Patents

Literature

41results about How to "Fast energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

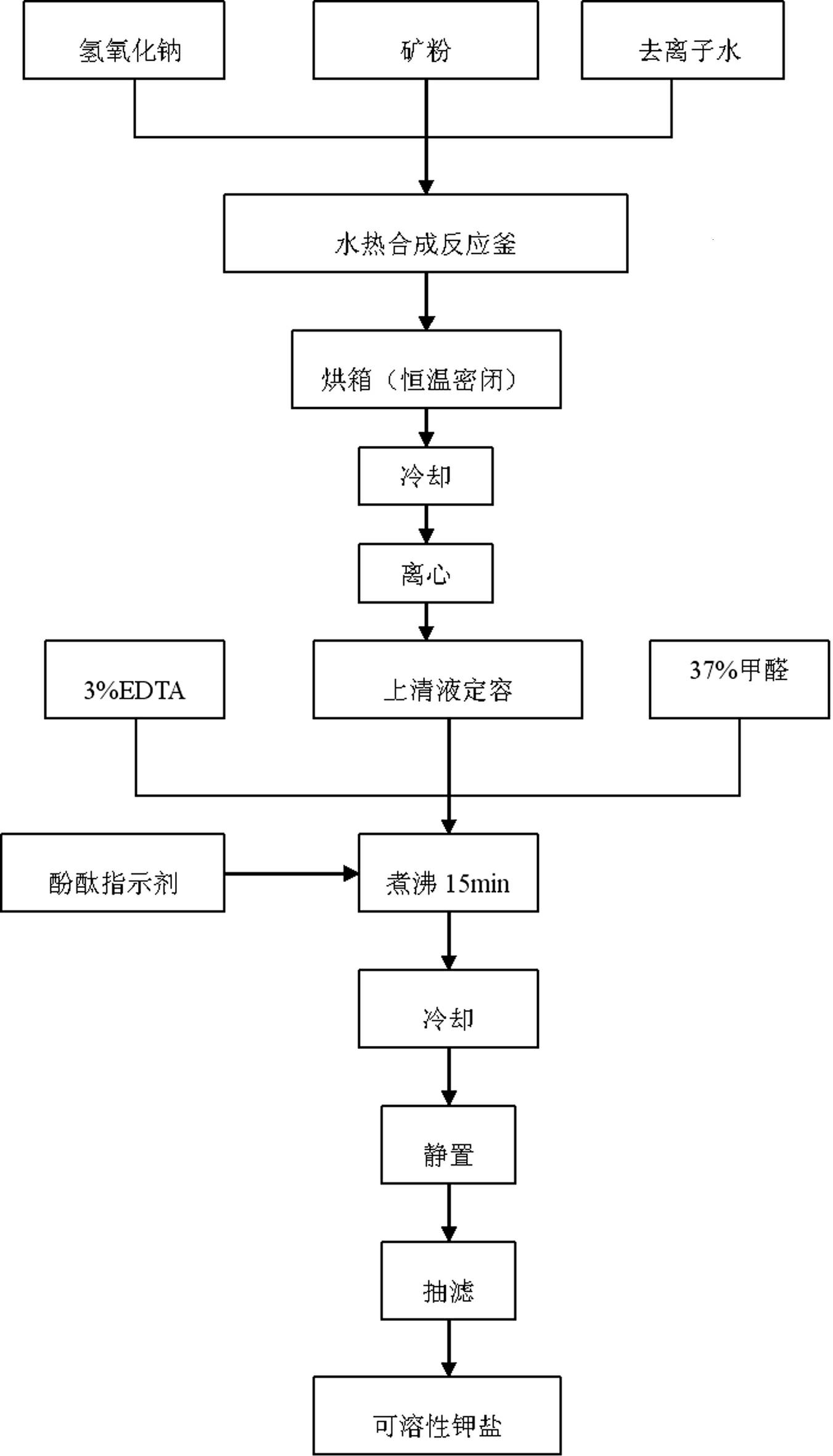

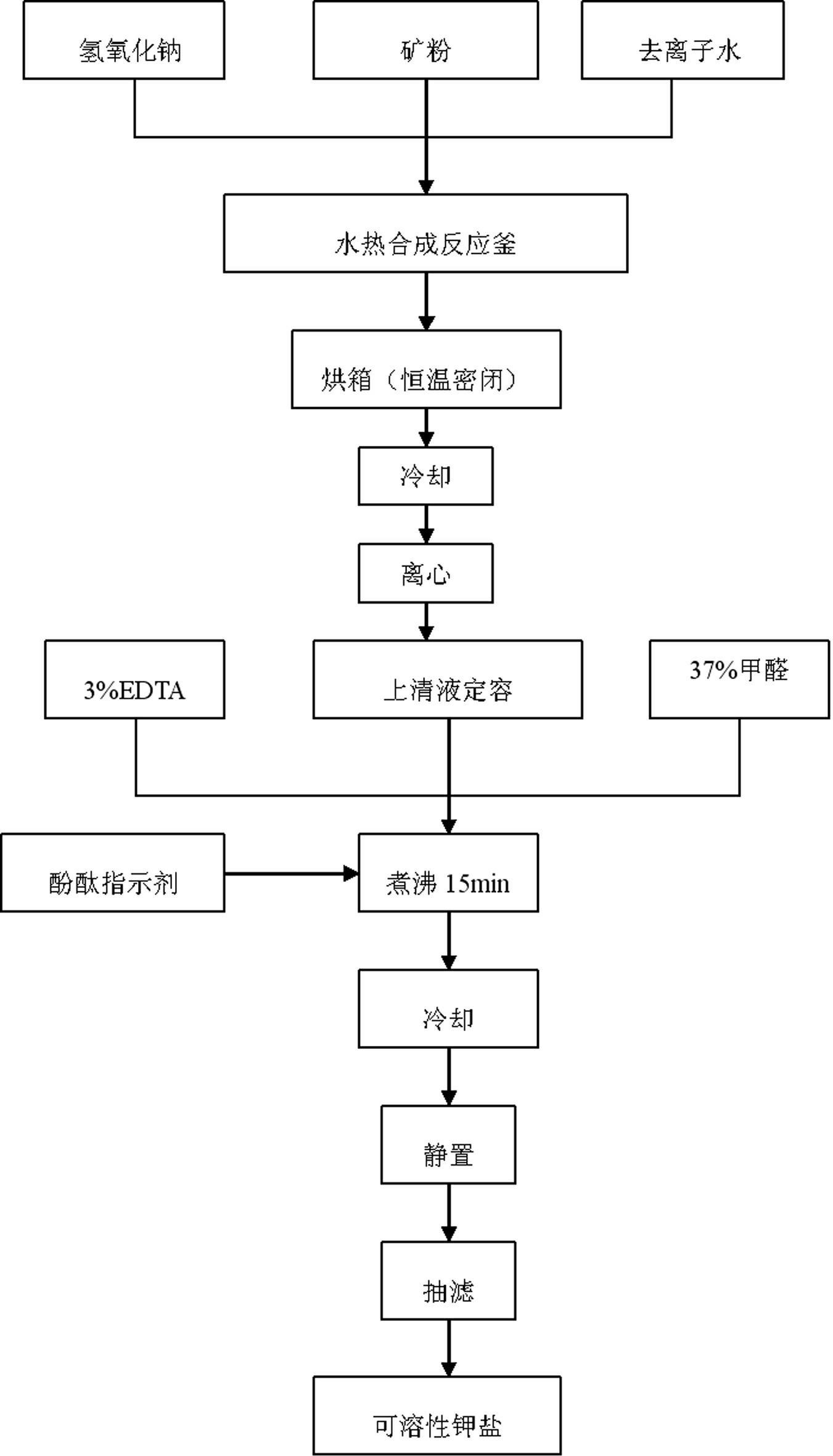

Method for quickly extracting soluble potassium at low temperature

InactiveCN102408256AEffective destructionAvoid disadvantages that are difficult to exploitPotassium fertilisersRoom temperatureHydrothermal synthesis

The invention relates to a method for quickly extracting soluble potassium at low temperature, which comprises the following steps of: uniformly mixing potassium feldspar mineral powder, NaOH assistant and de-ionized water in a certain ratio, placing in a hydrothermal synthesis reactor, reacting in a constant temperature closed oven for defined time and taking out; cooling the extracted product at room temperature, and centrifuging to obtain supernatant; and fixing volume of the supernatant, boiling, cooling and standing to obtain the soluble potassium salt. The NaOH is used as the assistant, so lattice structure in the potassium feldspar can be effectively destroyed to separate out difficultly soluble potassium to obtain soluble potassium; extraction rate reaches up to 93.5%; and this technology has the advantages of simple process, low energy consumption, less pollution, high extraction rate and the like, has quick reaction speed, no deposition, no filtering process, low equipment requirement and better industrial application prospect, and can avoid the defects that the reaction substrate in the technology is difficultly utilized.

Owner:YANTAI UNIV

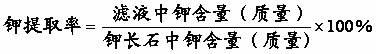

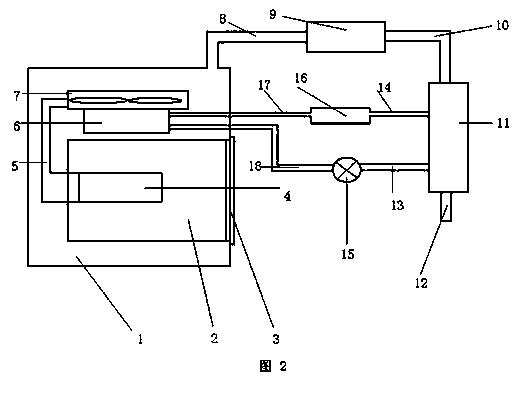

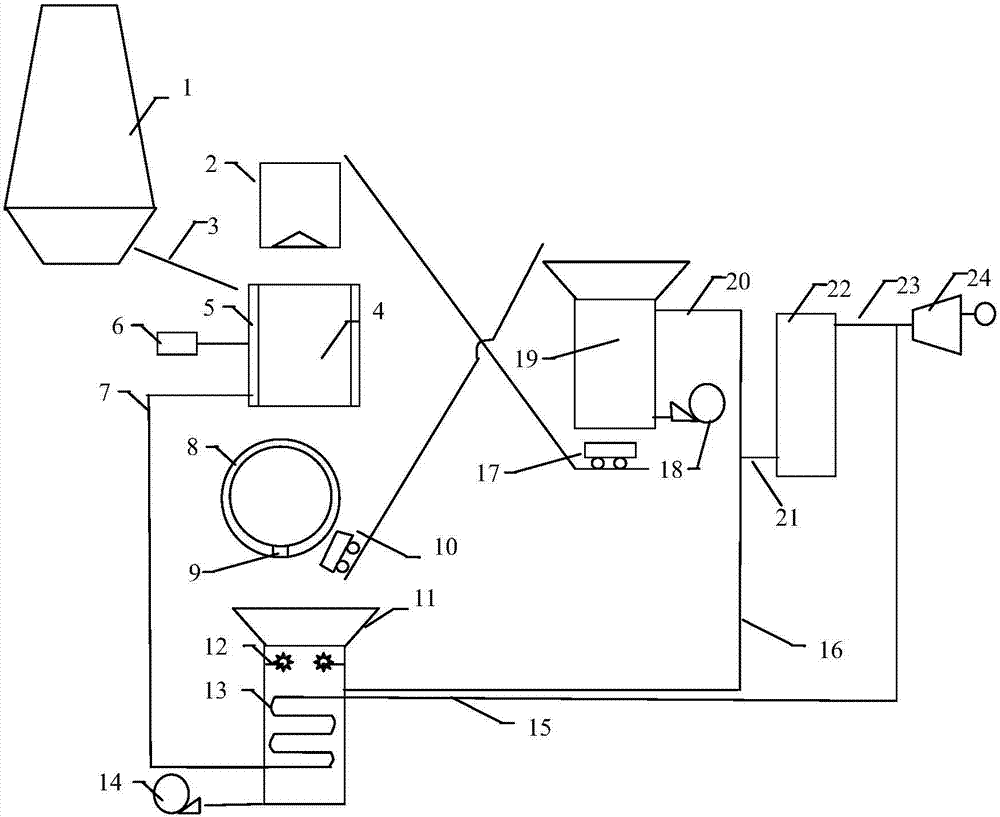

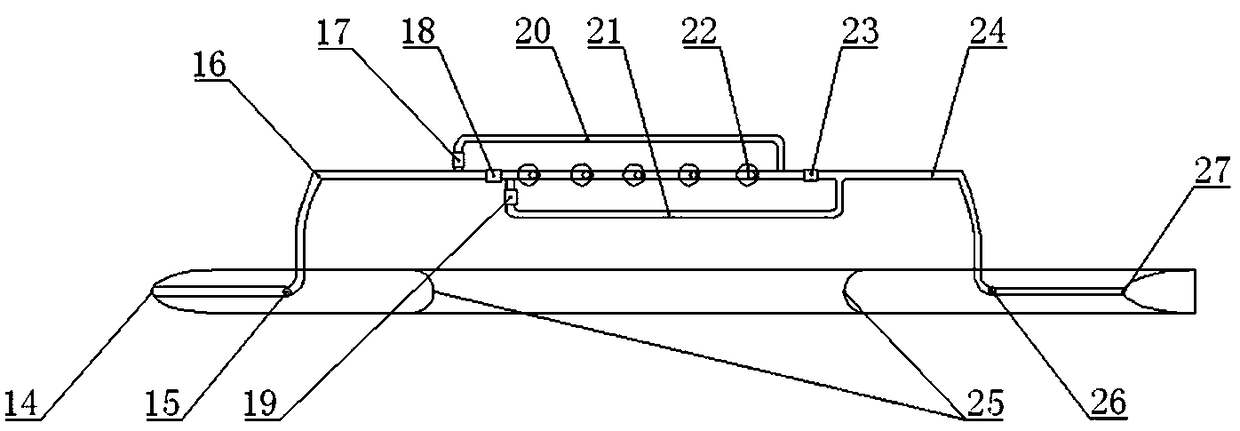

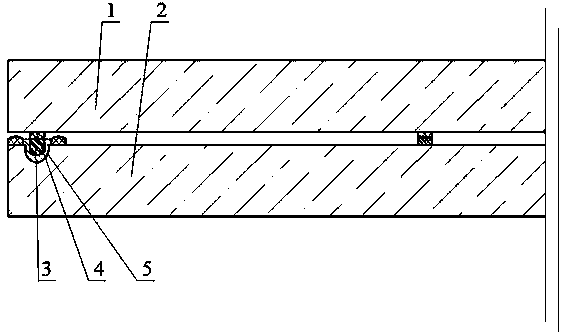

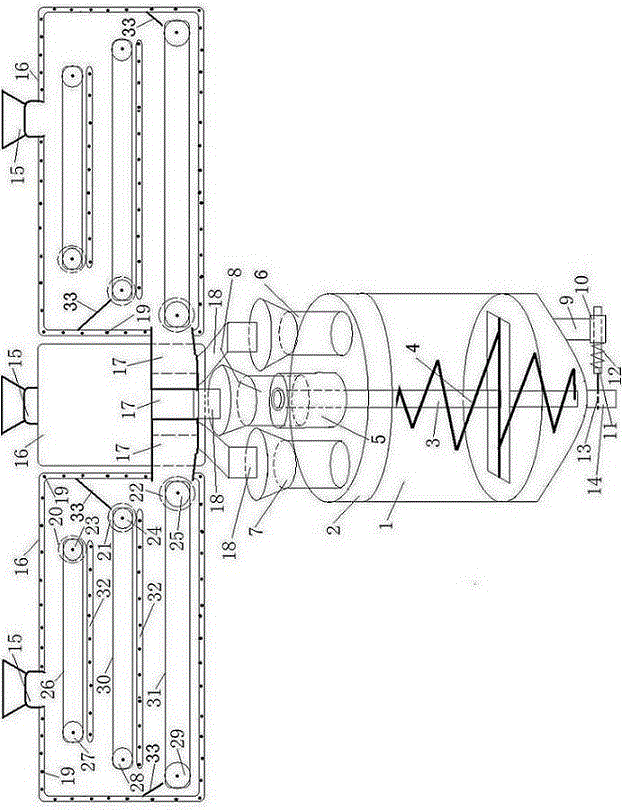

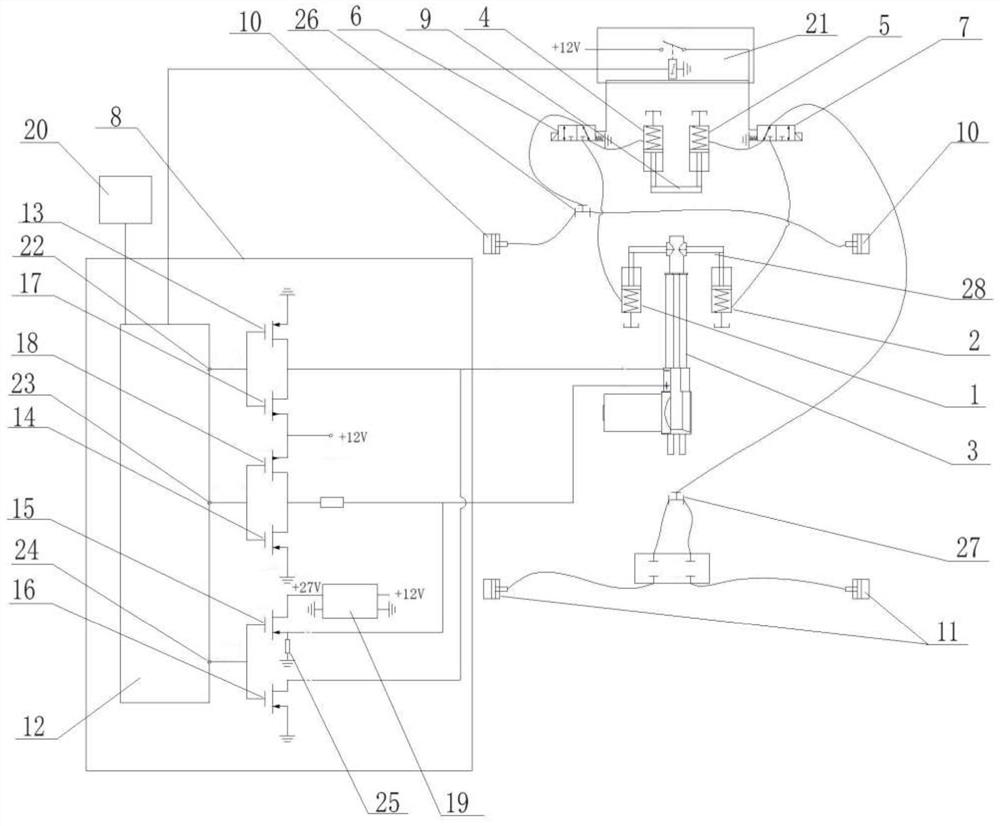

Heat pump negative pressure efficient drying machine and drying method thereof

InactiveCN103774396AFast energy consumptionFast dryingTextiles and paperLaundry driersControl systemEngineering

The invention discloses a heat pump negative pressure efficient drying machine and a drying method of the heat pump negative pressure efficient drying machine. The drying machine comprises a box body (1), a negative pressure vacuum pump (9), a heat pump compressor (16), an evaporator (12), a throttling valve (15) and a condensate water outlet (11), wherein a control system (19), a rotary drum (2), a condenser (6) and a centrifugal fan (7) are arranged in the box body (1). One end of the negative pressure vacuum pump (9) is connected with the box body (1) through a pipeline, and the other end of the negative pressure vacuum pump (9) is connected with the evaporator (12) through a pipeline. One end of the throttling valve (15) and one end of the heat pump compressor (16) are connected with the evaporator (12) through a pipeline, and the other end of the throttling valve (15) and the other end of the heat pump compressor (16) are connected with the condenser (6) through a pipeline. The condensate water outlet (11) is connected with the lower portion of the evaporator (12). According to the drying machine, wasted heat sources of kitchens, industrial wasted heat sources and other wasted heat sources can be fully utilized, water is rapidly evaporated through a negative pressure technology, and heat energy consumption and heat emission are reduced.

Owner:苟仲武

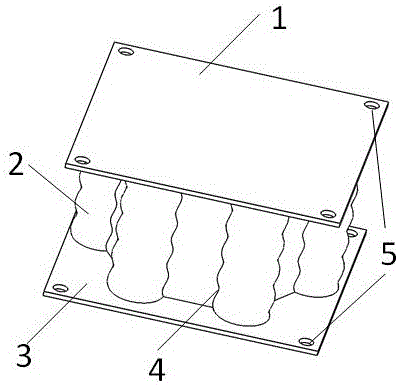

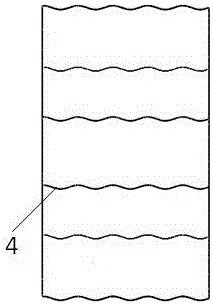

Bionic energy absorption box

InactiveCN106347463AExcellent deformation energy dissipation capacityTake full advantage of plastic deformation capabilitiesUnderstructuresBumpersBionicsEnergy absorption

The invention discloses a bionic energy absorption box. The bionic energy absorption box comprises a first connecting plate, a box body and a second connecting plate; the first connecting plate and the second connecting plate are respectively fixed to the two ends of the box body; the bionic energy absorption box is characterized in that the box body consists of grid walls of a polygonal grid unit and thin-walled columns which are arranged along the intersections of the grid walls; the thin-walled columns and the grid walls are waveforms with equal cross sections; a waveform deformation leading line is formed at the intersection of each grid wall and the corresponding thin-walled column. The energy absorption box disclosed by the invention is high in energy absorption capacity and stable in energy consumption; the speed of an automobile is effectively reduced after the automobile is collided, and the maximum safe speed of safety collision of the automobile is further improved; the bionic energy absorption box is particularly suitable for the field of design and manufacturing of automobile parts and similar structures with anti-collision requirements; the life safety of a main body and people can be effectively guaranteed.

