Method for magnetron sputtering low-temperature preparation of TiN film

A magnetron sputtering and thin film technology, which is applied in sputtering plating, ion implantation plating, metal material coating process, etc. Effect of small gas ionization rate and surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

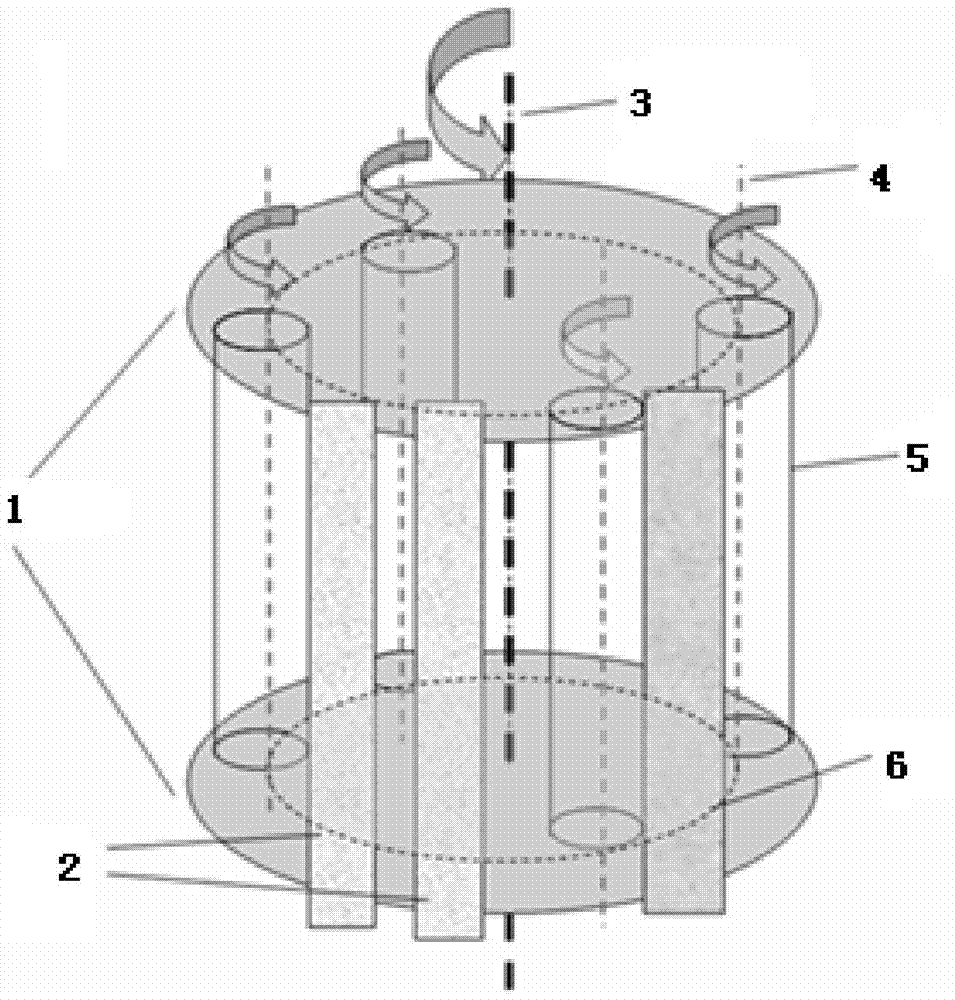

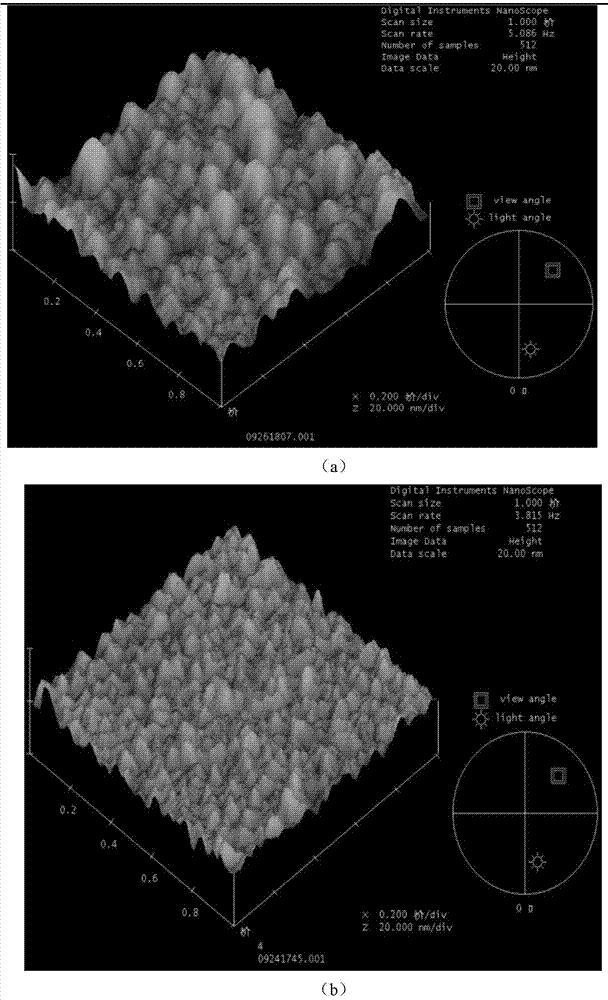

[0029] Put the 40×40×5mm steel sheet and the φ20 silicon sheet into the vacuum chamber of the equipment after cleaning and drying, vacuumize to -3 Pa, filled with argon gas, use a mass flow meter to control the argon gas intake flow rate to make it stable at 0.5Pa, turn on the revolution disk, the speed is stable at 5r / min, without ion source assistance, the Ti target power supply current is 9A, so that the Ti starts Hui, gradually increase the negative bias -80V. Nitrogen is introduced, and the mass flow meter controls the nitrogen intake flow rate to 18 sccm. Open the baffle, start timing, and prepare TiN hard films with different thicknesses by controlling the deposition time.

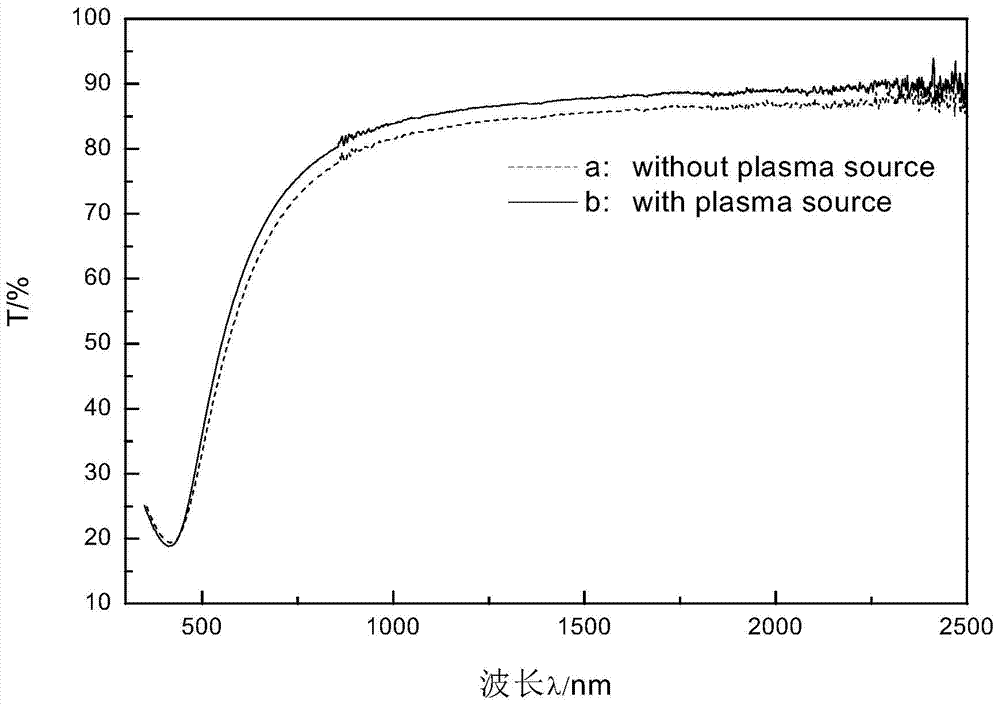

[0030] The prepared film was tested for transmittance by Lambda950 UV-Vis-NIR spectrophotometer of American PE Company, and the test results are as follows: figure 2 It can be seen from the curve a shown in the figure that the reflectivity of the titanium nitride film is low without plasma assista...

Embodiment 2

[0032]Put the 40×40×5mm steel sheet and the φ20 silicon sheet into the vacuum chamber of the equipment after cleaning and drying, vacuumize to <3Pa, open the high valve and heating pipe, wait for the temperature to stabilize at 100°C, and vacuum to 5 ×10-3Pa, fill with argon, use a mass flow meter to control the argon gas intake flow rate to keep it stable at 0.5Pa, turn on the revolution disk, and keep the speed at 5r / min, gradually increase the ion source power to 500W, Ti target power supply current To 9A, make Ti glow, and gradually increase the negative bias -80V. Nitrogen is introduced, and the mass flow meter controls the nitrogen intake flow rate to 18 sccm. Open the baffle, start timing, and prepare TiN hard films with different thicknesses by controlling the deposition time.

[0033] Utilize the photometer to carry out transmittance test to the prepared film, test result is as follows figure 2 As shown in curve b, it can be seen from the figure that the reflectivi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com