Axial-movement temperature-controlled glass heat tube

A technology of glass heat pipe and axial movement, which is applied in the field of solar collector tube structure, and can solve problems such as system overheating and system damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

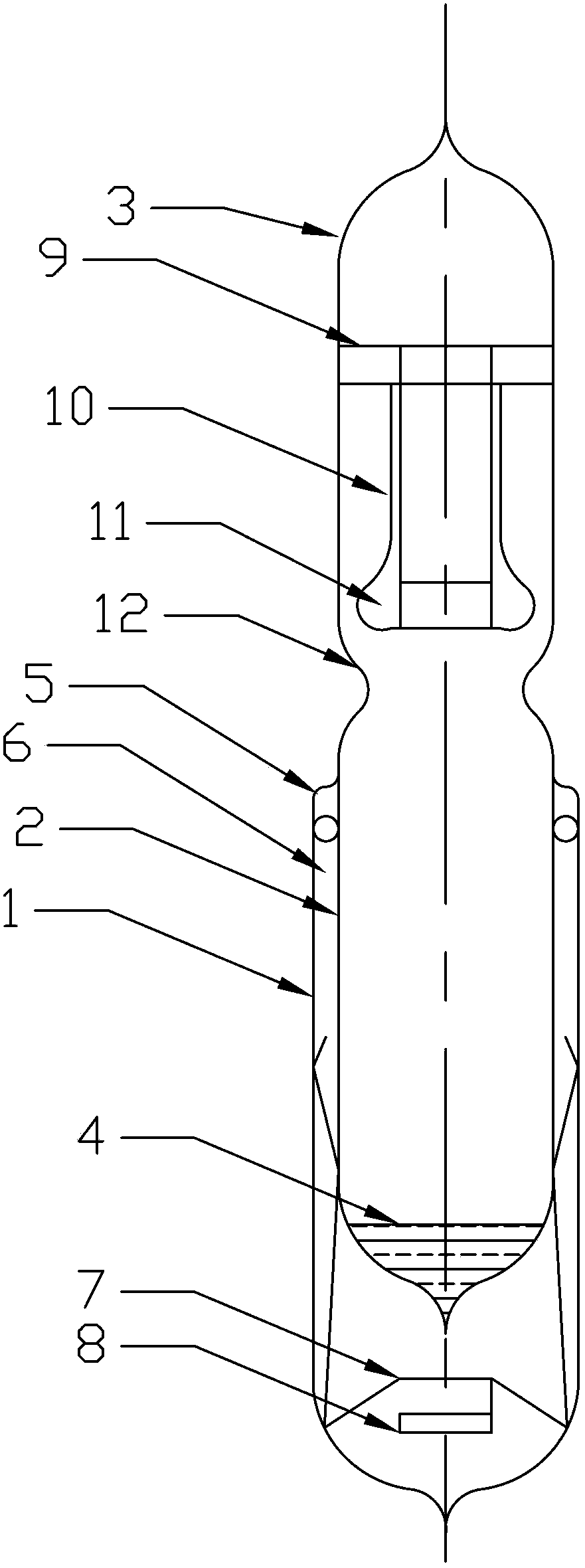

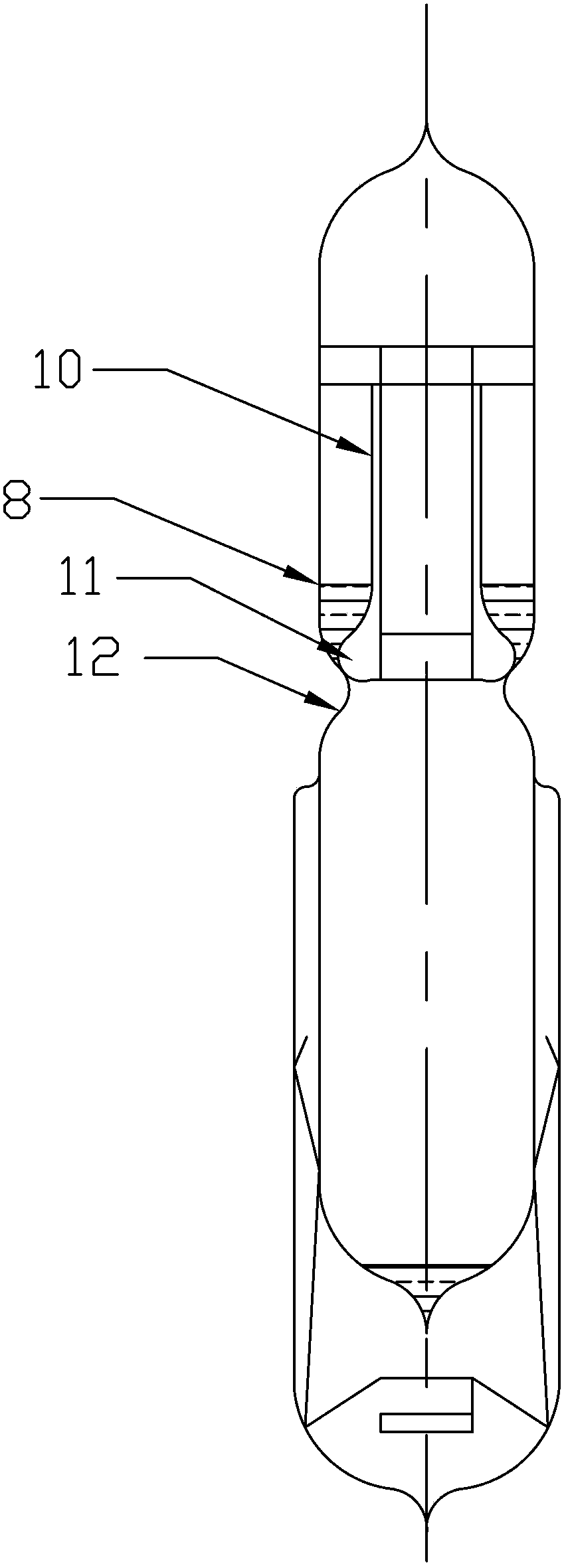

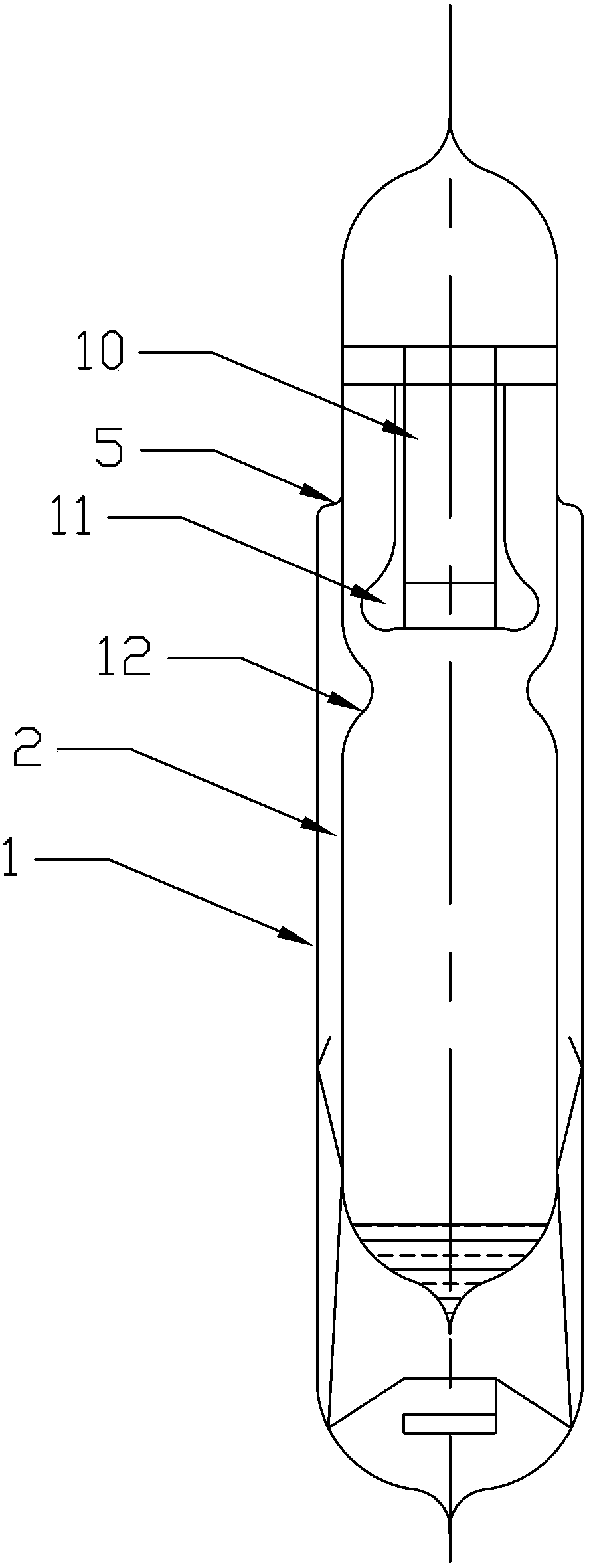

[0023] Such as figure 1 Shown is an axially moving temperature-controlled glass heat pipe provided by the present invention. The glass heat pipe includes a cover glass tube 1 and an inner tube 2. The lower end of the inner tube 2 is a heat collecting end, and the upper end is a condensing end 3. A heat-absorbing working fluid 4 is placed in the heat collecting end of the inner tube 2, the cover glass tube 1 is welded to the inner tube 2 through a ring seal 5, and the cover glass tube 1 is connected to the inner tube 2. A vacuum interlayer 6 is formed between the heat-collecting ends of the tubes 2, and a getter 8 is fixed inside the vacuum interlayer 6 with clips 7. When sunlight passes through the cover glass tube 1 and shines on the heat-collecting end of the inner tube 2 In the process, the working medium 4 will be vaporized by heat and then evaporated to the condensation end 3, and the gasified working medium 4 will condense into a liquid state again after releasing heat a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com