Chemical vapor deposition solid precursor continuous supply system

A precursor, solid-state technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problem of difficulty in uniform and continuous supply, restricting the preparation of refractory metal carbide coatings and substrates, and difficult to obtain. Problems with molten metal carbide coatings or substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

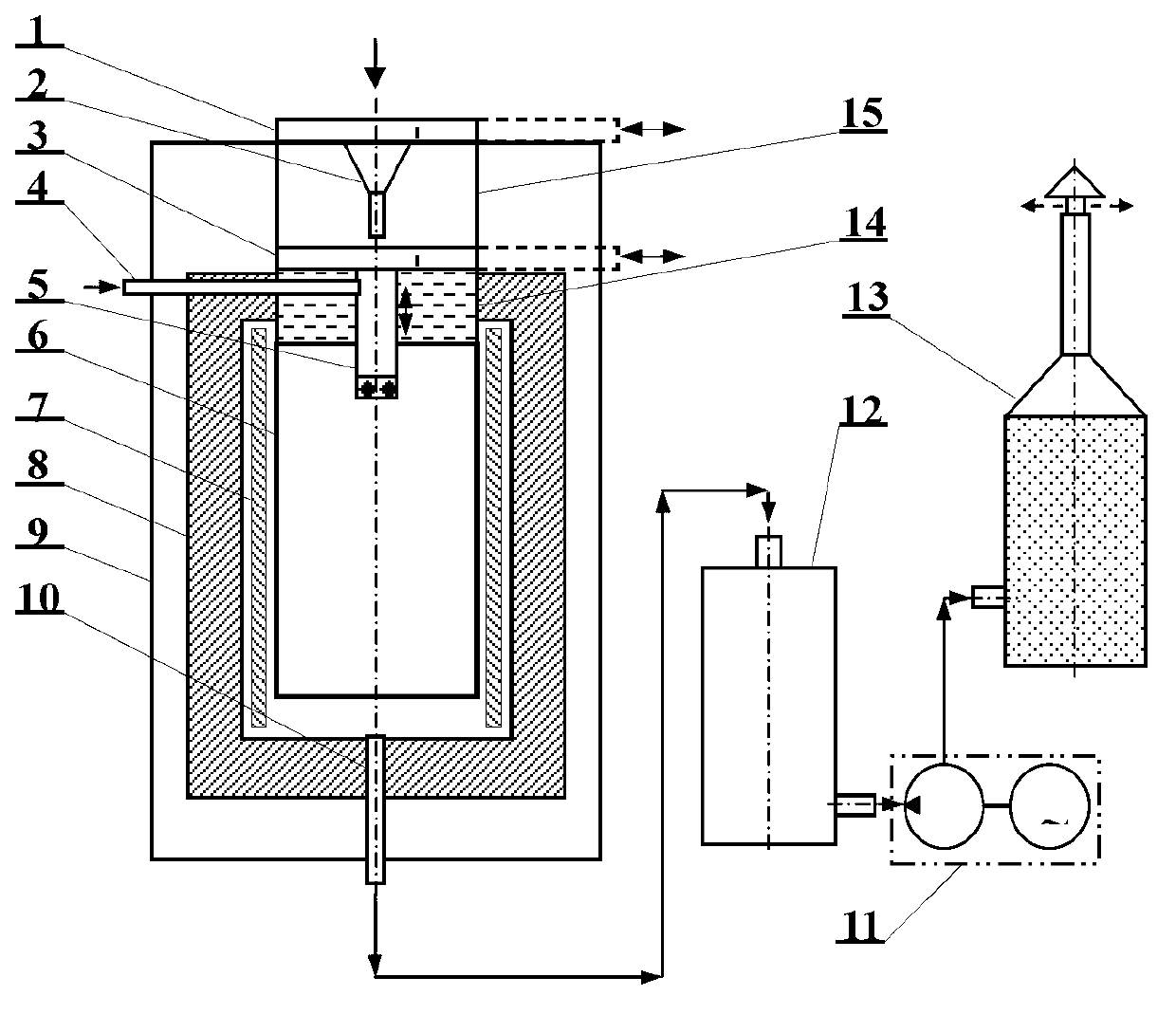

[0018] This embodiment is a continuous supply system of solid precursors for chemical vapor deposition.

