Patents

Literature

40results about How to "Good liquefaction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

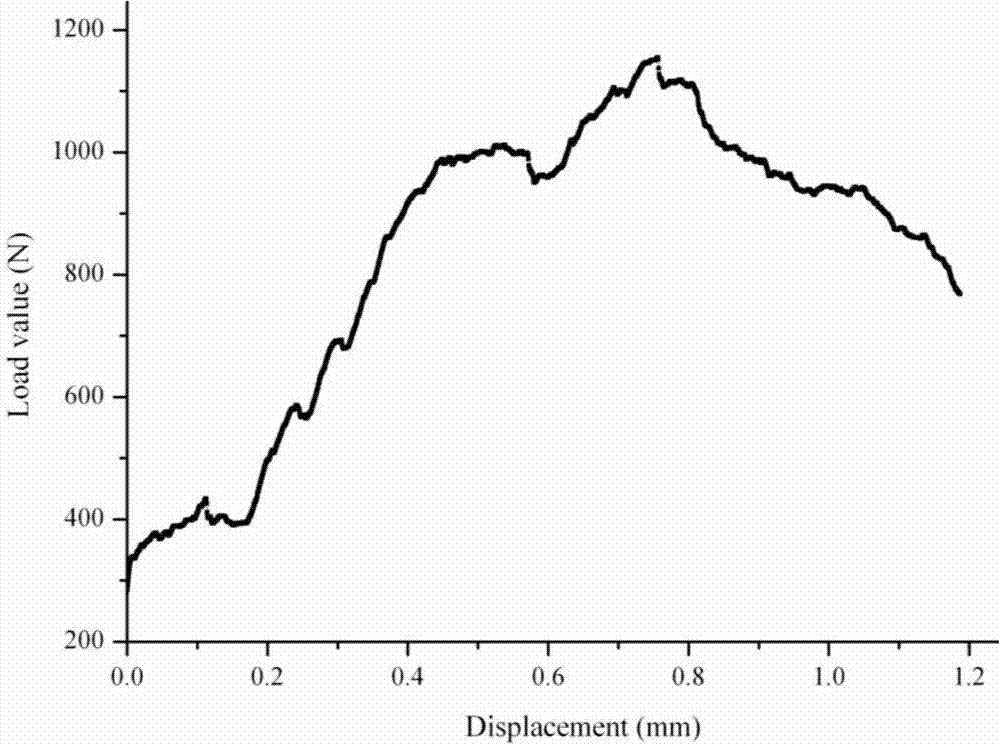

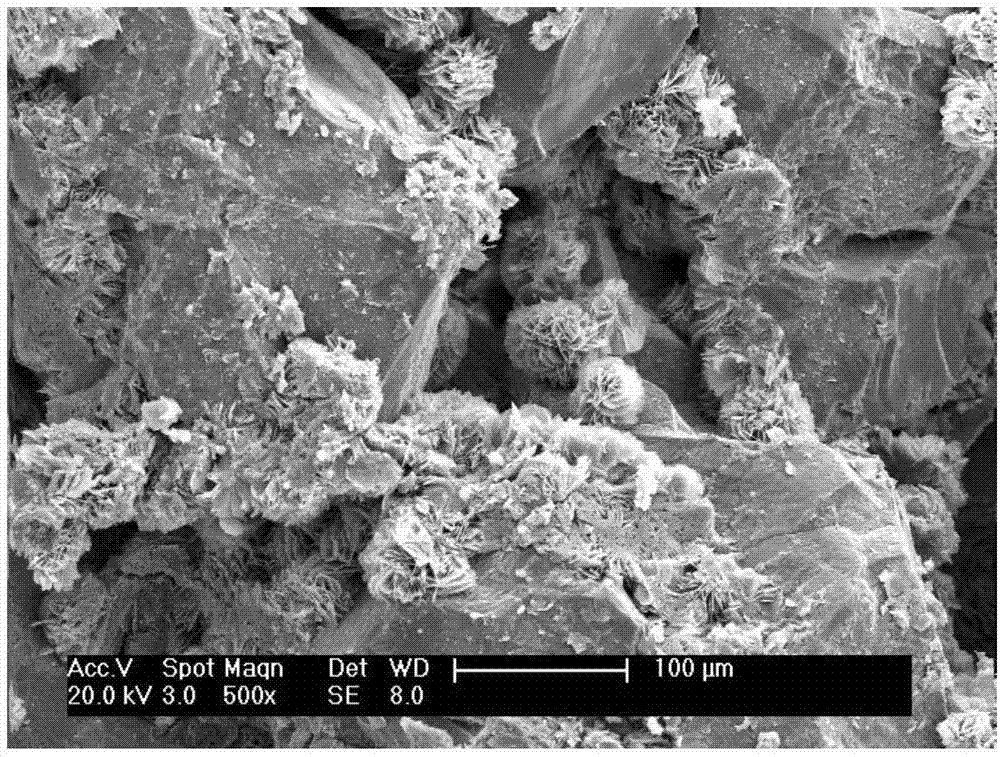

Method utilizing phosphate mineralized bacteria to solidify and loosen loose sand particles

ActiveCN103266592AProtect ecological functionsLess prone to secondary pollutionBuilding constructionsOrganic fertilisersPeristaltic pumpChemical solution

