Method for quickly extracting soluble potassium at low temperature

A soluble, low-temperature technology, applied in potash fertilizers, inorganic fertilizers, fertilization devices, etc., can solve the problems of many reaction by-products and slow reaction rate, and achieve the effect of fast reaction rate, low equipment requirements and high extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

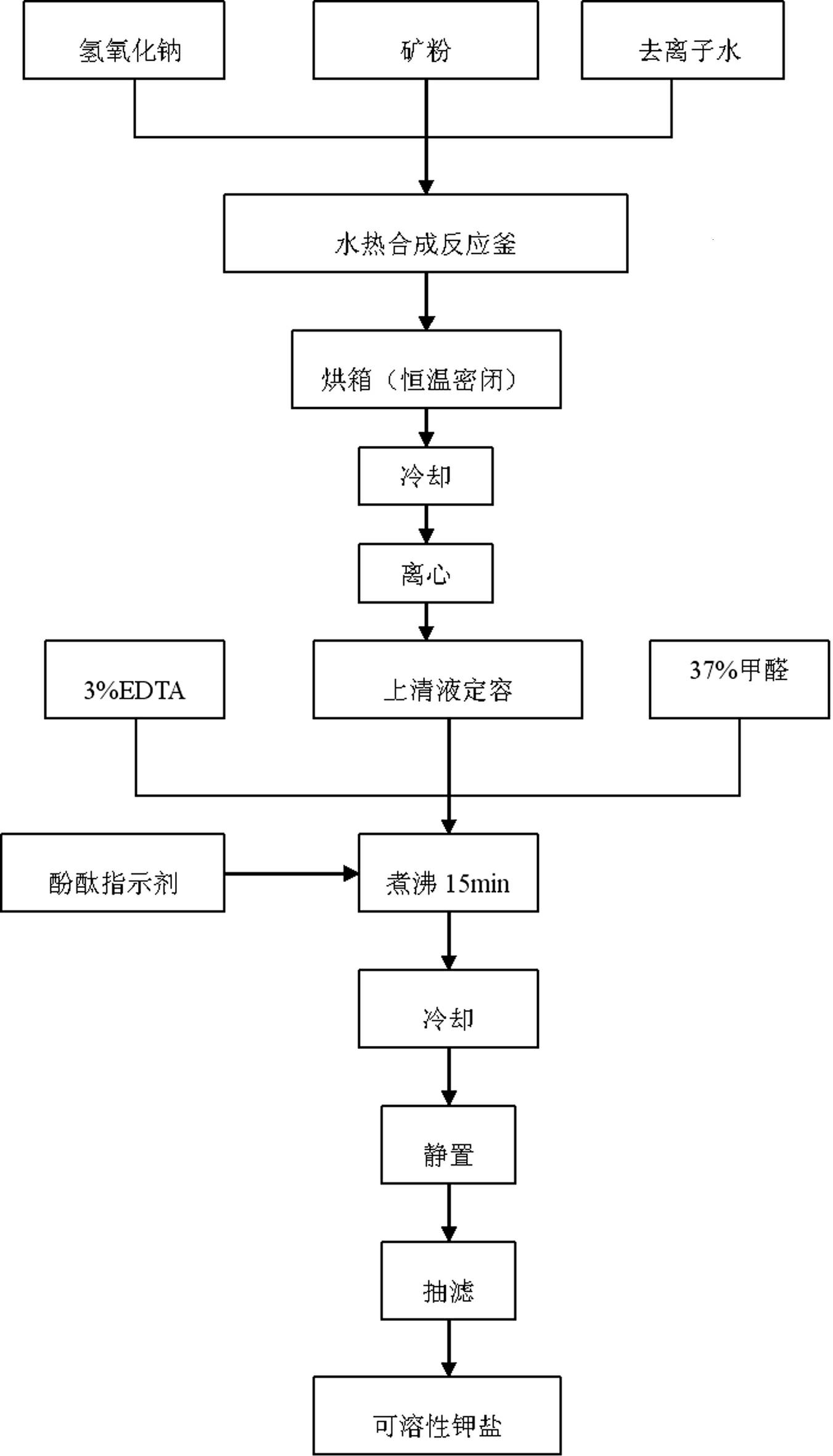

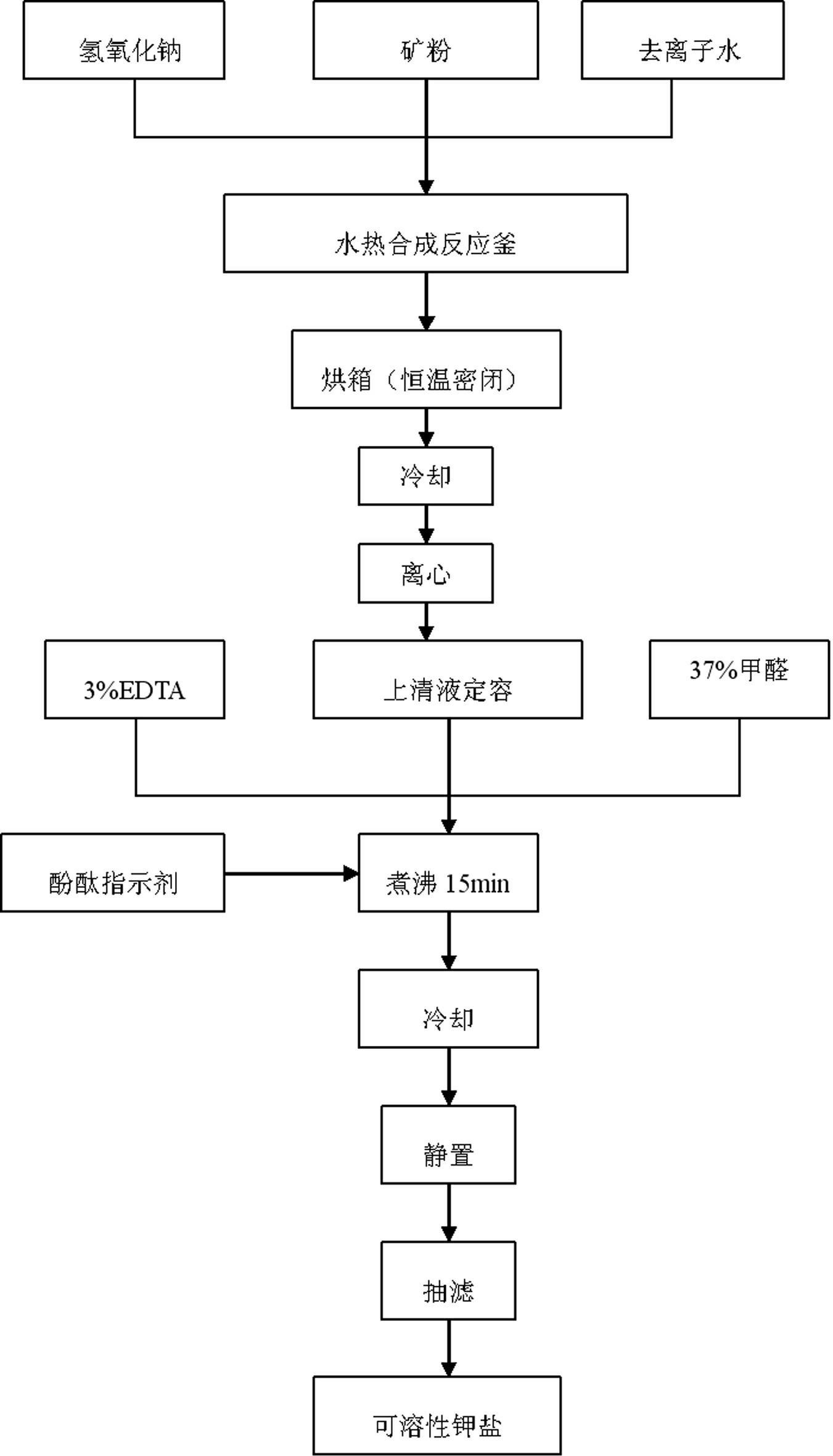

Method used

Image

Examples

Embodiment 1

[0026] Mix potassium feldspar powder, NaOH additive and deionized water in a certain ratio (7:1:2), put it in a hydrothermal synthesis reaction kettle (180°C), and place it in a closed oven at a constant temperature (120°C) , take it out after reacting to 0.5 h; cool the product taken out at room temperature and then centrifuge to obtain the supernatant; take 81ml of the supernatant, add 5ml of 3% EDTA solution and 37% formaldehyde solution to the supernatant 10ml, then add 0.1ml of phenolphthalein indicator, adjust to red with 3.9ml of 0.5% NaOH solution, and set the volume to 100ml, heat and boil in the fume hood for 15min, cool, and after standing for 0.5h, the soluble potassium salt can be obtained .

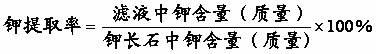

[0027] The potassium extraction rate of the method for extracting soluble potassium from potassium feldspar in Example 1 is 87.65%.

Embodiment 2

