Battery diaphragm sulphonation equipment and sulphonation treatment technique

A battery diaphragm and equipment technology, applied in the field of MH-NI battery diaphragm sulfonation equipment and sulfonation treatment process, can solve the problems of strict sulfonation process control requirements, unsuitable for sulfur trioxide reagent, high cost of waste liquid treatment, etc., to achieve The effect of simple structure, good performance and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

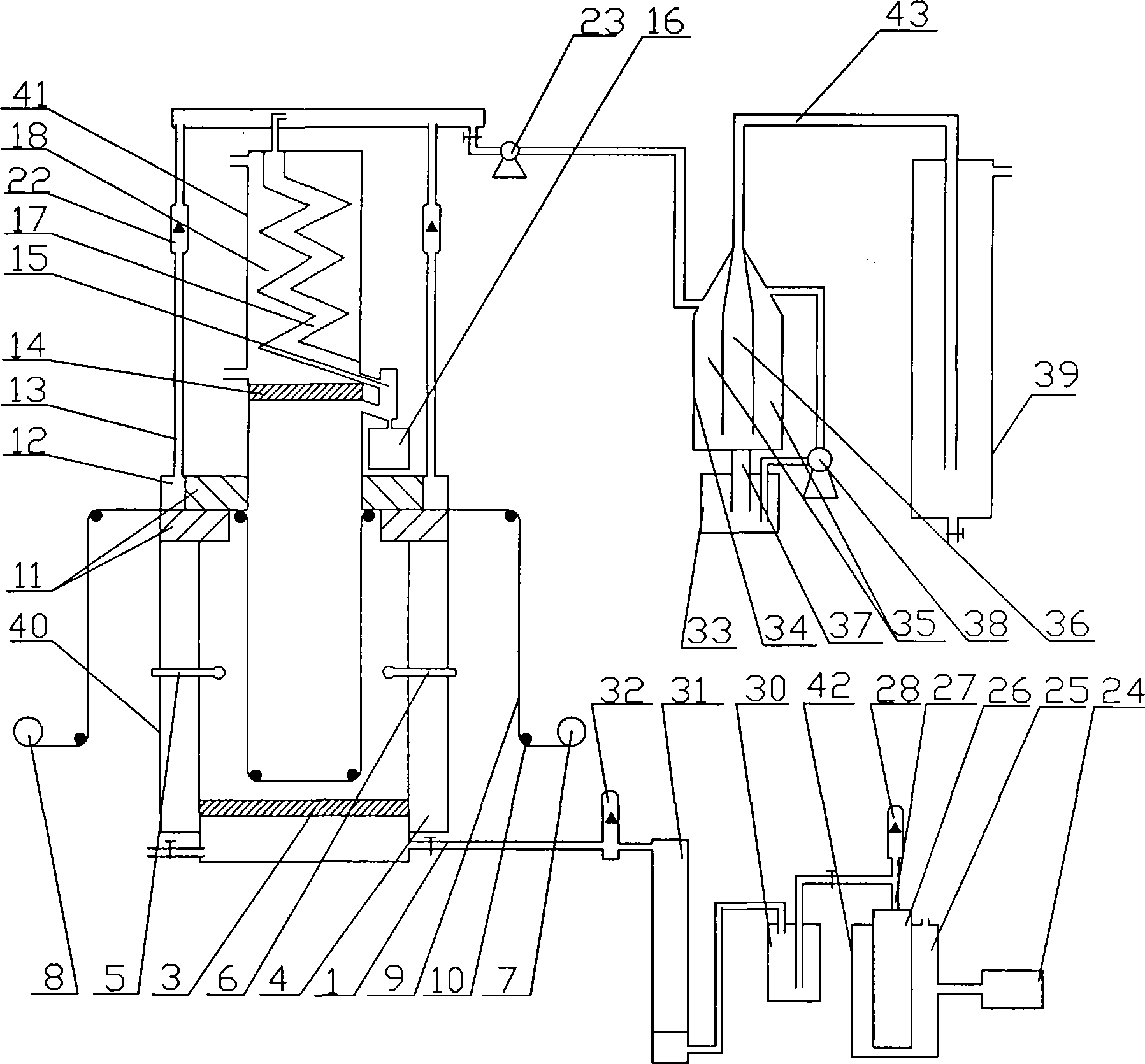

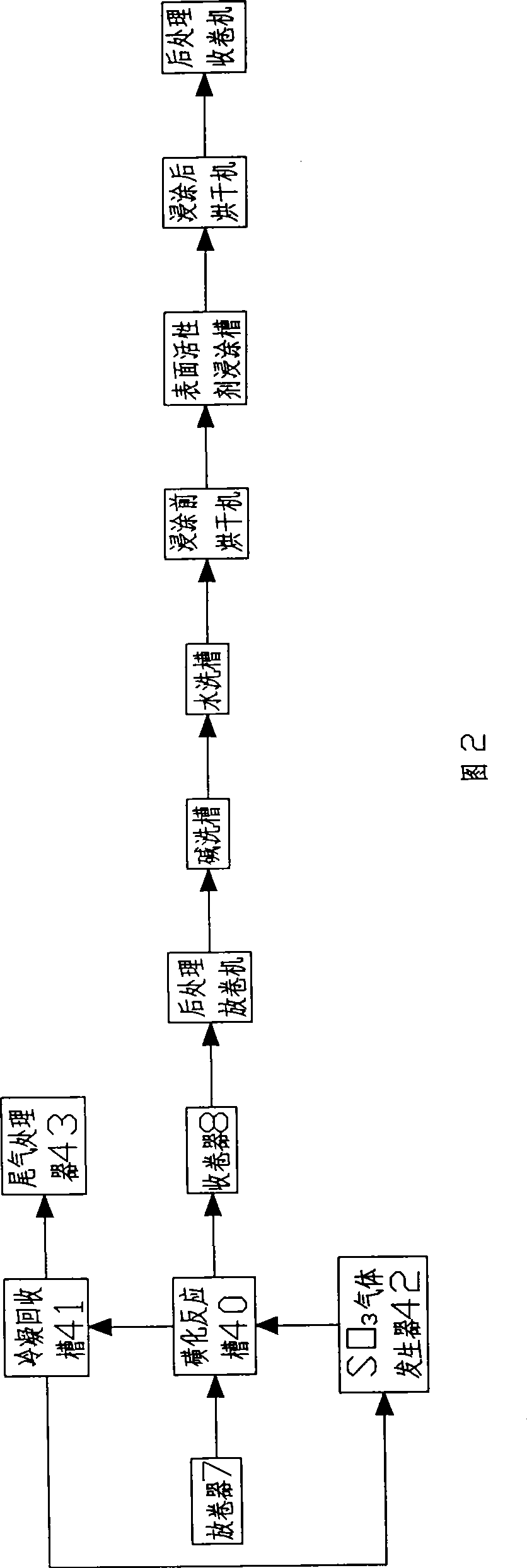

[0024] Such as figure 1 As shown, the sulfonation reaction tank 40 of the sulfonation reaction device is a flat cuboid with an open upper end, usually with a height of 0.5-2m, a width of more than 0.1m, and a thickness slightly larger than the film width of the polyolefin fiber membrane 9. The tank of this embodiment The height is 1m, the width is 0.35m, and the shell is made of stainless steel. The heating insulation cover 4 around the shell is constructed by the heater of the sulfonation reaction tank 40 and the asbestos cloth insulation material, and the heater is an electric heating wire. The winder 8 and the unwinder 7 are respectively located on the left and right sides outside the tank, and the two ends of the fiber membrane 9 are connected to the winder 8 and the unwinder 7 respectively, and the fiber membrane 9 passes through the sulfonation reaction tank 40 around the rotating shaft 10 . Temperature sensor 5 and SO are installed in the middle of the tank 3 Concentr...

