Patents

Literature

93 results about "Plasma zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

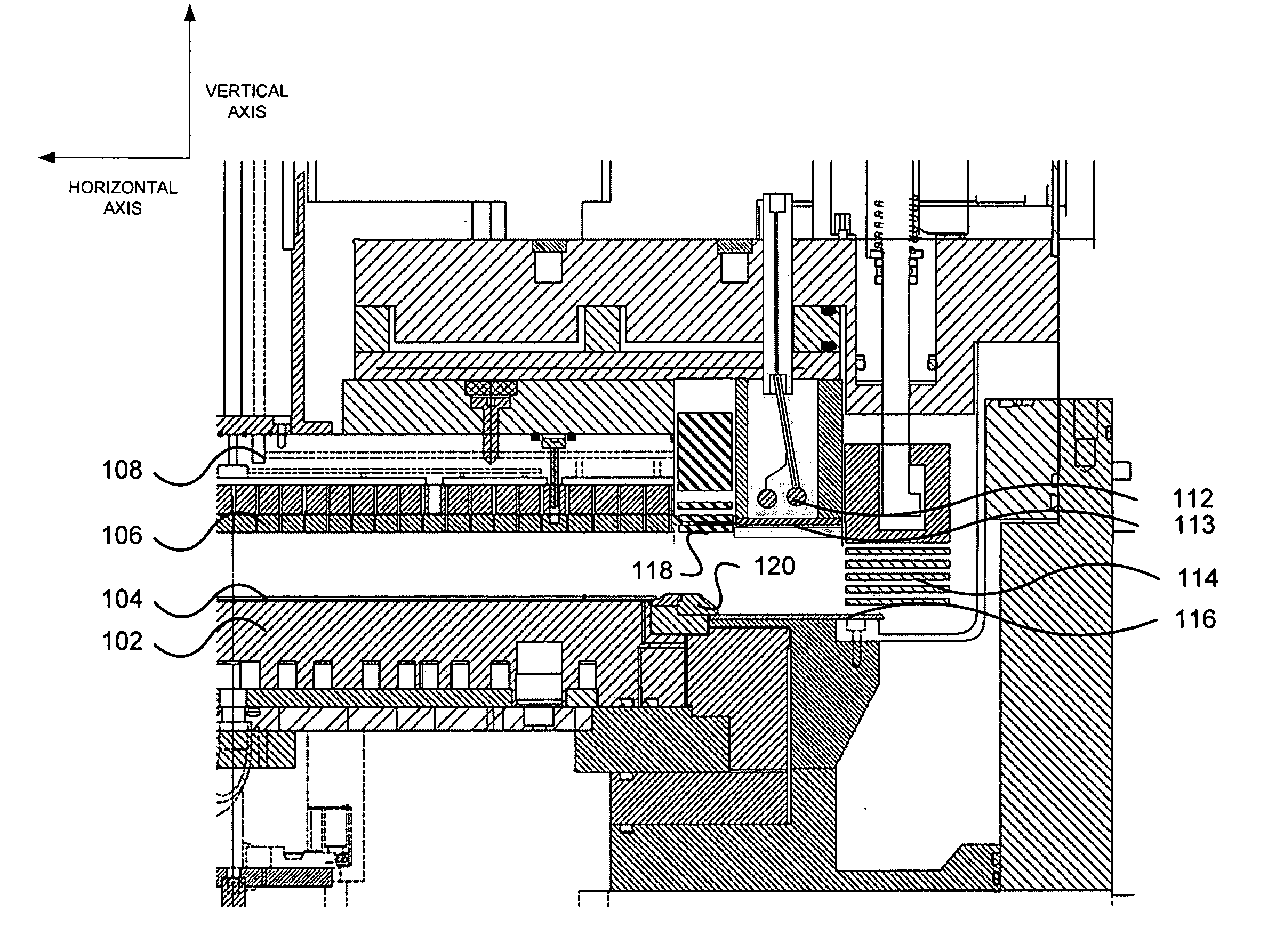

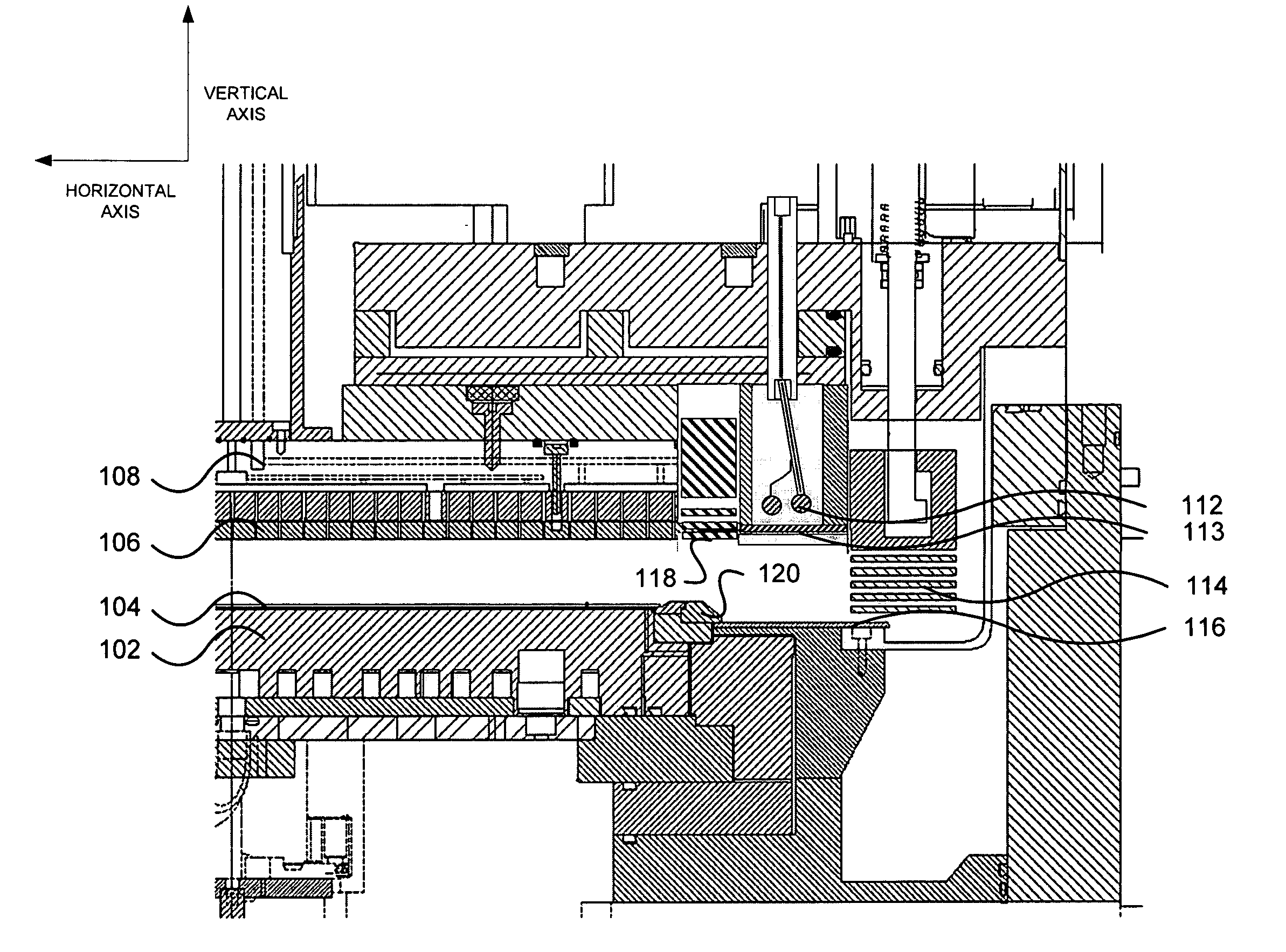

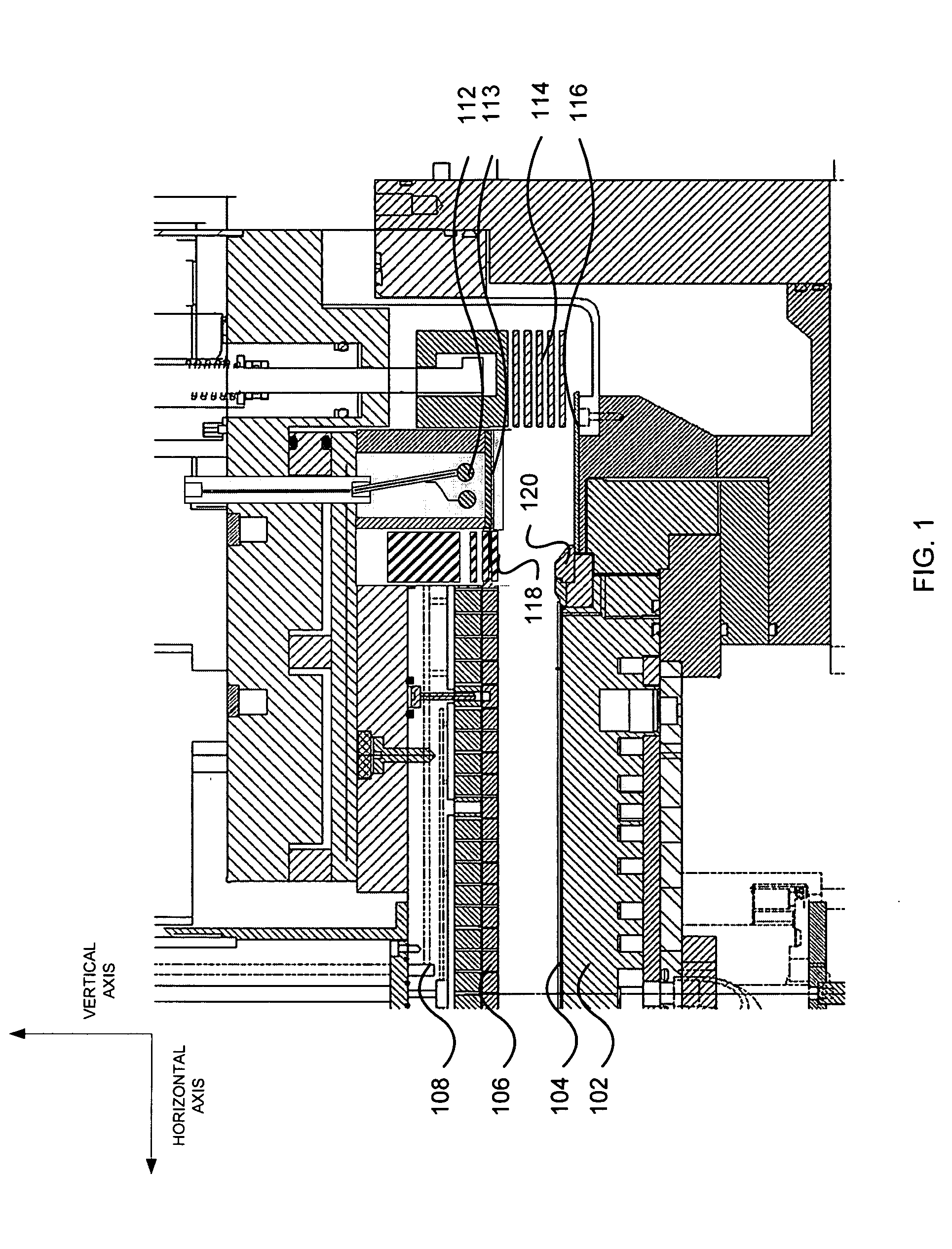

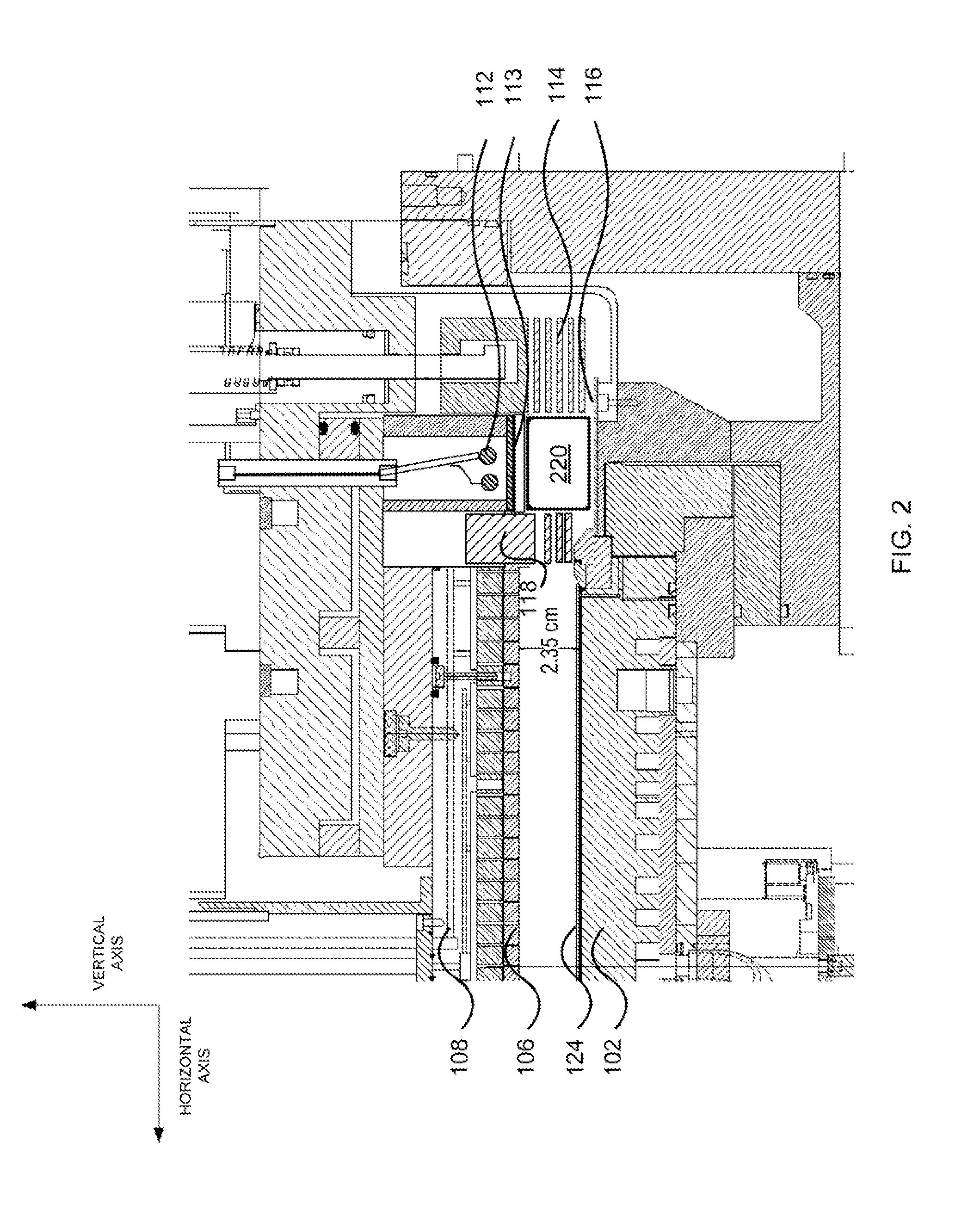

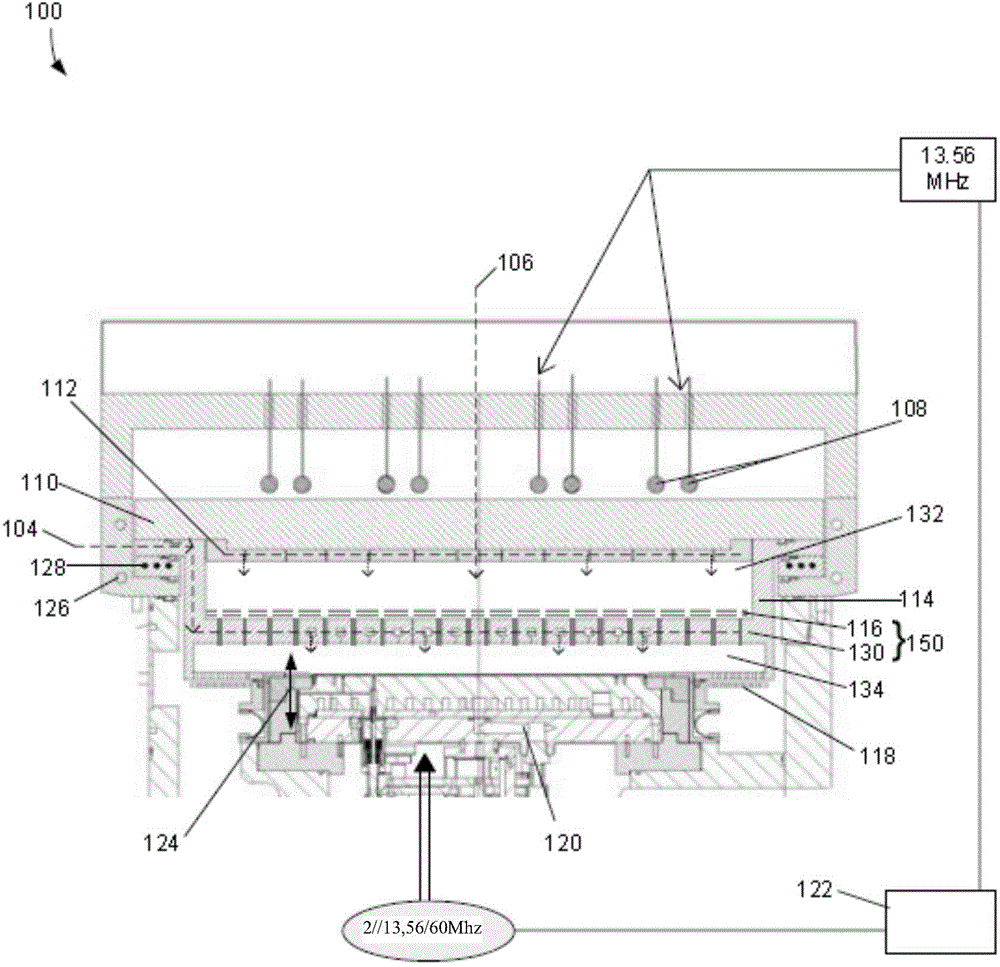

Inductive plasma sources for wafer processing and chamber cleaning

InactiveUS20130034666A1Electric discharge tubesChemical vapor deposition coatingInduction plasma technologyBiological activation

Methods and systems for depositing material on a substrate are described. One method may include providing a processing chamber partitioned into a first plasma region and a second plasma region. The method may further include delivering the substrate to the processing chamber, where the substrate may occupy a portion of the second plasma region. The method may additionally include forming a first plasma in the first plasma region, where the first plasma may not directly contact the substrate, and the first plasma may be formed by activation of at least one shaped radio frequency (“RF”) coil above the first plasma region. The method may moreover include depositing the material on the substrate to form a layer, where one or more reactants excited by the first plasma may be used in deposition of the material.

Owner:APPLIED MATERIALS INC

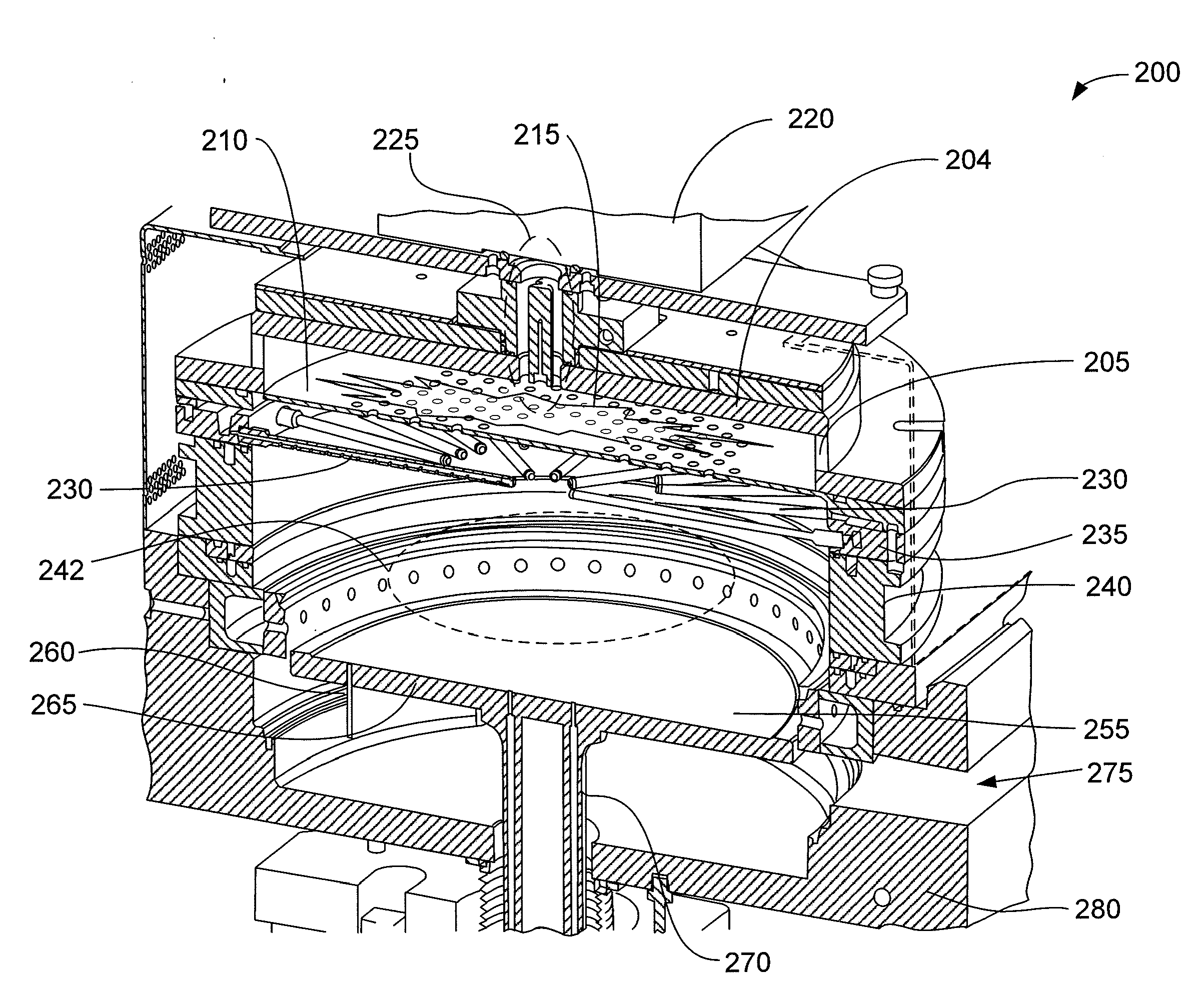

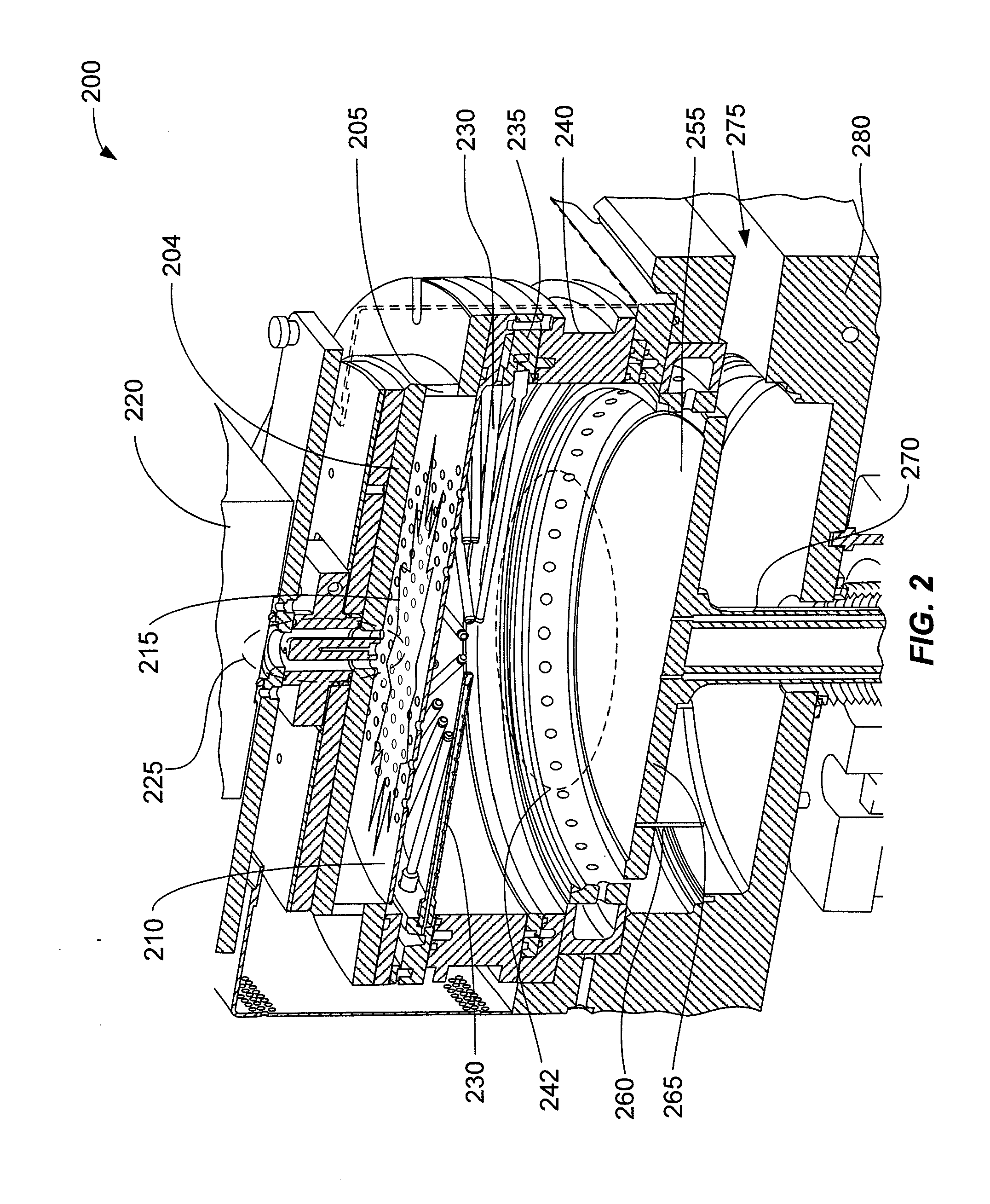

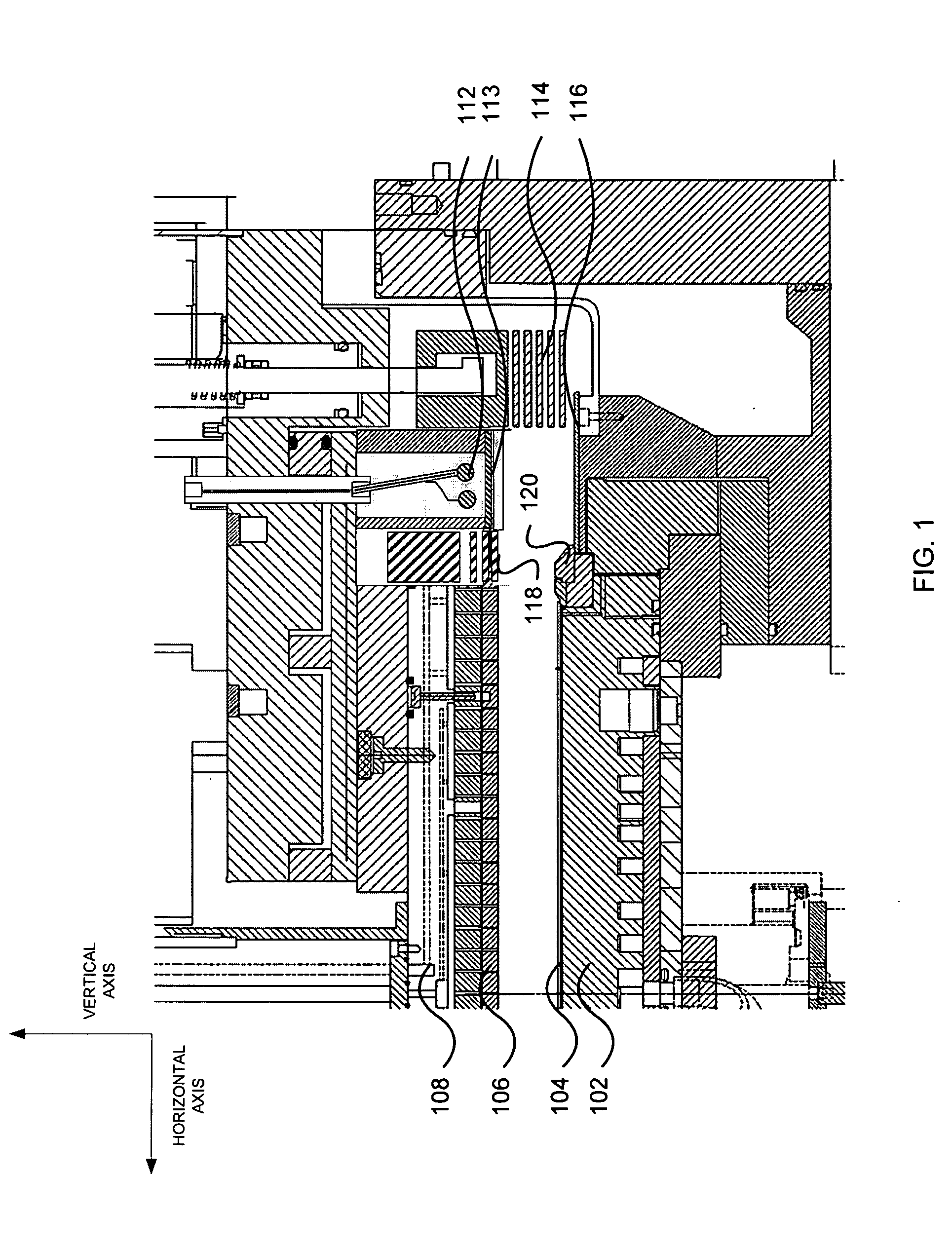

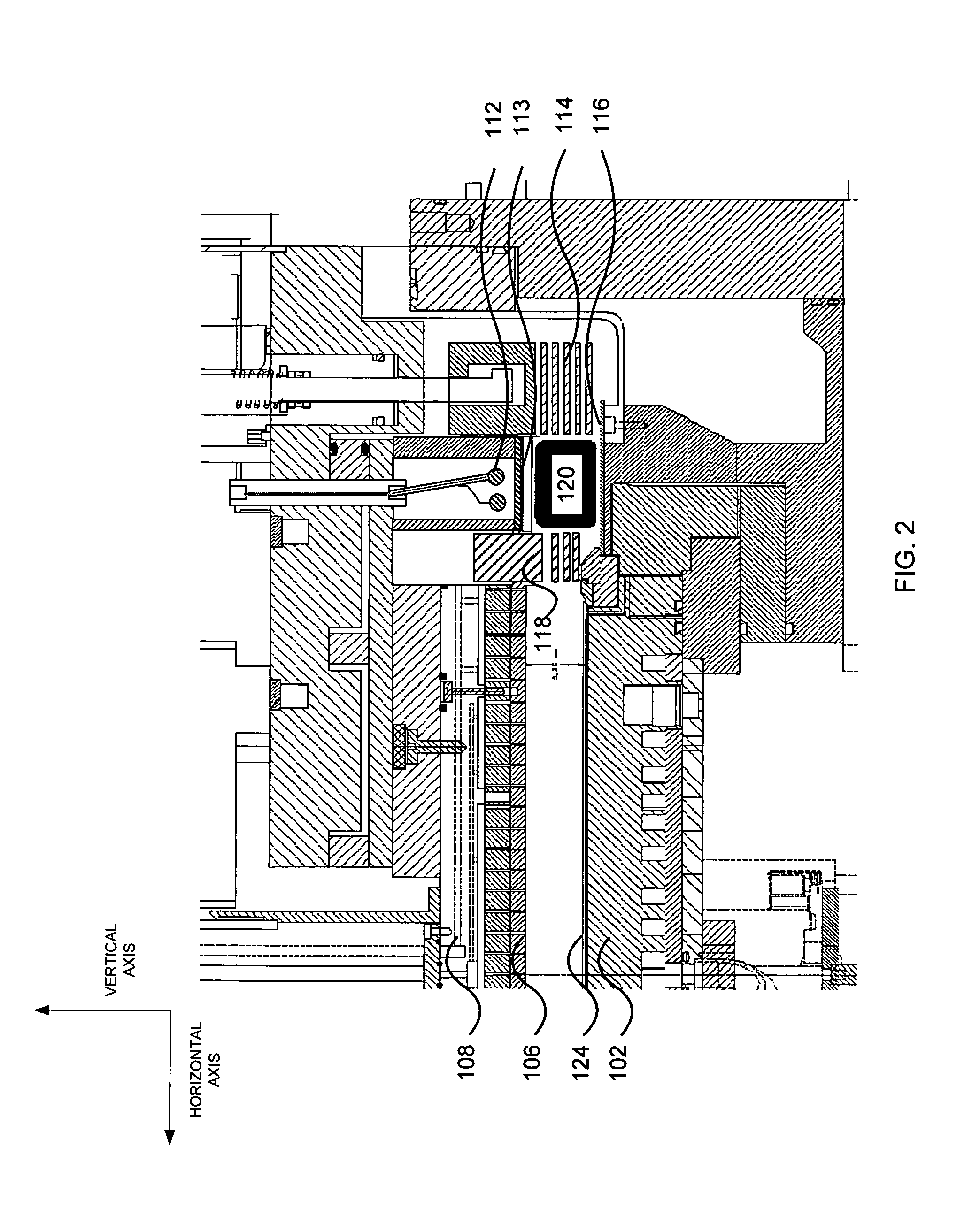

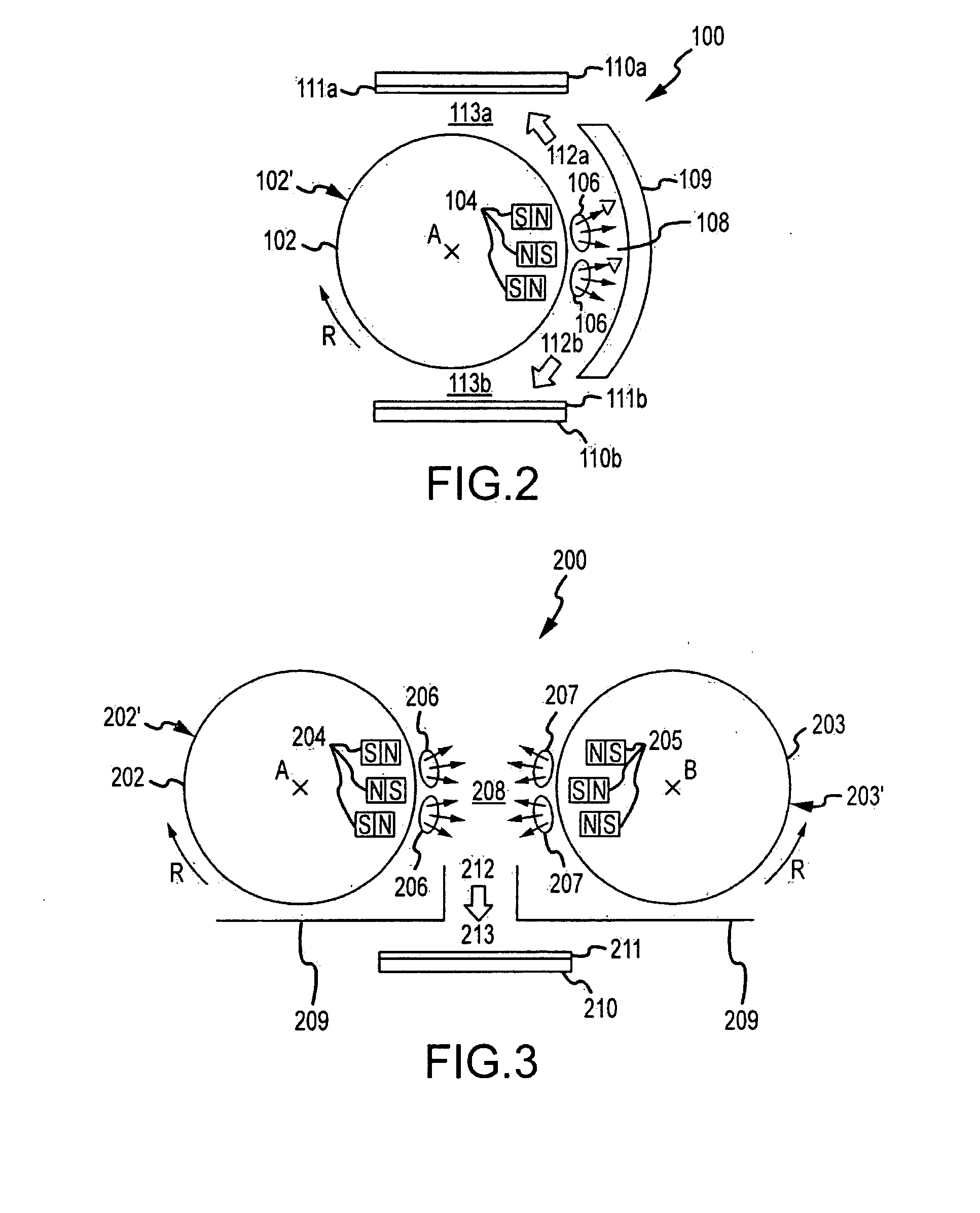

Methods and apparatus for selective pre-coating of a plasma processing chamber

ActiveUS20070204797A1Minimize contaminationSimple manufacturing processElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringDelivery system

An apparatus for selectively pre-coating a plasma processing chamber, including a chamber wall is disclosed. The apparatus includes a first set of RF electrodes, the first set of RF electrodes configured to strike a first pre-coat plasma, the first set of RF electrodes defining a first plasma chamber zone. The apparatus also includes a first set of confinement rings disposed around the first set of RF electrodes; and a second set of confinement rings disposed between the first set of confinement rings and the chamber wall. The apparatus further includes a gas delivery system configured to apply a first pre-coat layer to the first plasma zone when a first pre-coat gas is delivered and the first set of RF electrodes is energized. The apparatus also includes the gas delivery system configured to apply a second pre-coat layer to the second plasma zone when a second pre-coat gas is delivered and the second set of RF electrodes is energized.

