Method and device for continuously producing chlorinated polyvinyl chloride by low-temperature plasma circulating bed

A technology of low-temperature plasma and chlorinated polyvinyl chloride, which is applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physicochemical processes using energy, etc., can solve problems such as production efficiency decline and waste of raw materials. Achieve the effect of prolonging equipment life and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

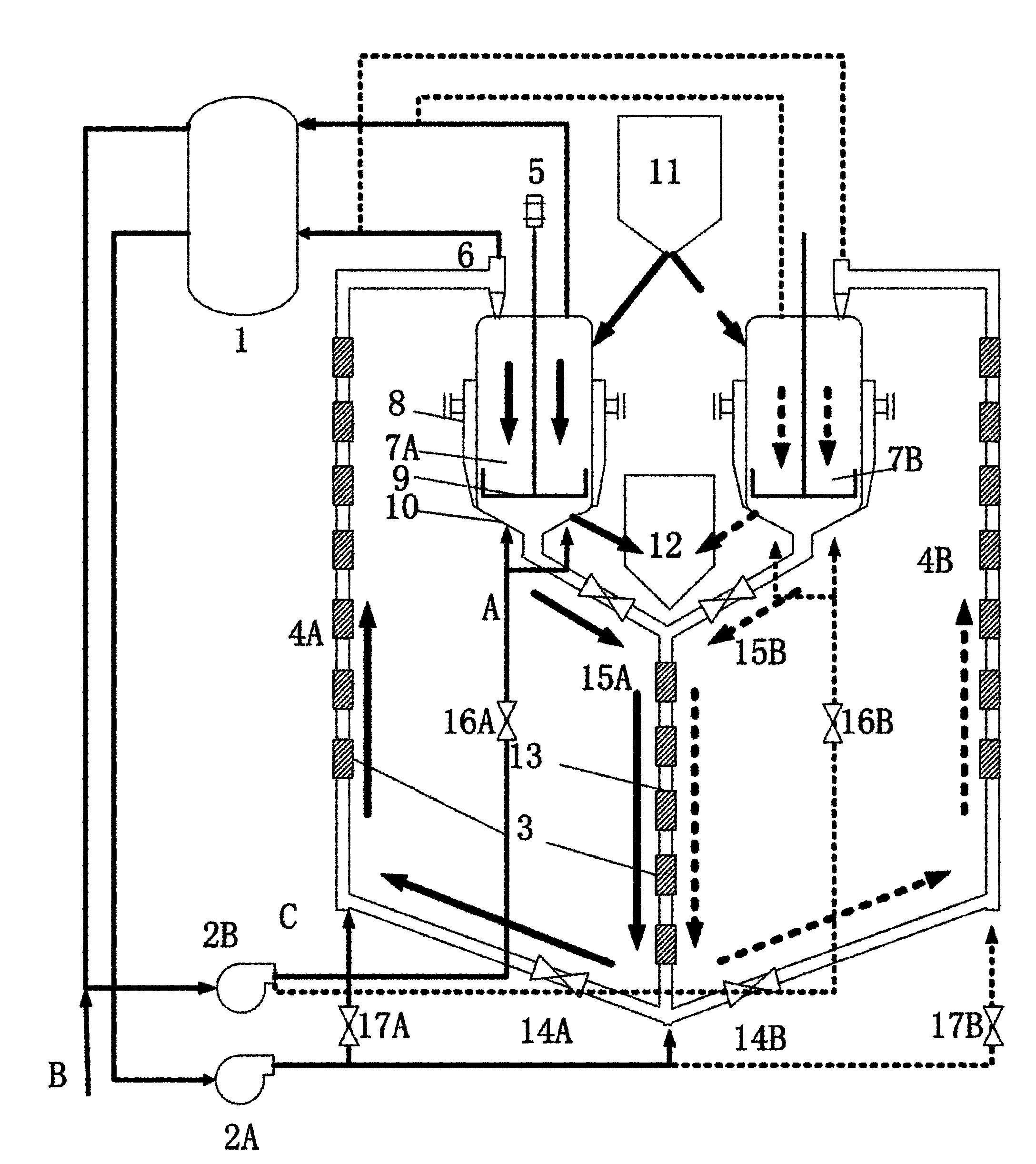

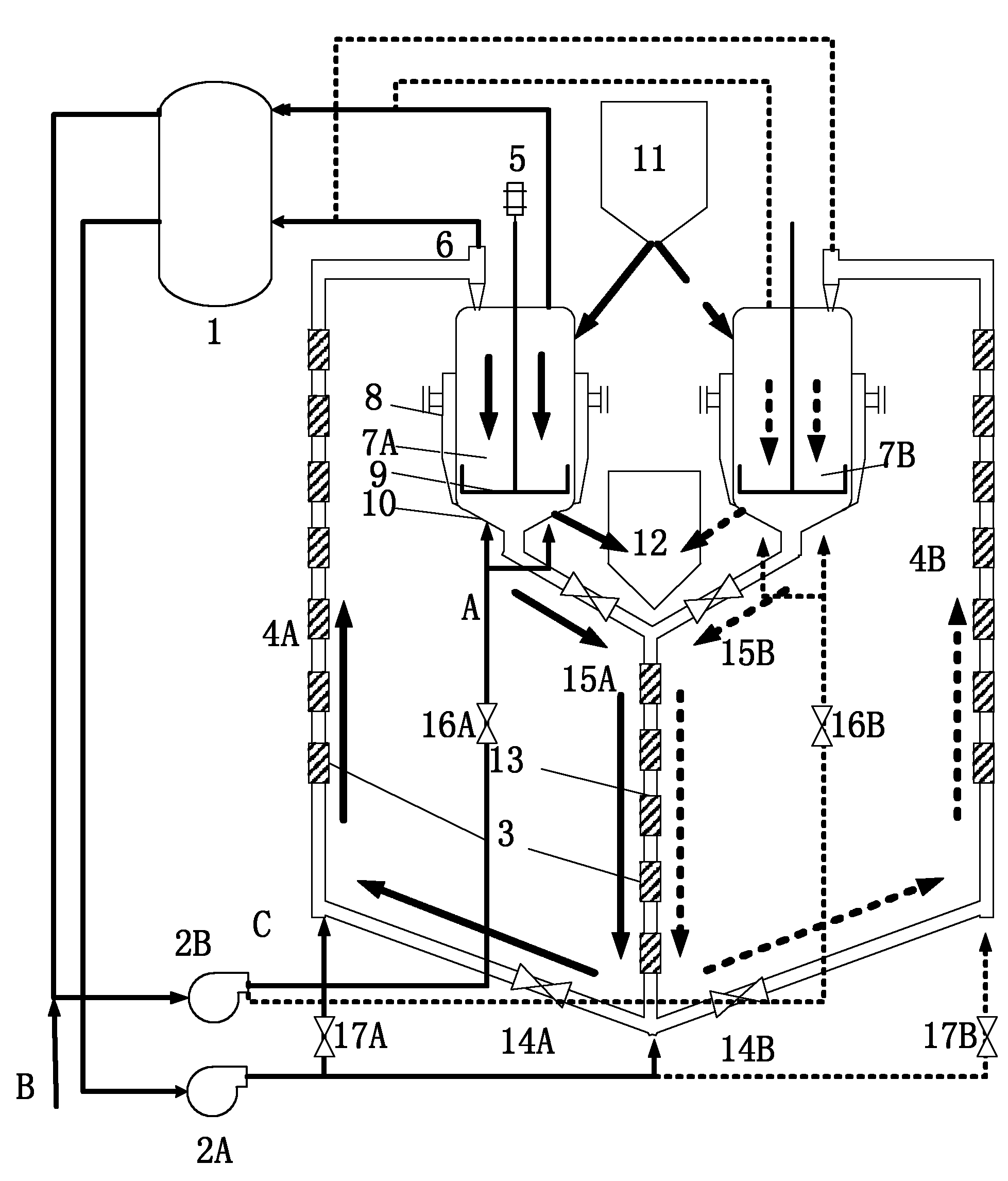

[0027] PVC particles with an average particle size of 150 μm are loaded into the first fluidized bed through the charging port, and the charging amount is 1 ton. Turn on the circulation fan to blow Cl 2 Concentration of 30% Cl 2 / Ar mixed gas is passed into the fluidized bed, and the stirring is started to make the PVC particles well fluidized. Add heating oil to the jacket to keep the temperature of PVC particles in the fluidized bed at 100°C. The control valve between the first fluidized bed and the low-temperature plasma down-bed reactor is opened to allow PVC particles to enter the low-temperature plasma down-bed reactor and the riser reactor to initiate chlorination in the low-temperature plasma zone. The riser and downer bed are operated under normal pressure, the temperature is 100°C, and the particle residence time is 20s. Solid PVC particles are separated by gas and solid, and returned to the first fluidized bed to complete a particle cycle. The residence time of ...

Embodiment 2

