy heat exchanger especially for use with solar gas processors

InactiveUS20090277441A1Solar heating energySolar heat devicesWater-gas shift reactionProcess engineering

An apparatus and method for solar energy powered gas processing. There is disclosed a processor assembly for use in heating a process or feed gas by means of a convective heat exchanger which receives solar energy from a focused solar energy collector. A specialized heat exchanger is described, which maximizes the area upon which solar energy can radiate, as well as the available area for heat transfer to the flowing gas. Various modes for operating the processor assembly are described. The apparatus and method may be utilized to heat a gas to drive a heat engine. The apparatus and method also may be used to heat feed gasses to drive a gas processing reaction, such as for steam methane reformation or a reverse water-gas shift reaction.

Owner:JENSEN REED

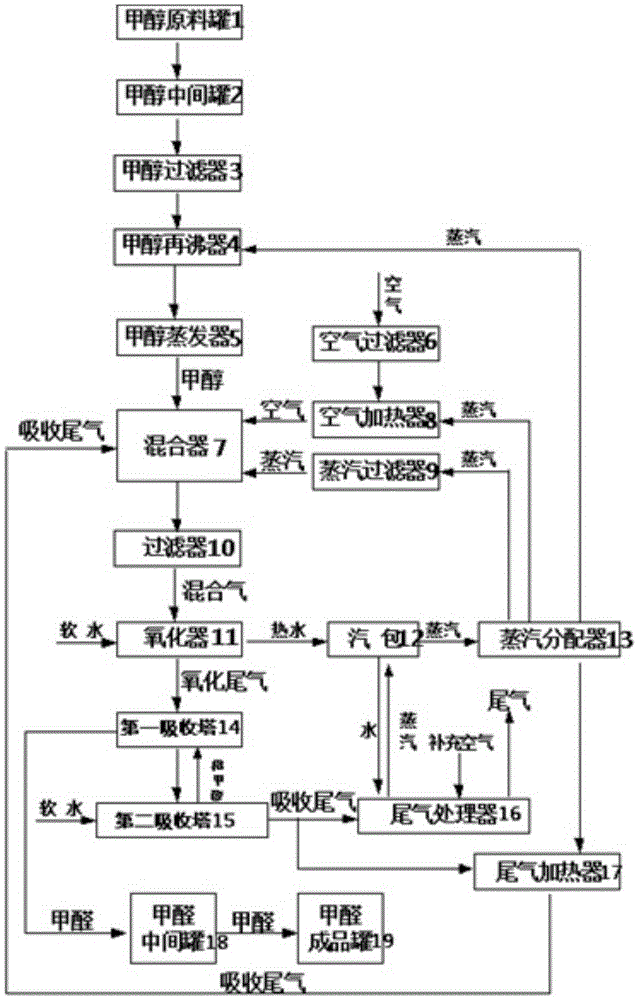

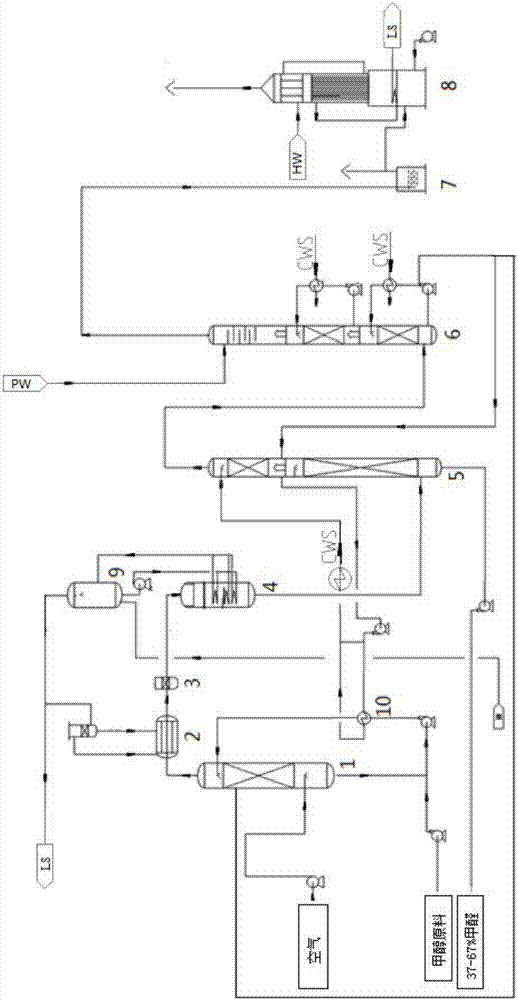

Formaldehyde production system

The invention provides a formaldehyde production system. The system comprises a methanol raw material tank, a methanol intermediate tank, a methanol reboiler, a methanol evaporator, a quaternary mixer, a methanol evaporator, an air heater, a steam filter, a tail gas heater, a filter, an oxidizer, a first absorption tower, a second absorption tower, a tail gas processor, a tail gas heater, and a formaldehyde intermediate tank. The system completes the following steps: (1) evaporation and gas production: obtaining qualified quaternary mixed gas; (2) oxidization: oxidizing and dehydrogenizing methanol in the presence of an electrolytic silver catalyst so as to convert methanol into formaldehyde, wherein a few of byproducts are generated during the process; (3) absorption: taking water and formaldehyde solution as the absorbents, and carrying out continuous counter-current absorption in a packed absorbing tower to produce an industrial formaldehyde solution. The provided system can fully utilize tail gas circulation to produce formaldehyde, the utilization rate of raw materials is high, and little waste is generated.

Owner:ANHUI ZHONGYUAN CHEM

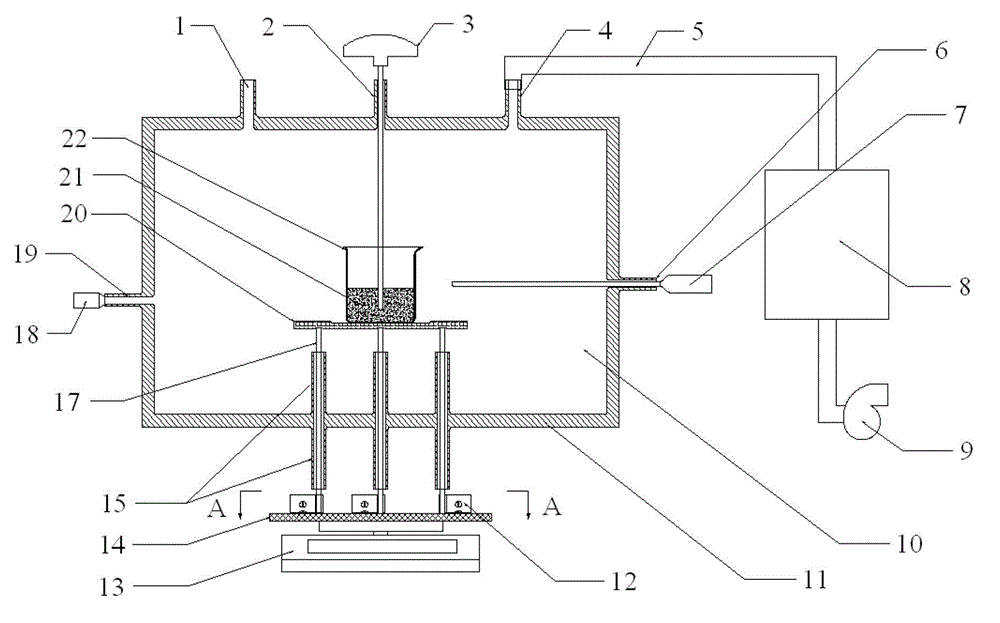

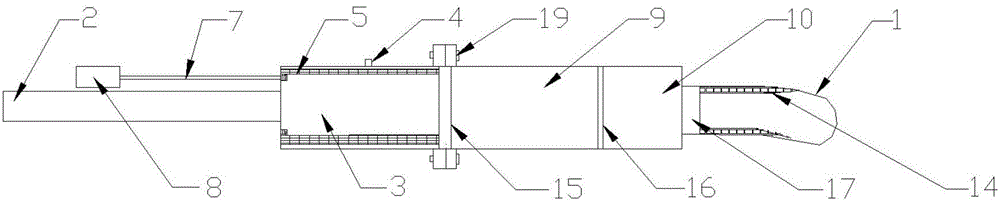

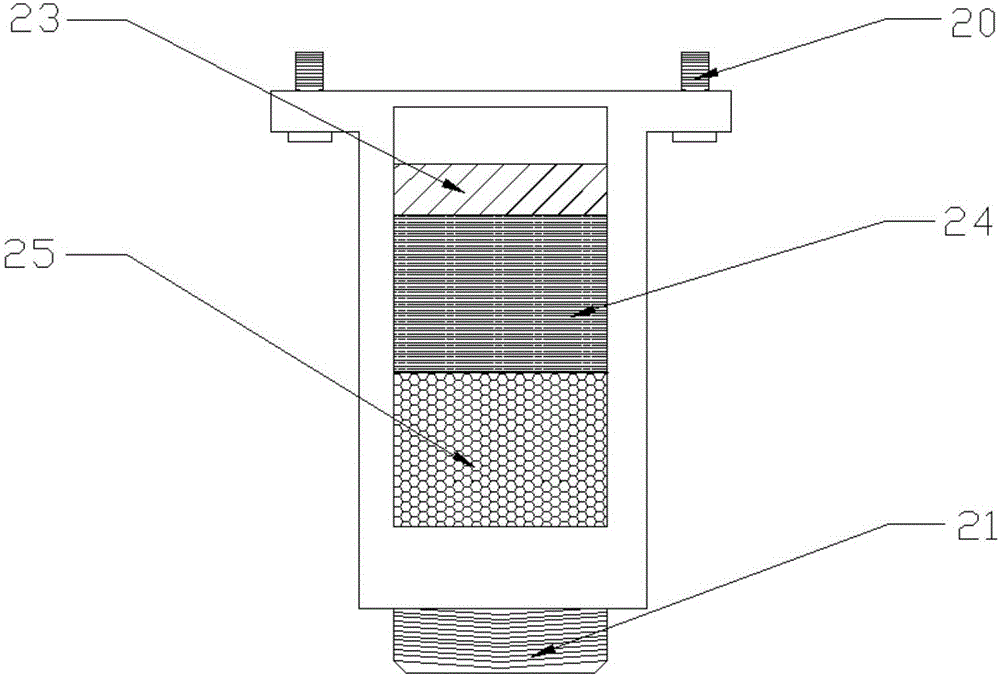

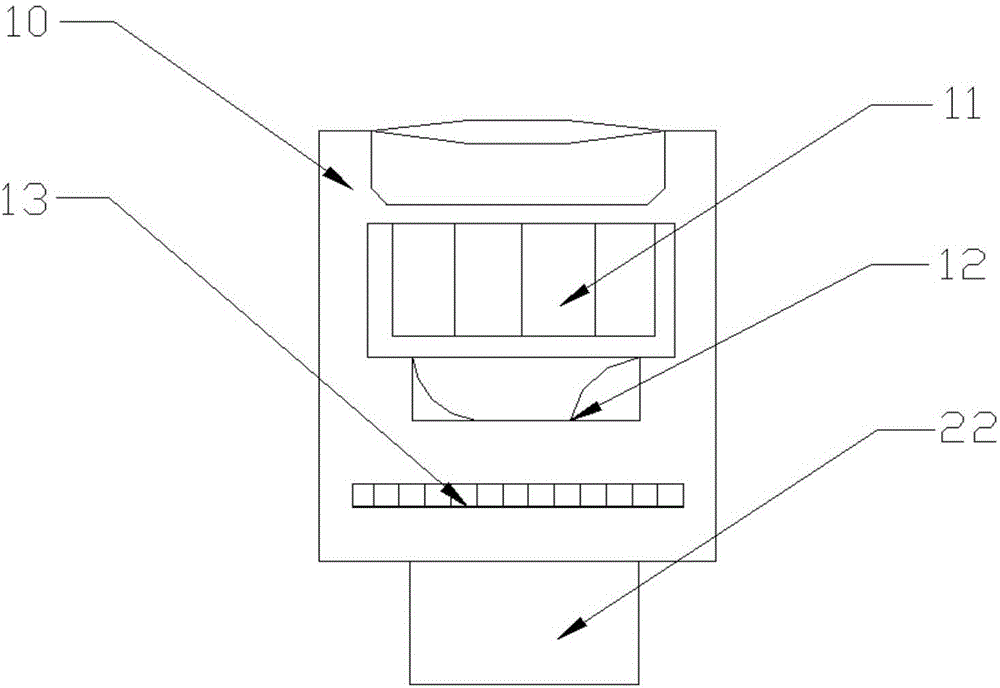

Microwave heating weight detection device

The invention discloses a microwave heating weight detection device which comprises a gas treating device, a microwave inner cavity shell, a ceramic plate which is arranged in a microwave inner cavity and is used for placing a quartz bottle, and a supporting plate arranged at the outer bottom part of the microwave inner cavity shell, wherein one end of a quartz rod is arranged on the supporting plate through a fixing clip and the other end of the quartz rod penetrates through a quartz rod jack at the bottom of the microwave inner cavity shell to stretch into the microwave inner cavity to support, so as to support the ceramic plate; the gas treating device comprises a gas treater and a fan; one end of the gas treater is communicated with a gas outlet of the microwave inner cavity shell through a gas guide pipe and the other end of the gas treater is communicated with the fan through a pipeline; and a pressure sensor stretches into the microwave inner cavity through a pressure sensor jack. According to the microwave heating weight detection device disclosed by the invention, pressure of the inner cavity can be stabilized in a microwave heating process and pressure in the inner cavity is adjusted to be a pre-set pressure value, so that the online change of the weight in the microwave heating process and a pyrolysis process can be detected; and the microwave heating weight detection device is low in construction cost and strong in practical applicability, and meets environment-friendly requirements.

Owner:SOUTH CHINA UNIV OF TECH

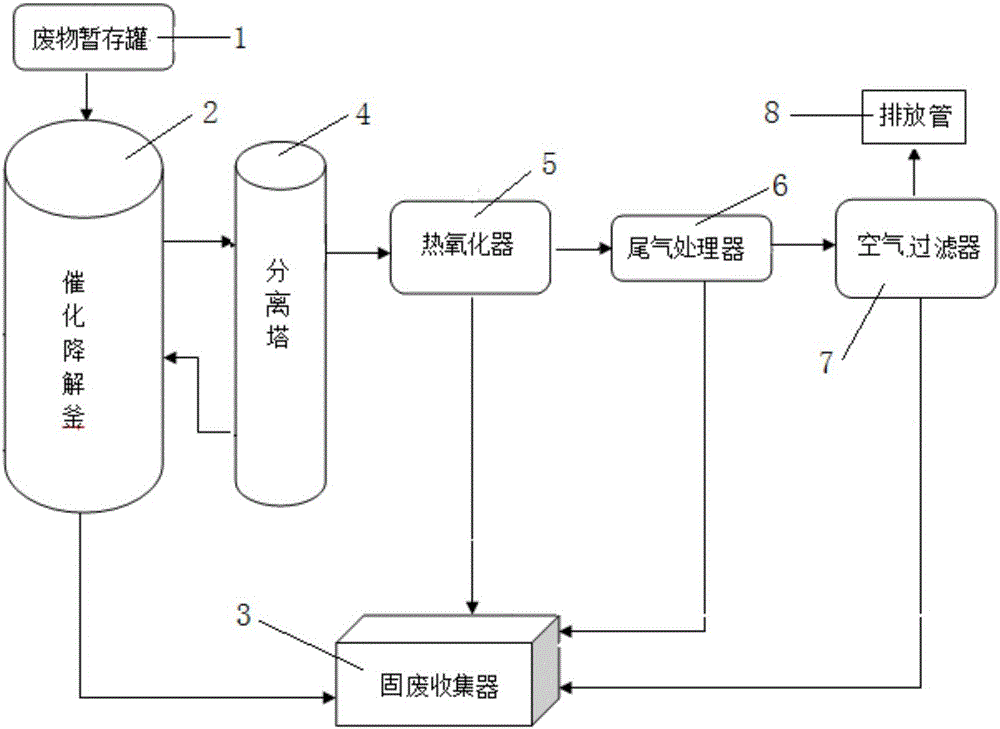

Radioactive organic waste treatment device

ActiveCN105810276ASafe and reliable performanceSimple structureRadioactive decontaminationAir filterAdditive ingredient

The invention belongs to the technical field of radioactive substance treatment equipment and relates to a radioactive organic waste treatment device. A main body structure comprises a waste temporary storage tank, a catalytic degradation kettle, a solid waste collector, a separation tower, a thermal oxidation device, a tail gas processor, an air filter and a discharging pipe, the catalytic degradation kettle and the separation tower are in bidirectional fixed connection through a pipe, the waste temporary storage tank is fixedly connected with the catalytic degradation kettle through a pipe, the separation tower is fixedly connected with the thermal oxidation device through a pipe, the thermal oxidation device is fixedly connected with the tail gas processor through a pipe, the tail gas processor is fixedly connected with the air filter through a pipe, the air filter is fixedly connected with one end of the discharging pipe through a pipe, the other end of the discharging pipe is directly communicated with the atmospheric environment, the catalytic degradation kettle, the thermal oxidation device, the tail gas processor and the air filter are fixedly connected with the solid waste collector through pipes, and organic ingredients in radioactive organic waste are converted into inorganic ingredients according to the catalytic cracking principle. The radioactive organic waste treatment device is simple in structure, scientific and reliable in principle, reasonable in cost, safe in performance, capable of saving energy and protecting the environment and environmentally friendly in use.