Owner:LAM RES CORP

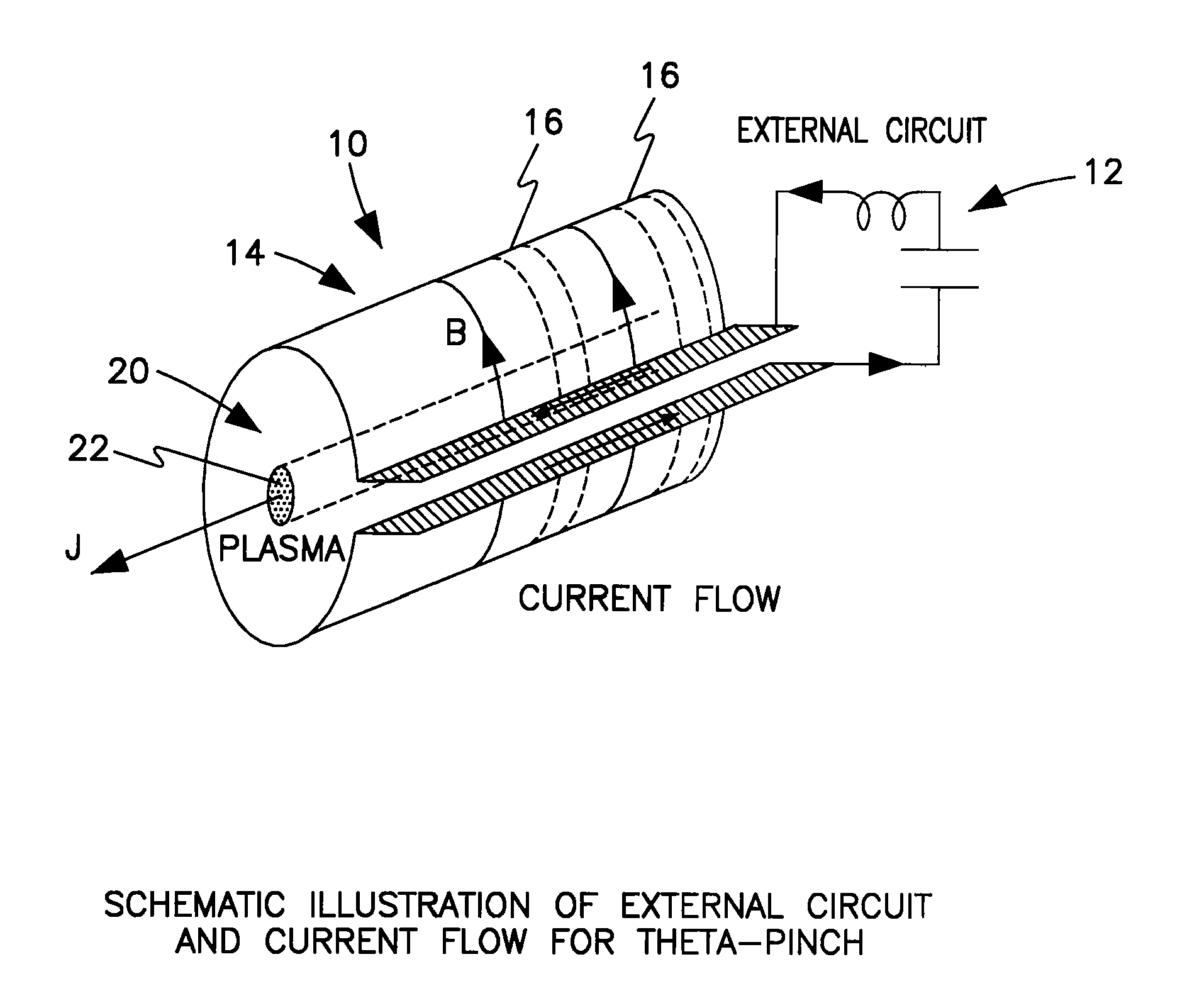

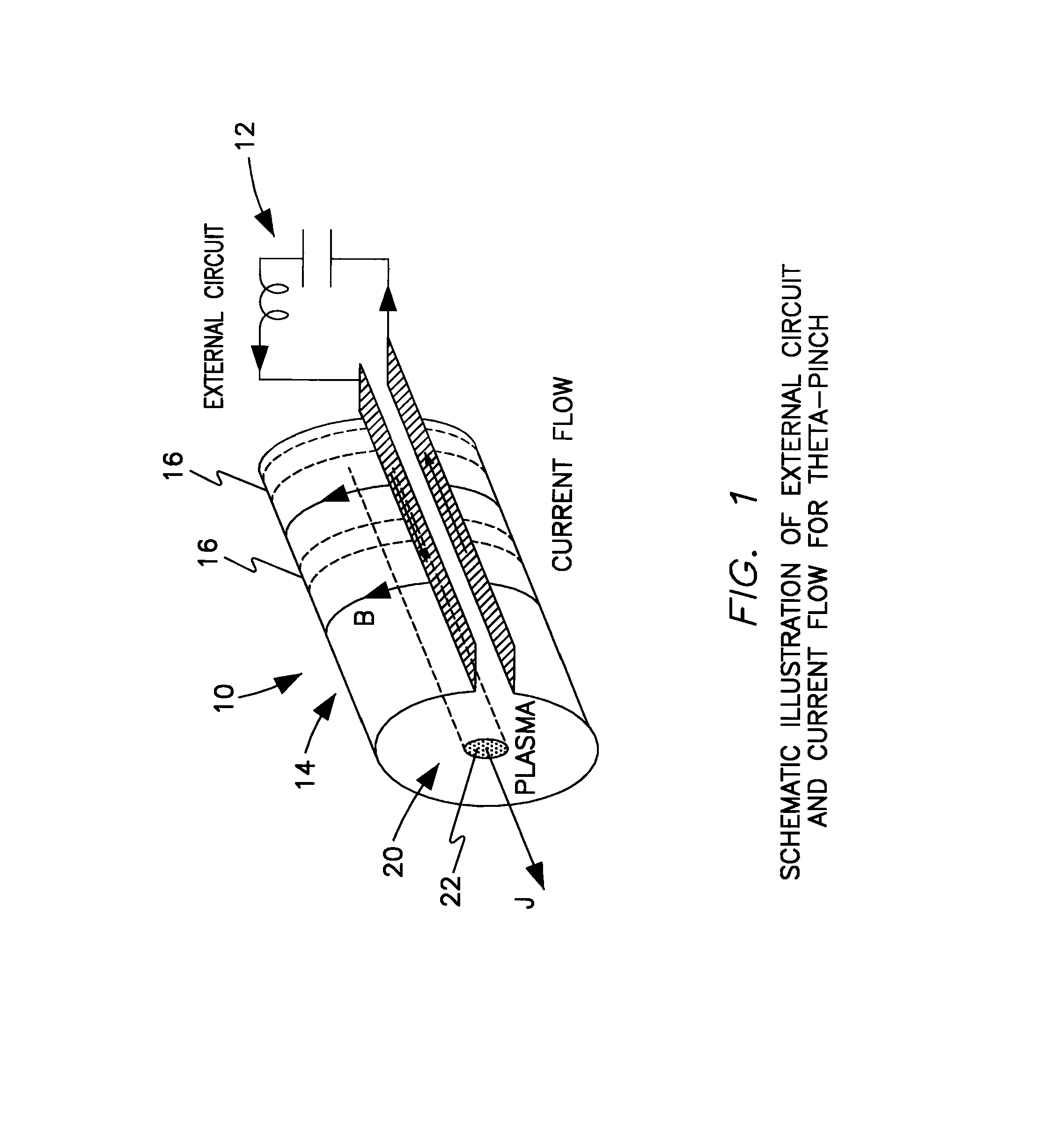

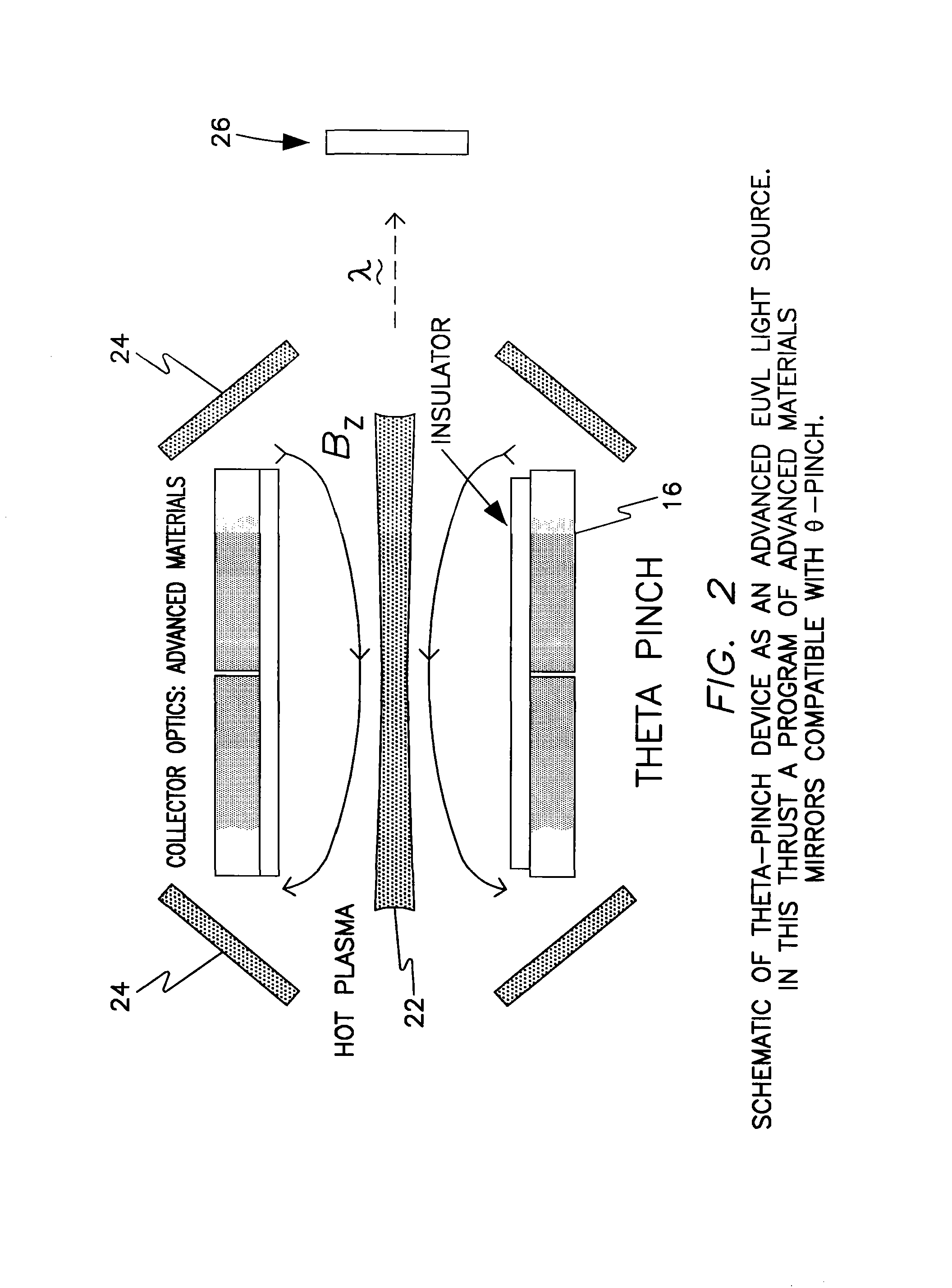

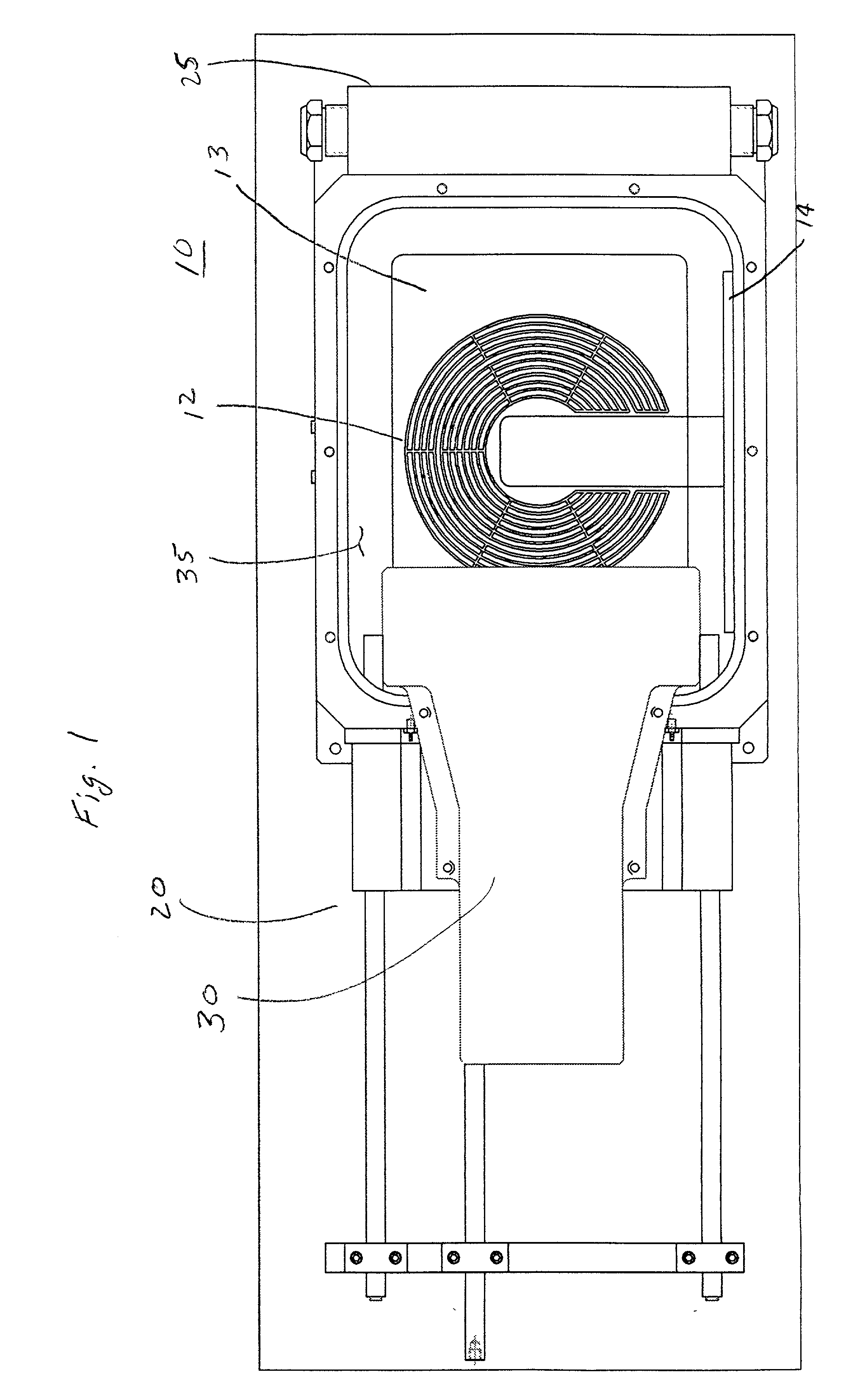

Method for plasma formation for extreme ultraviolet lithography-theta pinch

A device and method for generating extremely short-wave ultraviolet electromagnetic wave, utilizing a theta pinch plasma generator to produce electromagnetic radiation in the range of 10 to 20 nm. The device comprises an axially aligned open-ended pinch chamber defining a plasma zone adapted to contain a plasma generating gas within the plasma zone; a means for generating a magnetic field radially outward of the open-ended pinch chamber to produce a discharge plasma from the plasma generating gas, thereby producing a electromagnetic wave in the extreme ultraviolet range; a collecting means in optical communication with the pinch chamber to collect the electromagnetic radiation; and focusing means in optical communication with the collecting means to concentrate the electromagnetic radiation.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

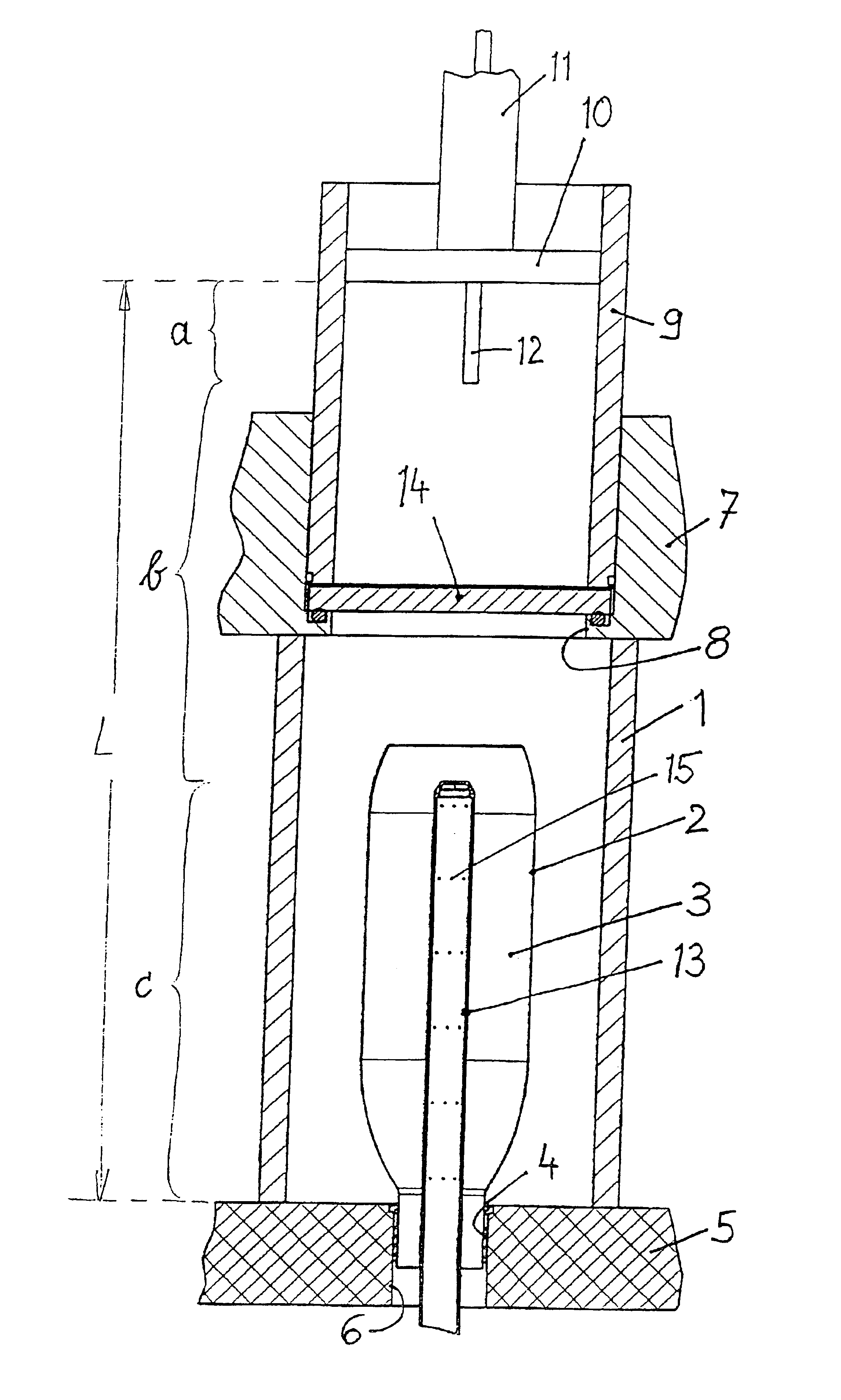

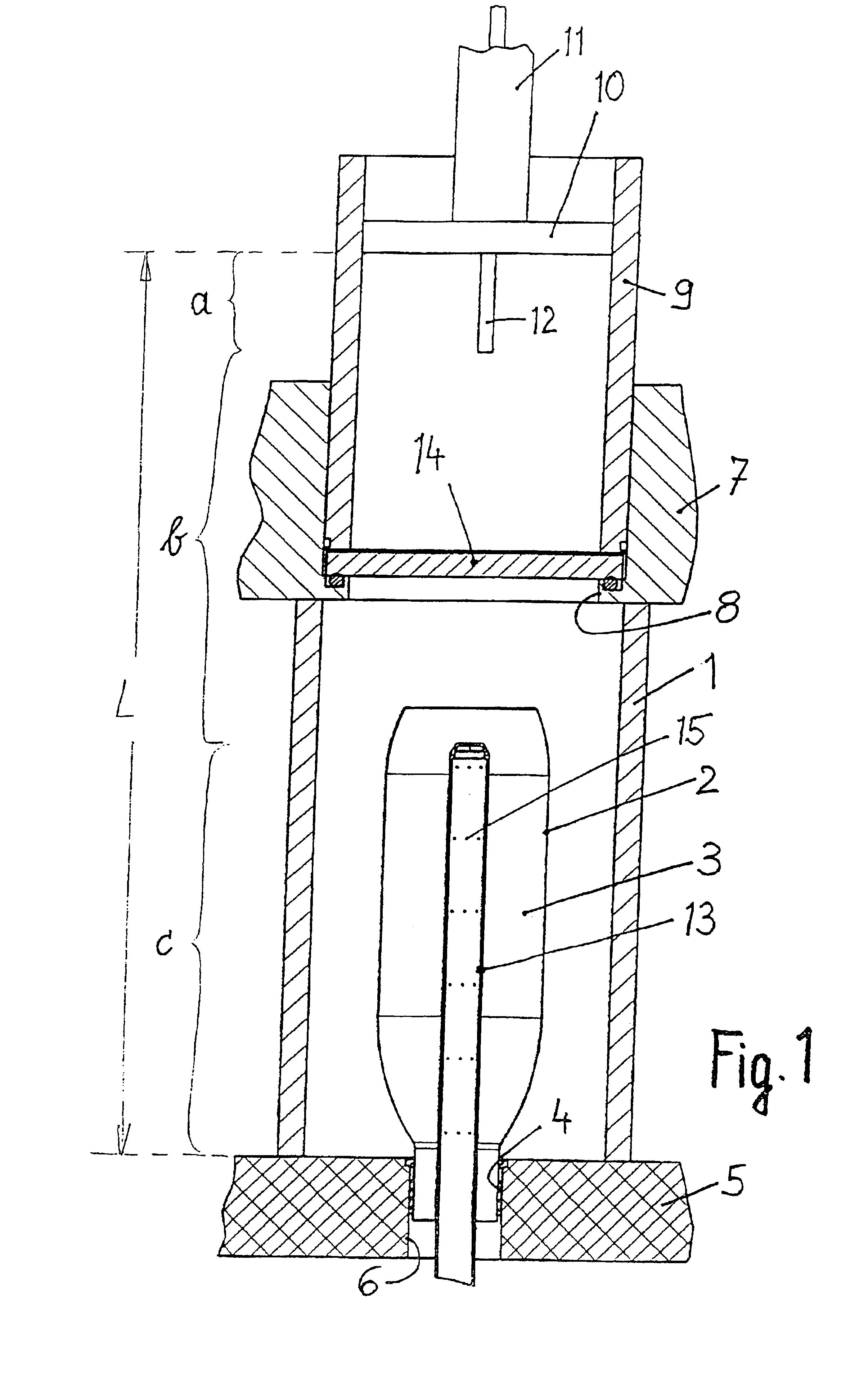

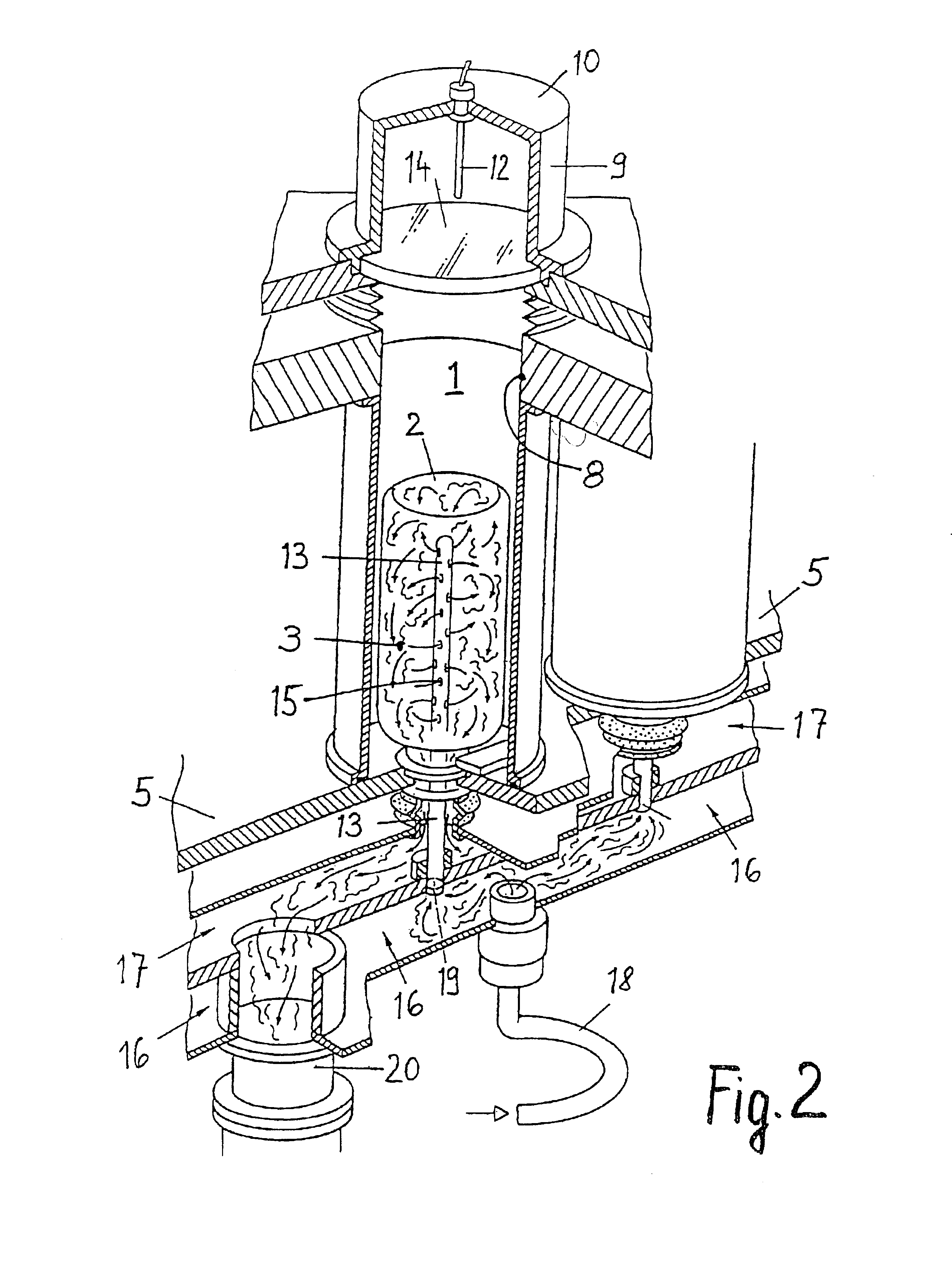

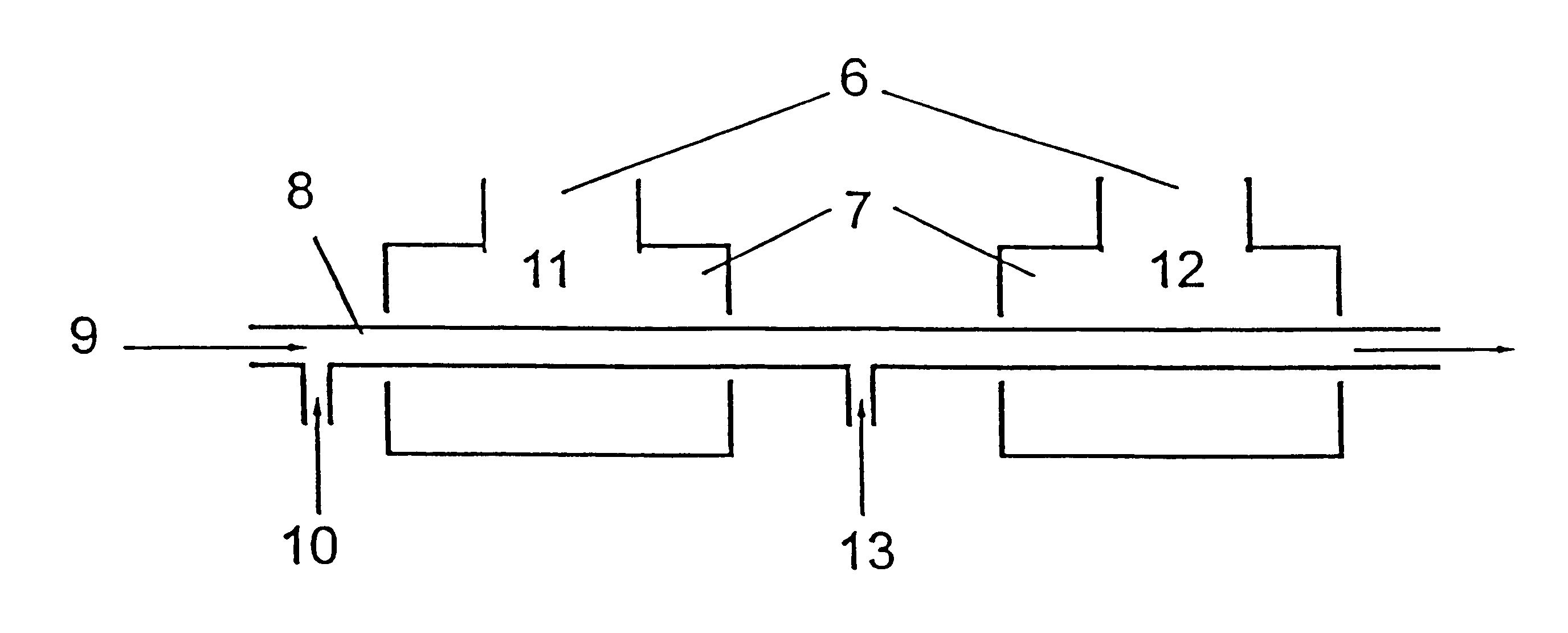

Arrangement for coupling microwave energy into a treatment chamber

InactiveUS6952949B2Moderate reflection factor drop in powerReduce reflected powerElectric discharge tubesUsing liquid separation agentElectrical conductorCoaxial waveguides

An arrangement for coupling microwave energy into a plasma CVD coating chamber (3) disposed in a cavity resonator (1) has a microwave feed (11) and a microwave waveguide (9, 1). So that a plastic container of a size and configuration which differ to a certain degree can be effectively coated in its interior, it is provided that the arrangement is of a substantially cylindrical structure, such that provided at the rear end is a first coaxial waveguide (in the region a) with an internal conductor in the form of an antenna (12), an approximately cylindrical waveguide (in the region b) follows in the centre of the arrangement and provided at the front end (in the region c) is a second coaxial waveguide (1) with internal conductor (13), wherein gas can be introduced through a gas feed tube (13) into the second coaxial waveguide (in the region c), which gas can be activated into the plasma state by the coupled-in microwave energy, and wherein a TM-mode is produced by the antenna (12) in the plasma region (1, c).