Owner:SOUTHEAST UNIV

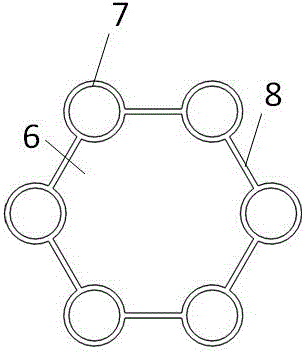

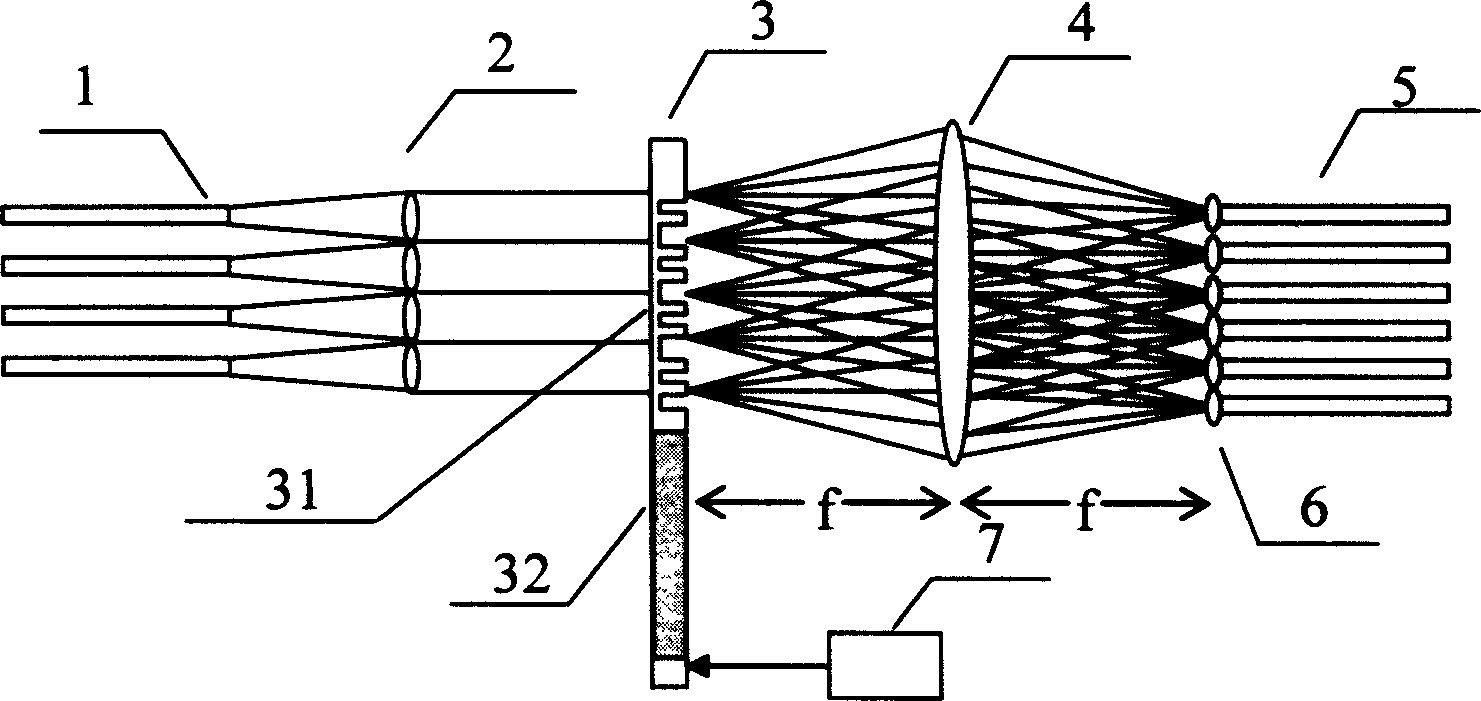

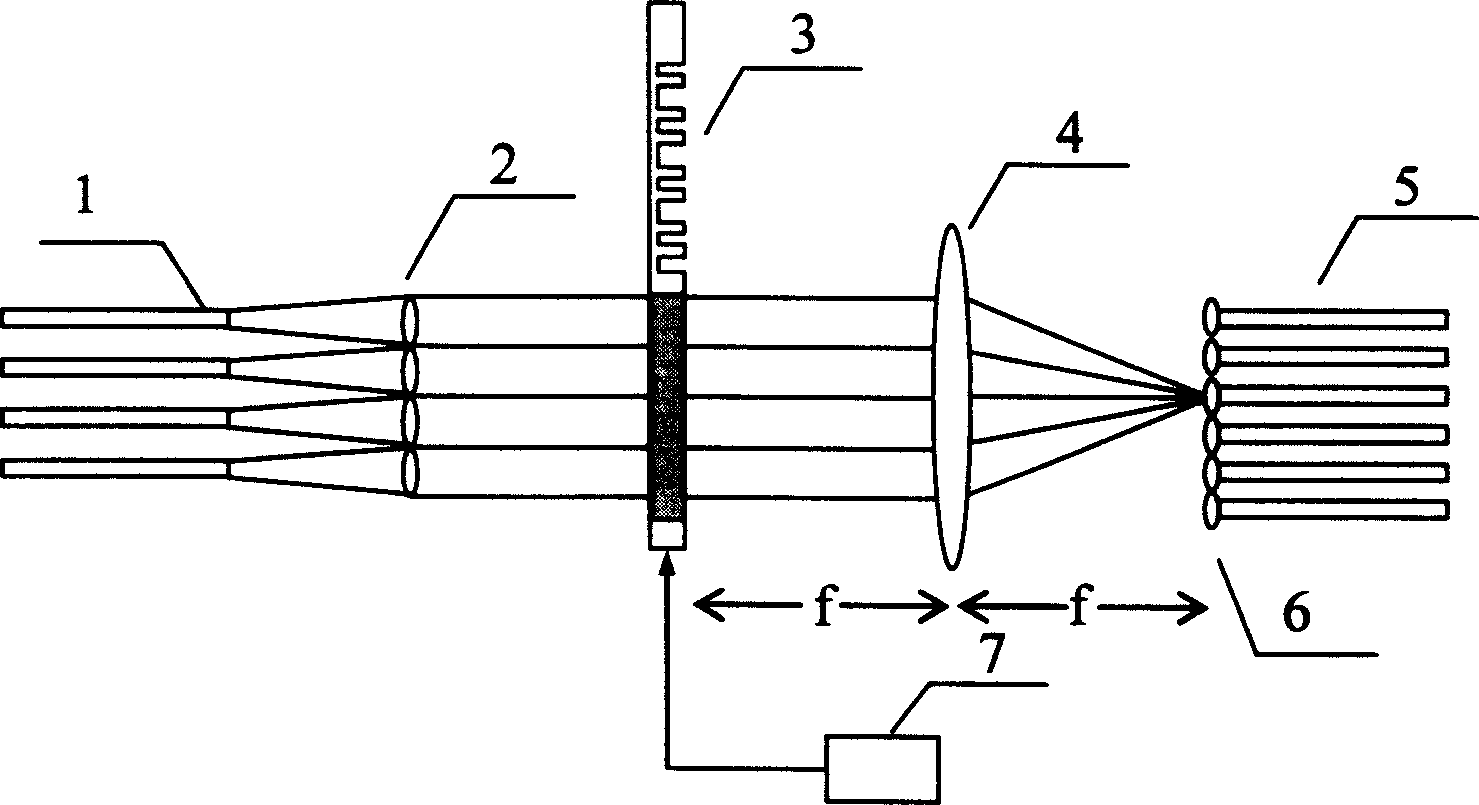

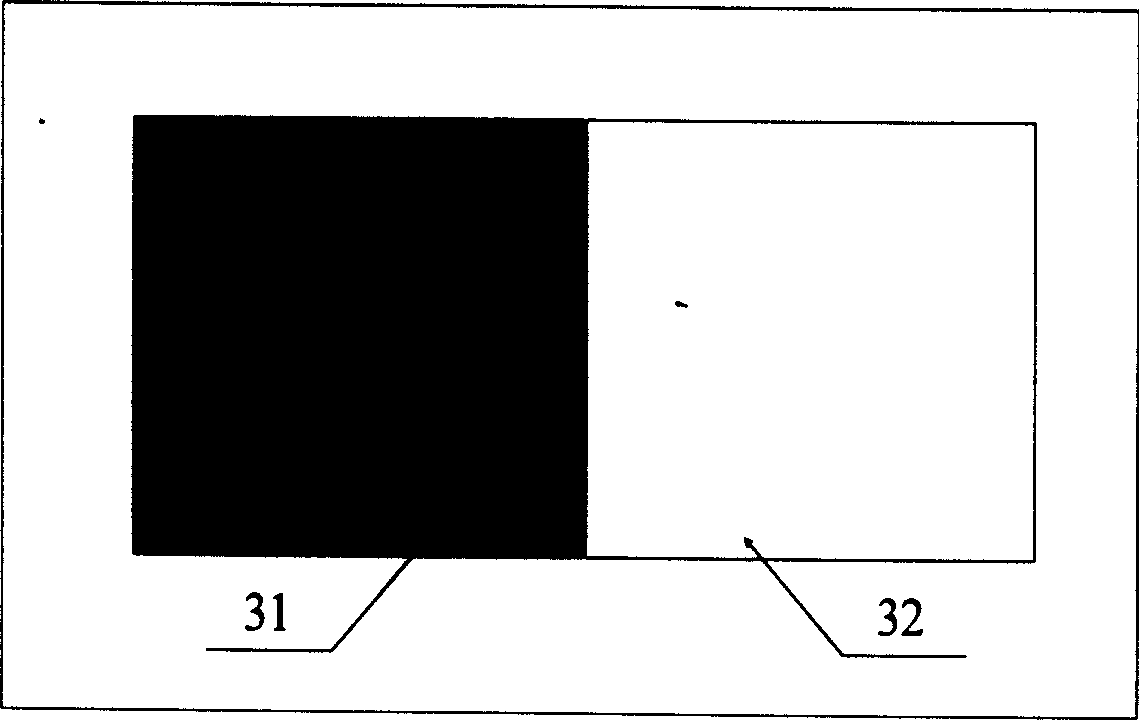

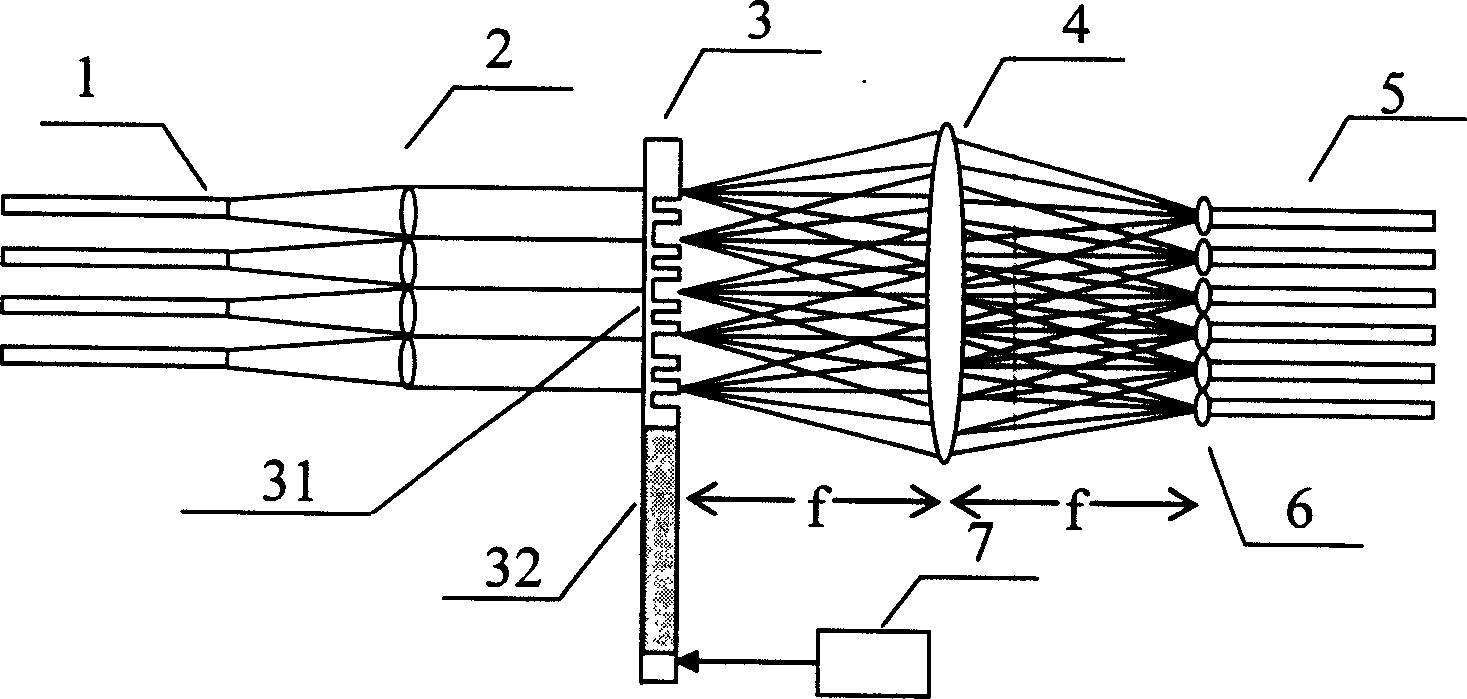

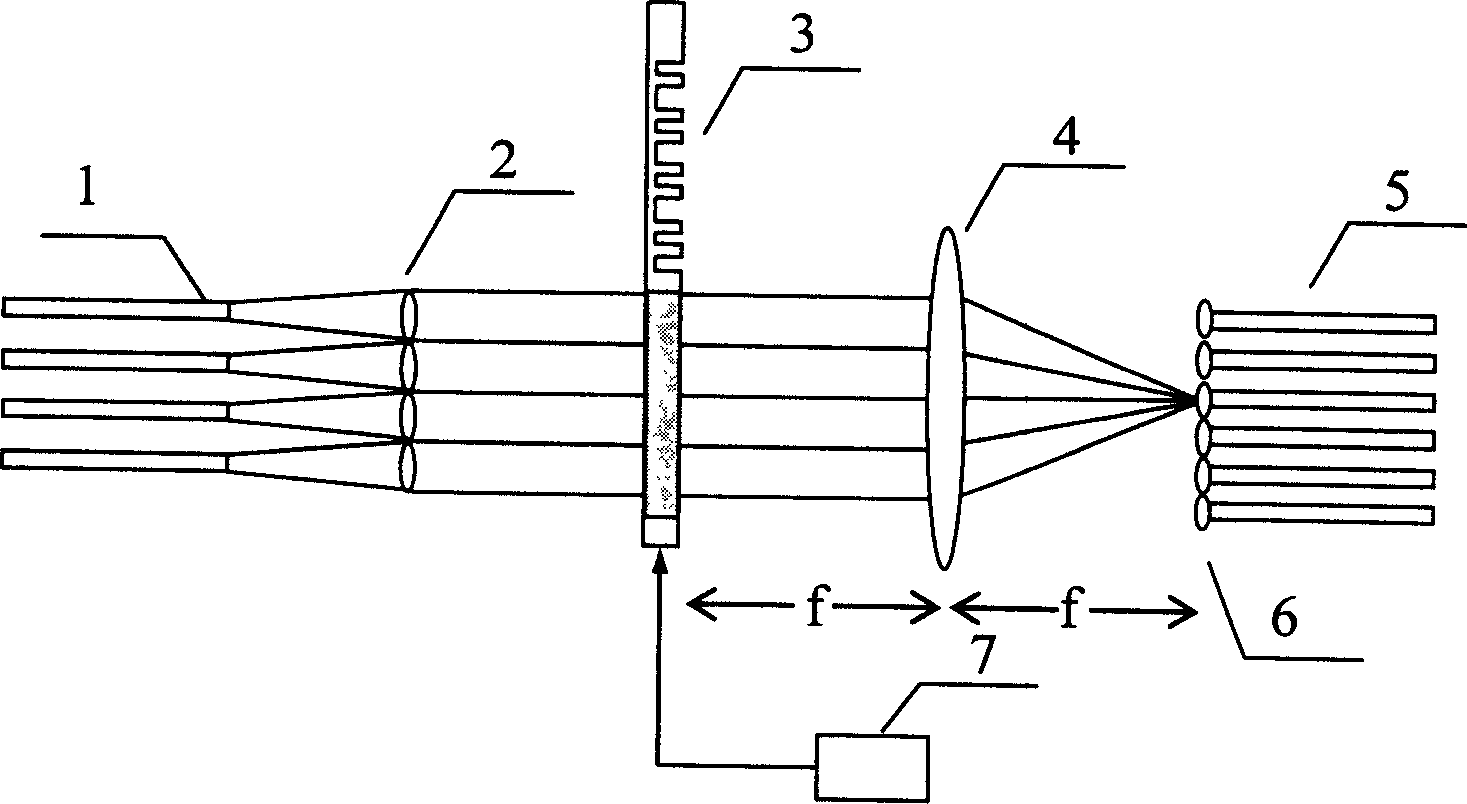

Dynamic light coupler

InactiveCN1584646AImplement beam splittingRealize dynamic conversionCoupling light guidesGratingNumerical aperture

A dynamic light coupler consists of input optical fibre set, collimation lens set, Daman grating phase plate, convergent lens and output optical fibre set in sequence on one light path. It is featured as setting input optical fibre set on front focal plane of collimation lens, phase plate at back focal plane, output optical fibre set on back focal plane of convergent lens; overlapping convergent lens front focal plane to back focal plane of collimation lens set.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