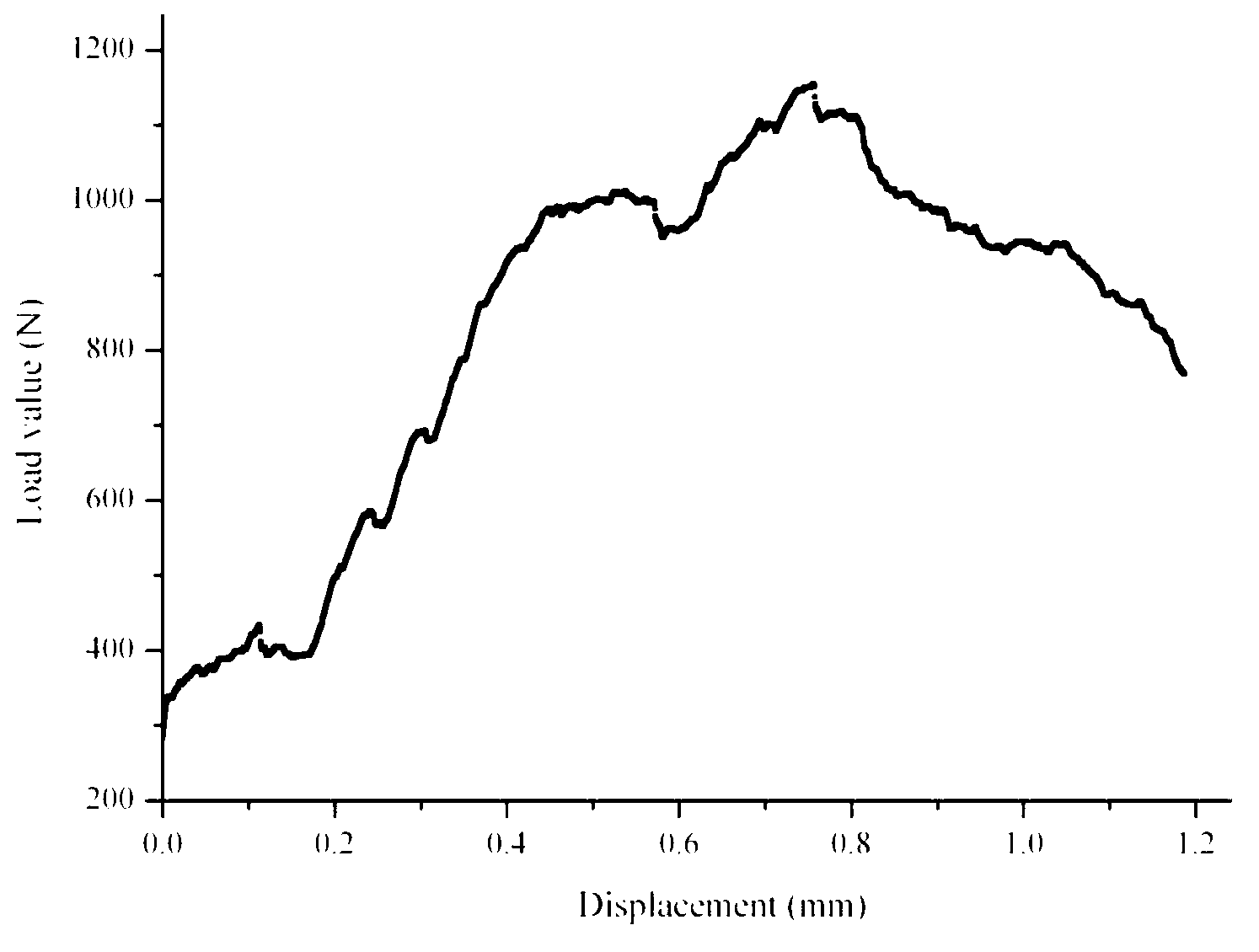

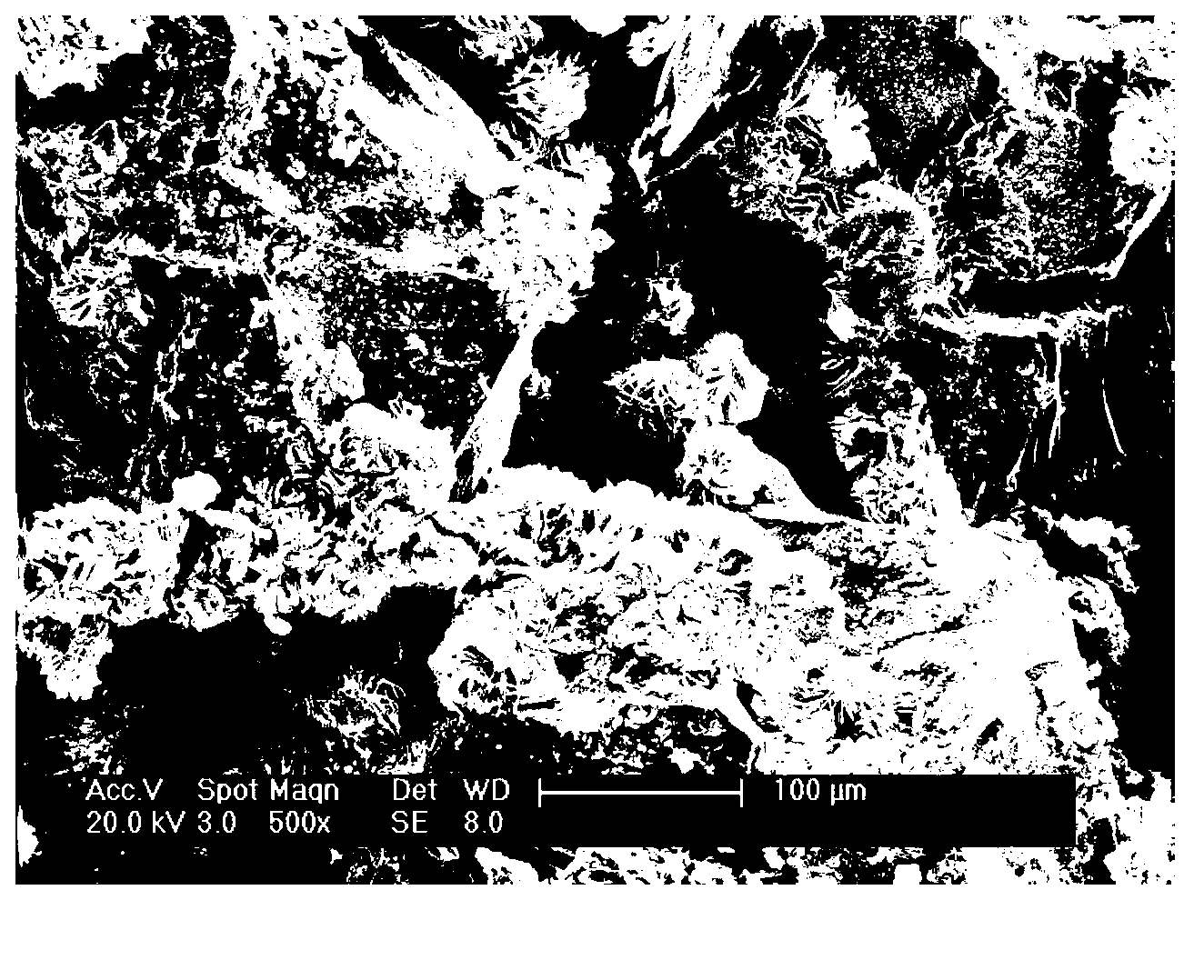

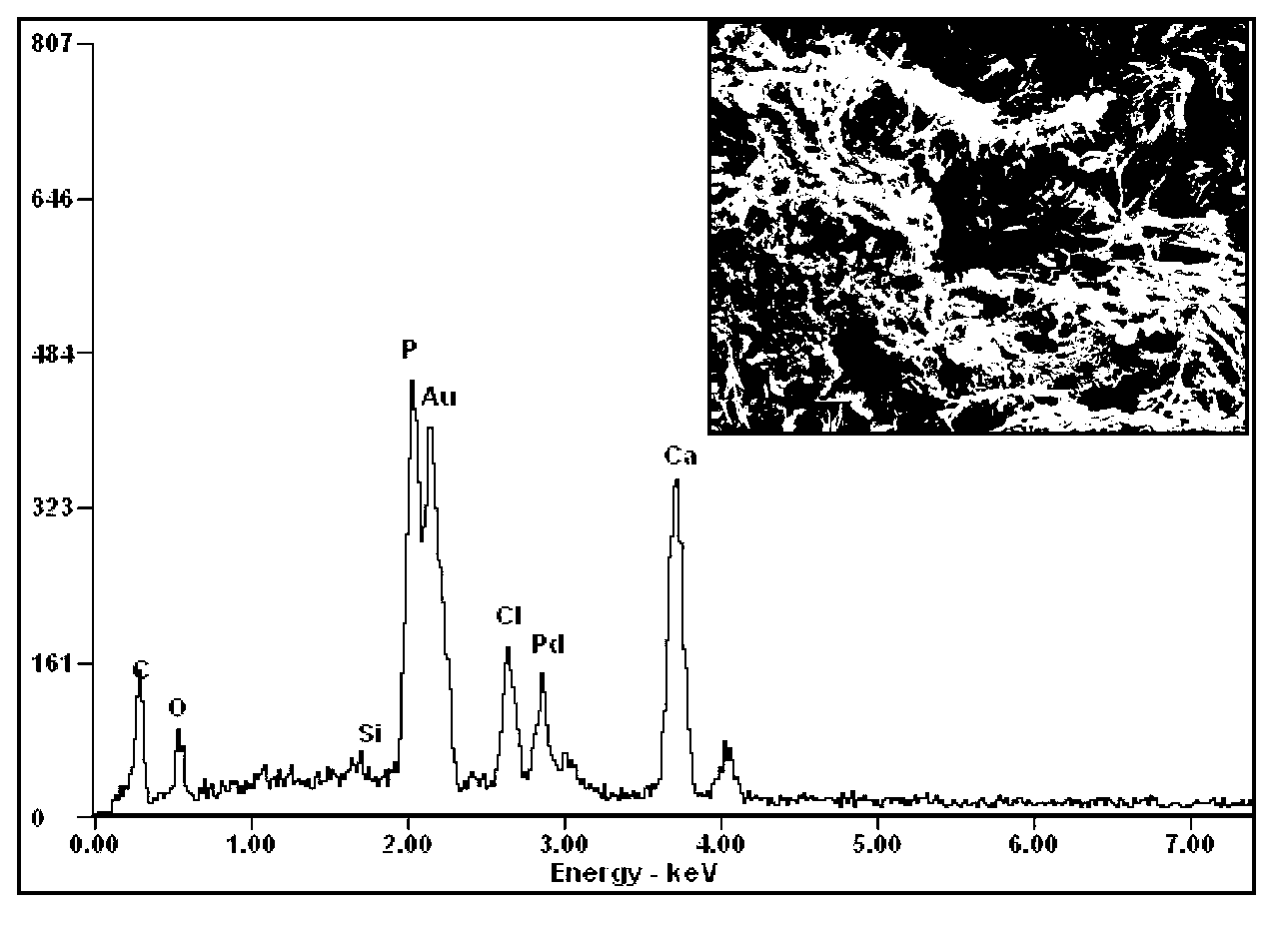

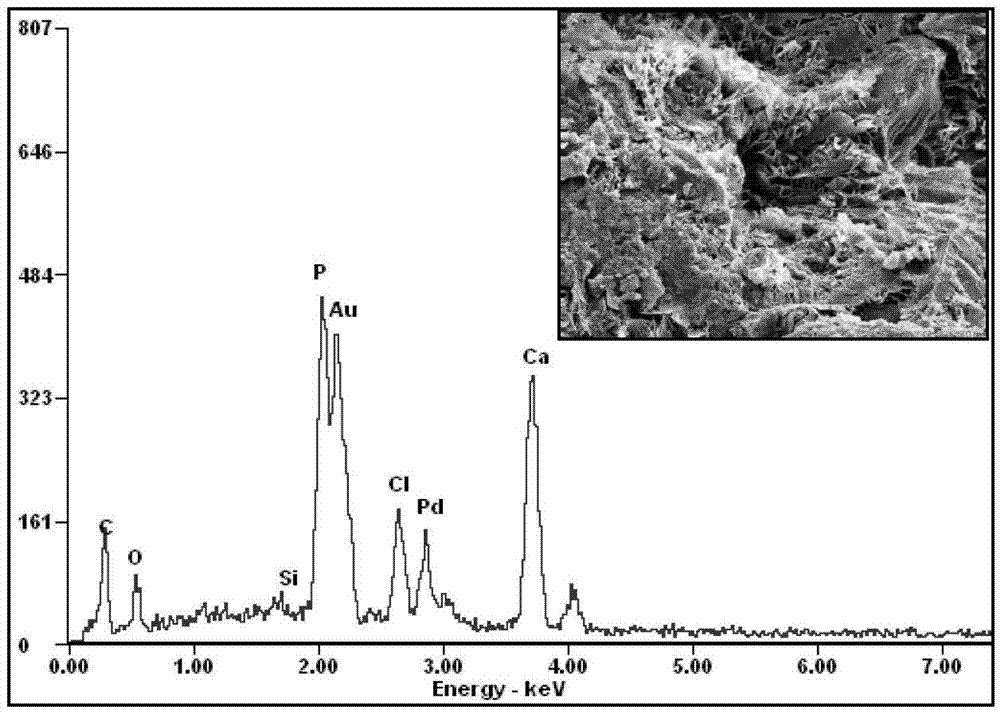

The invention discloses a method utilizing phosphate mineralized bacteria to solidify and loosen loose sand particles. The method comprises the steps that bacillus subtilis is inoculated to beef extract and a peptone culture medium for obtaining bacterial liquid, then disodium phenyl phosphate is added to the prepared bacterial liquid, an anhydrous calcium chloride solution with the concentration of 0.5-1.5mol / L is prepared, 70-90g of sand with two levels of less than 0.15mm and of 0.15-0.30mm is prepared according to the closest Fuller packing method and then loaded into a trial mould with a buffering pad and a sand filter, the bacterial liquid and a chemical solution are respectively poured into the prepared sand in the third step through a peristaltic pump according to a volume ratio of 1:1, the flowing speed of the bacterial liquid is controlled to be 4-6mL / min, the flowing speed of the chemical solution is 10-15mL / min, continuous pouring is carried out for 8-15 days, and the sand with the mould is placed into an oven of 60 DEG C for being conserved for 48h and then taken out and released from the mould. The compressive strength of the sand can reach 1.0MPa.

Owner:SOUTHEAST UNIV

Prepn of solution maghesium source

The present invention is a preparation process of solution magnesium source. The said preparation process includes: adding solid magnesiumocene and dimethyl magnesiumocene to an organic solvent of 110 deg.C boiling point and stirring for homogeneity; dropping over C9 alkane, over C9 tertiary amine or aromatic aldehyde or aromatic ketone, over C5 primary amine or aliphatic aldehyde or Schiff base formed by ketone and primary amine; further heating while stirring; and decompression distilling to eliminate solvent to obtain solution magnesium source. The said solvent has excellent solid magnesiumocene and dimethyl magnesiumocene liquefying capacity and one portion of the solvent can liquefy three or more portions of magnesiumocene and dimethyl magnesiumocene completely.

Owner:NANJING UNIV

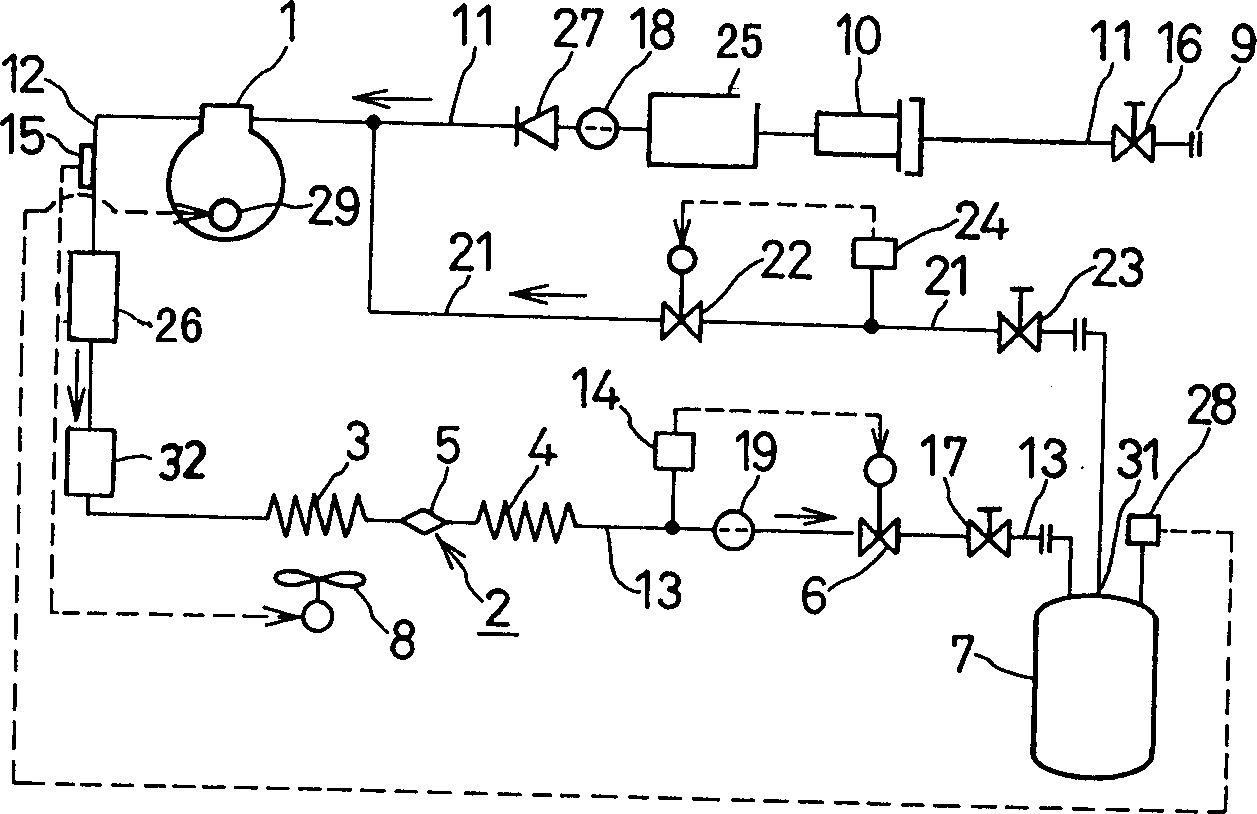

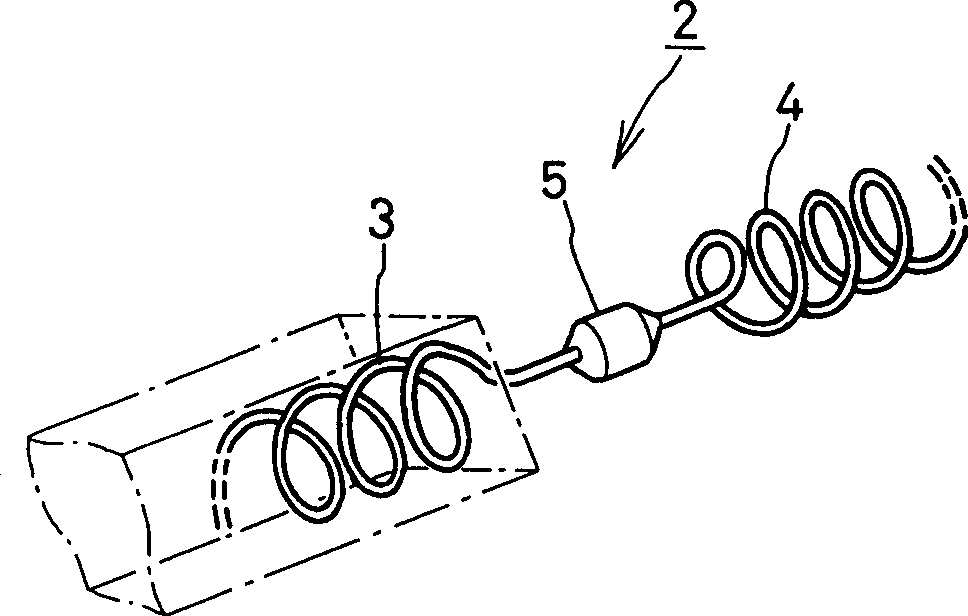

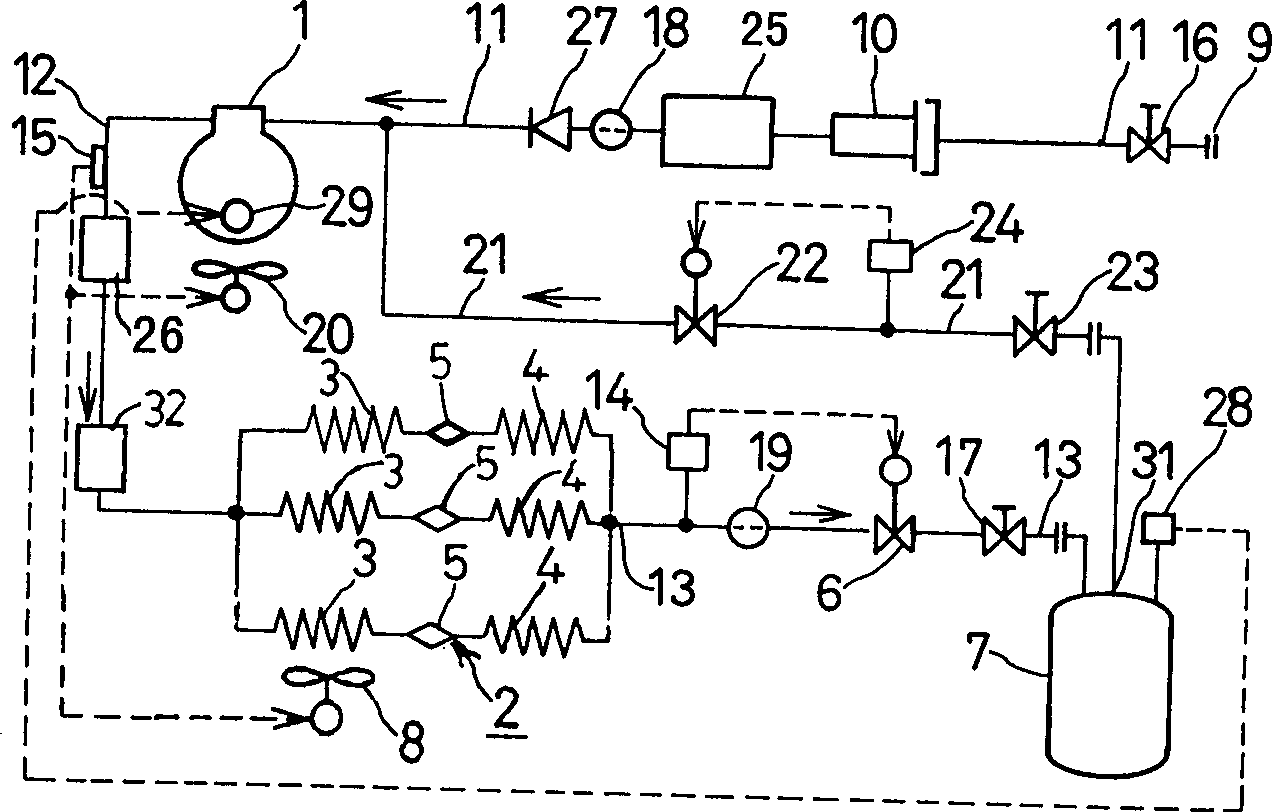

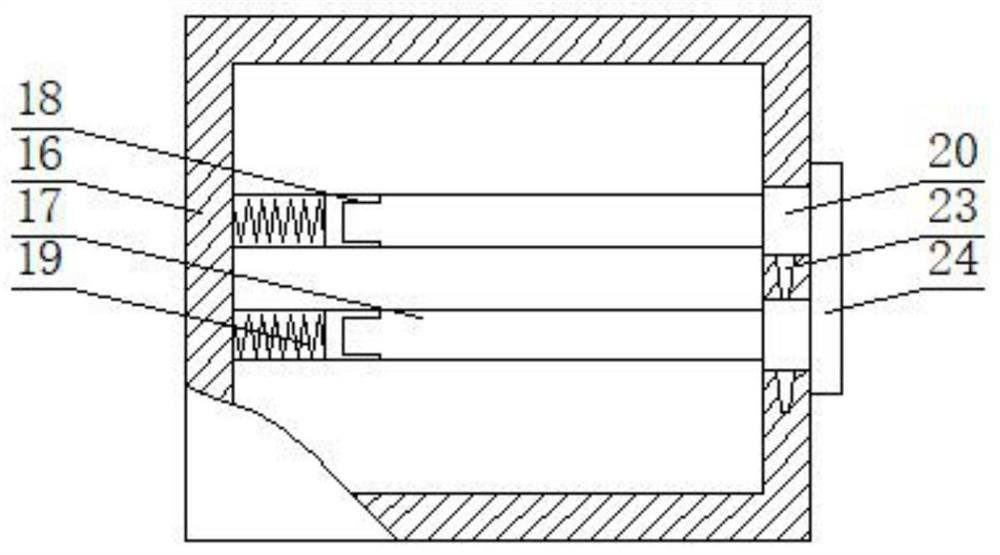

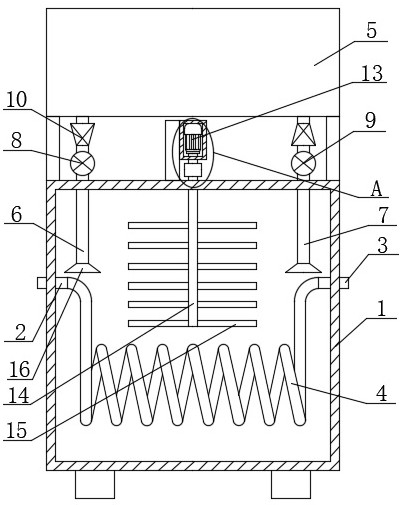

Refrigerant recovery device

InactiveCN1346957AEasy to operateLow costMechanical apparatusStationary conduit assembliesRefrigerant reclamationSolenoid valve

A refrigerant recovery device comprises a compressor 1 which draws in chlorofluorocarbons gas. Chlorofluorocarbons gas that has increased pressure and temperature by being discharged from the compressor 1 is conducted through a heat exchange device 2 to become liquid refrigerant. The liquid refrigerant is conducted by a liquid pipe 13 to a refrigerant recovery tank 7. Gas of the refrigerant inside the refrigerant recovery tank 7 is conducted to the compressor 1 by a gas pipe 21. The heat exchange device 2 comprises the first helical piping 3 formed by winding a small diameter heat transfer pipe, a large diameter tube 5 with a cross-sectional area larger than the previous heat transfer pipe and the second helical, small-diameter piping 4 with a structure similar to the first helical small-diameter piping 3, these elements being connected in serial as a single unit, or alternatively the heat exchange device comprises two or more single units connected together. The liquid pipe 13 comprises a solenoid valve 6 that is controlled by a pressure sensor 14 to open at a preset upper value and to close at a preset lower value. The gas pipe 12 comprises a solenoid valve 22 that is controlled by a pressure sensor 24 to open at a preset upper value and to close at a preset lower value. The present invention provides a refrigerant recovery device that is cheap, compact and is portable and easy to operate for inexpensively recovering chlorofluorocarbons.