Owner:TETRA LAVAL HLDG & FINANCE SA

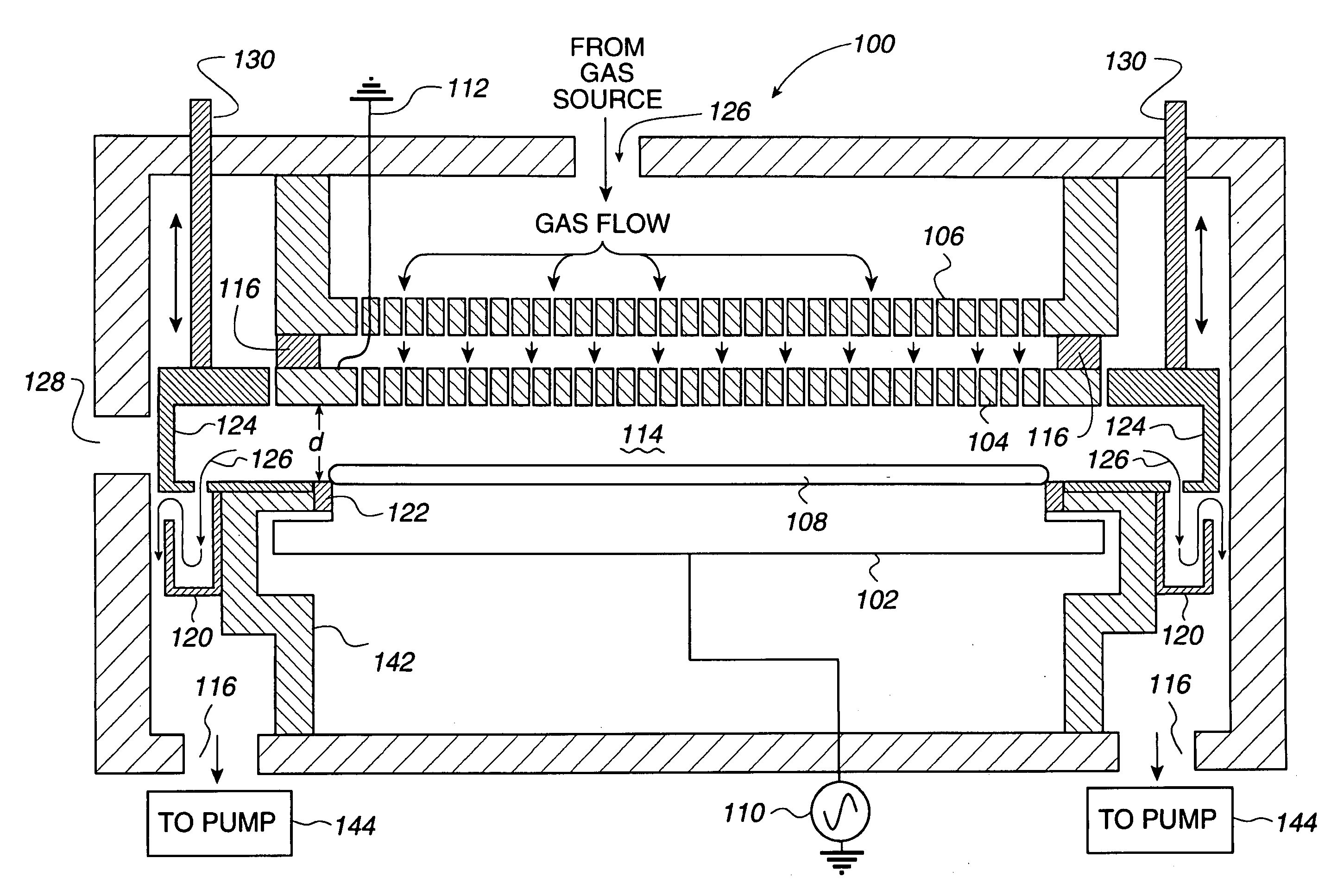

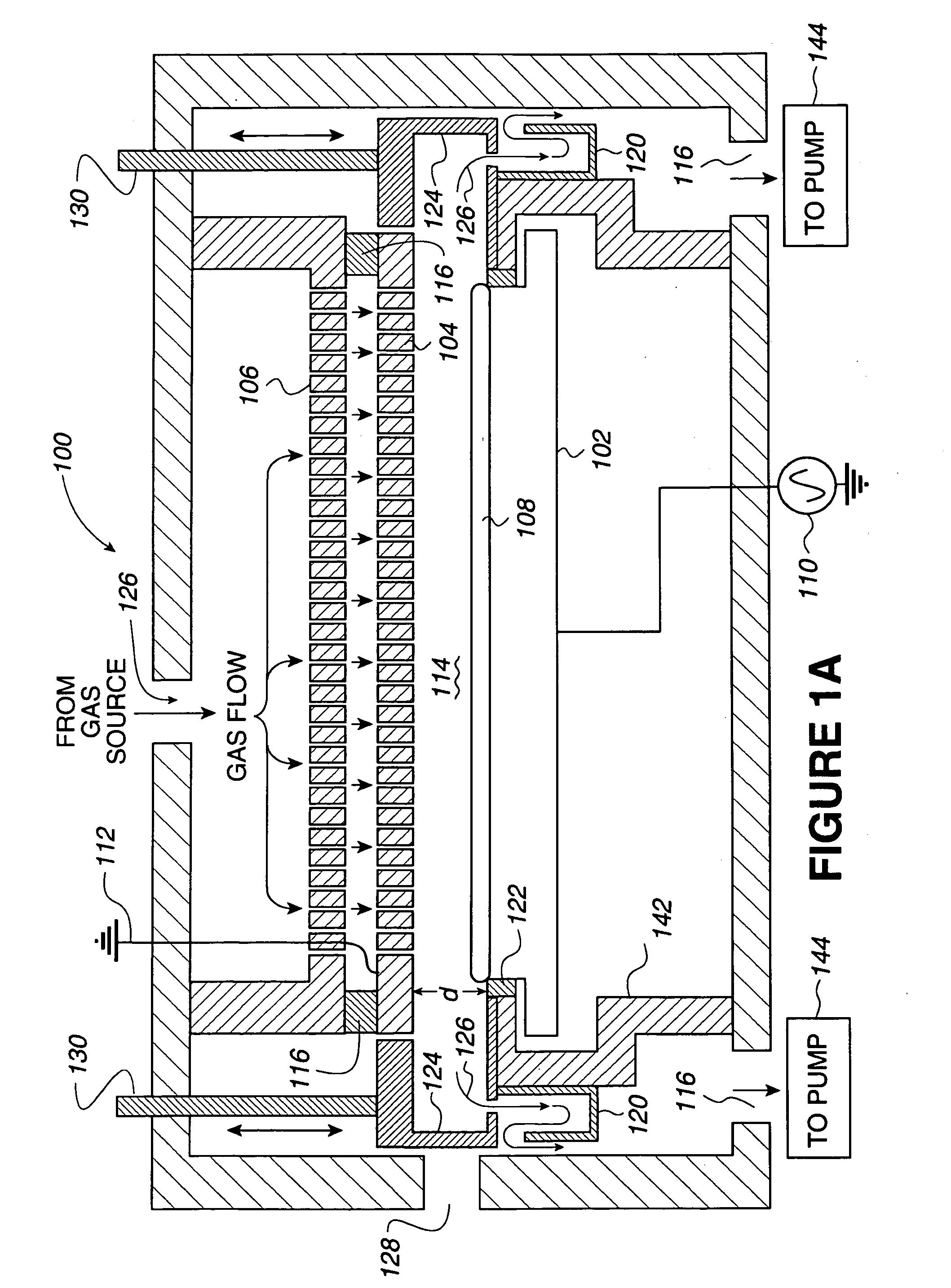

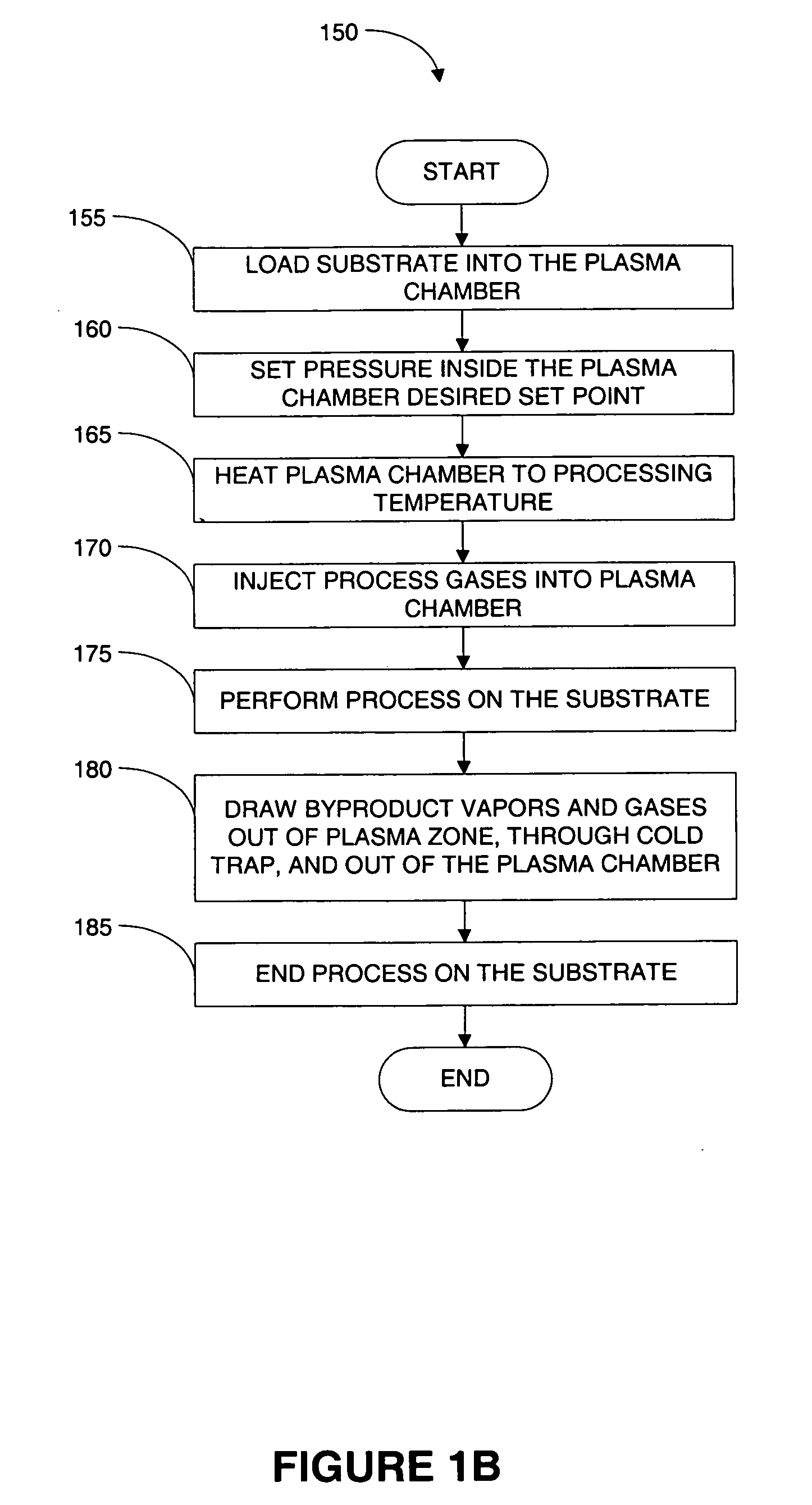

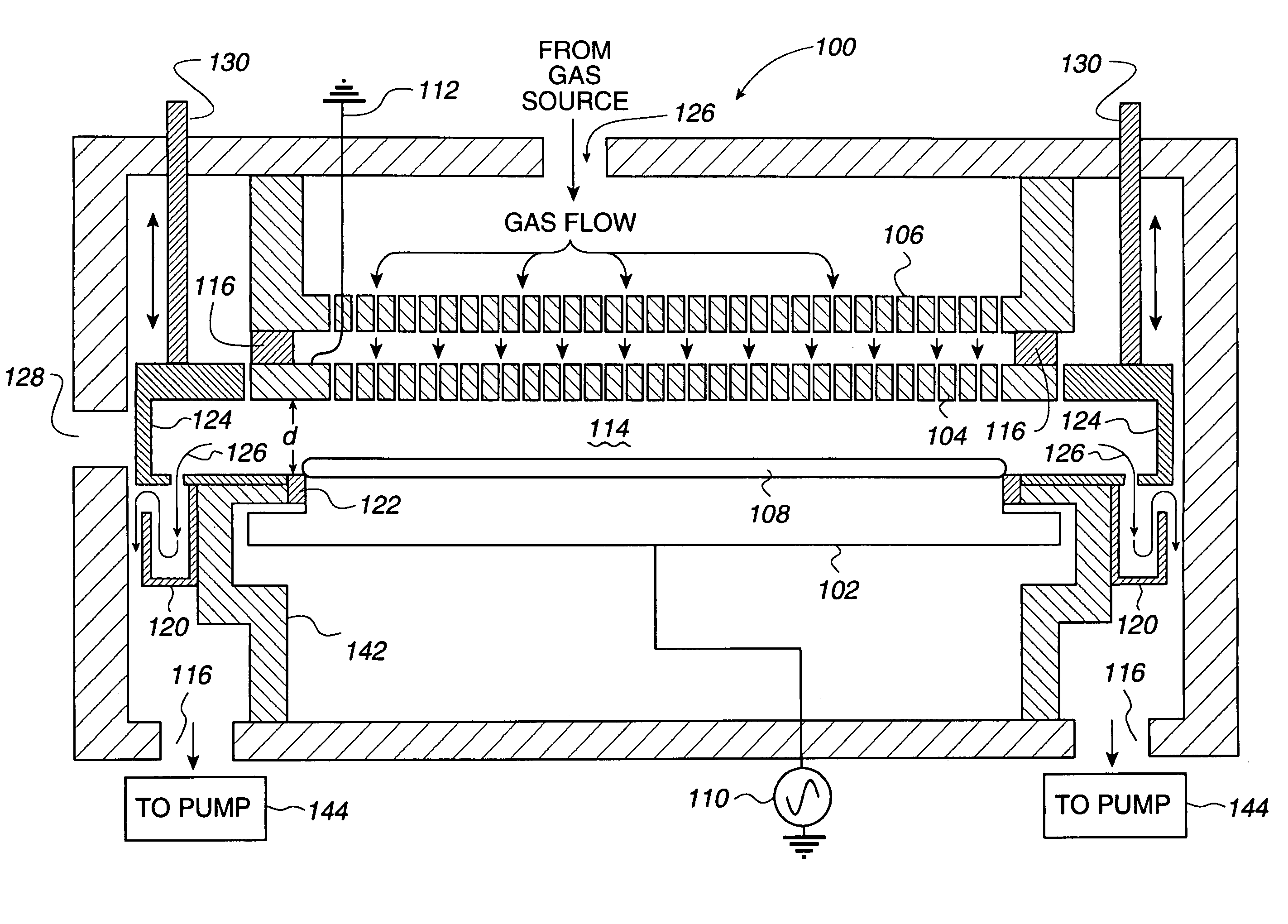

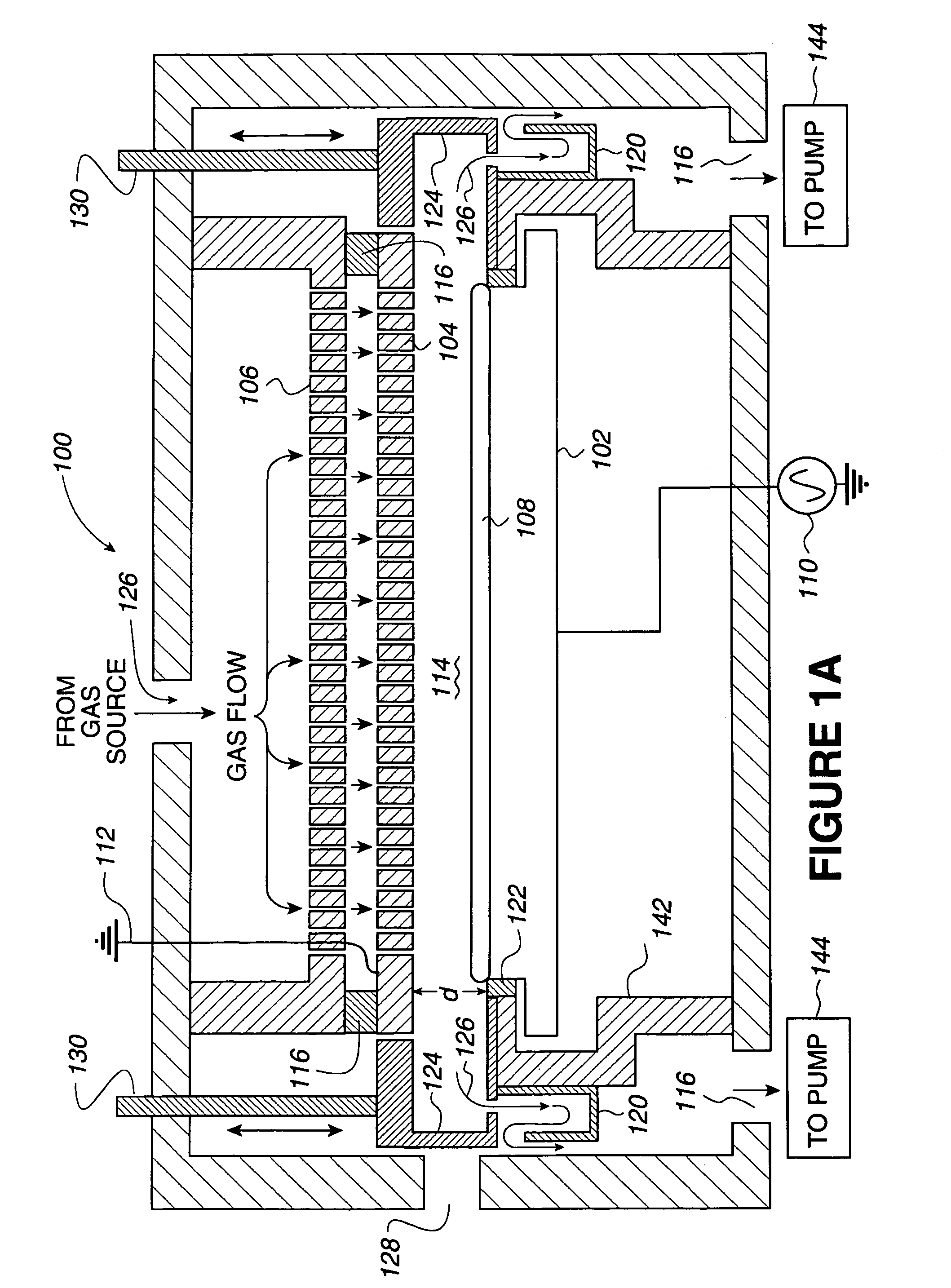

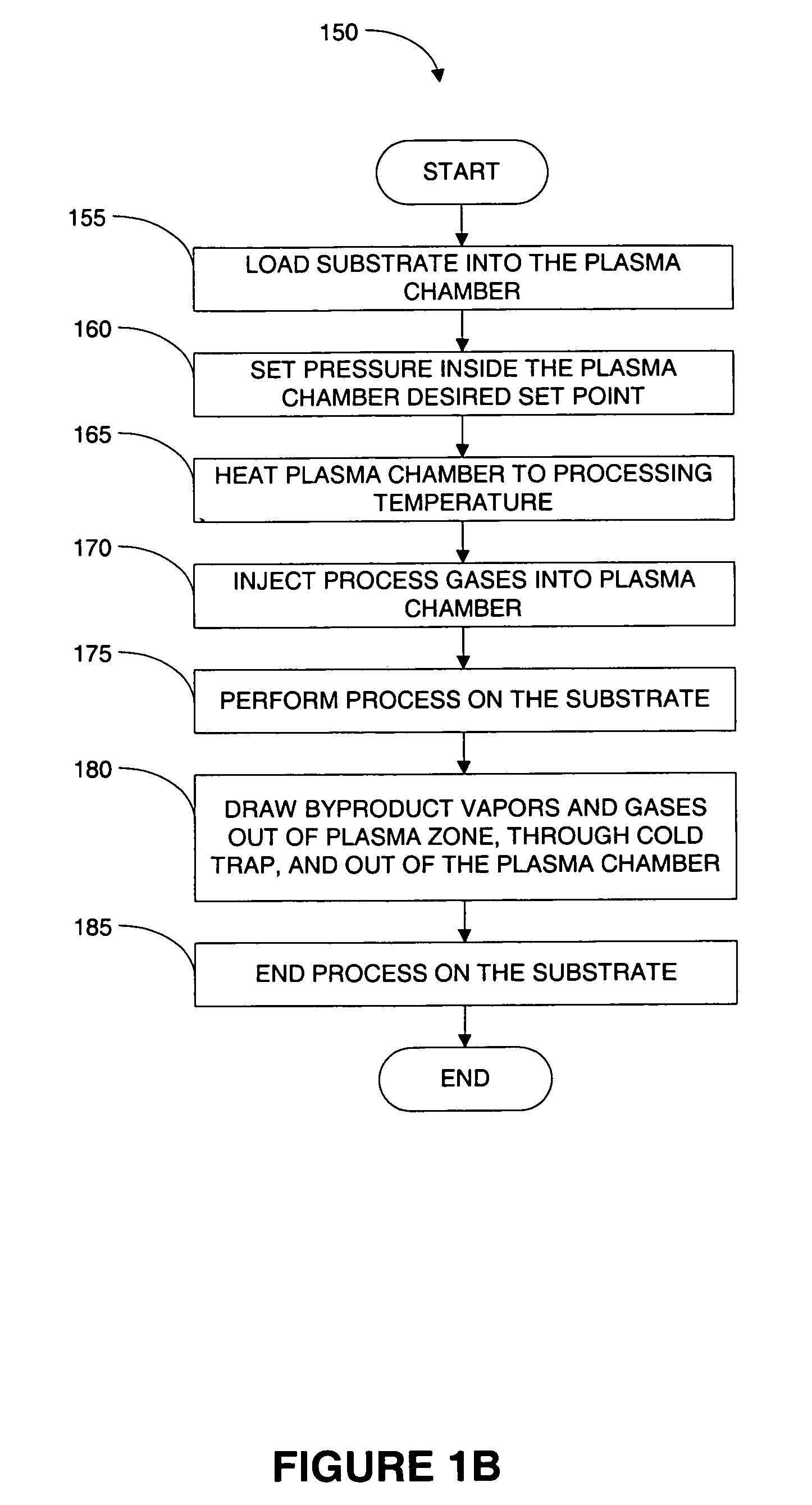

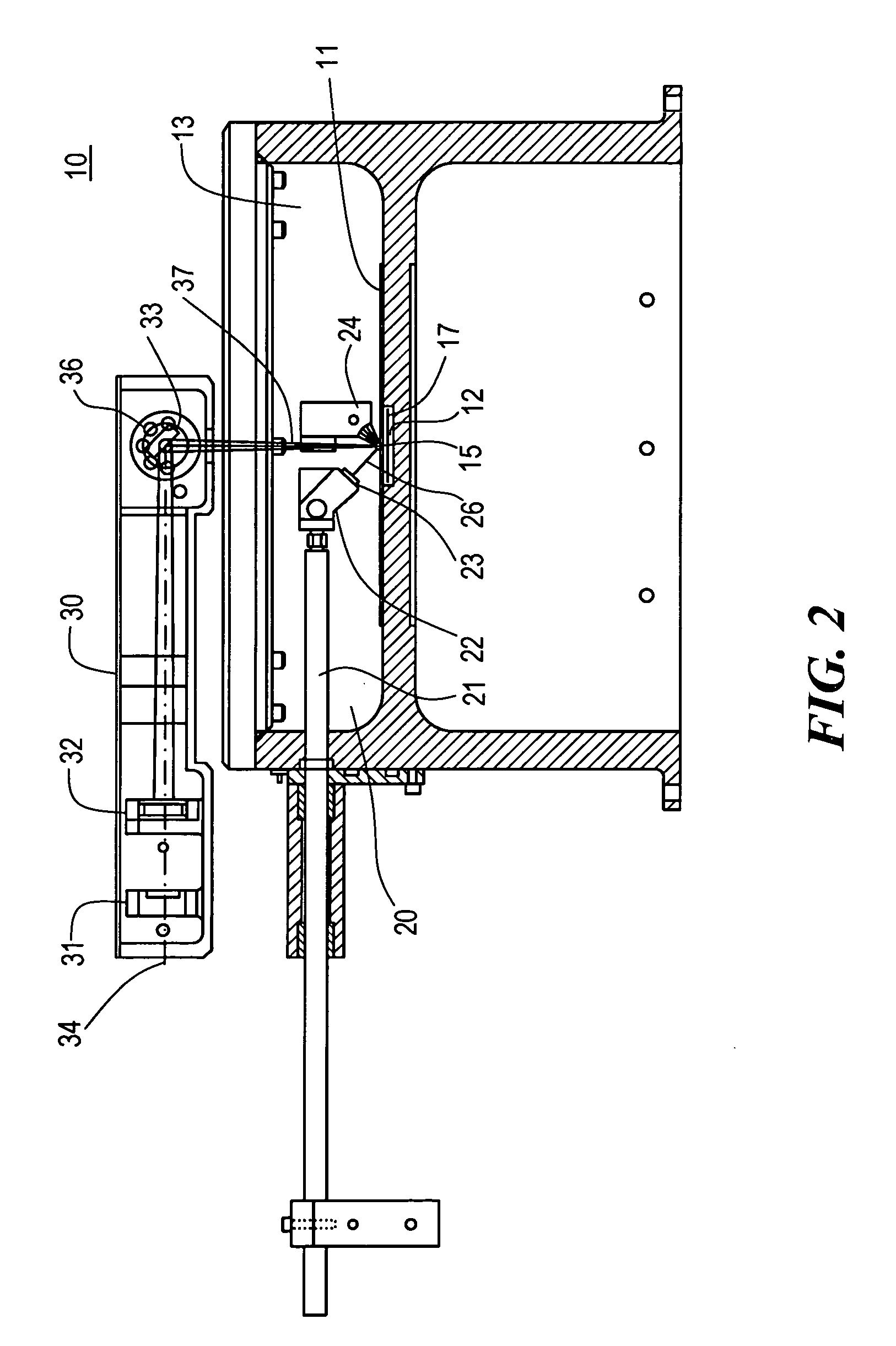

Small volume process chamber with hot inner surfaces

InactiveUS20050070105A1Inhibit migrationMinimizing particle generationElectric discharge tubesSemiconductor/solid-state device detailsSet pointMaterials science

A system and method of processing a substrate including loading a substrate into a plasma chamber and setting a pressure of the plasma chamber to a pre-determined pressure set point. Several inner surfaces that define a plasma zone are heated to a processing temperature of greater than about 200 degrees C. A process gas is injected into the plasma zone to form a plasma and the substrate is processed.

Owner:LAM RES CORP

Small volume process chamber with hot inner surfaces

InactiveUS7009281B2Inhibit migrationEliminate condensationElectric discharge tubesSemiconductor/solid-state device detailsSet pointMaterials science

A system and method of processing a substrate including loading a substrate into a plasma chamber and setting a pressure of the plasma chamber to a pre-determined pressure set point. Several inner surfaces that define a plasma zone are heated to a processing temperature of greater than about 200 degrees C. A process gas is injected into the plasma zone to form a plasma and the substrate is processed.

Owner:LAM RES CORP

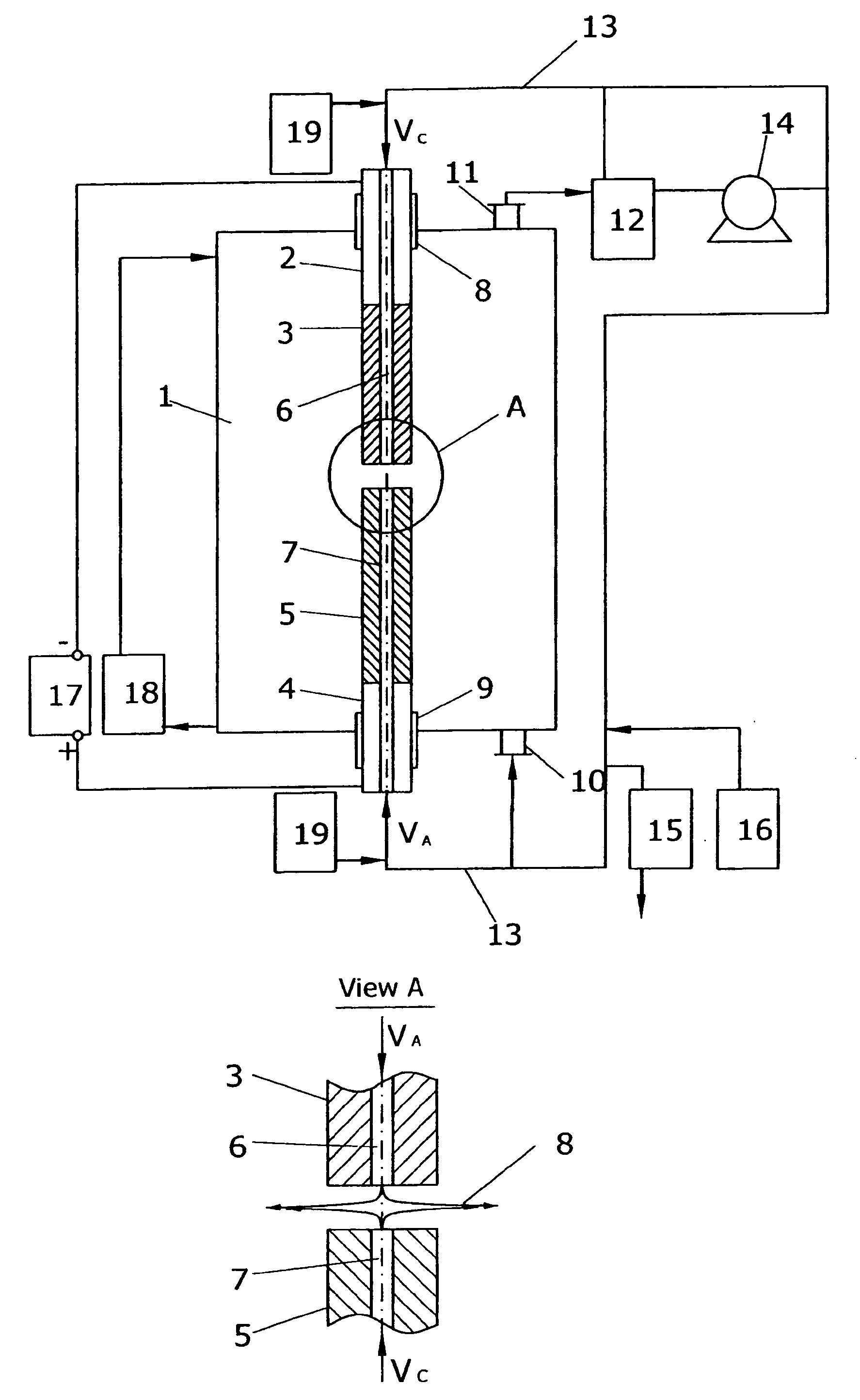

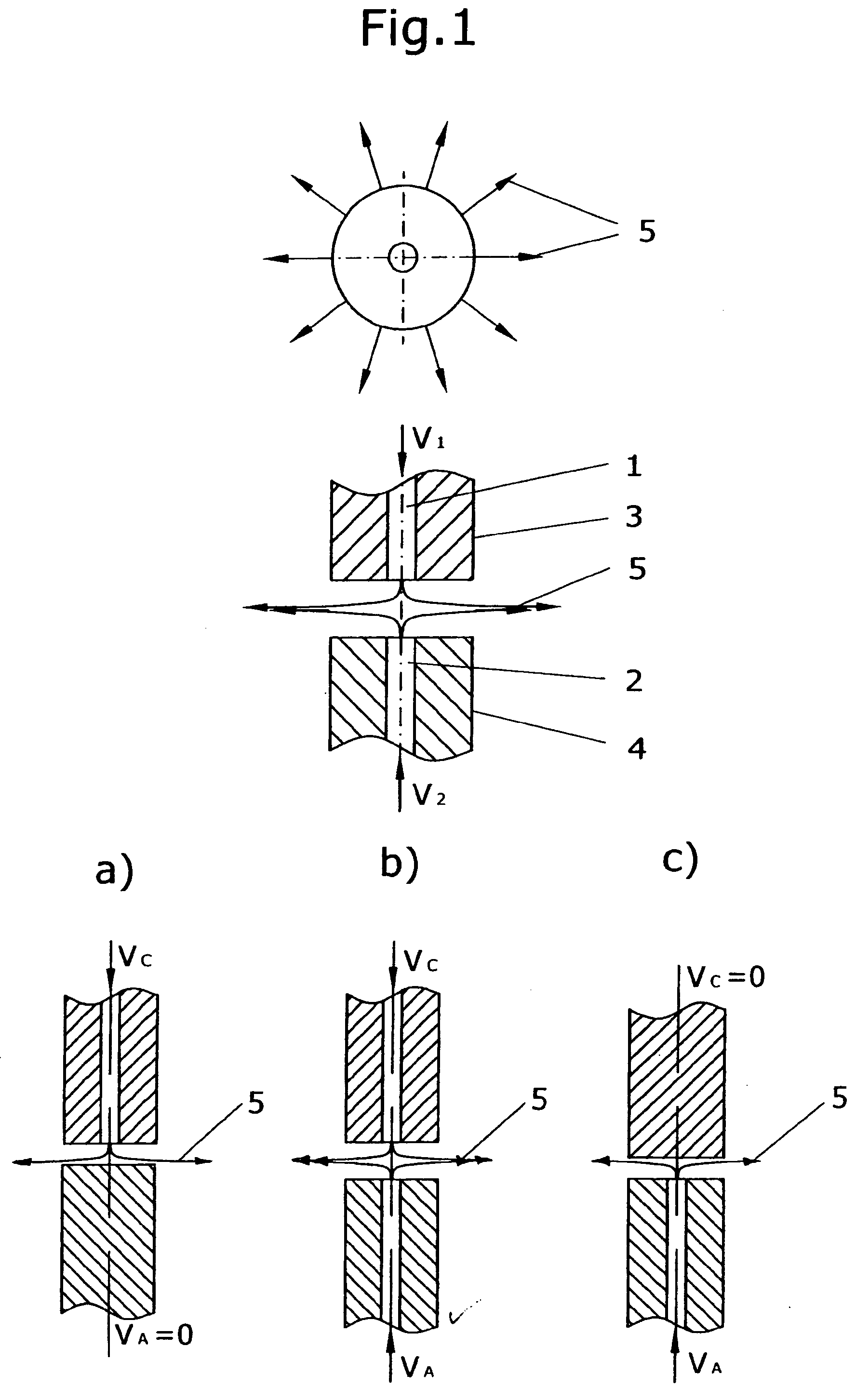

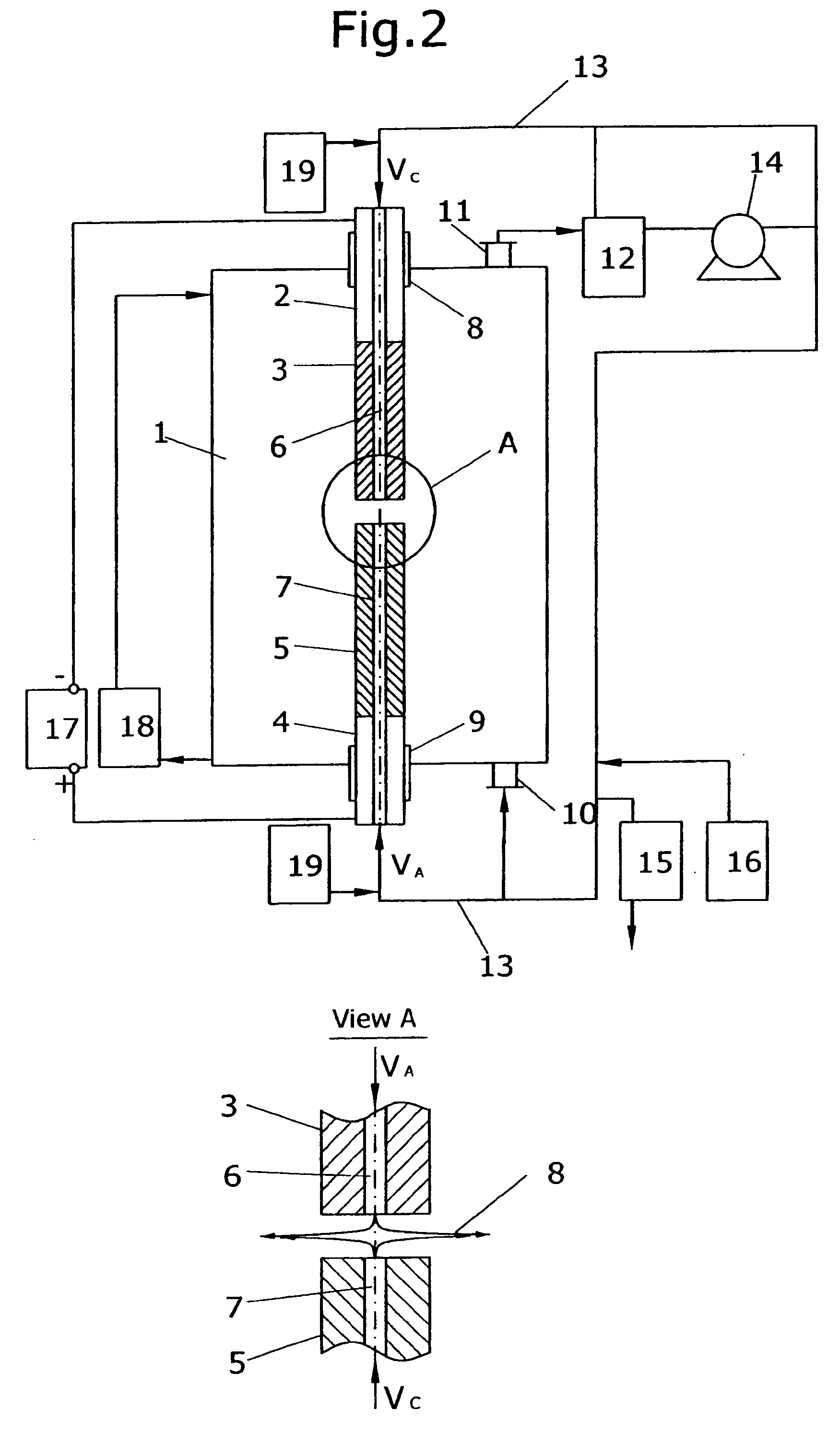

Method and apparatus for carbon allotropes synthesis

InactiveUS20050230240A1Easy and inexpensiveEliminate the problemMaterial nanotechnologyFullerenesOxygenCarbon allotrope

A method and apparatus for synthesis of fullerenes and nanotubes in large quantities at an economical cost from graphite in electric arc plasma process are presented. Different embodiments of channeled graphite electrodes for both direct current (DC) and alternative current (AC) processes are disclosed. High productivity of the carbon allotropes is achieved by feeding consumable graphitic electrode into hot plasma zone, injecting of feedstock, catalyst and buffer gas flow through the longitudinal inner channel electrodes into the hot plasma zone and creating the radial gas outflow in the gap between electrodes, and following removal of produced carbon and catalytic vapors from the hot plasma zone into an oxygen deprived reaction vessel for quenching and condensing. Deposited after condensation soot containing carbon allotropes is collected and carbon allotropes are recovered by known techniques. The final products of recovering are fullerenes C60, C70 and higher fullerenes or nanotubes.