Owner:青岛天和清原科技有限公司

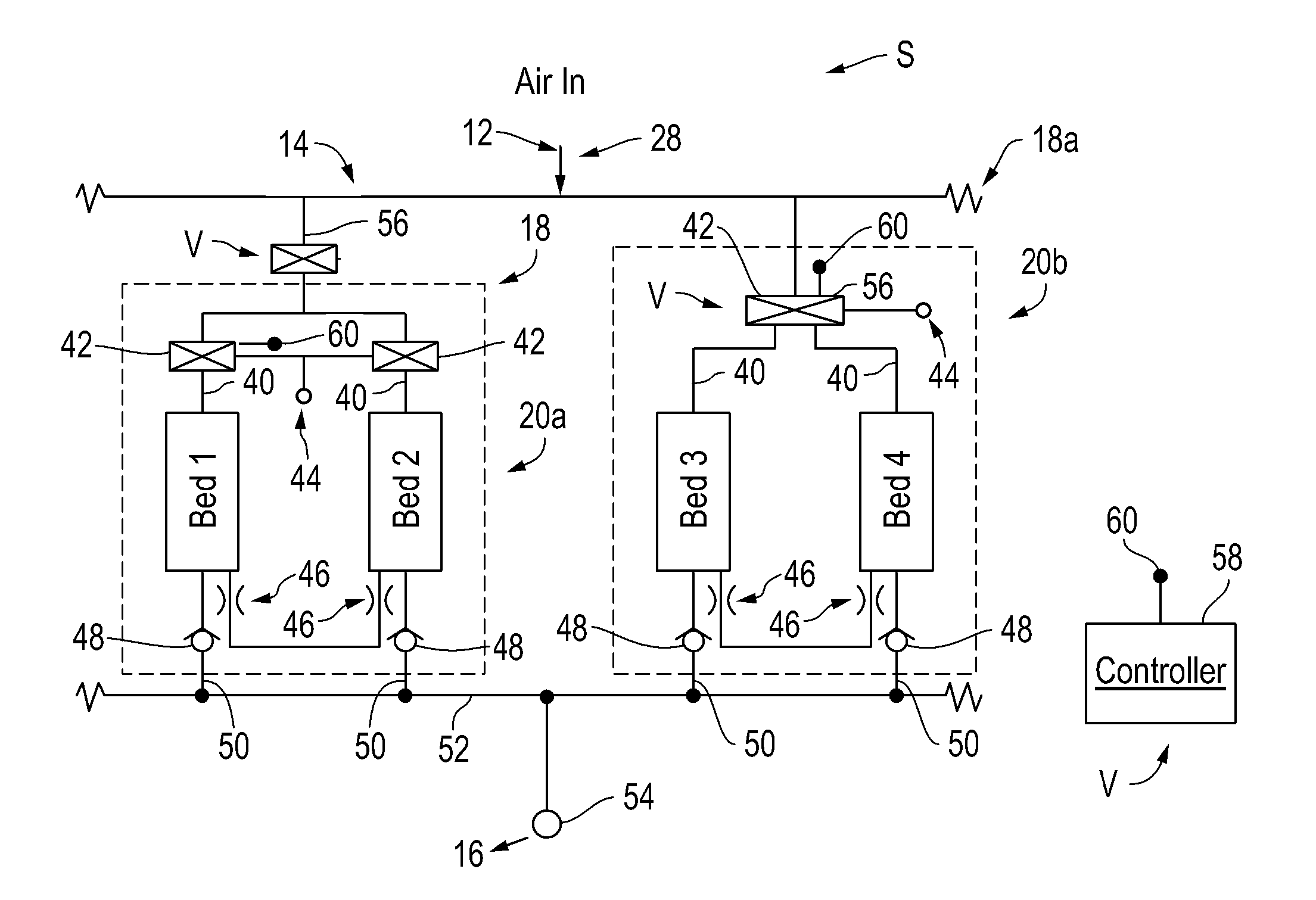

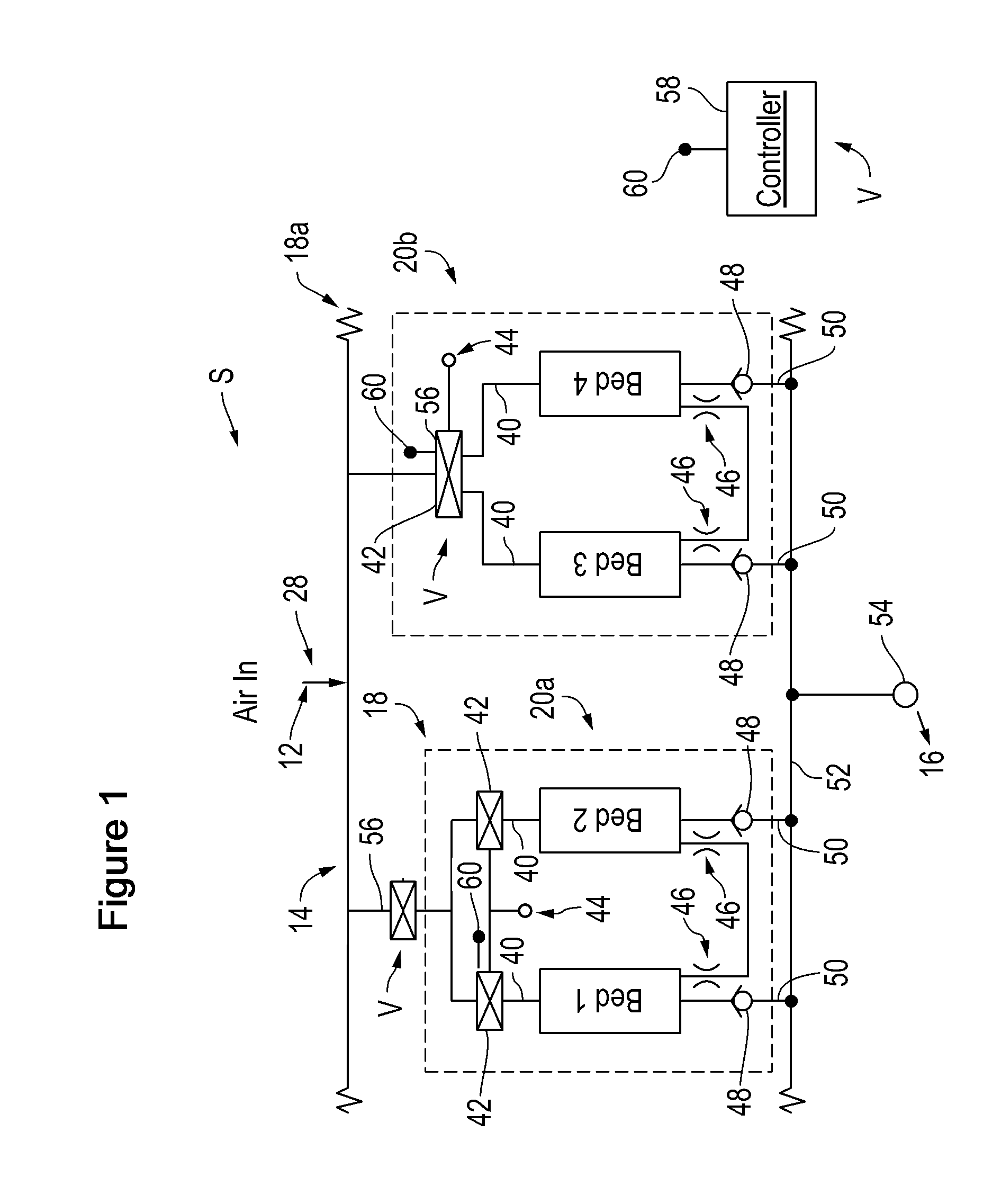

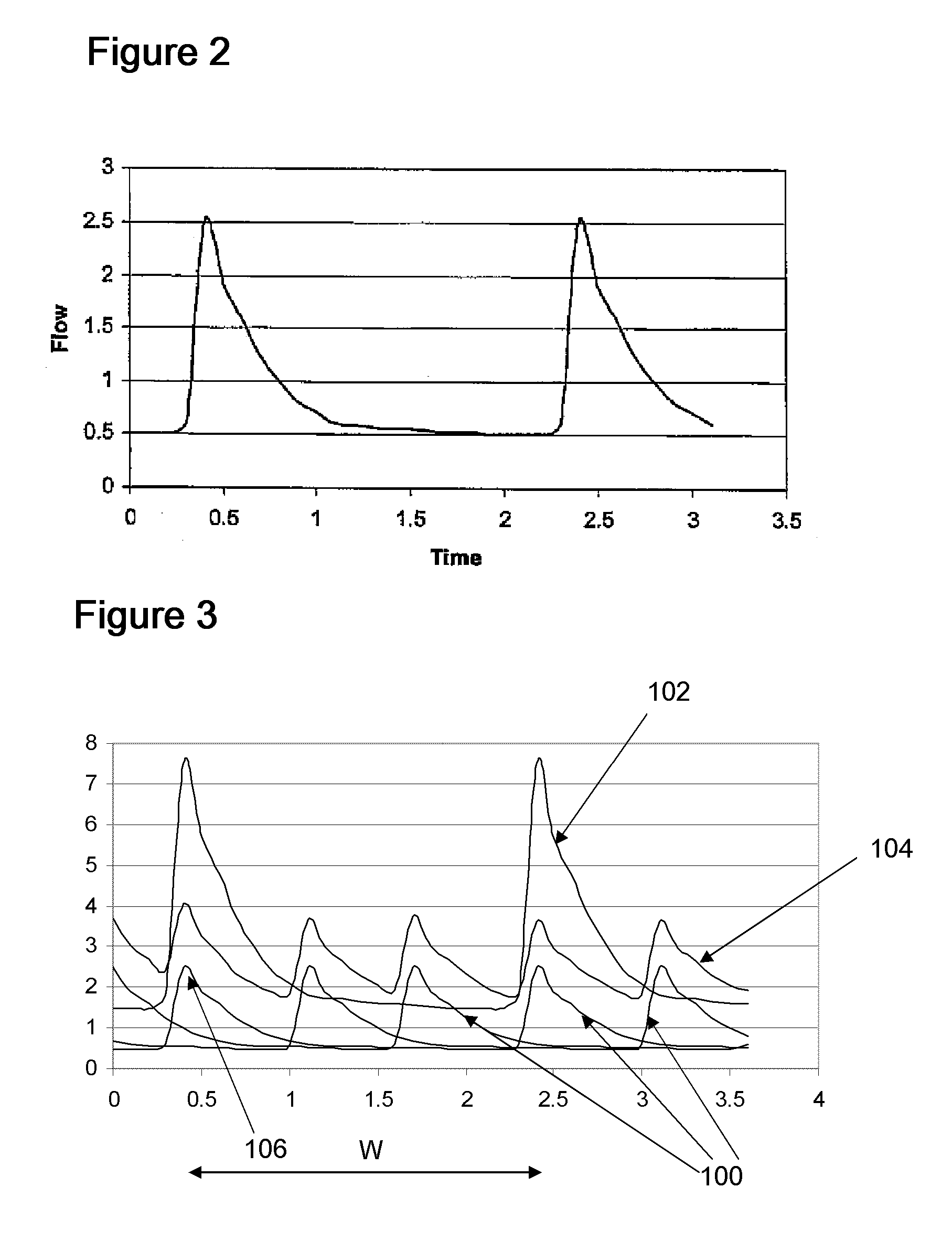

Method for operating gas generators in tandem

A gas generating system (S) has a plurality of product gas generating modules (18) each of which comprises a plurality of molecular sieve beds (bed 1, bed 2) generating a product gas acting in a repetitive cycle with each cycle having a period of the cycle with peak product gas flow (106). A manifold (52) combines the product gas from the plurality of modules (18). The processor (58) generates a control signal that is communicated to the gas generating modules (18) such that the peak product gas flow period (106) of the repetitive cycle of the modules (18) is adjusted in response to the control signal. The processor (58) causes the peak period (106) for the modules (18) to be timed across the repetitive cycles in a controlled distribution.

