Continuous drying system for production of vanadium-free rare earth-based titanium tungsten powder

A drying system, rare earth-based technology, applied in the direction of drying, drying machine, drying gas arrangement, etc., can solve the problem that the drying process cannot be carried out continuously

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

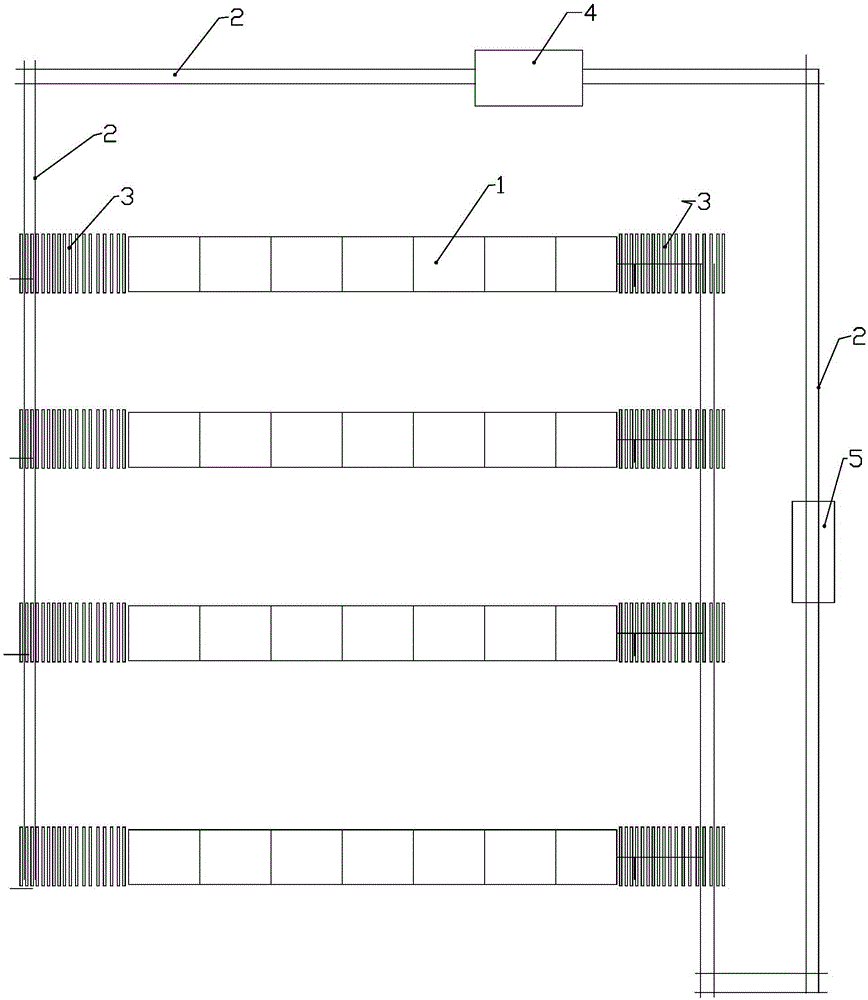

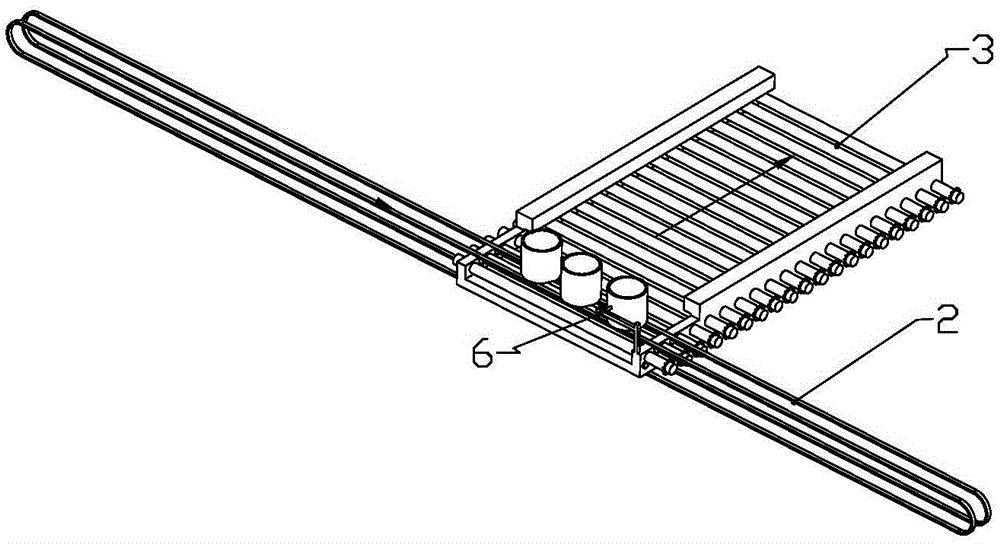

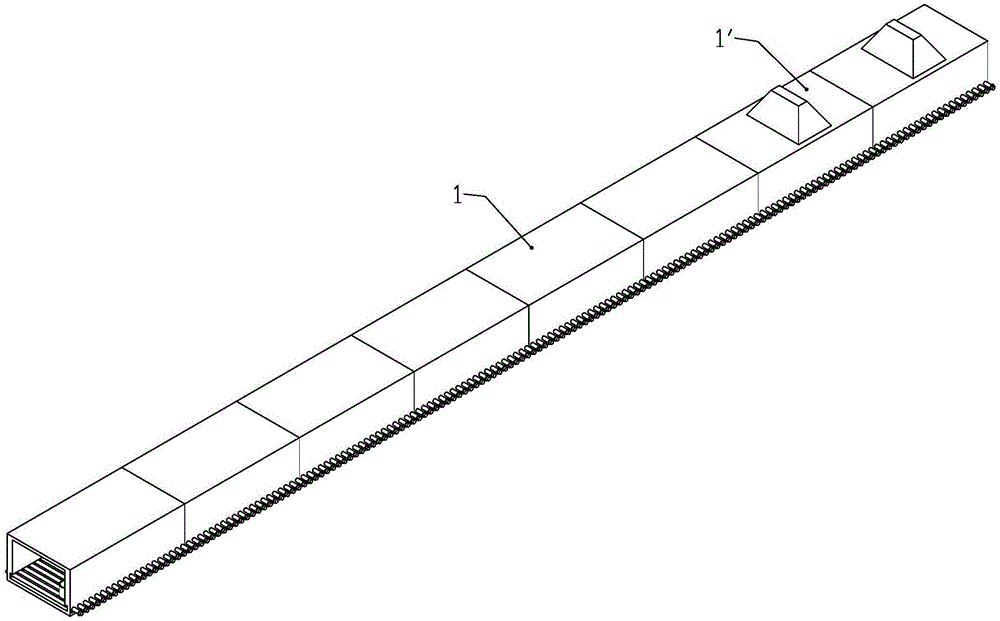

[0031] Such as Figure 1 to Figure 9 As shown, for existing defects, the subject of protection of the present invention is as follows:

[0032] The development is a continuous drying system for the production of vanadium-free rare earth-based titanium and tungsten powder. The use of the bowl enables the materials in the sagger to heat up and cool down at the fastest speed, improving the roasting efficiency. At the same time, the roasting mode is segmented and controlled in different temperature segments to achieve a multi-gradient temperature control mode and consider energy saving. The problem of gradient utilization of thermal energy.

[0033] At the same time, the saggers are grouped, and through the joint action of the transmission system, multiple batches can be carried out at the same time, the drying efficiency can be improved, and continuous and circular production can be realized.

[0034] Based on the above description, the structural part includes a continuous dry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com