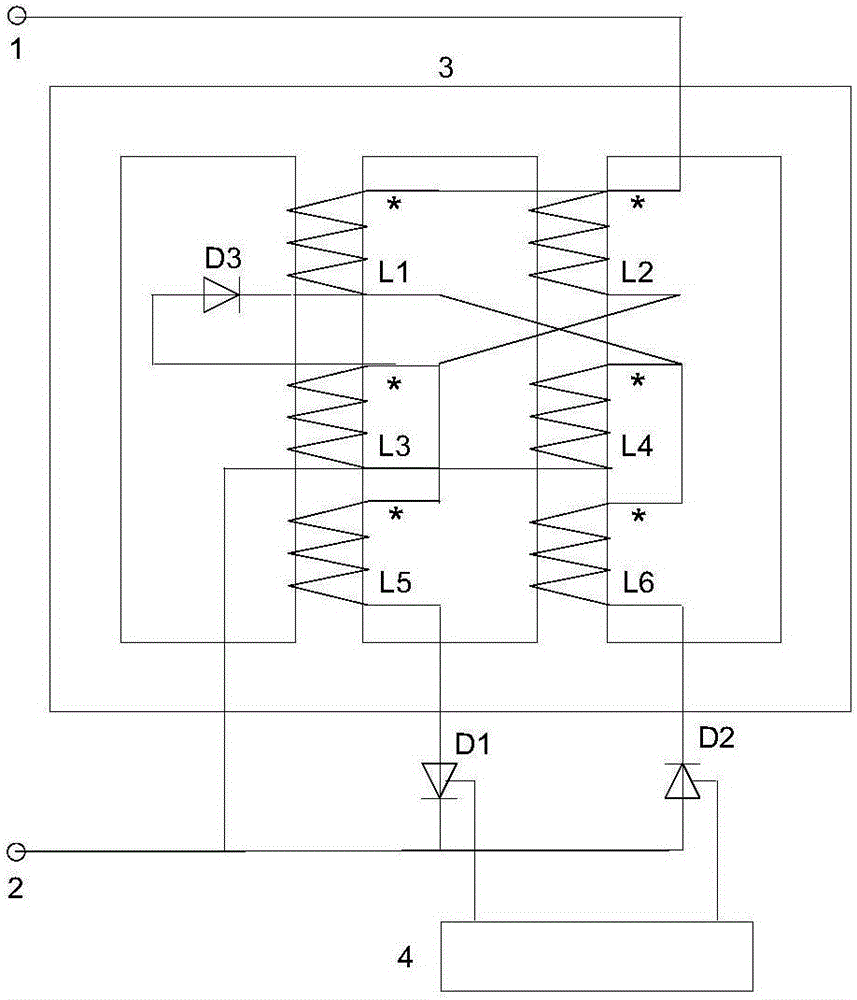

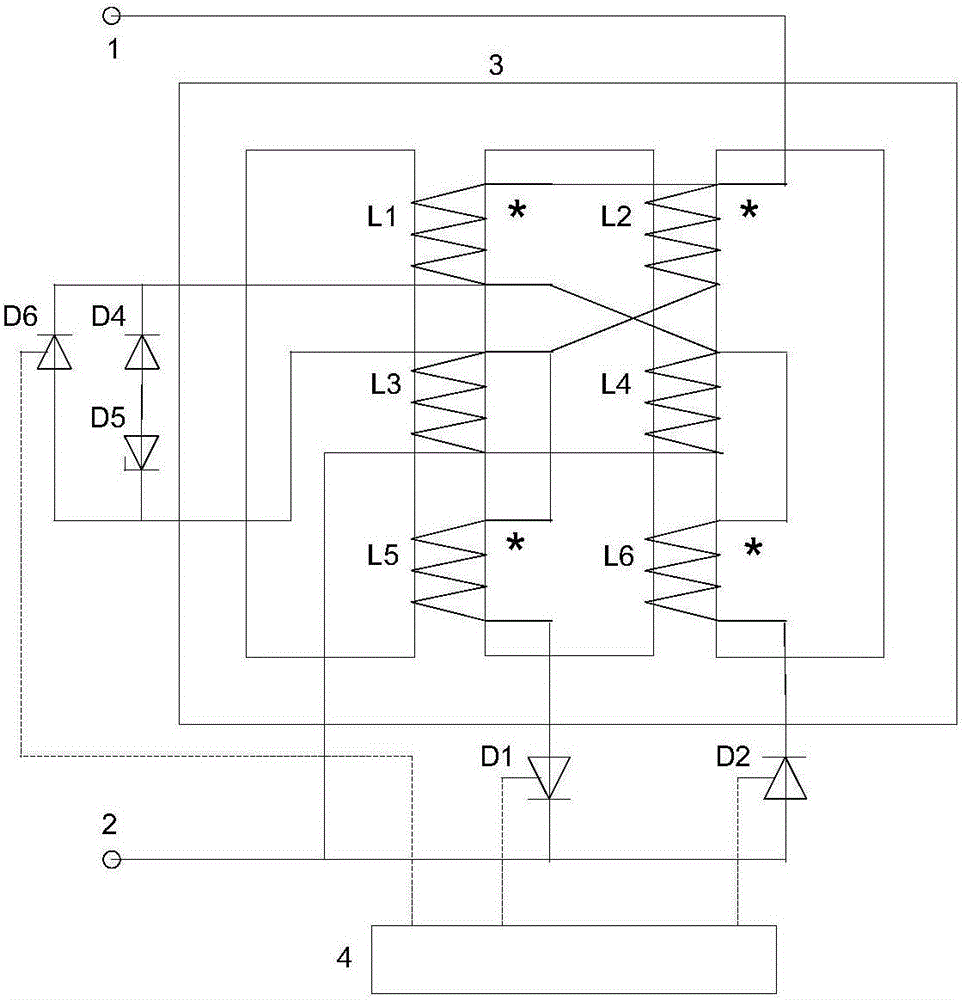

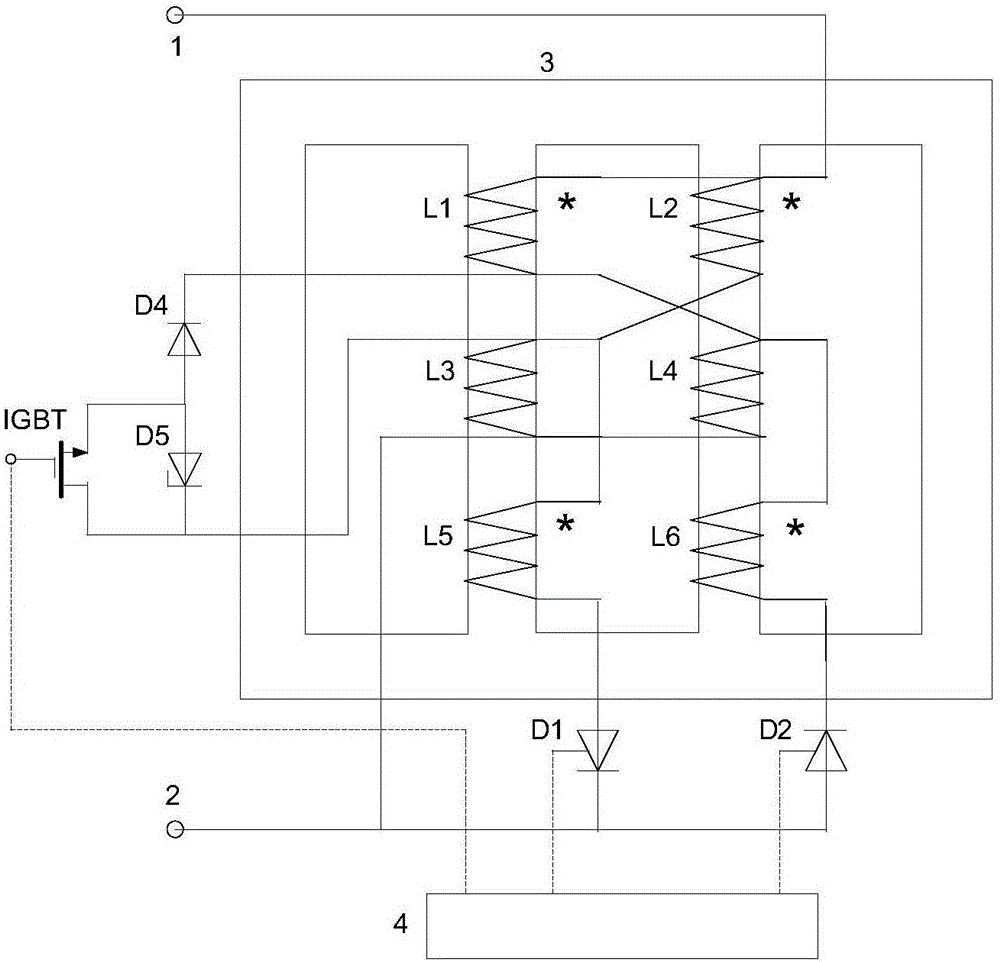

Fast response saturation reactor

ActiveCN106026813AFast energy consumptionImprove energy consumptionConversion without intermediate conversion to dcContinuously variable inductances/transformersZener diodeContinuous current

The invention relates to a fast response saturation reactor which comprises a saturation reactor and a continuous current and demagnetization circuit which substitutes the original continuous current diode of the saturation reactor. The continuous current and demagnetization circuit comprises a thyristor D6, a diode D4, a high power zener diode D5. The diode D4 and the high power zener diode D5 are in reverse series connection and then are in parallel connection with the thyristor D6. The diode D4 and the thyristor D6 are in the same direction. The control terminal of the thyristor D6 is controlled by a control module, and high power zener diode D5 consumes energy in a fastest way in a condition of not exceeding stable voltage.

Owner:李晓明 +1

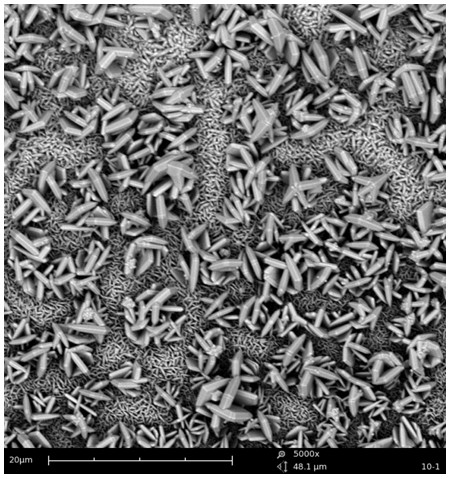

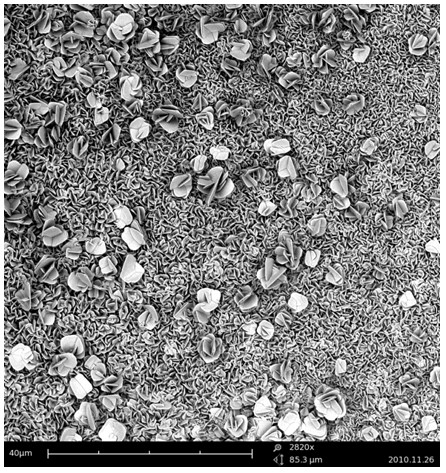

Preparation method of three-dimensional TiO2 crystal film

InactiveCN102418089AEasy to manufactureStrong visible fluorescenceChemical vapor deposition coatingPlasma jetFluorescence

The invention provides a preparation method of a three-dimensional TiO2 crystal film. The method comprises steps of: letting discharge gas in medium block discharge plasma reactor by employing a normal pressure low temperature radio frequency medium block glow discharge method; the discharge gas discharging to generate plasma jet by radio frequency alternating current; sending a precursor and carrying gas to a plasma zone to carry out reaction and precipitate on a substrate, so as to obtain the three-dimensional TiO2 crystal film. The method is characterized in that the precipitate is inner glow precipitate. The TiO2 obtained by the invention has a large proportion of {001} active surface and a unique three-dimensional structure forming by intersecting growth of a {101} surface, a {001} surface and a {101} surface; and the titanium dioxide film irradiates strong visible fluorescence by excitation of laser of 325 nm wavelength at room temperature.

Owner:DONGHUA UNIV

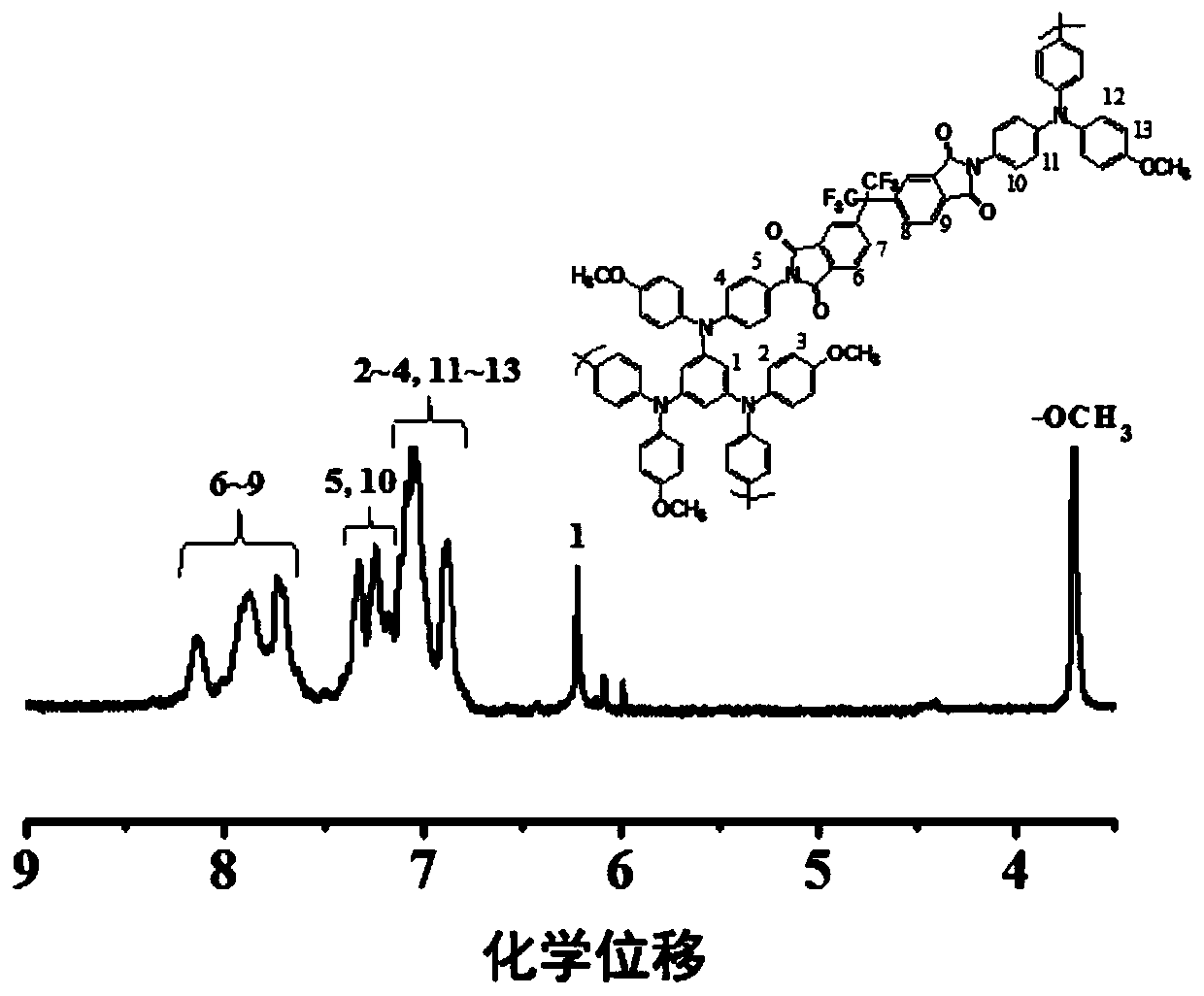

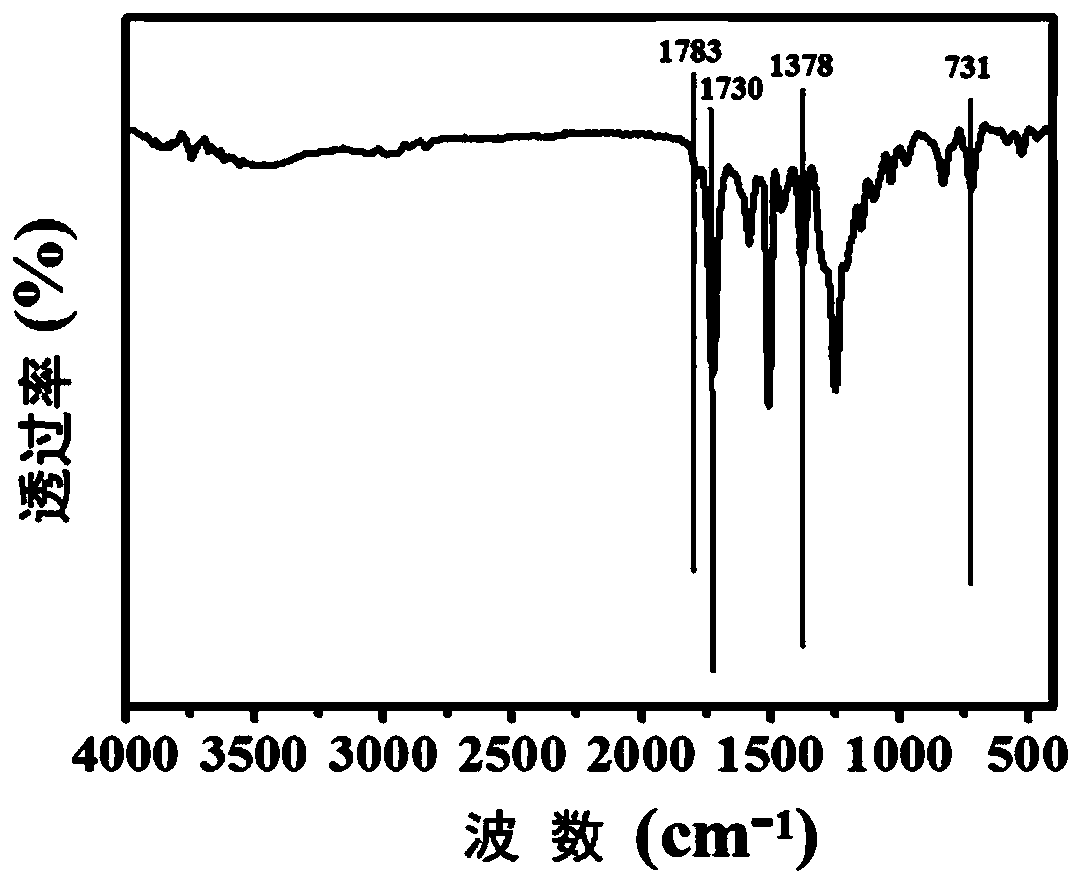

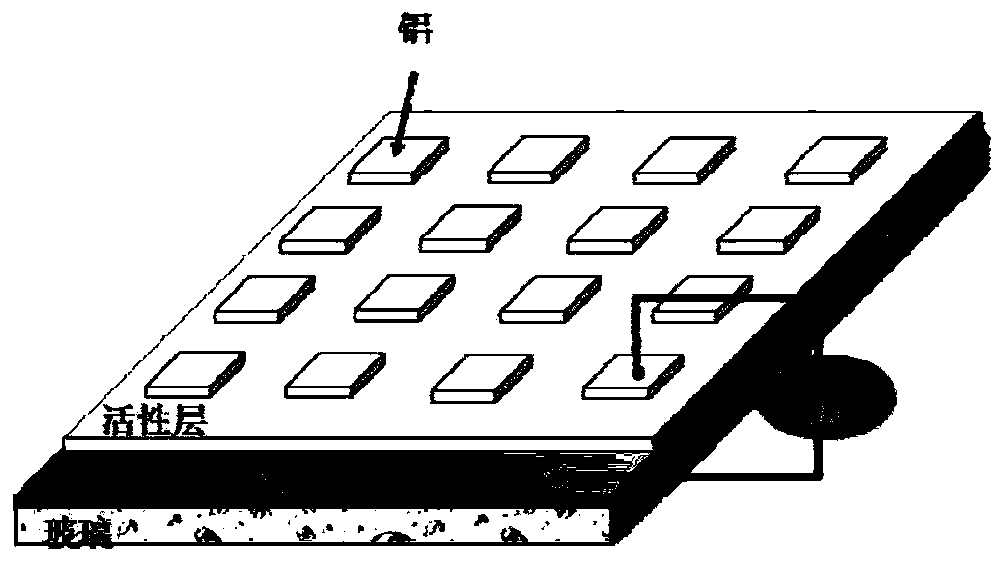

Electrochromism/electricity storage bifunctional material and preparation method and application thereof

ActiveCN110408025AImprove performanceColor changing high contrastSolid-state devicesSemiconductor/solid-state device manufacturingSolubilityElectricity

The invention provides an electrochromism / electricity storage bifunctional material and a preparation method and application thereof, and belongs to the technical field of polymer materials. The structural formula of the bifunctional material is shown in the description. The preparation method comprises the steps of mixing of diamine and dianhydride, a polymerization reaction, copolymerization with triamine, final dehydration and the like. The electrochromism / electricity storage bifunction material can be used for preparing an electrical storage device or an electrochromic device. The bifunctional material has the advantages that the preparation method is simple, the solubility is good, the chemical stability and thermal stability are high, the electrochromic device prepared by the material has excellent performance, the color change contrast is high, the coloring efficiency is good, the response speed is high, and three kinds of color changes are achieved; the prepared electrical storage device has low energy consumption, accurate information reading and good information stability.

