Nano-molybdenum sulfide antibacterial material and synthetic method thereof and application thereof

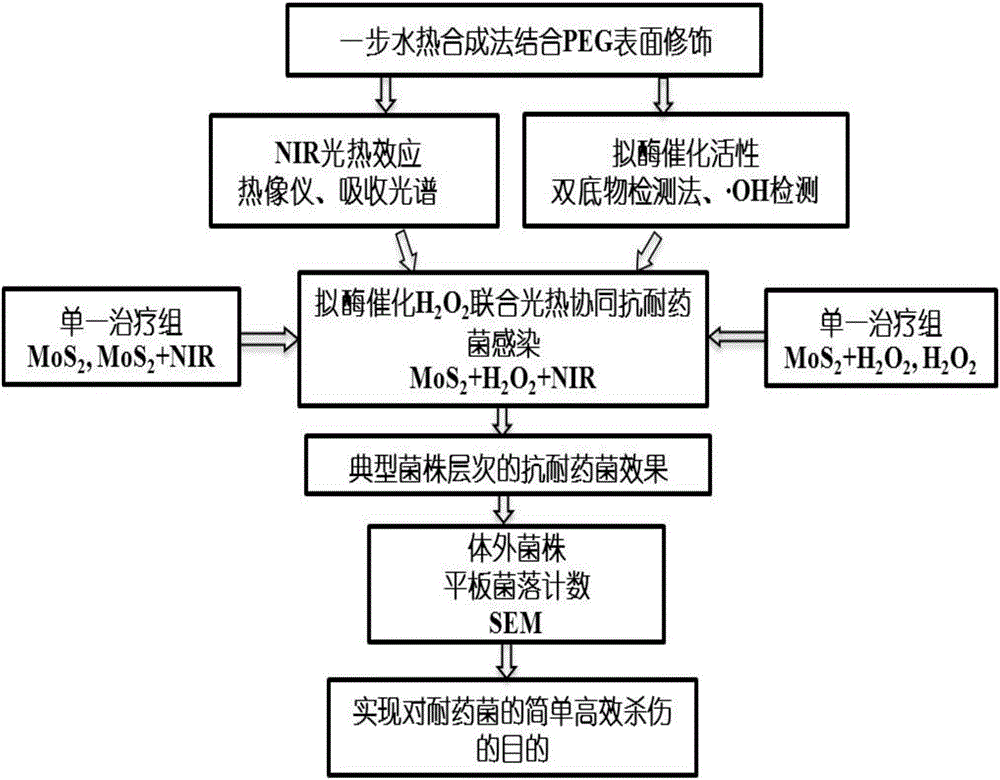

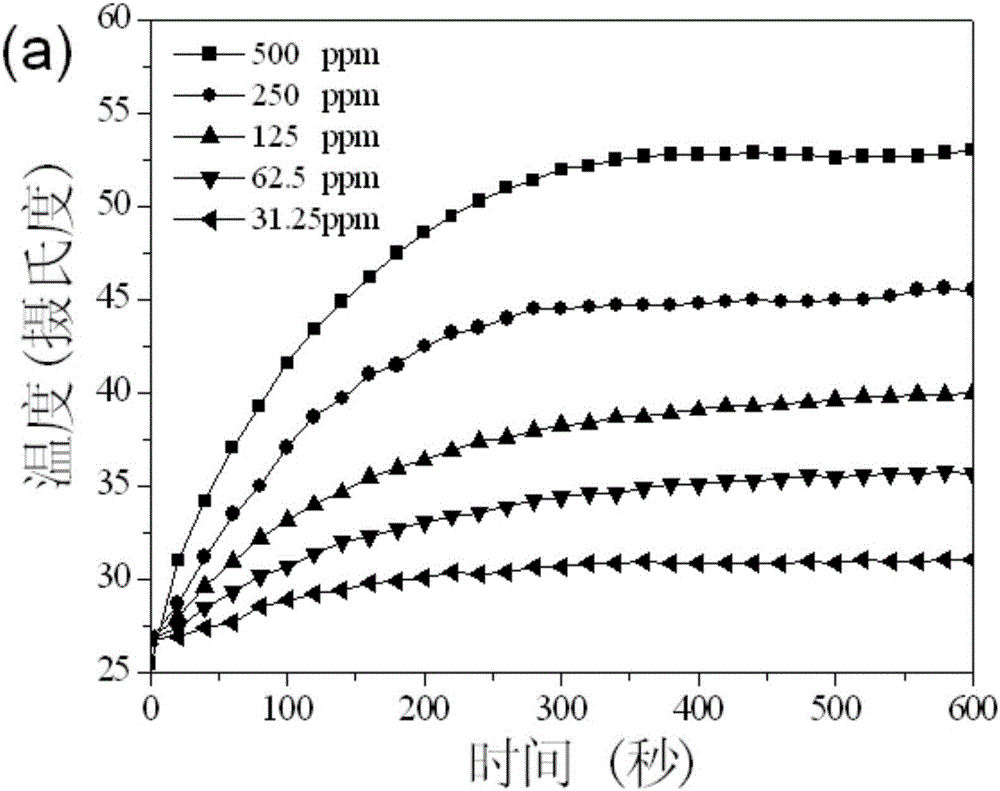

A technology of antibacterial materials and synthesis methods, applied in the directions of molybdenum sulfide, antibacterial drugs, nanotechnology, etc., can solve the problems of difficult control of the size of nanosheets, difficult to effectively capture bacteria, low yield of sheet products, etc. Antibacterial time, increase heat sensitivity, improve the effect of antibacterial aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a kind of synthetic method of nano molybdenum sulfide antibacterial material, comprises the following steps:

[0038] (1) Polyethylene glycol solid is dissolved in water, ultrasonic in the ultrasound tank until the polyethylene glycol is completely dissolved, then add the ammonium heptamolybdate solid, and ultrasonicate again to completely dissolve the ammonium heptamolybdate to obtain a mixed solution;

[0039] (2) Take thiourea solid and dissolve it in water, add it to the mixed solution after stirring and dissolving, place it in a hydrothermal reaction kettle with a polytetrafluoroethylene liner after stirring again, seal it, and heat it to react to obtain a black precipitate, namely It is nano molybdenum sulfide antibacterial material.

[0040] Preferably, the black precipitate is repeatedly washed with absolute ethanol and secondary water for 3-5 times, and prepared as a 1 mg / mL aqueous solution for storage.

[0041] Preferably, in the step ...

Embodiment 1

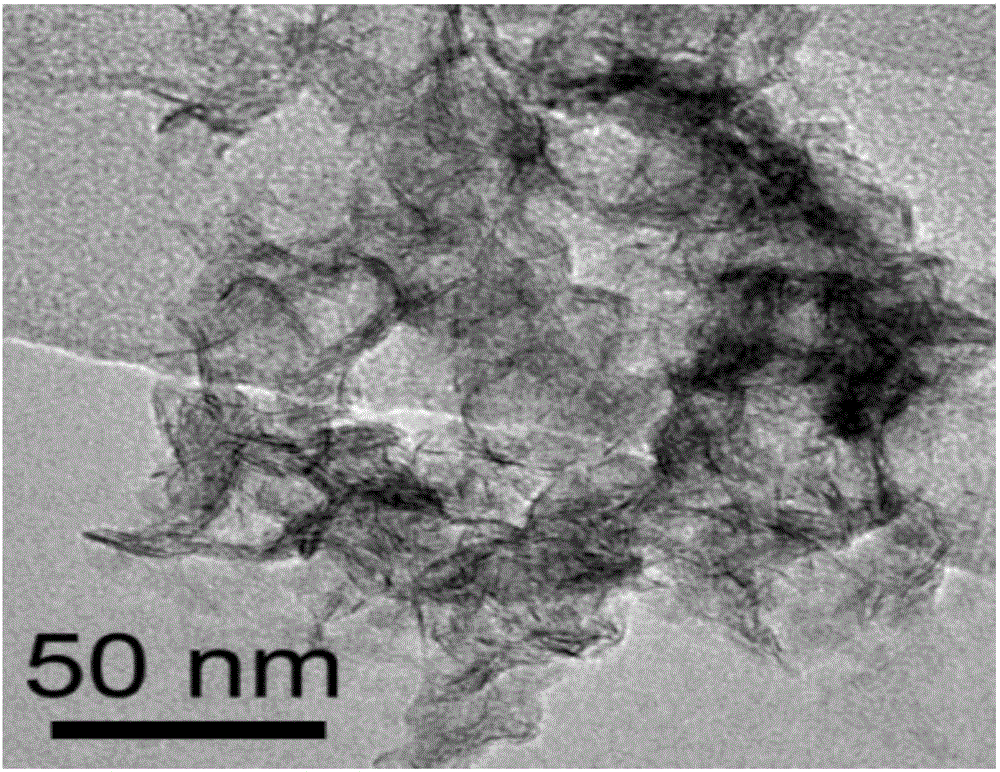

[0049] One-step hydrothermal synthesis method of nano molybdenum sulfide antibacterial material:

[0050] Dissolve 0.5g of polyethylene glycol (PEG) solid with a molecular weight of 20,000 in 20mL of deionized water, sonicate in the ultrasonic tank until the PEG is completely dissolved, add 0.1766g of ammonium heptamolybdate solid, and ultrasonically dissolve it completely for 10 minutes to obtain a mixed solution. Dissolve 2 mmol of solid thiourea in 10 mL of deionized water, stir to dissolve, add to the above mixed solution, stir for 10 minutes, place in a polytetrafluoroethylene-lined hydrothermal reactor, seal, and react at 180°C for 12 hours. The obtained black precipitate was repeatedly washed with absolute ethanol and secondary water for 3-5 times, and prepared as a 1 mg / mL aqueous solution for storage.

Embodiment 2

[0052] It is basically the same as Example 1, the difference is:

[0053] In the step (1), the mass volume ratio of polyethylene glycol to water is 0.4g:20mL.

[0054] The mass ratio of polyethylene glycol to ammonium heptamolybdate is 0.3:0.1766.

[0055] The mass molar ratio of polyethylene glycol and thiourea is 0.4g:2mmol.

[0056] In the step (2), the molar volume ratio of thiourea to water is 2mmol:15mL.

[0057] In the step (2), the stirring time is 5 minutes again, and / or the heating temperature is 200° C., and the reaction time is 10 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com