Patents

Literature

77results about How to "Increase liquefaction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

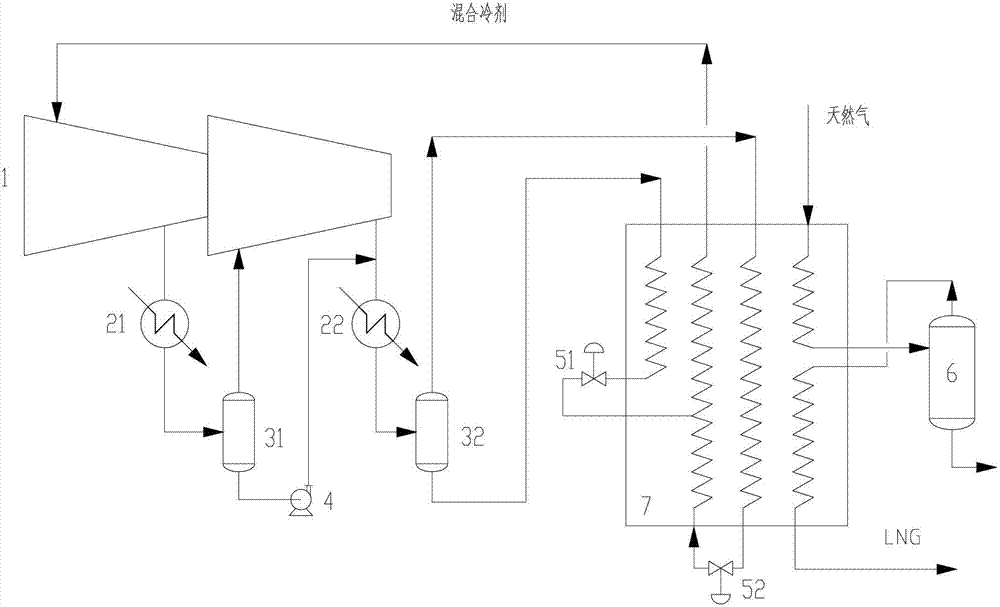

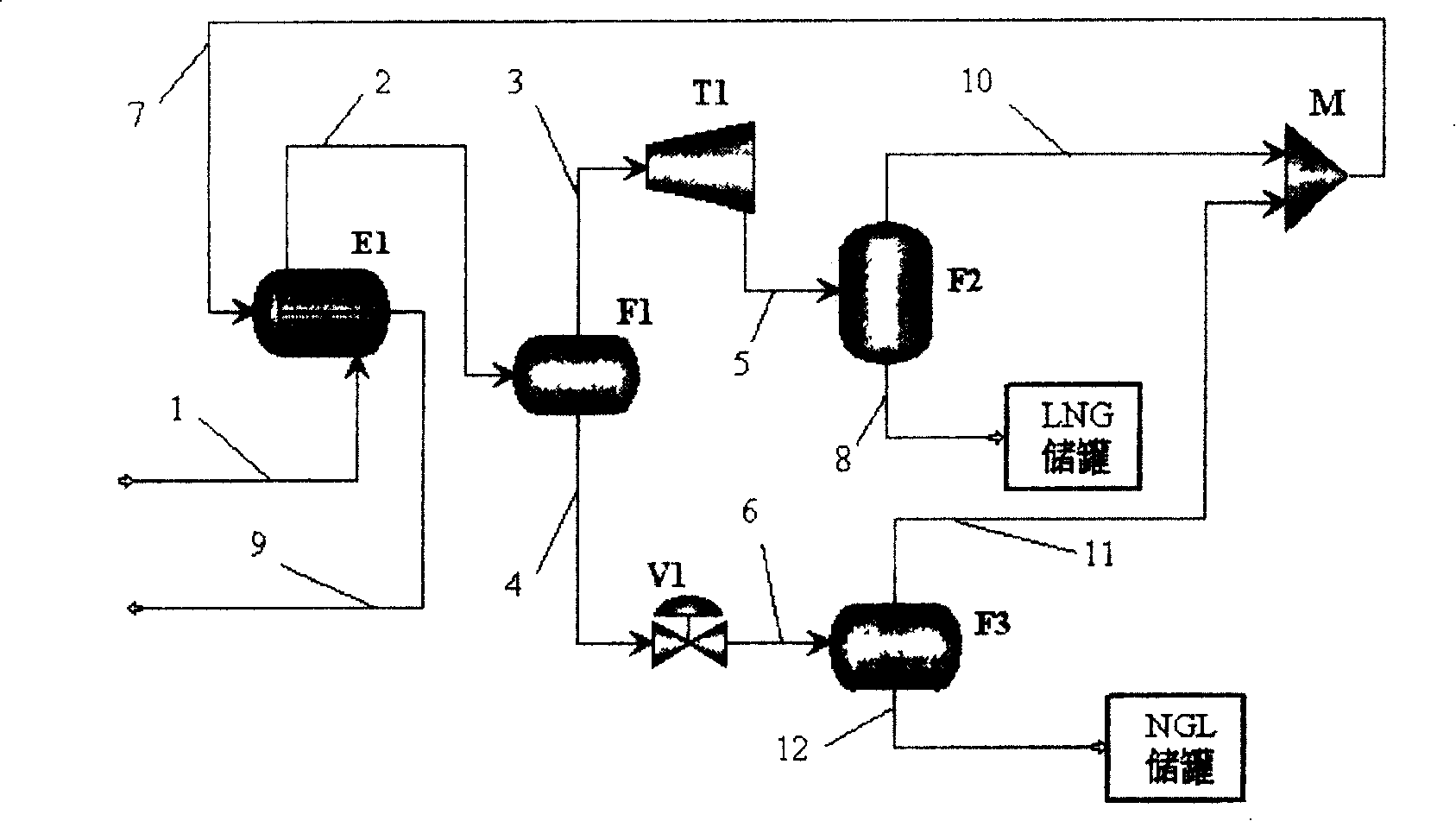

