Heat pump negative pressure efficient drying machine and drying method thereof

A dryer and negative pressure technology, applied in the field of drying, can solve the problems of large energy consumption, unfavorable waste heat and then look back, and damage to the dried items, so as to improve the heat utilization rate, reduce the heat emission, and achieve a fast drying speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

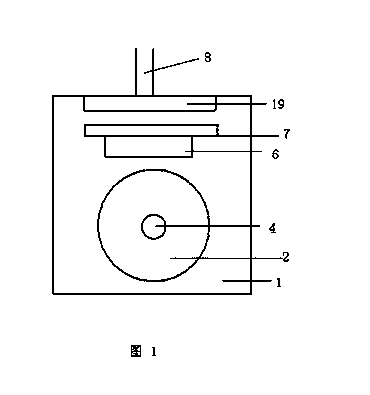

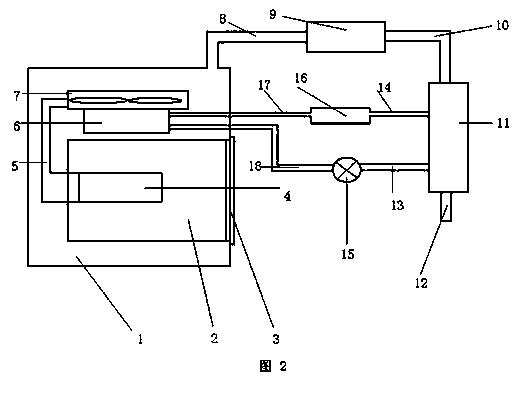

[0031] The following with attached figure 1 , figure 2 The heat pump negative pressure high-efficiency dryer and the heating method using the heater of the present invention will be further described in detail.

[0032] For the heat pump negative pressure high-efficiency dryer of the present invention, please refer to figure 1 , figure 2 , which includes a box body 1, a negative pressure vacuum pump 9, a heat pump compressor 16, an evaporator 12, a throttle valve 15, a control system 19, a temperature sensor, a humidity sensor, and a pressure sensor (not shown in the figure), wherein the box A control system 19 is installed on the outside of the top of the body 1, a drum 2 is installed in the box, a humidity sensor, a pressure sensor, and a temperature sensor are installed on the outside of the drum 2, a sealed door 3 is installed on the outside of the drum 2, and a condenser is installed on the top of the drum 2 6. A centrifugal fan 7 is installed on the upper part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com