Owner:DUBROVSKY ROMAN +1

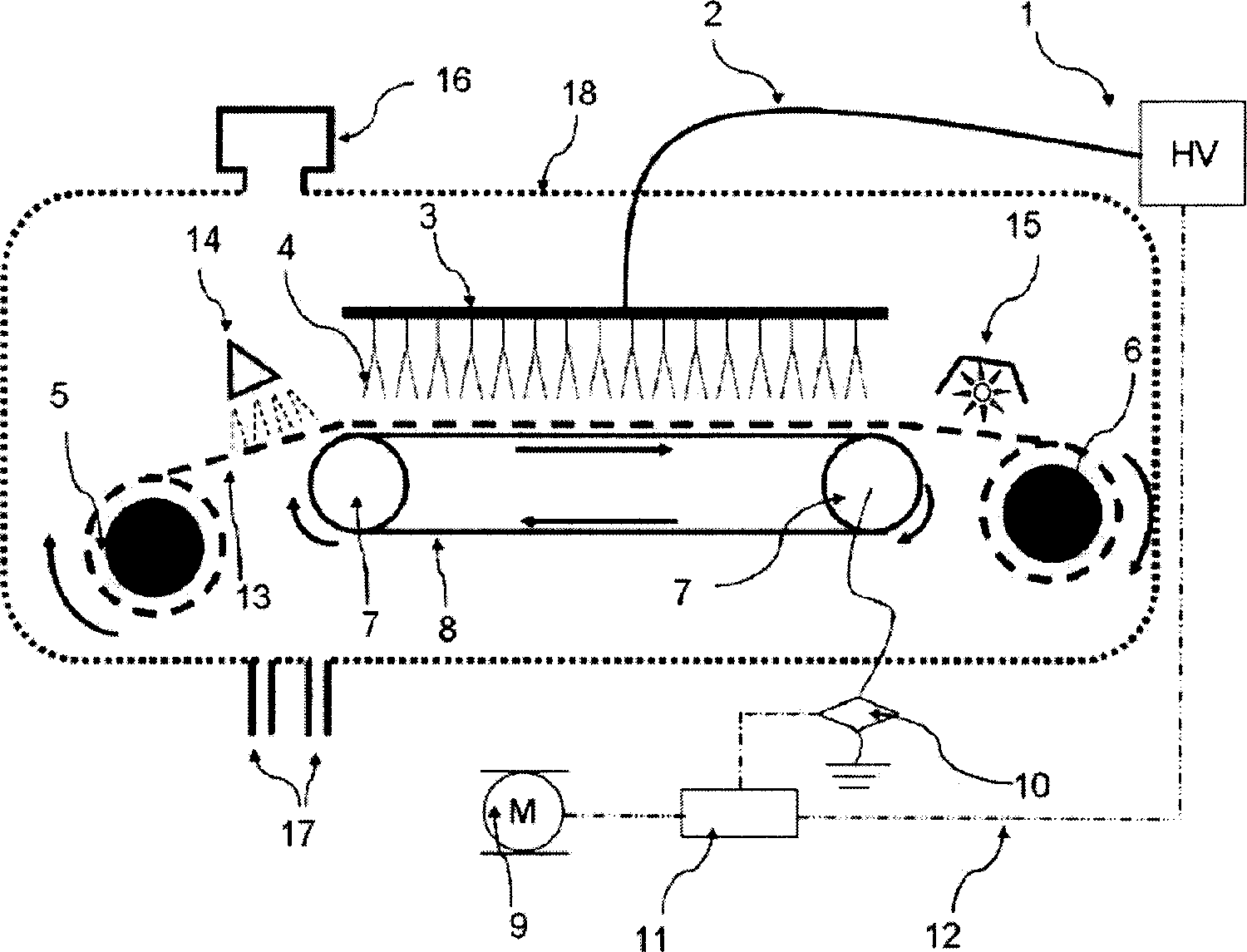

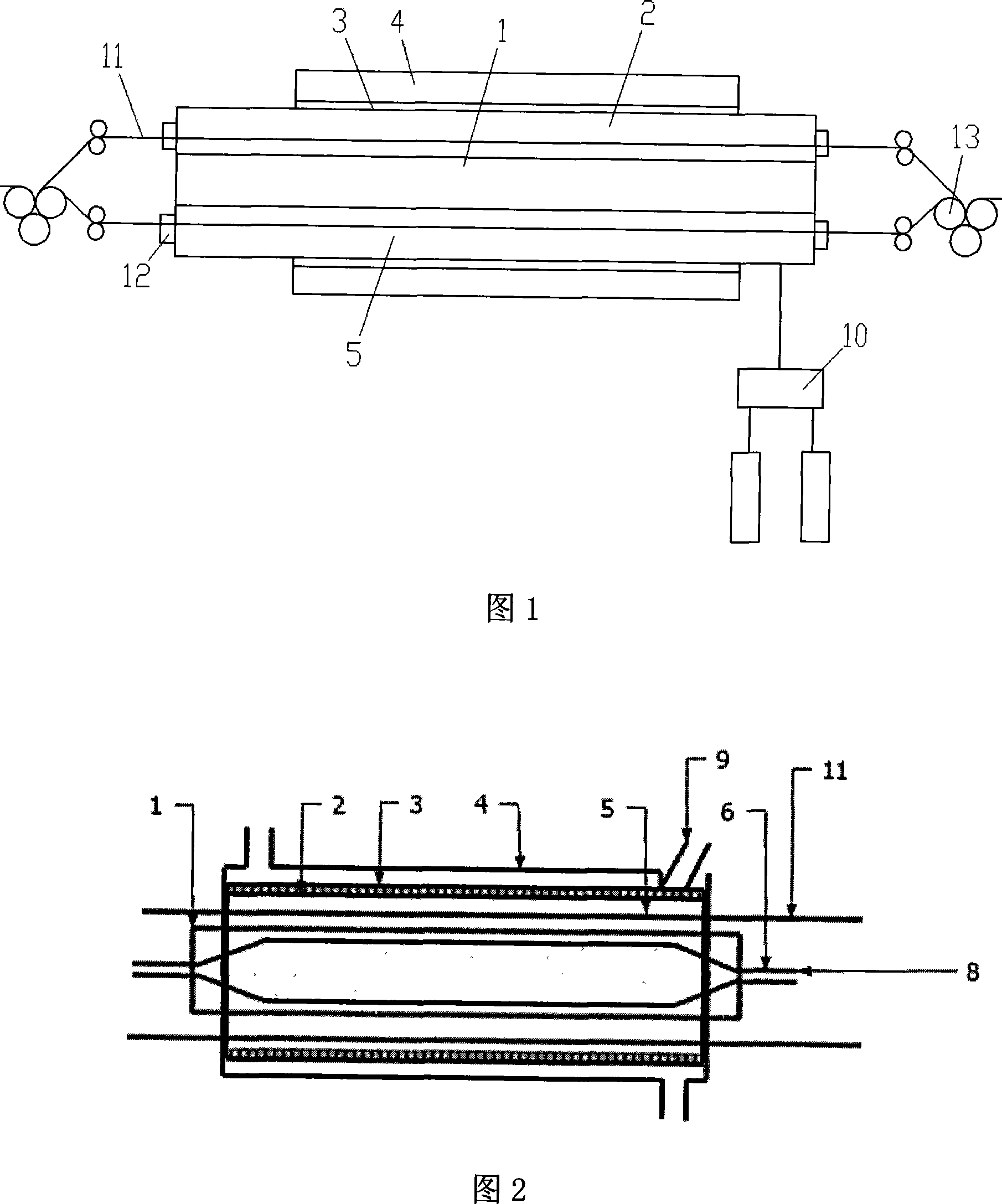

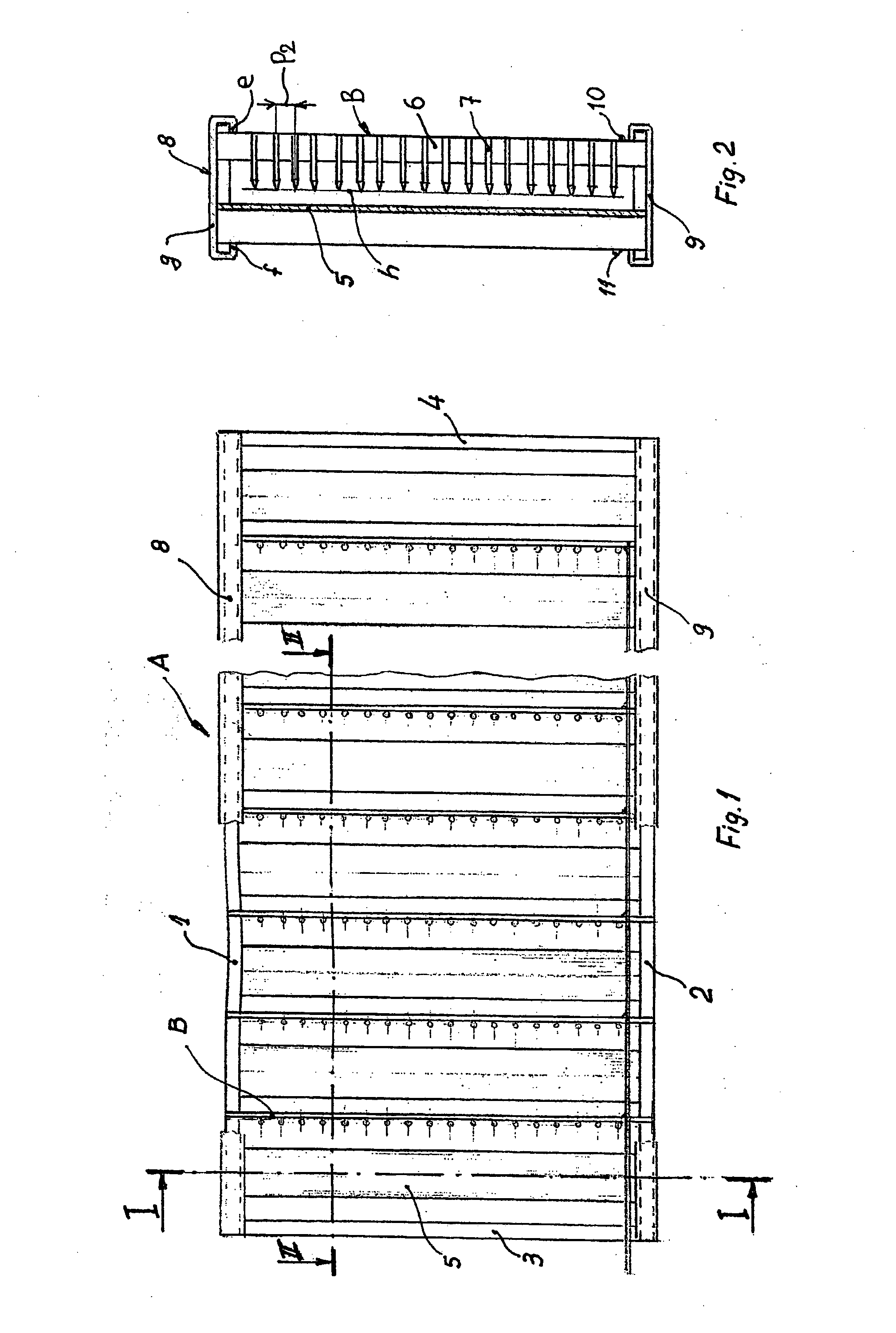

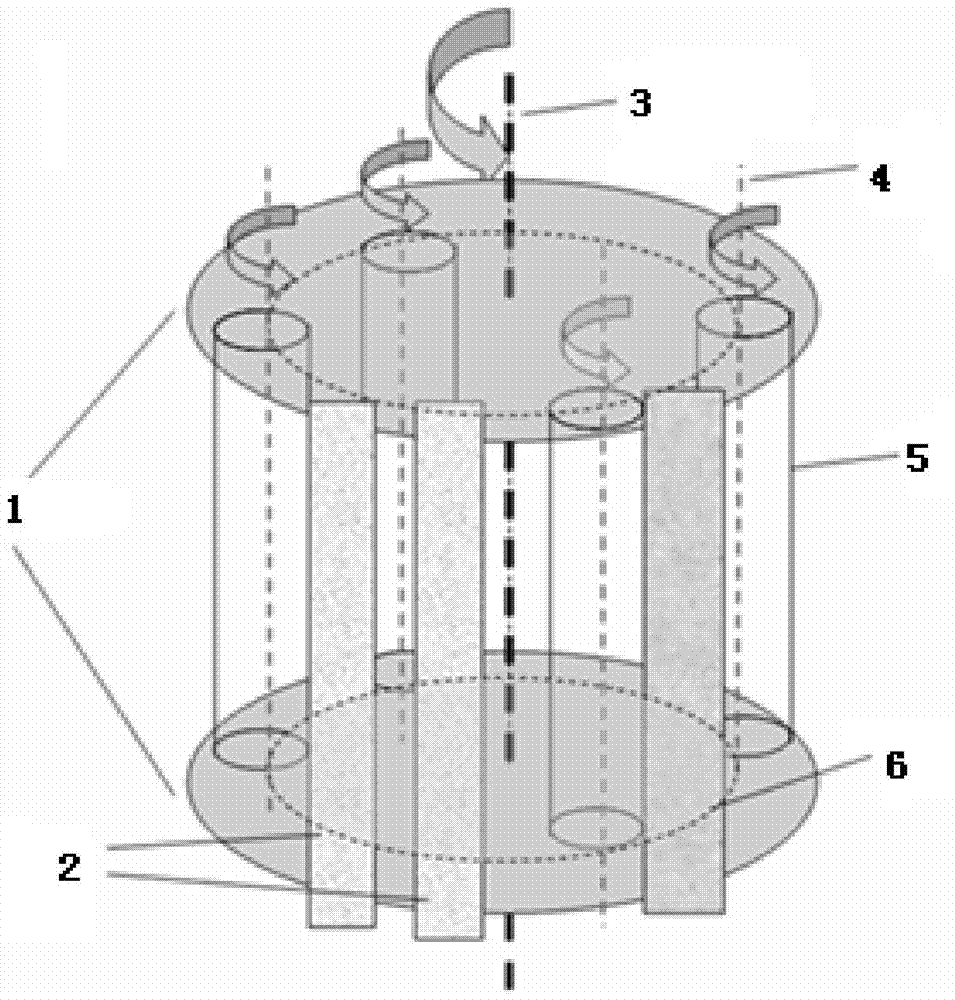

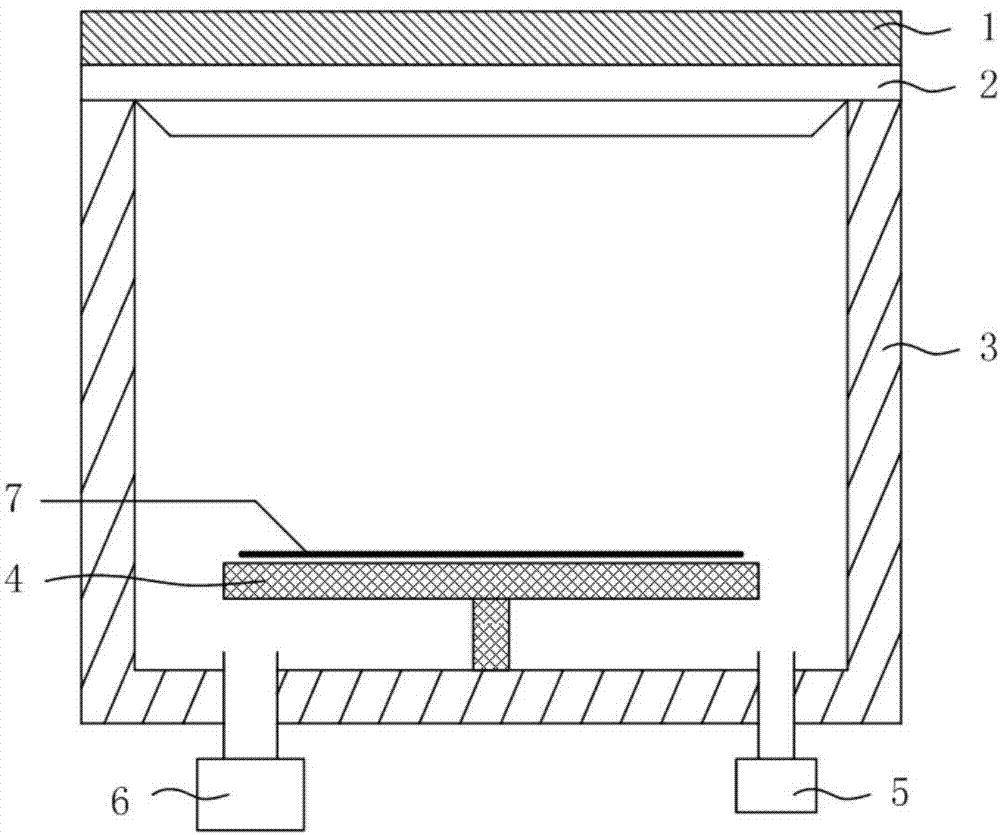

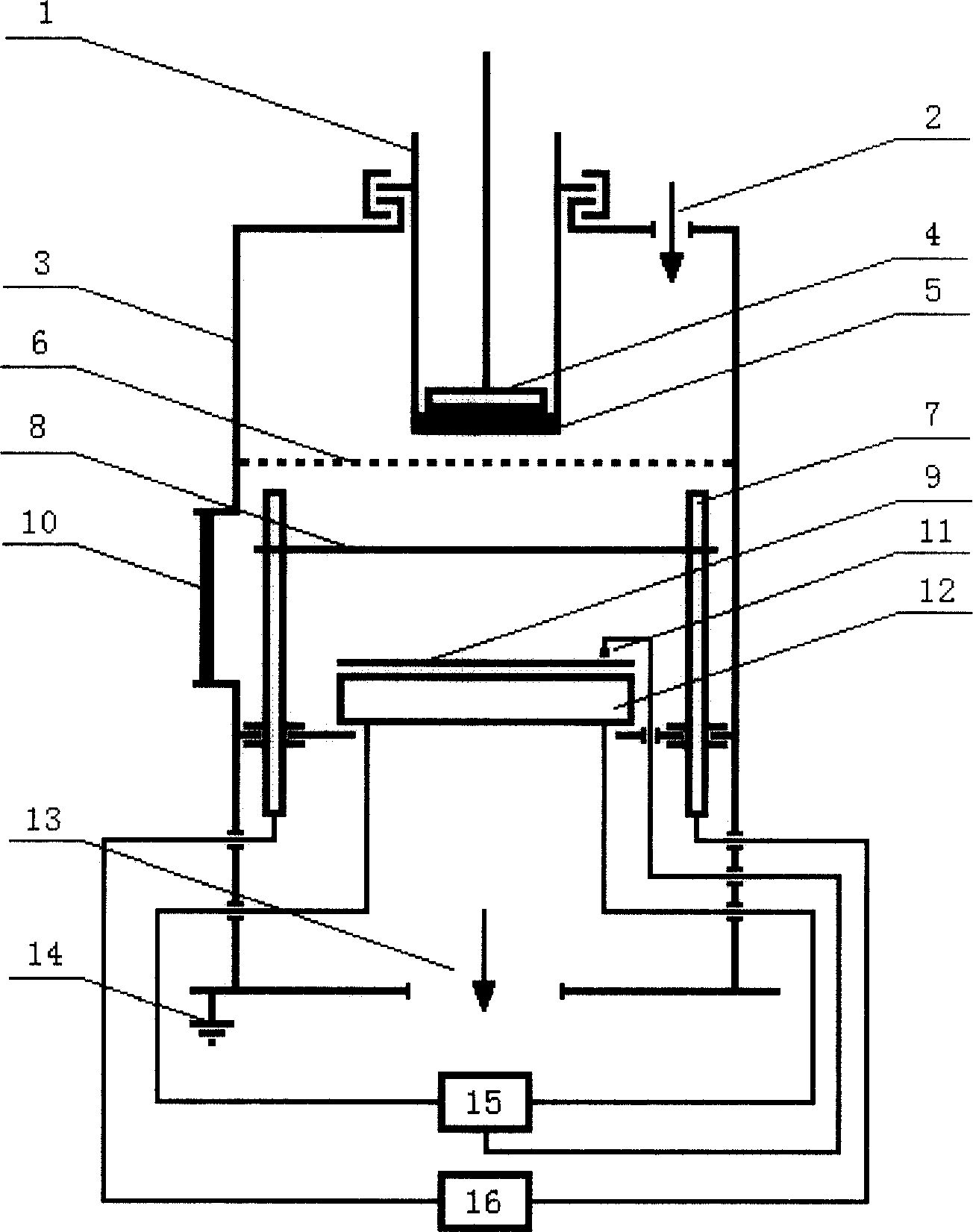

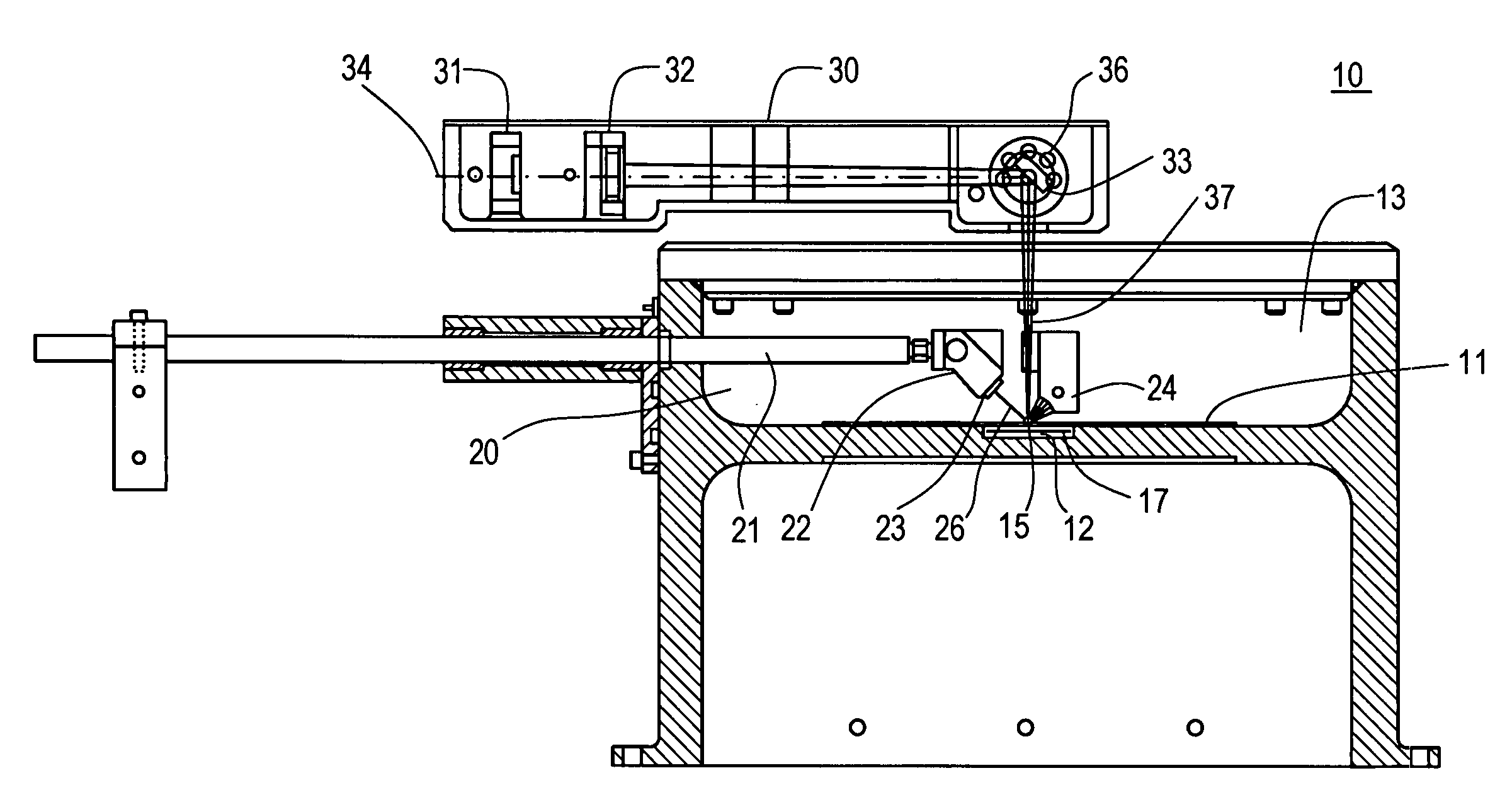

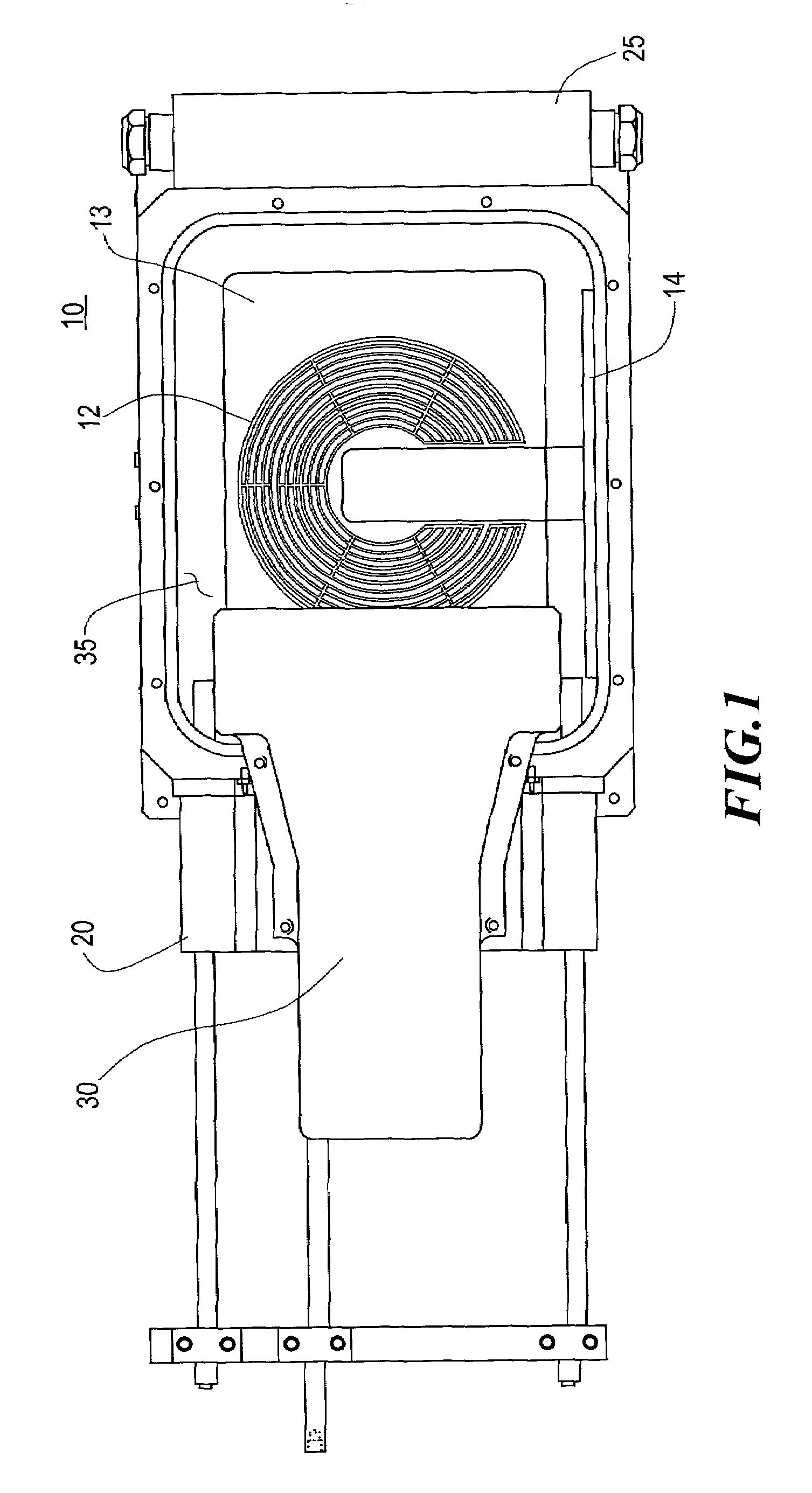

Modifying treating device for corona discharge low temperature plasma fabric surface

InactiveCN1900408ASimple structureUniform and strong dischargeUltrasonic/sonic fibre treatmentAutomatic controlControl system

The present invention relates to low temperature plasma fabric modifying processing unit, in particular relating to corona discharge low temperature plasma fabric modifying processing unit. It features utilizing ultrathin flake electrode array trigering strong corona discharge to generate activity plasma zone, through regulating discharge gas component to generate plasma zone having different modifying effect, to make fabric continuously to obtain processing through said activity plasma zone. Said device mainly consists of material feed system, electrode system, humidity regulating device, infra-red drying device, leak-tight system, power supply and automatic control system.

