Coiled heat exchanger with beam spreader especially for use with solar-powered gas processors

a heat exchanger and beam spreader technology, applied in solar heat systems, solar thermal energy generation, lighting and heating apparatus, etc., can solve the problems of increasing construction costs, reducing and reducing the source of non-renewable energy, so as to increase the efficiency of solar heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

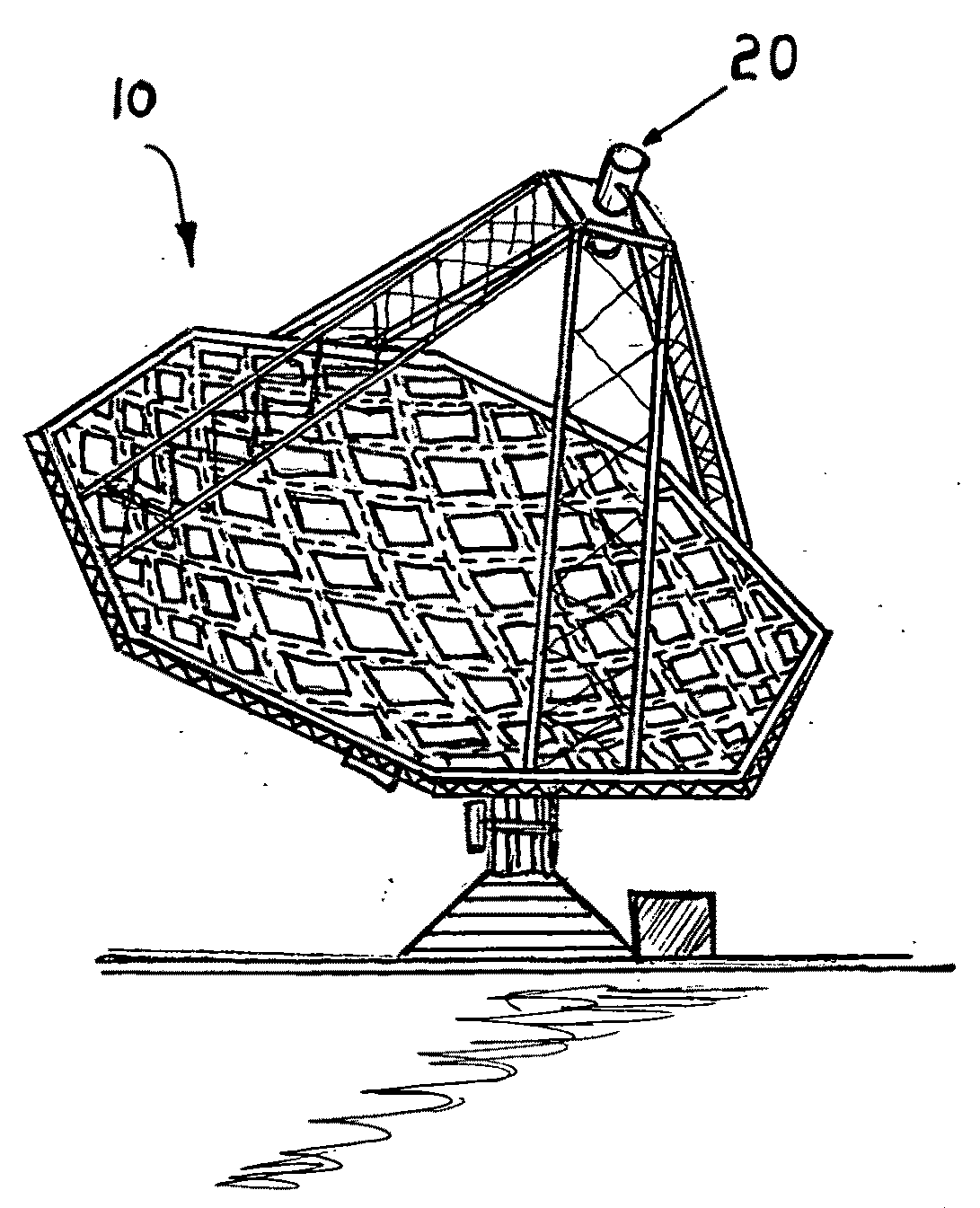

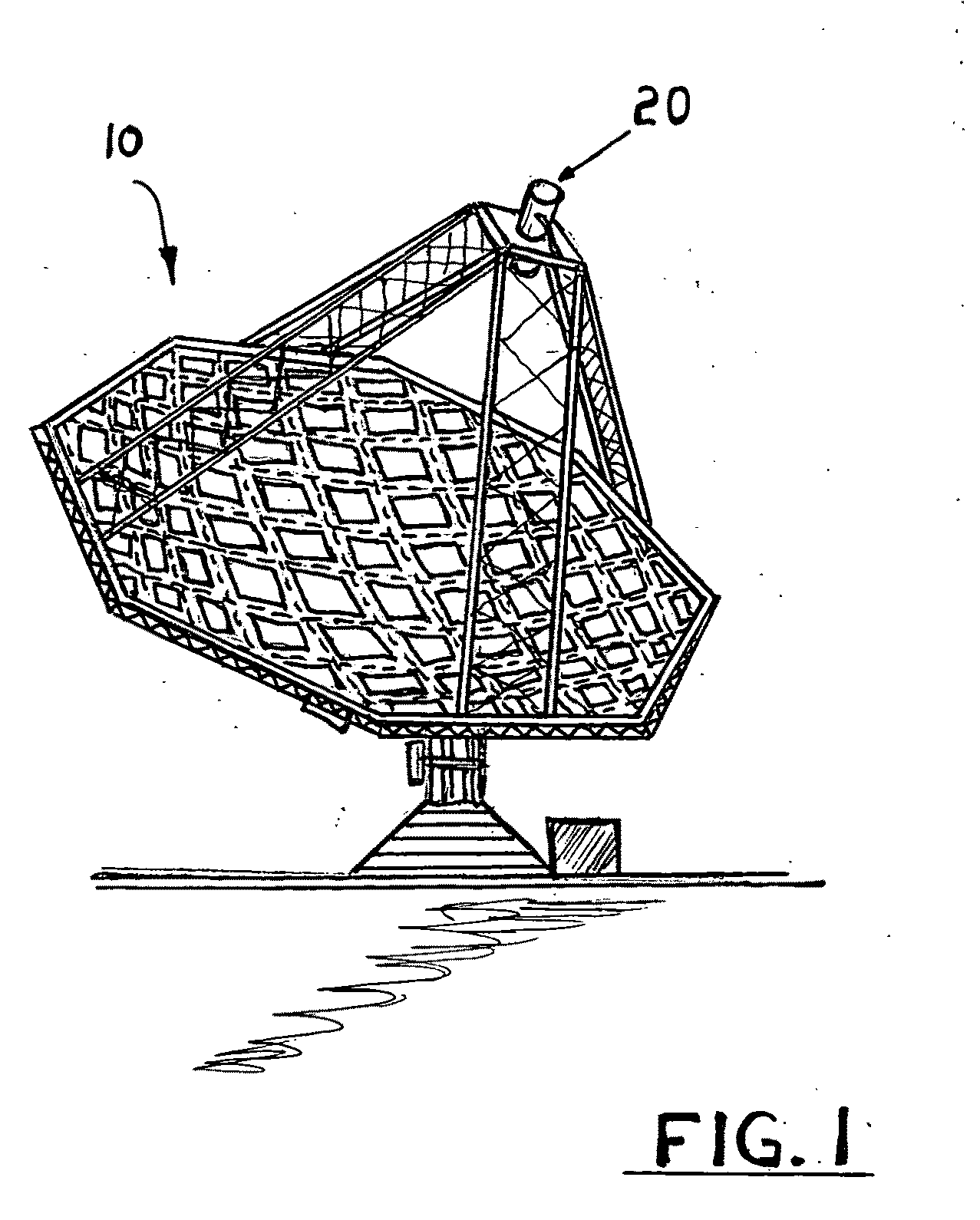

