System for processing radioactive wastes

A technology for processing system and waste, which is applied in the field of nuclear industry and nuclear power plant waste processing system, which can solve the problems of increased nuclide scattering, high storage cost, and large storage space, so as to reduce storage space and reduce environmental pollution , the effect of low storage cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

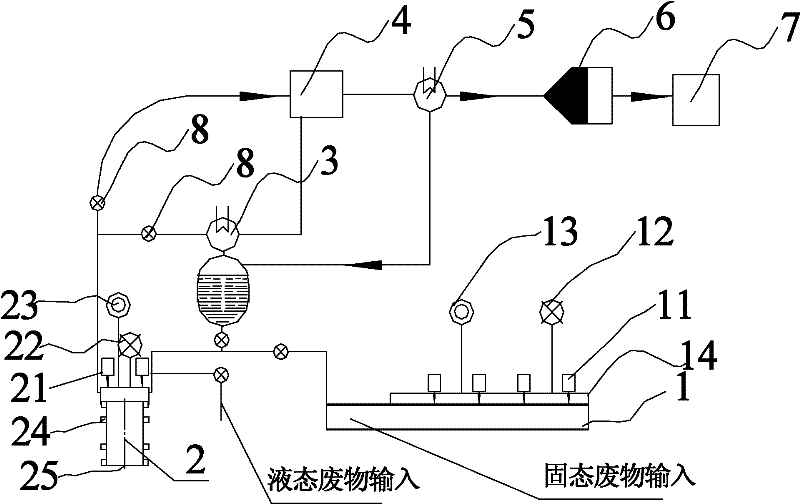

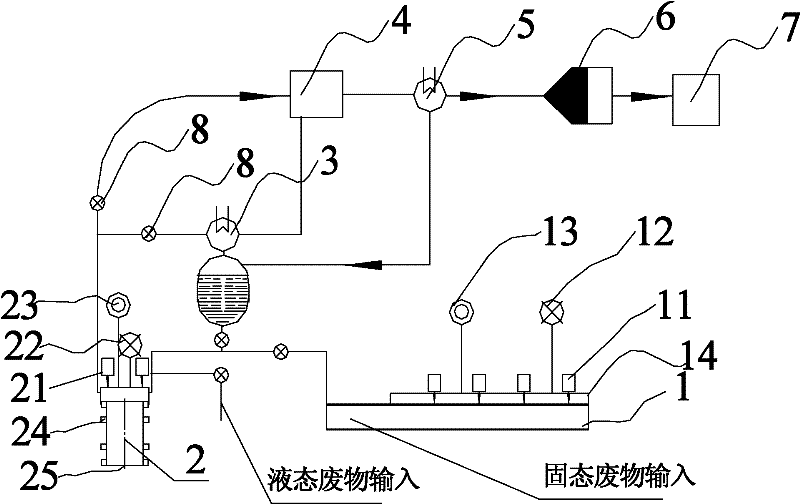

[0015] see figure 1 , the present invention provides a treatment system containing radioactive waste, which is carried out according to certain conditions for the survival or generation of various nuclides and substances, such as the half-life of 17.53 years 90 Sr, melting point 770°C, boiling point 1382°C, half-life 30 years 137 Cs, melting point 28.44°C, boiling point 671°C, half-life 2.062 years 134 Cs, melting point 28.4°C, boiling point 678.4°C, half-life 5.26 years 60 Co, melting point 1495°C, boiling point 2927°C, half-life 87.8 years 238 Pu, melting point 640°C, boiling point 3234°C, half-life 458 years 241 Am, melting point 994°C, boiling point 2607°C. In the standard state, dioxin is a colorless and odorless solid substance with a melting point of 303-305°C. Its half-life in soil is as long as 9-12 years, and its half-life in humans and animals is 5-10 years. 7 years or so. It is very stable below 705°C, non-volatile at room temperature, and difficult to oxidiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com