Owner:DALIAN UNIV OF TECH

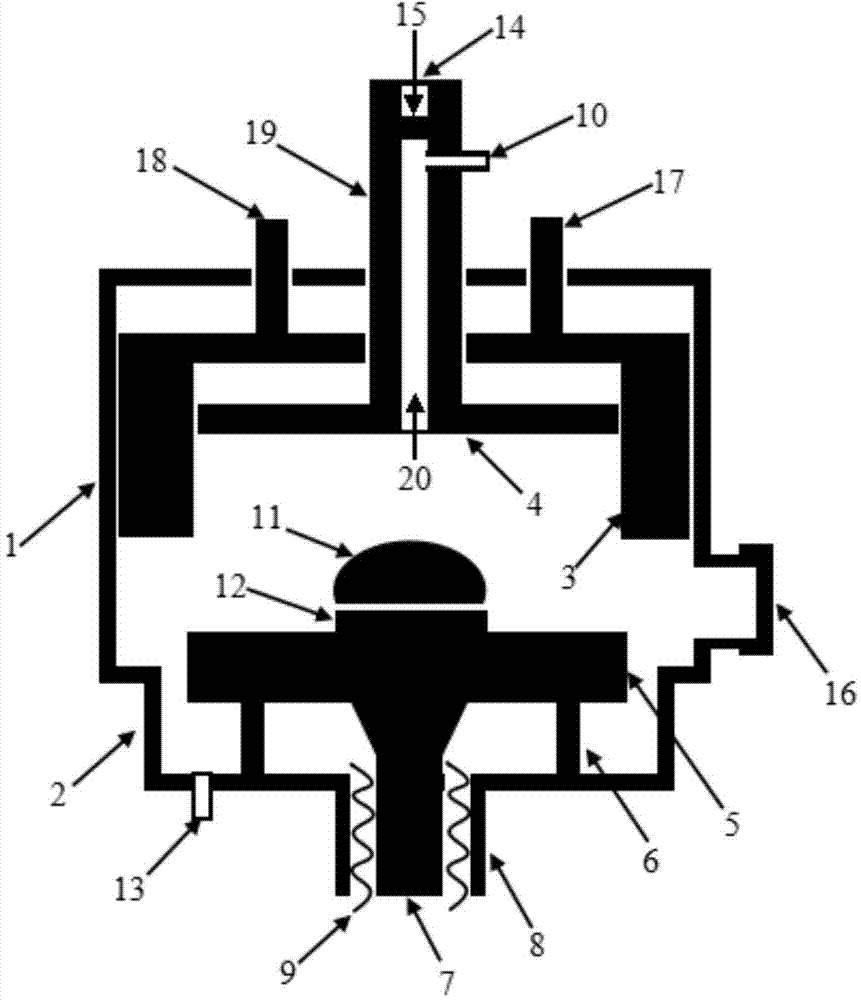

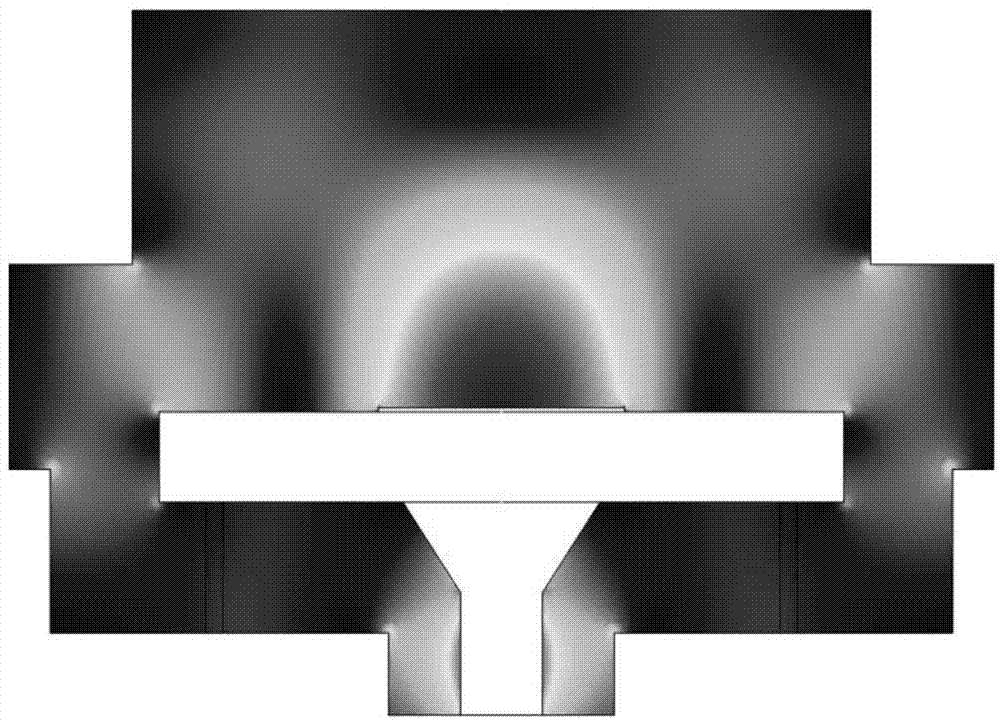

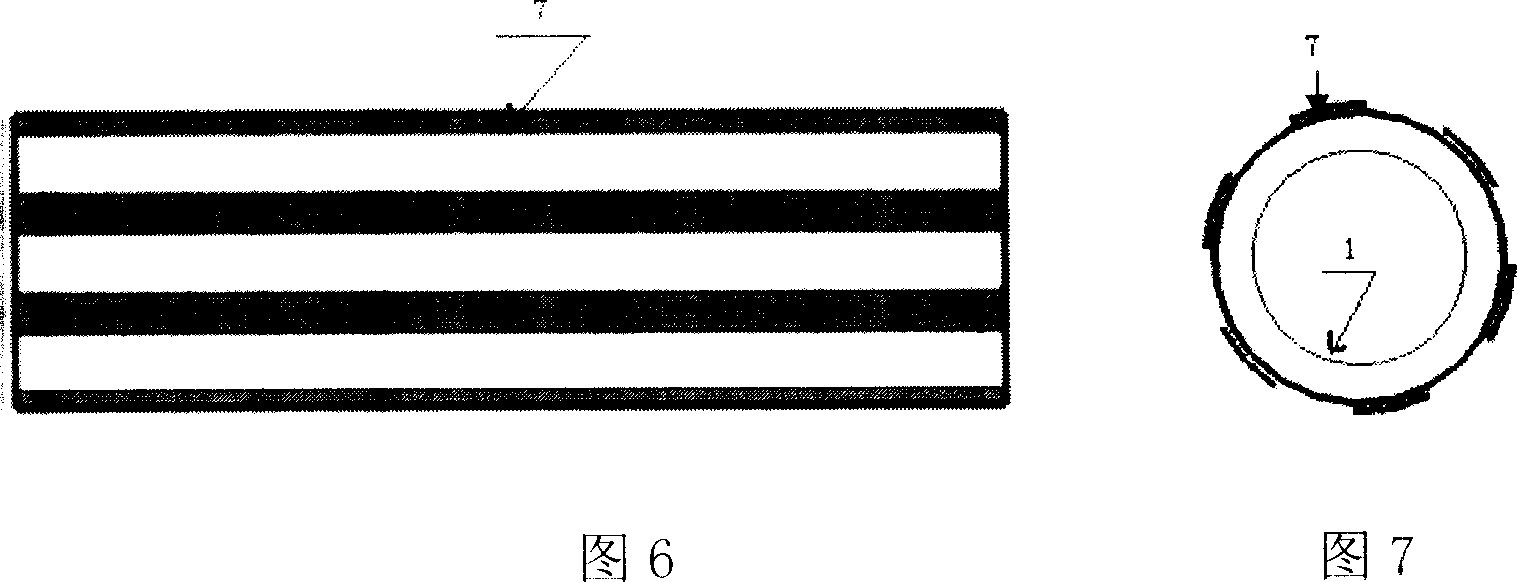

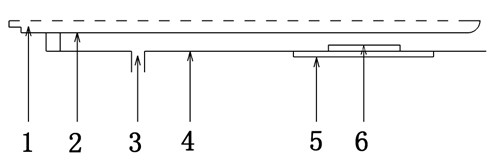

TM021 modal high-power microwave plasma diamond film deposition device

ActiveCN103695865ADeposition high speedStable positionElectric discharge tubesChemical vapor deposition coatingResonant cavityMaterials science

The invention provides a TM021 modal high-power microwave plasma diamond film deposition device. The TM021 modal high-power microwave plasma diamond film deposition device comprises an upper cylinder, a lower cylinder, an adjustable upper cavity, a microwave reflecting plate, a deposition table, a microwave coaxial excitation port, a microwave quartz port, a gas inlet, a gas outlet, a temperature measuring hole, an observing window and the like. The TM021 modal high-power microwave plasma diamond film deposition device has TM021 modal electric field distribution and the characteristics of centralized electric field distribution in a microwave resonator and stable excited plasma locations. The distribution of plasmas in the device can be optimized in real time through a regulating mechanism of the device. An annular microwave quartz window placed below the deposition table can be prevented from being excessively heated, polluted and etched by the plasmas. The inner wall of a resonant cavity is far away from a high-temperature plasma zone, so that the thermal radiation on the inner wall of the cavity is weakened, and foreign matter deposition is avoided. Each main part of the device can be directly water-cooled. Due to the advantages, the device can be applied to the input of relatively high-power microwaves, and the high-efficiency deposition of large-area high-quality diamond films is realized.

Owner:HEBEI PLASMA DIAMOND TECH

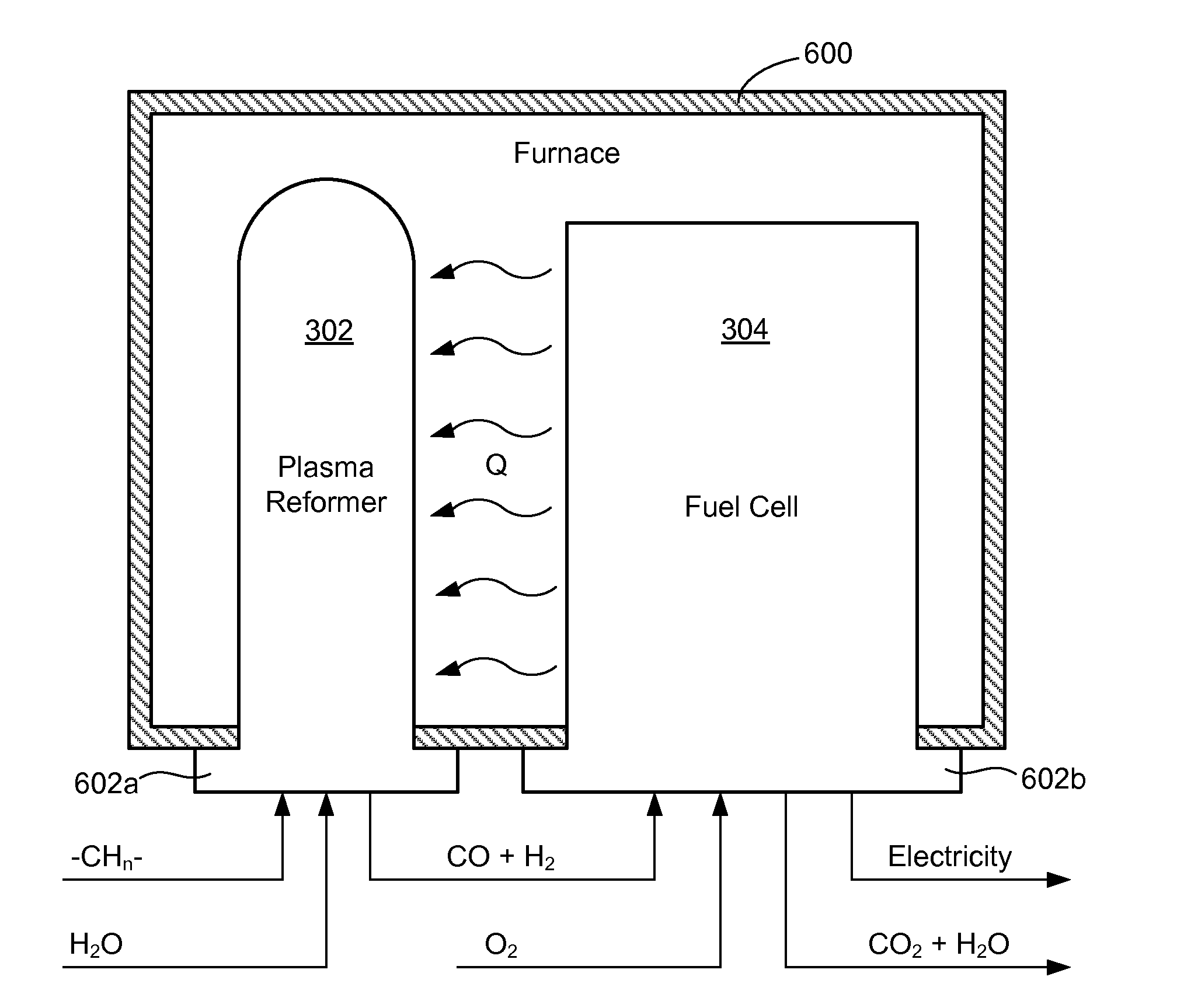

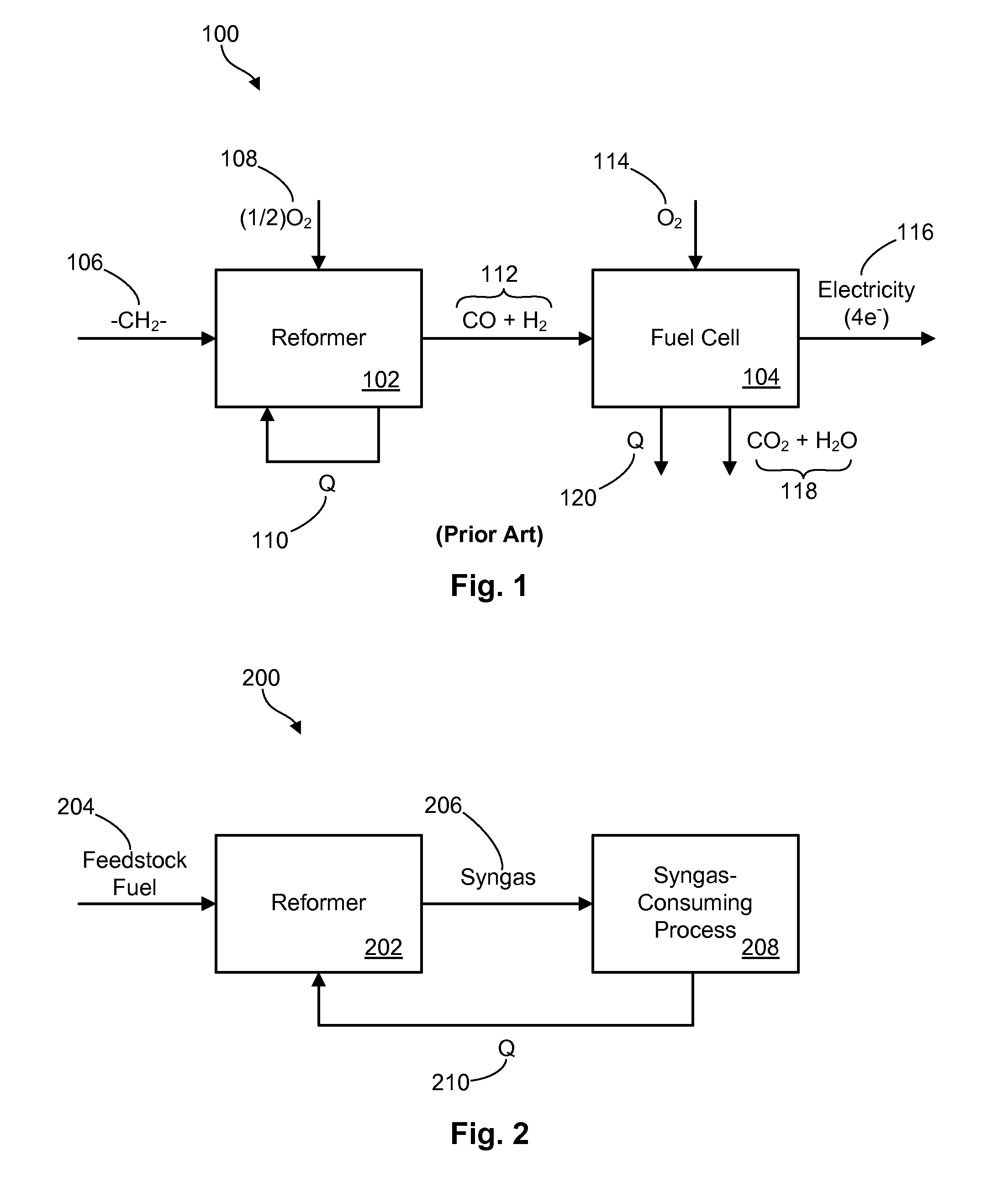

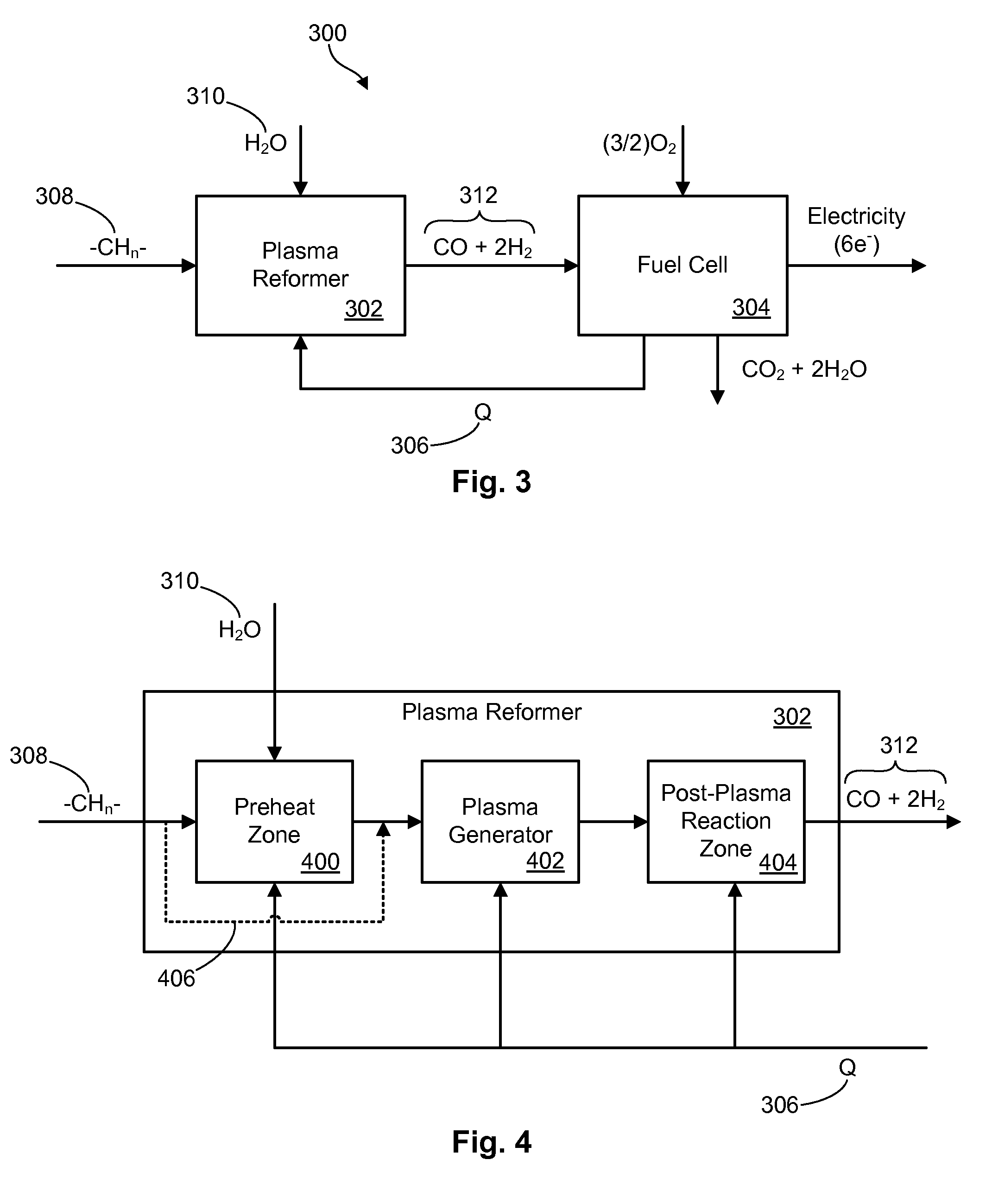

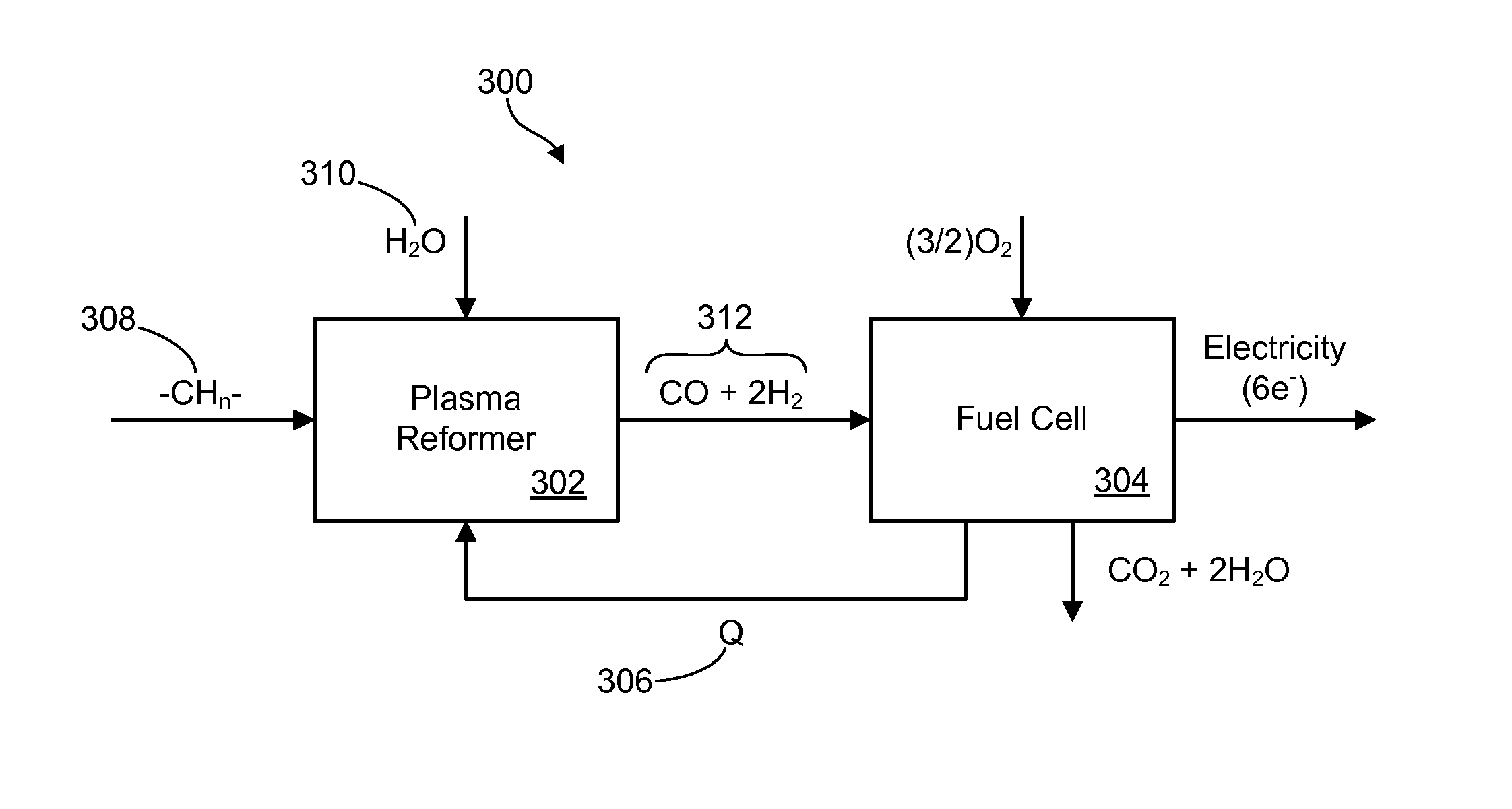

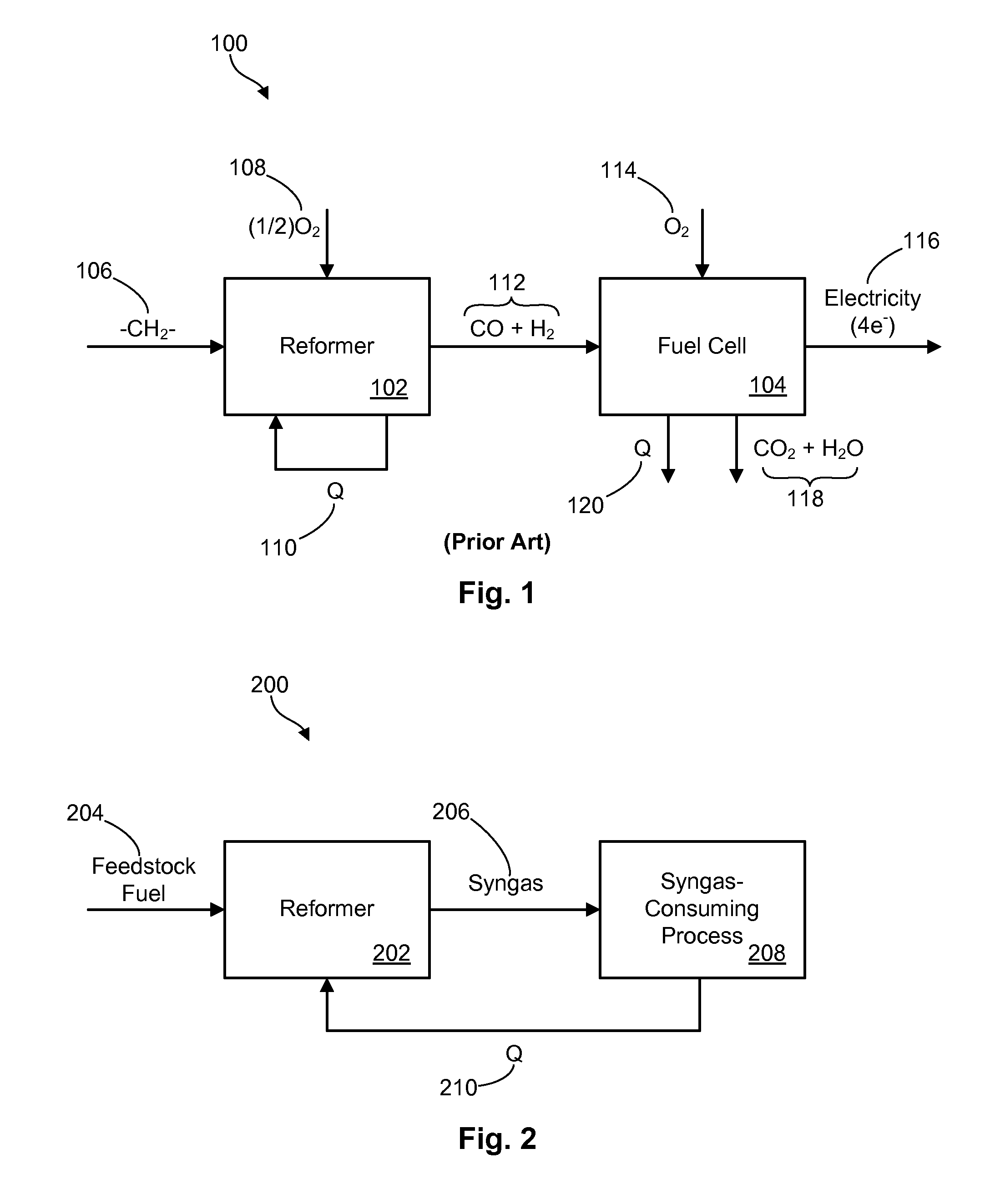

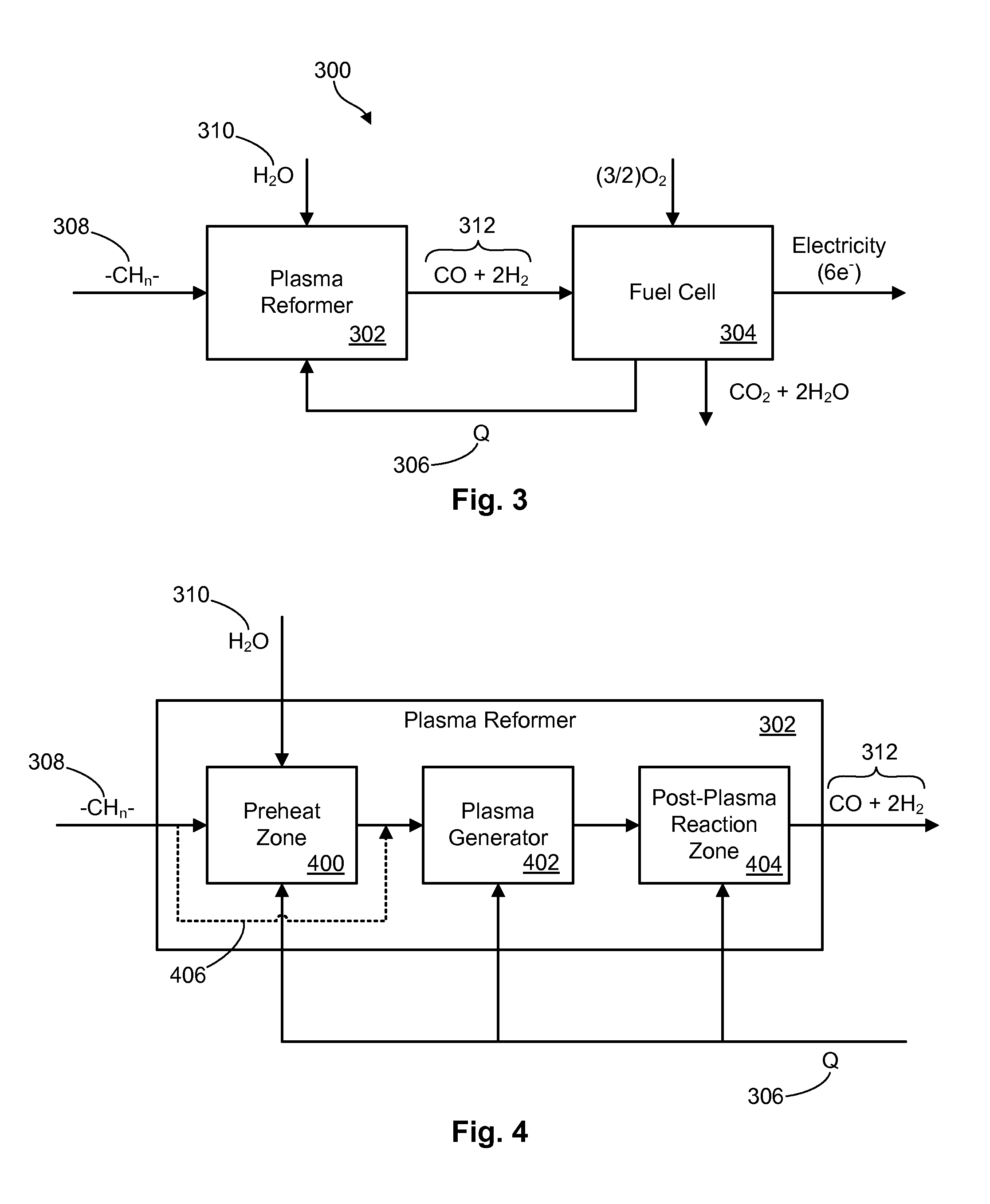

Plasma-catalyzed fuel reformer

A reformer is disclosed that includes a plasma zone to receive a pre-heated mixture of reactants and ionize the reactants by applying an electrical potential thereto. A first thermally conductive surface surrounds the plasma zone and is configured to transfer heat from an external heat source into the plasma zone. The reformer further includes a reaction zone to chemically transform the ionized reactants into synthesis gas comprising hydrogen and carbon monoxide. A second thermally conductive surface surrounds the reaction zone and is configured to transfer heat from the external heat source into the reaction zone. The first thermally conductive surface and second thermally conductive surface are both directly exposed to the external heat source. A corresponding method and system are also disclosed and claimed herein.

Owner:COORSTEK INC

Method for the production of coated particles

InactiveUS6358562B1Easy to wearIncrease resistancePigmenting treatmentPretreated surfacesMicrowaveFerrocene

A method for producing coated particles includes the steps of converting particles consisting of a compound of one of (a) a metal with a non-metal or (b) a semi-metal with a non-metal to an aerosol form; contacting the particles in aerosol form with a gas including at least one aromatic compound; and guiding the particles in aerosol form together with the gas through a plasma zone of a microwave plasma. The at least one aromatic compound is preferably selected from the group consisting of benzol, benzol derivatives, naphthalene, and naphthalene derivatives. The gas preferable further includes at least one metallocene which is preferably selected from the group consisting of ferrocene or magnesocene.