Owner:岩崎 照皇

Production method of bamboo phenolic alcohol liquefied products

InactiveCN102504275AMild reaction conditionsSafe working environmentPolyethylene glycolAcid catalyzed

The invention relates to a method for producing liquefied products by crushed small-diameter bamboo materials and bamboo material processing residues under the simultaneous effect of phenolic alcohol compounds. The invention has a purpose that a better liquefying effect can be obtained by various chemical ingredients in the bamboo materials by the provided method, in addition, the reaction temperature is lower, the reaction pressure is lower, and the safety is higher. The method has the technical scheme that a production method of bamboo phenolic alcohol liquefied products comprises the following steps that: 1) firstly, small-diameter bamboo or / and bamboo material processing residues are crushed to 20 to 80 meshes and are baked until the moisture content is lower than 10 percent for standby; 2) 100 mass parts of bamboo powder, 50 to 75 mass parts of phenol, 50 to 75 mass parts of polyethylene glycol and 15 to 30 mass parts of acid catalysts are added into a reaction container, the normal-pressure reaction lasts 30 to 90 minutes, the reaction temperature is 110 DEG C to 170 DEG C, the temperature is reduced to the room temperature after the reaction completion, and 15 to 30 mass parts of caustic soda solution is added for neutralization to obtain the bamboo material liquefied products.

Owner:ZHEJIANG FORESTRY ACAD

Method for preparing biodegradable polyurethane rigid foam from bamboo waste liquefaction products

InactiveCN101362818BRealize the purpose of turning waste into treasureReduce dependencePolymer sciencePolyethylene glycol

The invention discloses a method for preparing biodegradable rigid polyurethane foam with liquefaction products of bamboo waste, which comprises the following steps: 1 mass portion of crude glycerin / polyethylene glycol liquefying solvent and 0.02-0.04 mass portion of concentrated sulfuric acid are added into a reaction vessel, heated till the temperature reaches 120-180 DEG C after a reflux condensation tube is connected to the reaction vessel; 0.2-0.5 mass portion of crushed and dried bamboo waste is added, reacted for 90-180min with stirring, taken out and cooled and neutralized by MgO tillbeing neutral; 1 mass portion of liquefaction products of bamboo waste, 0.02-0.08 portion of a dibutyl tin dilaurate / triethylene diamine mixed catalyst, 0.02-0.06 portion of silicone oil, 0.02-0.1 portion of water and 0.1-0.15 portion of fire retardant are added into a container, premixed for 20-30s when stirred at 2,000r / min, added with sufficient PAPI with the molar ratio between isocyanato-NCOin PAPI and hydroxyl group-OH in bamboo waste liquefaction products being 0.6-1.2, stirred for 10s-15s at 1,000r / min, put into a mould, foamed with standing at room temperature, placed for slaking and mould separating at room temperature for 24h-72h after reaction. The method fully utilizes resources, reduces liquefaction cost, and has a mild reaction temperature and stable liquefaction products;the performance of obtained foam meets the national standard and biodegradability.

Owner:NANCHANG UNIV

Process for corn starch sugar by enzyme method

ActiveCN101117647AStrong shear forceFully cookedFermentationGlucose productionFlocculationIon exchange

The present invention provides a process of corn starch sugar producing by an enzymatic technique. The process step mainly includes hydrolysis liquefaction, flash braise, saccharification, bleaching, ion exchange and enrichment of amylum material under the action of enzyme preparation; wherein the hydrolysis liquefaction uses a water heater as the braising and boiling reactor, and the water heater has an adjustable clearance for material entering into. In the process of the hydrolysis liquefaction, the pressure difference of the feeding amylum material and the discharged amylum material on the water heater can be controlled between 0.15-0.30MPa, and 0.20-0.25MPa are optimal; the single braising and boiling temperature is controlled between 110-130 DEG C, and 110-125 DEG C are optimal. The water heater adopted by the present invention can ensure a curtain pressure difference of the feeding material and the discharged material, can bring strong cut force, and can ensure zymolyte molecules sizes of the liquefaction liquid to be regular and proportioned. The present invention adopts high temperature braising and boiling, which can make the protein denaturation more rapid, more complete, and the flocculation better, and can facilitate the protein removing.

Owner:COFCO RONGS BIOTECH

Preparation method of solution trimethyl indium source

A process for preparing the solution as the source of trimethyl indium source includes such steps as preparing schiff base by dewatering reaction between aromatic aldehyde (or ketone) and the primaryamine or fatty aldehyde or ketone, adding trimethyl indium to low-boiling-point solvent, stirring while heating, adding schiff base, pressure-reduction distilling to remove solvent and to obtain the mating member of schiff base and trimethyl indium.

Owner:NANJING UNIV

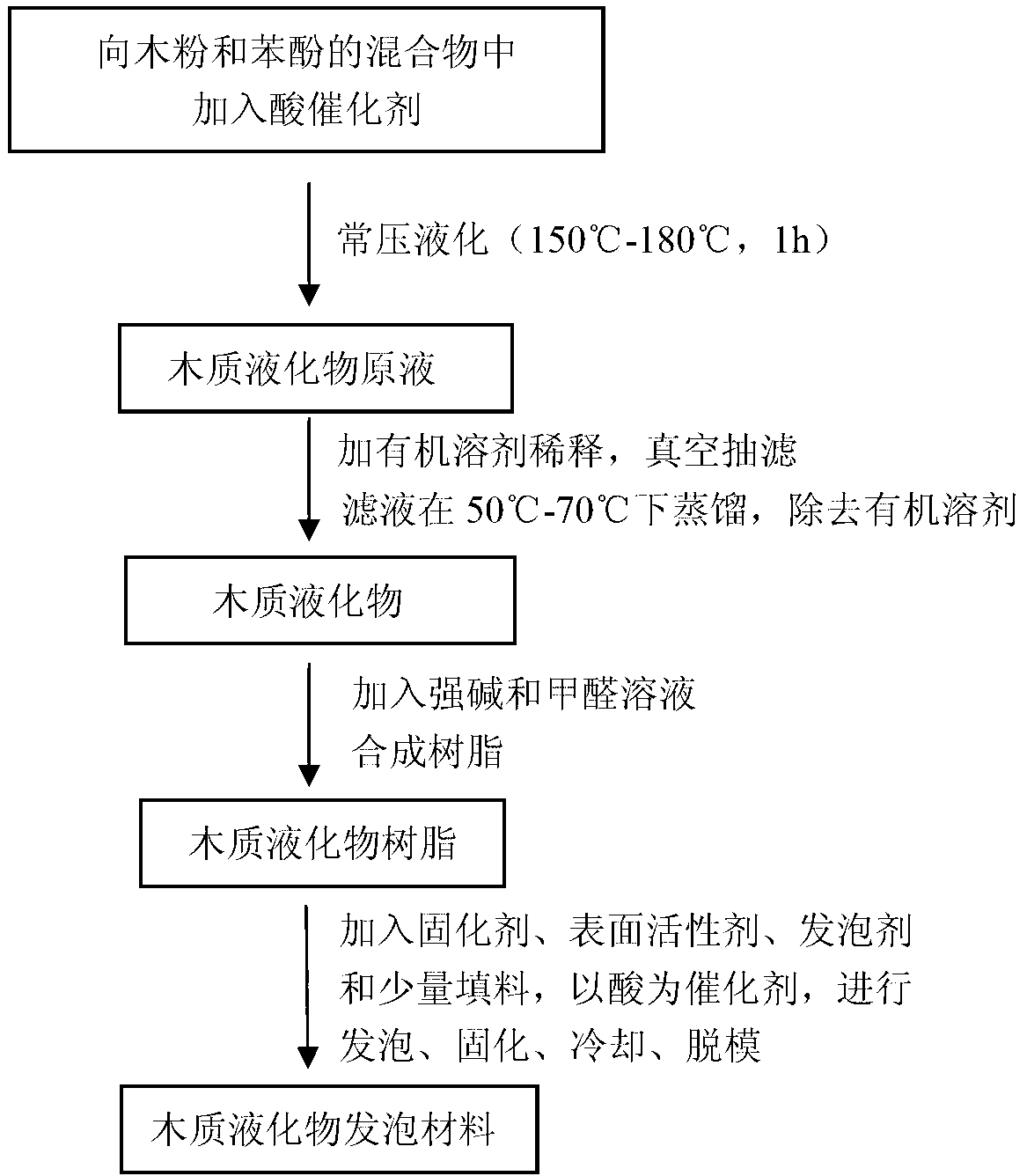

Wood liquefied substance foamed material and preparation method thereof

The invention provides a novel wood liquefied substance foamed material and a preparation method thereof. The preparation method comprises the following steps: putting wood meal in a liquefying plant, and adding a liquefier phenol and an acidic catalyst to prepare a wood liquefied substance; and carrying out resin synthesis on the liquefied substance to obtain a wood liquefied substance resin, adding certain amounts of curing agent, foaming agent, catalyst and surfactant, and foaming in a drying oven to obtain the wood liquefied substance foamed material, of which the apparent density is 0.11-0.28 g / cm<3> and the compression strength is 1.6-5.1 MPa. By using the wood biomass as the raw material, the invention fully utilizes recyclable resources, such as forestry processing wastes, agricultural wastes or any other biomass raw material, instead of petroleum resources to substitute oil with wood, thereby effectively solving the problem of shortage of energy in future, and providing a new way for developing novel chemical products from renewable recourses.