[0030] PVC particles with an average particle size of 200 μm are loaded into the first fluidized bed through the charging port, and the charging amount is 1 ton. Turn on the circulation fan to blow Cl 2 Concentration of 30% Cl 2 / Ar mixed gas is passed into the fluidized bed, and the stirring is started to make the PVC particles well fluidized. Add heating oil to the jacket, gradually raise the temperature of the particles from 70°C to a constant temperature, and keep the temperature of the PVC particles in the fluidized bed at 100°C. The control valve between the first fluidized bed and the low-temperature plasma down-bed reactor is opened to allow PVC particles to enter the low-temperature plasma down-bed reactor and the riser reactor, and chlorination is initiated in the low-temperature plasma zone. The riser and downer are operated under normal pressure, the temperature is 20°C, and the particle residence time is 2min. Solid PVC particles are separated by gas and solid,...

Embodiment 3

[0033] PVC particles with an average particle size of 150 μm are loaded into the first fluidized bed through the charging port, and the charging amount is 1 ton. Turn on the circulation fan to blow Cl 2 Concentration of 30% Cl 2 / Ar mixed gas is passed into the fluidized bed, and the stirring is started to make the PVC particles well fluidized. Add heating oil into the jacket and gradually raise the temperature to make the maximum temperature of PVC particles in the fluidized bed rise to 140°C. The control valve between the first fluidized bed and the low-temperature plasma down-bed reactor is opened to allow PVC particles to enter the low-temperature plasma down-bed reactor and the riser reactor to initiate chlorination in the low-temperature plasma zone. The riser and downer are operated under normal pressure, the temperature is 140°C, and the particle residence time is 10s. Solid PVC particles are separated by gas and solid, and returned to the first fluidized bed to com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com