Owner:COBHAM MISSION SYST DAVENPORT LSS INC

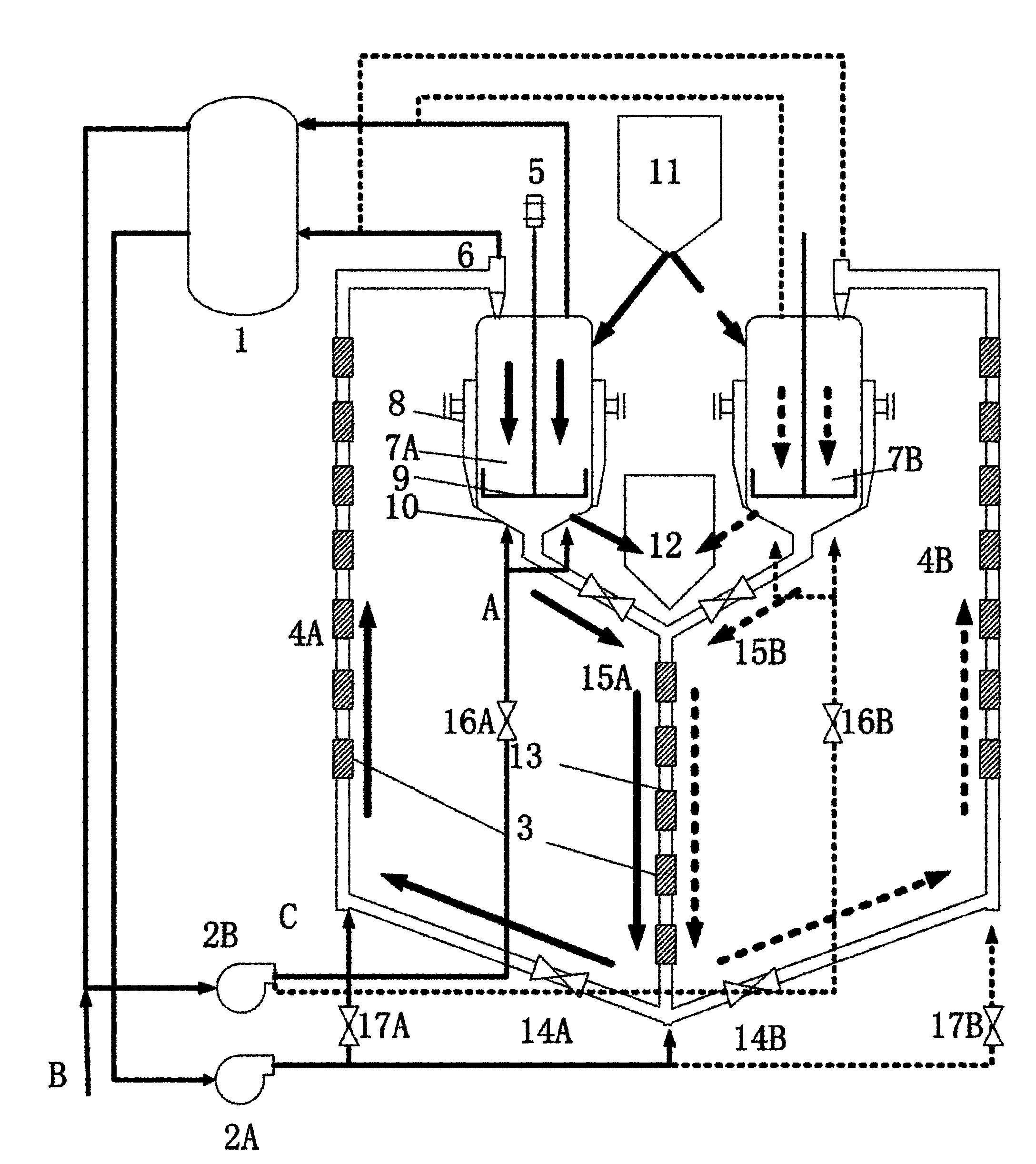

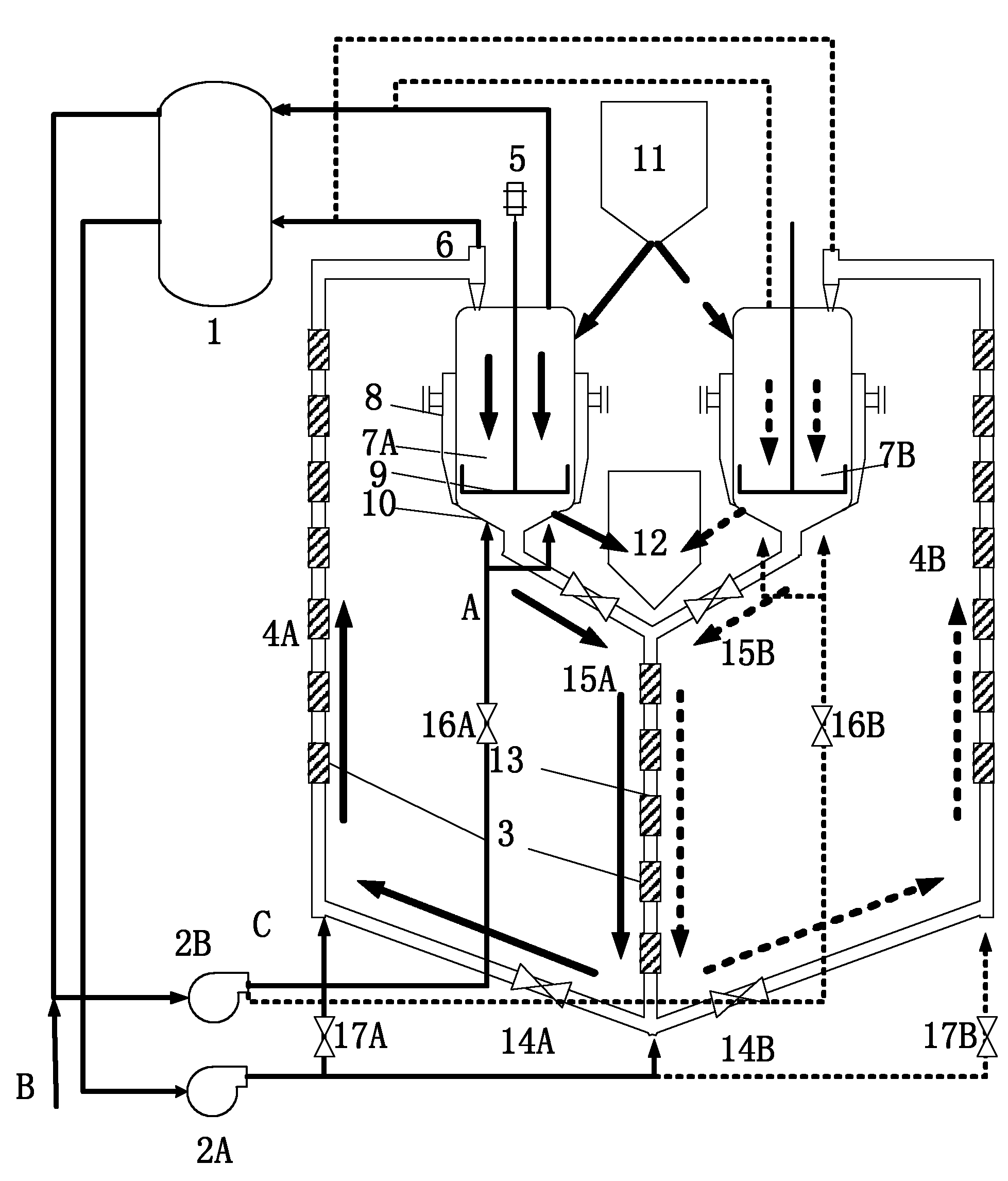

Method and device for continuously producing chlorinated polyvinyl chloride by low-temperature plasma circulating bed

ActiveCN102161718ARealize continuous productionAvoid problems such as corrosionEnergy based chemical/physical/physico-chemical processesFluidized bedChlorinated polyvinyl chloride

The invention discloses a method and device for continuously producing chlorinated polyvinyl chloride by a low-temperature plasma circulating bed, relating to a production technology and equipment for macromoleclar polymer chlorinated polyvinyl chloride. The device comprises a chlorinated polyvinyl chloride particle storage bin, a chlorinated polyvinyl chloride storage bin, two parallel fluidized bed reactors, two parallel riser reactors, a downer, a tail gas purifier and two circulating fans which are respectively used for transporting riser conveying gas and transporting raw material gas. In the device, the low-temperature plasma is utilized to simultaneously activate chlorine and PVC (poly vinyl chloride) raw material particles to quickly chloridize PVC in the circulating fluidized bed; and meanwhile, two groups of fluidized bed reactors are adopted for operation in turn to realize continuous production. Thus, the problems of low production efficiency and the like brought by that the reactor stops and unloads can be avoided, the phenomenon that fans, tail gas processors and the like are restarted after stopping can be eliminated, energy consumption is saved, and the service life of equipment is prolonged.

Owner:TSINGHUA UNIV

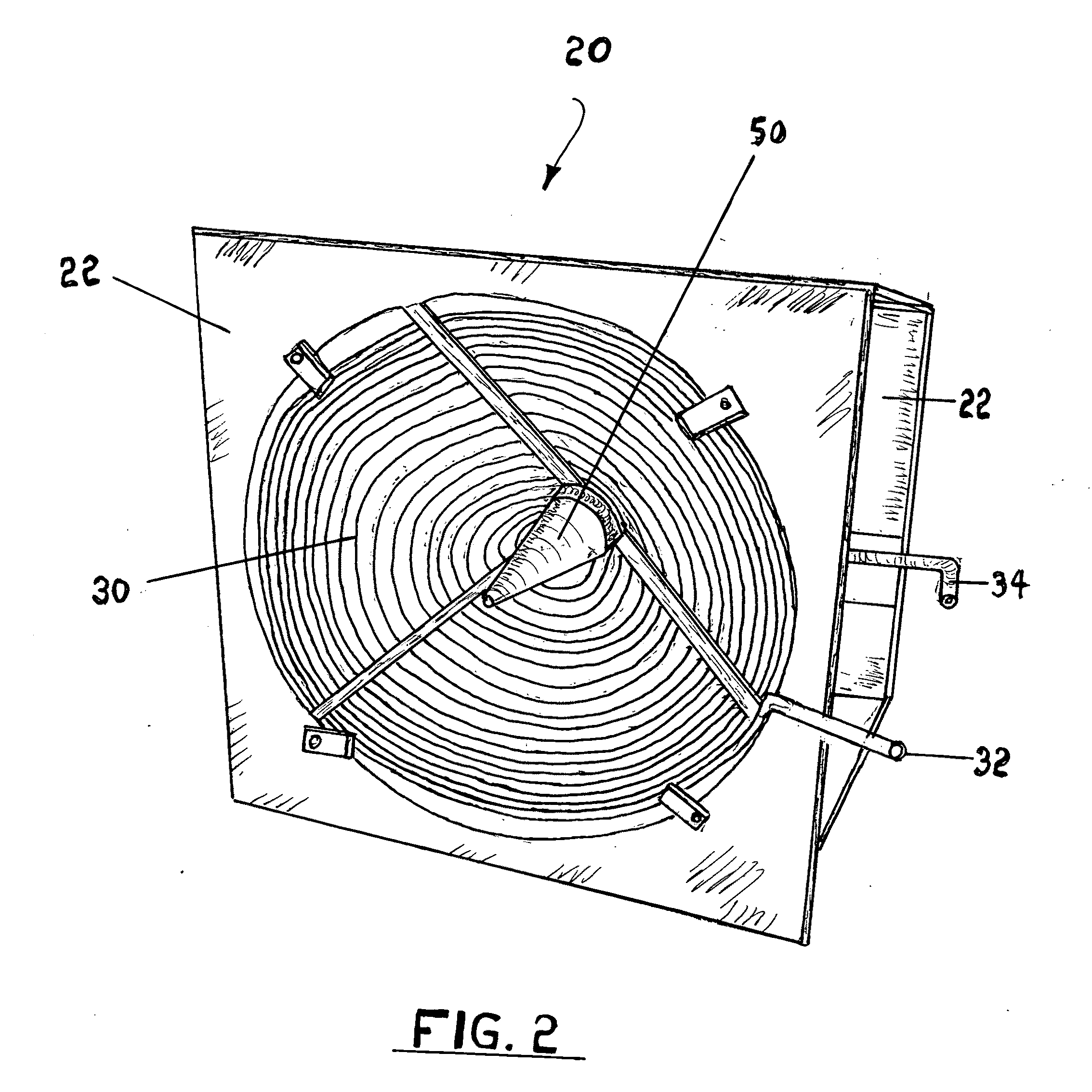

Coiled heat exchanger with beam spreader especially for use with solar-powered gas processors

InactiveUS20090277442A1Improve efficiencySolar heating energySolar heat devicesEngineeringSolar energy harvesting

An apparatus and method for solar energy powered gas processing. There is disclosed a processor assembly for use in heating a process or feed gas by means of a convective heat exchanger which receives solar energy from a focused solar energy collector. A specialized heat exchanger is described, which includes a conical envelope into which a metal tube is spirally wound, such that the tube is coiled into a conical spiral corresponding generally to the envelope. A reflective beam spreader is situated near the vertex of the envelope cone to re-direct incident solar radiation toward the exchanger tube. The apparatus thus has a cavity into which solar energy is focused to be incident upon the exchanger tube to superheat a gas or gas mixture flowing through the tube. The heated gas can be used in various gas reaction processes, such as steam methane reformation, a reverse water-gas shift reaction, or to drive a heat engine. Various auxiliary features are disclosed for increasing the efficiency of the solar heat transfer into the flowing process gas.

Owner:JENSEN REED

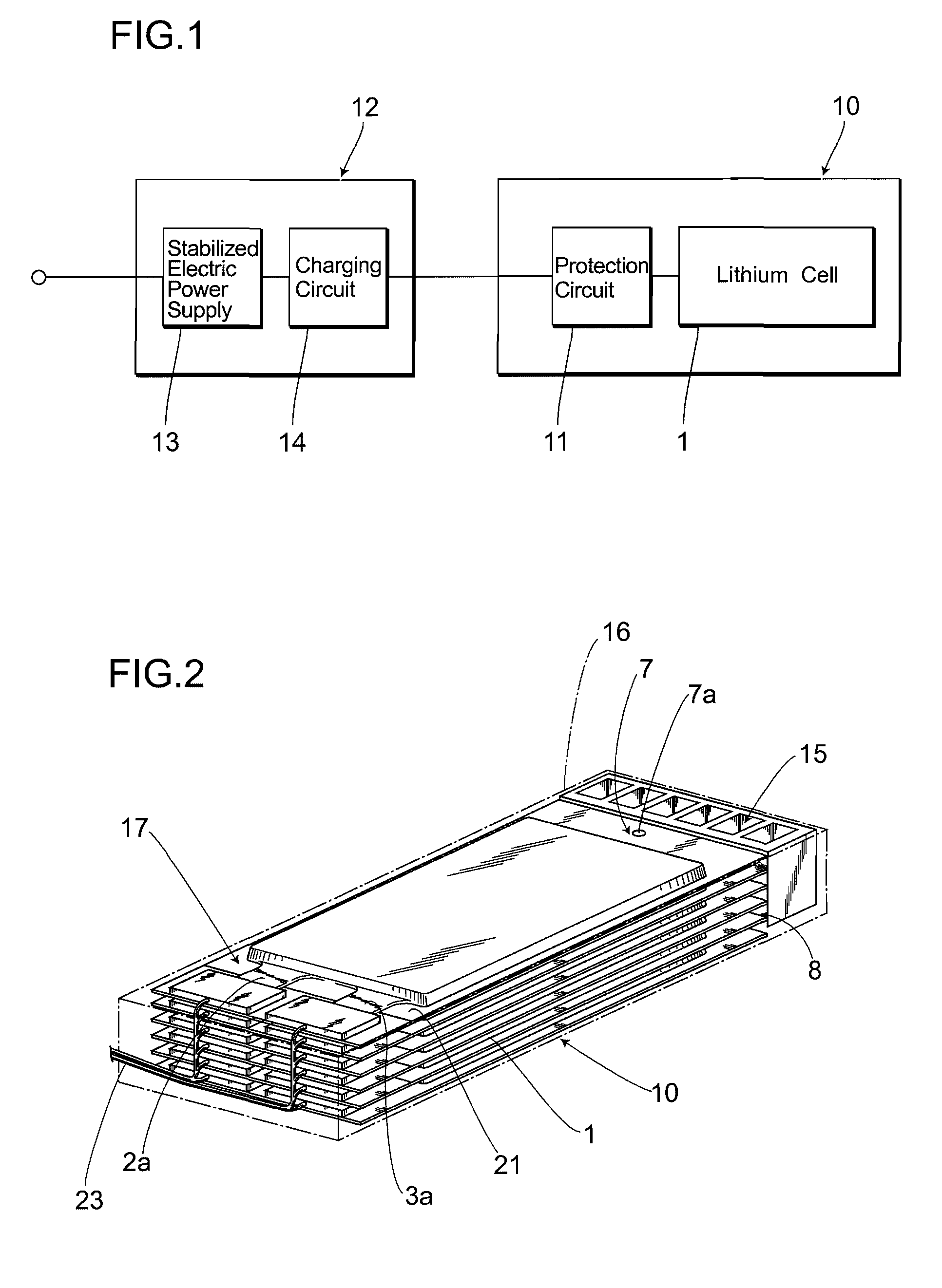

Battery pack

InactiveUS7964300B2Efficient liquefactionAvoid residueBattery isolationVent arrangementsOvervoltageEngineering

There is provided a risk-free and easy-to-use battery pack using battery cells 1 as a secondary battery, in which internal gases evaporated by applying overvoltage or the like thereto are processed inside a case to be prevented from leaking to the outside of the case and thereby even if the case has been led to rise in pressure due to a thermorunaway of the battery, the case is free from breaking. To realize this performance, the battery pack 10 is provided with a battery cell housing 17 for housing lithium cells 1 and a gas processor 15 for liquefying the internal gases g generated from the lithium cells 1.

Owner:TDK LAMBDA CORP

System for processing radioactive wastes

ActiveCN102201271AAchieve retentionAvoid siltingRadioactive decontaminationRadioactive wasteEngineering

The invention relates to a system for processing radioactive wastes, which is integrated in a movable shelter including a volume-reduction device and a tail-gas processor connected to a pipeline of the volume-reduction device; and both the volume-reduction device and the tail-gas processor are placed in a vacuum environment. The invention provides a movable system for processing radioactive wastes, which reduces storage space, causes little pollution to the environment and is low in storage cost.

