Heating terminal machine

A technology of terminals and racks, which can be used in household heating, space heating and ventilation details, heating methods, etc. It can solve the problems of low electrothermal conversion efficiency, inconvenient use, uncontrollable temperature, etc. Efficiency improvement and rapid heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in further detail now in conjunction with accompanying drawing.

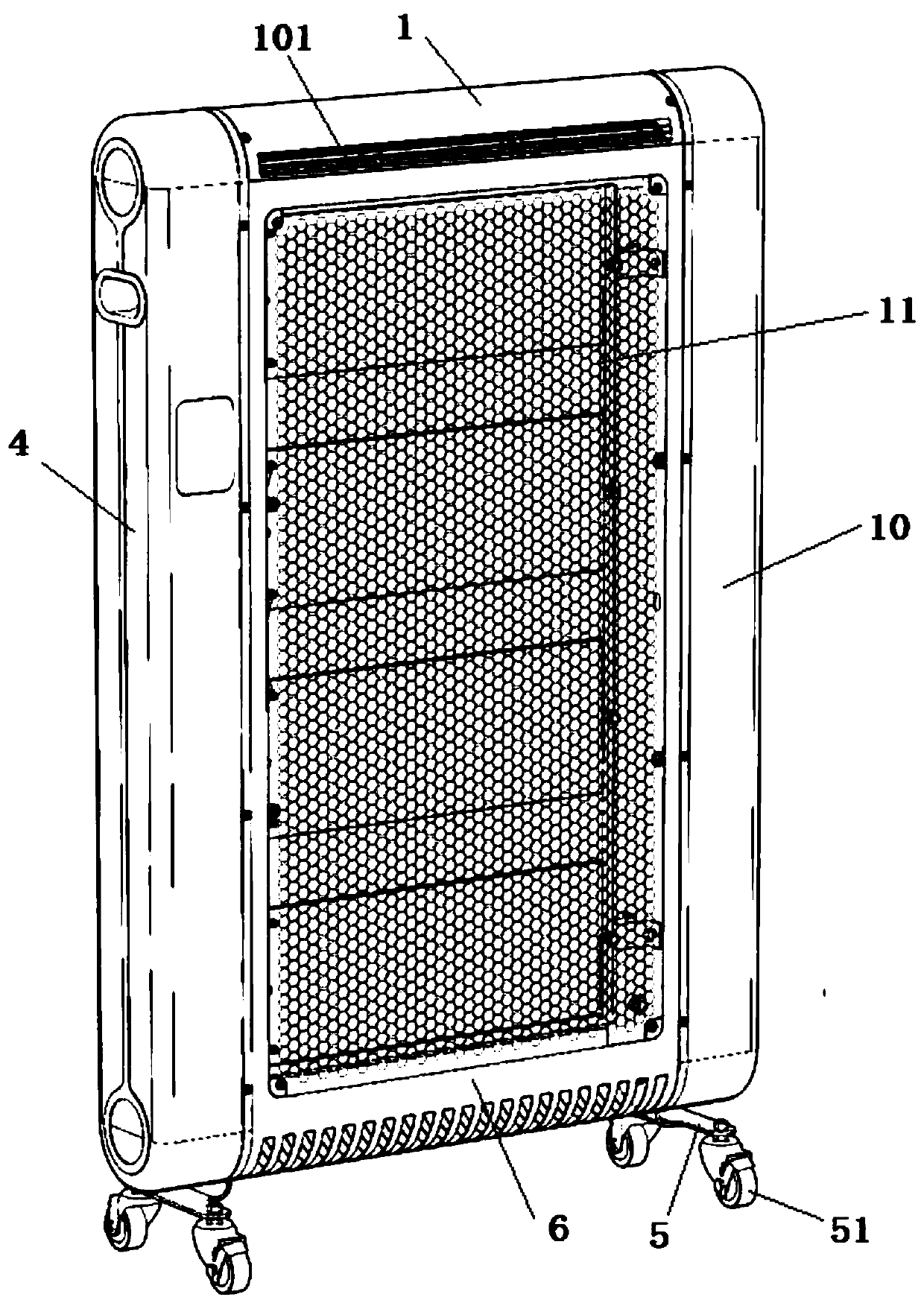

