Radioactive organic waste treatment device

A technology for organic waste and treatment equipment, which is applied in the field of radioactive organic waste treatment equipment, can solve the problems of superheated steam catalytic degradation technology and the application of radioactive organic waste, etc., and achieve the effects of environmental friendliness, reasonable cost and safe performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

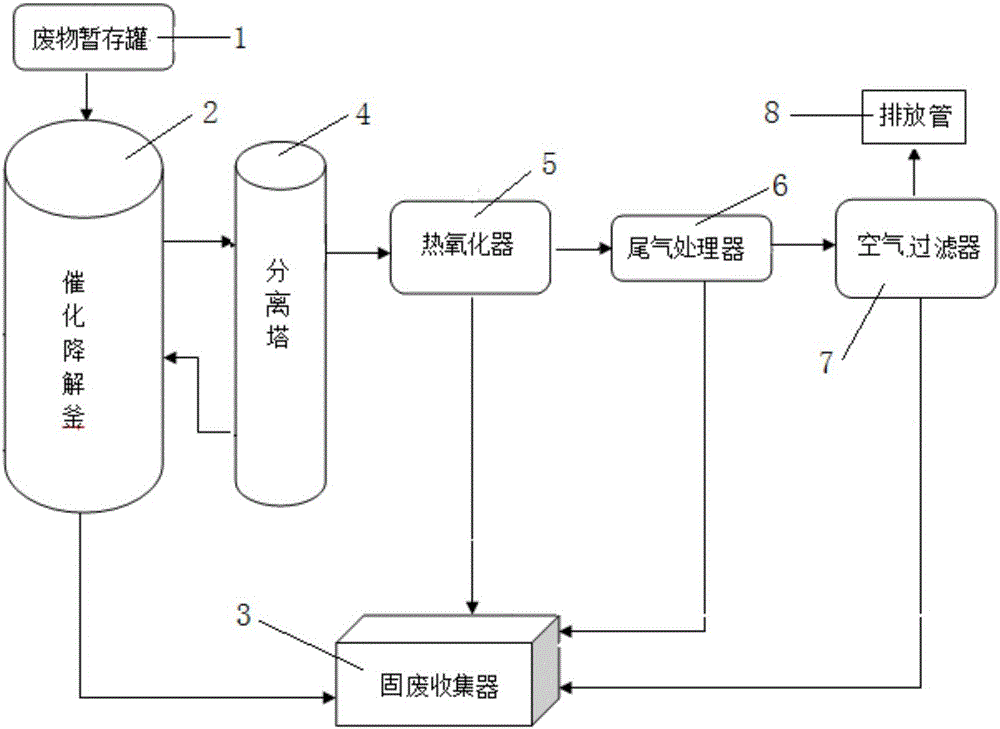

[0012] The main structure of the radioactive organic waste treatment device involved in this embodiment includes a waste temporary storage tank 1, a catalytic degradation kettle 2, a solid waste collector 3, a separation tower 4, a thermal oxidizer 5, an exhaust gas processor 6, an air filter 7 and Discharge pipe 8; the waste temporary storage tank 1 is connected to the catalytic degradation kettle 2 in a pipeline type, the catalytic degradation kettle 2 is connected to the separation tower 4 in a pipeline type bidirectional connection, the separation tower 4 is connected to the thermal oxidizer 5 in a pipeline type, and the thermal oxidizer 5 is connected to the tail gas treatment Device 6 is connected in pipeline, exhaust processor 6 is connected in pipeline with air filter 7, air filter 7 is connected in pipeline with one end of discharge pipe 8, and the other end of discharge pipe 8 is directly connected to atmospheric environment, catalytic degradation kettle 2, thermal oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com