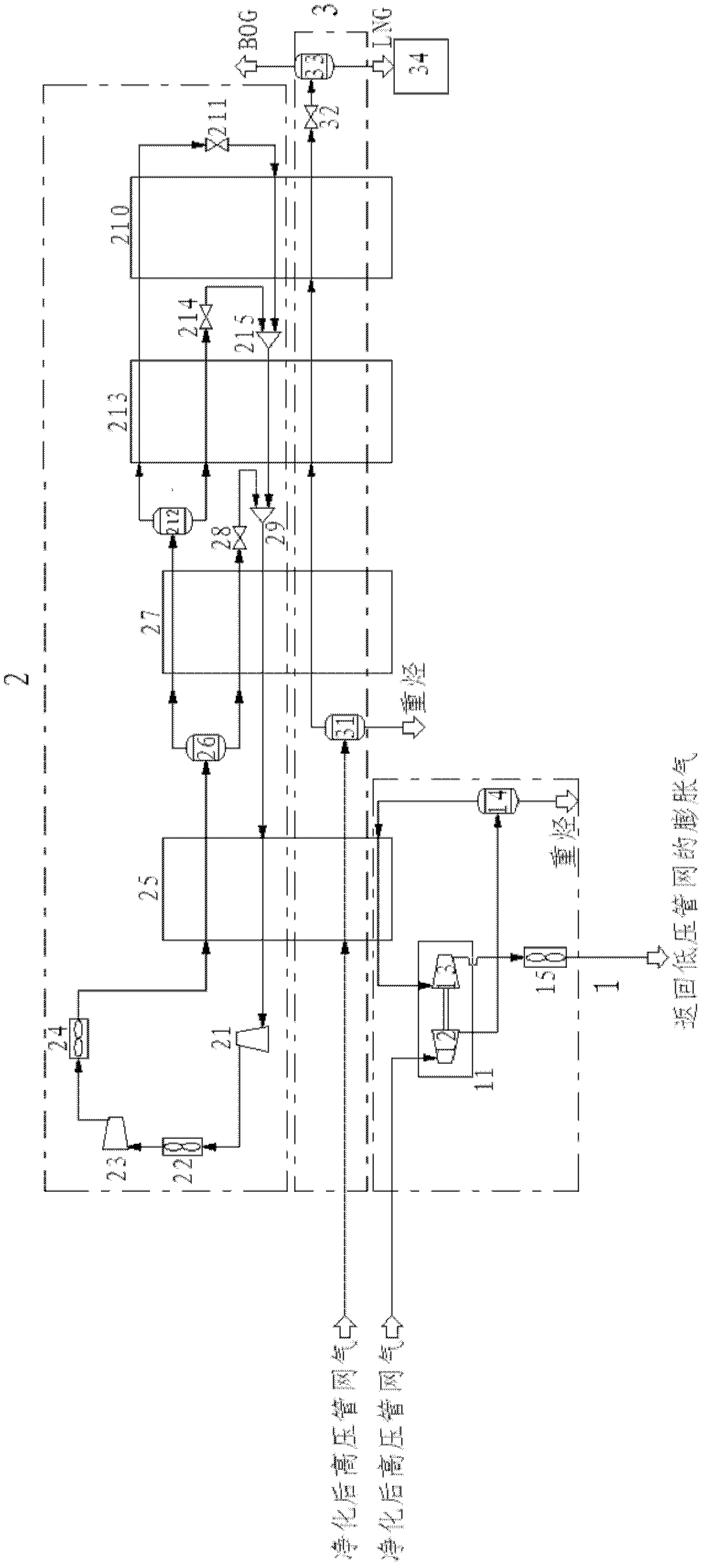

Method and device for carrying out liquefaction and heavy hydrocarbon treatment on natural gas

ActiveCN103031169AEconomical and reliableReasonable designSolidificationLiquefactionGas phaseLarge range

