Assembling technology for lithium ion battery roll core after packaging the bottom

A lithium-ion battery and assembly process technology, applied to secondary batteries, circuits, electrical components, etc., can solve the problems of increasing defective products and increasing difficulty of completion, so as to improve the yield of good products, regulate operation standards, and avoid ear shaping bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation, structure and features provided by the present invention are described in detail as follows:

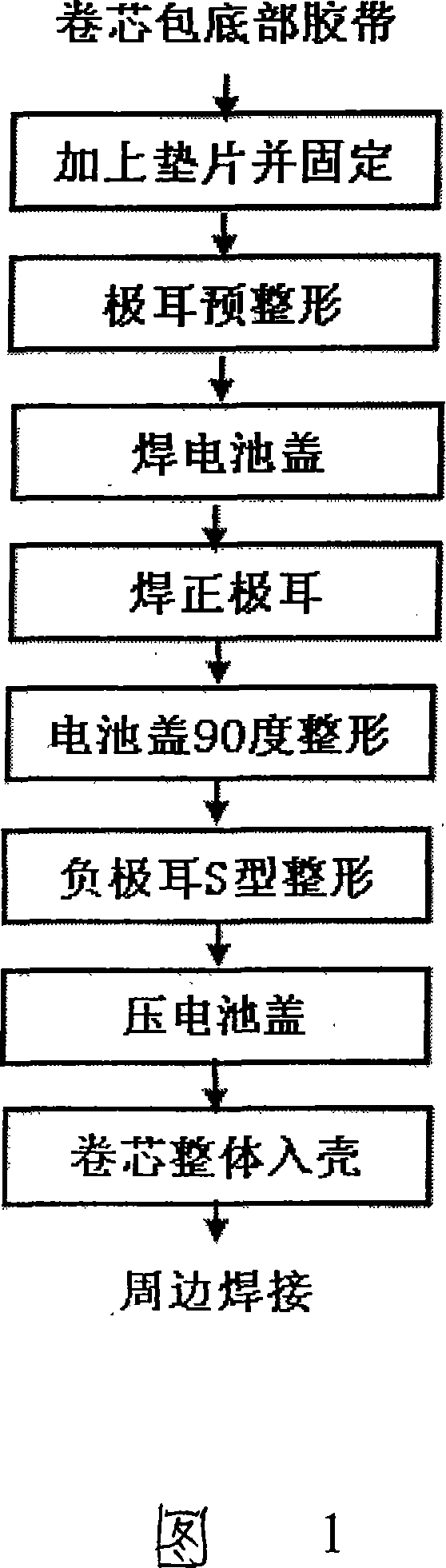

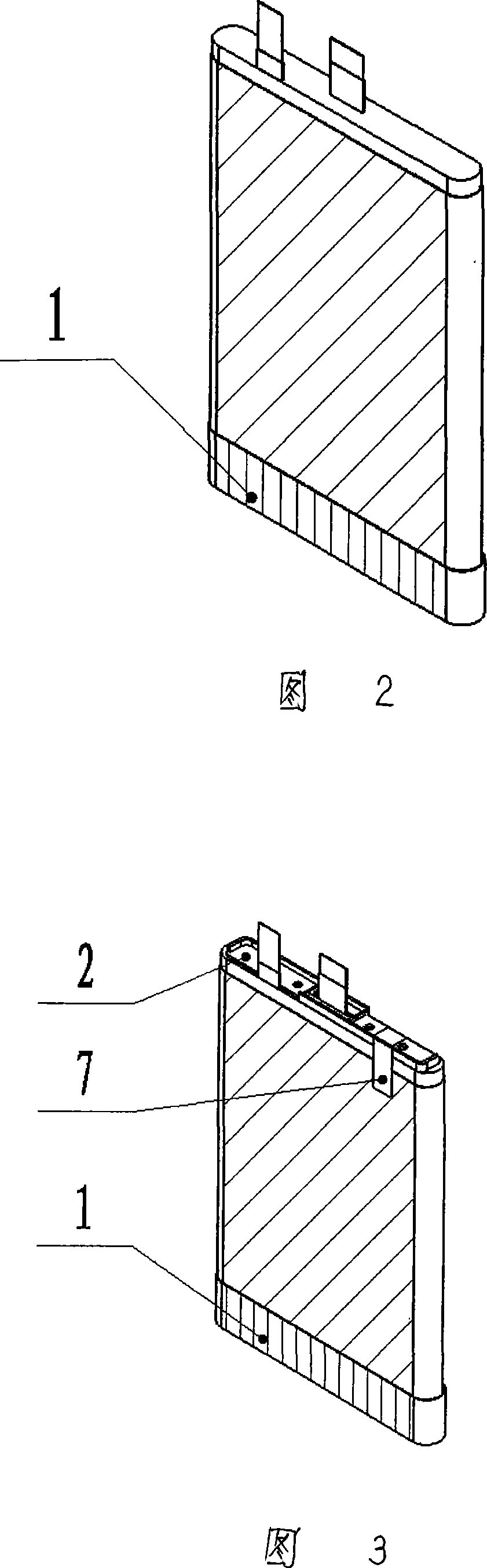

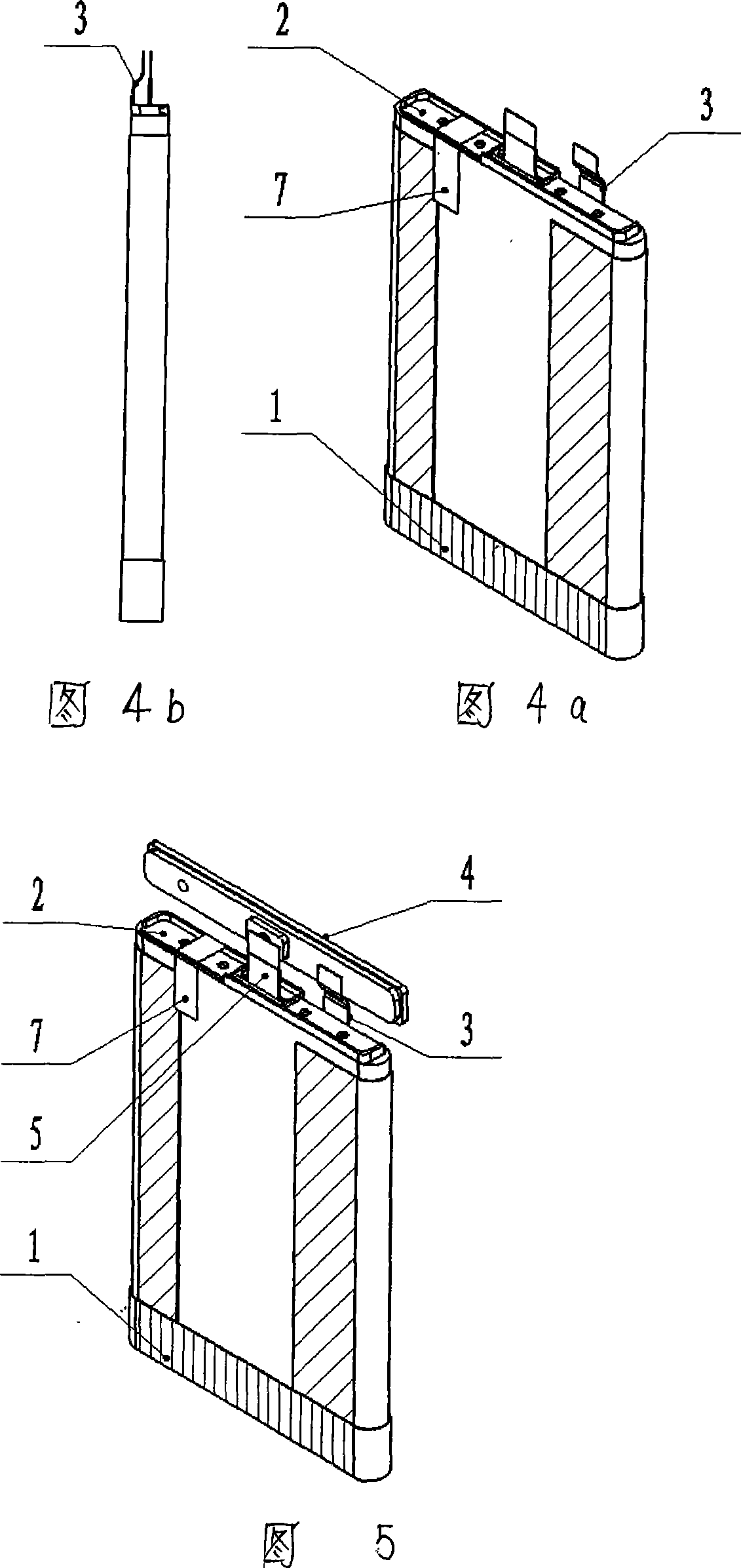

[0043] As shown in Figure 1-Figure 9b, an assembly process for a lithium-ion battery winding core after wrapping the bottom, is characterized in that the specific implementation steps are as follows:

[0044] (1) Carry out the battery roll core flattening and shaping according to the routine;

[0045] This process requires the roll core to be flattened and wrapped with protective tape at the bottom. It is required that the protective tape be wrapped tightly and evenly, and the outward warping of both ends should be kept within 0.5mm.

[0046] (2) Add gasket and fix it;

[0047] This process is to add the upper gasket on the upper part of the core wrapped with the bottom tape. After the upper gasket is installed, fix it with a narrow protective tape on one side. The prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com