Bulk collecting and intensive placing spinning cake device for semiautomatic joint spinning machine

A kind of spinning machine, semi-automatic technology, applied in the field of loose collection and release of silk cake device, can solve the problems that hinder the rapid development of chemical fiber enterprises, increase the labor intensity of workers, and increase the pressure of enterprise recruitment, so as to realize streamlined operation and reduce labor frequency , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0029] Example.

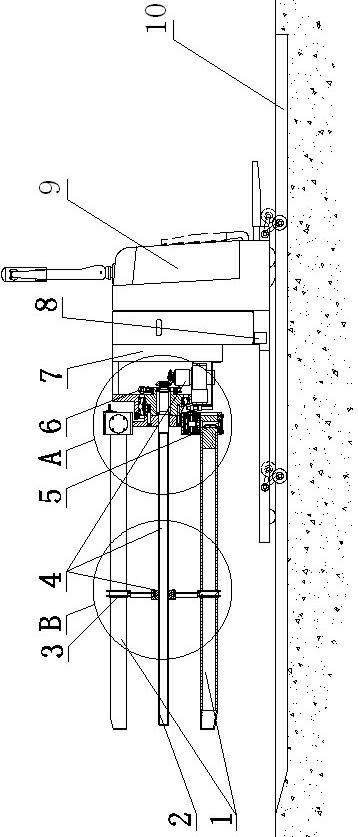

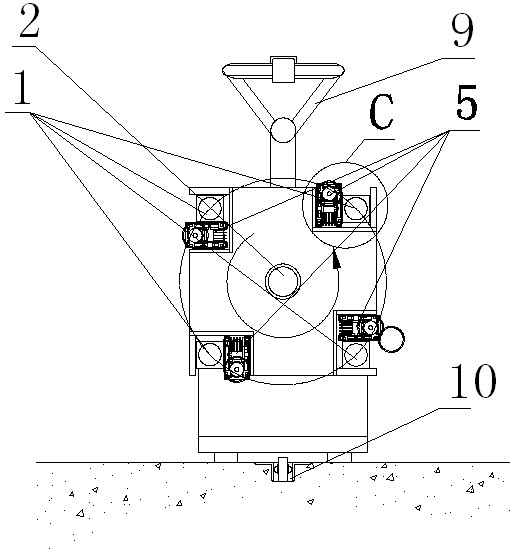

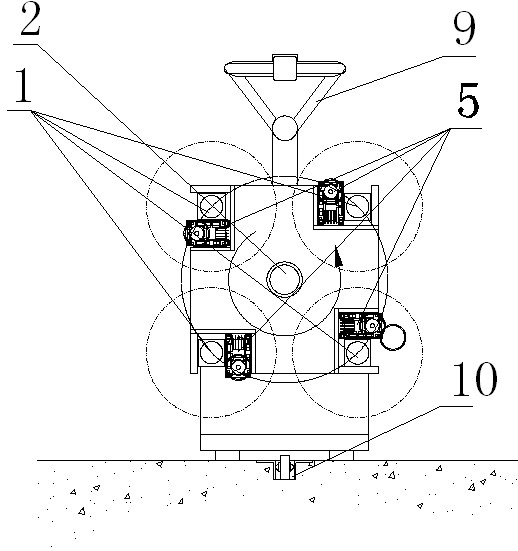

[0030] see Figure 1 to Figure 9In this embodiment, the semi-automatic connecting spinning machine loosening and collecting silk cake device includes four silk cake storage rods 1, silk cake push rod 2, four silk cake pushing heads 3, driving parts 4, and four sets of silk cakes Rod storage steering device 5, silk cake storage rod transposition device 6, silk cake storage rod side shifting device 7, photoelectric centering device 8, forklift truck body 9, rail 10 and control device, silk cake storage rod 1, The numbers of the silk cake pushing head 3 and the silk cake storage rod steering device 5 are equal, and their numbers can be set according to actual needs. Usually, the number of the silk ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com