Owner:HUANCHUANG XIAMEN TECH

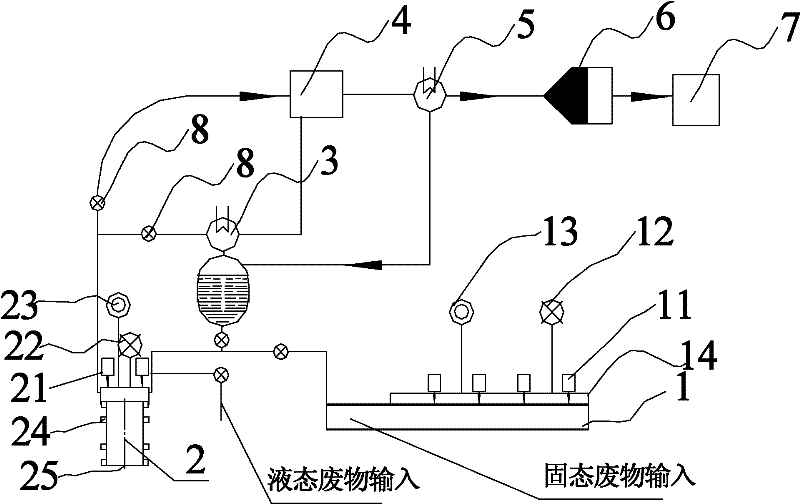

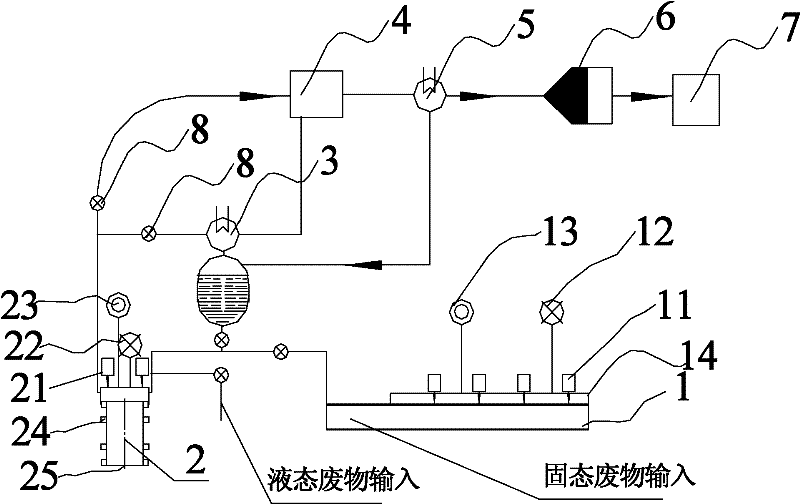

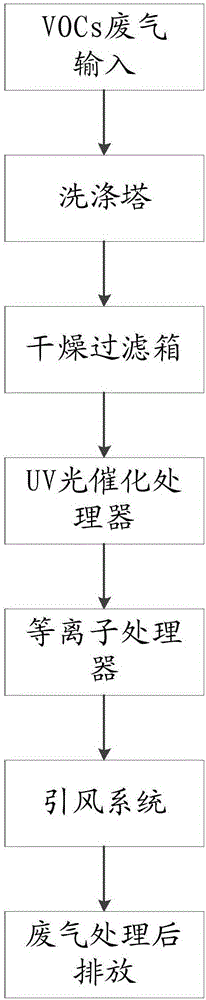

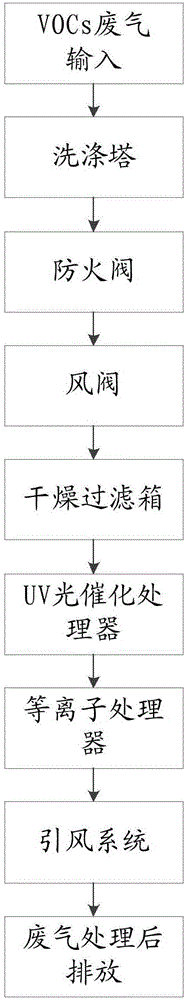

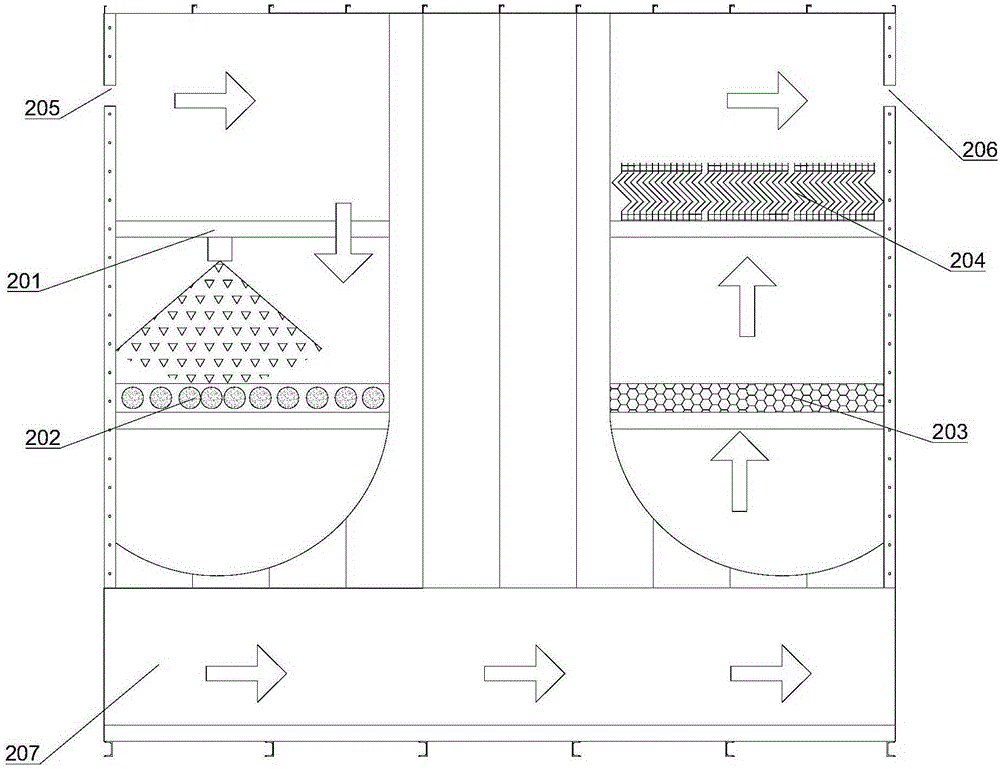

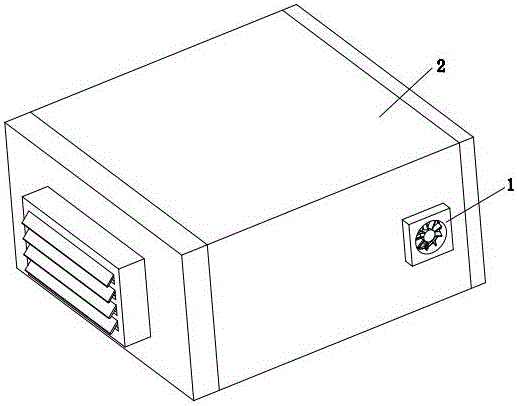

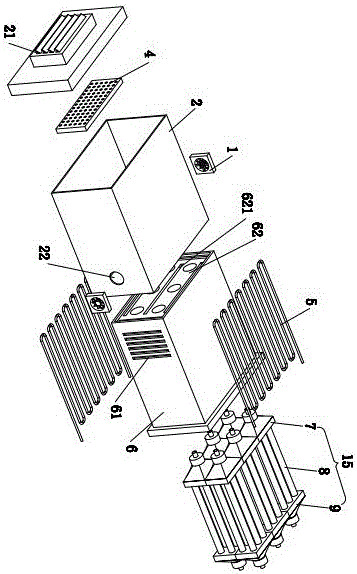

Equipment for treating waste gas containing VOCs (volatile organic compounds)

ActiveCN105194965AReduce energy consumptionEasy maintenanceCombination devicesDispersed particle filtrationEnvironmental engineeringChemical waste

The invention provides equipment for treating waste gas containing VOCs (volatile organic compounds) and belongs to the technical field of chemical waste gas. The equipment for treating the waste gas containing the VOCs comprises a washing tower, a dry filter tank, gas treatment devices and an induced draught system, wherein the gas treatment devices comprise a UV (ultraviolet) photocatalysis treatment device and a plasma treatment device. The equipment for treating the waste gas containing the VOCs has higher treatment efficiency and higher safety and treats waste gas more thoroughly. Besides, the energy consumption can be greatly reduced when the equipment is utilized to treat waste gas containing the VOCs, and the use cost is greatly reduced due to the fact that the equipment is simple in structure and convenient to maintain.

Tubular fuel cell

ActiveCN106816618AReasonable heat exchangeImprove thermal efficiencyFuel cell heat exchangeElectric heatingGas processor

The invention relates to a tubular fuel cell which is characterized by comprising an outer shell, a thermal insulation inner shell, a first louvre damper, a second louvre damper, sub-stacks, an electric heating tube and a fan, wherein a ventilation opening and an exhaust opening are formed in the outer shell; the thermal insulation inner shell is integrally arranged in an inner cavity of the outer shell; the thermal insulation inner shell is in clearance fit with the outer shell to form an air flow channel; ventilation holes are formed in the thermal insulation inner shell; a front thermal insulation end plate and a rear thermal insulation end plate are respectively arranged at a front end part and a rear end part of the thermal insulation inner shell; a tail gas outlet is formed in the rear thermal insulation end plate; the first louvre damper and the second louvre damper are respectively arranged inside the ventilation opening and the exhaust opening; the sub-stacks are arranged in the thermal insulation inner shell and are in clearance fit with each other; the sub-stacks comprise tail gas processors, ceramic tubes and fuel gas distributors; a gas inlet tube and a gas outlet tube of each fuel gas distributor are respectively communicated with external fuel gas and a gas inlet of each ceramic tube; the gas inlet tube and the gas outlet tube of each tail gas processor are respectively communicated with the gas outlet and the exhaust opening of each ceramic tube; two adjacent ceramic tubes are in clearance fit with each other to form a cathode air flow channel; the electric heating tube heats the cathode air flow channel. The tubular fuel cell has the advantages of having high thermal efficiency, preventing outer walls of the ceramic tubes from depositing carbon, and having compact and ordered structure.

Owner:FOSHAN SUOFUKE HYDROGEN ENERGY CO LTD

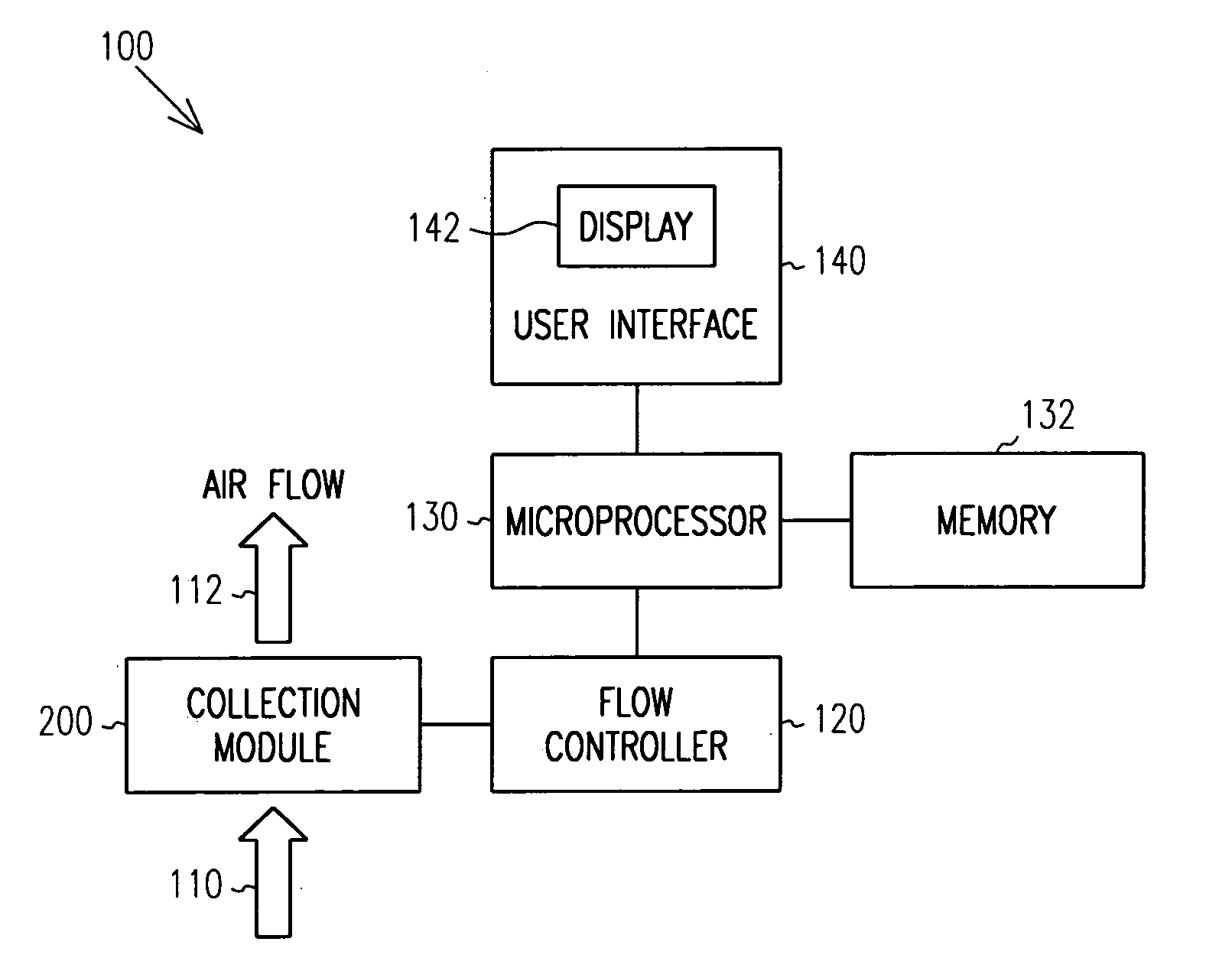

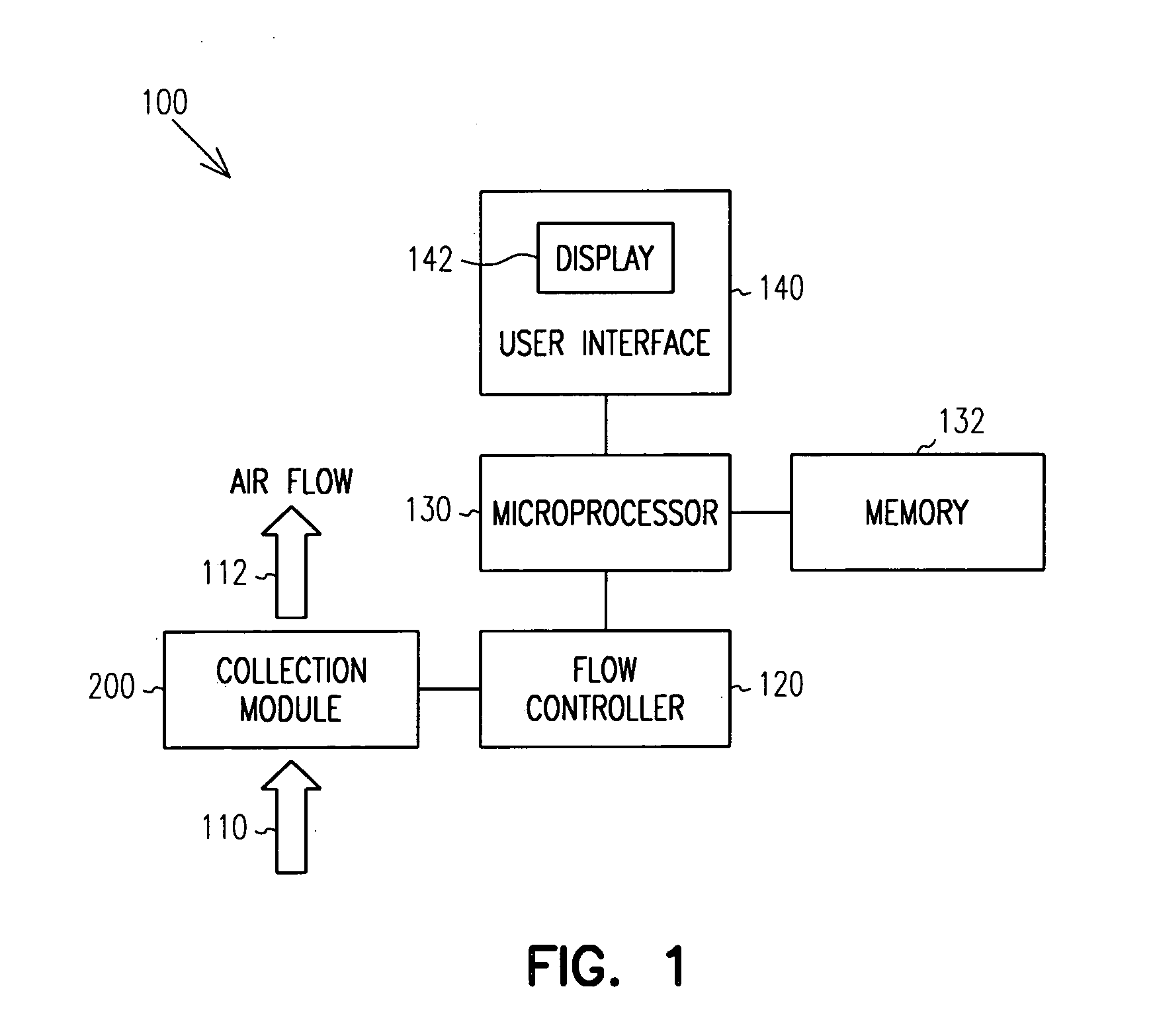

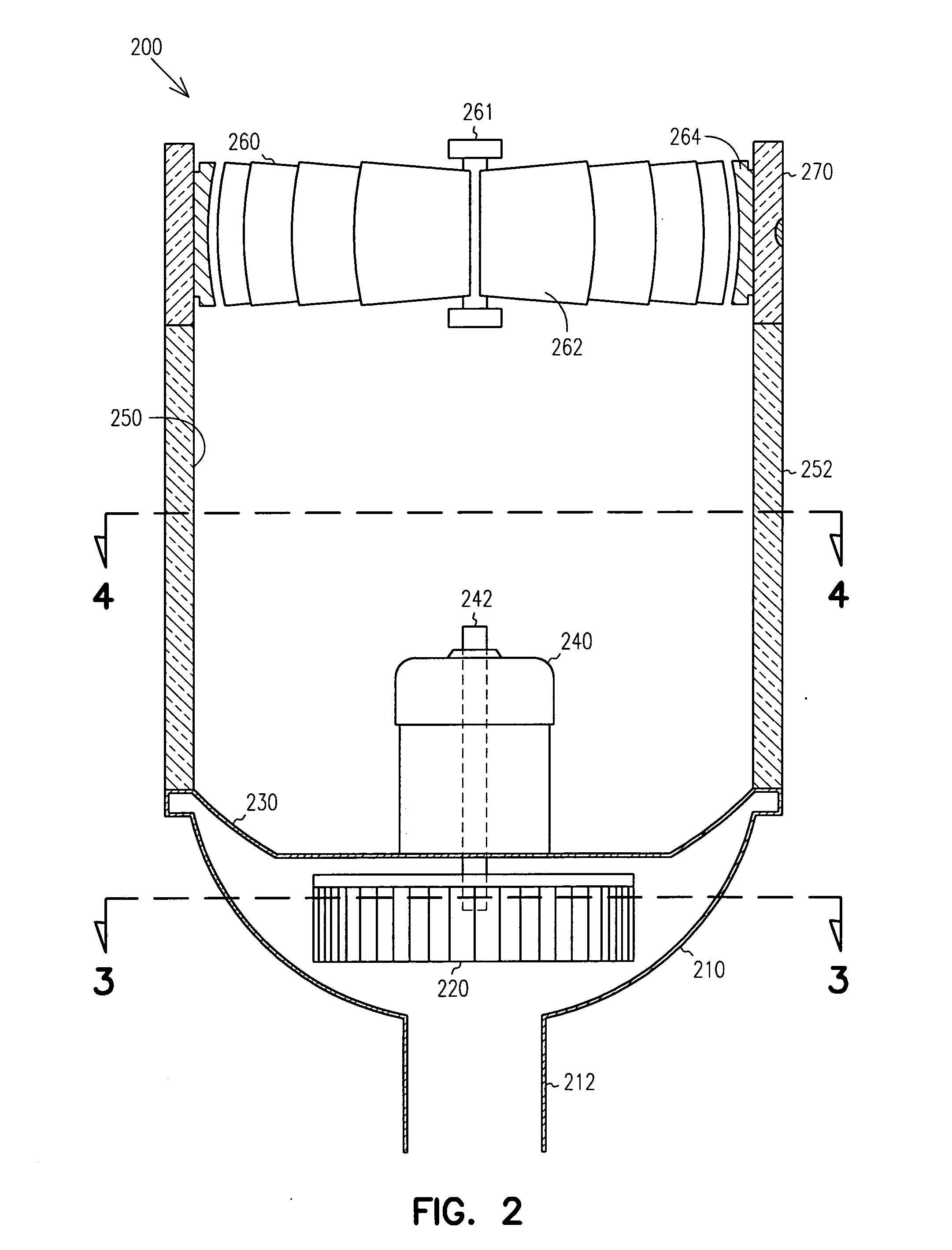

Air sampling apparatus and method

A sampling system includes a collection module including a gas handler, and a flow controller in communication with the gas handler of the collection module. The flow controller controls the gas handler to move a selected volume of gas through the collection module.