Owner:BEIJING FORESTRY UNIVERSITY

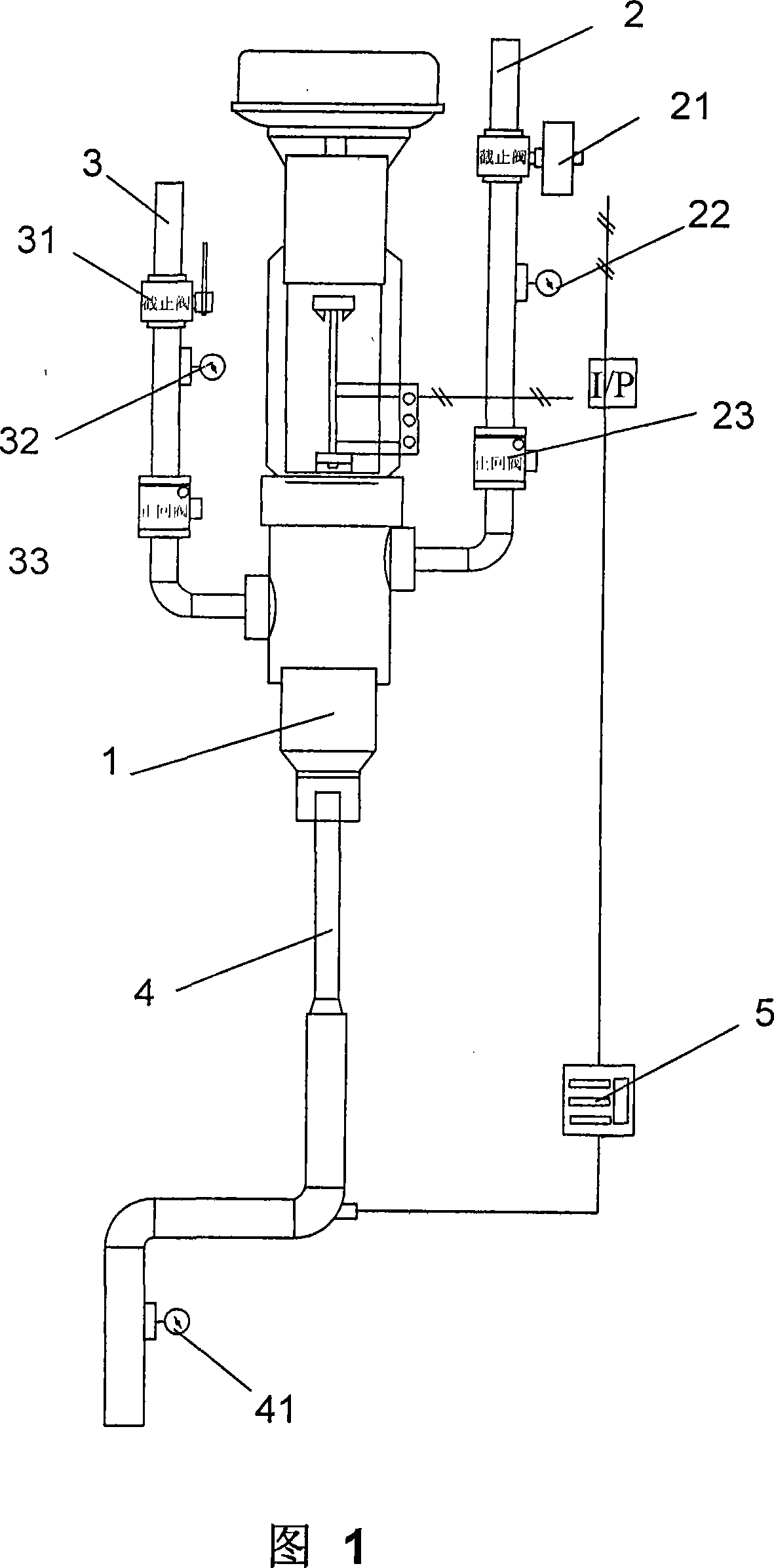

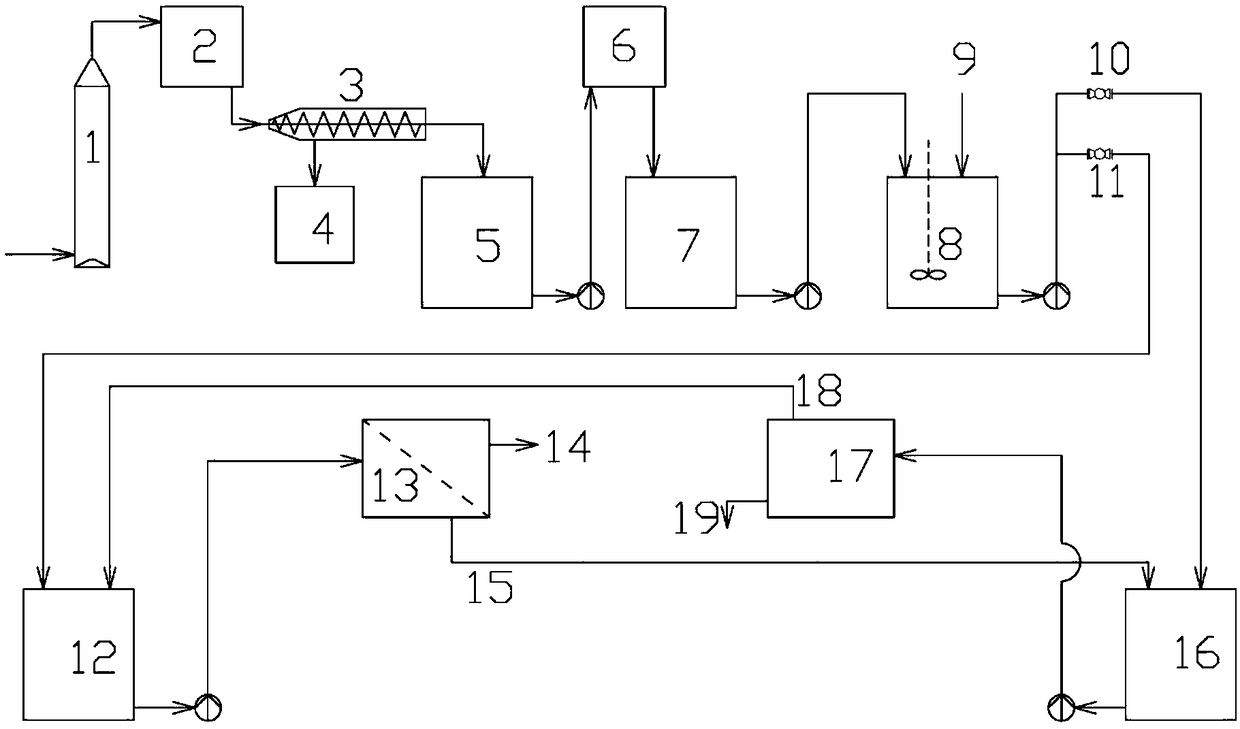

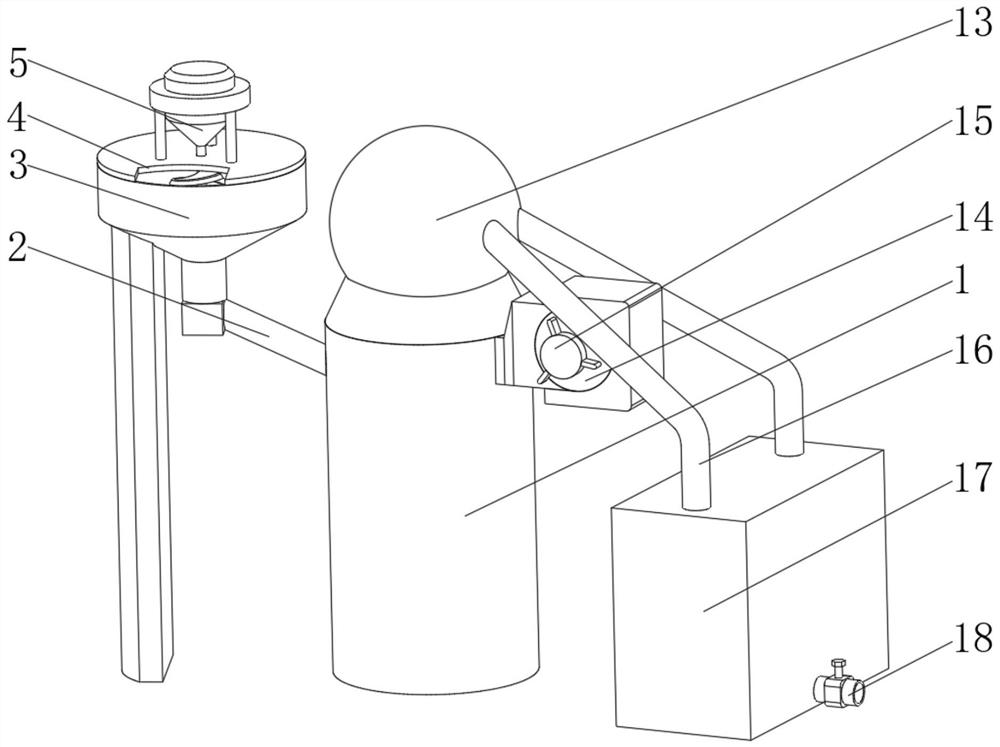

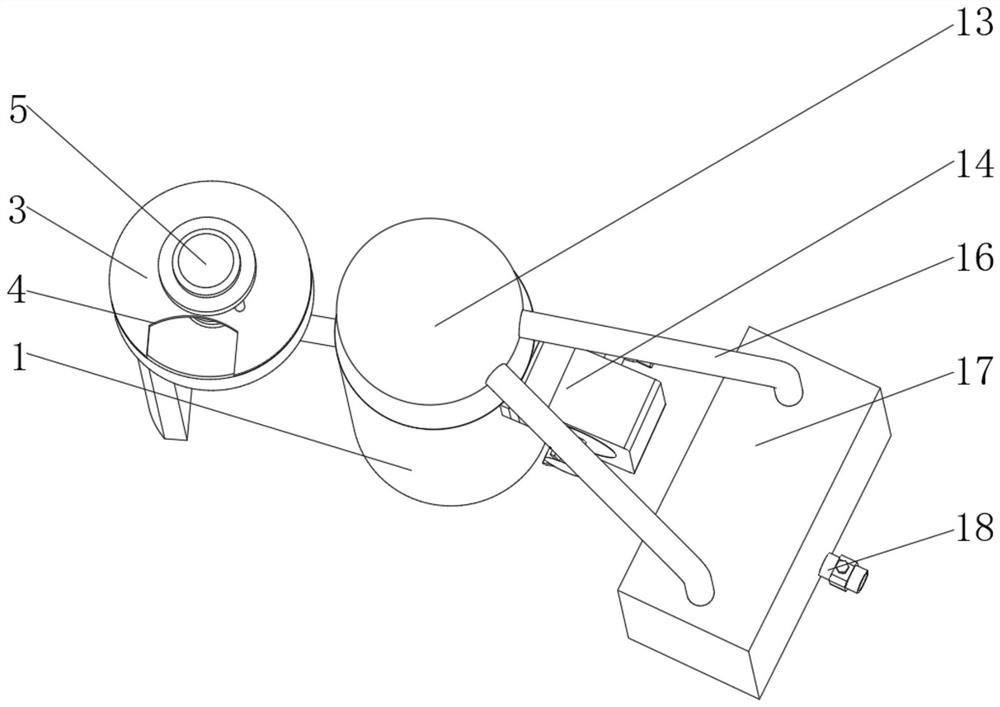

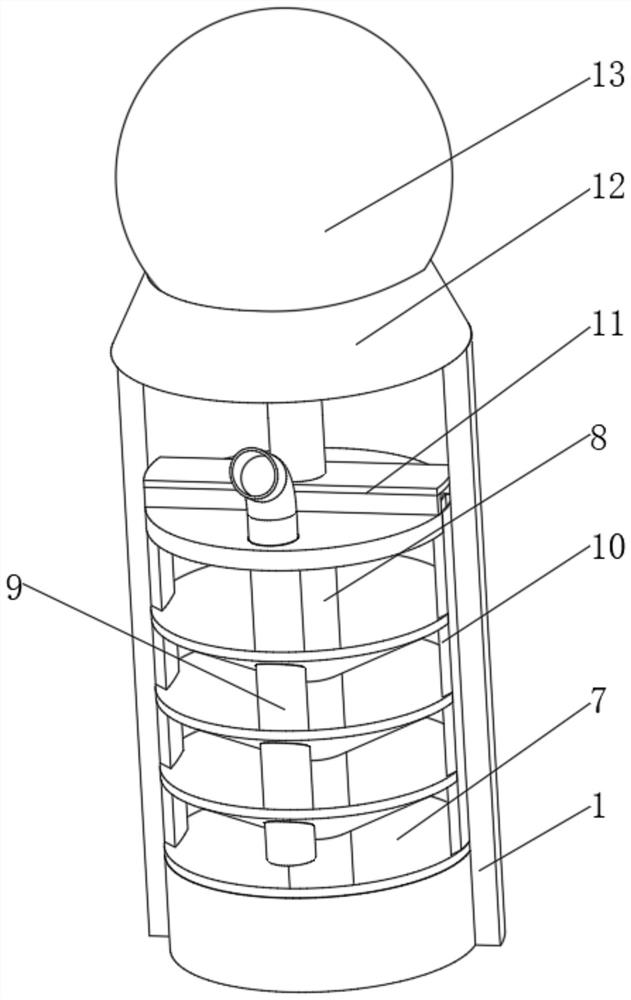

Flue gas treatment system and treatment method for PVC glove production workshop

The invention discloses a flue gas treatment system and treatment method for a PVC glove production workshop, and belongs to the field of glove production equipment. The system and method are characterized in that a spraying device for carrying out spraying cooling on gloves on a glove die (3) is arranged above a glove die line and is connected with a circulation water supply device; a smoke recycling treatment system is further included and comprises a smoke liquefying device, an oil and water separating device and a heat exchange device; an inlet of the smoke liquefying device is communicated with the workshop through a chimney (18); and a mixed liquid outlet of the smoke liquefying device is communicated with a mixed liquid inlet of the oil and water separating device, and a water outlet of the oil and water separating device is communicated with the smoke liquefying device. According to the flue gas treatment system for the PVC glove production workshop, self-cleaning stable running all year around can be achieved, power consumption is low, organic components in smoke exhausted from the workshop can be recycled in a liquefied manner through the treatment method, the recycling effect is good, and raw material consumption is low.

