Method of dielectric barrier discharge plasma hot wire chemical gaseous phase deposition and its device

A dielectric barrier discharge, plasma technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve problems such as affecting plasma stability and uniformity, reducing hot wire life, affecting film quality, etc. , to achieve the effect of enriching species, increasing concentration, increasing quality and deposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

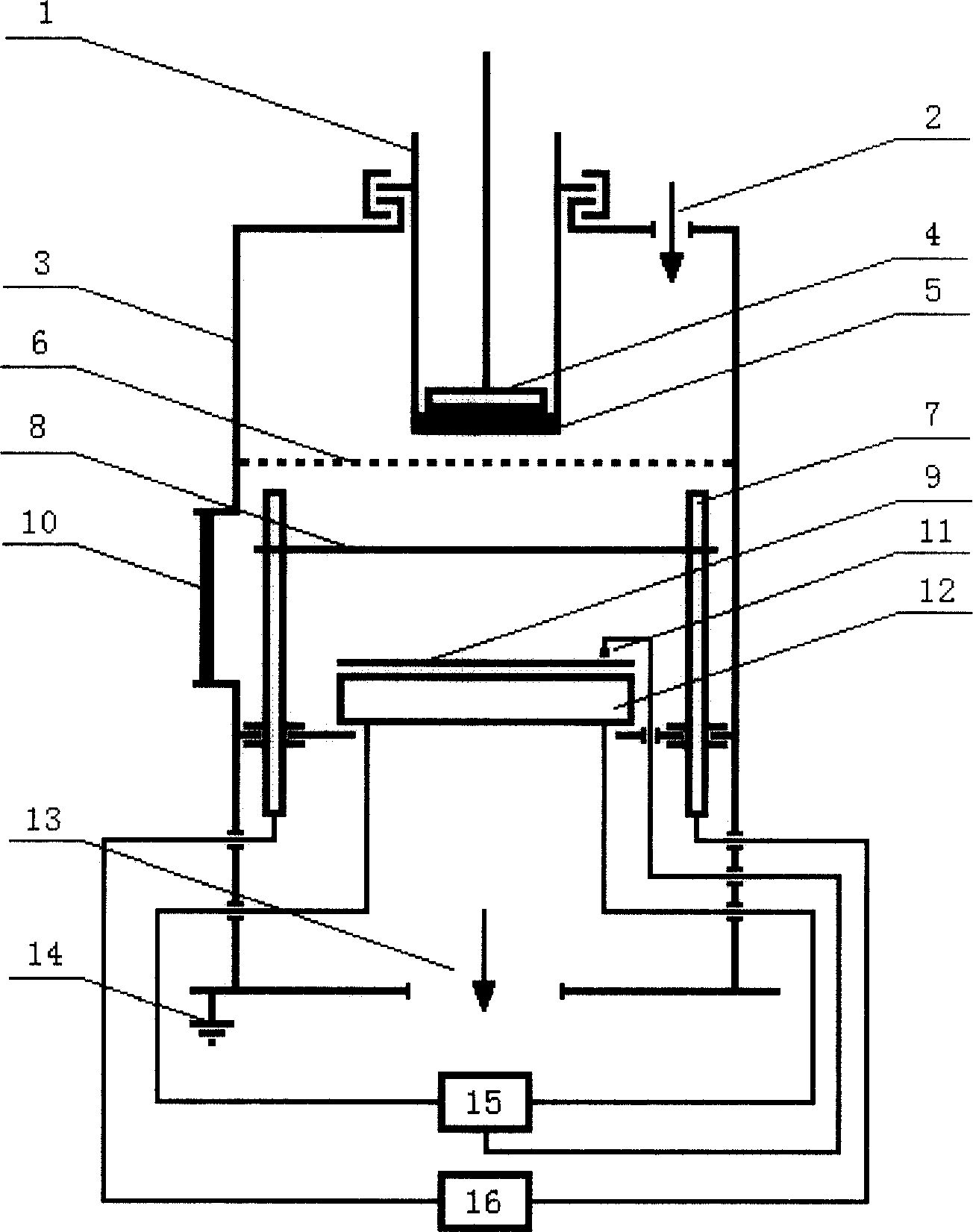

[0016] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0017] As shown in the attached picture. Firstly, the required hot wire 8 is selected and fixed on the two hot wire electrodes 7 in the vacuum chamber 3, and the material of the hot wire 8 can be replaced according to different requirements of the experiment. Next, the substrate material to be deposited is processed, and then placed on the sample stage 9 in the center of the bottom of the vacuum chamber. Close the vacuum chamber, turn on the sample heating power supply and the temperature controller 15 after pumping the vacuum to an appropriate value, and start heating the substrate. When the temperature of the substrate reaches the desired value, the reaction gas is introduced, and the hot wire 8 is heated by the hot wire heating power supply 16 . At the same time, high-voltage alternating current is applied to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com