Embodiment 2

[0040] The difference between embodiment 2 and embodiment 1 is: the temperature in the sulfonation reaction tank 40 is controlled at 55±5°C, the SO in the sulfonation reaction tank 40 3 When the gas concentration is 90%, the speed control mechanism controls the fiber membrane 9 to run at a stable speed of 2m / min, and then controls the fiber membrane 9 and SO 3 The reaction time of gas contact is 30S, the concentration of KOH lye in the alkali washing tank is 3±1%, the temperature of the dryer before dipping is 50±5°C, the drying time is 30S, and the anion in the surfactant dipping tank is resistant to strong acid and alkali The surfactant concentration is 1.5±0.5‰, the temperature is 35±5°C, and the dipping time is 10S.

Embodiment 3

[0042] The difference between embodiment 3 and embodiment 1 is: the temperature in the sulfonation reaction tank 40 is controlled at 95±5°C, the SO in the sulfonation reaction tank 40 3 When the gas concentration is 100%, the speed control mechanism controls the fiber membrane 9 to run at a stable speed of 30m / min, and then controls the fiber membrane 9 and SO 3 The reaction time of gas contact is 2S, the concentration of KOH lye in the alkali washing tank is 19±1%, the temperature in the dryer before dipping is 95±5°C, the drying time is 10S, and the anion in the surfactant dipping tank is resistant to strong acid and alkali The surfactant concentration is 9.5±0.5‰, the temperature is 60±5°C, and the dipping time is 2S.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com