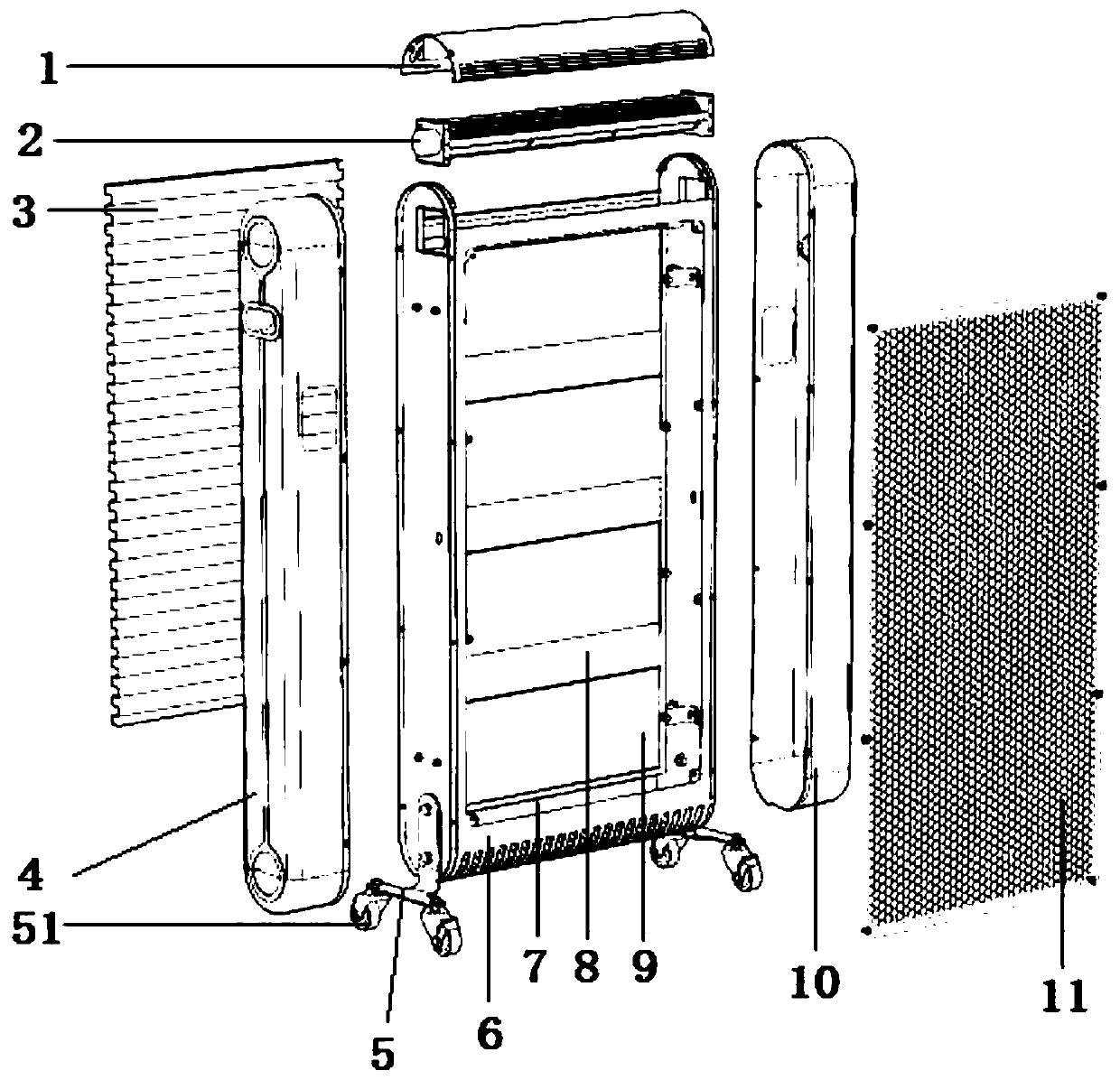

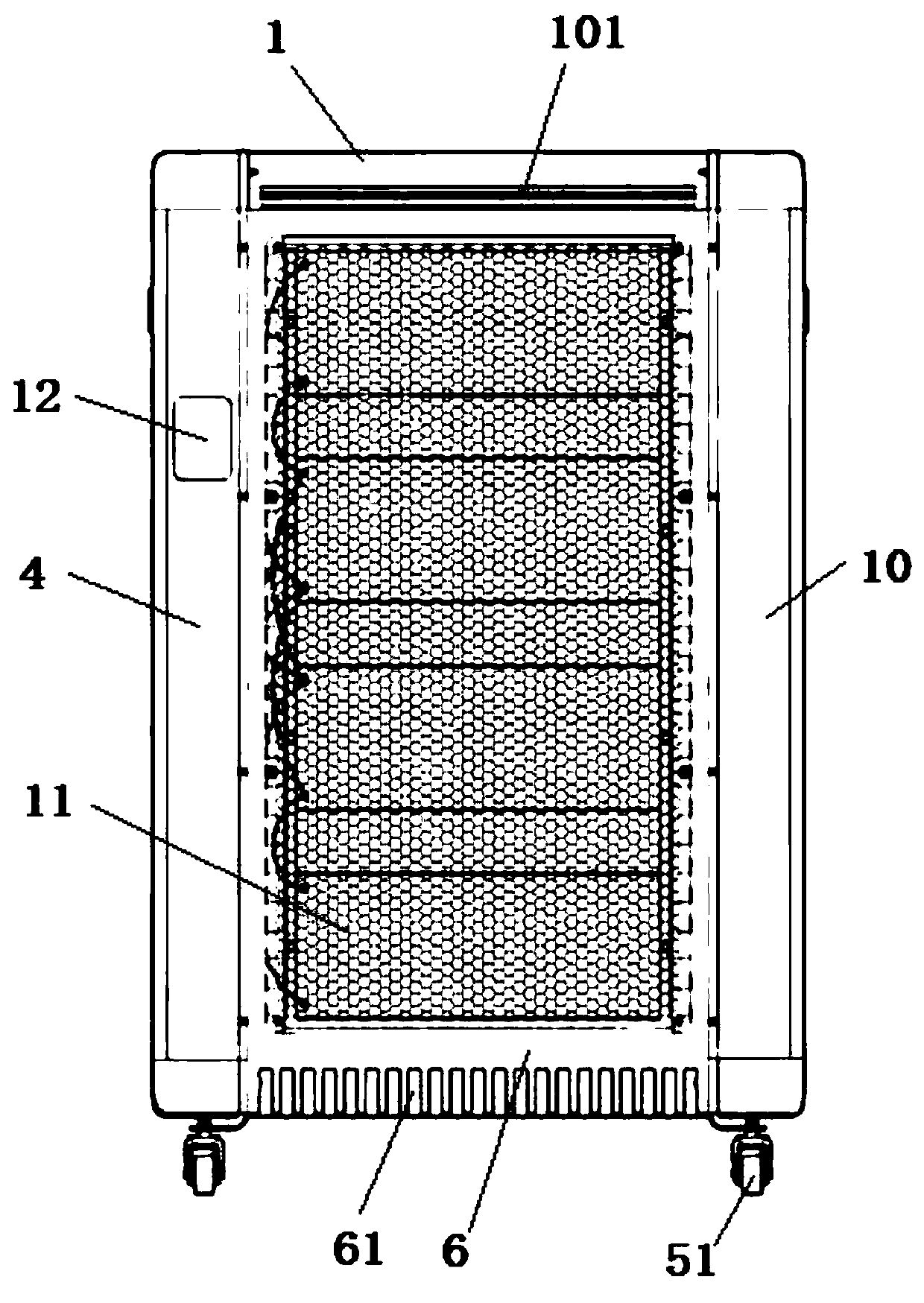

[0027] Such as Figure 1-9 The heating terminal machine shown includes a frame shell 6, a left frame shield 4, a right frame shield 10, and an upper air outlet mask 1, and ten thousand to the wheel support frame, at least two universal wheels are installed under the universal wheel support frame, a heating plate fixing frame 7 is arranged in the middle of the frame housing 6, and a plurality of Heating plate monomer 9, isolating plate 8 is arranged between two adjacent heating plate monomers 9, the front side of described frame housing 6 is equipped with protective grid 11, the rear side of frame housing 6 A heat conduction heating plate 3 is installed, a cross-flow fan 2 is installed on the upper end of the frame casing 6, a left frame shield 4 is installed on the left side of the frame casing 6, and a left frame shield 4 is installed on the right side of the frame cas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com