Owner:CHANGCHUN UNIV OF TECH

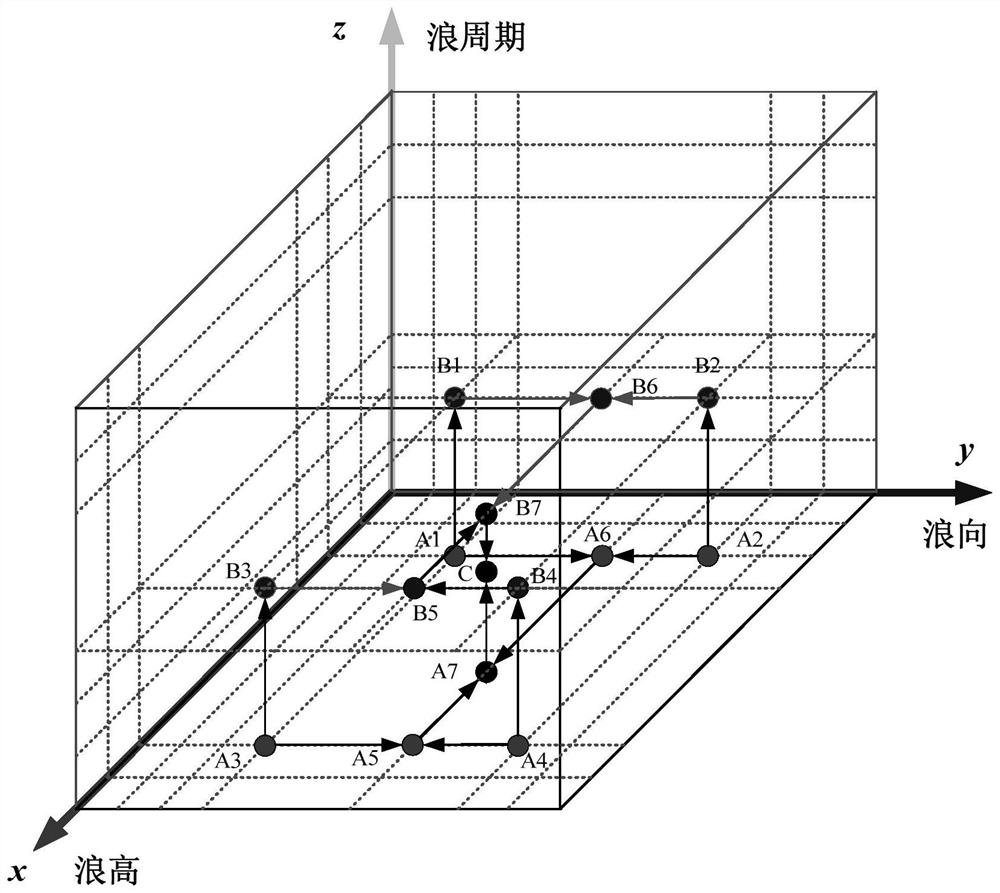

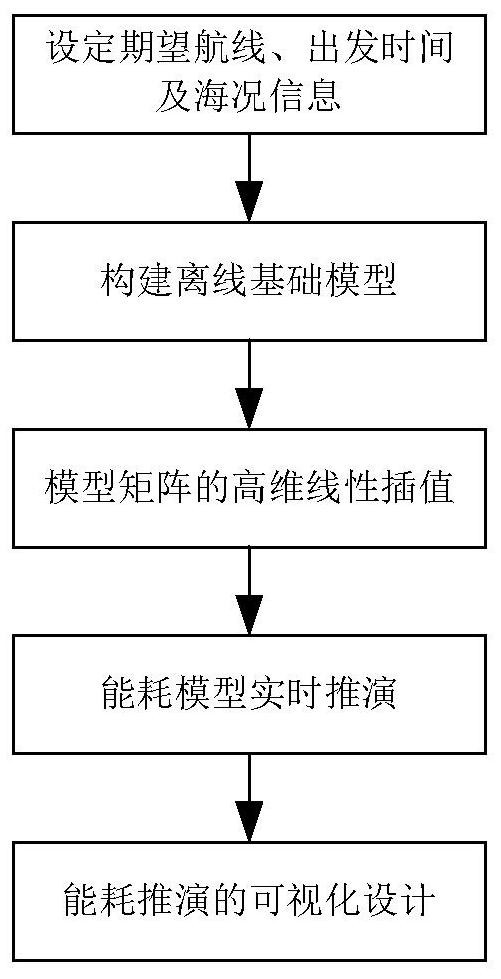

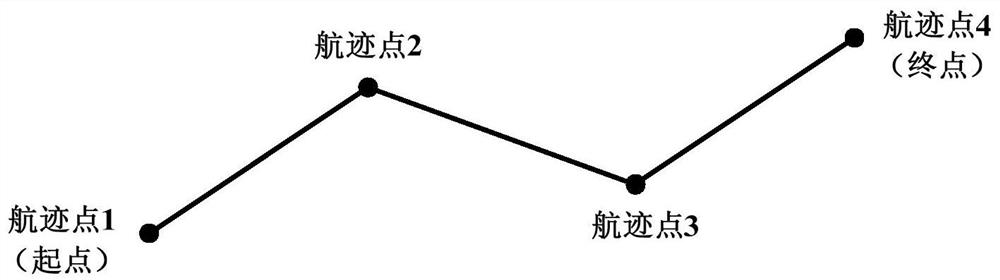

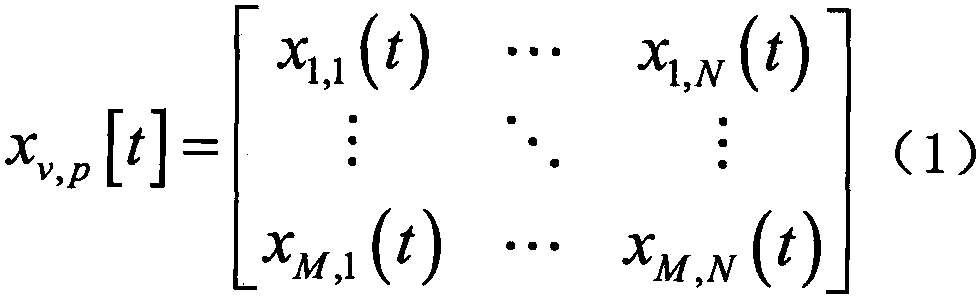

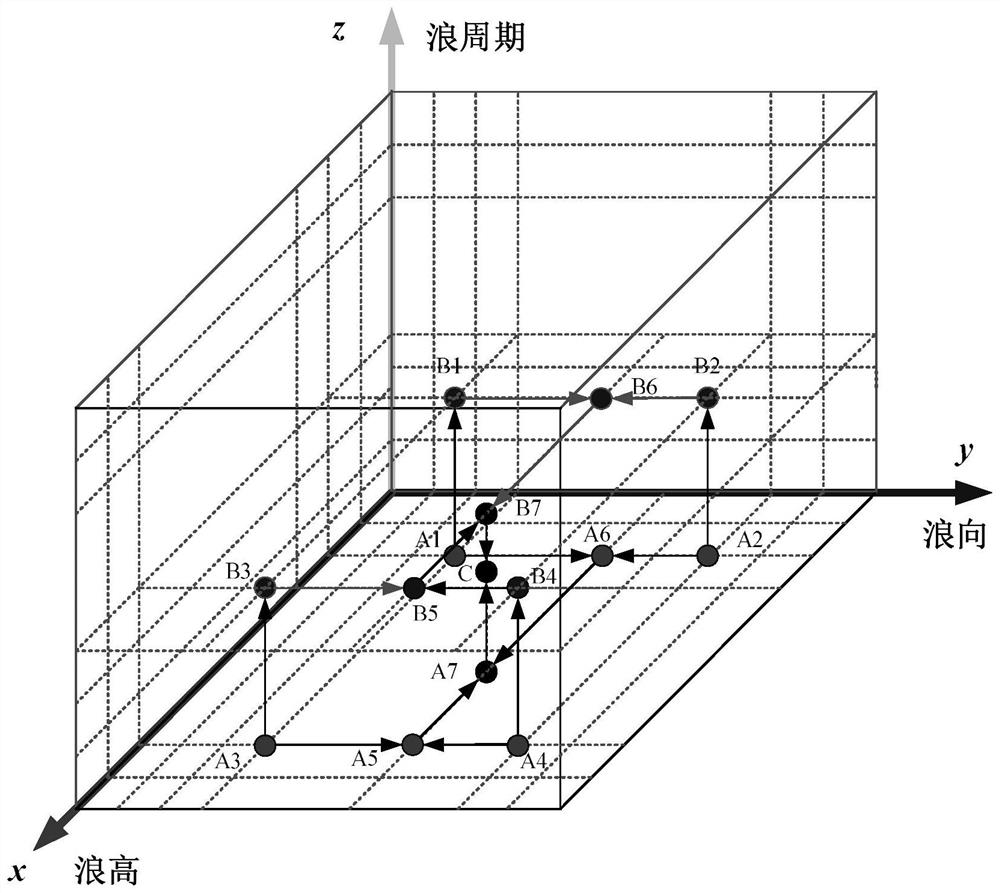

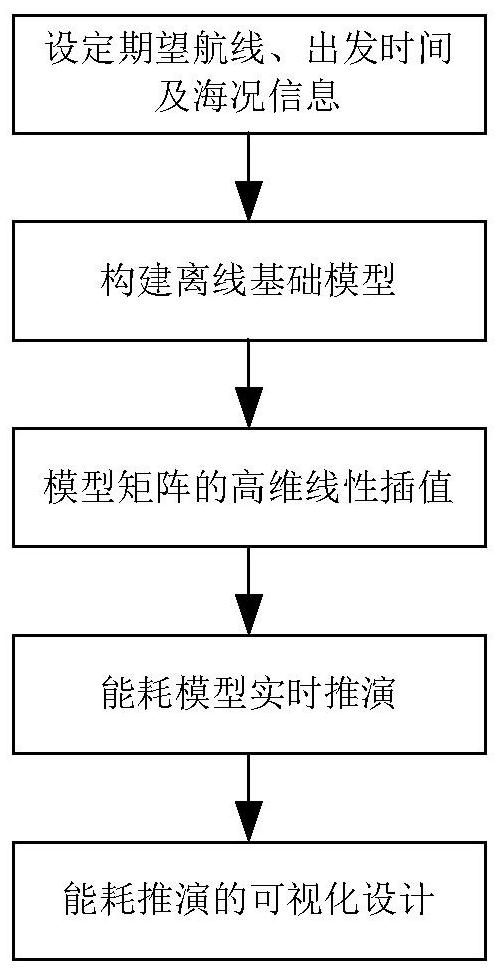

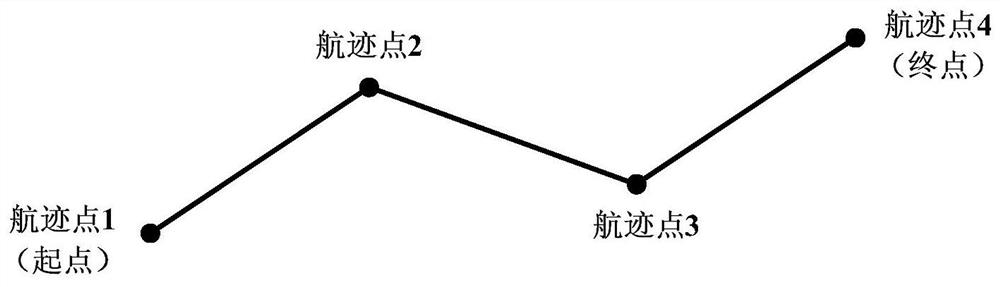

Ship energy consumption prediction method based on data driving

ActiveCN112550592AFast energy consumptionFor quick replacementGeometric CADVessel designingMarine engineeringPredictive methods

The invention belongs to the technical field of ship energy consumption prediction, and particularly relates to a ship energy consumption prediction method based on data driving. The method comprisesthe following steps: acquiring an expected ship route, departure time and sea condition information of a ship; constructing an offline basic model which comprises a ship-to-water steady-state navigational speed model, an engine power model and an engine oil consumption model; performing high-dimensional linear interpolation on discrete grid matrixes of the ship to the water steady-state navigationspeed model and the engine power model; carrying out one-dimensional linear interpolation on the discrete grid matrix of the engine oil consumption model; and deducing a ship energy consumption modelin real time. According to the method, a set of data matrix is used as support, rapid calculation of the energy consumption of the long route of the ship is achieved, and the data matrix in the method can be obtained in various modes and is convenient and rapid to replace. According to the method, the thought of an original ship dynamics simulation model is not influenced, and the method and thedynamics simulation model coexist in an actual simulation verification and evaluation system and are respectively responsible for different types of simulation calculation.