Owner:KERNFORSCHUNGSZENTRUM KARLSRUHE GMBH

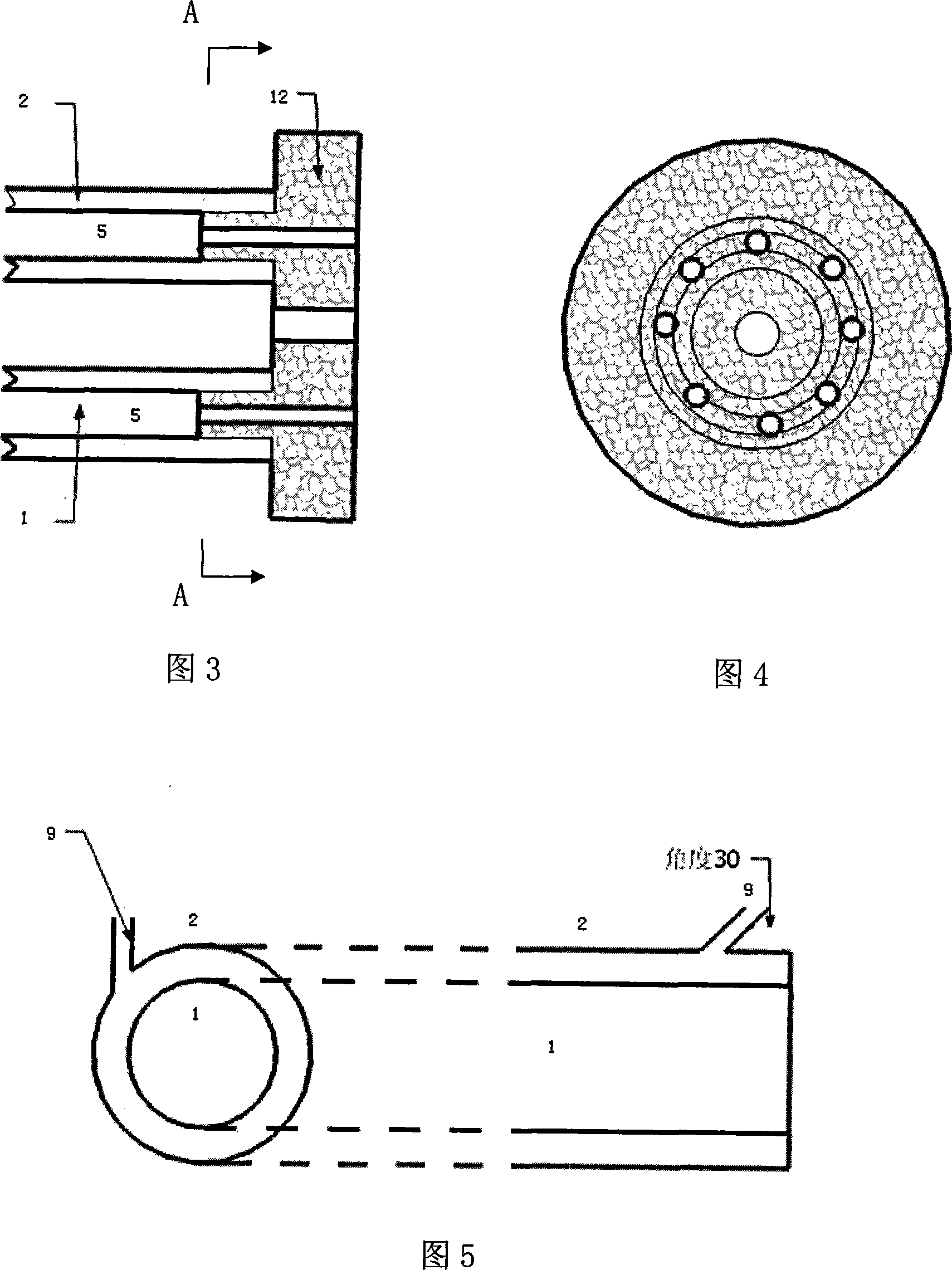

Atmosphere pressure plasma treatment fasciculus or fibre string surface device and method thereof

InactiveCN101096820AImprove surface structureImprove surface propertiesFibre typesUltrasonic/sonic fibre treatmentFiberPower parameter

The invention discloses an atmosphere pressure plasma dealing fiber tuft or fiber thread surface device and method, which is characterized by the following: arranging quartz liner pipe in coaxial cover; constructing gas discharging plasma zone with quartz outer tube; forming high pressure electrode with inner surface or outer surface of the quartz linear through vacuum deposition plated metallic film; cup-jointing stainless steel cloth and water coat sandwich on the outer surface of the quartz outer tube; constructing earth electrode; using coaxial quartz glass tube to construct asymmetric electrode structure of medium discharge resistance; keeping special laminar flow disperse for gas in sandwich; diminishing consumption of gas; decreasing treating temperature effectively. This invention can choose proper high pressure electrode form, gas component, power parameter and treating speed according to different fiber material, which can proceed highly effective, low consumption and environment protection treat for the surface of fiber tuft or fabric cord.

Owner:DONGHUA UNIV

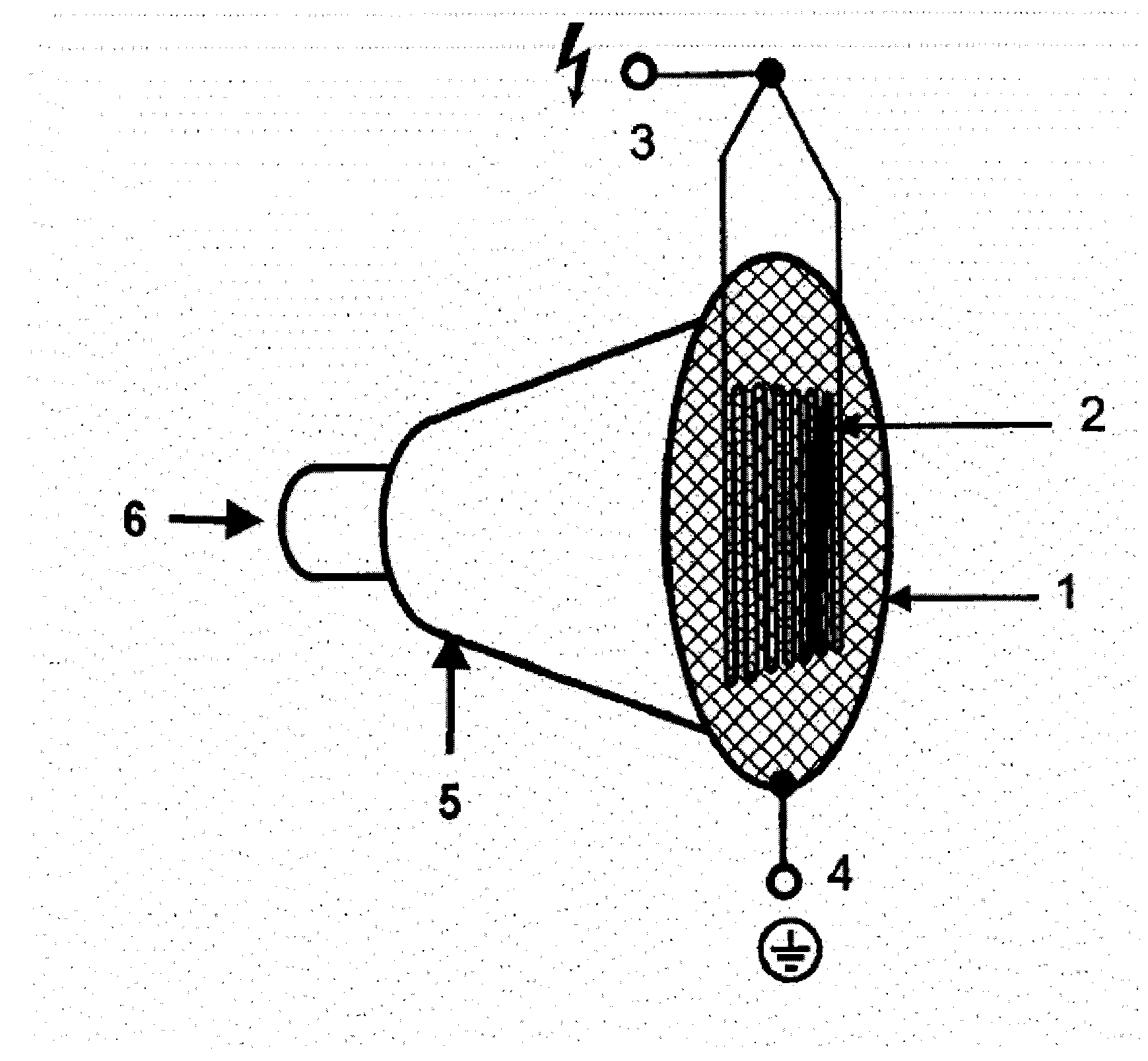

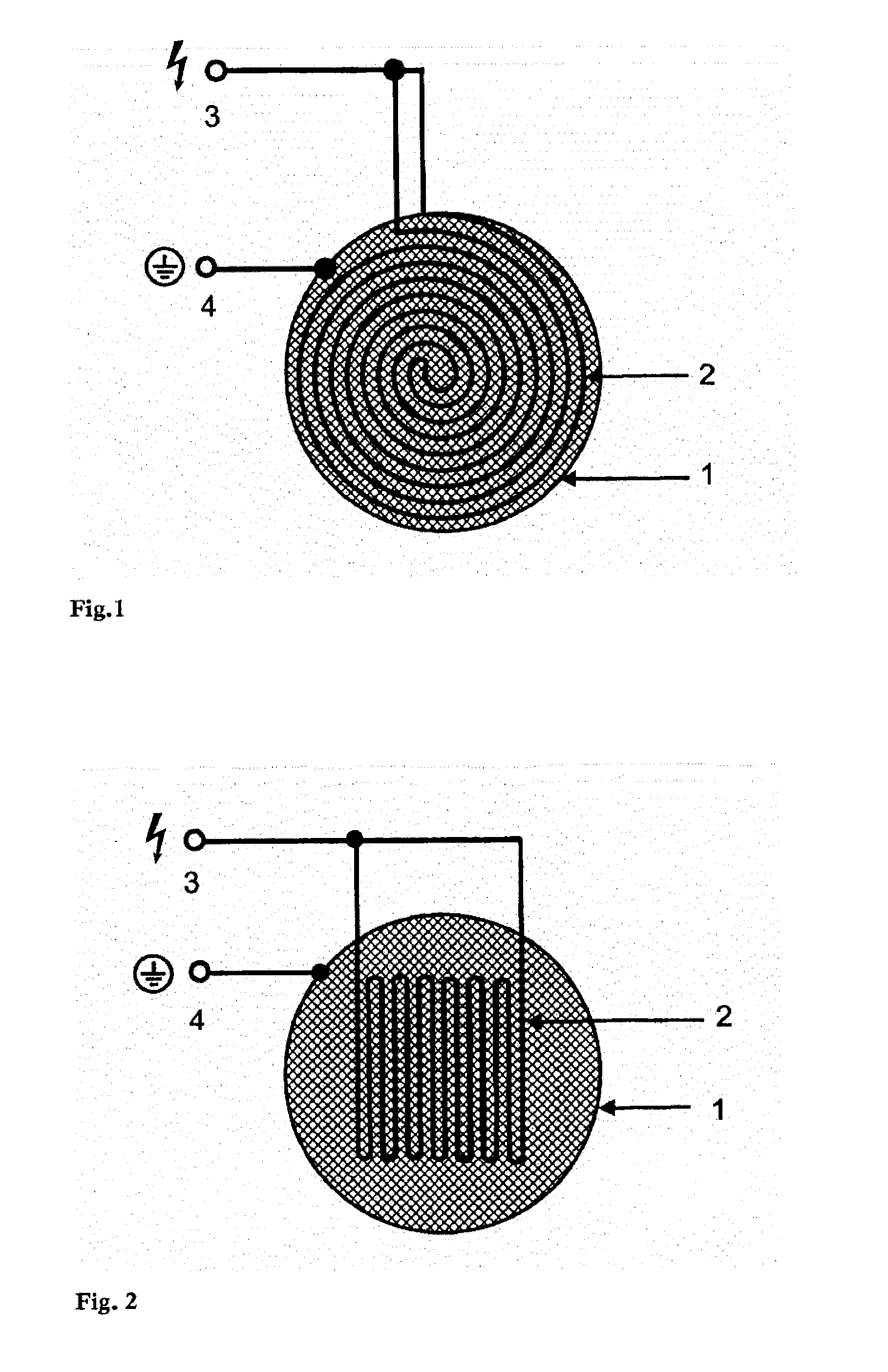

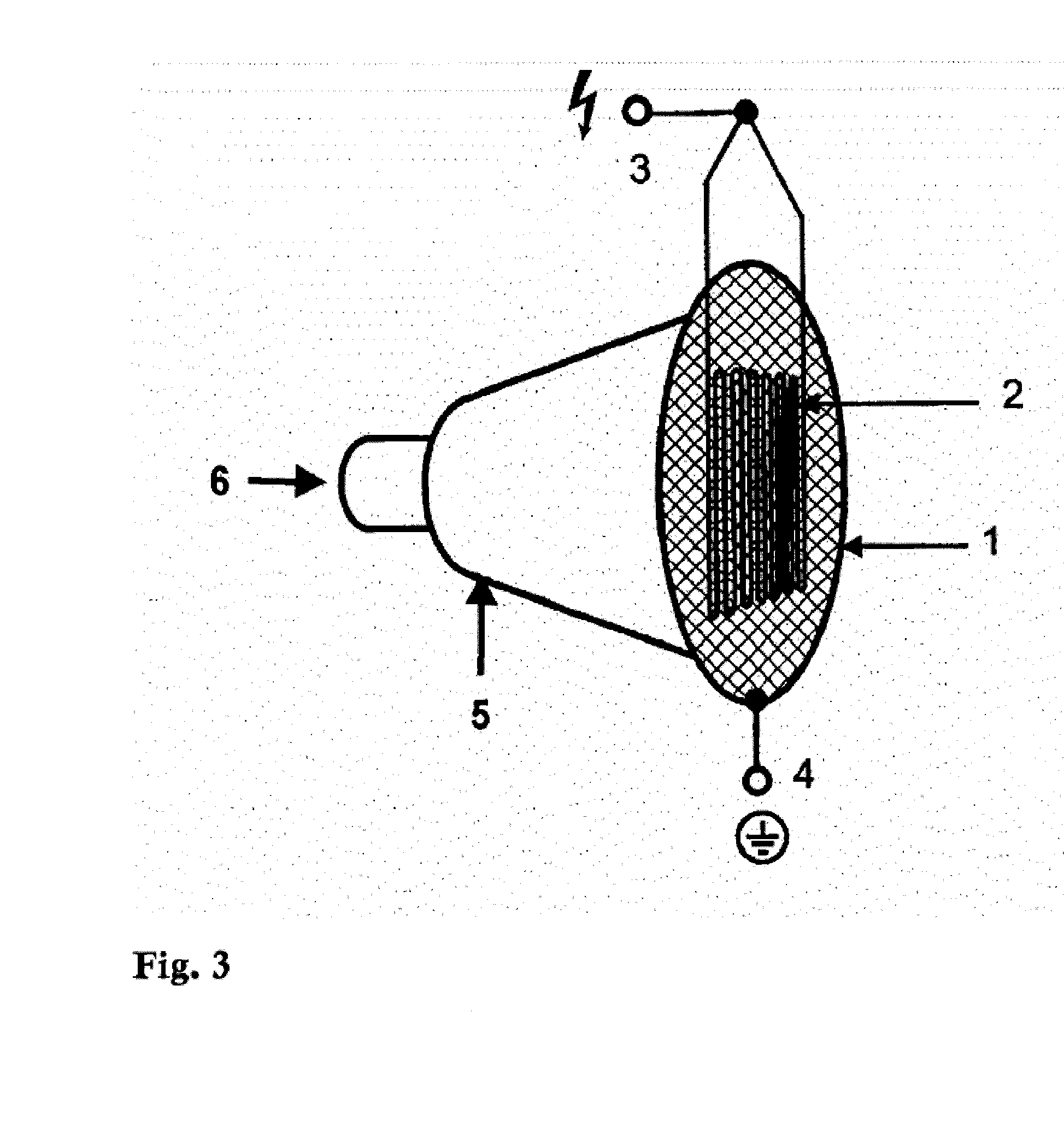

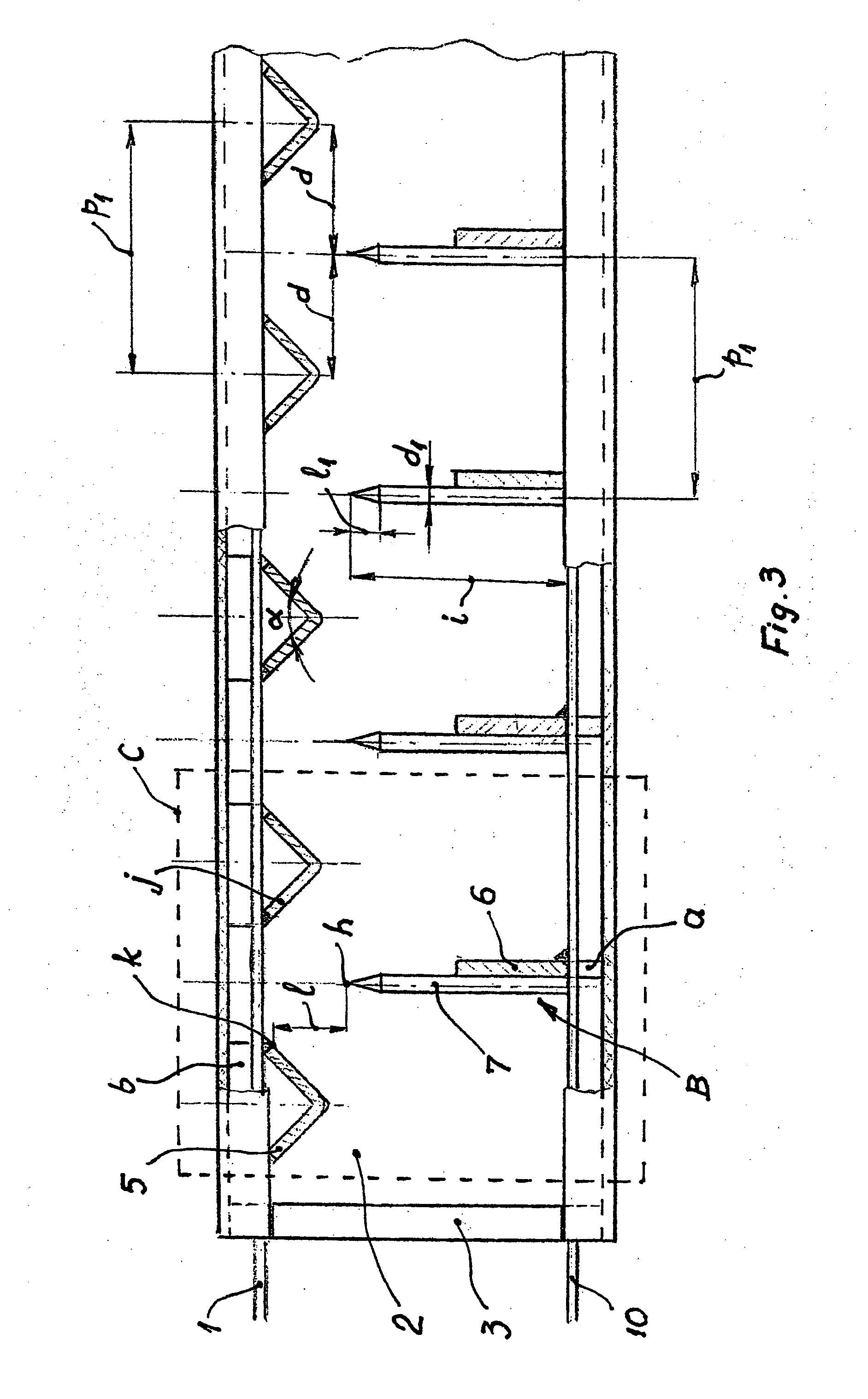

Device for the plasma treatment of human, animal or plant surfaces, in particular of skin or mucous membrane areas

The invention relates to a device for the treatment of free-form areas and zones of human or animal skin areas or plant surfaces by means of cold atmospheric-pressure plasma. The core of the device is a specific, preferably gas-permeable, electrode arrangement for generating a dielectrically impeded surface discharge where the earthed electrode is composed of electrically conductive textile material and the high-voltage electrode consists of a thin wire or electrically conductive thread which is sheathed with an insulting layer which has to meet specific requirements. On the basis of the present invention, it is possible to generate, in the area of diseased skin parts of the human body, in direct proximity to the skin surface or to wounds, a flat plasma for the treatment of the diseased areas which is acceptable in respect of the stress on the skin caused by temperature and electric potentials. The advantage of the gas-permeable textile sheet-like structure consists especially in that the arrangement can be placed flexibly onto variously curved surfaces and, in addition, offers the possibility of a gas exchange with the environment and / or the targeted dosing of a specific process gas mixture across the textile material into the active plasma zone.

Owner:LEIBNIZ INST FUR PLASMAFORSCHUNG & TECH

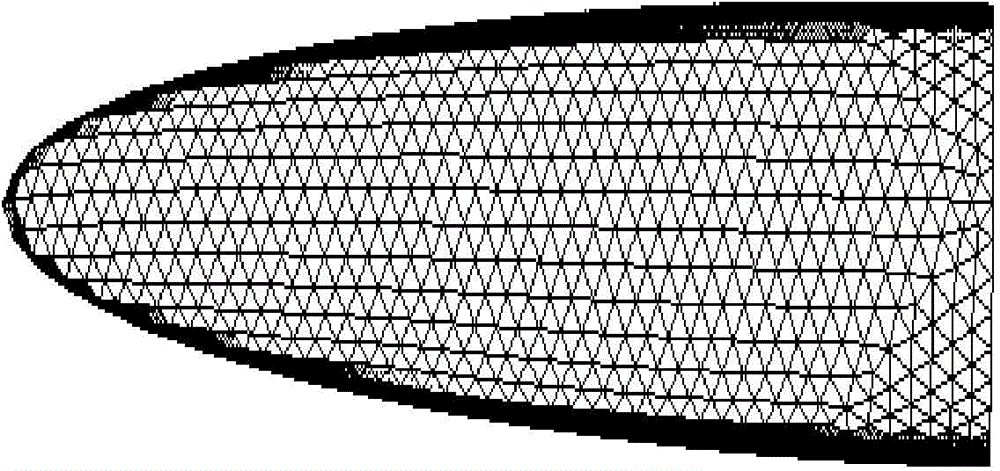

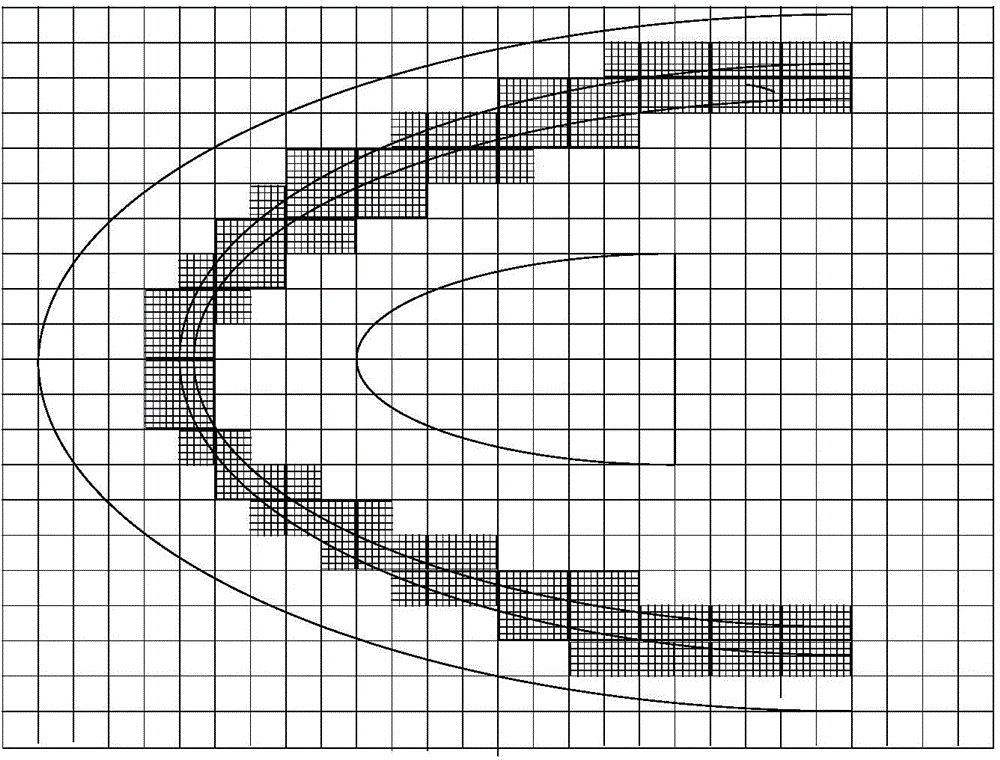

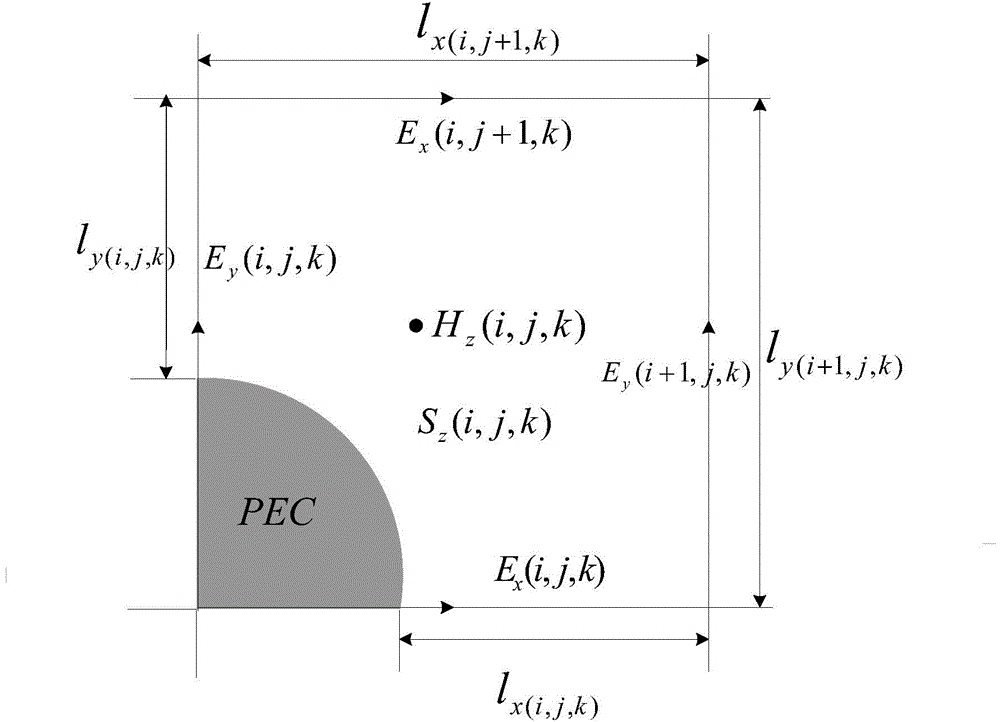

Simulation method for super speed aircraft conformal sub-grid electromagnetic scattering characteristic analysis

ActiveCN105653747AFit closelyImprove adaptabilitySpecial data processing applicationsFinite difference methodRadar cross-section

The invention discloses a simulation method for super speed aircraft conformal sub-grid electromagnetic scattering characteristic analysis. The simulation method includes the following steps: performing aerothermodynamics simulation according to an aerodynamic configuration, the flight speed and the flight height of an aircraft, and determining the plasma collision frequency and the plasma oscillation frequency of all parts through simulation information; performing subdivision on an aircraft model and a plasma sheath through a tetrahedron to obtain structure information of the aircraft model; mapping flow field point information to ridges of a finite difference time domain computing grid, and determining a zone with a relative dielectric constant more than 6 according to the collision frequency and the oscillation frequency on the ridges to perform sub-grid processing; processing junctions between the ridges of the finite difference time domain computing grid and a metal surface through a finite difference universal time domain method; and computing the plasma zone through an iterative formula of plasma to finally determine the radar cross section of the super speed aircraft. The simulation method has good adaptability and high computational efficiency.

Owner:NANJING UNIV OF SCI & TECH

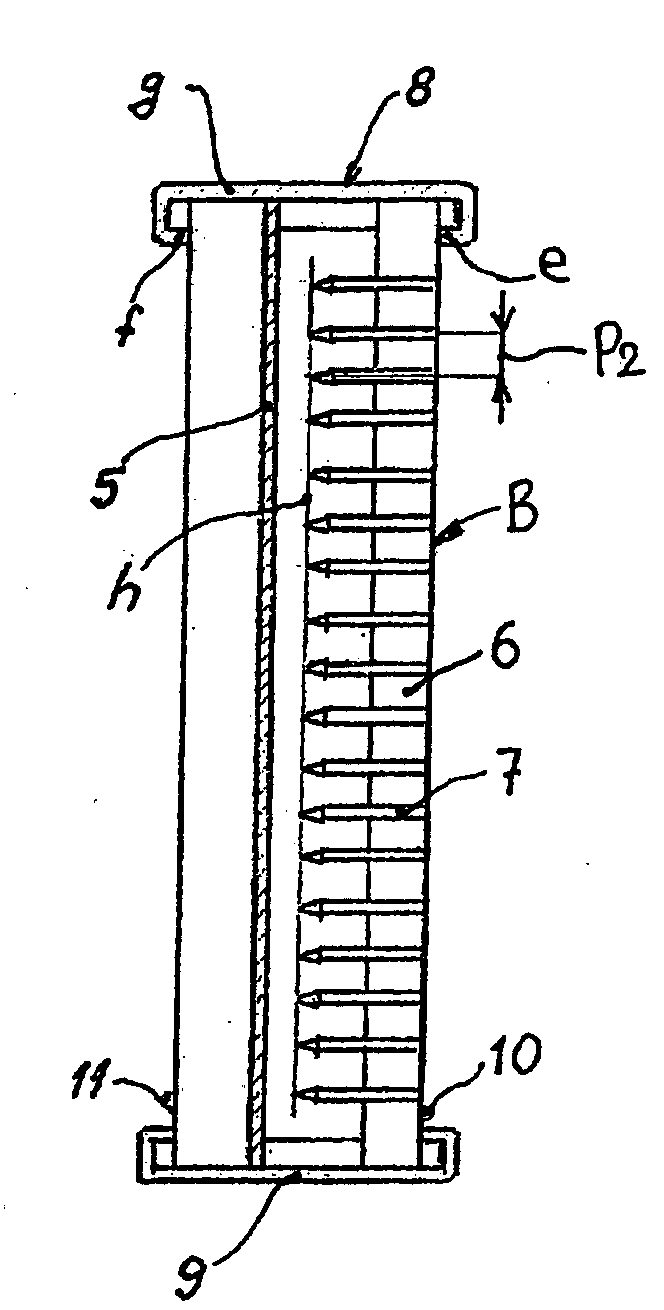

Method for Manufacturing an Optical Preform

InactiveUS20080063812A1Improve efficiencyIncrease deposition rateGlass making apparatusPlasma techniqueChemical vapor depositionPhotochemistry

The present invention relates to a method for manufacturing an optical preform by carrying out one or more chemical vapor deposition reactions in a substrate tube. The method includes the steps of (i) supplying one or more doped or undoped glass-forming precursors to a substrate tube and (ii) effecting a reaction between these glass-forming precursors to form one or more glass layers on the interior of the substrate tube via the creation of a pulsed plasma zone in the interior of the substrate tube.

Owner:DRAKA COMTEQ BV

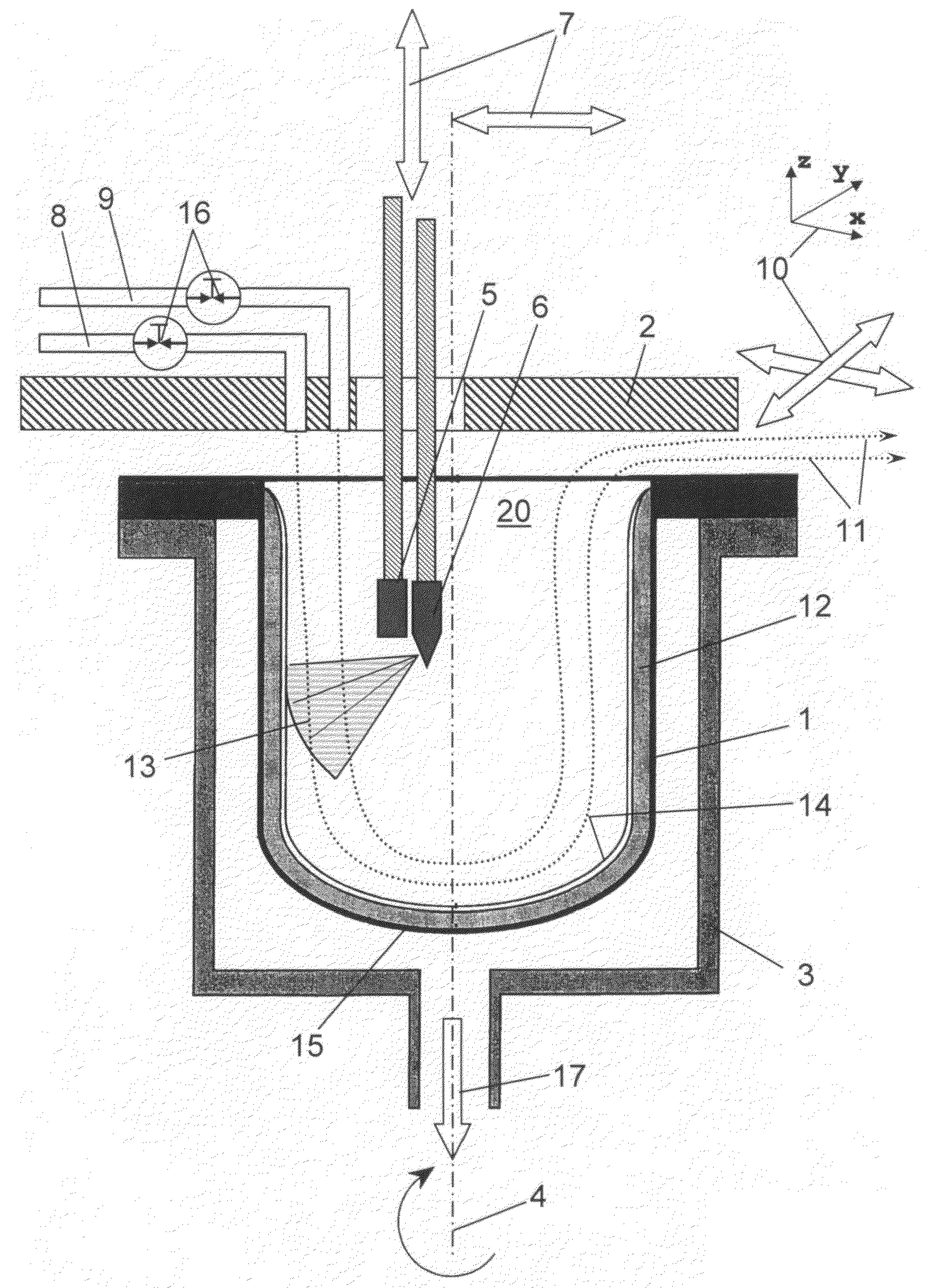

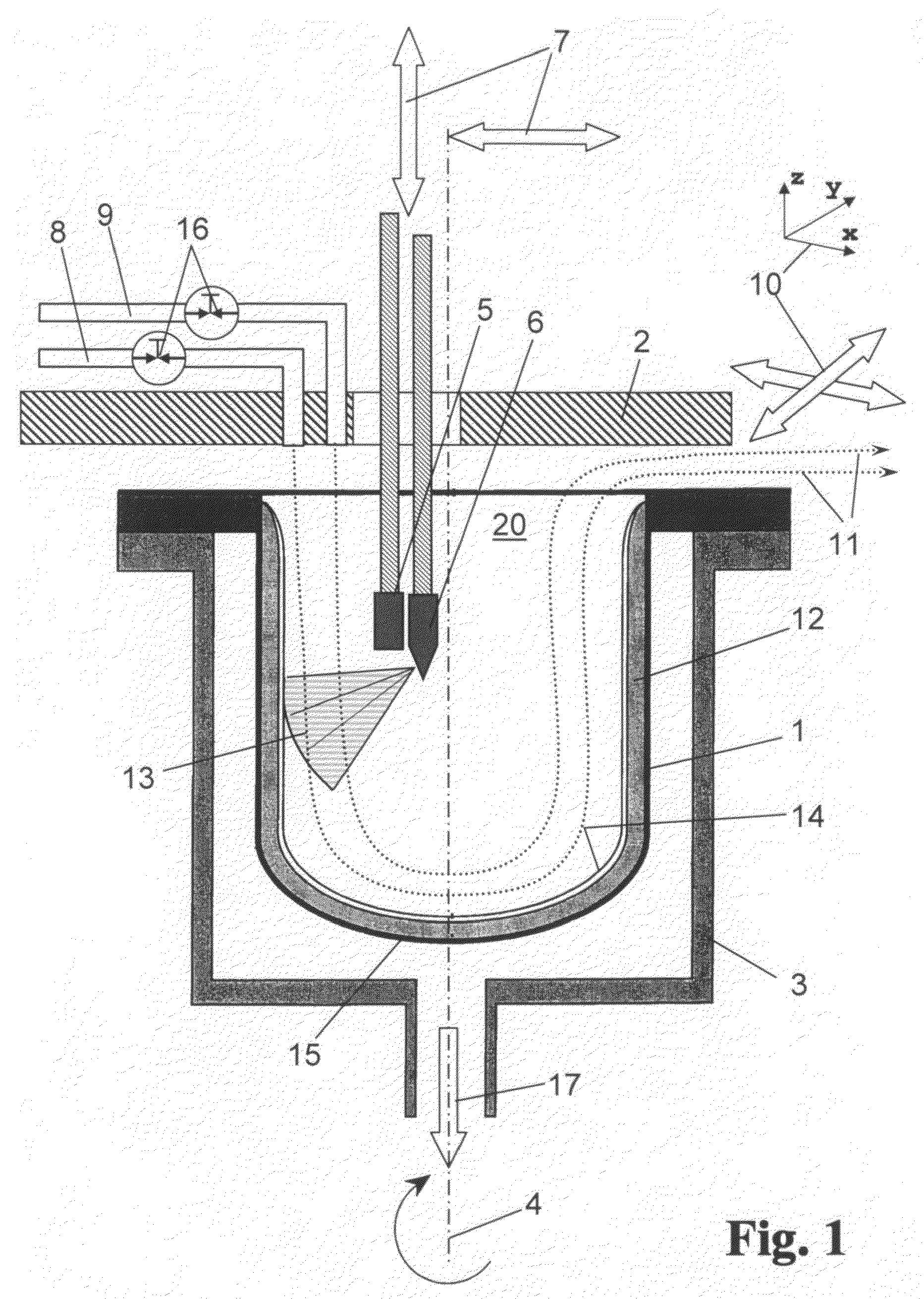

Method and apparatus for producing a crucible of quartz glass

InactiveUS20090277223A1The material is lowAfter-treatment apparatusBy pulling from meltVitrificationCrucible

The invention starts from a method for producing a crucible of quartz glass in that SiO2 inner layer granules are vitrified in a rotating melting mold, which is covered at least in part by a heat shield, in a light gas-containing atmosphere under the action of a plasma to obtain a transparent inner layer, at least part of the light gas being supplied to the melting mold through a gas inlet of the heat shield. In order to form an inner layer with a particularly low bubble content and with minimal efforts in terms of energy and material, it is proposed that in a layer forming step preceding the vitrifying step a granule layer consisting of the SiO2 inner layer granules is formed on the inner wall of the crucible, and that the plasma zone and the heat shield are movable together with the gas inlet and are moved laterally in the direction of the granule layer during the vitrifying step taken for vitrifying the granule layer.