Owner:HEALTH DIAGNOSTICS TOOLS

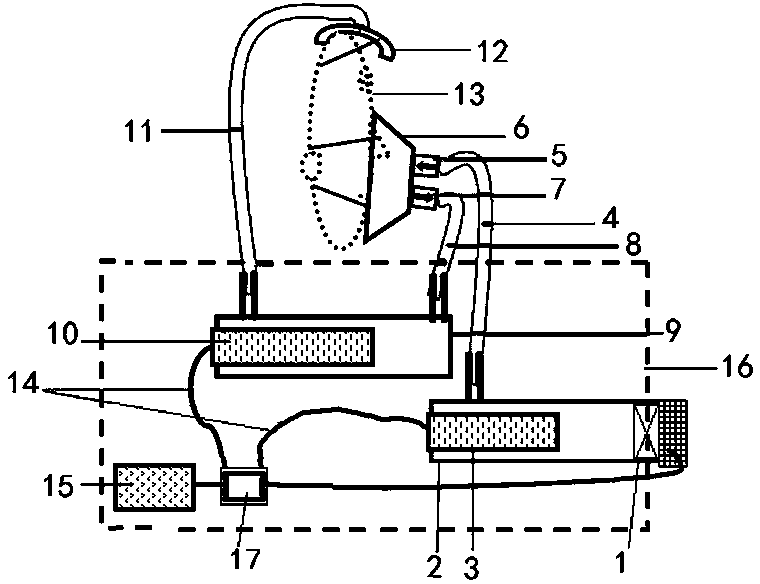

Large-ventilation mask for preventing virus transmission

The invention relates to a large-ventilation mask for preventing virus transmission. The invention has the following technical solution: a mouth and nose mask is provided with an inhalation single-flow valve and an exhalation single-flow valve, the inhalation single-flow valve is connected to an inhalation end sterilizer in a gas processor through an inhalation pipeline, the exhalation single-flowvalve is connected to an exhalation end sterilizer in the gas processor through an exhalation pipeline, and an outlet of the exhalation end sterilizer is connected to an air collecting hood installedon a face of a person through a discharge pipeline. The mask has the following beneficial effects: a fan is installed, so that a gas can be actively inhaled to form positive pressure on the mouth andnose mask to avoid inhalation of unsterilized air caused by inadequate fit of the mouth and nose mask and the face; the exhaled gas together with sterilized air sucked by the fan are conveyed throughthe pipeline to the air collecting hood located above the face and blown downwards to form a gas barrier that reduces the chance of the face being infected with viruses in air; and the inhaled and exhaled air is sterilized by ultraviolet lamps, and the entire mask has a large ventilation amount to avoid breathlessness and hypoxia.

Owner:齐胜利

Gas Handler, Riser Assembly, and Method

Method, riser assembly and gas handler for diverting gas from a riser. The riser assembly includes a riser having a first end and a second end and a conduit extending from the first end to the second end; a gas handler connected to the riser and provided between the first end and the second end, the gas handler having an external casing; plural pipes attached to an outside of the riser such that at least one pipe of the plural pipes enters through the external casing; and a gas vent pipe configured to start at the gas handler and extend towards the second end of the riser and the gas vent pipe is further configured to divert a gas from the gas handler through the outside of the riser.

Owner:HYDRIL USA DISTRIBUTION LLC

A growth method of silicon germanium material

InactiveCN101106079ASimple structureLow costSemiconductor/solid-state device manufacturingFrom chemically reactive gasesGas phaseWorking pressure

The invention discloses a production method of silicon and germanium materials. The equipment used in the invention is a device for growing SiGe material with SiH4 as the gas source RPCVD, and replacing silicon hydride with SiH2Cl2 as the gas source so as to grow silicon and germanium extended material with the pressure-reduction chemical gas-phase sedimentation method. Gases used in the growth include H2, N2, SiH2Cl2, GeH4, PH3, and B2H6, growth temperature 700-900 DEG C, and working pressure 60-100Torr. Since the exhausted gas generated in the production process of the invention does not contain silicon hydride, the gas can be treated in water with the hydrolytic method directly. Therefore, structure of the exhausted gas processor of production equipment can be extremely simple, and cost of exhaust gas treatment can be low relatively.