Owner:HARBIN ENG UNIV

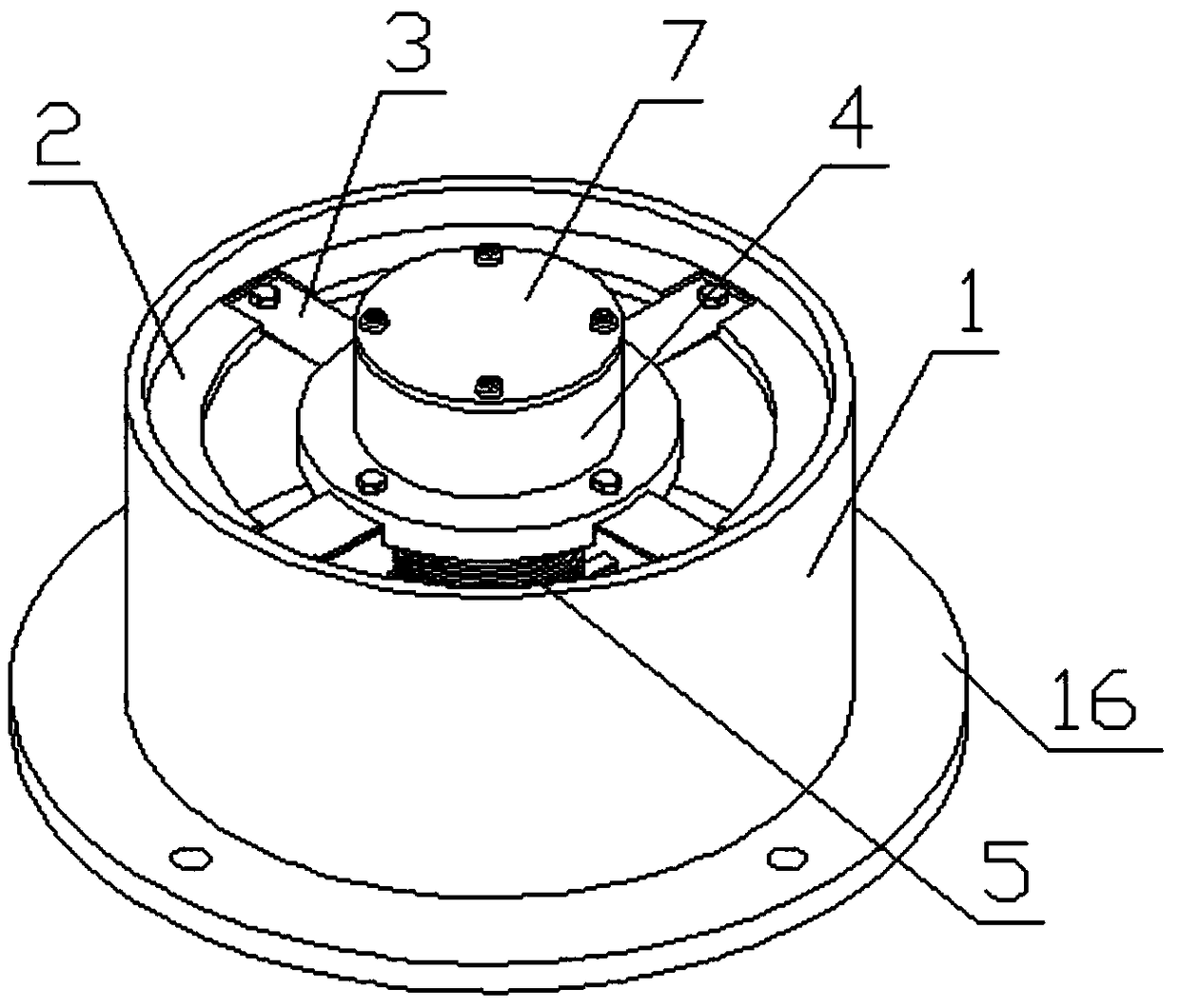

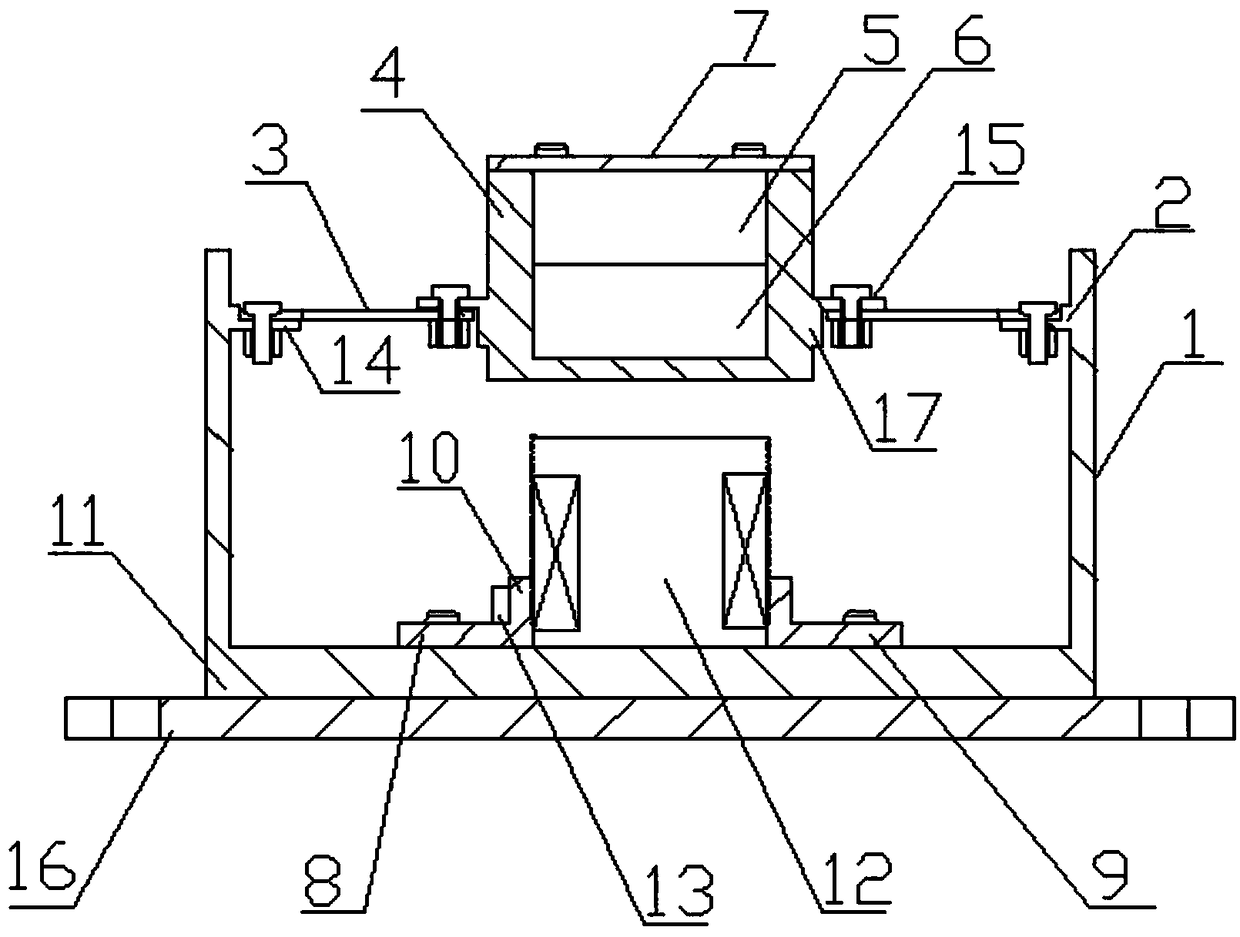

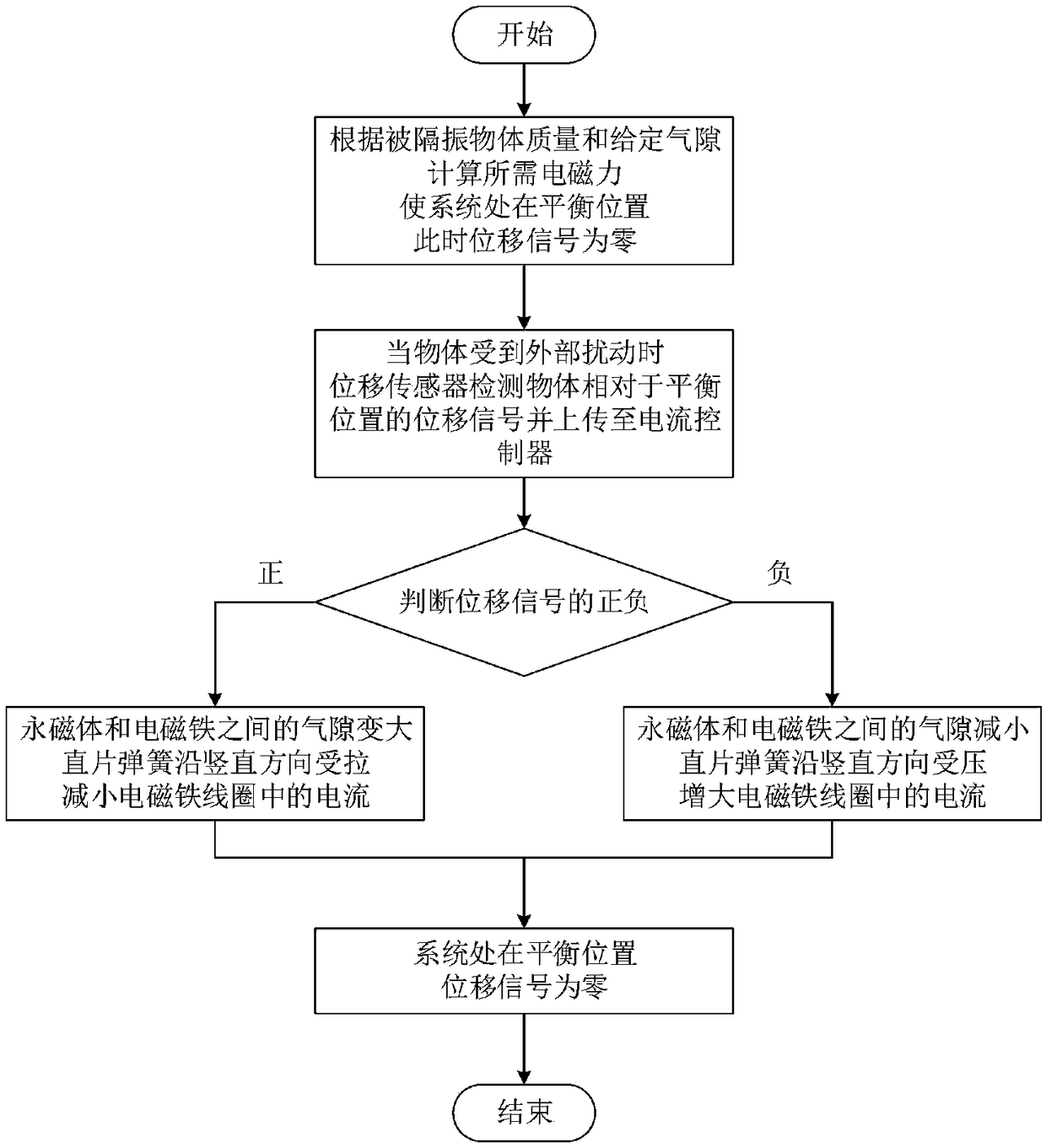

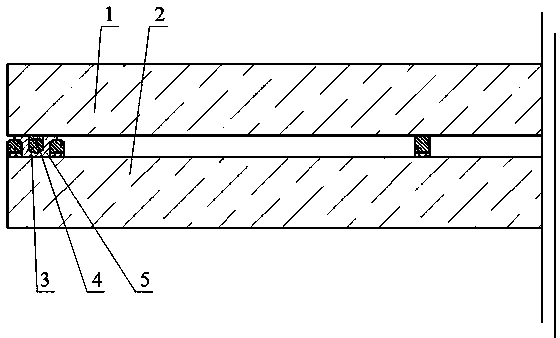

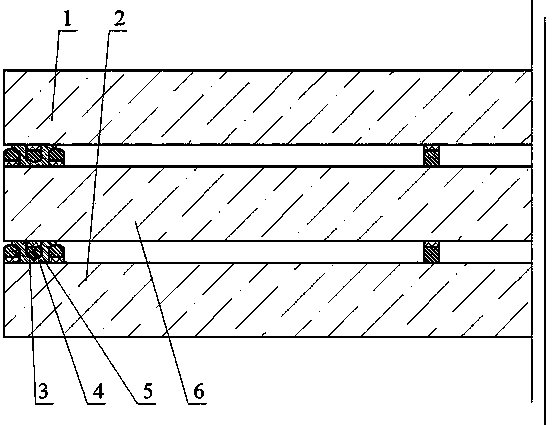

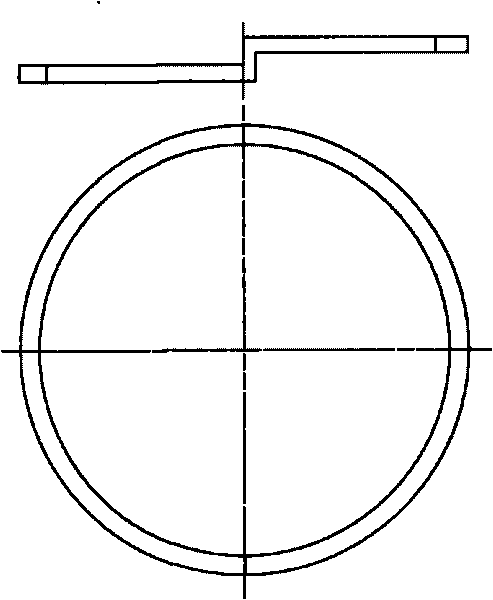

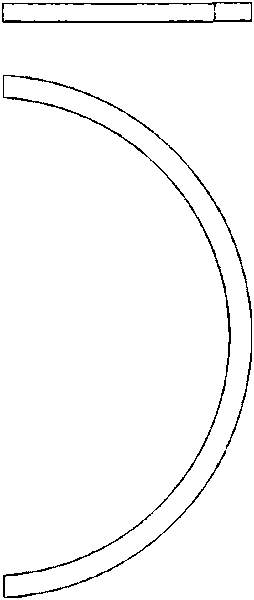

Semi-active vibration isolation device

The invention discloses a semi-active vibration isolation device. The bottom of a barrel-shaped shell body is sealed by a bottom plate, an annular connection plate is arranged at a position close to an upper-end opening, in the barrel-shaped shell body, and the outer circumference of the annular connection plate is fixedly connected with the inner wall of the barrel-shaped shell body; a carrying table is arranged at the inner center of the annular connection plate; the carrying table is connected with the annular connection plate through a plurality of straight-sheet springs; a permanent magnet is assembled in the carrying table; an electromagnet and the permanent magnet are correspondingly and fixedly installed on the bottom plate, an air gap is reserved between the electromagnet and thepermanent magnet, and the upper end of the electromagnet has the same magnetic pole as the lower end of the permanent magnet after being electrified; and a displacement monitoring control system is composed of a displacement sensor, a signal converter, a current controller and an intelligent control terminal, the displacement sensor is fixedly arranged below the carrying table, the displacement sensor is connected with an input end of the intelligent control terminal through the signal converter, and an output end of the intelligent control terminal is connected with the electromagnet throughthe current controller. The device is simple and compact in structure, easy to control, and good in vibration isolation effect.

Owner:CHINA UNIV OF MINING & TECH

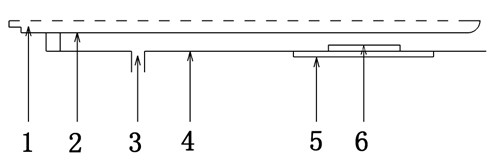

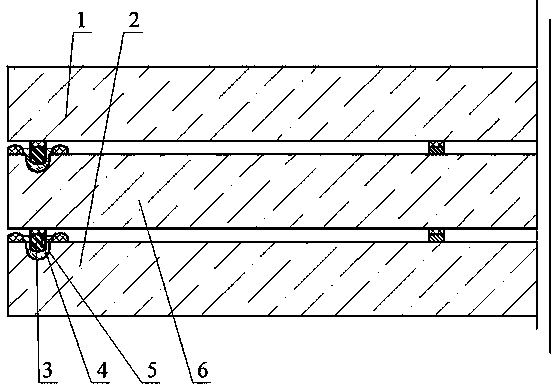

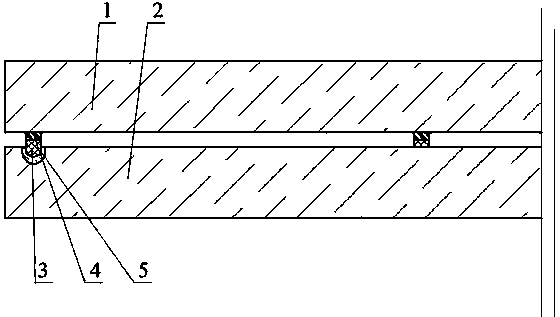

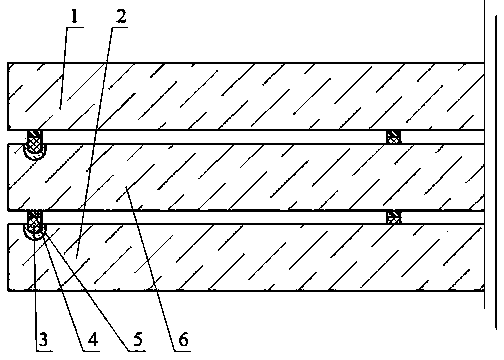

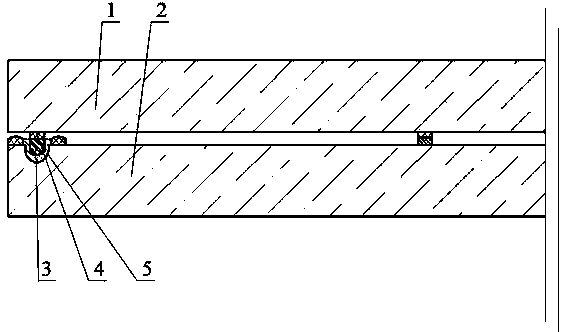

Glass-solder microwave-welded planar tempered vacuum glass edge-sealed by using bar frames

InactiveCN104291597AReduce stressReduce the breakage rate of glassGlass reforming apparatusGlass productionElastomerMicrowave

The invention relates to glass-solder microwave-welded planar tempered vacuum glass edge-sealed by using bar frames. The glass is characterized in that upper glass and lower glass are common tempered glass or plated tempered glass. Edge-sealing bar frames are provided at the peripheries of the upper glass and lower glass. The peripheries of the upper and lower glass are welded together with microwaves by using a glass solder. A sealed vacuum layer is formed between the upper glass and lower glass. One or two layers of supporters are provided in the vacuum layer. The edge-sealing bar frames and the supporters are composed of tempered glass ink and a high-polymer. The high-polymer is first prepared into a pre-polymer. When the glass is tempered, the pre-polymer is prepared on the glass or on the tempered glass ink. The pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapt to the changes in the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum. The method provided by the invention is suitable for mechanized and automated productions. With the method, mass productions of high-performance and low-cost tempered vacuum glass can be realized.

Owner:戴长虹

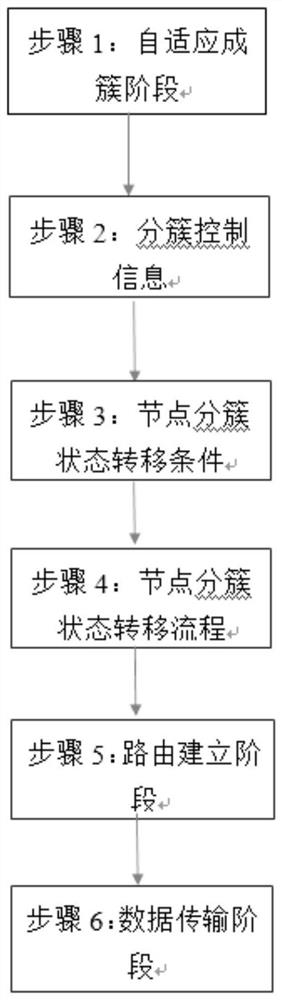

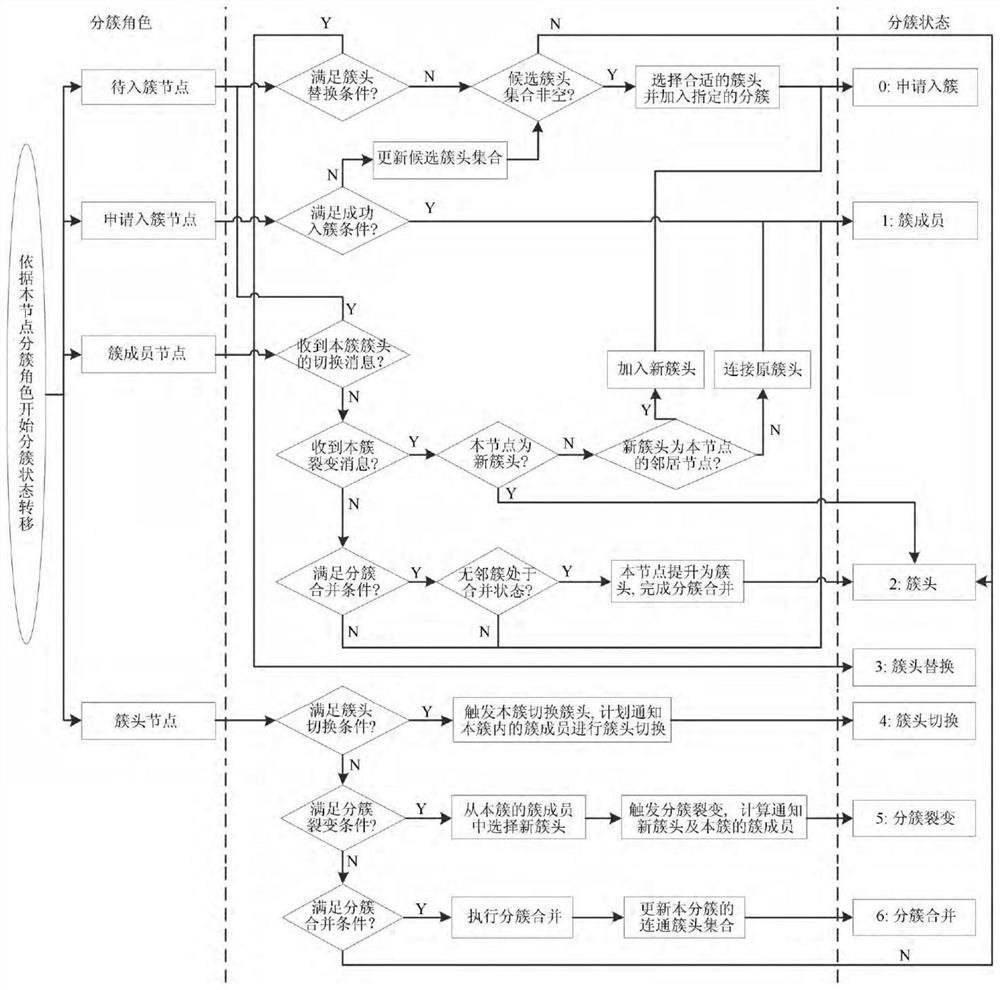

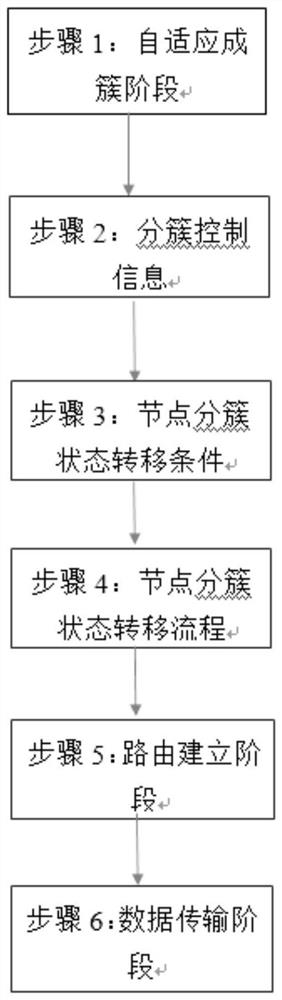

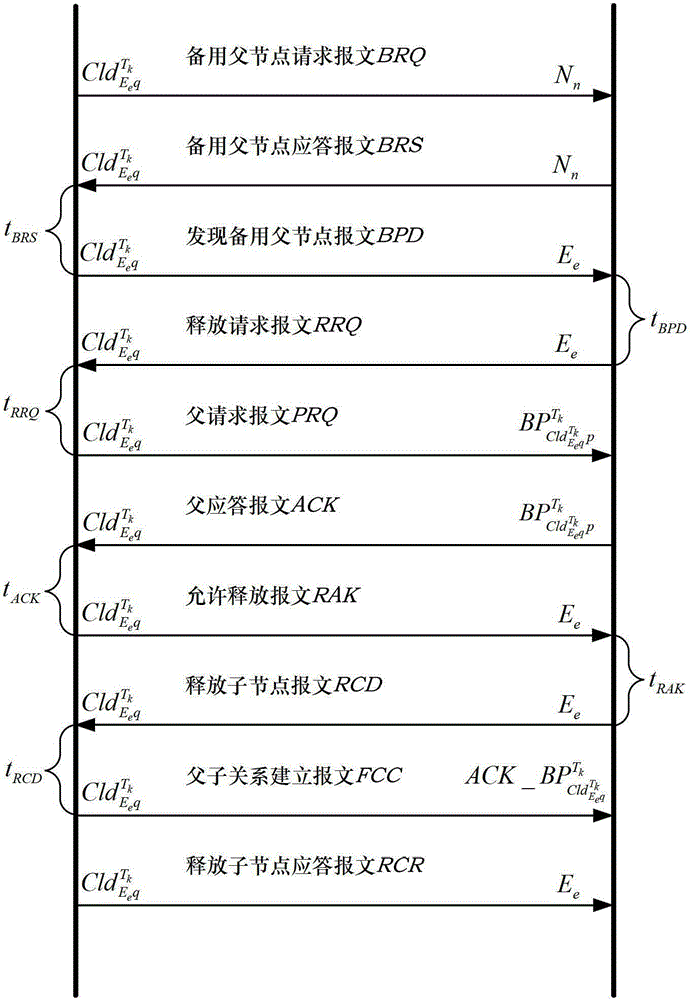

Sensor data acquisition method based on adaptive clustering network

PendingCN113965948AAdaptableScale upNetwork topologiesHigh level techniquesInformation controlData acquisition

The invention discloses a sensor data acquisition method based on an adaptive clustering network. The method comprises the following steps that step 1, network nodes are interactively triggered by utilizing clustering control information to finish adaptive clustering; step 2, clustering information control is performed, including cluster head weight of each node, a clustering state, a destination node ID, a connected cluster head set and a neighbor list; step 3, in the multi-hop self-organizing network, after any node receives the clustering control information of the neighbor node, a self-learning function module extracts different states of the node for analysis; 4, in the multi-hop self-organizing network, network nodes transfer conditions according to clustering roles and clustering states of the nodes; step 5, after the cluster is established, the Sink propagates the Rup in the current round of virtual backbone network in a transmission range outside the cluster until all cluster heads have levels; the member nodes in the cluster send monitoring information to the cluster head in the TDMA time slot, and the member nodes detect the channel after sending the information. According to the method, the average routing overhead of the whole network can be quickly converged.

Owner:辽宁铭钉科技有限公司

Method for preparing enzyme by using lemons and galangal as main materials

InactiveCN106418498AIncrease profitReduce the risk of slow salesFood ingredient as flavour affecting agentVinegar preparationRoom temperatureMusa basjoo

The invention discloses a method for preparing enzyme by using lemons and galangal as main materials. The method comprises the specific steps that 1, 35-45 parts of lemons, 15-20 parts of galangal, 2-5 parts of turmeric, 8-15 parts of rhizoma zedoariae, 8-15 parts of grapefruit and 8-15 parts of musa basjoo are selected and cleaned for usage; 2, the lemons are firstly extruded to make peels broken and expose pulp, then the galangal, the turmeric, the rhizoma zedoariae, the grapefruit and the musa basjoo are cut into galangal slices, turmeric slices, rhizoma zedoariae slices, grapefruit slices and musa basjoo slices which are 0.3-2 cm in thickness, and then the materials are mixed evenly to obtain a mixture; 3, the mixture is put in a sealed container, honey and water are added for even mixing, then the mixture is put in a room, sealed fermentation is performed under room temperature condition, one time of stirring is performed every day in previous 5-7 days, later one time of stirring is performed every 7 days, the cycle is kept for one month, then sealing is performed, and fermentation continues for 6 months. The enzyme prepared by adopting the method retains the effects of original foods, is rich in probiotics and nutrition and long in shelf life and has a good taste.

Owner:唐妙红

Method and device for sensible heat recovery of quenched dry crushing molten blast furnace slag

ActiveCN103820588BShorten the heat transfer solidification timeAchieve zero usageMetal recyclingProcess efficiency improvementRecovery methodSlag

Owner:SINOSTEEL ANSHAN RES INST OF THERMO ENERGY CO LTD

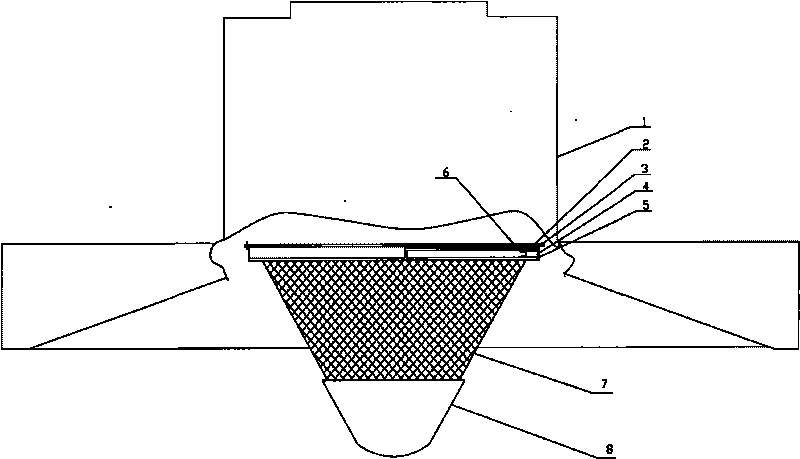

Heating oil-collecting mesh hood of range hood

InactiveCN101701727AGood liquefaction effectAvoid passingDomestic stoves or rangesLighting and heating apparatusHeating oilInsulation layer

The invention discloses a heating oil-collecting mesh hood of a range hood, comprising an oil-collecting mesh (7) and a heater mounted on the oil-collecting mesh (7). The heater comprises a heat-conducting plate, a heating block (4) and a heater binding post (6), wherein the heating block (4) is connected with the heater binding post (6), and the heat-conducting plate which is mounted on the oil-collecting mesh (7), is provided with a heat-insulating pad (2) and comprises an upper heat-conducting plate (3) and a lower heat-conducting plate (5); both heat-conducting plates are connected with the heating block (4) and mounted above the oil-collecting mesh (7); and the heating block (4) is wrapped by an insulation layer. Oil dirt stuck to the oil-collecting mesh hood is heated and liquefied before flowing to an oil-collecting cup so that oil is thoroughly cleaned and the non-cleaning effect is achieved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

Cloud data center resource allocation algorithm based on cluster framework

ActiveCN109101315ADistribute quicklyHigh speedResource allocationEnergy efficient computingResource utilizationAllocation algorithm

The invention relates to a cloud data center resource allocation algorithm based on a packet cluster framework, which establishes a packet cluster framework and realizes an improved Hungarian algorithm of the packet cluster framework. The invention realizes resource sharing. According to the proposed package cluster structure, the virtual machine resources can be easily shared with each other. When part of the virtual machine resources are idle, this part of the computing resources can be released to other virtual machines that need resources; the other is the multi-objective optimization of the data center. Through the cluster framework, the measurement and monitoring of the server are clearer, and the modeling and optimization of the cloud computing cost, energy consumption, resource utilization and other objectives are simpler. The third is the fine management of virtual machine and server: the virtual machine placement strategy transforms the flat mapping relationship between virtual machine and physical machine into the mapping relationship between package and cluster, which further degrades the mapping problem between virtual machine and physical machine, and improves the allocation efficiency and speed of virtual machine.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