Owner:HERAEUS QUARZGLAS

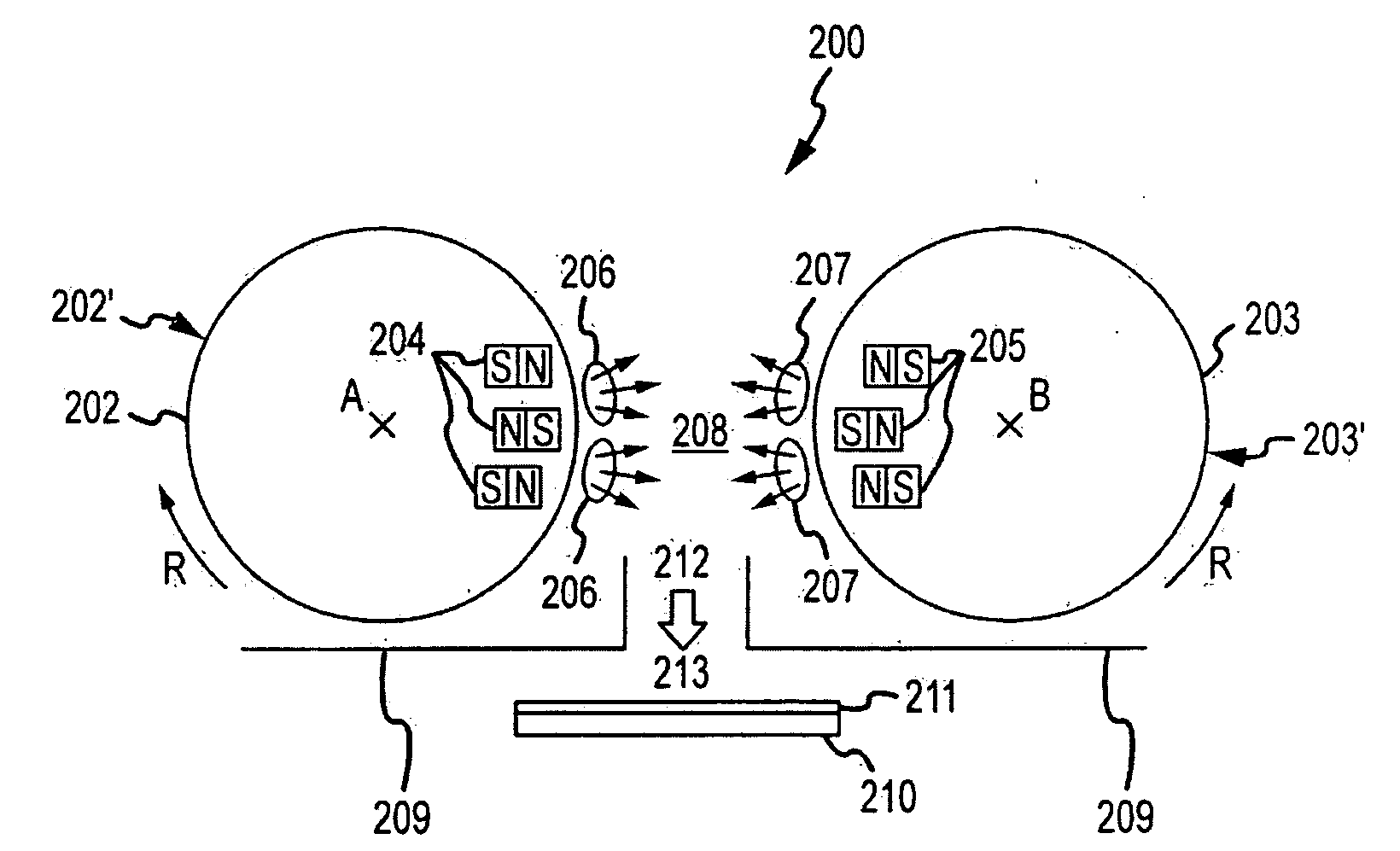

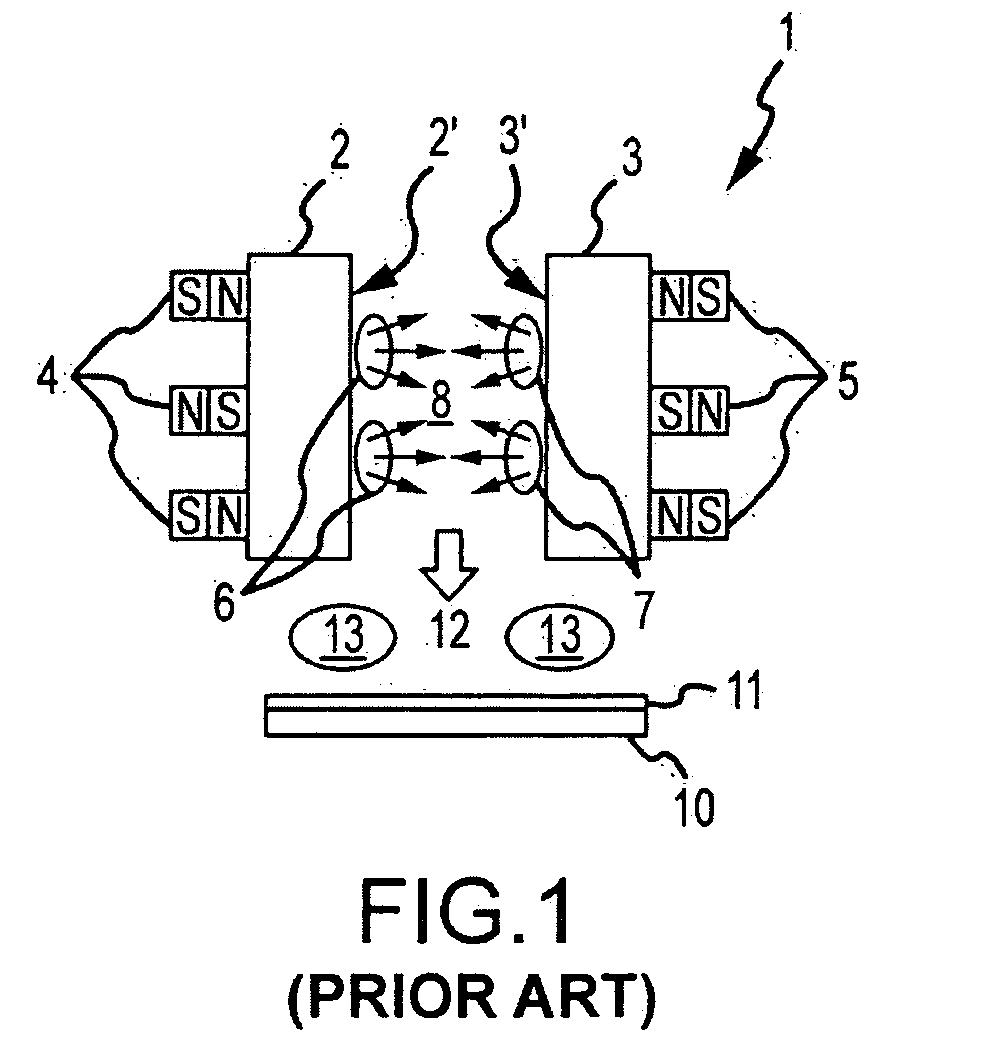

Sputter coating device and method of depositing a layer on a substrate

InactiveUS20090020416A1Easy maintenanceHigh yieldCellsVacuum evaporation coatingSputteringTarget surface

A sputter coating device comprises a vacuum coating chamber, substrates arranged within the coating chamber, a cylindrical hollow cathode including a rotatable target rotating around a central axis A, and a magnet assembly which is arranged within the hollow cathode such that confining plasma zones are generated in an area above the surface of the target. At least one substrate is to be coated. The substrate has an OLED layer deposited on the substrate surface. An intermediate area is arranged between the surface of the target and a shield that shields particles sputtered from the surface of the target that move in a direction toward the shield. On each side of the shield, passages are provided between the intermediate area and coating area. Through the passage, only sputtered particles that have been scattered in the intermediate area may enter the coating area via the passage, and impinge the OLED layer.

Owner:APPLIED MATERIALS INC

Methods and apparatus for selective pre-coating of a plasma processing chamber

ActiveUS7578258B2Minimize contaminationSimple manufacturing processElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringDelivery system

Owner:LAM RES CORP

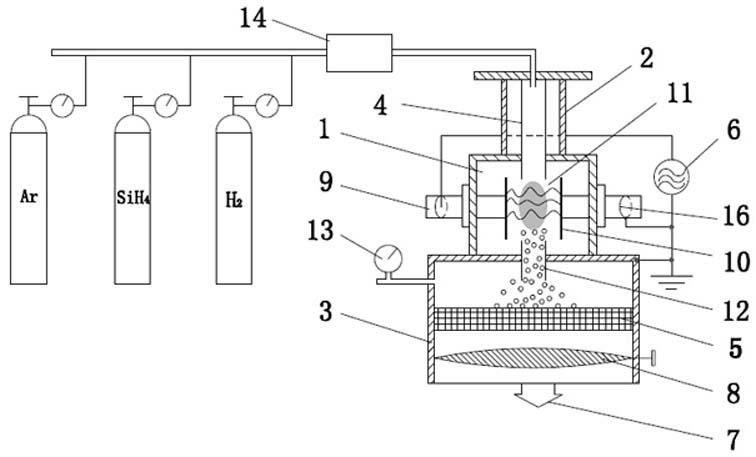

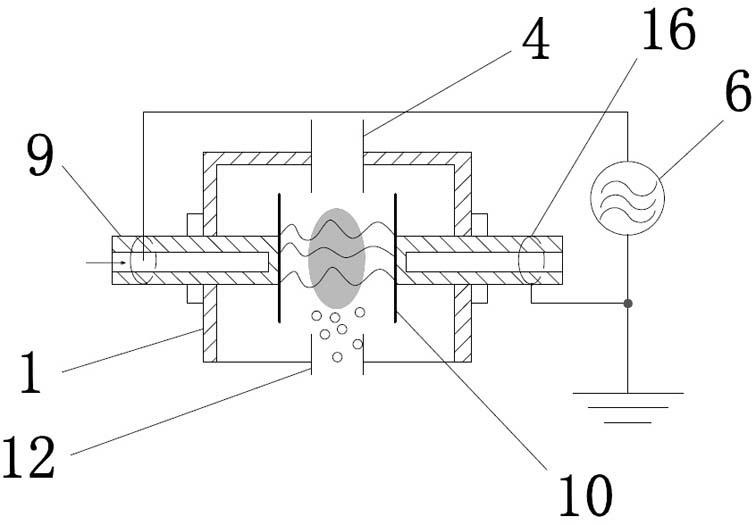

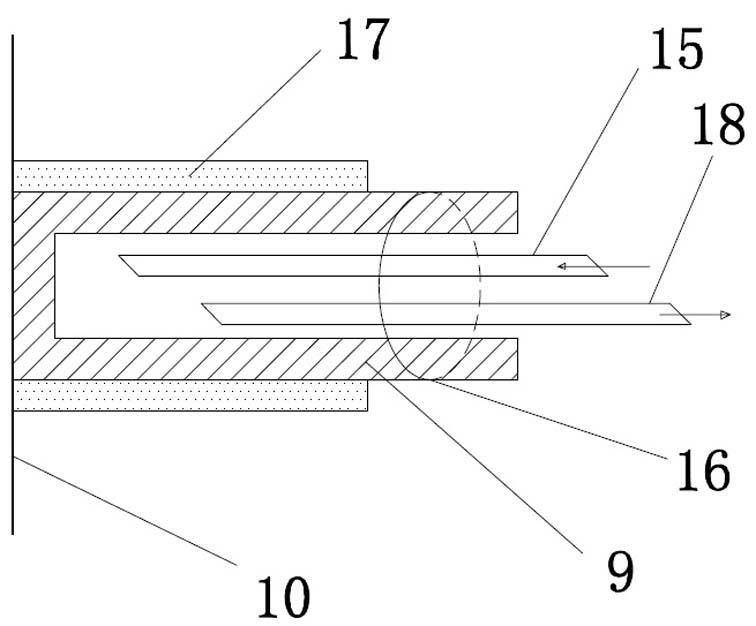

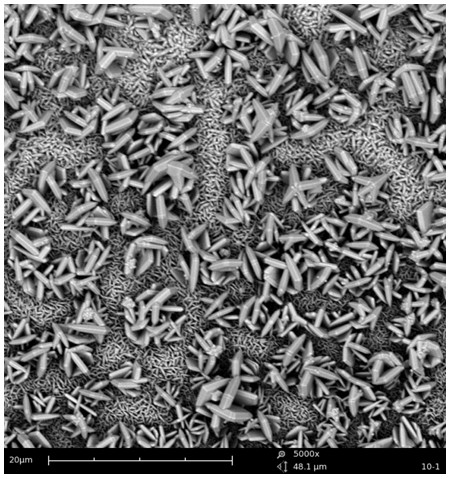

Method for growing nanocrystalline silicon powder

The invention discloses a method for growing nanocrystalline silicon powder. The method comprises the following steps: introducing gas mixture into a reaction chamber from gas inlet pipelines; inputting radio frequency alternating current into electrodes which are vertically arranged by a radio frequency source to cause working gases to discharge to form a plasma zone between quartz plates; enabling reactive gases to be decomposed by plasmas in the plasma zone, and enabling fragments obtained after decomposition to form nanocrystalline silicon cores; controlling the time spent on flowing through the plasma zone by the reactive gases by adjusting the flow of the introduced gases and / or adjusting the pressure of the reaction chamber, and controlling the sizes of the grown nanocrystalline silicon particles by controlling the retention time; and enabling the nanocrystalline silicon particles to stop growing after flowing out of the plasma zone along with airflow, and carrying out collection on a connection net to obtain the nanocrystalline silicon powder with uniformly distributed particle sizes. The method disclosed by the invention is simple to operate, has lower requirements for temperature, dispenses with heating devices, can be used for producing nanocrystalline silicon powder with uniformly distributed and controllable particle sizes, and can realize industrial production.

Owner:HEBEI UNIVERSITY

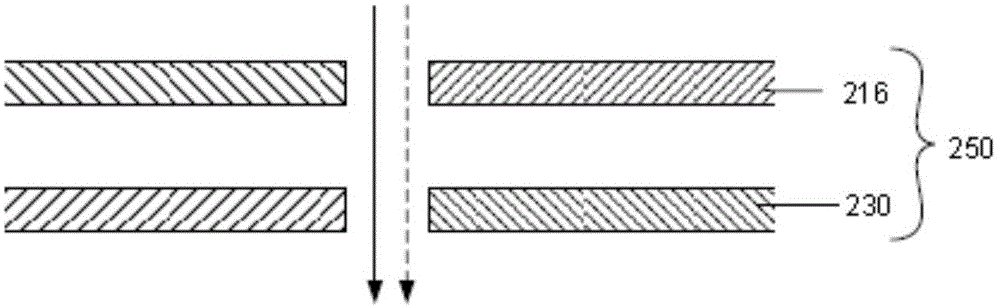

Ion to neutral control for wafer processing with dual plasma source reactor

The disclosed techniques relate to methods and apparatus for etching a substrate. A plate assembly divides a reaction chamber into a lower and upper sub-chamber. The plate assembly includes an upper and lower plate having apertures therethrough. When the apertures in the upper and lower plates are aligned, ions and neutral species may travel through the plate assembly into the lower sub-chamber. When the apertures are not aligned, ions are prevented from passing through the assembly while neutral species are much less affected. Thus, the ratio of ion flux:neutral flux may be tuned by controlling the amount of area over which the apertures are aligned. In certain embodiments, one plate of the plate assembly is implemented as a series of concentric, independently movable injection control rings. Further, in some embodiments, the upper sub-chamber is implemented as a series of concentric plasma zones separated by walls of insulating material.

Owner:LAM RES CORP

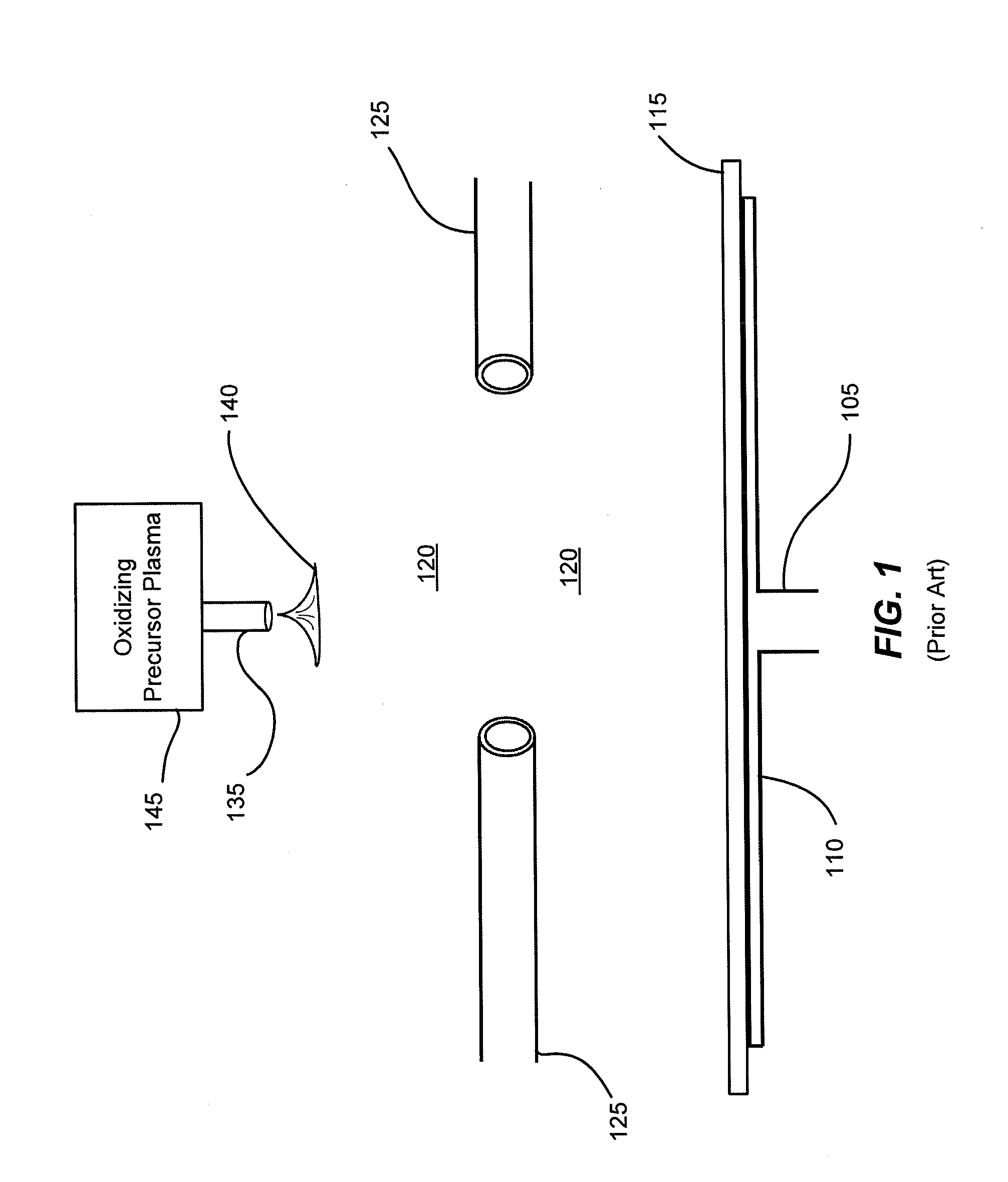

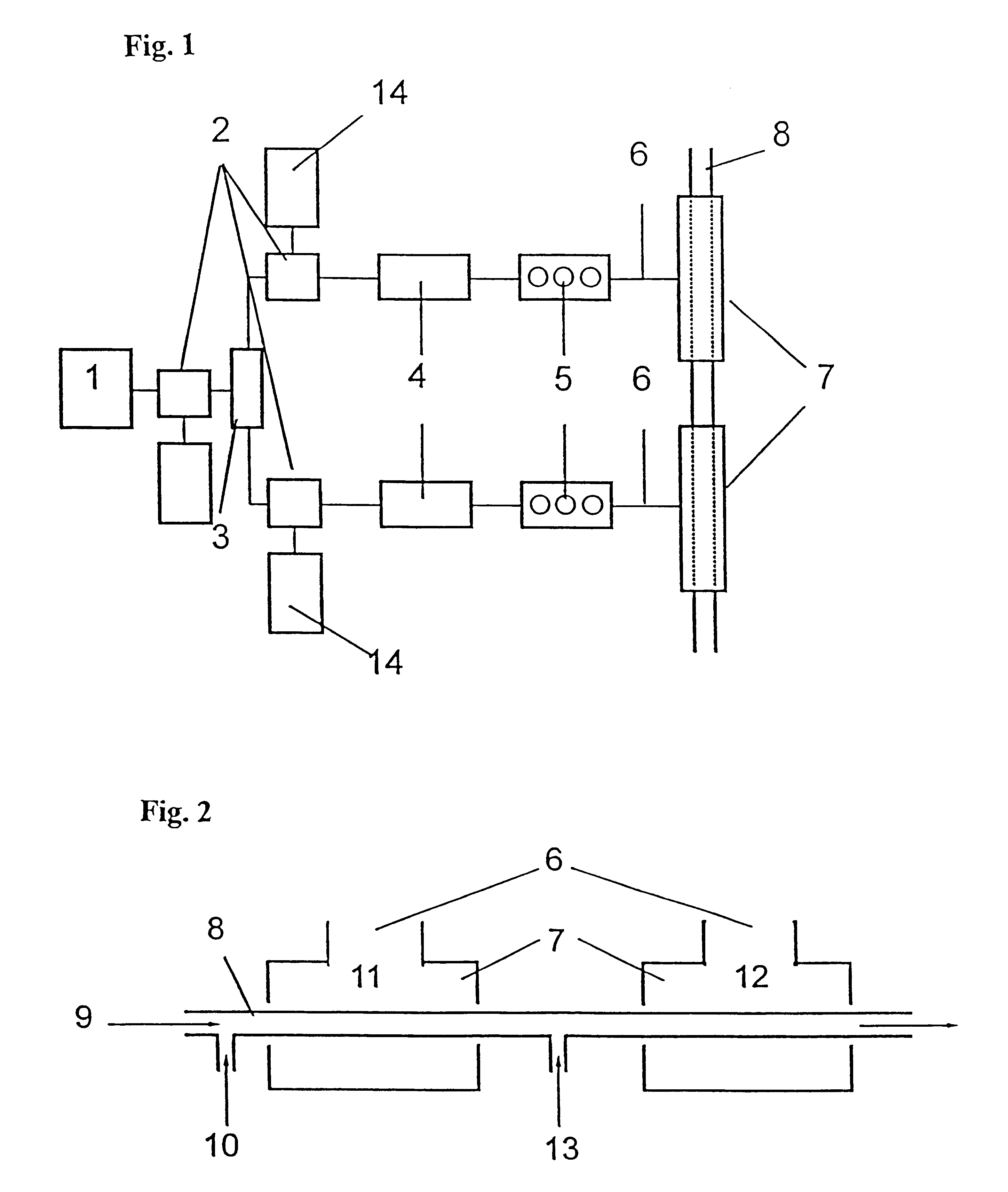

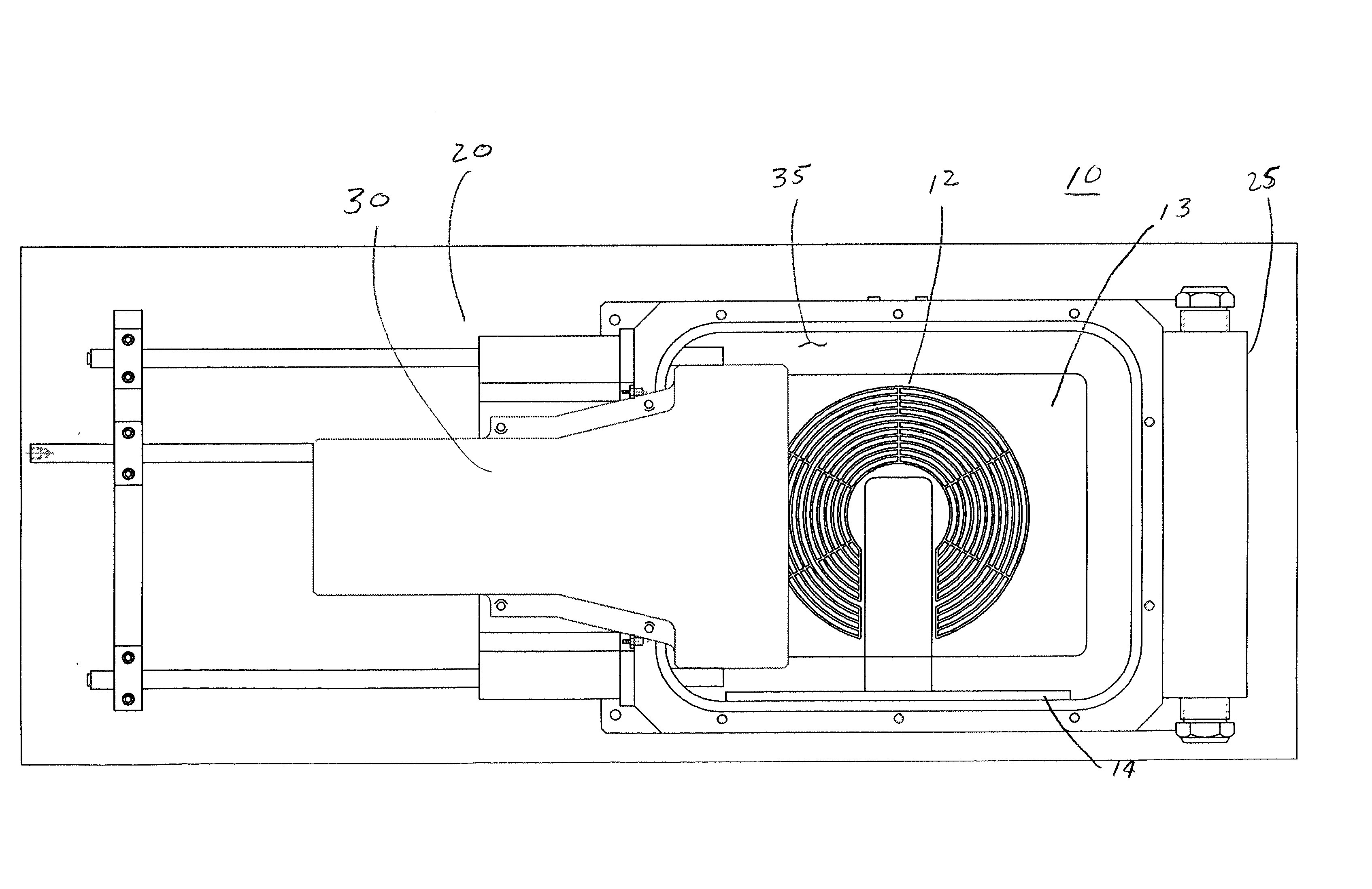

Scanning plasma reactor

InactiveUS20020069966A1Reduce eliminateElectric discharge tubesVacuum evaporation coatingComputer moduleReaction zone

A scanning plasma reactor for exciting reactant gases at a substrate surface including a beam forming module, a gas injection module, a reaction chamber with a window and a vacuum chuck, a gas exhaust module. Radiation from the beam forming module and the reactant gas create an excited plasma zone. The excited plasma zone is translated across the substrate like a windshield wiper blade, or the substrate is conveyed under a fixed gas reaction zone.

Owner:NOVELLUS SYSTEMS

Air purifier

InactiveUS20100135863A1Improve efficiencyIncrease ratingsFire rescueDeodrantsElectricityTransverse plane

An air sterilizer that operates by electro-kinetic conversion of energy is provided. The sterilizer can have an electro-kinetic converter, rows of needles fastened along support plates, and neutralizing electrodes. The converter can have a rectangular frame with two armatures joined by electrically insulating transverse plates. The armatures can be provided on one of the margins with a row of rectangular notches, equally-spaced with a constant pitch. In the notches, the ion-generating electrodes can be introduced. On their opposed margin, the plates can be interleaved at the same pitch and with V-shaped openings where the neutralizing electrodes can be introduced. The electrodes can be affixed by insulating covers, in the shape of the letter U. Each cover can be elastically deformable. The power supply can derive from an impulse generator with sufficient voltage to form an intense electric field which can ionize surrounding air and create a plasma zone.