Owner:HEBEI POSHING ELECTRONICS TECH

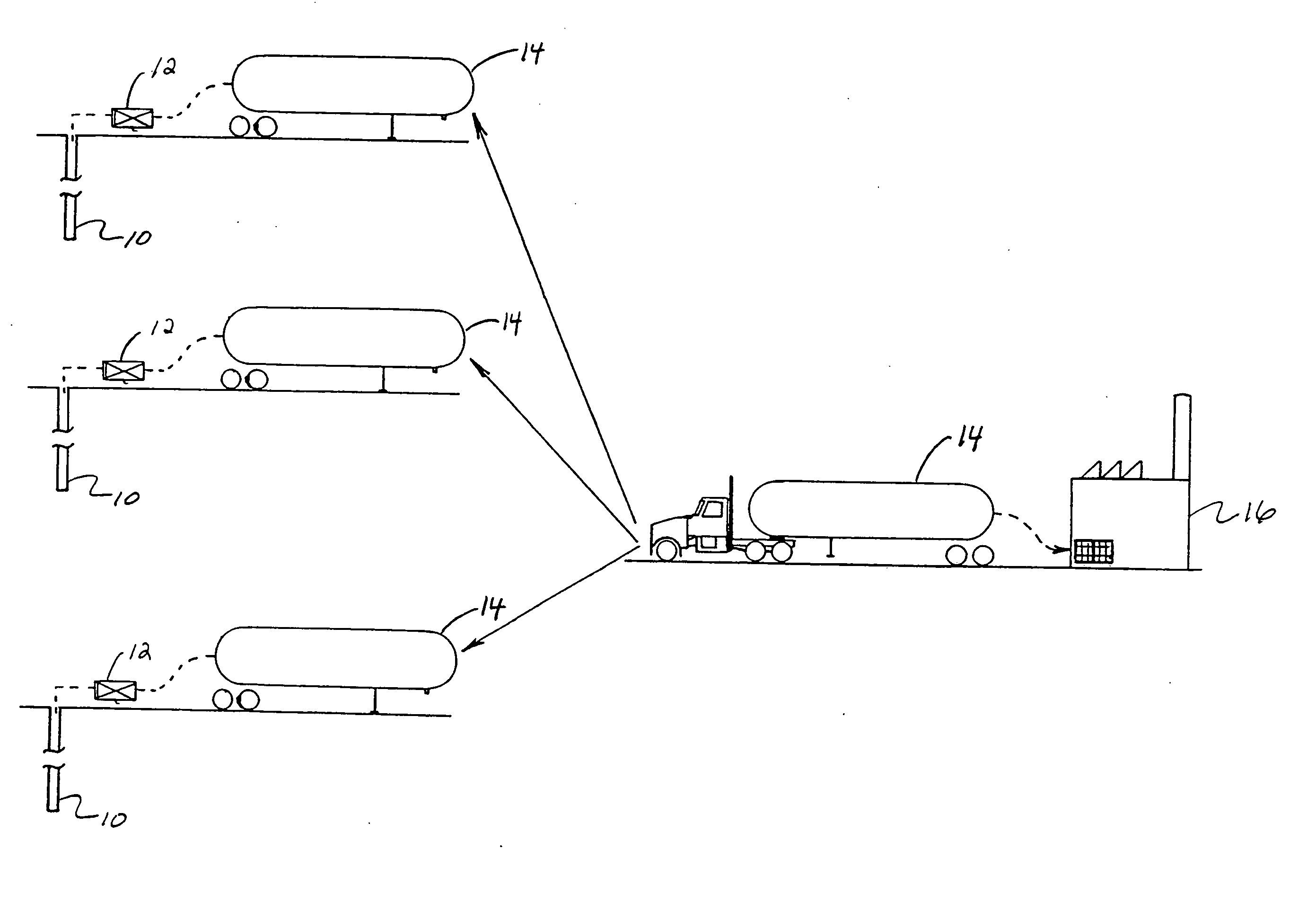

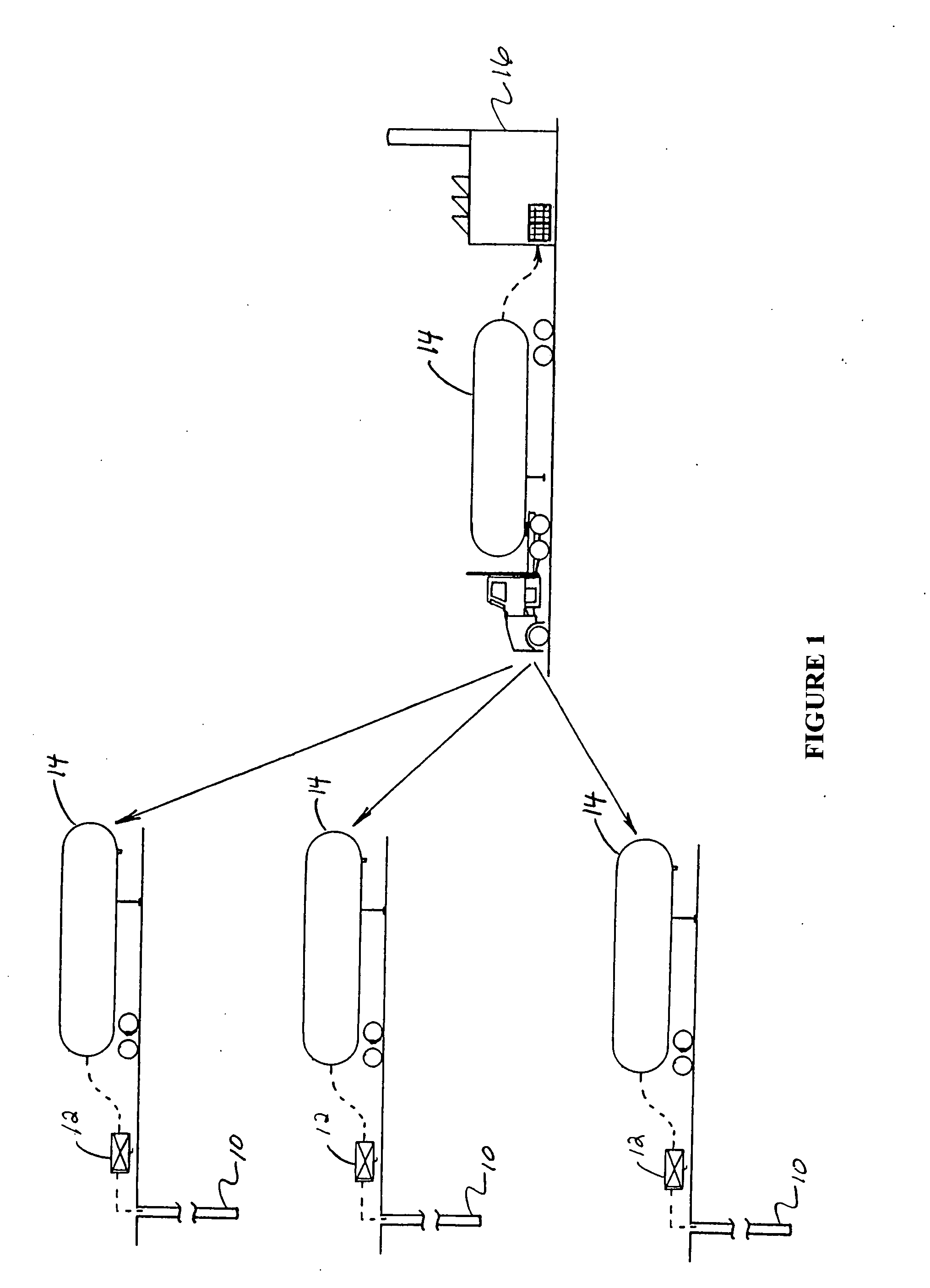

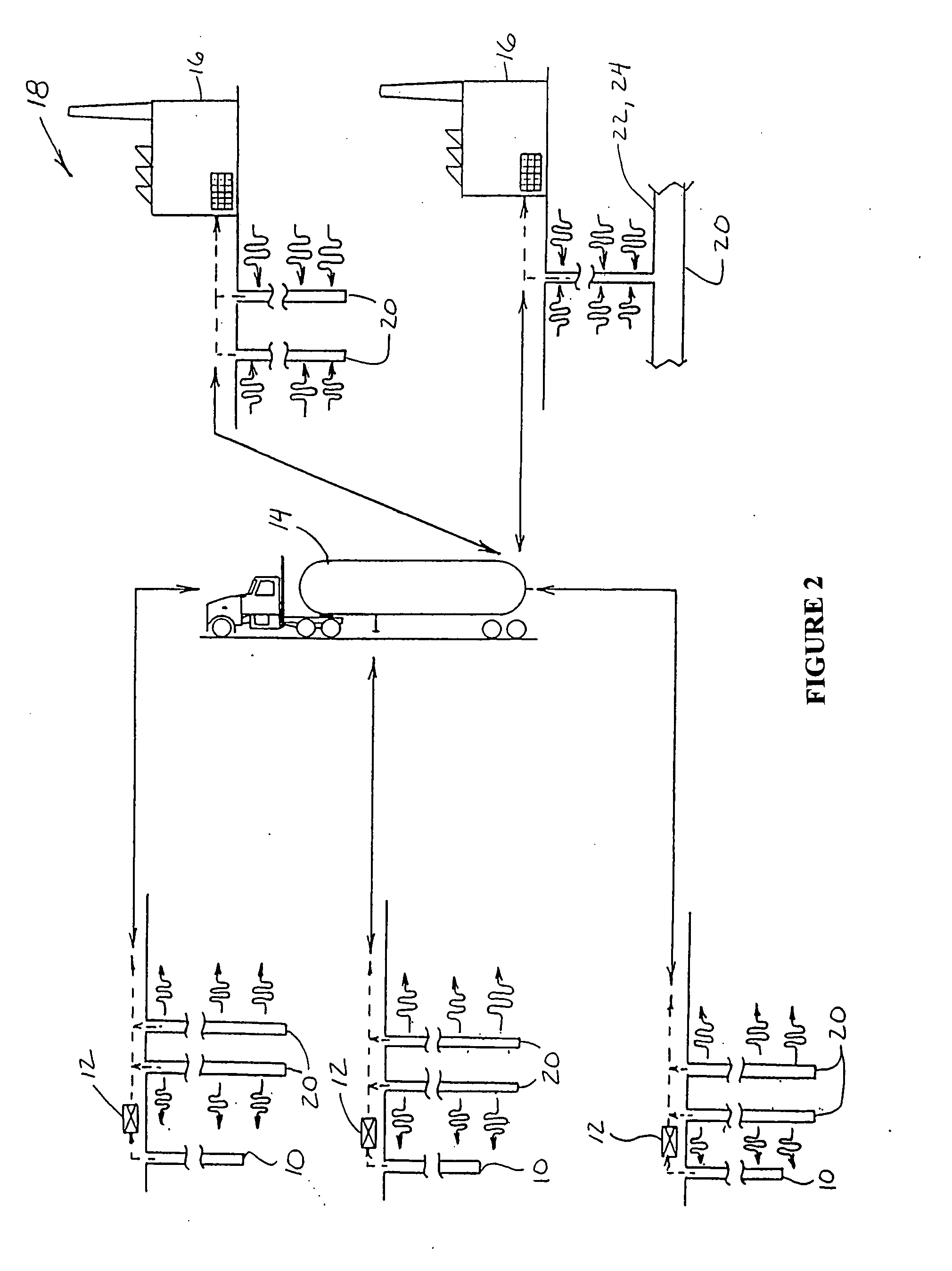

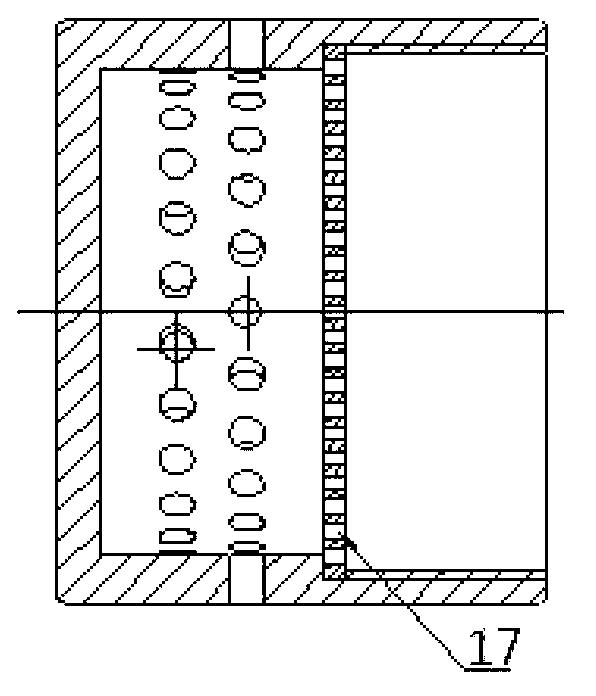

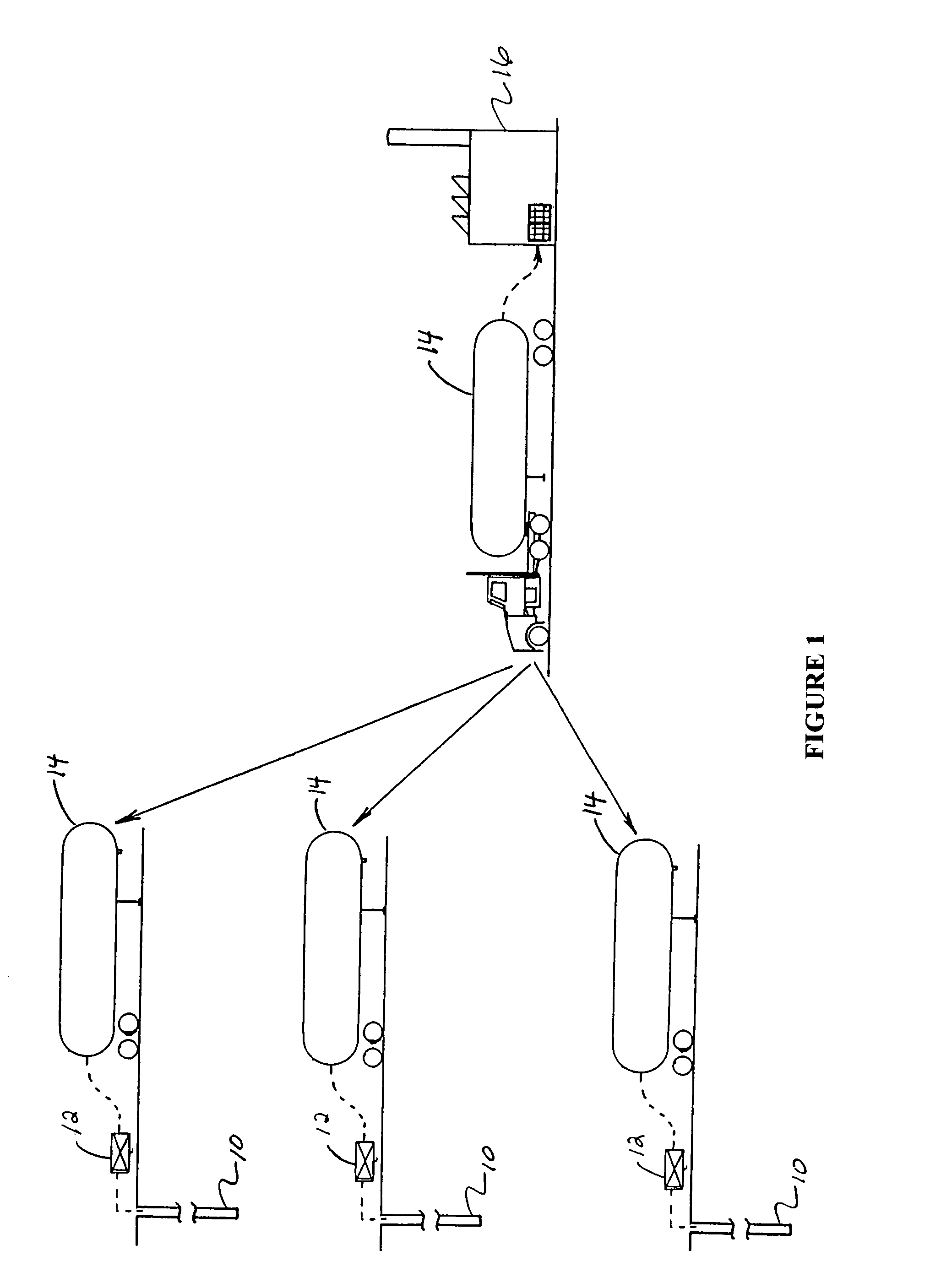

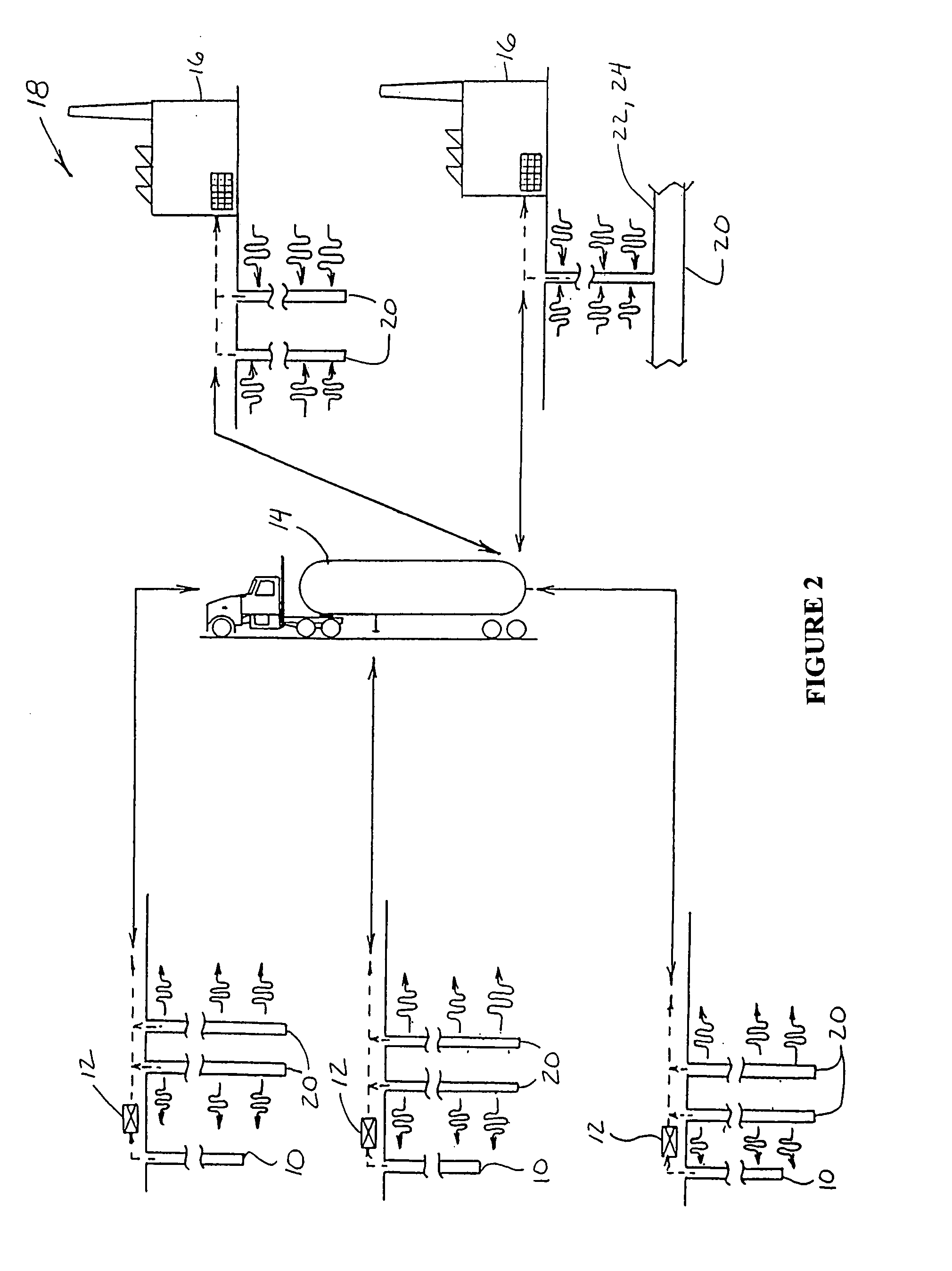

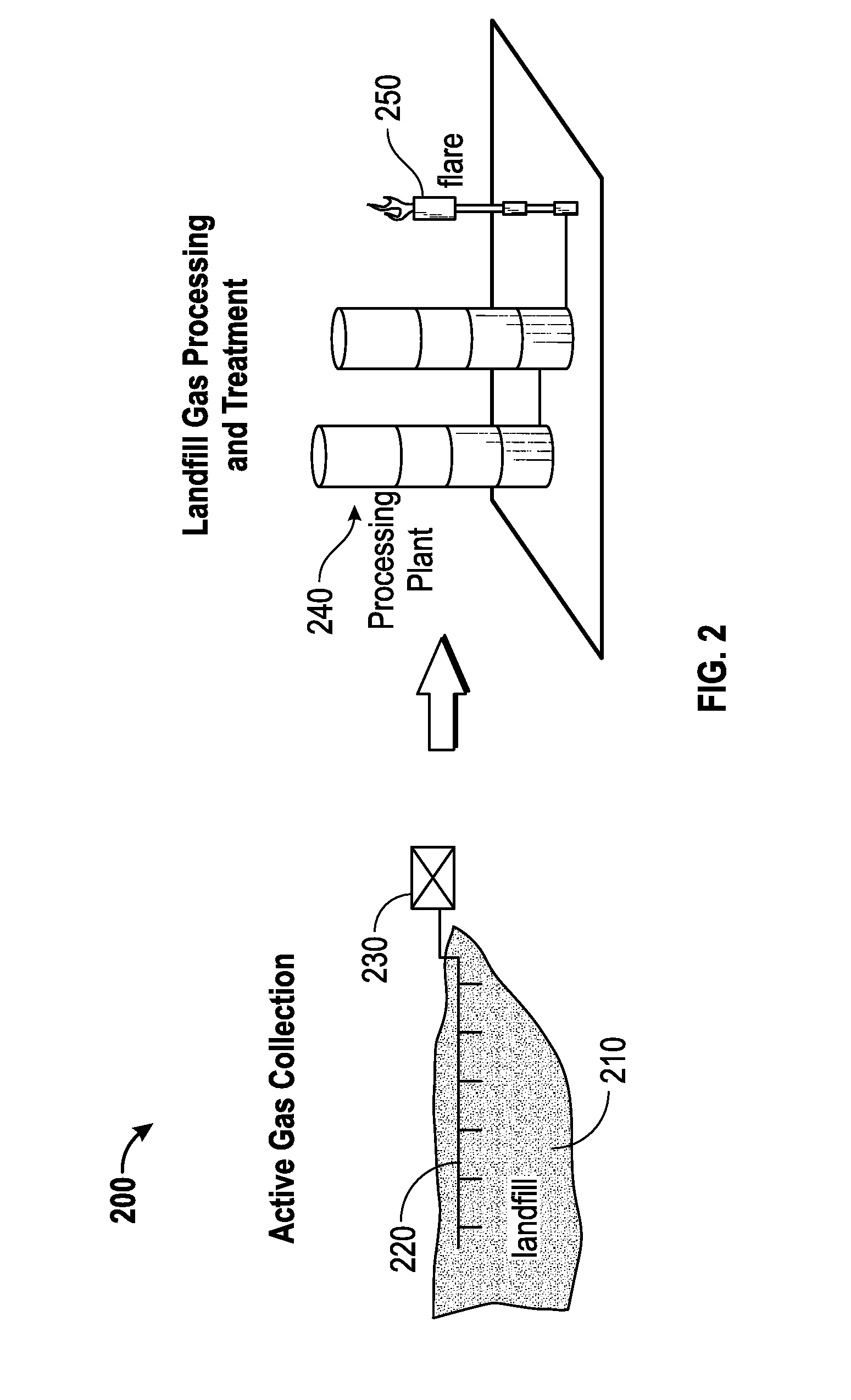

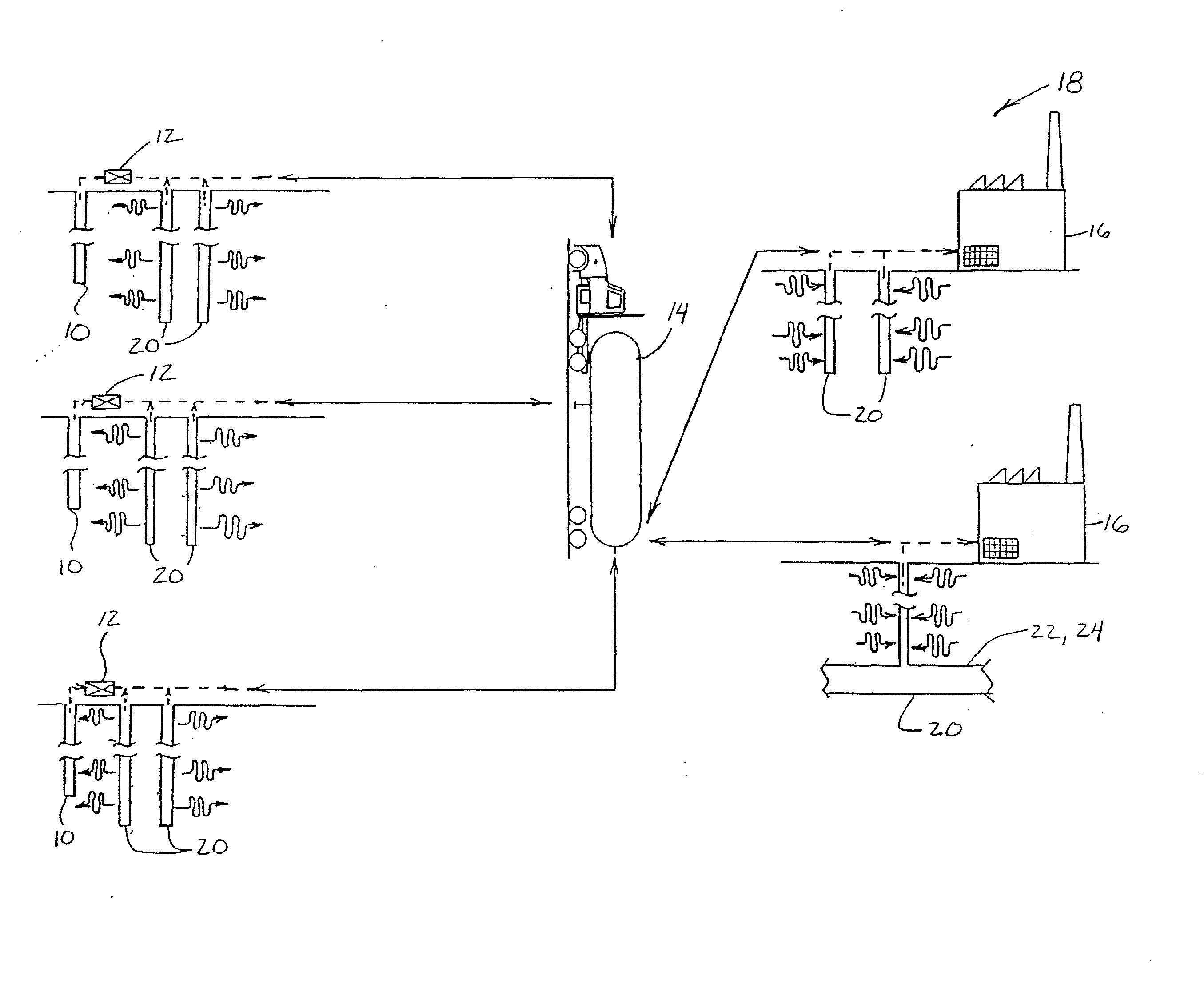

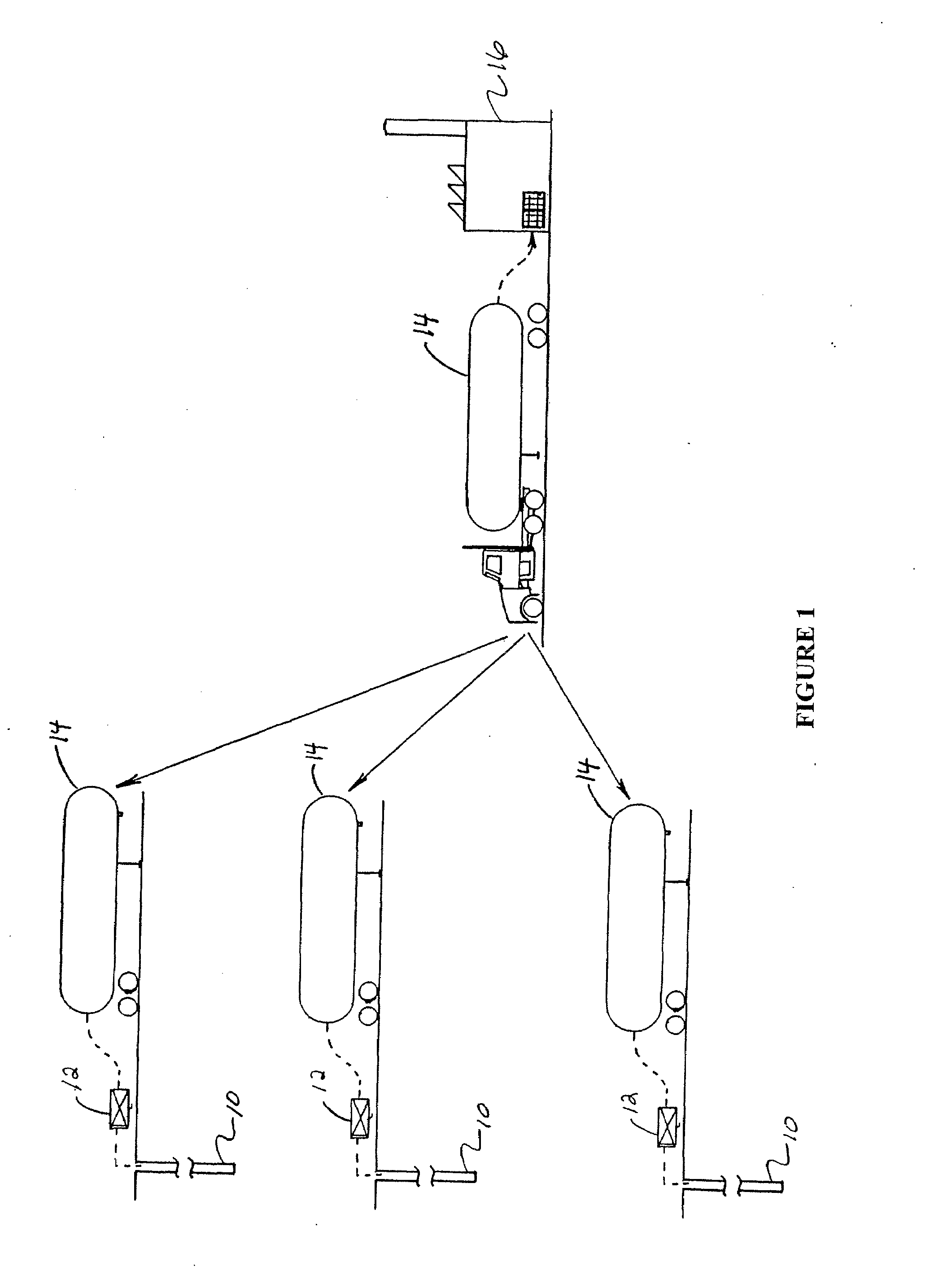

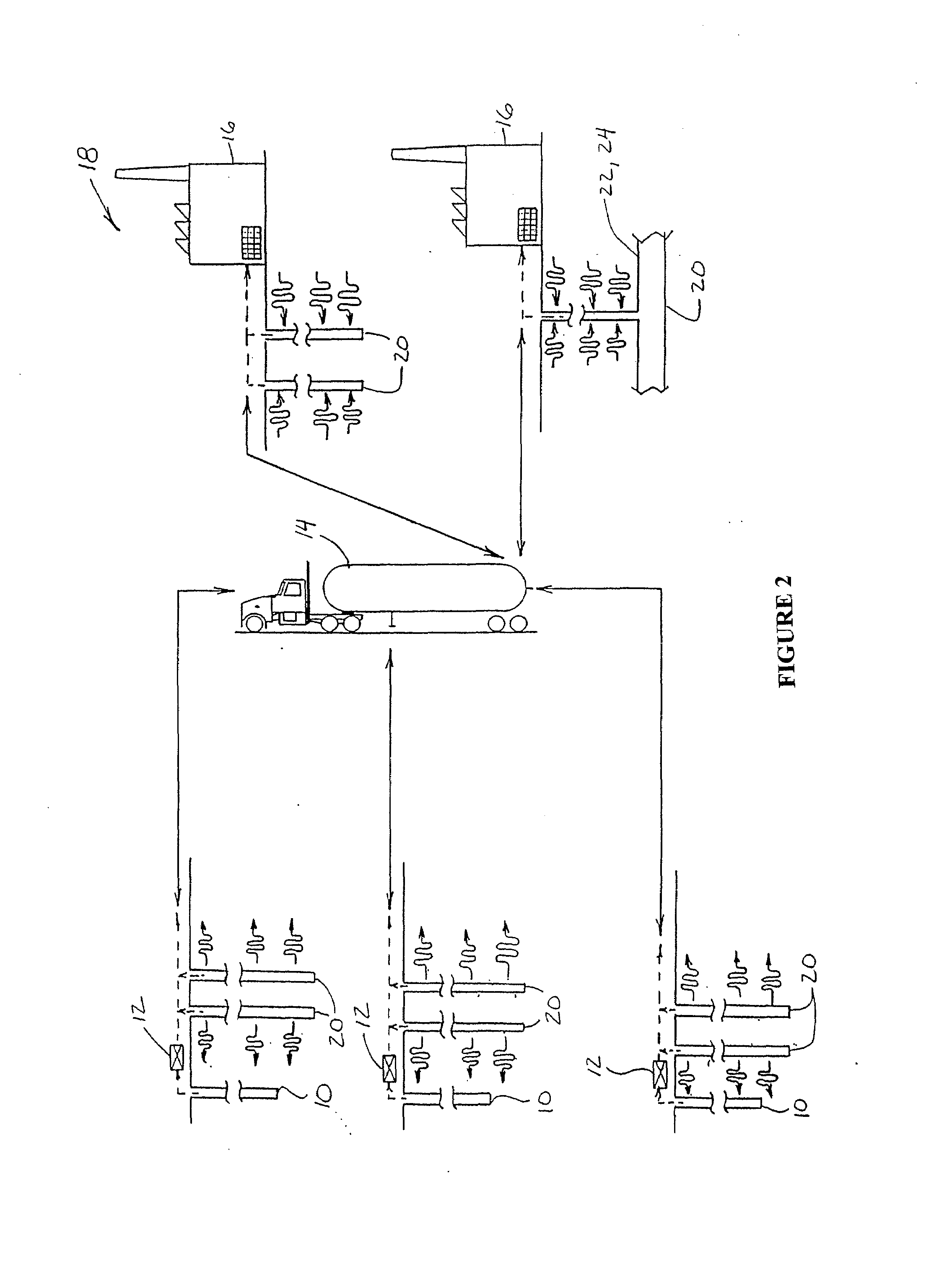

Method and apparatus for recovering and transporting methane gas

InactiveUS20070221382A1Easy to transportPressure dropDrilling rodsGas handling applicationsPower stationProcess engineering

This invention relates to the field of the recovery of methane gas from a coal mine and conventional Natural Gas. More particularly, it involves an apparatus and method for economically recovering methane gas from a coal mine and transporting the methane gas to an end user or other location. The invention further provides an apparatus and method for economically recovering Natural Gas that is stranded due to high impurities that requires processing and / or Natural Gas that is not located near a pipeline. According to a first preferred embodiment of the invention, such methods for recovering and transporting gas comprise (a) transferring gas from a producing well to a first subterranean capacitor and storing the gas in said capacitor and (b) transferring gas from the first subterranean capacitor to a second subterranean capacitor, a pipeline, an end user, a gas processor, or a power plant.

