Connector

A technology of connectors and buckle parts, which is applied in the direction of connection, parts of connection devices, fixed/insulated contact members, etc., which can solve the problems of terminal holding force drop, damage, and falling out of the housing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

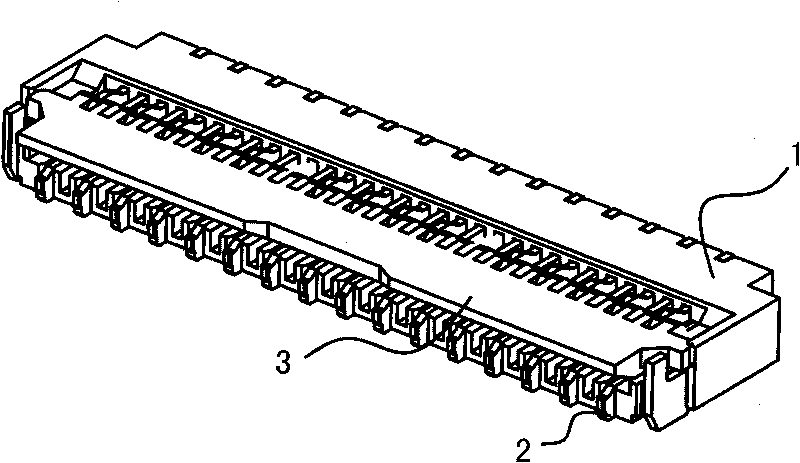

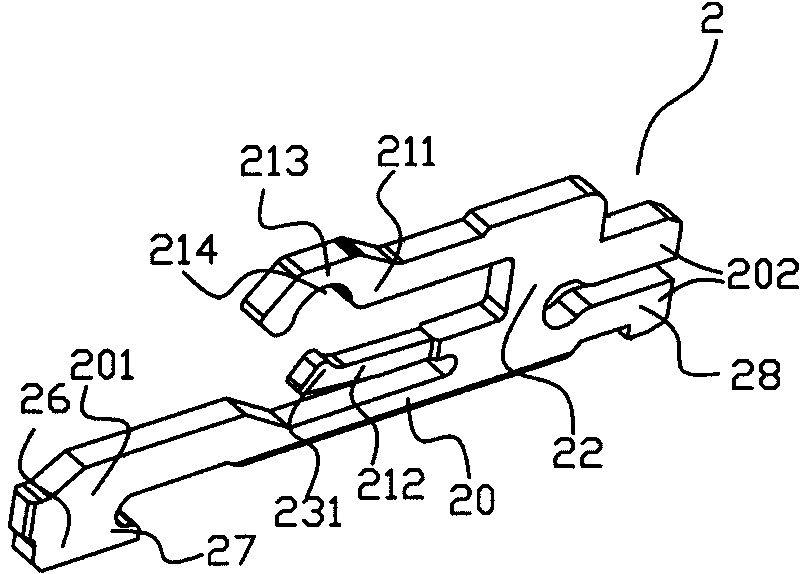

[0024] Such as Figures 2 to 4 As shown, the connector in the first embodiment of the present invention includes a housing 1 , terminals 2 held in the housing 1 , and a pressing member 3 . The housing 1 has an upper wall 10 and a lower wall 11, the front end 101 of the upper wall 10 and the front end 111 of the lower wall 11 constitute the front part 18 of the housing, the rear end 102 and the rear end 102 of the upper wall 11 The rear end portion 112 of the lower wall 11 constitutes the housing rear end portion 19 . The terminal has a fixing portion 20 substantially horizontally disposed along the lower wall 11 , and a clamping portion 21 disposed above the fixing portion, and the clamping portion 21 and the fixing portion 20 are connected by a connecting portion 22 .

[0025] In this embodiment, the clamping portion 21 includes a first elastic arm 211 and a second elastic arm 212 . The first elastic arm 211 extends substantially horizontally from the connecting portion 22 ...

Embodiment 2

[0033] Embodiment two of the present invention is as Figure 6 As shown, the first buckle part 40 is similar to the second buckle part 28 in the first embodiment, and the second buckle part 41 is similar to the hook-shaped first buckle part 27 in the first embodiment.

Embodiment 3

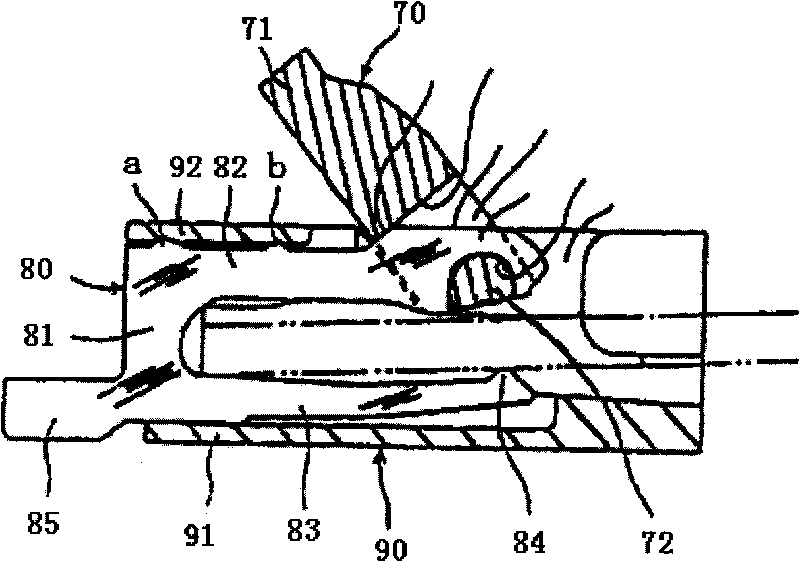

[0035] Embodiment three of the present invention is as Figure 7 As shown, the terminal shown is a seesaw-shaped terminal, the clamping portion is disposed at one end, the pressing member is disposed at the other end, and the fixing portion 64 is substantially horizontally disposed on the lower wall 52 . The pressing member includes a pulling part 71 and a cam 72 arranged at one end of the pulling part, and the cam has a longer axis and a shorter axis. The terminal has a first elastic arm 61 and a second elastic arm 62 connected to each other, one end of the first elastic arm 61 and the fixing portion 64 forms a clamping portion, and the cam 72 of the pressing member is held by the second The elastic arm 62 and the other end of the fixed part are limited. The first elastic arm 61 is connected to the second elastic arm 62 and connected to the fixed part 64 through the connecting arm 63. The first buckle part 65 of part 521 has the second buckle part 66 that is fastened to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com