Owner:BLUE SAIL MEDICAL

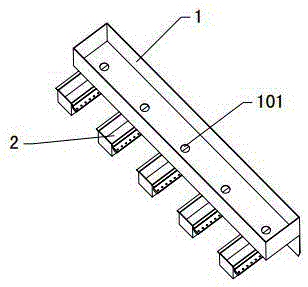

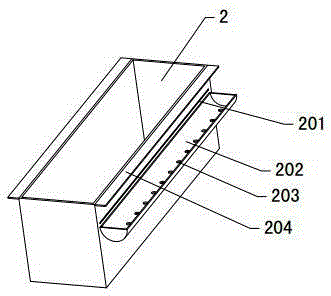

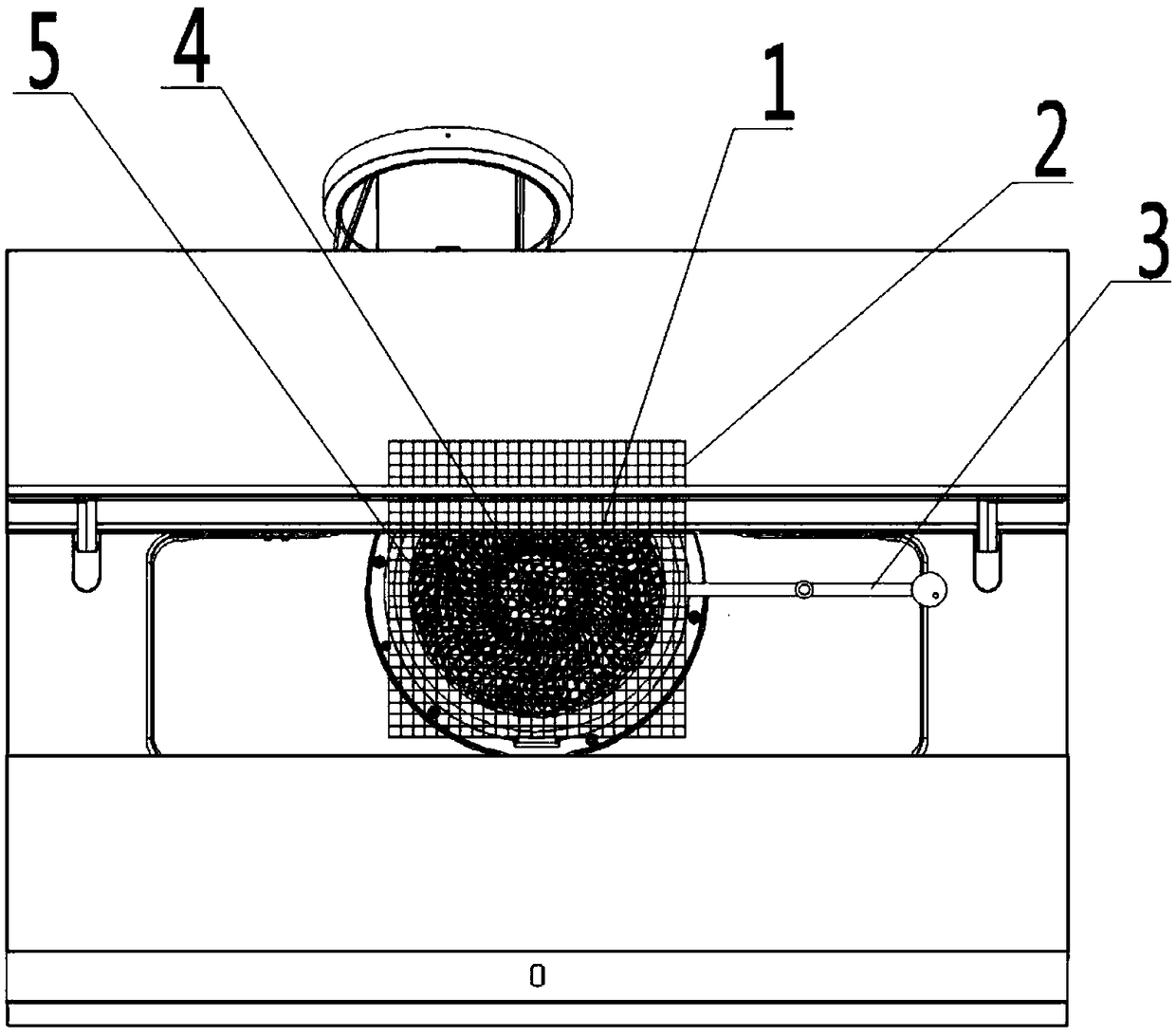

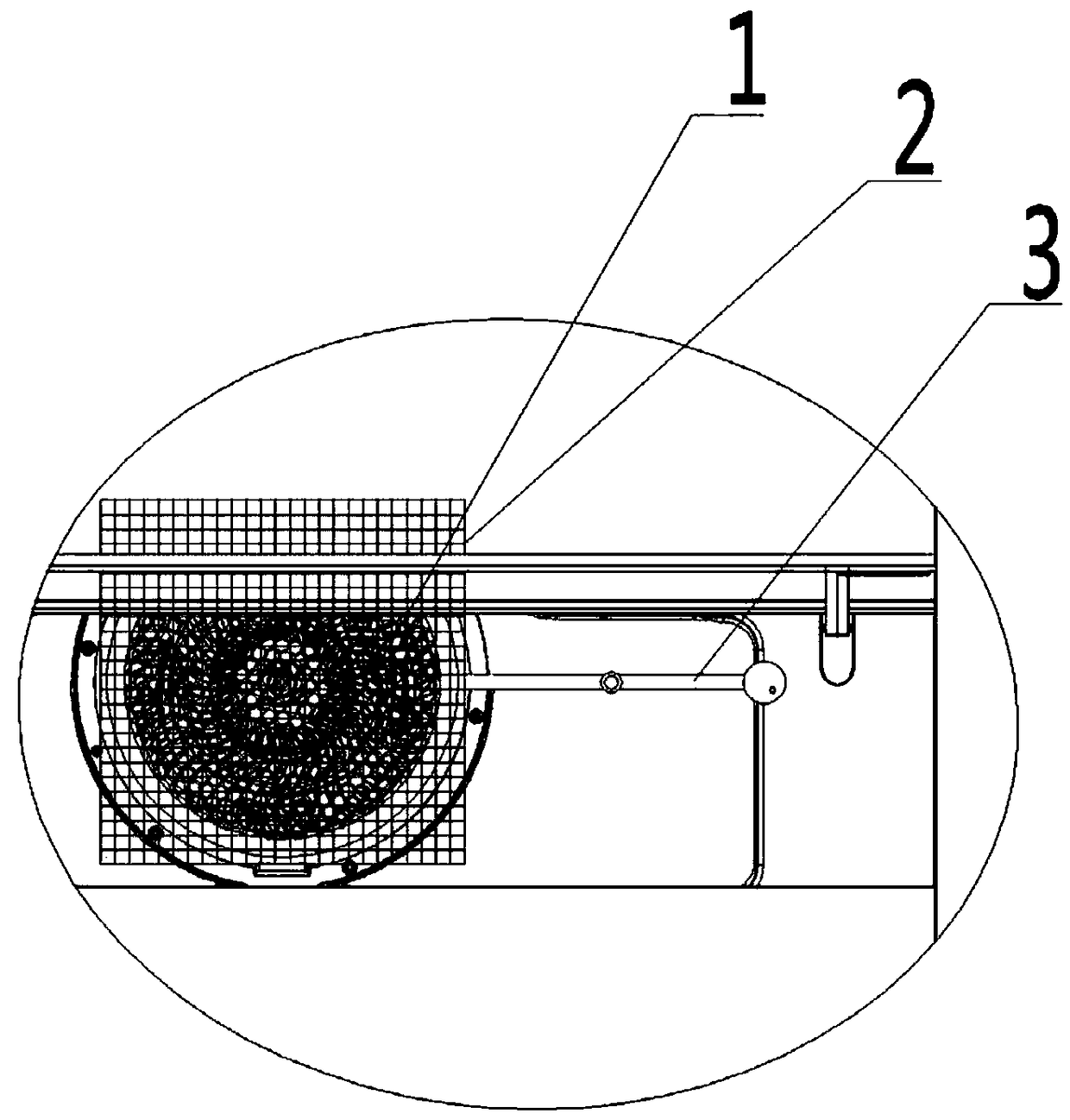

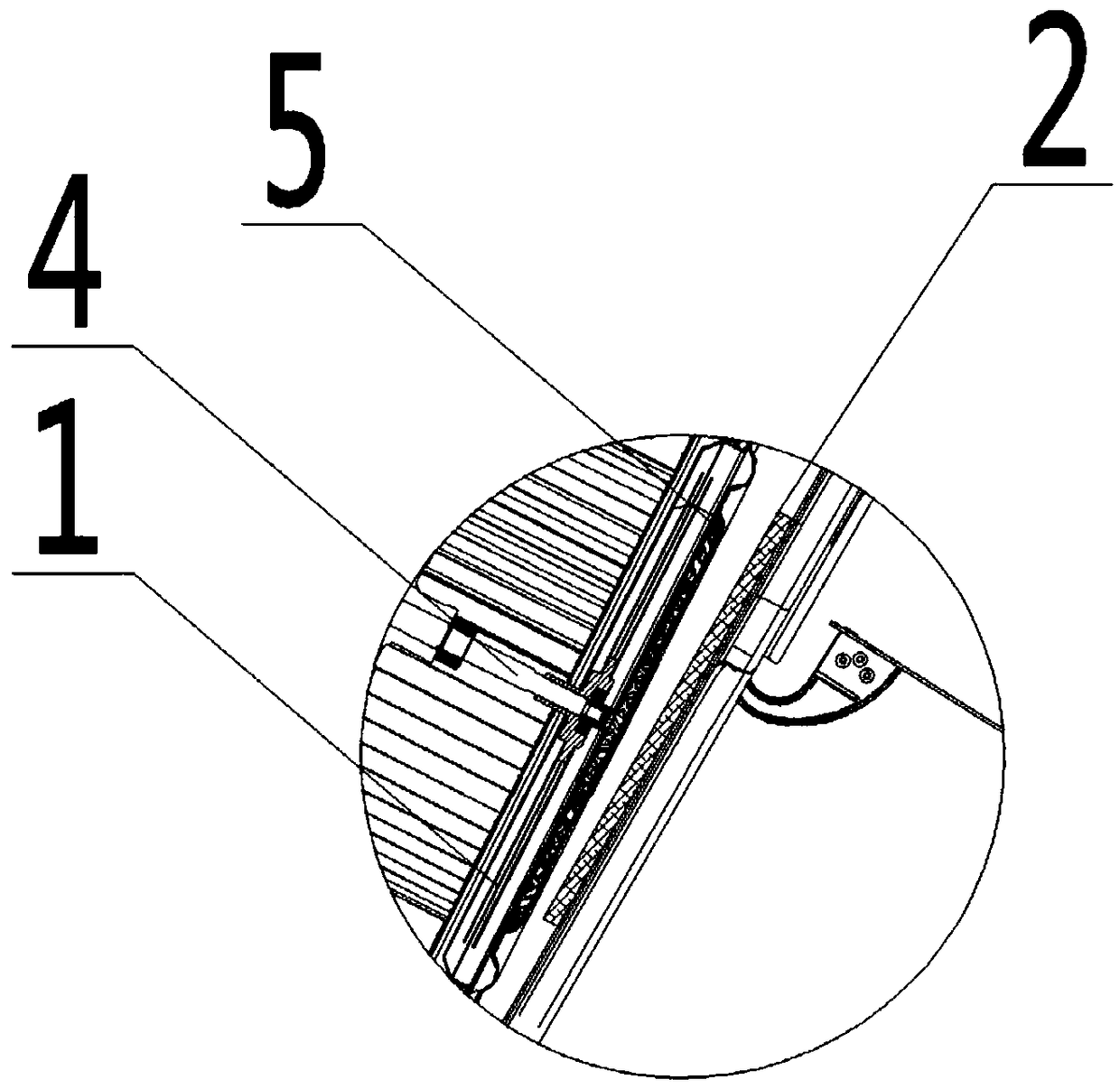

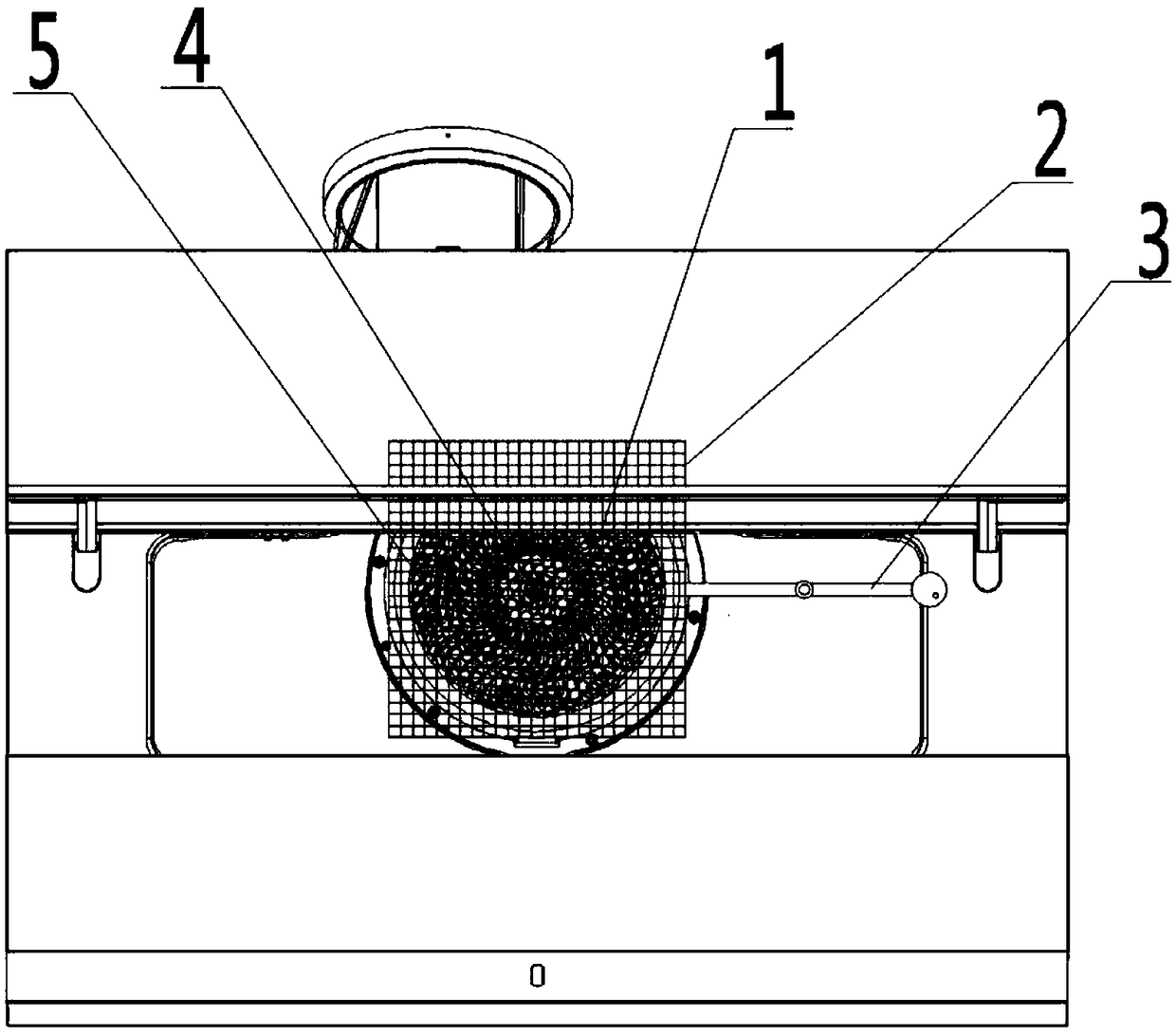

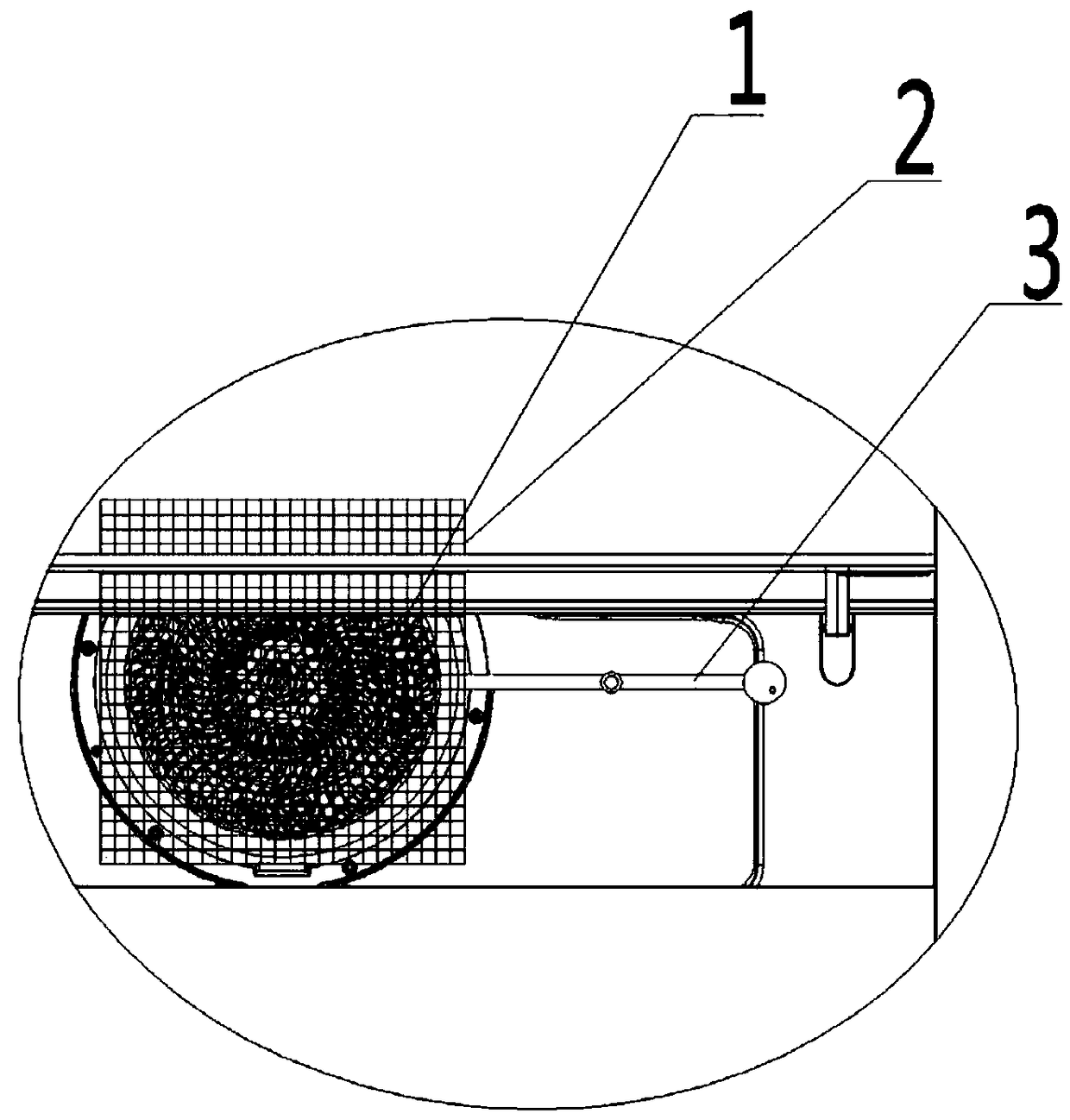

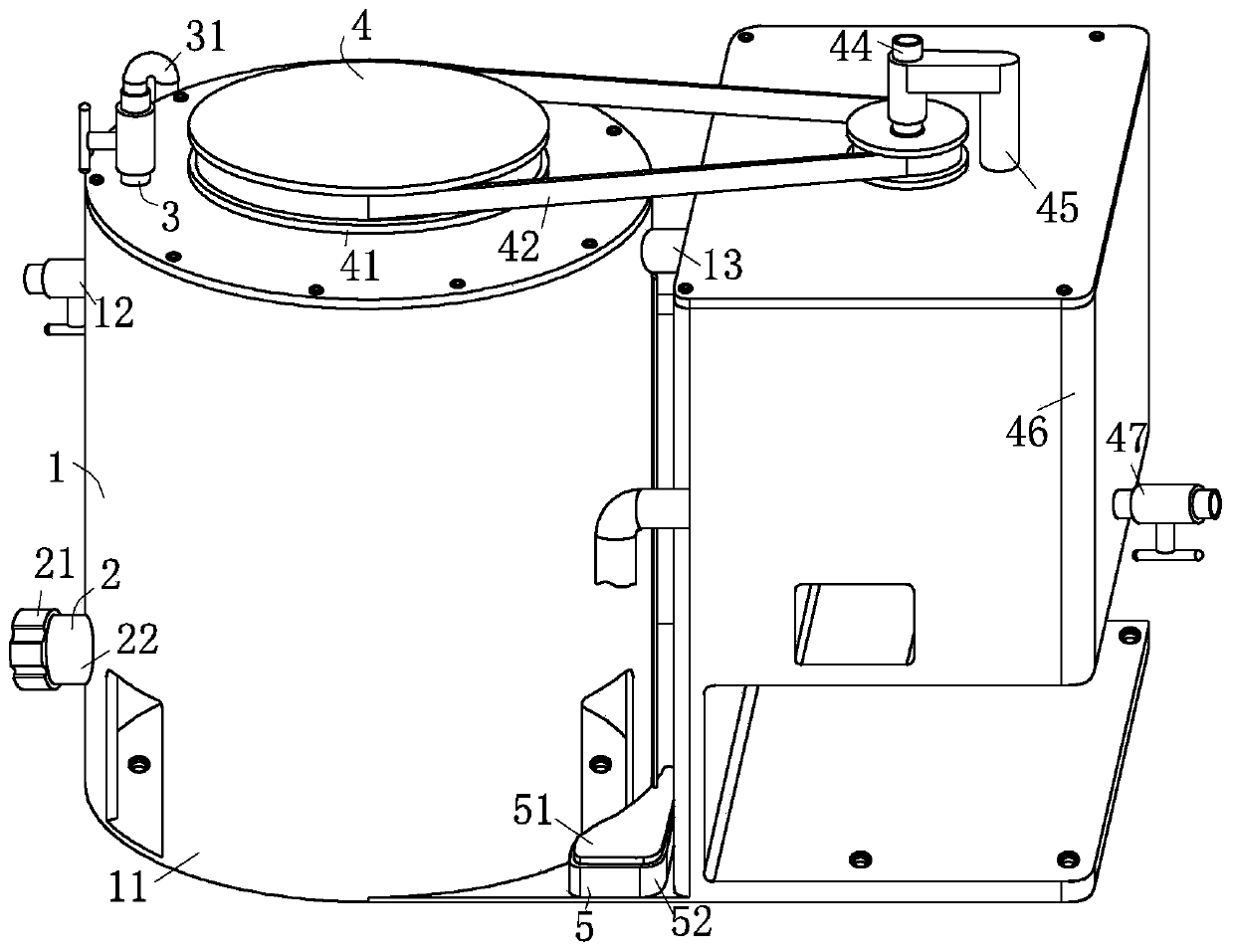

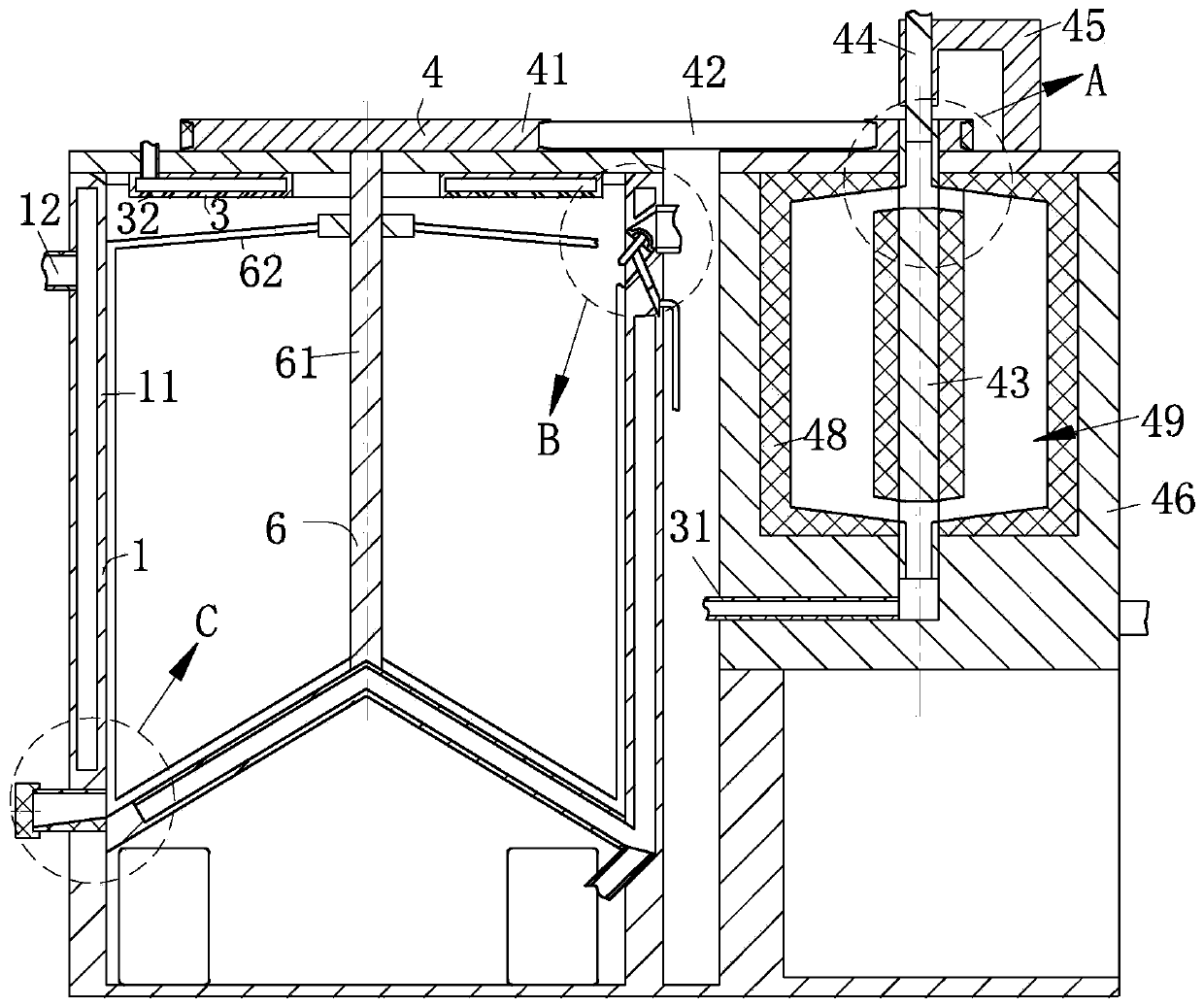

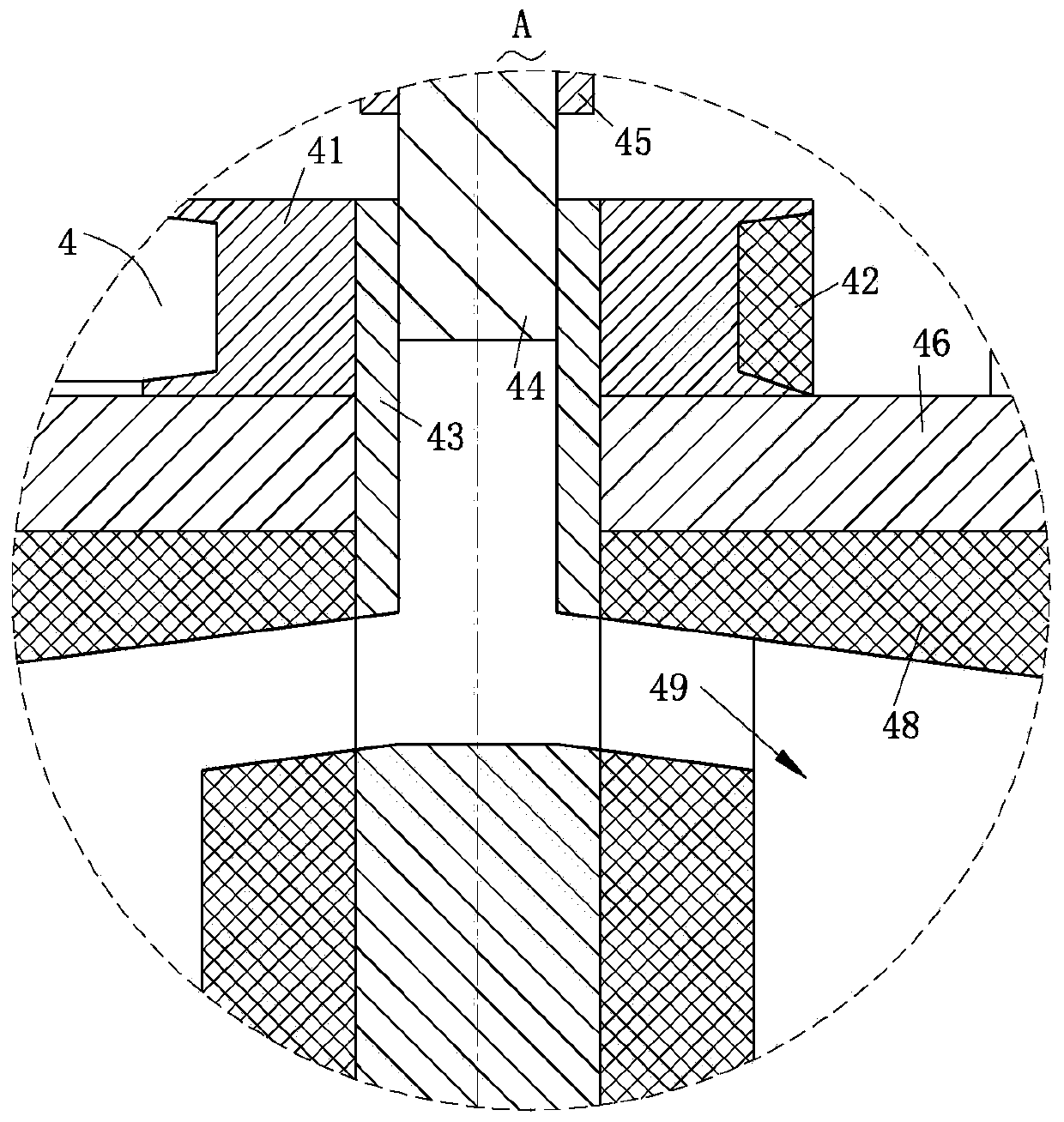

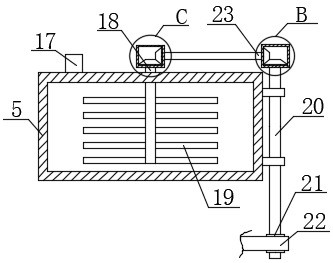

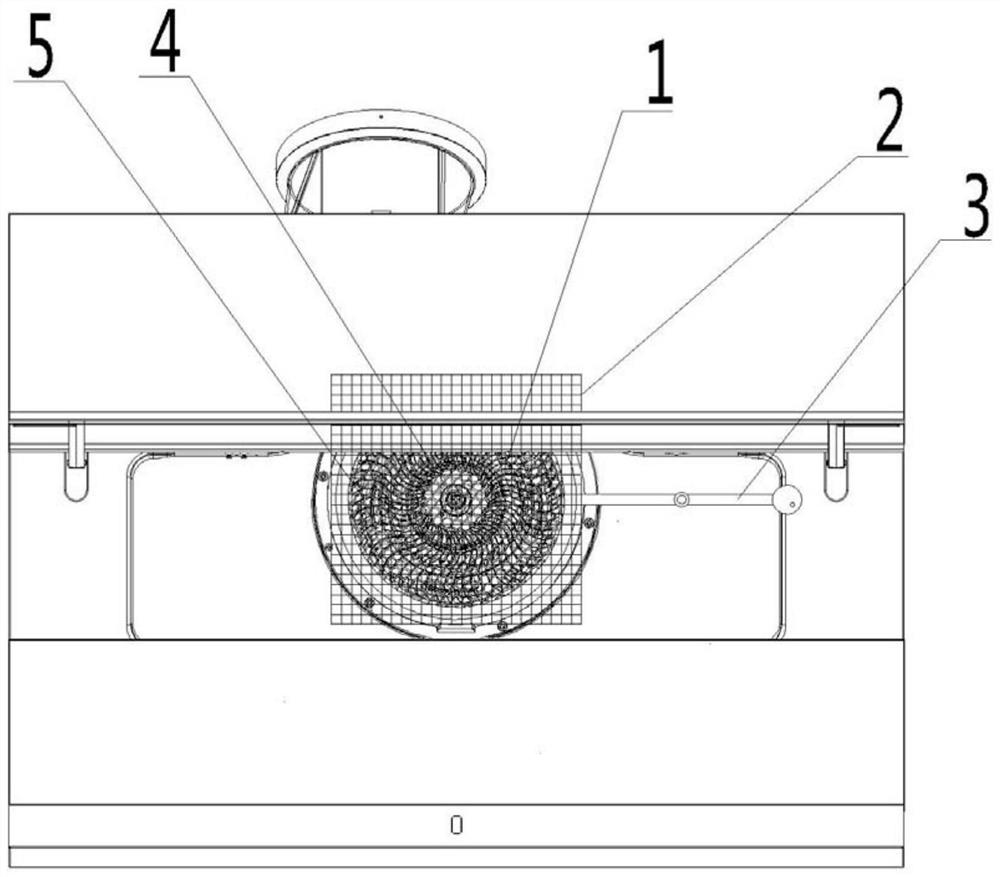

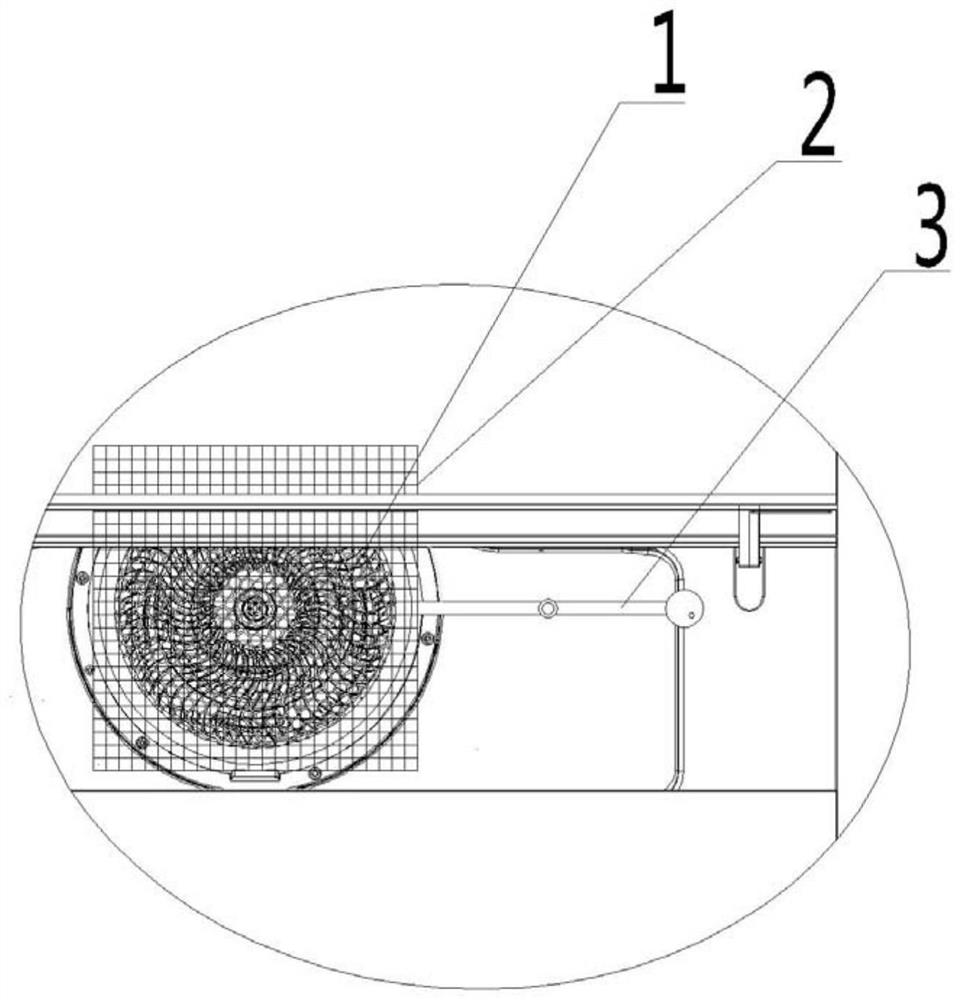

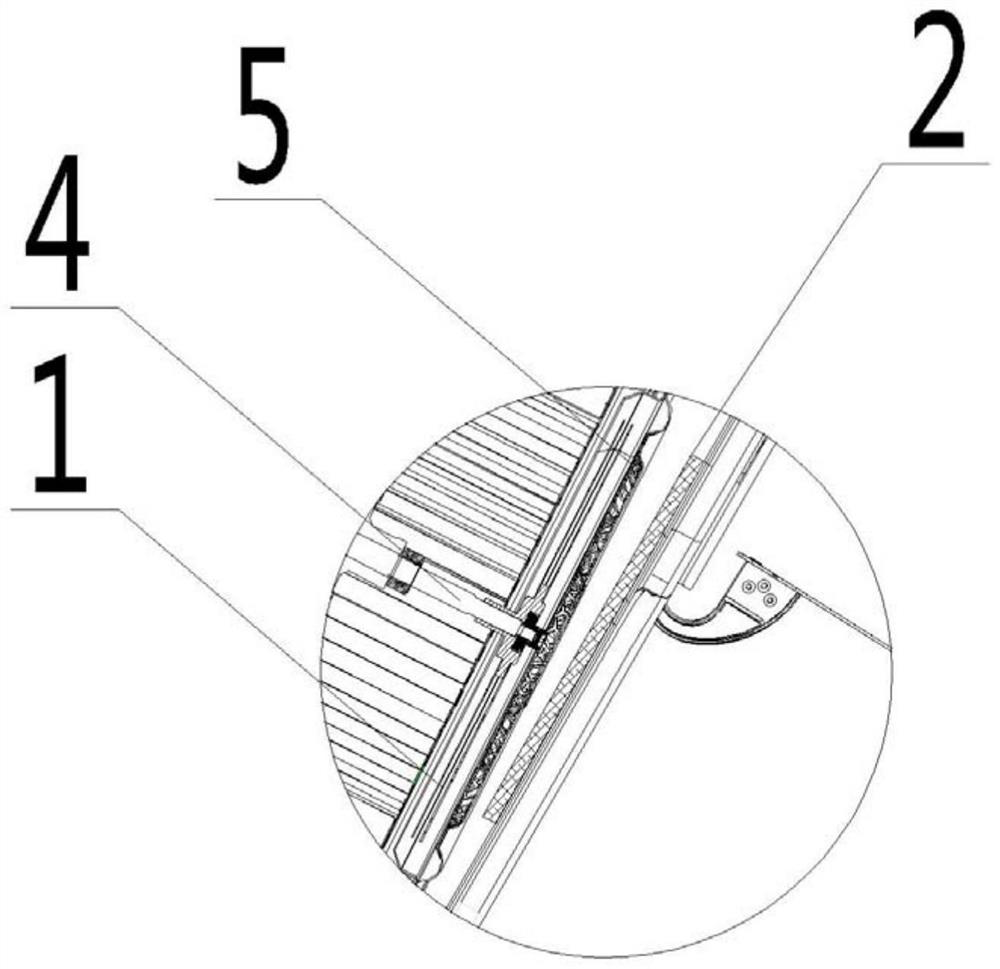

Self-cleaning structure and method of range hood and range hood

ActiveCN109268888APromote softeningGood liquefaction effectDomestic stoves or rangesLighting and heating apparatusEngineeringAir heating

The invention relates to the field of range hoods, and particularly provides a self-cleaning structure and method of a range hood and the range hood. The self-cleaning structure of the range hood comprises a motor, an inner oil screen which is arranged on an oil fume suction opening of the range hood, and is driven by the motor to act and to intercept oil in oil fume, and a hot air heating devicewhich is arranged on the range hood, and cleans the inner oil screen by heating the inner oil screen, wherein the hot air heating device comprises a fan and an air outlet which is connected with the fan, and is used for heating the inner oil screen. According to the self-cleaning structure and method of the range hood and the range hood, the inner oil screen is arranged to intercept oil particlesin the oil fume, the situation that the oil enters the range hood, and pollutes a wind wheel and an air duct in the range hood to improve the