Quick enriching reaction equipment for anammox

An anammox bacteria, enrichment reaction technology, applied in the field of rapid enrichment reaction equipment for anammox bacteria (Anammox), can solve the problem of long generation cycle of anammox bacteria, complex operation of reaction equipment, and reactor start-up To solve problems such as long time, to achieve rapid start-up and stable operation, to improve the operating yield and selectivity of the target product, and to achieve good denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

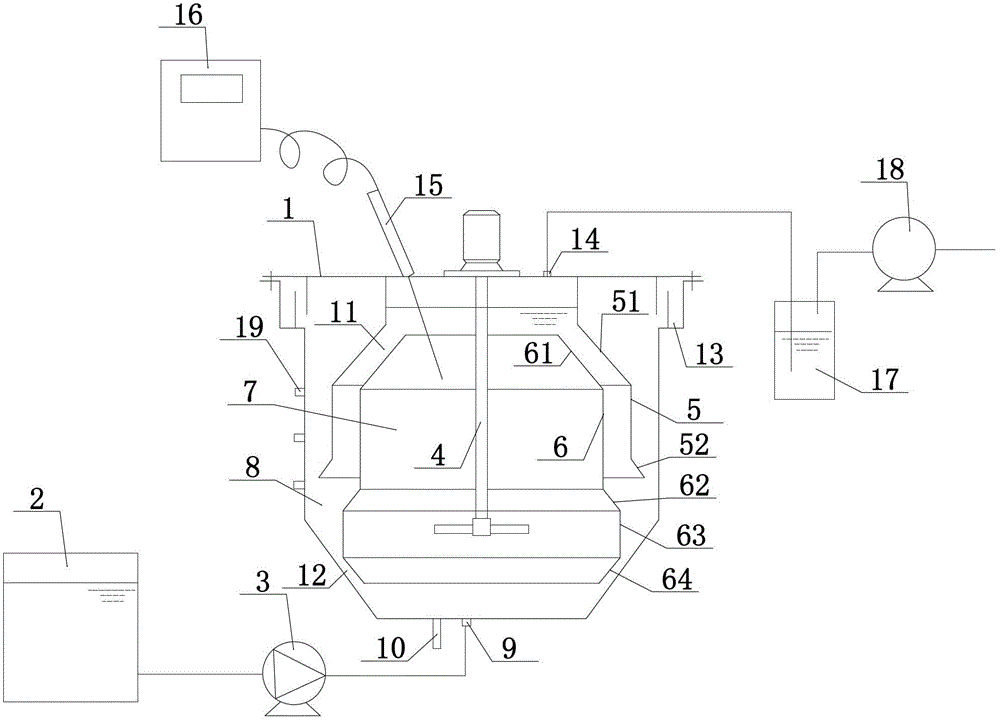

[0040] Such as figure 1 A kind of rapid enrichment reaction equipment for anammox bacteria shown, the reaction equipment includes a reactor 1, a heating device 15, a peristaltic pump 3 and a water inlet tank 2, the reactor 1 adopts a continuous stirring tank reactor 1, and the reaction The bottom of the device 1 is provided with a water inlet 9 and a mud discharge pipe 10, and the water inlet tank 2 is connected with the water inlet 9 through a peristaltic pump 3. The heating device 15 is installed on the outer surface of the reactor 1, and the heating device 15 is connected with a temperature controller 16. Considering that the anammox bacteria have a good treatment effect under medium temperature conditions, the temperature controller 16 is used to control the heating. The temperature of the device 15 was varied to keep the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com