Preparation method of three-dimensional TiO2 crystal film

A crystal film, three-dimensional technology, applied in the field of preparation of three-dimensional TiO2 crystal film, can solve the problems of dense film, difficulty in obtaining regular shape, single crystal size, large free path of particles, etc., and achieve simple equipment, low price and low pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

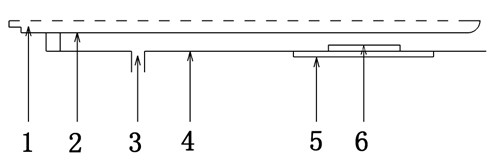

[0040] Such as figure 1 As shown, it is a schematic structural diagram of a capacitively coupled coaxial plasma reactor, and the capacitively coupled coaxial plasma reactor includes a coaxial inner tube 2 of a barrier medium and an outer tube 4 of a barrier medium; the barrier medium is quartz, and the inner tube of the barrier medium Both the tube 2 and the barrier medium outer tube 4 have a thickness of 1 mm. The lower end of the barrier medium inner tube 2 is closed and the upper end is open, and conductive powder copper powder is housed inside, and the outer diameter of the barrier medium inner tube 2 is 7mm. The inner diameter of the barrier medium outer tube 4 is 11 mm, the discharge gap of the dielectric barrier discharge plasma reactor is 2.5 mm, and the right end of the barrier medium outer tube 4 is open. Air inlets 3 with a diameter of 2 mm are respectively provided on the sides of the upper part of the barrier medium outer tube 4 . A metal sheet 5 (copper sheet) ...

Embodiment 2

[0045] Such as figure 1 As shown, it is a schematic structural diagram of a capacitively coupled coaxial plasma reactor, and the capacitively coupled coaxial plasma reactor includes a coaxial inner tube 2 of a barrier medium and an outer tube 4 of a barrier medium; the barrier medium is quartz, and the inner tube of the barrier medium Both the tube 2 and the barrier medium outer tube 4 have a thickness of 2 mm. The lower end of the barrier medium inner tube 2 is closed and the upper end is open, and conductive powder copper powder is housed inside, and the outer diameter of the barrier medium inner tube 2 is 5mm. The inner diameter of the barrier medium outer tube 4 is 15 mm, the discharge gap of the dielectric barrier discharge plasma reactor is 5 mm, and the right end of the barrier medium outer tube 4 is open. Air inlets 3 with a diameter of 5 mm are respectively provided on the sides of the upper part of the barrier medium outer tube 4 . A metal sheet 5 (copper sheet) wi...

Embodiment 3

[0050] Such as figure 1 As shown, it is a schematic structural diagram of a capacitively coupled coaxial plasma reactor, and the capacitively coupled coaxial plasma reactor includes a coaxial inner tube 2 of a barrier medium and an outer tube 4 of a barrier medium; the barrier medium is quartz, and the inner tube of the barrier medium Both the tube 2 and the barrier medium outer tube 4 have a thickness of 1.5 mm. The lower end of the barrier medium inner tube 2 is closed and the upper end is open, and conductive powder copper powder is housed inside, and the outer diameter of the barrier medium inner tube 2 is 6 mm. The inner diameter of the barrier medium outer tube 4 is 12 mm, the discharge gap of the dielectric barrier discharge plasma reactor is 3 mm, and the right end of the barrier medium outer tube 4 is open. Air inlets 3 with a diameter of 2 mm are respectively provided on the sides of the upper part of the barrier medium outer tube 4 . A metal sheet 5 (copper sheet)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com