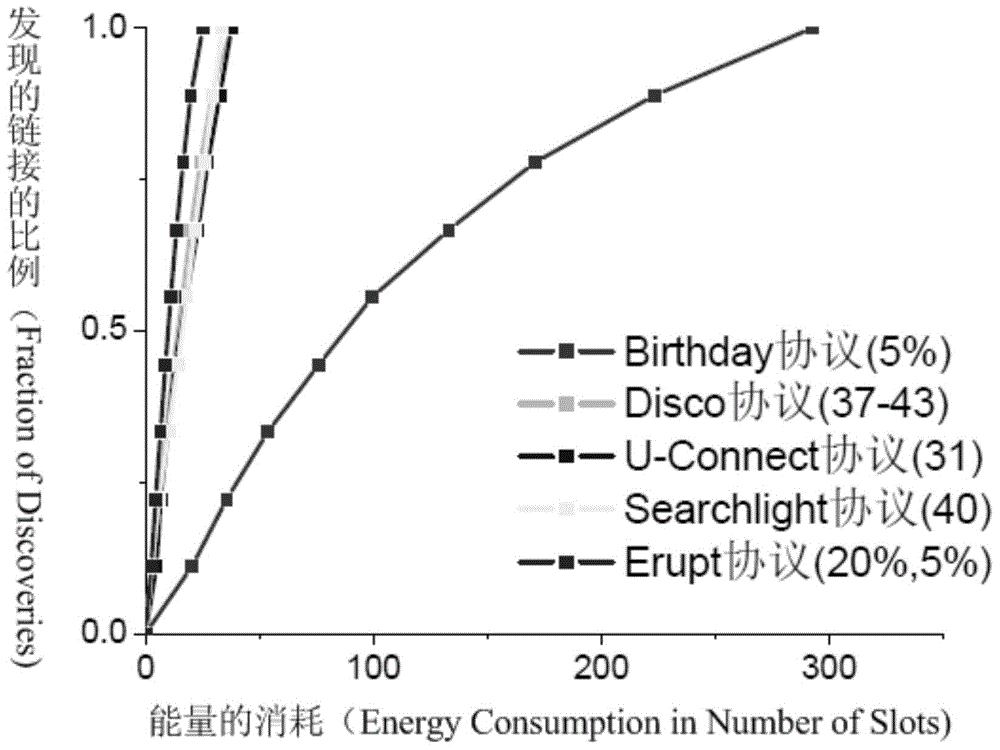

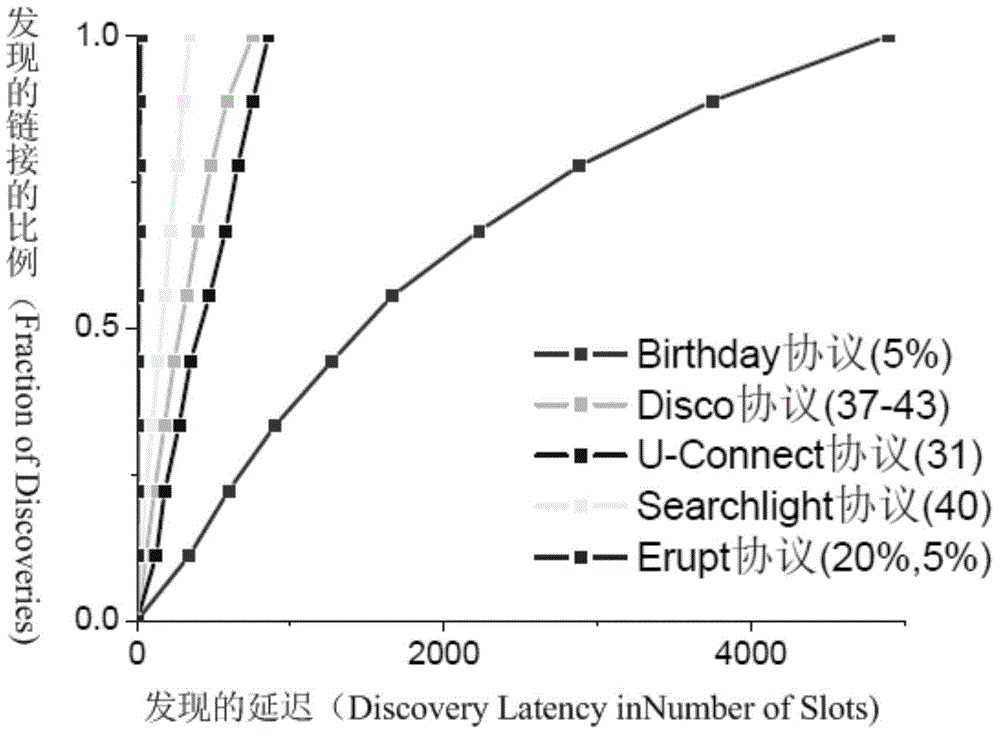

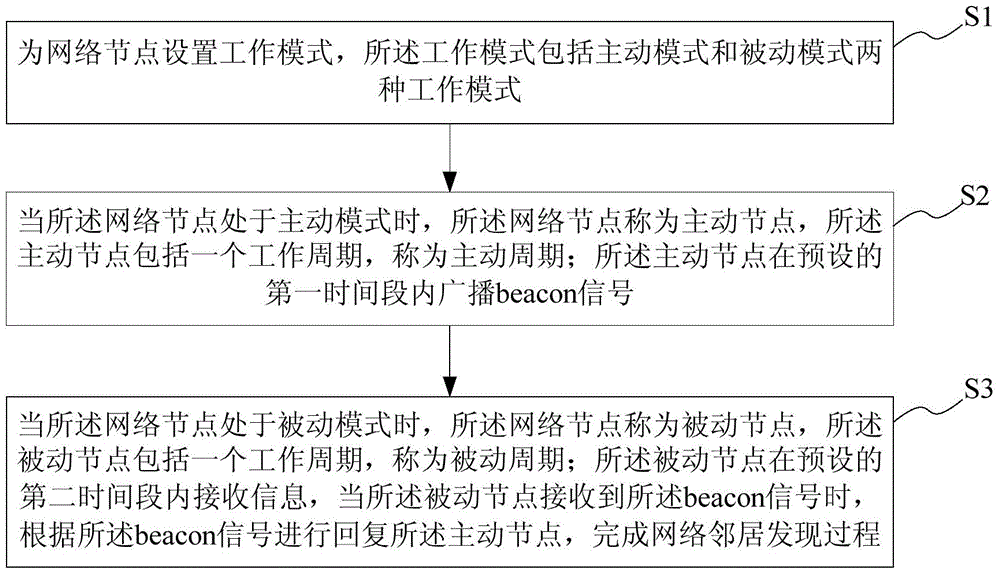

Network neighbor discovery method and system

InactiveCN105792164AImprove discovery efficiencyQuick discoveryAssess restrictionNetwork data managementActive modeReal-time computing

The invention provides a network neighbor discovery method and system. The network neighbor discovery method comprises the following steps: a working mode is set for a network node, wherein the working mode includes an active mode and a passive mode; when the network node is in the active mode, the network node is called active node, and the active node comprises a working period called active period and broadcasts a beacon signal in a preset first time interval; and when the network node is in the passive mode, the network node is called passive node, and the passive node comprises a working period called passive period, receives information in a preset second time interval, and makes a reply to the active node according to the beacon signal when the passive node receives the beacon signal in order to finish a network neighbor discovery process. Through the scheme, the network neighbor discovery efficiency of the active node can be increased on the premise of not remarkably increasing network consumed energy.

Owner:TONGJI UNIV

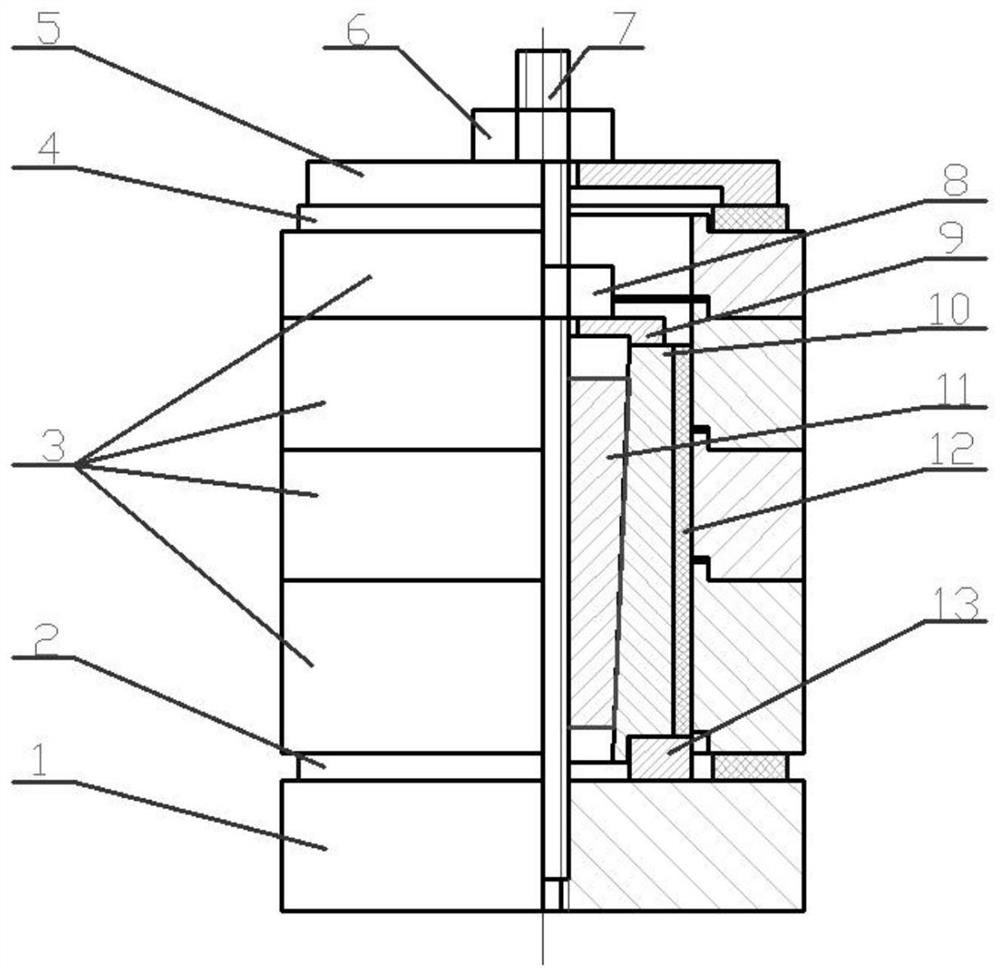

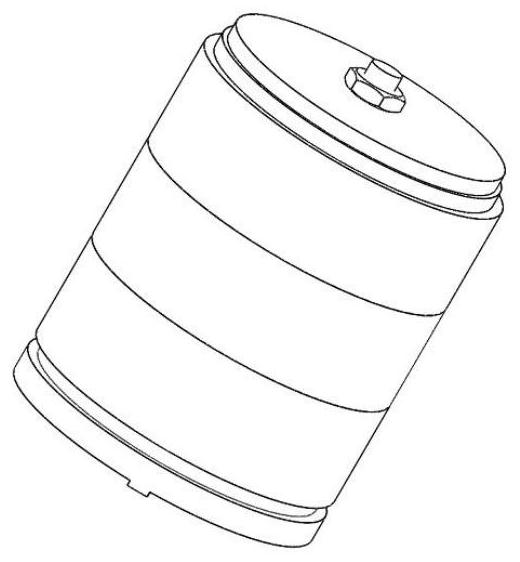

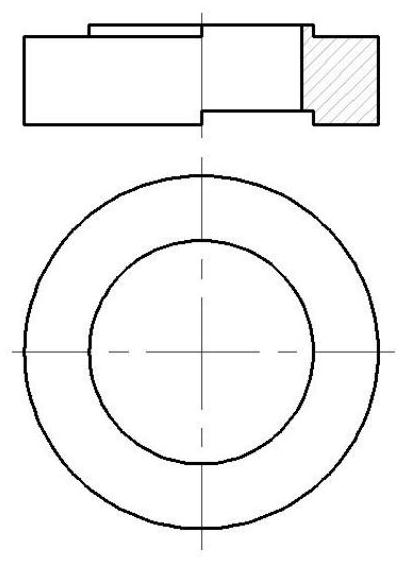

Shock absorber capable of changing damping and adjusting mass and rigidity and rigidity quantitative regulation method

ActiveCN111810567APosition vibration precise controlPrecise Control of VibrationNon-rotating vibration suppressionShock absorbersPhysicsCompressive stiffness

The invention discloses a shock absorber capable of changing damping and adjusting mass and rigidity and a rigidity quantitative regulation method. The shock absorber comprises a base, two rubber washers, a mass block, a top end cover, a nut, a screw rod, an internal end cover, a lining, a regulating stopper, a rubber sleeve and a guide rail seat. When a system vibrates, the mass block vibrates under support of the rubber washers to absorb part of energy, and the interior of each of the rubber washers vibrates to consume part of energy, so that the purpose of realizing vibration attenuation ofa main system is realized. Mass regulation of the shock absorber is realized through the number of the mass block; vibration of the external diameter of the lining is controlled through the depth screwed into the regulating stopper to adjust damping of the shock absorber; the top end nut is screwed to adjust the compressing degree of the upper and lower rubber washers; quantitative regulation ofthe shock absorber rigidity is realized according to the relationship of the compression amount and the compressing rigidity of the rubber washers, and a better damping effect is realized without an experiment. The shock absorber is simple and compact in structure, can realize quantitative regulation of rigidity and mass and is wide in applicable range.

Owner:BEIJING UNIV OF TECH

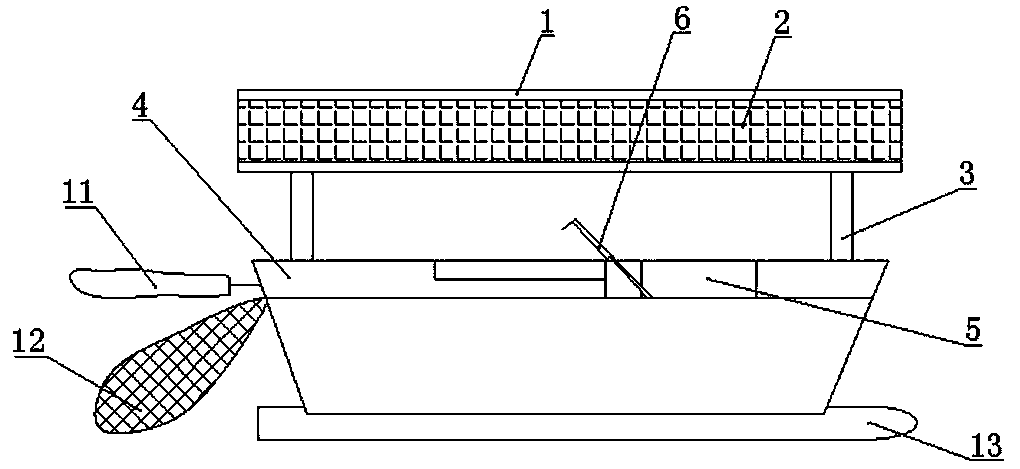

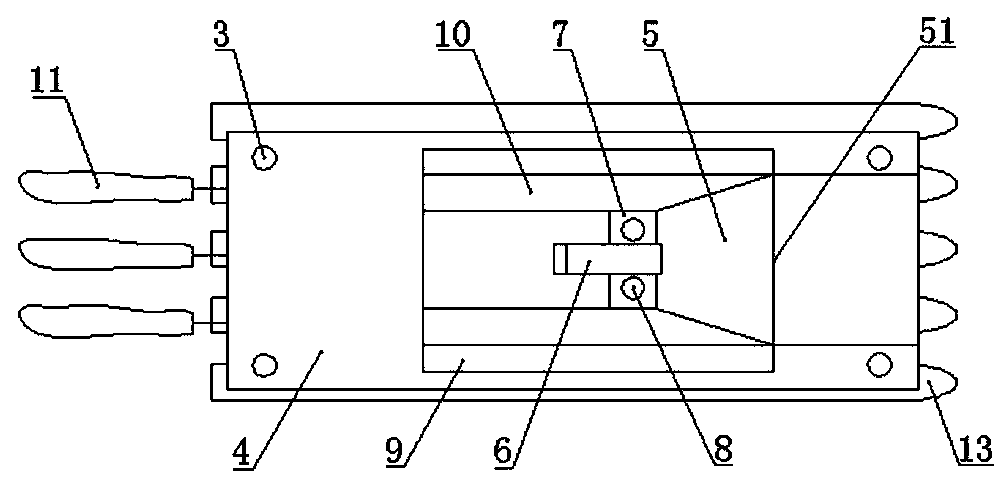

Multifunctional environment-friendly dredging device

InactiveCN108203973AReduce manufacturing costGuaranteed tightnessWater cleaningWaterborne vesselsWater dischargeWind wave

The invention discloses a multifunctional environment-friendly dredging device. The dredging device mainly comprises a ship body and a sunshade; a collecting bin is arranged on the upper part of thefront end of the ship body, a water hyacinth inlet is formed in the front end of the collecting bin, the lower end of a water hyacinth lifting and conveying device extends into the collecting bin, anda water pumping pump is further arranged in the collecting bin; a net bag for containing water hyacinth is arranged at the tail end of the ship body, a dredging net is arranged on the position, on the outer wall of the ship body, of the lower sides of the net bags, the dredging net is in a horn shape, and the bottom edge of the dredging net is an arc-shaped line; a water discharging bin and a guiding device are further arranged on the ship body; and the environment-friendly dredging device is provided with round buoys at the bottom part of the ship body, the buoys are arranged in parallel atequal intervals along the width direction of the ship body, and the lengths of the buoys are slightly larger than the length of the ship body. The dredging device has the beneficial effects that the water hyacinth can be treated while conventional water area garbage is dredged; the solar energy can be utilized so that diesel pollution can be reduced to a certain extent, and the dredging device hasthe beneficial effects of environment friendliness; and operation is stable, so that the wind wave impact can be effectively defended.

Owner:诺传百世(成都)教育科技有限公司

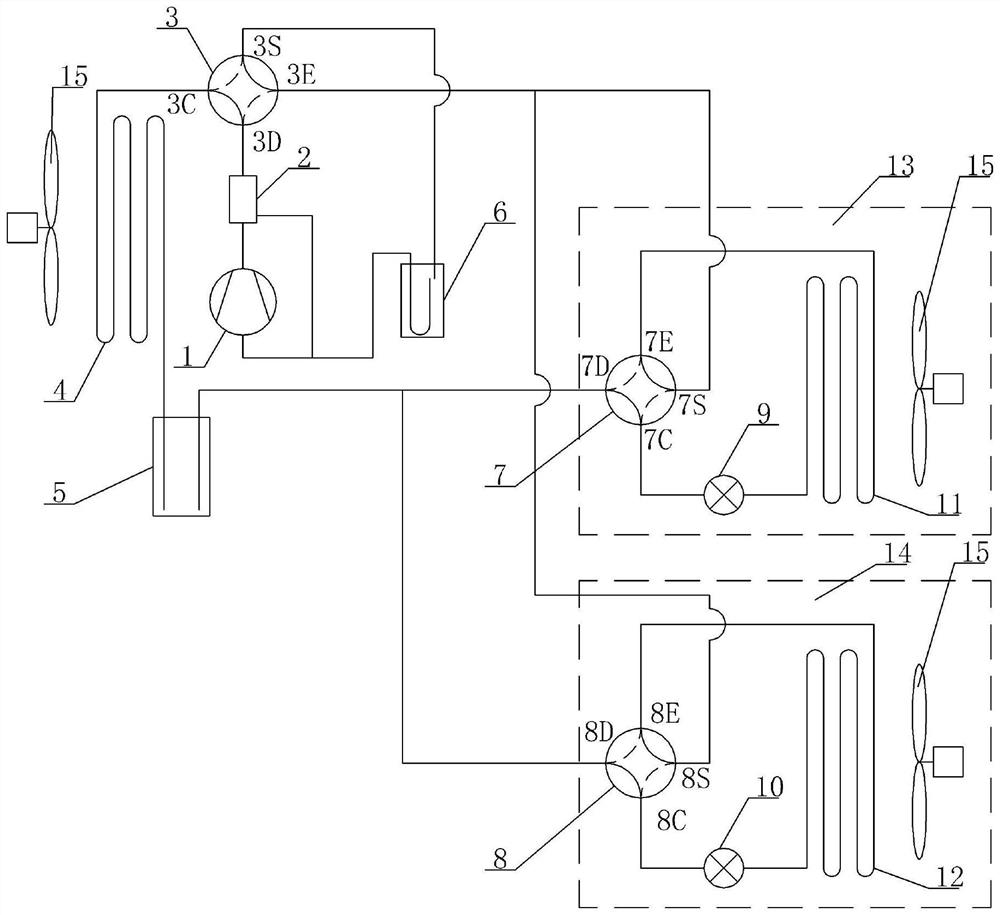

Novel one-driving-two freezing, refrigerating and drying system

PendingCN112902536AFast energy consumptionReduce energy consumptionSludge treatment by de-watering/drying/thickeningDomestic refrigeratorsFour-way valveCool storage

The invention provides a novel one-driving-two freezing, refrigerating and drying system. According to the novel one-driving-two freezing and refrigerating drying system, the requirements of a freezing warehouse and a refrigerating warehouse are met through one set of system, defrosting is fast, energy consumption is low, heat pump drying is taken into account, and a heat pump drying function can be provided for places with drying requirements. A first warehouse heat exchanger is arranged in a first warehouse, a second warehouse heat exchanger is arranged in a second warehouse, an air outlet of a compressor is connected with an oil separator, the air output end of the oil separator is connected with a port D of a first four-way valve, a port C of the first four-way valve is connected to a first medium port of an outdoor heat exchanger, a second medium port of the outdoor heat exchanger is connected with a first port of a liquid storage device, a second port of the liquid storage device is connected to a port D of a second four-way valve in parallel and a port D of a third four-way valve, a port C of the second four-way valve is connected with a first expansion valve and then connected with a first port of the first warehouse heat exchanger, a second port of the first warehouse heat exchanger communicates to a port E of the second four-way valve, and a port S of the second four-way valve is connected to a port E of the first four-way valve through a pipeline.

