A growth method of silicon germanium material

A growth method and technology of silicon germanium, applied in the field of manufacturing silicon germanium materials, can solve the problems of increased difficulty and cost, high consumption, dangerous cost, etc., and achieve the effects of low surface roughness, high production efficiency, and fast growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

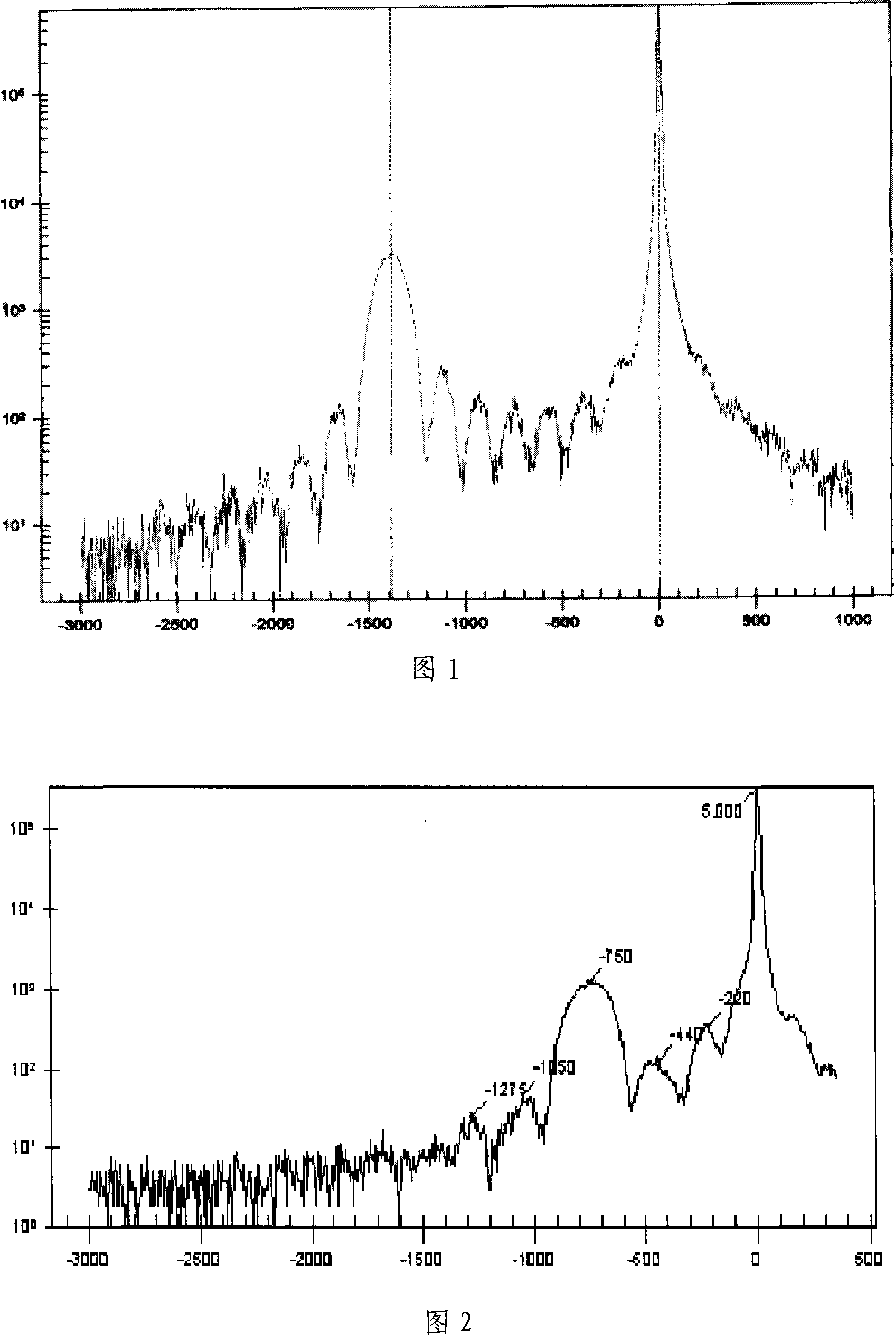

Image

Examples

Embodiment Construction

[0025] The following is a further detailed description of the present invention by comparing the prior art methods:

[0026] Our test substrate is a heavily As-doped silicon substrate with a size of 150mm. 0.85 Ge 0.15 The epitaxial layer grows in the crystal direction of the substrate; SiH is used as the gas source 4 And DCS as growth gas. The equipment used is a RPCVD deposition system, the length of the heating zone of the equipment is 200mm, and the system leakage rate is less than 10mTorr / min.

[0027] Use SiH 4 The growth process for gas source is the existing process: its working atmosphere includes H 2 , N 2 , SiH 4 , GeH 4 , PH 3 , B 2 H 6 , Where H 2 The purity is greater than 99.999999%; H 2 The flow rate is 50L / min; the growth temperature is 520℃, and the pressure is 50 Torr.

[0028] The process parameters of using DCS as a gas source are: the atmosphere used for growth includes H 2 , N 2 , SiH 2 Cl 2 , GeH 4 , PH 3 , B 2 H 6 ; H 2 The flow rate is 40L / min; where H 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com