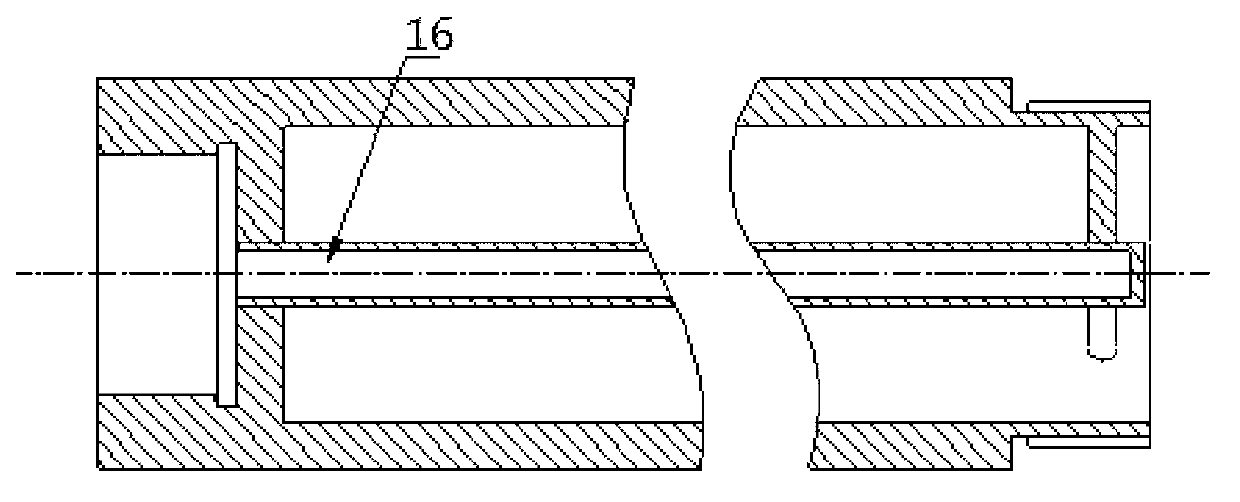

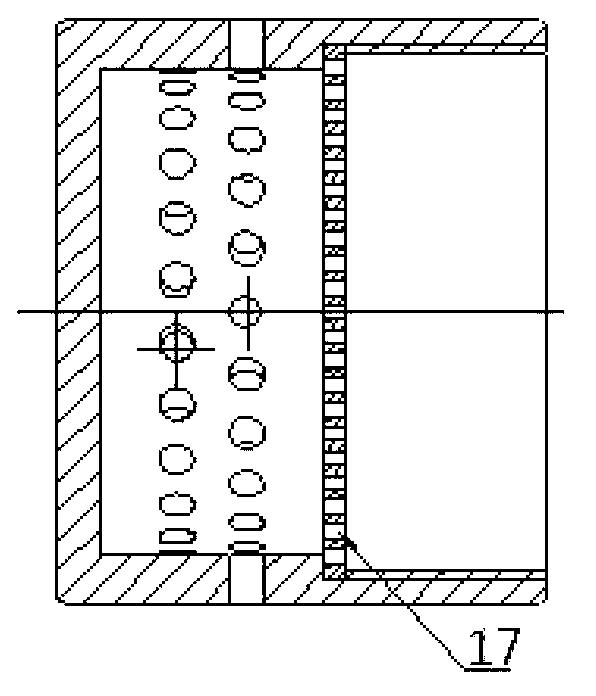

[0019] refer to figure 1 , figure 2 , image 3 , the continuous supply system of chemical vapor deposition solid precursor of the present invention is composed of a vacuum chamber 9, a vacuum unit 11, a chemical exhaust gas adsorber 12, a chemical exhaust gas processor 13, a crucible 6, a heating element 7, an insulating layer 8, a vacuum isolation chamber 15, The upper feeding vacuum valve 1, the lower feeding vacuum valve 3, the solid precursor charging chamber 2, and the controllable solid precursor volatilization device 5 are composed; the vacuum isolation chamber 15 is installed on the upper part of the vacuum chamber 9, and the crucible 6 is fixedly installed in the vacuum chamber 9 Inside, the heating element 7 surrounds the outer side of the crucible 6, the crucible 6 and the heating element 7 are embedded in the insulation layer 8, the top part of the insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com