Owner:COMPRESSED ENERGY SYST LLC

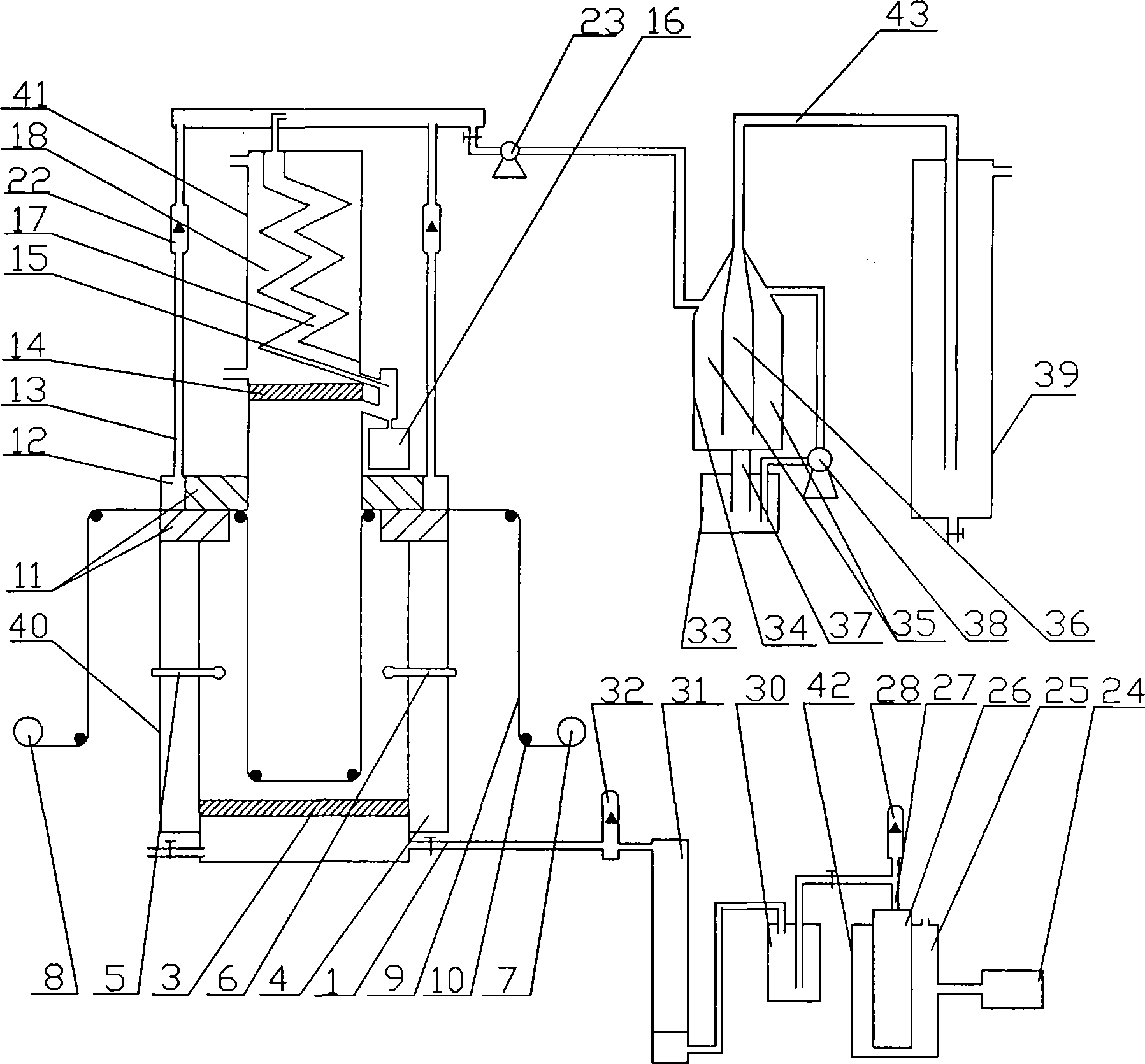

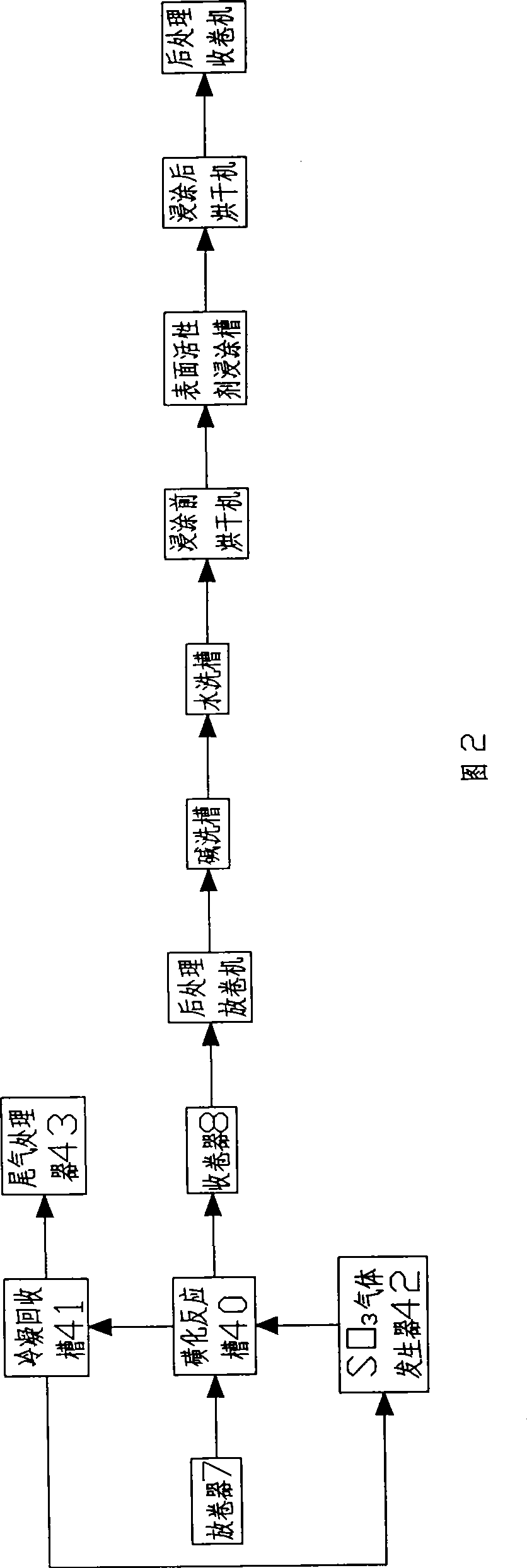

Battery diaphragm sulphonation equipment and sulphonation treatment technique

The invention provides battery-diaphragm sulfonation equipment, which has a sulfonation reaction device and a sulfonation reaction post-treatment device, wherein a sulfonation reaction tank of the sulfonation reaction device is provided with a SO3 gas inlet, and is in hermetic connection with a condensation recovery tank collecting escaping SO3 gas; the SO3 gas escaping from the sulfonation reaction tank enters a condensation tube in the condensation recovery tank; and the lower end of the condensation tube is communicated with a liquid-state SO3 recovery pot. The invention also provides a process of adopting the device to perform sulfonation reaction treatment and post-treatment of sulfonation reaction to battery diaphragms. In the process, fiber membrane is in contact with the SO3 gas for sulfonation. The sulfonation equipment has the advantages that the sulfonation reaction device is simple in structure, convenient to treat, low in cost and free from environmental pollution. The sulfonation equipment can reuse the escaping SO3 gas, and thoroughly eliminates the hidden trouble of polluting environment as the condensation tube is communicated with a tail gas processor.