[0029] Mix potassium feldspar powder, NaOH additive and deionized water in a certain ratio (5:2:3), put it in a hydrothermal synthesis reactor at 200°C, and react in a closed oven at a constant temperature of 105°C for 1 hour Then take it out; cool the product taken out at room temperature and then centrifuge to obtain a supernatant; take 55ml of the supernatant, add 20ml of 3% EDTA solution and 20ml of 37% formaldehyde solution to the supernatant, and then add 0.3 1 ml of phenolphthalein indicator, adjust to red with 4.7 ml of 0.5% sodium hydroxide solution, set the volume to 100 ml, heat and boil in a fume hood for 15 minutes, cool, and let it stand for 1 hour to obtain soluble potassium salt.

[0030] The potassium extraction rate of the method for extracting soluble potassium from potassium feldspar in Example 2 is 83.52%.

Embodiment 3

[0032] Mix potassium feldspar powder, NaOH additive and deionized water in a certain ratio (8:1:1), put it in a hydrothermal synthesis reaction kettle (200°C), and place it in a closed oven at a constant temperature (100°C) , take it out after reacting to the specified time (1.5h); cool the product taken out at room temperature and then centrifuge to obtain a supernatant; take 80ml of the supernatant, add 8ml of 3% EDTA solution to the supernatant and 10ml of 37% formaldehyde solution, add 0.2ml of phenolphthalein indicator, adjust to red with 1.8ml of 0.5% NaOH solution, set the volume to 100ml, heat and boil in a fume hood for 15min, cool, and stand for 0.5h to prepare Soluble potassium salt.

[0033] The potassium extraction rate of the method for extracting soluble potassium from potassium feldspar in Example 3 is 90.06%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com