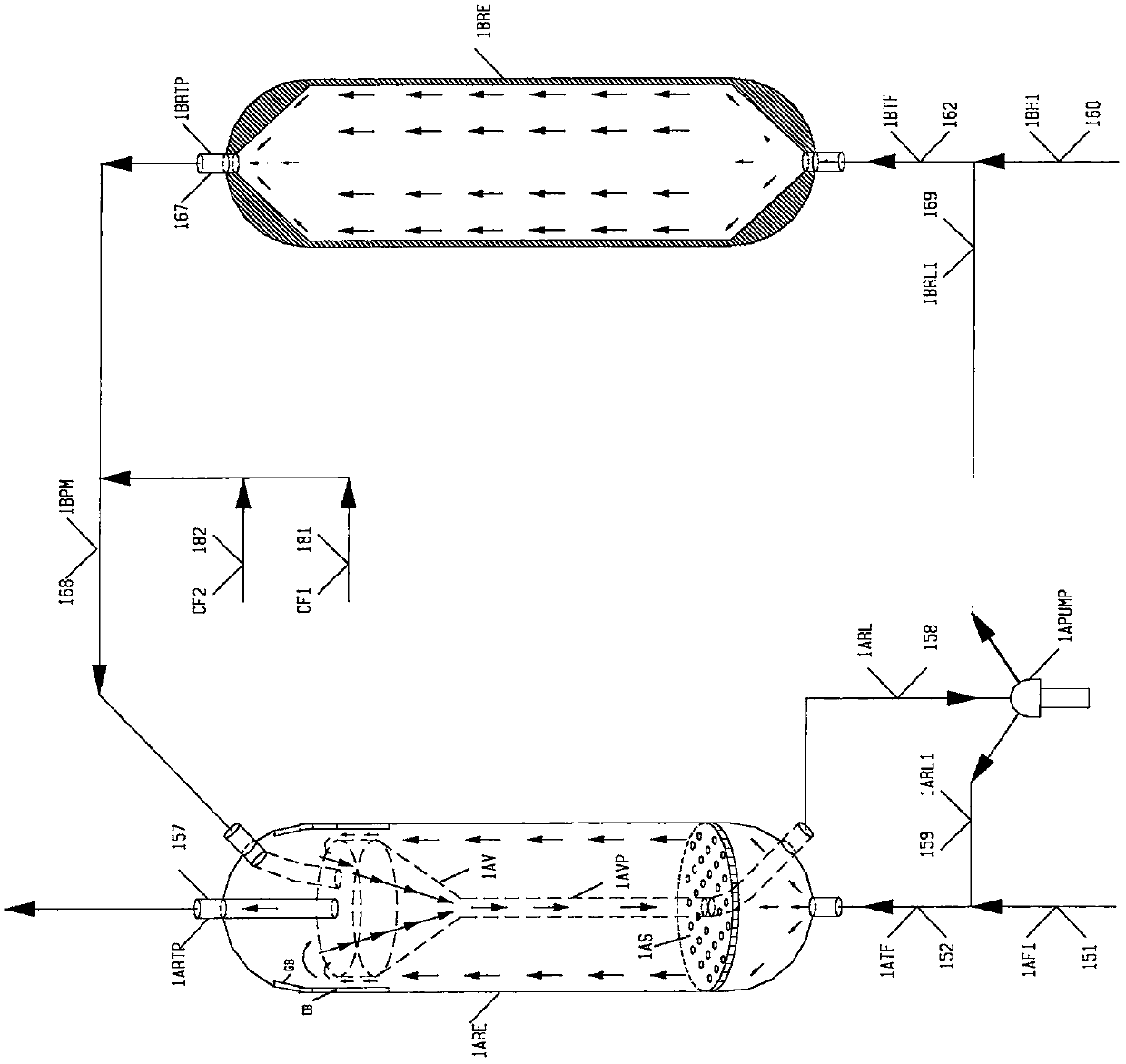

The invention relates to a process for carrying out liquefaction and heavy hydrocarbon treatment on natural gas, which comprises a low temperature liquefaction process and a heavy hydrocarbon treatment process. The low temperature liquefaction process comprises the following step that mixed refrigerant provides refrigerating capacity for the natural gas which is subjected to partial heavy hydrocarbon removal in the heavy hydrocarbon treatment process so as to implement cooling, complete heavy hydrocarbon removal and liquefaction on the natural gas in a cold box to obtain LNG (Liquefied Natural Gas); the heavy hydrocarbon treatment process comprises the following steps that the natural gas rich in heavy hydrocarbon is subjected to partial heavy hydrocarbon in a heavy hydrocarbon washing tower and the removed heavy hydrocarbon sequentially enters a deethanizing column and a rectifying column to be subjected to removal of light components and be separated into LPG (Liquefied Petroleum Gas) and light oil. According to the process disclosed by the invention, by-products, i.e. the LPG and the light oil, are also produced when the LNG is produced, the process route is advanced and the process is economical and reliable; the process can be suitable for the condition that raw material gas comprises aromatic hydrocarbon such as benzene and the like, the aromatic hydrocarbon such as the benzene and the like are removed along with the heavy hydrocarbon component and the cold box is prevented from being frozen and blocked; the process has large operation elasticity and can be suitable for natural gas heavy hydrocarbon content in a large range; the mixed refrigerant is adopted to circulate the flow and provide refrigerating capacity and