cleaning difficulty is avoided, by heating the inner oil screen, the oil is fast cleaned away, there is no need to heat the wind wheel or the air duct, the heating efficiency is high, the cleaning effect is better, and the range hood cleaning cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

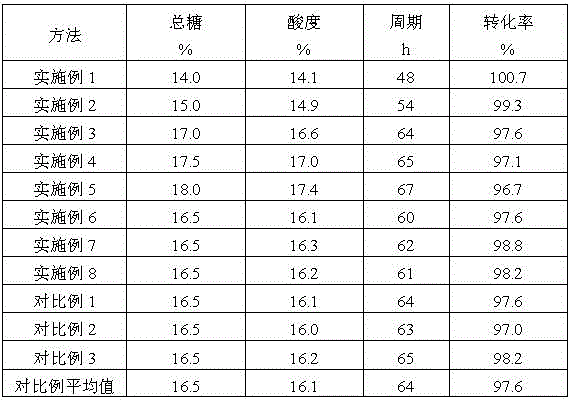

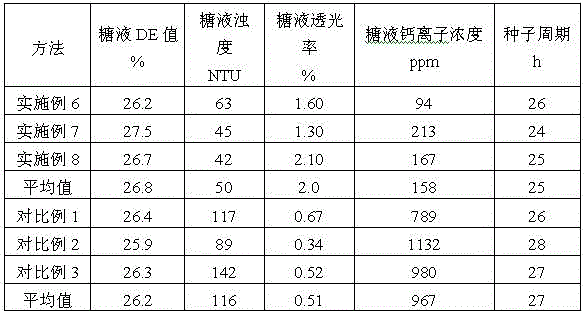

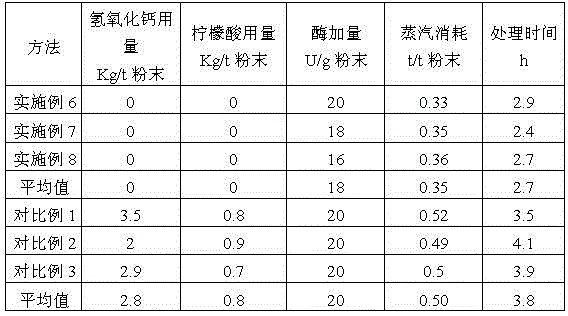

Processing method for starchiness materials and application of processing method in citric acid preparing industry

InactiveCN105567749AGood flocculation effectReduce dosageMicroorganism based processesFermentationAmylaseSide effect

The invention discloses a processing method for starchiness materials. According to the processing method, citric-acid waste water is utilized as a raw material. The processing method comprises the steps of material smashing, pulp mixing, once enzyme supplementation, once spraying, flashing and solid-liquid separation; and the enzyme is selected from acid-resisting alpha- thermostable amylase. The processing method is suitable for low-pH liquefying conditions. According to the processing method, the operation is greatly simplified, the energy consumption and producing cost are reduced, the ideal protein flocculating and purifying effect is guaranteed, and the side effects caused to following fermentation and purification are reduced. When the processing method is applied to the critic acid preparing industry, the seed growing speed is obviously increased, the seed cultivating period is shortened, the fermentation index is further improved, the fermentation period is shortened, and the converting rate is improved. Thus, the processing method has important industrial application value.

