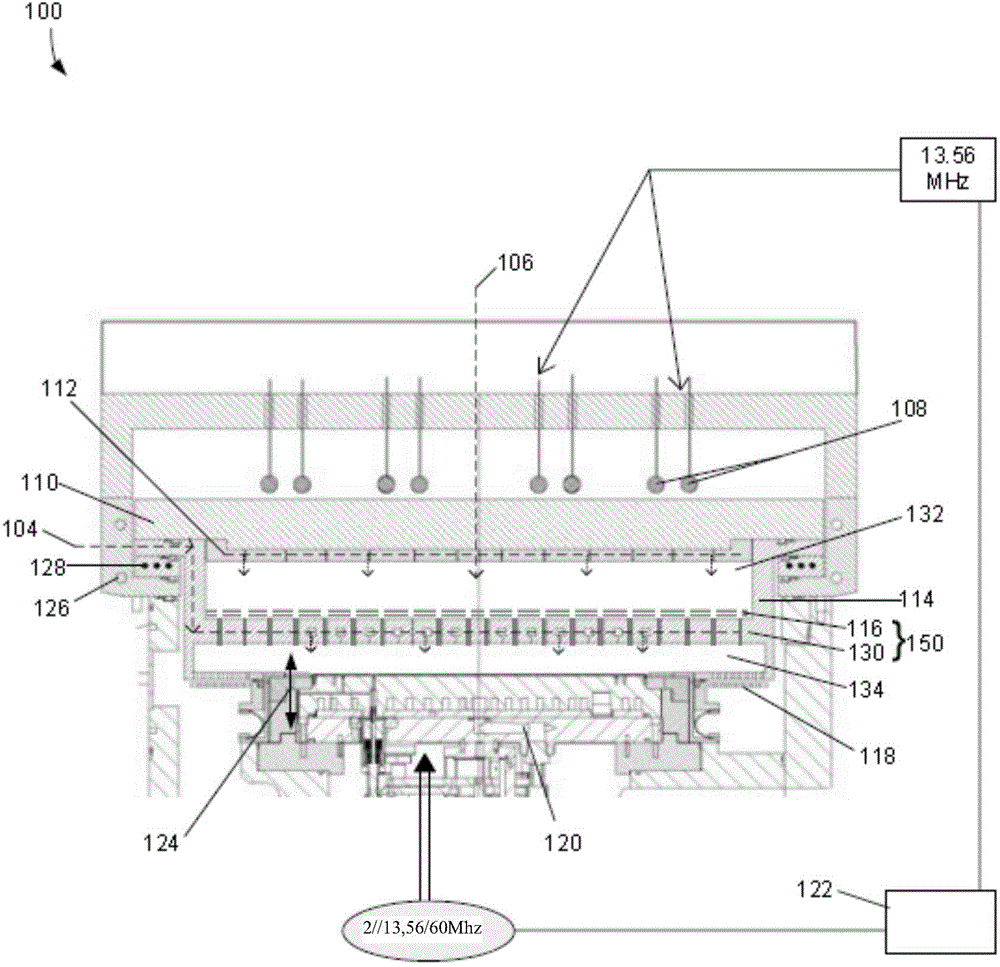

Ion to neutral control for wafer processing with dual plasma source reactor

A plasma and ion technology, which is applied in the field of control of the ratio of ions to neutral substances in an ion source reactor for processing wafers, and can solve problems such as being unsuitable for a second etching process and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

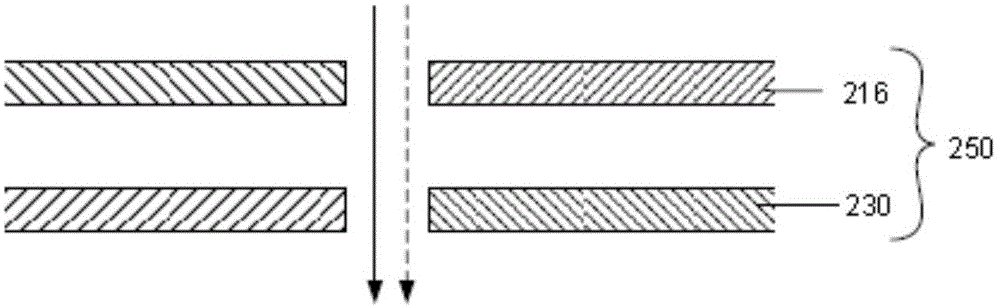

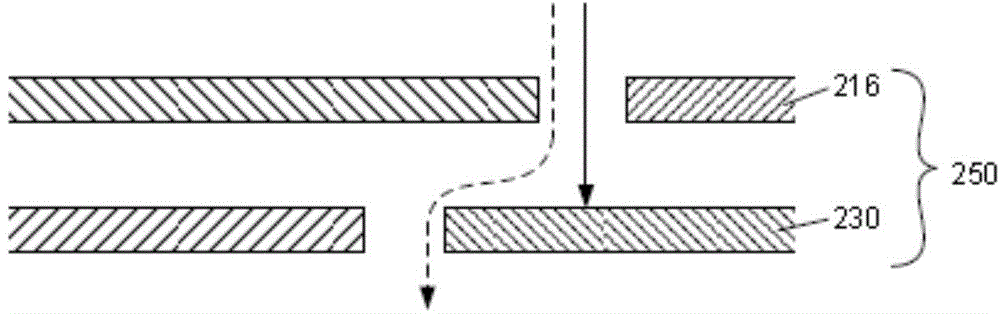

Method used

Image

Examples

Embodiment Construction

[0021]In this application, the terms "semiconductor wafer", "wafer", "substrate", "wafer substrate" and "partially fabricated integrated circuit" are used interchangeably. Those skilled in the art will appreciate that the term "partially fabricated integrated circuit" may refer to a silicon wafer during any of the many stages of fabrication of an integrated circuit on the silicon wafer. Wafers or substrates used in the semiconductor device industry typically have a diameter of 200 mm, or 300 mm, or 450 mm. Also, the terms "plate" and "grid" are used interchangeably. The following detailed description assumes that the invention is implemented on a wafer. However, the present invention is not limited thereto. Workpieces can be of various shapes, sizes, and materials. In addition to semiconductor wafers, other workpieces that may utilize the present invention include various items such as printed circuit boards and the like.

[0022] In the following description, numerous spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com