Owner:莱州联友金浩新型材料有限公司

Chemical vapor deposition solid precursor continuous supply system

ActiveCN103122457ASolve the problem of continuous and uniform supplyIncrease Controlled VolatilityChemical vapor deposition coatingCarbide coatingCrucible

The invention discloses a chemical vapor deposition solid precursor continuous supply system composed of a vacuum chamber, a vacuum set, a chemical tail gas adsorber and a chemical tail gas processor, wherein a vacuum isolation chamber is arranged at the upper part of the vacuum chamber; a crucible and a heating body are embedded in the vacuum chamber; an air inlet is arranged on the outer wall of the vacuum chamber and is communicated with a controllable solid precursor volatilization device; a vacuum opening is arranged at the lower end of the vacuum chamber and is communicated with the chemical tail gas adsorber; and the chemical tail gas adsorber is communicated with the chemical tail gas processor via the vacuum set. According to the system, solid precursor can be continuously supplied and the volatilization temperature of the solid precursor can be accurately controlled by adjusting the position of the material in a furnace via a servo mechanism, so that the flow rate of the solid precursor can be accurately controlled; the supply system is simple in structure and easy to be compatible with common chemical vapor deposition equipment; and the controllable volatility, the continuity and the uniformity of the solid precursor in a chemical vapor deposition process are effectively increased and the implementation of the deposition of infusible metal carbide coatings or matrixes is ensured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method and apparatus for recovering and transporting methane gas

InactiveUS7571763B2Easy to transportPressure dropDrilling rodsGas handling applicationsPower stationProduct gas

Owner:COMPRESSED ENERGY SYST LLC

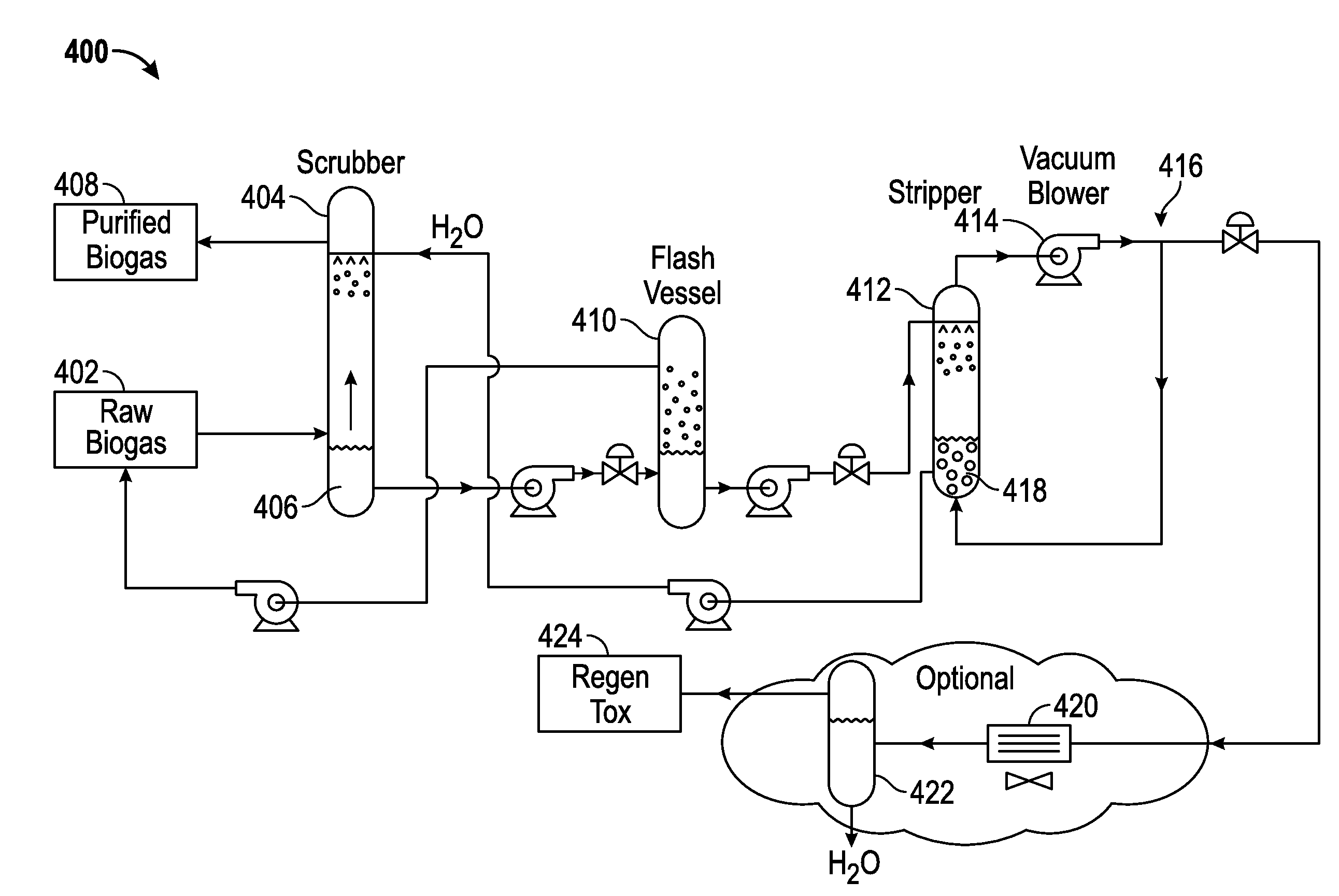

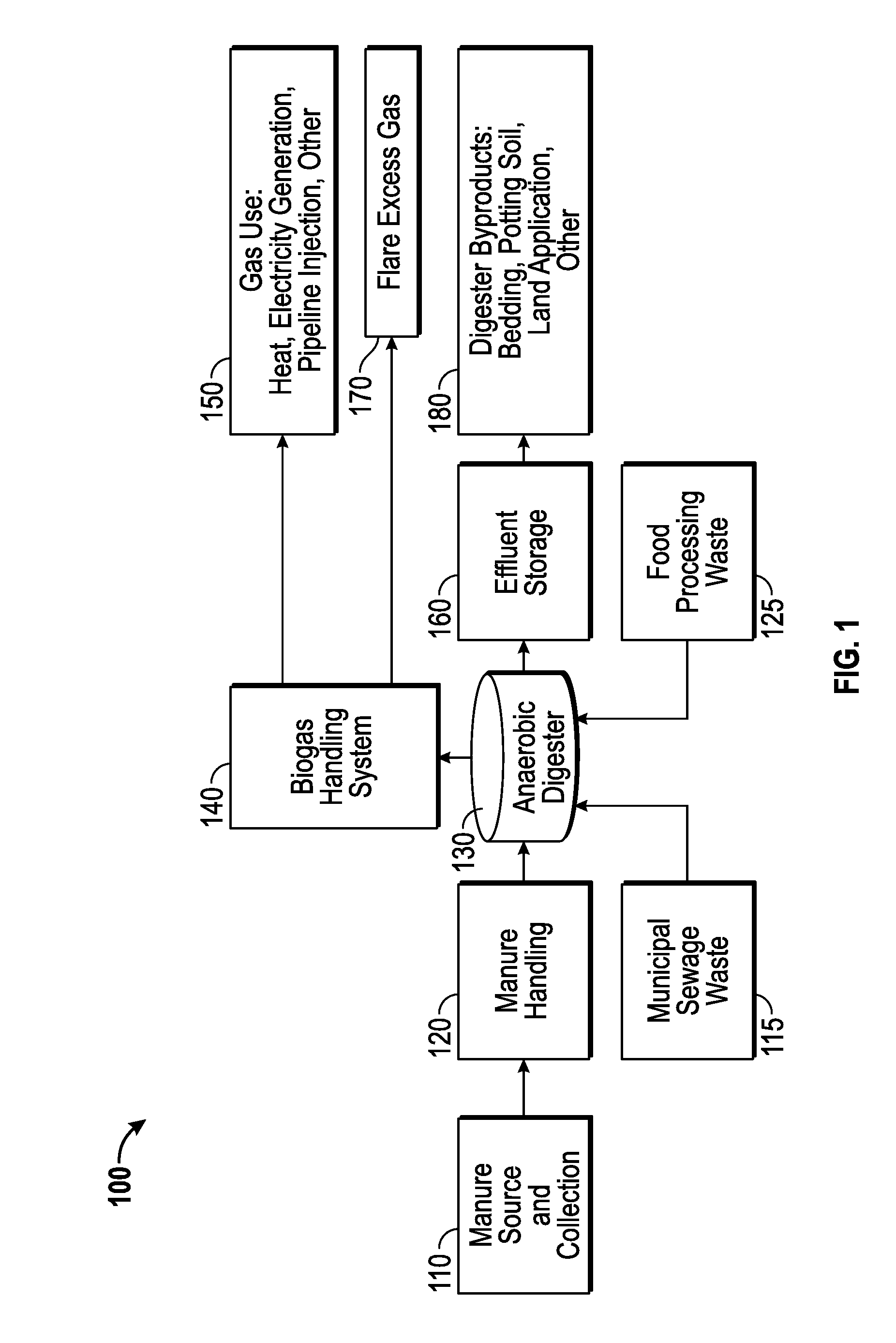

System for the treatment and purification of biogas with elimination of airflow from a scrubber system

InactiveUS20140134710A1Reduce the amount requiredBioreactor/fermenter combinationsLiquid degasificationEnvironmental engineeringScrubber

Systems and methods are presented for the purification of a biogas. The systems comprise: a gas processor for reducing CO2, volatile organic compounds, and H2S in the biogas, the gas processor comprising a scrubber tank and a scrubber liquid; and a scrubber liquid processor in fluid connection with the gas processor for reducing the amount of absorbed gas in the scrubber liquid. The scrubber liquid processor comprises a stripper tank, and is configured to reduce or eliminate airflow through the stripper tank.

Owner:CLEAN ENERGY RENEWABLE FUELS

Environmental-friendly automobile tail gas emission device

ActiveCN106285849AEasy to useReduce noiseInternal combustion piston enginesExhaust apparatusHazardous substanceEngineering

The invention discloses an environmental-friendly automobile tail gas emission device which comprises an exhaust pipe; a gas inlet pipe is arranged on one side of the exhaust pipe; a tail gas processor is arranged at one end of the gas inlet pipe; a hydraulic driver control button is arranged on the top of the tail gas processor; an electromagnet is arranged on the inner side of the tail gas processor; a rubber wiping ring is arranged at the bottom of the electromagnet; a transmission telescopic rod is arranged on one side of the rubber wiping ring; a hydraulic driver is arranged on one side of the transmission telescopic rod; a tail gas filter is arranged on the other side of the tail gas processor; an exhaust blower is arranged on one side of the tail gas filter; the exhaust pipe is arranged on one side of the exhaust blower; and an anechoic tile is arranged on the inner side of the exhaust pipe. According to the environmental-friendly automobile tail gas emission device, the tail gas processor and the tail gas filter can lower harmful substances in tail gas; the anechoic tile in the exhaust pipe can effectively lower noise generated by the automobile tail gas exhaust pipe; with detachable parts, the device is more convenient to use; and the rubber wiping ring can clean the surface of the electromagnet.

Owner:全椒精诚模具有限公司

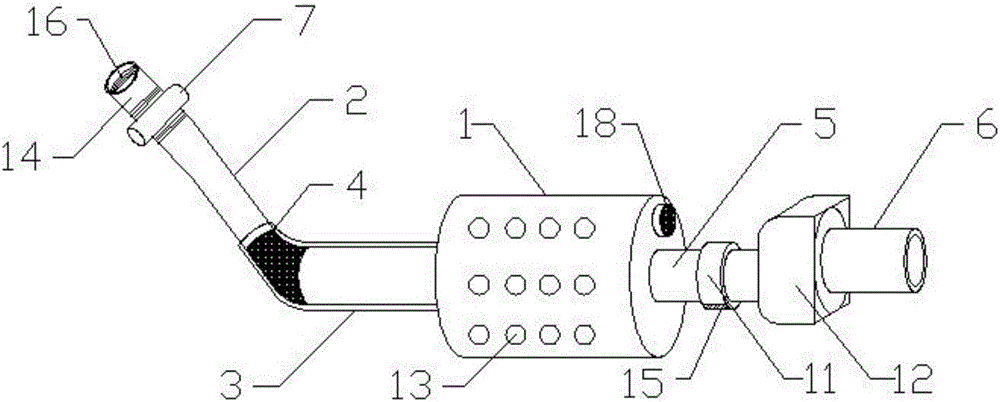

Hydrogen recovery and purification system and control method thereof

PendingCN108100994AIncrease concentrationRelieve pressureHydrogen separation by selective and reversible uptakeGas treatmentHydrogen concentrationMetal alloy

The invention relates to the chemical field and specifically discloses a hydrogen recovery and purification system and a control method thereof. The system comprises a tail gas processor, a water removal device, a compressor, a first buffer tank, a first gas separation membrane module, a first hydrogen storage device and a second buffer tank, the above parts are orderly connected, an exhaust outlet and an air inlet of an industrial device are respectively connected to the tail gas processor and the second buffer tank, the compressor compresses the gas until pressure of greater than or equal to5 bar, a membrane material of the first gas separation membrane module is prepared from a ceramic material, and a hydrogen storage material of the first hydrogen storage device is a metal alloy hydrogen storage material. The tail gas processor initially purifies hydrogen. Through the separation membrane prepared from the ceramic material, the hydrogen is further purified until the hydrogen purityof 99% or more. Through the alloy hydrogen storage material, the hydrogen concentration is increased to the 5N level. The system solves the problem that the hydrogen recovery and recycling device inthe non-pan semiconductor industry is not suitable for hydrogen recovery and recycling in the pan semiconductor industry.

Owner:SUZHOU REFINETEK CO LTD

Novel environment-friendly automobile exhaust pipe

InactiveCN106762075AImprove the noise reduction effectExtended service lifeInternal combustion piston enginesExhaust apparatusToxic gasLow noise

The invention discloses a novel environment-friendly automobile exhaust pipe which comprises a silencer, wherein a rear exhaust pipe is arranged on one side of the silencer; a temperature sensor is arranged at the top end of the rear exhaust pipe; a front exhaust pipe is mounted on one side of the temperature sensor; a carburetor is mounted at the top of the front exhaust pipe; an exhaust pipe port is formed in one side of the carburetor; a curve pipe is mounted in the silencer; and a baroceptor is arranged on one side of the curve pipe. The novel environment-friendly automobile exhaust pipe adopts the silencer, a second silencer and a noise reduction ceramic chip to effectively lower noise caused by the exhaust pipe and operation of an engine; the front exhaust pipe, the rear exhaust pipe and a tail end pipe greatly reduce temperature and heat of gas; the temperature sensor and the baroceptor can monitor temperature and air pressure in the exhaust pipes and silencers in real time; and a tail gas processor can filter, purify and treat toxic tail gas to effectively reduce emission of toxic gas.

Owner:SHIYAN RUIYU IND & TRADE CO LTD

Ultrahigh-scale formaldehyde production method and system

InactiveCN107056593AReduce joinMeet the needs of different concentrations of productsCarbonyl compound preparation by oxidationCarbonyl compound separation/purificationDehydrogenationReaction temperature

The invention discloses an ultrahigh-scale formaldehyde production method and system. The production method comprises the following steps: mixing a gas mixture of methyl alcohol steam from an evaporator, water steam, formaldehyde steam and air with a part of water steam; passing by a heater and a filter and then entering an oxygenizer; reacting and generating formaldehyde and other side products under the conditions that the temperature is 590-625 DEG C and the mole ratio of oxygen to methyl alcohol is 0.33-0.37 and under the effect of a silver catalyst in the oxygenizer; dealcoholizing and absorbing the high-temperature reaction generated gas by a first absorbing tower and a second absorbing tower in turn; extracting the product from the bottom of the first absorbing tower; supplementing some absorbing liquid extracted from the bottom of the second absorbing tower and returning into the evaporator; and guiding the dealcoholized tail gas in high hydrogen content into a tail gas processor, burning and recycling the waste heat. In the ultrahigh-scale formaldehyde production method provided by the invention, a lower mole ratio of oxygen to methyl alcohol and lower reaction temperature are set, so that the ratio of dehydrogenation reaction can approach to 48-50%.

Owner:TANGSHAN ZHONGHAO CHEM

Method and Apparatus for Recovering and Transporting Methane Gas

InactiveUS20090269138A1Easy to transportPressure dropGas handling applicationsLarge containersPower stationProcess engineering

This invention relates to the field of the recovery of methane gas from a coal mine and conventional Natural Gas. More particularly, it involves an apparatus and method for economically recovering methane gas from a coal mine and transporting the methane gas to an end user or other location. The invention further provides an apparatus and method for economically recovering Natural Gas that is stranded due to high impurities that requires processing and / or Natural Gas that is not located near a pipeline. According to a first preferred embodiment of the invention, such methods for recovering and transporting gas comprise (a) transferring gas from a producing well to a first subterranean capacitor and storing the gas in said capacitor and (b) transferring gas from the first subterranean capacitor to a second subterranean capacitor, a pipeline, an end user, a gas processor, or a power plant.

Owner:COMPRESSED ENERGY SYST LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com