Owner:JIANGSU GUOXIN UNION ENERGY CO LTD +1

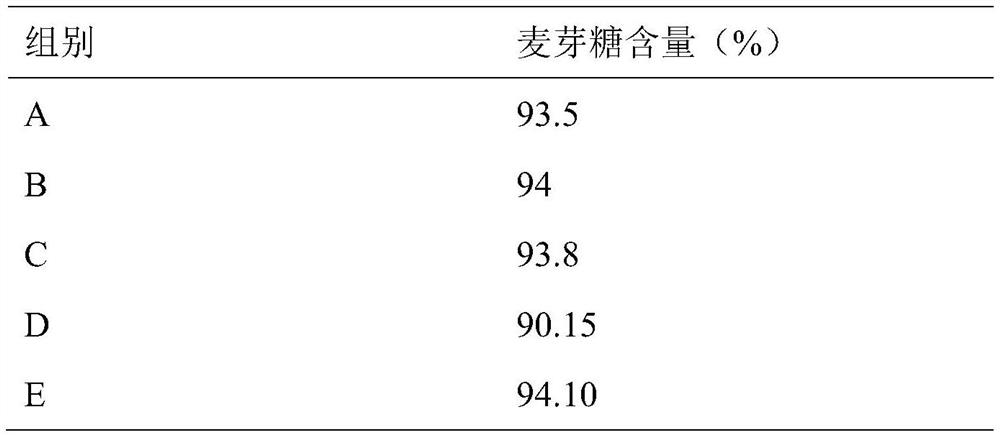

Preparation method of maltose powdered sugar with high maltose content

PendingCN113215208AReduce manufacturing costHigh degree of glycationSugar derivativesDisaccharidesGlucanOligosaccharide

The invention relates to a preparation method of maltose powdered sugar with high maltose content. The method comprises the steps of pretreatment, acid enzyme liquefaction, impurity removal, saccharification and refining, indica rice with poor eating quality is used as a raw material to produce maltose, and fungus alpha-amylase, pullulanase and maltotriase are added during saccharification for synergistic effect; the saccharification reaction is performed for a period of time, dextranase is added for a hydrolysis reaction, and enzyme deactivation is performed to obtain saccharification liquid; by controlling the conditions such as a liquefied DE value and the addition amount of various enzymes, the production cost can be reduced while starch is catalyzed to be degraded to generate maltose, and better conditions are provided for maltose formation in the subsequent saccharification step; and the dextranase deeply catalyzes and hydrolyzes glucan into glucose or oligosaccharide, non-maltose parts are removed during refining, the purity of maltose is further improved, the filterability of maltose sugar products is improved, and the viscosity is reduced. The maltose sugar powder with the maltose content being 90% or above can be prepared through the method of the invention, and the application prospect in the sugar product field is considerable.

Owner:JIANGSU OGO BIOTECH

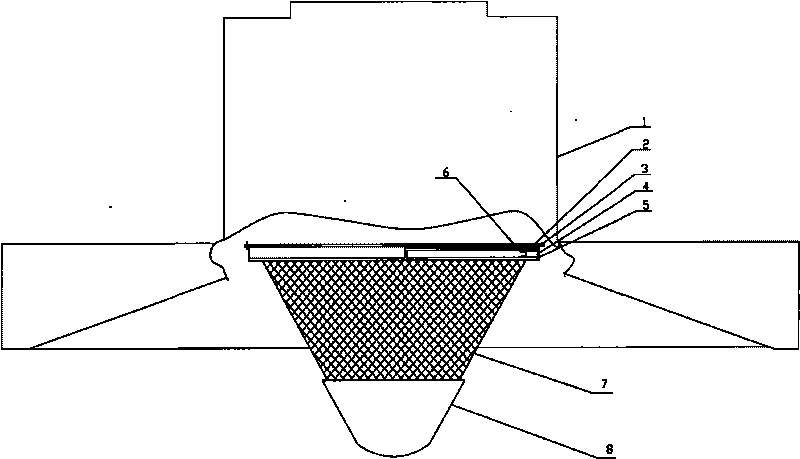

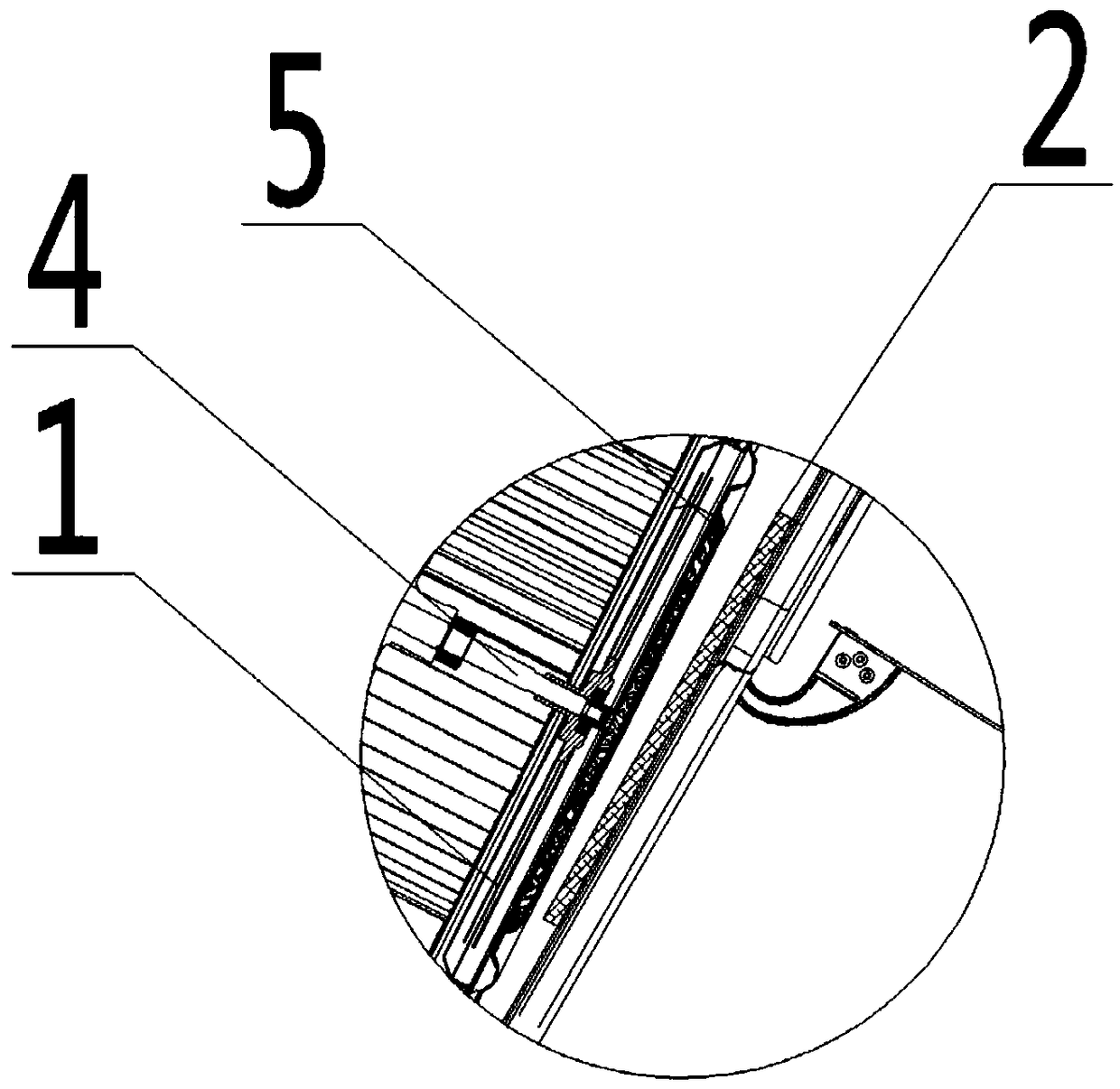

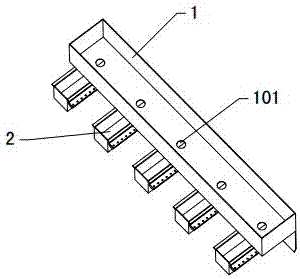

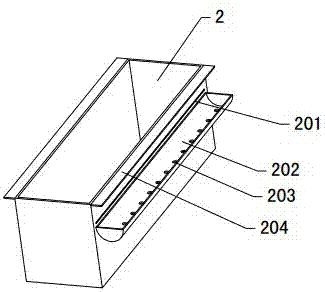

Heating oil-collecting mesh hood of range hood

InactiveCN101701727AGood liquefaction effectAvoid passingDomestic stoves or rangesLighting and heating apparatusHeating oilInsulation layer

The invention discloses a heating oil-collecting mesh hood of a range hood, comprising an oil-collecting mesh (7) and a heater mounted on the oil-collecting mesh (7). The heater comprises a heat-conducting plate, a heating block (4) and a heater binding post (6), wherein the heating block (4) is connected with the heater binding post (6), and the heat-conducting plate which is mounted on the oil-collecting mesh (7), is provided with a heat-insulating pad (2) and comprises an upper heat-conducting plate (3) and a lower heat-conducting plate (5); both heat-conducting plates are connected with the heating block (4) and mounted above the oil-collecting mesh (7); and the heating block (4) is wrapped by an insulation layer. Oil dirt stuck to the oil-collecting mesh hood is heated and liquefied before flowing to an oil-collecting cup so that oil is thoroughly cleaned and the non-cleaning effect is achieved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

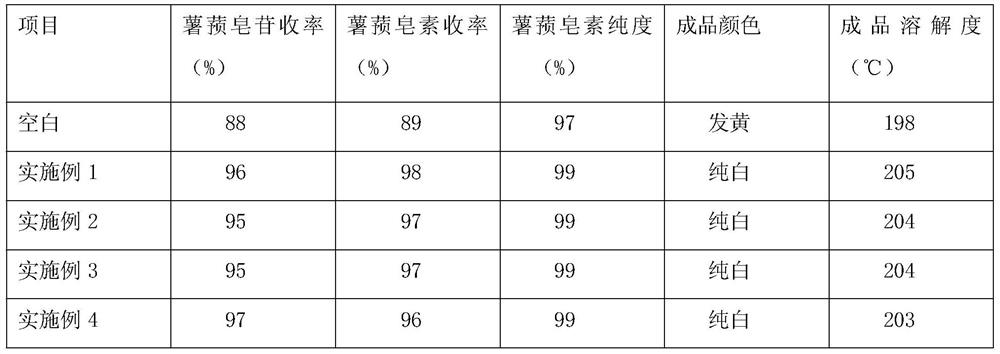

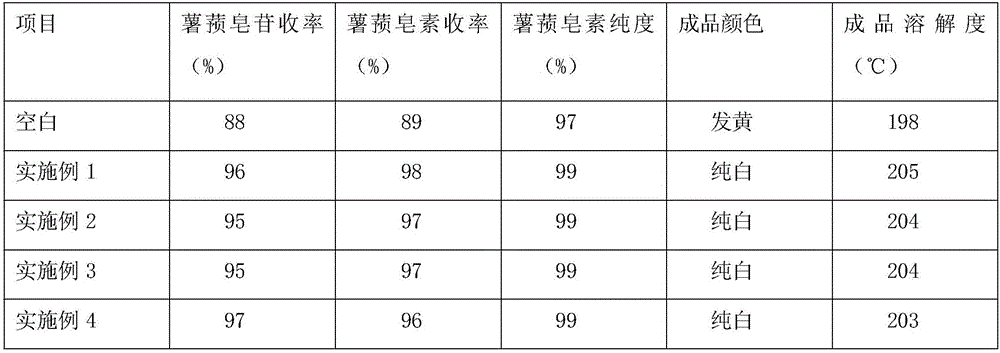

Preparation of immobilized enzyme and method for hydrolyzing diosgenin

ActiveCN105925559BGood liquefaction effectReduce pollutionOn/in organic carrierFermentationBiotechnologyAlglucerase

Owner:华慧海洋多糖生物技术(深圳)有限公司

Self-cleaning structure and method of range hood and range hood

ActiveCN109268889APromote softeningGood liquefaction effectDomestic stoves or rangesLighting and heating apparatusEngineeringHeating efficiency

The invention relates to the field of range hoods, and particularly provides a self-cleaning structure and method of a range hood and the range hood. The self-cleaning structure of the range hood comprises a motor, an inner oil screen which is arranged on an oil fume suction opening of the range hood, and is driven by the motor to act and to intercept oil in oil fume, and a heating device which isarranged on the range hood, and cleans the inner oil screen by heating the inner oil screen. According to the self-cleaning structure and method of the range hood and the range hood, the inner oil screen is arranged to intercept oil particles in the oil fume, the situation that the oil enters the range hood, and pollutes a wind wheel and an air duct in the range hood to improve the cleaning difficulty is avoided, by heating the inner oil screen, the oil is fast cleaned away, there is no need to heat the wind wheel or the air duct, the heating efficiency is high, the cleaning effect is better,and the range hood cleaning cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Method for preparing immobilized enzyme and hydrolyzing diosgenin

ActiveCN105925559AGood liquefaction effectReduce pollutionOn/in organic carrierFermentationAlgluceraseAdditional values

The invention belongs to the field of biomedicines and in particular relates to a method for preparing an immobilized enzyme and hydrolyzing diosgenin. The method comprises the following steps: crushing a dried turmeric raw material; adding water and immersing; carrying out enzymolysis and removing impurities, extracting dioscin and hydrolyzing the dioscin into the diosgenin with an immobilized enzyme preparation composition; extracting aviation kerosene to prepare a finished product. By utilizing an immobilized enzyme technology, rhamnosidase and beta-glucosidase, which have an expensive market price, are successfully applied to an industrial product with a lower additional value. A biological method is used for replacing traditional dioscin acidolysis, so that the environmental pollution is remarkably reduced; the method has moderate reaction conditions and a low cost.

Owner:华慧海洋多糖生物技术(深圳)有限公司

Device and method for preparing starch sugar for high-temperature corn drying

ActiveCN108893509AReduce modified starch contentSpeed up liquefactionBioreactor/fermenter combinationsBiological substance pretreatmentsFlocculationProduction effect

The invention relates to a device and method for preparing starch sugar for high-temperature corn drying. The method comprises the following steps: increasing the input concentration of coarse starchmilk which is processed from corn, separating the coarse starch milk through a disk type separator to obtain starch milk with reduced content of gluten water and modified starch; liquifying and separating the starch milk to obtain a starch milk light phase; saccharifying the starch milk light phase, performing protein flocculation on the saccharified liquid, and performing post-treatment to obtainthe starch sugar. According to the method, the content of modified starch in starch milk can be reduced, the liquifying and saccharifying effect can be greatly improved, and the integral production effect is remarkably promoted.