Owner:苏州聚焓新能源科技有限公司

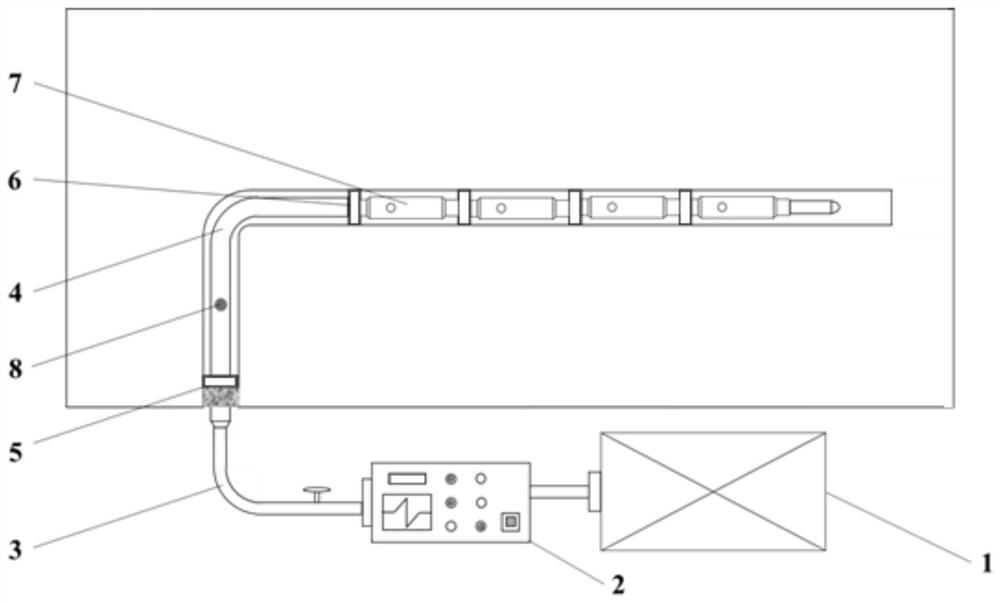

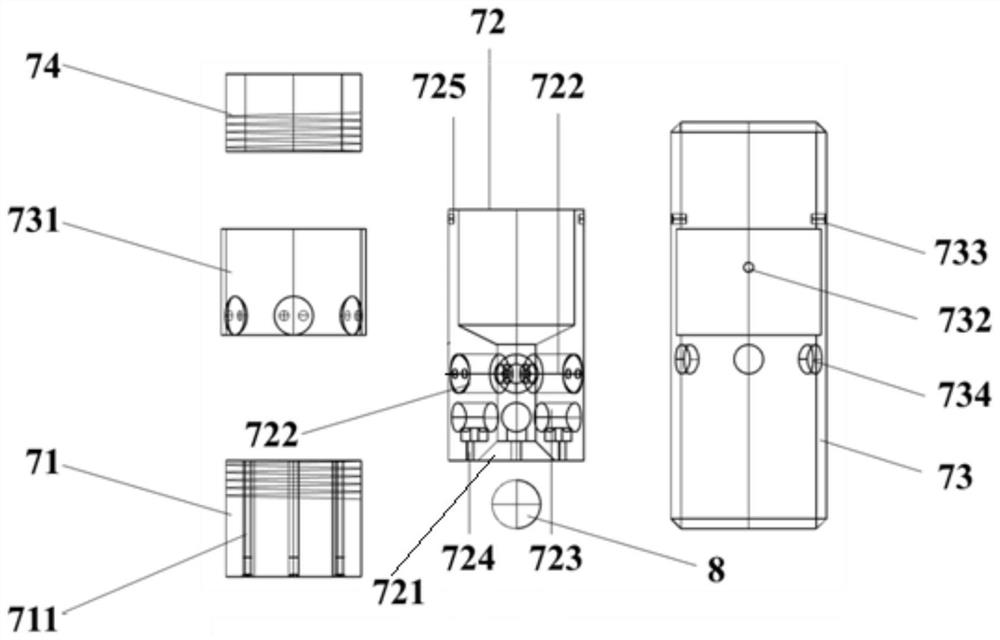

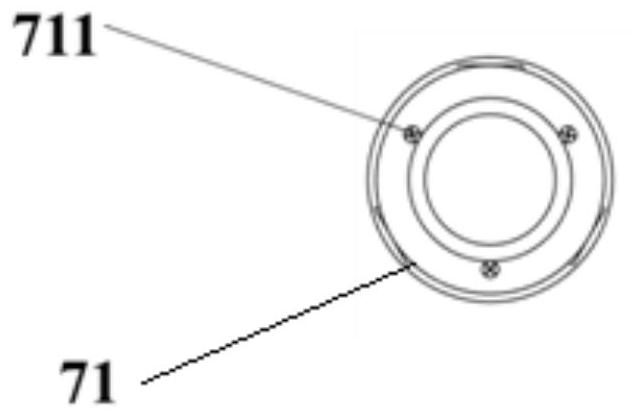

Coal seam ultrasonic activation staged fracturing device

PendingCN114737938ANo pollution in the processReduce energy consumptionConstructionsFluid removalPipe fittingFracturing fluid

The invention relates to the technical field of coal seam gas extraction, in particular to an ultrasonic activation staged fracturing device for a super coal seam. The coal seam ultrasonic activation staged fracturing device comprises a pipe fitting, one part of the pipe fitting extends into a coal seam drill hole, and the end, extending into the coal seam drill hole, of the pipe fitting is connected with at least two ball injection sliding sleeves in series; the ball throwing sliding sleeve is provided with a first liquid passing channel, a second liquid passing channel, an ultrasonic vibrator and a power supply, and the ball throwing sliding sleeve has an original state and a matched state; each ball injection sliding sleeve is provided with a fracturing ball, and the fracturing balls enter the matched ball injection sliding sleeves to block the first liquid passing channels; the ball injection sliding sleeve is provided with a limiting piece in a matched mode, the limiting piece limits the ball injection sliding sleeve in an original state, after the first liquid passing channel is blocked, the limiting piece loses efficacy, and the ball injection sliding sleeve is switched into a matched state from the original state. When the ball injection sliding sleeve is in an original state, the first liquid passing channel is used for circulating fracturing liquid and allowing a fracturing ball matched with the downstream ball injection sliding sleeve to penetrate through; and when the ball throwing sliding sleeve is in the matched state, the fracturing fluid flows through the second fluid passing channel.

Owner:CHONGQING UNIV

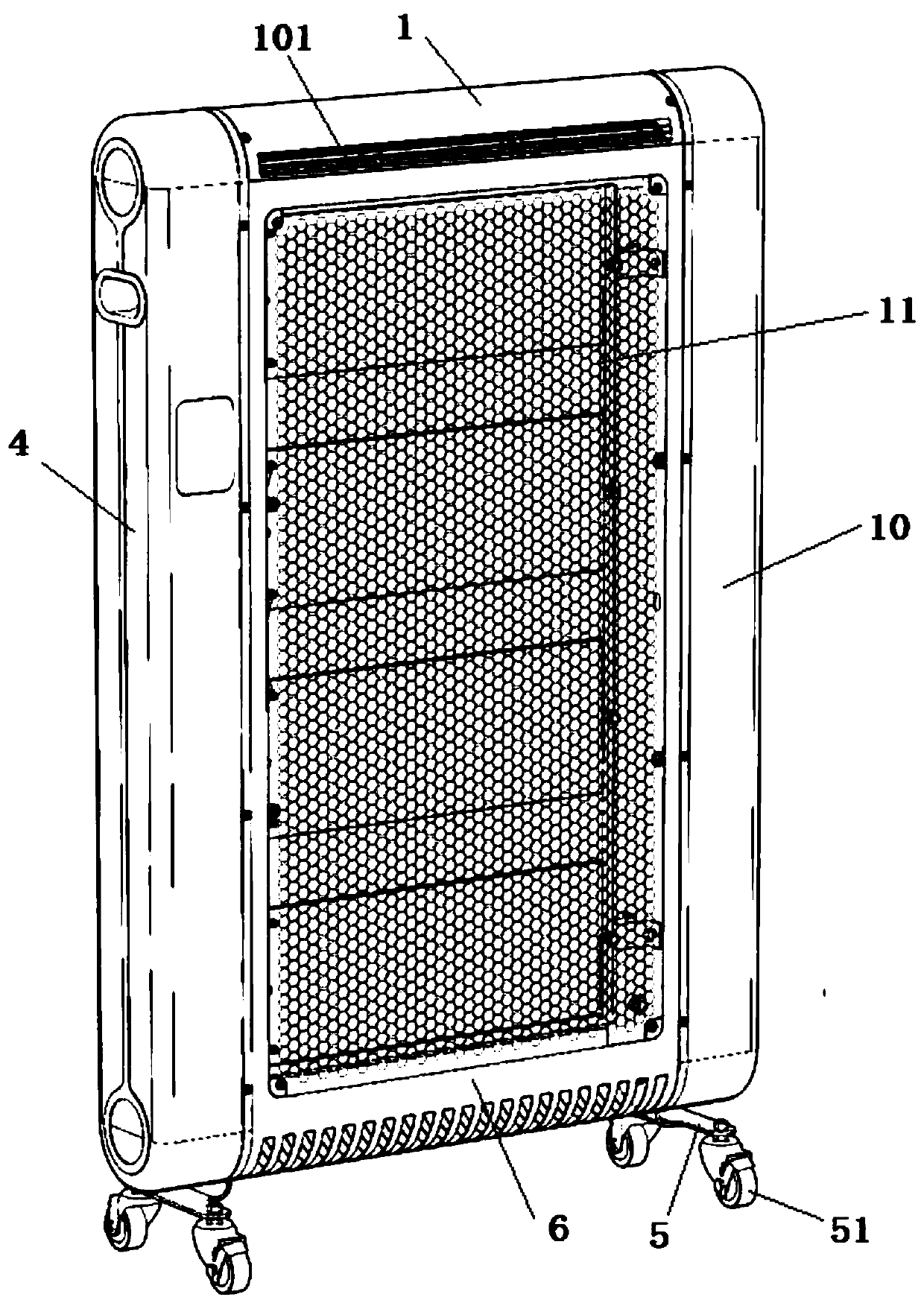

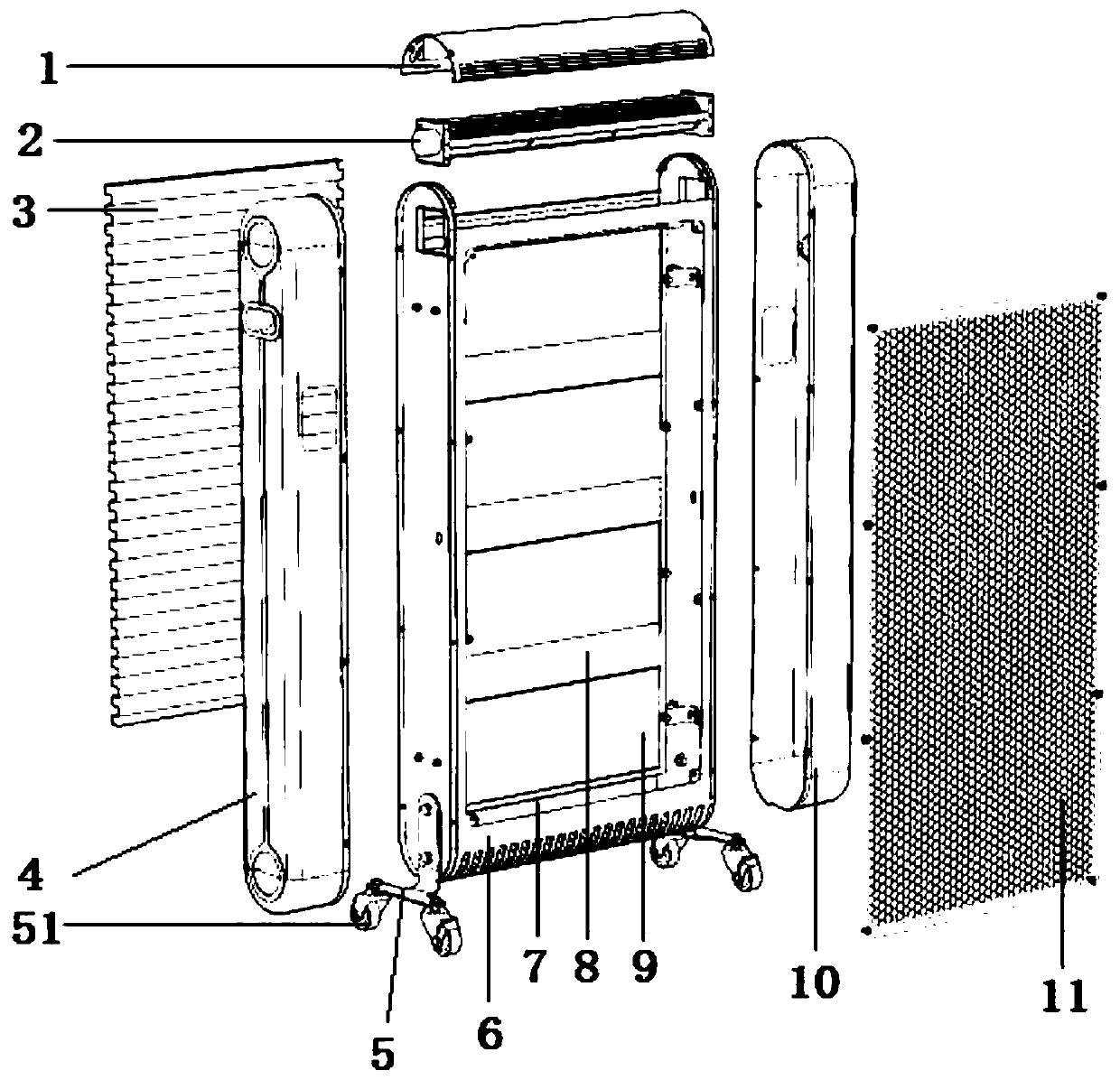

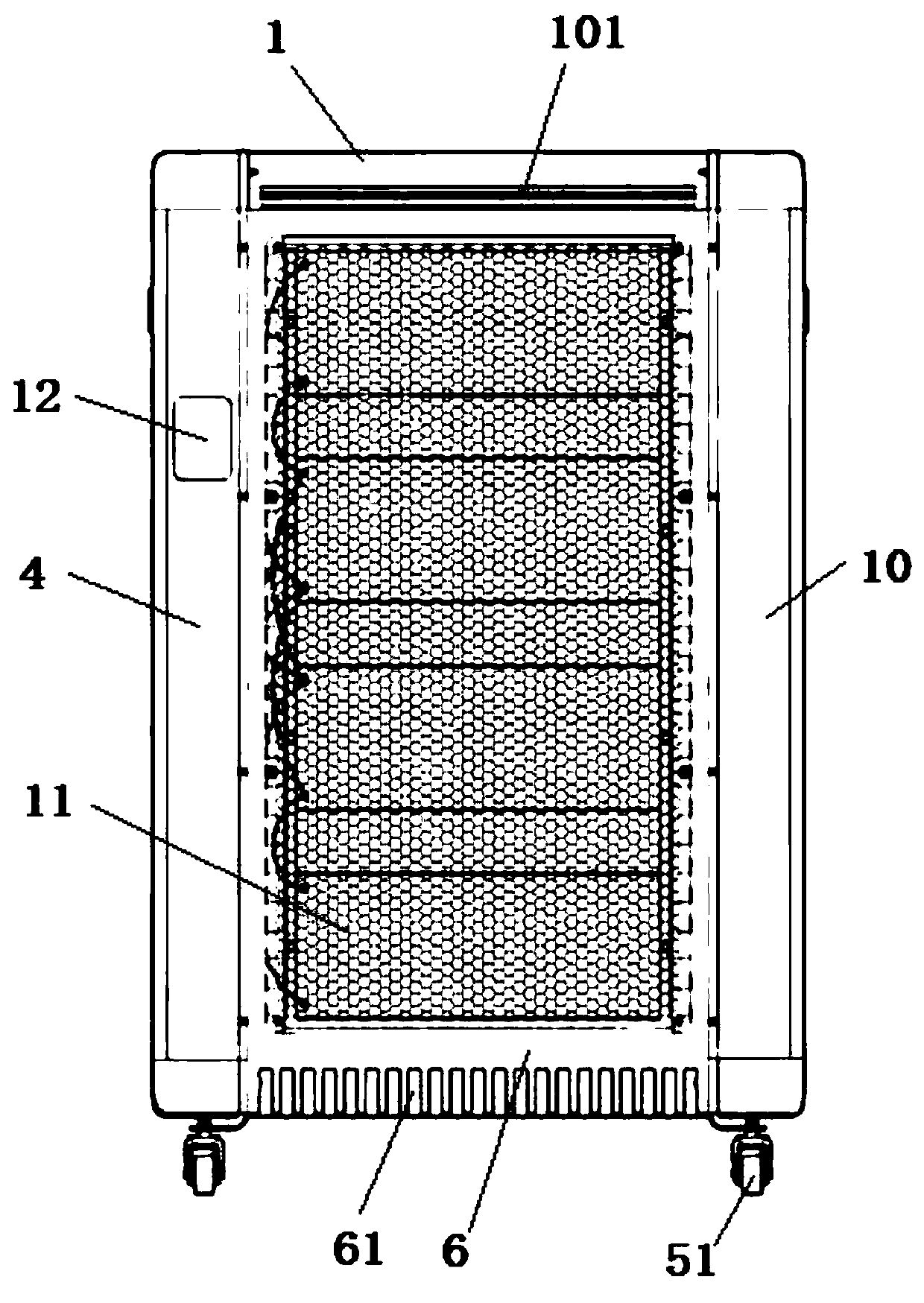

Heating terminal machine

PendingCN110454857ASmall amount of radial currentLight weightLighting and heating apparatusElectric heating systemTemperature controlFixed frame

The invention relates to a heating terminal machine. The heating terminal machine comprises a machine frame shell, a left machine frame shield, a right machine frame shieldand an upper air outlet cover, a heating plate fixing frame is arranged in the middle of the machine frame shell, a plurality of heating plate bodies are fixedly arranged in the heating plate fixing frame, an isolation plate isarranged between every two adjacent heating plate bodies, a protective grid network is arranged on the front side surface of the machine frame shell, a heat conduction heating plate is arranged on therear side surface of the machine frame shell, a cross-flow fan is arranged at the upper end of the machine frame shell, the left machine frame shield is arranged on the left side of the machine frameshell, the right machine frame shield is arranged on the right side of the machine frame shell, and the upper air outlet cover is buckled at the upper end of the machine frame shell. The heating terminal machine has the advantages that three modes of radiation, convection and conduction are adopted to release heat load to a heating space, the process is controlled by a preset intelligent temperature control unit, an intermittent heating linkage energy-saving operation mode is adopted, when the safety is ensured, the energy consumption is fast, the service life is long, and the designed service life can reach 25000 hours.

