Large-diameter porous spacing structure used in biological-cathode microorganism electrochemical system

A technology of microbial electrochemistry and spacer structure, applied in electrochemical generators, biochemical fuel cells, circuits, etc., can solve the problem of high cost of spacer materials, and achieve the effect of long service life, long life and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

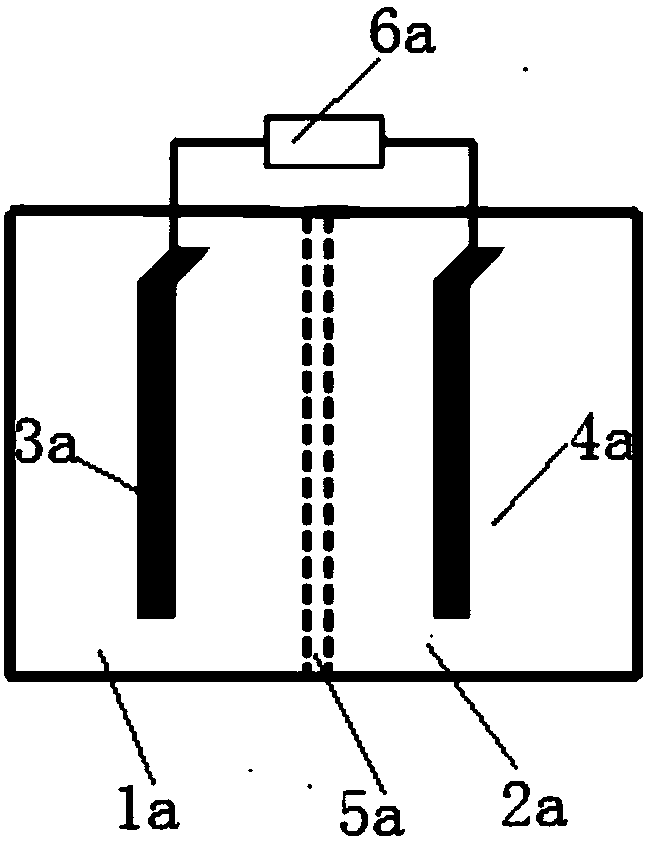

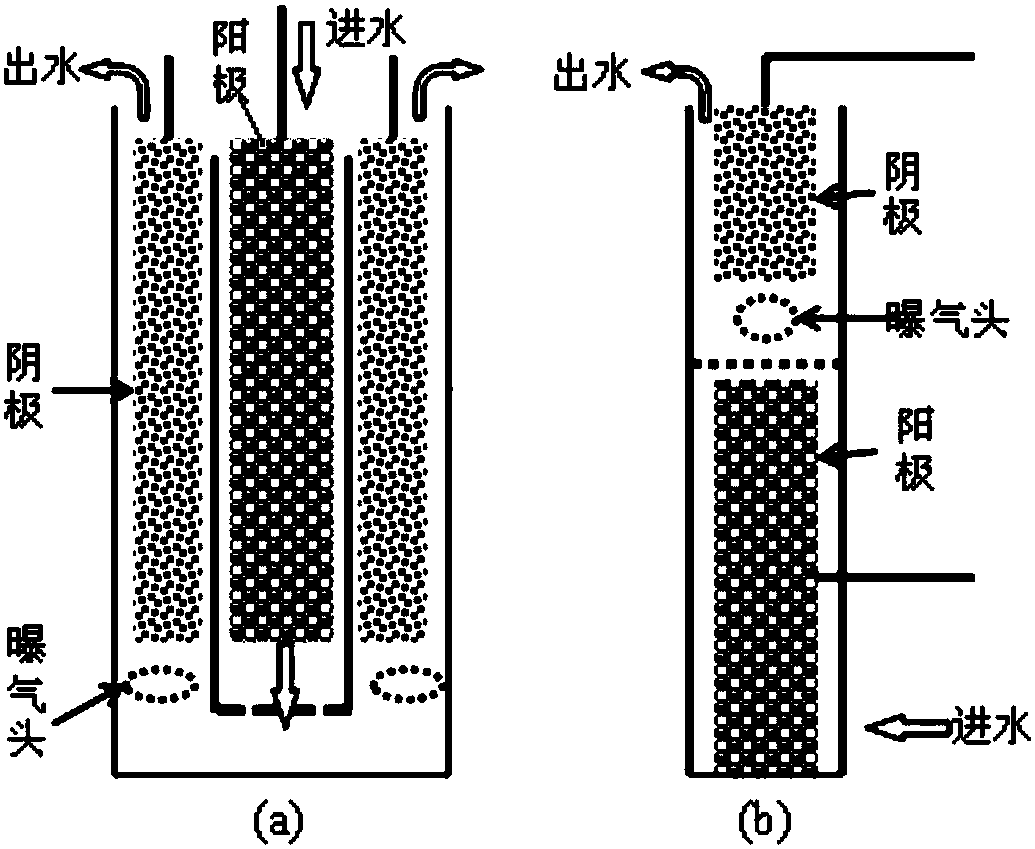

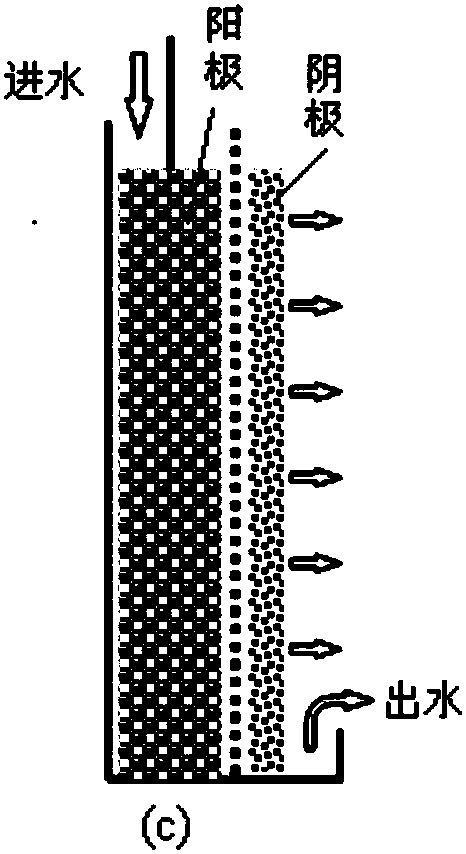

[0050] Specific embodiment 1: The main body of the large-aperture porous spacer structure used in the biocathode microbial electrochemical system in this embodiment is plate-shaped or cylindrical, and the main body of the structure is composed of at least one layer of large-aperture porous spacer material; and in the main body of the structure At least one layer of the large-aperture porous spacer material is an insulating material;

[0051] The thickness of the structural main body is 1 μm to 10 cm;

[0052] The pores of the large-diameter porous spacer material are open pores with a diameter of 0.1 μm˜5 mm.

[0053] This embodiment has the following beneficial effects:

[0054] One, the function of the large-aperture porous spacer structure used in the biocathode microbial electrochemical system in this embodiment is to be placed in the biocathode microbial electrochemical system and used to separate the cathode chamber and the anode chamber; this embodiment can be adjusted...

specific Embodiment approach 2

[0061] Embodiment 2: This embodiment differs from Embodiment 1 in that: the large-aperture porous spacer material is a self-supporting large-aperture porous spacer material or a flexible large-aperture porous spacer material. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0062] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the large-aperture porous spacer material is a self-supporting large-aperture porous spacer material or a flexible large-aperture porous spacer material. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com