Owner:TERPE HORATIU SORIN

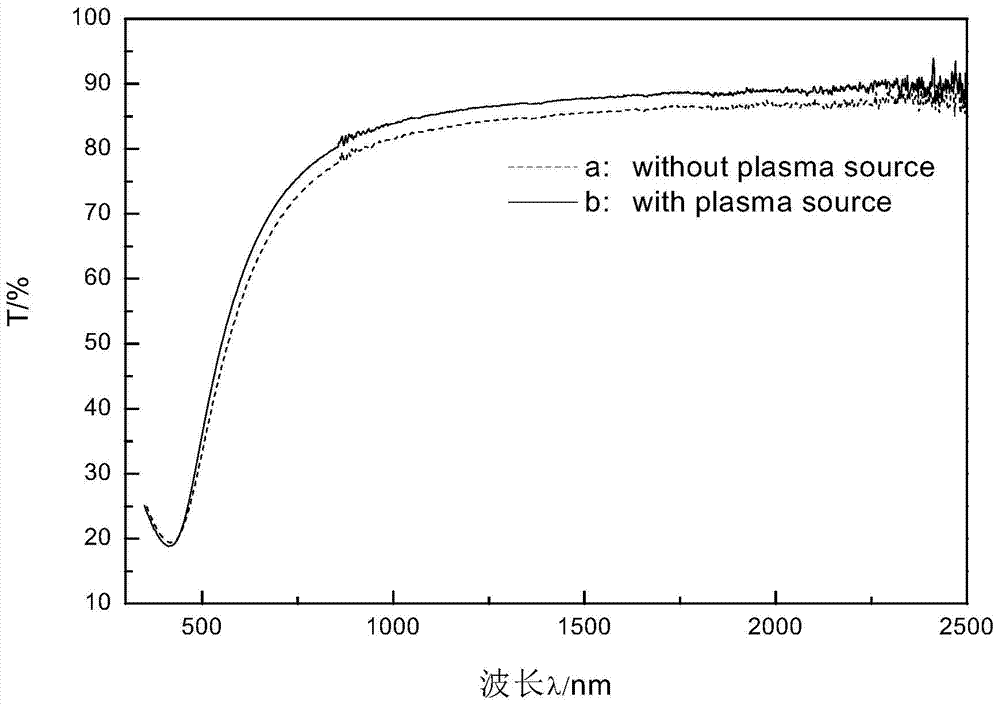

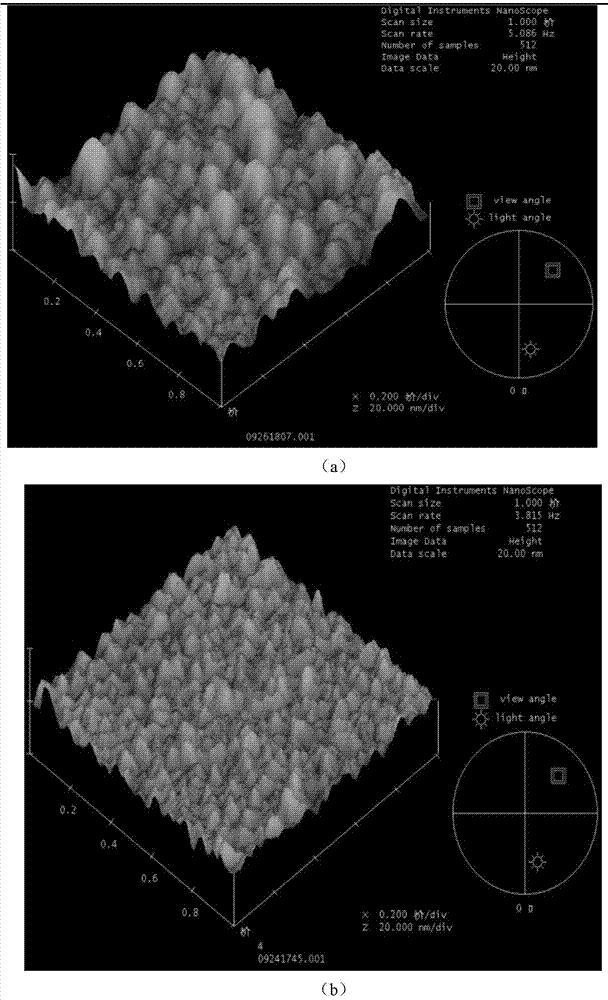

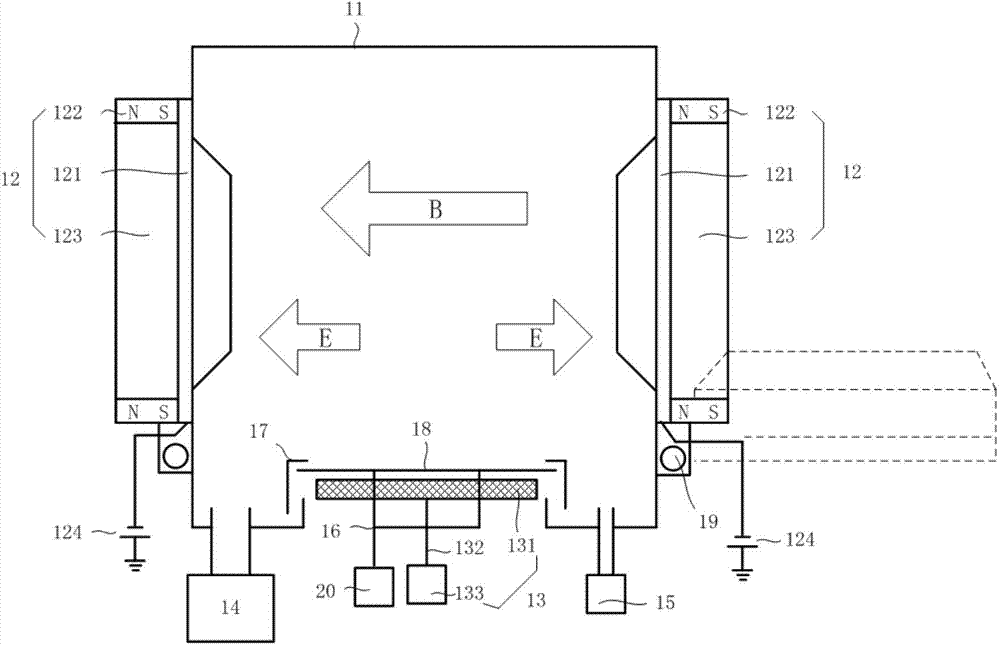

Method for magnetron sputtering low-temperature preparation of TiN film

InactiveCN104711527AHigh densityHigh crystallinityVacuum evaporation coatingSputtering coatingCrystallinityBinding force

The invention relates to a method for magnetron sputtering low-temperature preparation of a TiN film. Based on improvement of the traditional magnetron sputtering technology, a plasma zone is introduced into a vacuum chamber, and a Ti metal target is subjected to mid-frequency pulse direct current or direct current sputtering under the control of work gas pressure, temperature, time and sputtering power so that a TiN film is deposited on a substrate. The method can prepare the TiN film with good performances at a low temperature and the prepared TiN film has improved crystallization degree, compactness and hardness, small surface roughness, and high film-substrate binding force and produces local shedding difficultly. The method can provides a sample for hard film experiment research or industrial production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

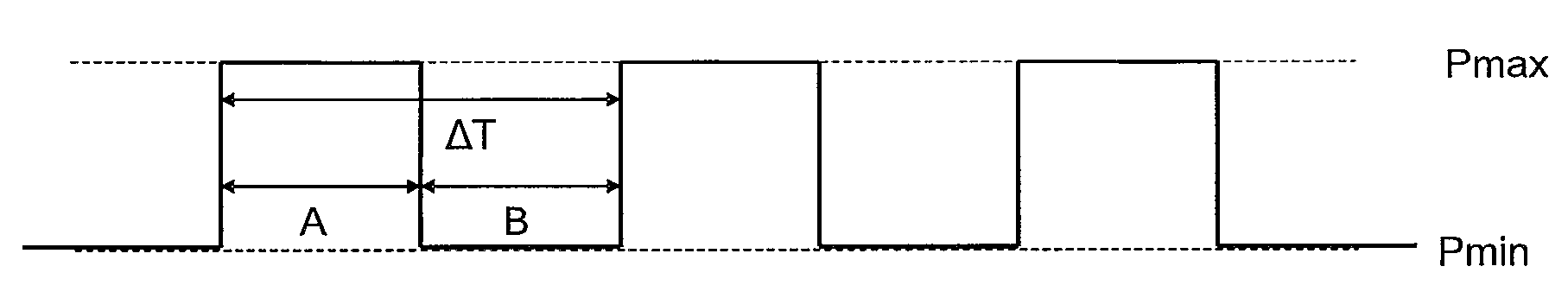

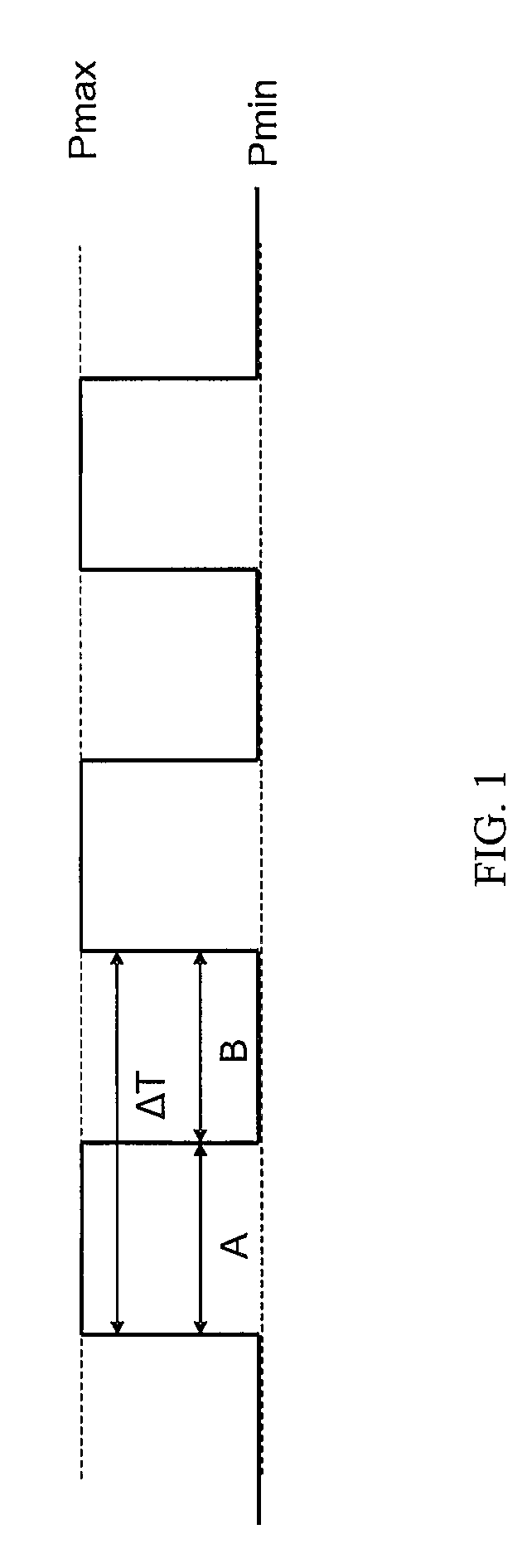

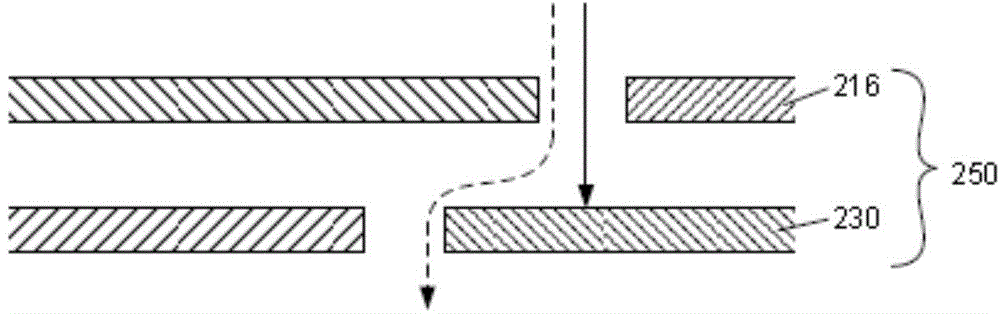

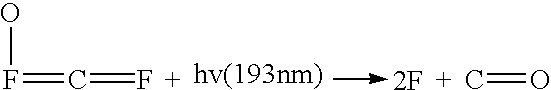

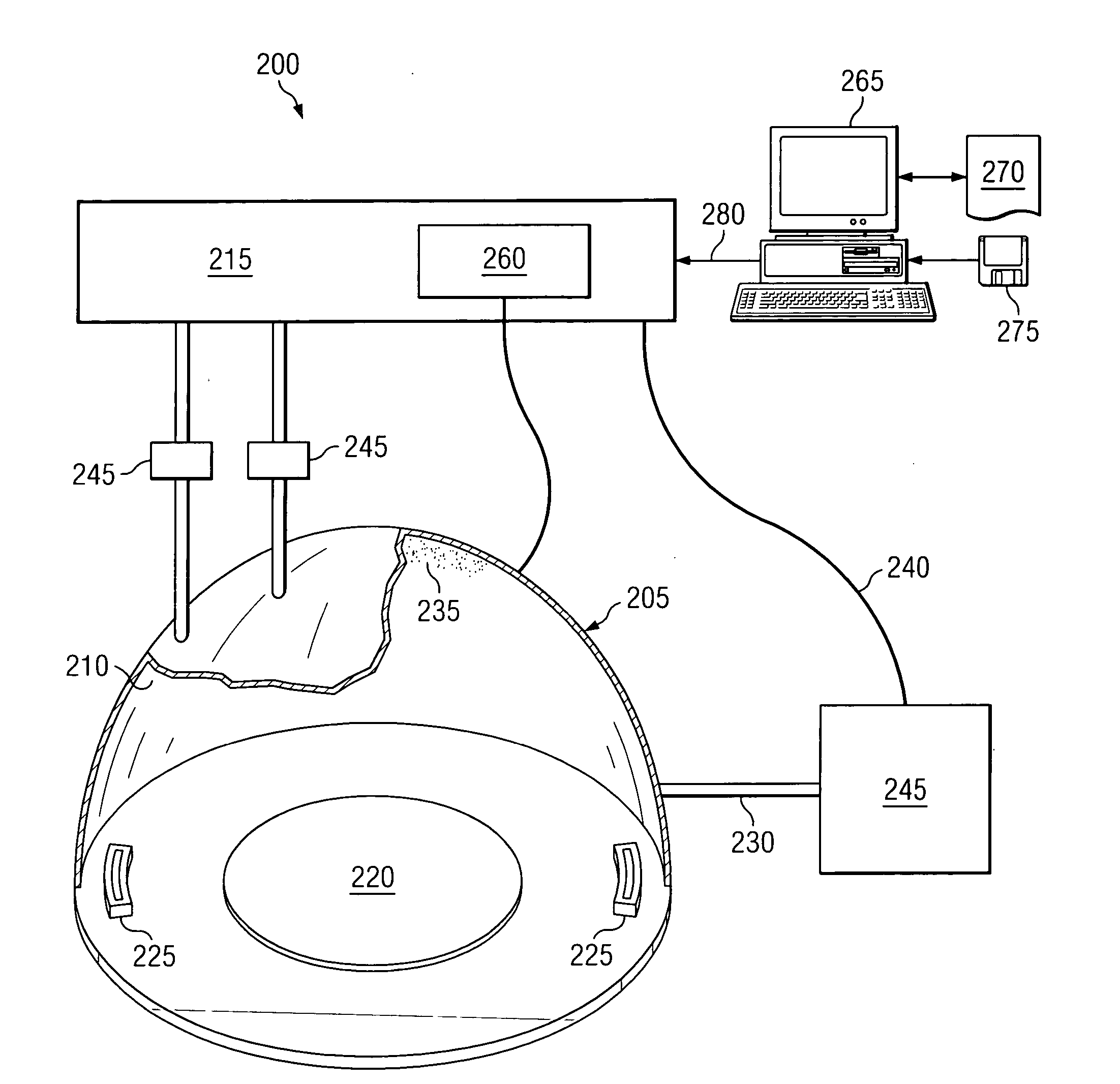

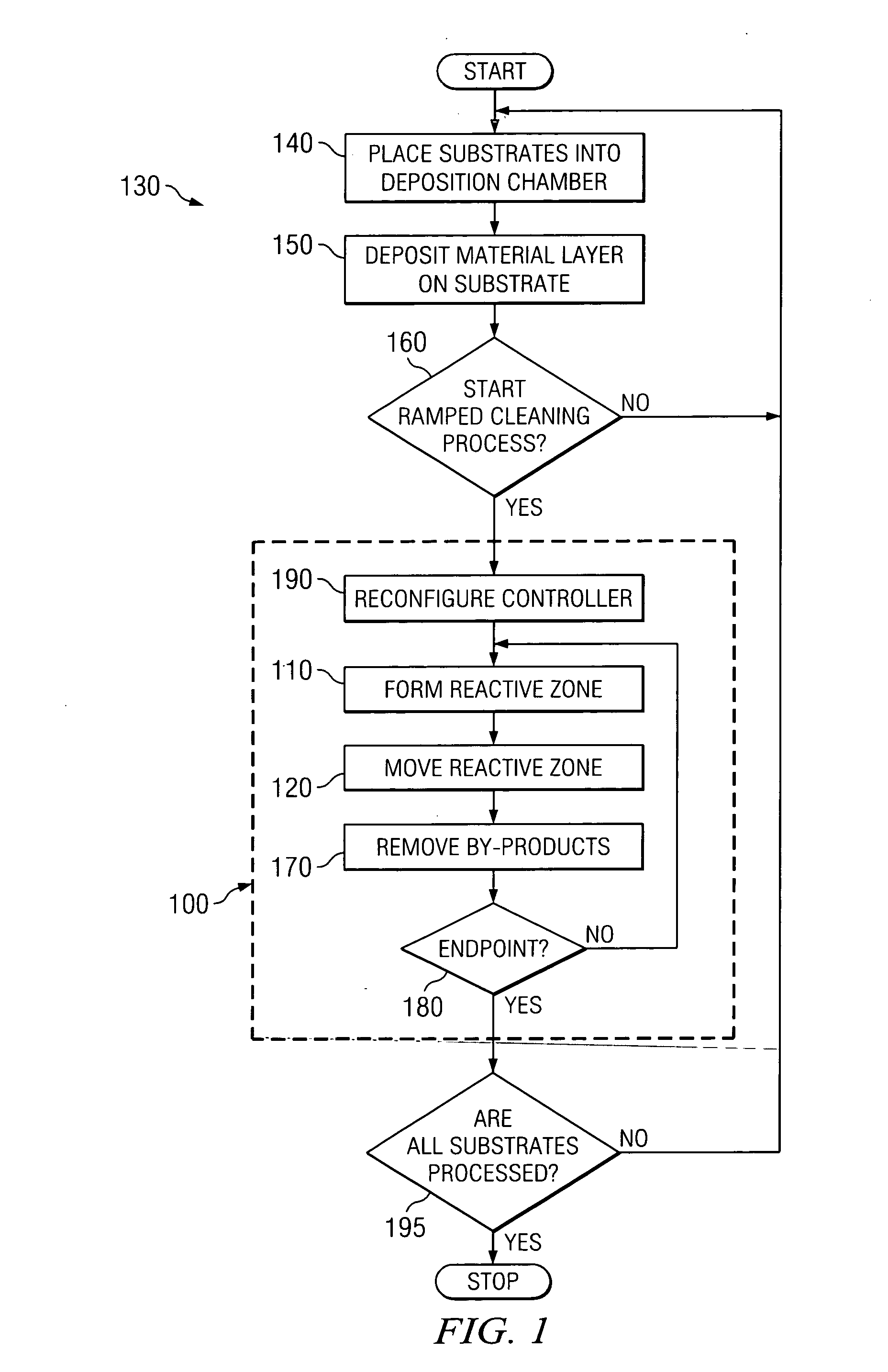

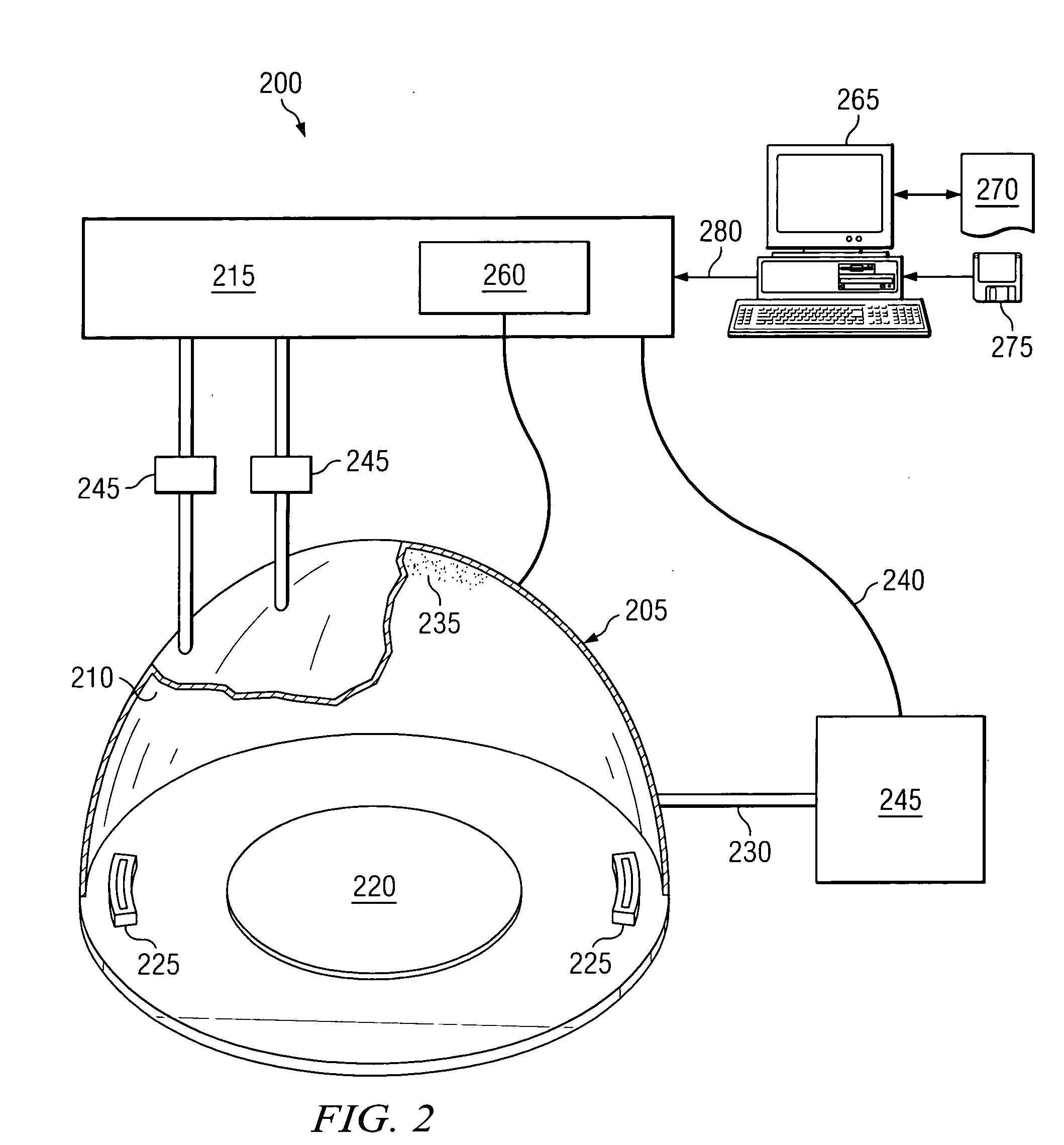

Deposition tool cleaning process having a moving plasma zone

ActiveUS20050045213A1Avoid accumulationElectric discharge tubesHollow article cleaningDevice materialReactive plasma

The present invention provides, in one embodiment, a process for cleaning a deposition chamber (100). The process includes a step (100) of forming a reactive plasma cleaning zone by dissociating a gaseous fluorocompound introduced into a deposition chamber having an interior surface and in a presence of a plasma. The process (100) further includes a step (120) of ramping a flow rate of said gaseous fluorocompound to move the reactive plasma cleaning zone throughout the deposition chamber, thereby preventing a build-up of localized metal compound deposits on the interior surface. Other embodiments advantageously incorporate the process (100) into a system (200) for cleaning a deposition chamber (205) and a method of manufacturing semiconductor devices (300).

Owner:TEXAS INSTR INC

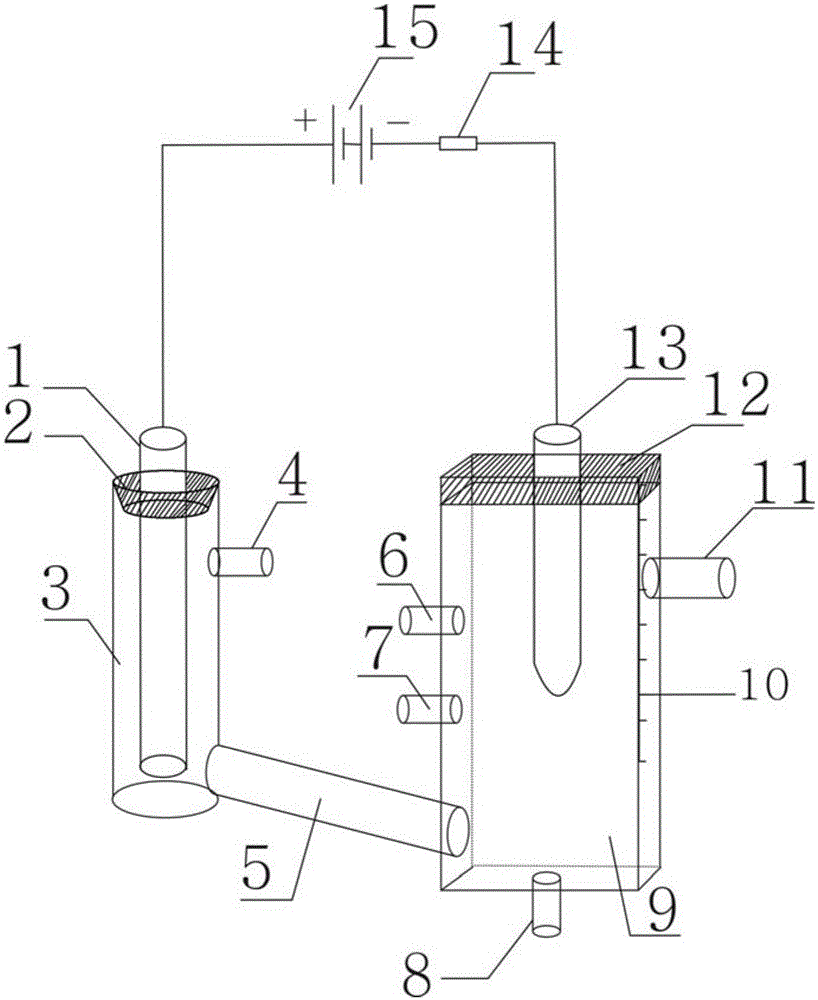

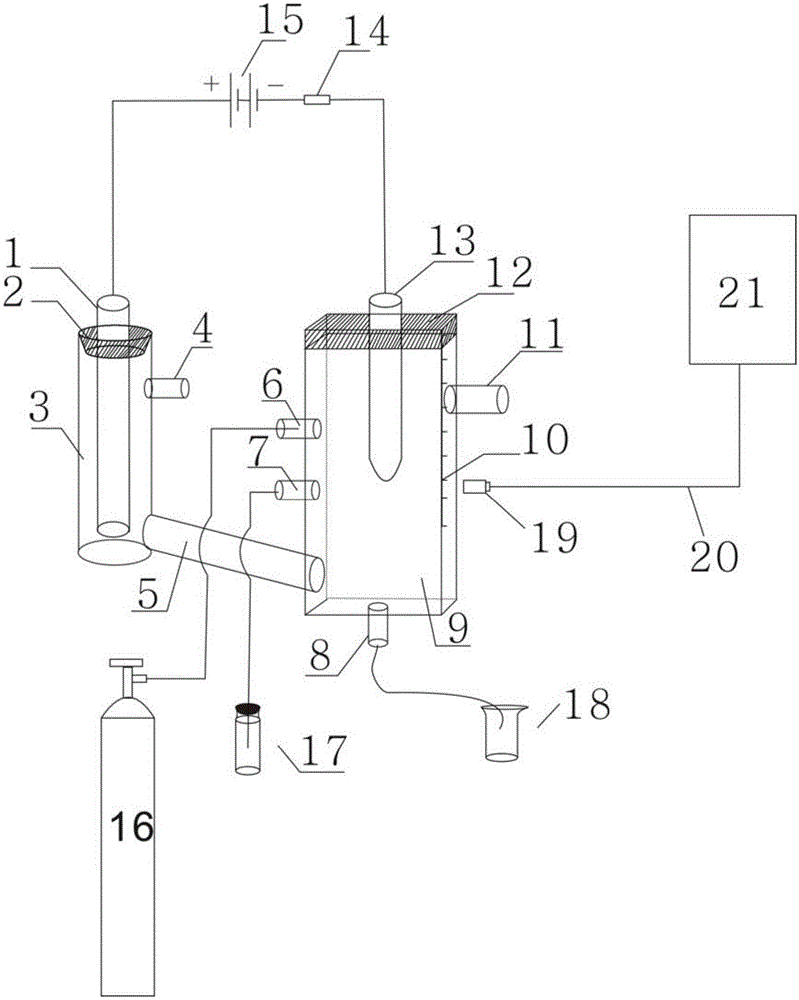

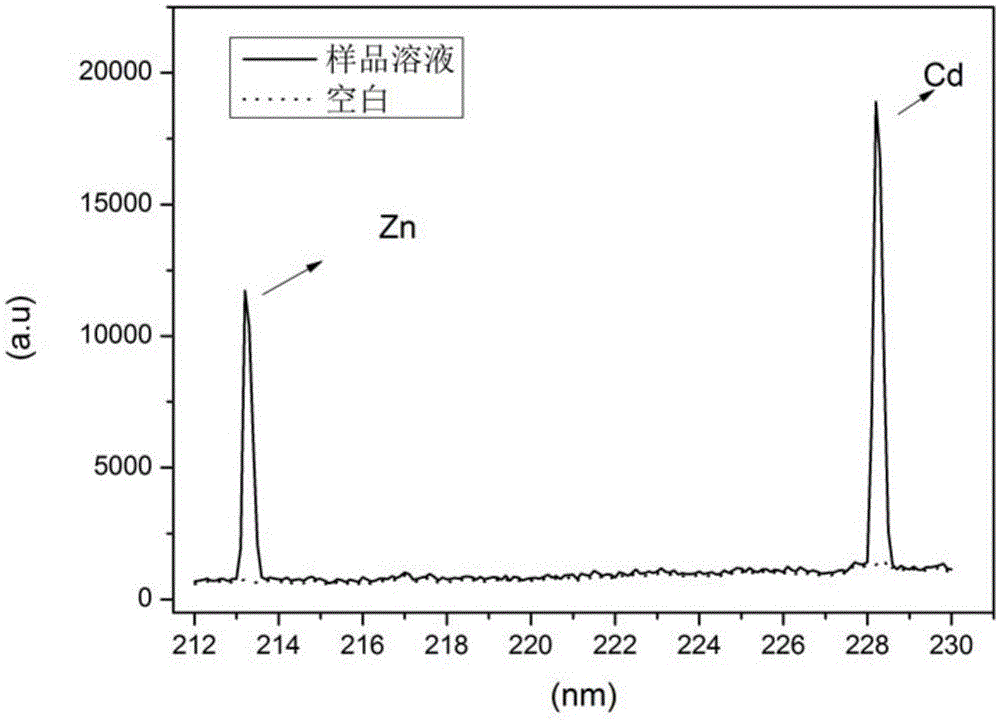

Liquid discharge micro-plasma excitation source apparatus and plasma excitation method

ActiveCN105004709AImprove excitation efficiencyImprove introduction efficiencyAnalysis by electrical excitationElectrochemical responseGas-discharge lamp

The present invention provides a liquid discharge micro-plasma excitation source apparatus, which comprises a discharge pool and a circuit portion, wherein the discharge pool comprises an anode pool and a cathode pool, the anode pool and the cathode pool are connected through an inclined conduct pipe, the anode pool is provided with a gas discharge port, the side wall of the cathode pool is provided with a protection gas inlet, a gas discharge port, a sample inlet and volume scales, the bottom portion is provided with a wastewater outlet, and the circuit portion comprises a direct current power supply and a current limiting resistor. The present invention further provides a plasma excitation method, which comprises that a solution containing a sample to be detected is introduced into a discharge pool, the discharge is achieved by reducing the distance between the cathode and the liquid level to produce the plasma, the element to be detected in the solution is introduced into the plasma zone and is excited, and the produced characteristic emission spectral line is analyzed so as to carry out qualitative and quantitative analysis on the element to be detected. According to the present invention, during the running, the plasma is adopted as the cathode and the electrochemical reaction is conducted on the plasma-solution surface to generate the gaseous compound of the element to be detected, and the gaseous compound enters the plasma zone and is excited so as to improve the plasma excitation efficiency and improve the sensitivity.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

A sputtering system

ActiveCN104746031AFast sputtering rateIncrease speedVacuum evaporation coatingSputtering coatingSputteringOptoelectronics

A sputtering system is provided. The sputtering system comprises a cavity, sputtering sources and a base. Plasma is produced in the cavity. The base is used for bearing a substrate. The sputtering system comprises at least one pair of the sputtering sources, and the sputtering sources in each pair are oppositely disposed. The base is disposed in the cavity and outside a plasma zone. The sputtering system is high in sputtering speed, low in damage to film and capable of achieving low-temperature sputtering.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

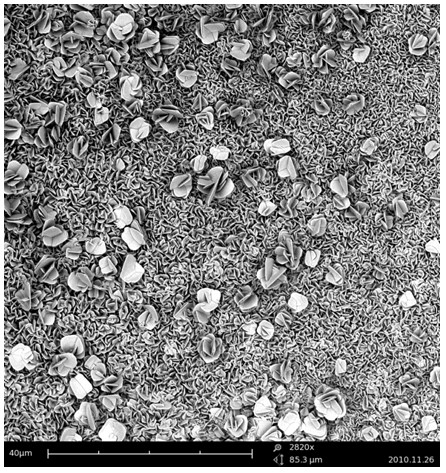

Preparation method of three-dimensional TiO2 crystal film

InactiveCN102418089AEasy to manufactureStrong visible fluorescenceChemical vapor deposition coatingPlasma jetFluorescence

The invention provides a preparation method of a three-dimensional TiO2 crystal film. The method comprises steps of: letting discharge gas in medium block discharge plasma reactor by employing a normal pressure low temperature radio frequency medium block glow discharge method; the discharge gas discharging to generate plasma jet by radio frequency alternating current; sending a precursor and carrying gas to a plasma zone to carry out reaction and precipitate on a substrate, so as to obtain the three-dimensional TiO2 crystal film. The method is characterized in that the precipitate is inner glow precipitate. The TiO2 obtained by the invention has a large proportion of {001} active surface and a unique three-dimensional structure forming by intersecting growth of a {101} surface, a {001} surface and a {101} surface; and the titanium dioxide film irradiates strong visible fluorescence by excitation of laser of 325 nm wavelength at room temperature.

Owner:DONGHUA UNIV

Method of dielectric barrier discharge plasma hot wire chemical gaseous phase deposition and its device

InactiveCN1948551ARich varietyIncrease concentrationChemical vapor deposition coatingHigh energyGas phase

The invention discloses a method and device of plasma heater chemical vapour deposition to bring plasma by dielectric-trap discharging. It is characterized in that: Zero equipotential planes supplied by wire netting is taken as zero potential electrode of dielectric-trap discharging. Heater is on the other side of wire netting, which realizes the separation of plasma zone and heater zone. Substrate below the heater is far away from plasma to avoid high-energy ion bombard. Compared with direct current, radio-frequency and microwave plasma, dielectric-trap discharging has strongpoint including simple device, low cost and small power consumption etc. The method and device can efficiently increase film sedimentation rate and film quality. The invention is applicable for preparation of polycrystal / amorphous Si, SiC, diamond, nanophase diamond and C nanophase tube.

Owner:DALIAN UNIV OF TECH

Plasma-catalyzed fuel reformer system

A thermally integrated system for producing electricity from a feedstock fuel is disclosed. The system utilizes a reformer that includes a plasma zone to receive a pre-heated mixture of reactants and ionize the reactants by applying an electrical potential thereto. A first thermally conductive surface surrounds the plasma zone and is configured to transfer heat from an external heat source into the plasma zone. The reformer further includes a reaction zone to chemically transform the ionized reactants into synthesis gas comprising hydrogen and carbon monoxide. A second thermally conductive surface surrounds the reaction zone and is configured to transfer heat from the external heat source into the reaction zone. The first thermally conductive surface and second thermally conductive surface are both directly exposed to the external heat source. A corresponding method and apparatus are also disclosed herein.

Owner:HARTVIGSEN JOSEPH J +3

Scanning plasma reactor

InactiveUS7270724B2Reduce eliminateHigh rateElectric discharge tubesVacuum evaporation coatingComputer moduleReaction zone

A scanning plasma reactor for exciting reactant gases at a substrate surface including a beam forming module, a gas injection module, a reaction chamber with a window and a vacuum chuck, a gas exhaust module. Radiation from the beam forming module and the reactant gas create an excited plasma zone. The excited plasma zone is translated across the substrate like a windshield wiper blade, or the substrate is conveyed under a fixed gas reaction zone.

Owner:NOVELLUS SYSTEMS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com