Owner:国粮武汉科学研究设计院有限公司

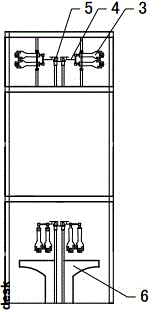

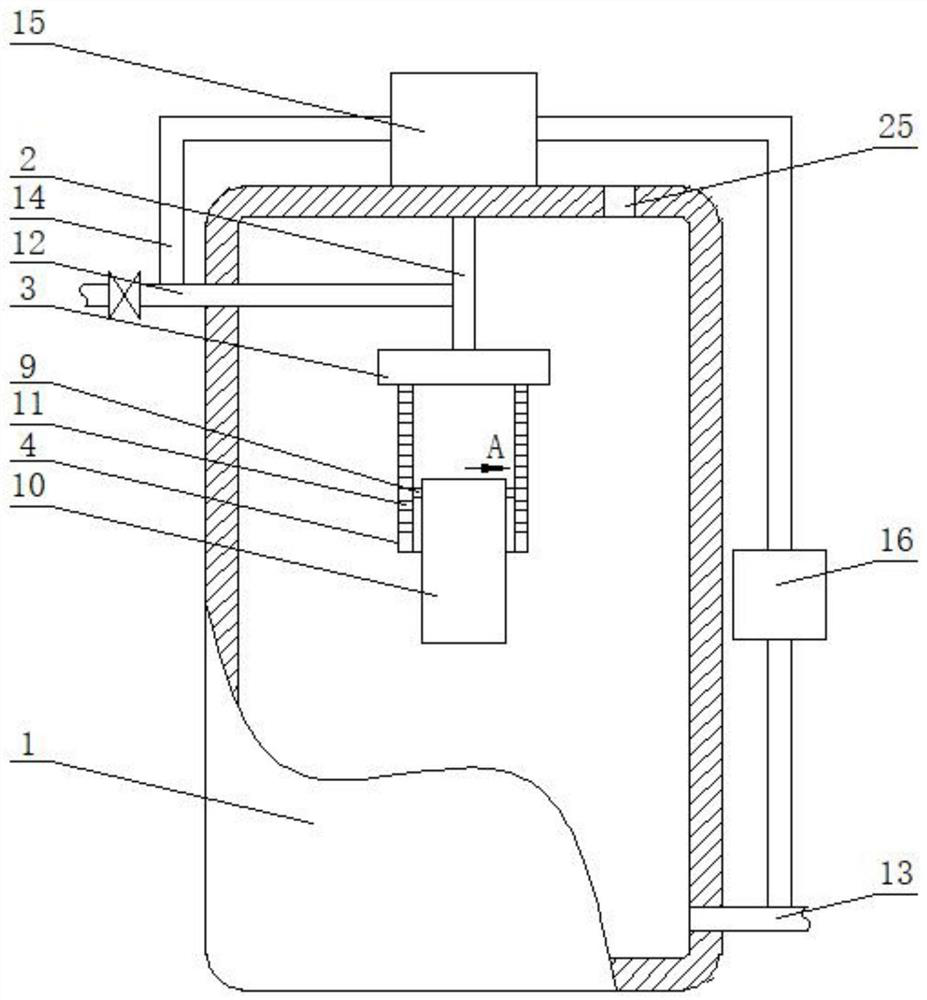

Steam injection device

ActiveCN112920938AExpand the spraying areaSimple structureBioreactor/fermenter combinationsBiological substance pretreatmentsFructoseInjection air

The invention provides a steam injection device, and mainly relates to the technical field of fructose production and processing. A steam injection device comprises a liquefying tank, a vertical pipe is installed on the inner wall of the top face of the liquefying tank, the bottom end of the vertical pipe is rotationally provided with a hollow connecting disc through a bearing and communicated with the interior of the connecting disc, a first air injection pipe is installed on the bottom face of the connecting disc, and the top end of the first air injection pipe is communicated with the interior of the connecting disc. Strip-shaped grooves are formed in the inner walls of the two sides of the first air spraying pipe correspondingly, and a guide rod is installed in each strip-shaped groove. The device has the beneficial effects that the device is simple in structure and convenient to operate, liquefaction and evaporation can be carried out at the same time, the technological process is shortened, the cost is saved, steam can be recycled and reused, raw steam is saved, waste steam is recycled, secondary jet liquefaction is adopted for liquefaction, the liquefaction and saccharification quality can be improved, raw steam is not wasted, and the energy consumption is reduced. the liquefaction effect is good.

Owner:SHANDONG XIWANG SUGAR +1

Prepn of solution maghesium source

The present invention is a preparation process of solution magnesium source. The said preparation process includes: adding solid magnesiumocene and dimethyl magnesiumocene to an organic solvent of 110 deg.C boiling point and stirring for homogeneity; dropping over C9 alkane, over C9 tertiary amine or aromatic aldehyde or aromatic ketone, over C5 primary amine or aliphatic aldehyde or Schiff base formed by ketone and primary amine; further heating while stirring; and decompression distilling to eliminate solvent to obtain solution magnesium source. The said solvent has excellent solid magnesiumocene and dimethyl magnesiumocene liquefying capacity and one portion of the solvent can liquefy three or more portions of magnesiumocene and dimethyl magnesiumocene completely.

Owner:NANJING UNIV

A flue gas treatment system and treatment method in a pvc glove production workshop

The invention discloses a flue gas treatment system and treatment method for a PVC glove production workshop, and belongs to the field of glove production equipment. The system and method are characterized in that a spraying device for carrying out spraying cooling on gloves on a glove die (3) is arranged above a glove die line and is connected with a circulation water supply device; a smoke recycling treatment system is further included and comprises a smoke liquefying device, an oil and water separating device and a heat exchange device; an inlet of the smoke liquefying device is communicated with the workshop through a chimney (18); and a mixed liquid outlet of the smoke liquefying device is communicated with a mixed liquid inlet of the oil and water separating device, and a water outlet of the oil and water separating device is communicated with the smoke liquefying device. According to the flue gas treatment system for the PVC glove production workshop, self-cleaning stable running all year around can be achieved, power consumption is low, organic components in smoke exhausted from the workshop can be recycled in a liquefied manner through the treatment method, the recycling effect is good, and raw material consumption is low.

Owner:BLUE SAIL MEDICAL

Heavy metal sewage treatment and reutilization device

InactiveCN110776031AImprove evaporation effectPromote aggregationDispersed particle filtrationSpecific water treatment objectivesSewageSewage treatment

The invention relates to the field of heavy metal sewage treatment and reutilization devices, in particular to a heavy metal sewage treatment and reutilization device. The device comprises an evaporation structure, a discharging structure, an atomization structure, a cooling structure, a first cleaning structure and a second cleaning structure, wherein the cooling structure is connected to the evaporation structure to convert kinetic energy of vaporization of the evaporation structure into kinetic energy of the cooling structure, meanwhile, the cooling structure absorbs waste heat while liquefying vaporized sewage so as to preheat sewage not subjected to evaporation treatment, the later evaporation vaporization efficiency of the sewage is higher, the utilization efficiency of the waste heat is improved greatly, meanwhile, the liquefying effect of vaporized sewage is better, the second cleaning structure is driven by vapor to rotate in the evaporation structure, bonding of heavy metal particles to the inner side wall of the evaporation structure is avoided, and the evaporation and heat exchange effects are better; and by arrangement of the first cleaning structure, the heavy metal particles can be effectively prevented from entering the cooling structure, and the treatment quality of the heavy metal particles is improved.

Owner:朱正直

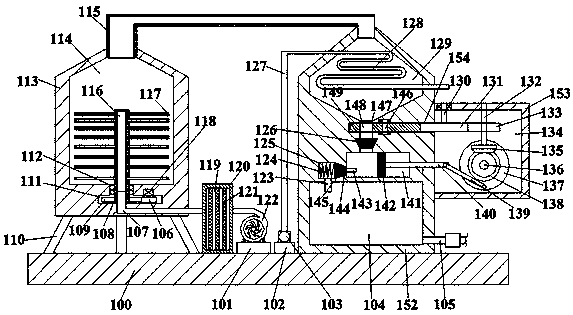

High-conversion-rate biomass liquefaction equipment

InactiveCN108795470AEasy maintenanceSimple structureLiquid hydrocarbon mixture productionEngineeringBiomass

The invention discloses high-conversion-rate biomass liquefaction equipment. The high-conversion-rate biomass liquefaction equipment comprises a base, and a reaction cylinder arranged at the top of the base, wherein foot stands, which are distributed in a triangular shape, are fixedly connected between the base and the reaction cylinder; the reaction cylinder is internally provided with a reactioncavity; a round hole is formed in the bottom of the reaction cavity in a communicating manner; a first cavity is formed in the bottom of the round hole in the communicating manner; a first rotating shaft, which extends upward and downward, is connected with the interior of the round hole in a rotary matching manner; a ventilation channel with a downward opening is formed in the first rotating shaft; the tail end of the bottom of the first rotating shaft stretches into the first cavity; the first cavity is internally provided with a first tooth rotating wheel which is fixedly connected with the first rotating shaft; a first motor is embedded into an inner wall of the top of the first cavity; the tail end of the bottom of the first motor is in power connection with a second tooth rotating wheel which is engaged and connected with the first tooth rotating wheel. The high-conversion-rate biomass liquefaction equipment is simple in structure, convenient to operate, obvious in liquefactioneffect and convenient to store, and the equipment is light and has high practical performance.

Owner:GUILIN ANXING ENVIRONMENTAL PROTECTION TECH CO LTD

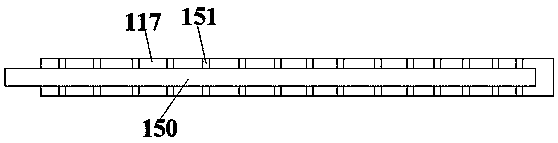

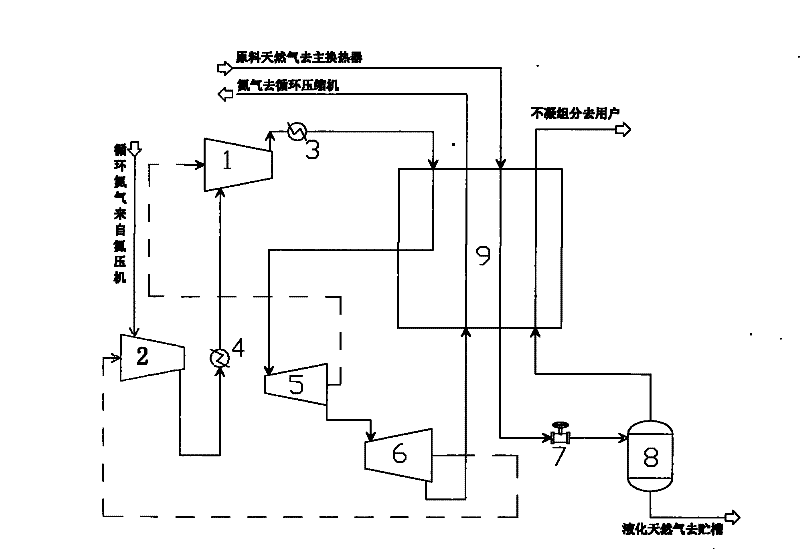

Method for liquefying high-low pressure nitrogen double-expansion natural gas

ActiveCN101608859BIncrease liquefaction rateGood liquefaction effectSolidificationLiquefactionLow-pressure areaHigh pressure

Owner:HANGZHOU FORTUNE CRYOGENIC EQUIP CO LTD

A kind of method of producing injection maltose crude drug

ActiveCN108676827BPromote flocculationUniform liquefactionDispersion deliverySugar derivativesBiotechnologyPullulanase

Owner:湖南金代科技发展有限公司

Main grid silver paste for silicon solar cell and preparation method thereof

PendingCN114843005AIncrease opening pressureImprove photoelectric conversion efficiencyFinal product manufactureQuartz/glass/vitreous enamelsPhysicsChemistry

The invention provides main grid silver paste for a silicon solar cell and a preparation method of the main grid silver paste, the main grid silver paste for the silicon solar cell has good auxiliary grid matching capability and high main grid line stripping strength, the main grid silver paste for the silicon solar cell comprises silver powder, glass powder and an organic carrier, and the total weight of the main grid silver paste for the silicon solar cell is 100%. The silver paste comprises the following components in percentage by weight: 80.0%-90.0% of silver powder; 0.3%-2.0% of glass powder; and 8.0%-15.0% of an organic carrier. The main grid silver paste for the silicon solar cell can be well matched with step-by-step printing of different types of cell pieces and can also be matched with different types of auxiliary grid silver paste, after matching, the opening voltage is high, the photoelectric conversion efficiency is high, the main grid peeling strength is high, and the service life is long. And the requirements of the current different types of sizing agents and battery pieces for printing the main grid sizing agents step by step can be well met.

Owner:上海银浆科技有限公司

Chemical waste gas cooling, liquefying and absorbing device

InactiveCN114471071AAvoid pollutionAvoid direct dischargeRecuperative heat exchangersDispersed particle separationExhaust fumesProcess engineering

The invention belongs to the technical field of chemical waste gas treatment, particularly relates to a chemical waste gas cooling, liquefying and absorbing device, and aims to solve the problem that when an existing chemical waste gas cooling, liquefying and absorbing device liquefies waste gas, after an exhaust pipe exchanges heat with cooling liquid, the cooling liquid is in a non-flowing state; in order to solve the problems of low use efficiency of the cooling liquid and great reduction of waste gas treatment efficiency due to the fact that the cooling liquid around an exhaust pipe cannot be exchanged with the surrounding cooling liquid in time after being heated, the invention provides the following scheme: the waste gas treatment device comprises a box body, a gas inlet pipe is fixedly mounted on one side of the box body, and a discharge pipe is fixedly mounted on the other side of the box body; liquefying pipes are fixedly installed on the air inlet pipe and the discharging pipe, and a heat exchange box is fixedly installed on the top of the box body. According to the device, waste gas can be liquefied and retreated, environmental pollution is avoided, the liquefaction effect of the device on the waste gas is good, and the waste gas treatment efficiency is greatly improved.

Owner:东营国滋电子科技有限公司

A lead-free continuous vacuum distillation equipment for lead-tin alloy

ActiveCN111893304BGuaranteed vacuum environmentImprove work efficiencyProcess efficiency improvementElectric machineEngineering

The invention relates to the technical field of vacuum distillation, and discloses a lead-tin alloy lead-free continuous vacuum distillation equipment, which includes a casing, and a feeding pipe is fixedly installed on the upper end of the left side of the casing, and the left side of the feeding pipe is fixed An injection cylinder is installed, the front of the top of the injection cylinder is provided with a material injection port, and the middle part of the top of the injection cylinder is fixedly installed with a first motor, and the bottom of the first motor is fixedly equipped with an agitator. The inner lower end is fixedly installed with a swash plate. This lead-tin alloy lead-free continuous vacuum distillation equipment achieves the purpose of high work efficiency by setting up tilting plates, electric heaters and shells, etc. The materials to be processed are continuously injected through the injection pipe, often at the bottom of the slope. The plate is filled first, and then filled up sequentially. The filled material is divided by the inclined plate, so the degree of accumulation is low. When the electric heater is heated, the electric heat energy can quickly enter each inclined plate.

Owner:贵溪三元金属有限公司

Smoke machine self-cleaning structure, method and smoke machine

ActiveCN109268888BPromote softeningGood liquefaction effectDomestic stoves or rangesLighting and heating apparatusOil and greaseElectric machine

The invention relates to the field of range hoods, and particularly provides a self-cleaning structure and method of a range hood and the range hood. The self-cleaning structure of the range hood comprises a motor, an inner oil screen which is arranged on an oil fume suction opening of the range hood, and is driven by the motor to act and to intercept oil in oil fume, and a hot air heating devicewhich is arranged on the range hood, and cleans the inner oil screen by heating the inner oil screen, wherein the hot air heating device comprises a fan and an air outlet which is connected with the fan, and is used for heating the inner oil screen. According to the self-cleaning structure and method of the range hood and the range hood, the inner oil screen is arranged to intercept oil particlesin the oil fume, the situation that the oil enters the range hood, and pollutes a wind wheel and an air duct in the range hood to improve the cleaning difficulty is avoided, by heating the inner oil screen, the oil is fast cleaned away, there is no need to heat the wind wheel or the air duct, the heating efficiency is high, the cleaning effect is better, and the range hood cleaning cost is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Preparation method of solution trimethyl indium source

Owner:NANJING UNIV

A method of consolidating loose sand particles using phosphate mineralizing bacteria

ActiveCN103266592BProtect ecological functionsLess prone to secondary pollutionBuilding constructionsOrganic fertilisersPeristaltic pumpChemical solution

The invention discloses a method utilizing phosphate mineralized bacteria to solidify and loosen loose sand particles. The method comprises the steps that bacillus subtilis is inoculated to beef extract and a peptone culture medium for obtaining bacterial liquid, then disodium phenyl phosphate is added to the prepared bacterial liquid, an anhydrous calcium chloride solution with the concentration of 0.5-1.5mol / L is prepared, 70-90g of sand with two levels of less than 0.15mm and of 0.15-0.30mm is prepared according to the closest Fuller packing method and then loaded into a trial mould with a buffering pad and a sand filter, the bacterial liquid and a chemical solution are respectively poured into the prepared sand in the third step through a peristaltic pump according to a volume ratio of 1:1, the flowing speed of the bacterial liquid is controlled to be 4-6mL / min, the flowing speed of the chemical solution is 10-15mL / min, continuous pouring is carried out for 8-15 days, and the sand with the mould is placed into an oven of 60 DEG C for being conserved for 48h and then taken out and released from the mould. The compressive strength of the sand can reach 1.0MPa.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com