Owner:山东鬼谷环保科技有限公司

Dynamic light coupler

InactiveCN1243261CImplement beam splittingRealize dynamic conversionCoupling light guidesGratingNumerical aperture

A dynamic light coupler consists of input optical fibre set, collimation lens set, Daman grating phase plate, convergent lens and output optical fibre set in sequence on one light path. It is featured as setting input optical fibre set on front focal plane of collimation lens, phase plate at back focal plane, output optical fibre set on back focal plane of convergent lens; overlapping convergent lens front focal plane to back focal plane of collimation lens set.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

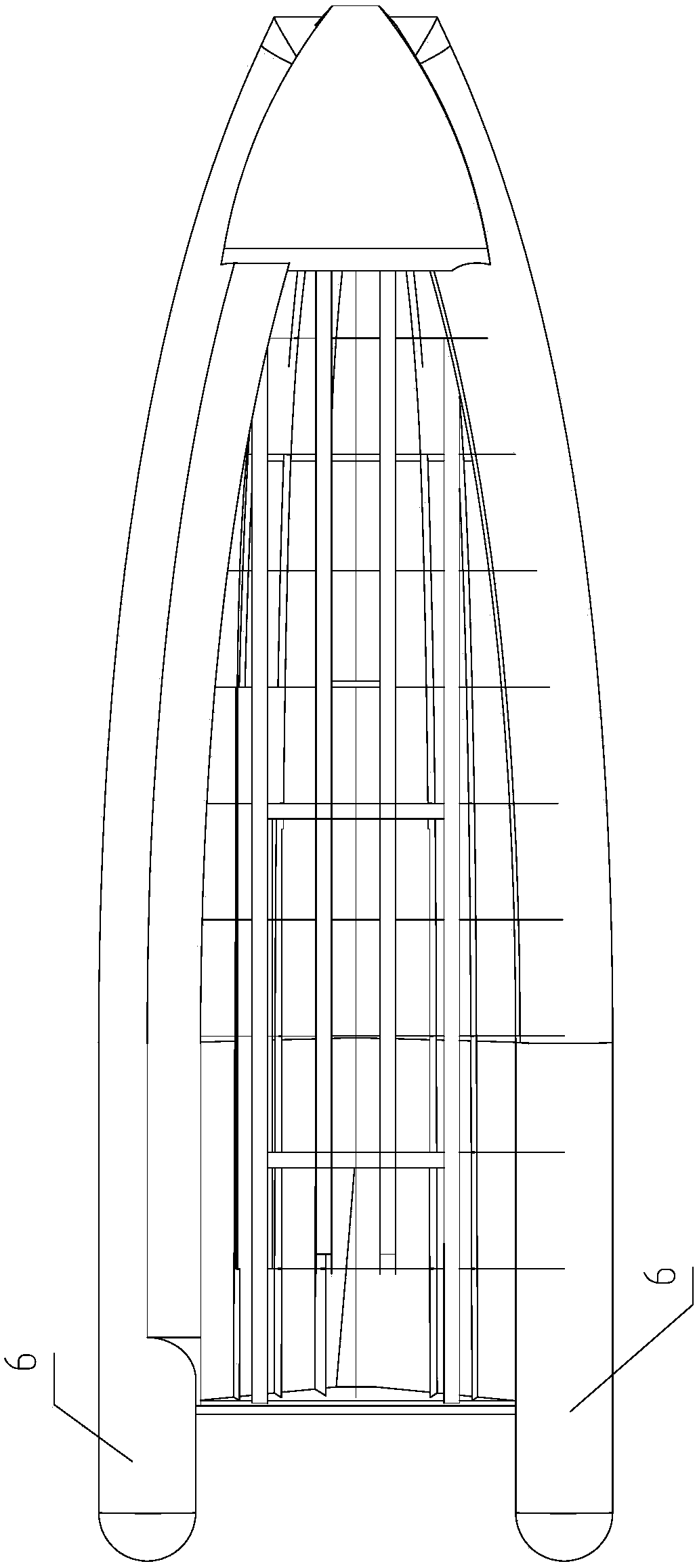

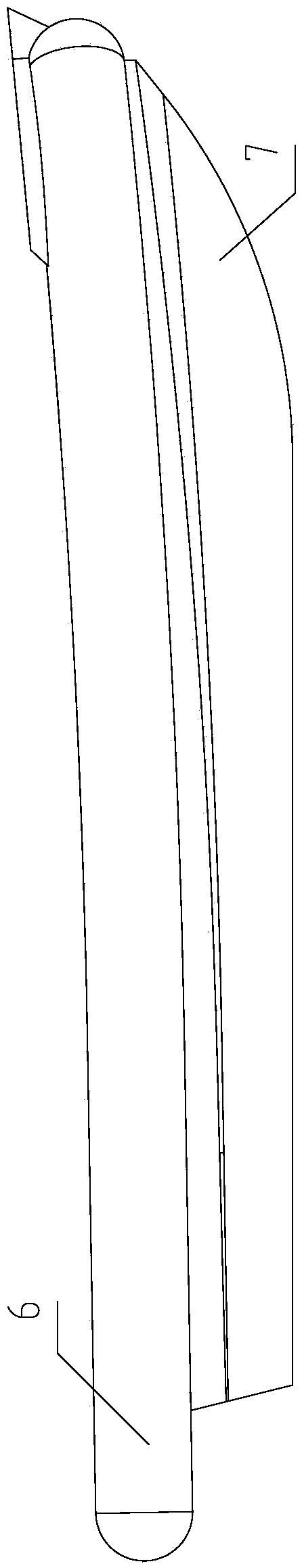

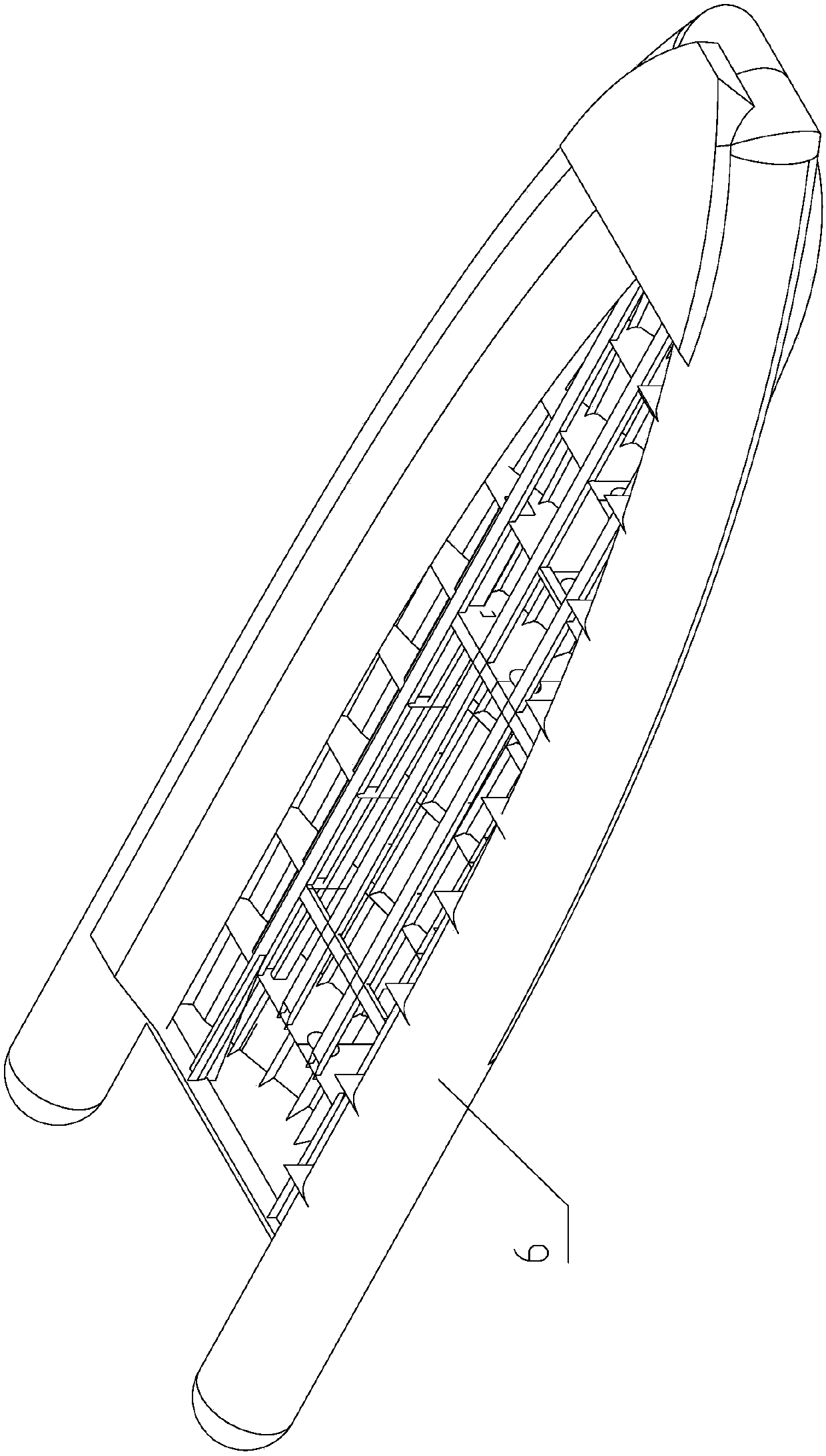

Composite inflatable-type high-speed craft

PendingCN107600309AIncrease buoyancyHigh strengthHull partsVessel salvagingMarine engineeringEnergy consumption

The invention provides a composite inflatable-type high-speed craft. According to the composite inflatable-type high-speed craft, the technical problems that an existing inflatable-type assault craftis made of a PVC material, thus when the inflatable-type assault craft sails in water, resistance is large, the speed cannot be too high, the resistance is larger especially in high-speed sailing, energy consumption is high, and meanwhile the load is small are solved. The composite inflatable-type high-speed craft is provided with a hull frame, and a craft bottom is arranged at the bottom of the hull frame. Inflatable buoyancy bag containing cavities are formed in the two sides of the hull frame, inflatable buoyancy bags are arranged in the inflatable buoyancy bag containing cavities, and theinflatable buoyancy bag containing cavities and the inflatable buoyancy bags form composite craft rails. The composite inflatable-type high-speed craft can be widely applied to yachts.

Owner:威海翔达游艇有限公司

A data-driven prediction method for ship energy consumption

ActiveCN112550592BFast energy consumptionDoes not affect thinkingGeometric CADVessel designingMarine engineeringAtmospheric sciences

The invention belongs to the technical field of ship energy consumption prediction, and in particular relates to a data-driven ship energy consumption prediction method. The present invention includes obtaining the expected route, departure time and sea state information of the ship; constructing an offline basic model, including the ship's steady-state speed model on the water, the engine power model and the engine fuel consumption model; High-dimensional linear interpolation of the discrete grid matrix; one-dimensional linear interpolation of the discrete grid matrix of the engine fuel consumption model; real-time deduction of the ship energy consumption model. Supported by a set of data matrix, the present invention realizes fast calculation of energy consumption of a ship's long voyage. The data matrix in the method can be obtained in various ways, and it is convenient and quick to replace. The present invention does not affect the idea of the original ship dynamics simulation model, and coexists with the dynamics simulation mode in the actual simulation verification evaluation system, and each is responsible for different types of simulation calculations.

Owner:HARBIN ENG UNIV

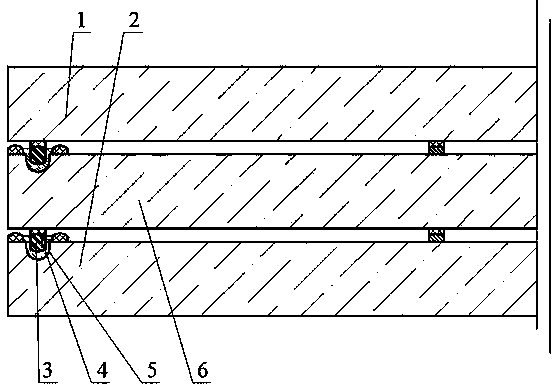

Planar tempered vacuum glass microwave-welded by using metal solder and edge-sealed by using bar frames and groove

The invention relates to a planar tempered vacuum glass which is microwave-welded by using a metal solder and which is edge-sealed by using bar frames and a groove. The glass is characterized in that upper glass and lower glass are planar tempered glass. An edge-sealing bar frame is provided on the periphery of the upper glass; an edge-sealing bar frame and an edge-sealing groove are provided on the periphery of the lower glass; the peripheries of the upper glass and the lower glass are welded together by using a metal solder, such that a sealed vacuum layer is formed. One or two layers of supporters are provided in the vacuum layer. The edge-sealing bar frames and the supporters are composed of tempered glass ink and a high-polymer. The high-polymer is first prepared into a pre-polymer; when the glass is tempered, the pre-polymer is prepared on the tempered glass ink; and the pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or the elastomer can be automatically adapted to the changes of vacuum layer height. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum. The method provided by the invention is suitable for mechanized and automated productions. With the method, mass production of tempered vacuum glass with high performance and low cost can be realized.

Owner:戴长虹

Planar toughened vacuum glass welded through metal solder by means of microwaves with edges being sealed by grooves

The invention discloses planar toughened vacuum glass welded through a metal solder by means of microwaves with edges being sealed by grooves. The planar toughened vacuum glass consists of upper glass and lower glass, and is characterized in that the periphery of the upper glass is provided with an edge-sealing strip border; the periphery of the lower glass is welded with an edge-sealing groove; the peripheries of the upper glass and the lower glass are welded together through the metal solder by means of microwaves; an enclosed vacuum layer is formed between the upper glass and the lower glass; one or two layers of support objects are arranged in the vacuum layer; the edge-sealing strip border and the support objects are made by compounding toughened glass ink and / or a high polymer; the high polymer is prepared into a prepolymer firstly; after toughening of the glass, the prepolymer is prepared on the glass or the toughened glass ink; the prepolymer is cured into an elastomer at a room temperature or a high temperature at last; the prepolymer or the elastomer can automatically adapt to the height change of the vacuum layer; and the elastomer exhausts own contained volatile gas at a high temperature and in high vacuum. Through adoption of a method disclosed by the invention, mechanical and automatic production can be implemented easily, and high-performance and low-cost toughened vacuum glass can be manufactured on a large scale.

Owner:戴长虹

Complete equipment for producing medical natural flavoring agents

The invention discloses complete equipment for producing medical natural flavoring agents, belonging to the technical field of healthcare food processing devices. At present, a device for drying mushroom raw materials and preparing flavoring agents from the totally natural food materials and complete equipment for producing flavoring agents from the dried mushroom raw materials as the totally natural food materials are unavailable. The technical scheme is as follows: an upper motor (20), a middle motor (21) and a lower motor (22) are mounted on the exterior of a heating container (16) respectively; a sealing cover (2) is screwed on a processing container (1); and the lower ends of a dry pleurotus eryngii slice inlet pipe (7), a dry coprinus comatus slice inlet pipe (8) and a dry lentinula edodes slice inlet pipe (6) are fixedly connected with the sealing cover (2) respectively. The complete equipment for producing medical natural flavoring agents has the following advantages: the production cost is low, and the popularization and promotion are facilitated; and as the world pioneer, the equipment can bring great benefits to patients.

Owner:李艳梅

Glass-solder microwave-welded planar tempered vacuum glass with edge sealed by using bar frames and groove

InactiveCN104291601AReduce stressReduce the breakage rate of glassGlass reforming apparatusGlass productionElastomerMicrowave

The invention relates to glass-solder microwave-welded planar tempered vacuum glass with the edge sealed by using bar frames and a groove. The glass is characterized in that upper glass and lower glass are planar tempered glass. An edge-sealing bar frame is provided on the periphery of the upper glass. An edge-sealing bar frame and an edge-sealing groove are provided on the periphery of the lower glass. The peripheries of the upper glass and the lower glass are welded together with a glass solder by using microwave, such that a sealed vacuum layer is formed. One or two layers of supporters are provided in the vacuum layer. The edge-sealing bar frames and the supporters are composed of tempered glass ink and a high-polymer. The high-polymer is first prepared into a pre-polymer. When the glass is tempered, the pre-polymer is prepared on the tempered glass ink. the pre-polymer is cured into elastomer under room temperature or high temperature. The pre-polymer or elastomer can be automatically adapted to the changes of the height of the vacuum layer. Volatile gases in the elastomer can be eliminated under high temperature and high vacuum. The method provided by the invention is suitable for mechanized and automated productions. With the method, mass productions of high-performance and low-cost tempered vacuum glass can be realized.

Owner:戴长虹

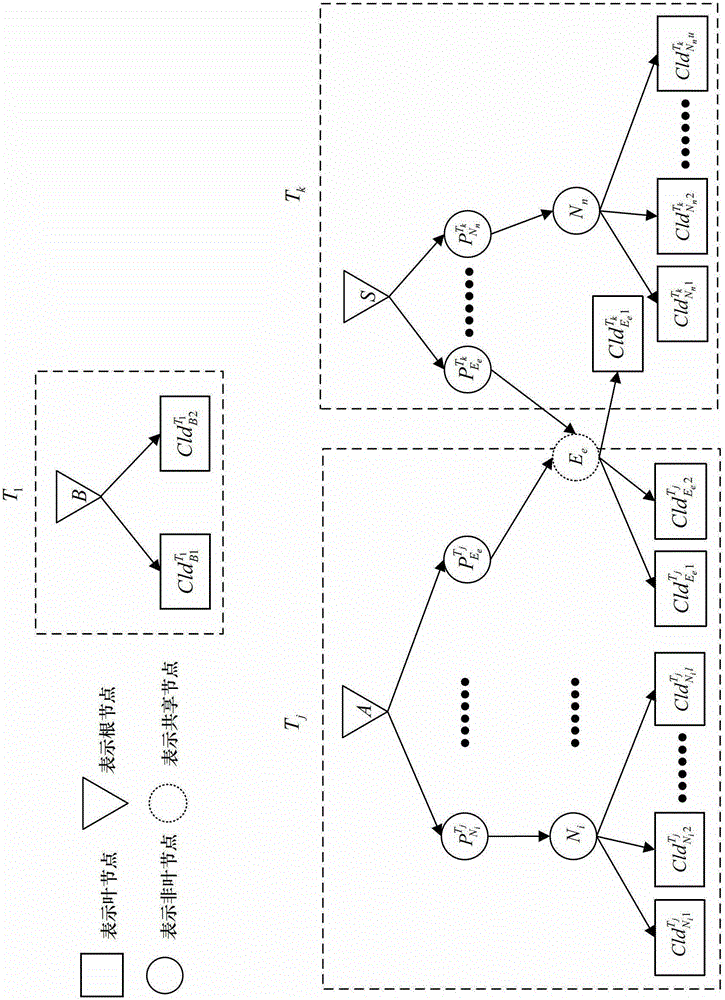

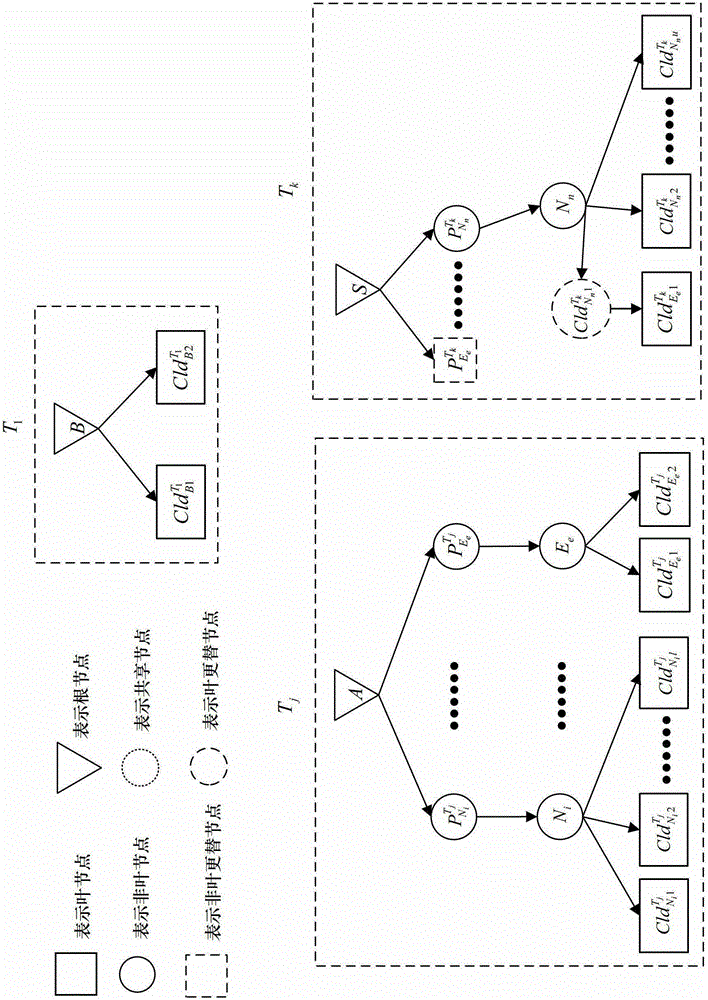

A method for adjusting the long life of multicast tree based on dfm strategy

InactiveCN103209133BBalanced energy consumptionProlong survival timeData switching networksWireless sensor networkingData transmission

The invention discloses a method for adjusting the long life of a multicast tree based on a DFM strategy. In the method, firstly, the shared nodes are sorted according to the number of occupied multicast trees, and then the sorted shared nodes are sorted from participating multicast trees one by one. Separation; in the process of separating the shared nodes, select the participating multicast tree according to the number of child nodes, find a backup parent node for the child nodes of the shared node in the selected multicast tree, and then execute DFM by sending and receiving messages Strategy. The method of the present invention solves the problem of using the DFM strategy to separate the shared nodes when there may still be some shared nodes after the establishment of multiple multicast trees, so that as many shared nodes as possible can be transformed into ordinary multicast nodes only in one multicast tree. The nodes in the tree prolong the working time of the wireless sensor network, maintain long-lived multicast data transmission, and balance the energy consumption among nodes.

Owner:北京航空航天大学深圳研究院

FSAC racing car active braking system based on manned and unmanned driving modes

ActiveCN113071458ACompact structureMeet strategic needsBraking action transmissionSwitching frequencyLoop design

The invention provides an FSAC racing car active braking system based on manned and unmanned driving modes. The FSAC racing car active braking system comprises a first active braking cylinder, a second active braking cylinder, a linear motor, a first passive braking cylinder, a second passive braking cylinder, a first two-position three-way electromagnetic valve, a second two-position three-way electromagnetic valve and an unmanned driving control system. Compared with an existing scheme of a servo motor and a mechanical transmission mechanism, the control circuit is adopted to accurately control the linear motor to move, and then the service braking function of an unmanned driving mode is achieved. The manned driving mode and the unmanned driving mode are independent from each other through switching of different driving modes, and the active mode and the passive mode are both of a double-loop design, so that safety is guaranteed. The innovation lies in that an MOSFET is applied, the size is dozens of times smaller than that of a relay, the switching frequency is high, the response speed is high, noise is avoided, energy consumption is low, physical contacts are avoided, and electromagnetic interference is avoided, so that the problems of limited space and light weight of an automobile are solved.

Owner:JILIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com