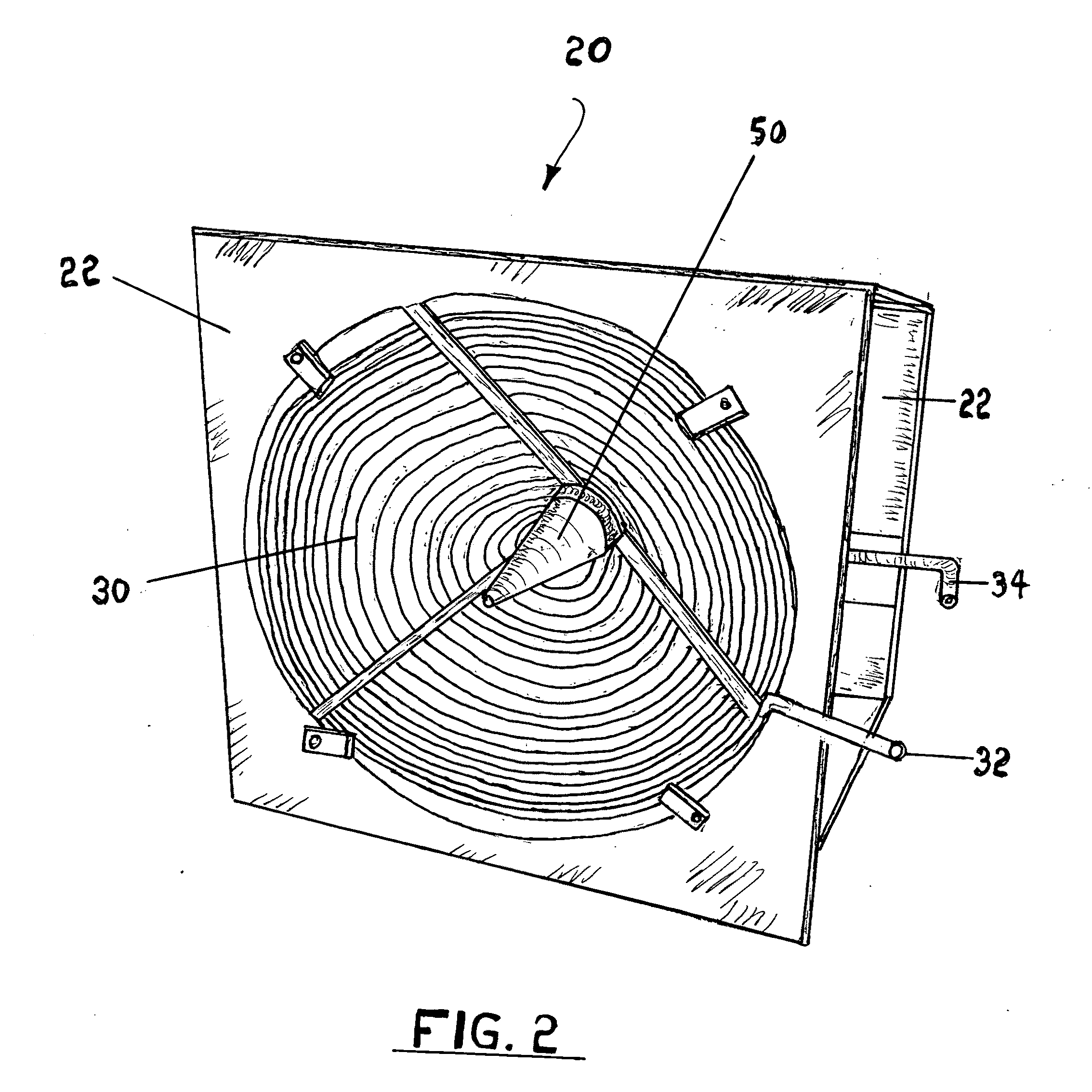

[0020]The present disclosure pertains to an apparatus and method for solar heating gases, such as to heat a feedstock gas to drive an engine, or to heat a gas for processing, for example for methane reformation or to drive a reverse water-gas shift. There is provided by the disclosure a processor by which a feed or process gas, which can be a gas relatively transparent to much of the solar spectrum, can be effectively heated by solar energy so that the hot gas can be harnessed to drive an engine, or for use in the production of useable fuels.

[0021]Succinctly, the presently disclosed apparatus and method allow for collected solar energy to be transferred by convection into a flowing feed or process gas. Convective heating of a flowing liquid is, of course, well-known in the art of heat exchangers generally, but the present invention enables the efficient exploitation of solar energy to heat a flowing process gas. Among advantages of the present invention is its capability to provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com