gas-phase and liquid-phase refrigerants respectively enter the cold box to carry out heat exchange, so that heat exchange curves of cold and hot fluids are further matched; and the adopted refrigerating flow can effectively avoid liquid accumulation at the bottom of the cold box.

Owner:XINDI ENERGY ENG TECH

Wood liquefier and method for preparing surfactant using liquidated wood

InactiveCN101396838AImprove liquefactionLow costTransportation and packagingWood treatment detailsEpoxyActive agent

The invention provides a preparation method for a wood liquefacient. A discarded PET bottle is crashed into powder, which is mixed with polylol and added with 0.01-0.5wt% of catalyst, and the mixture is stirred uniformly and heated to react, thus obtaining the wood liquefacient. The invention also relates to a method for preparing a surfactant by using the liquefacient to liquefying wood, which includes the steps: 0.5-10wt% of inorganic acid catalyst and glycerin are added into the mixture of the liquefacient and the wood meal of broad leaved forests or coniferous forests, which reacts by heating to obtain a coarse liquefied wood product; the product is cooled to room temperature, diluted in absolute ethyl alcohol or acetone and then filtered in vacuum to form the filtrate, which is subsequently decompressed and distilled so as to obtain refined liquefied wood; the sodium hydroxide solution of the fully dissolved liquefied wood is added with propylene oxide according to the mass morality of total hydroxide radical to propylene oxide being 1:3-10 for reaction, and then epoxy ethane is entered for end capping, after that, the pH value is adjusted to 7, then the liquefied wood polyethenoxy ether of the surfactant is obtained as the final product.

Owner:JIANGSU QIANGLIN BIO ENERGY

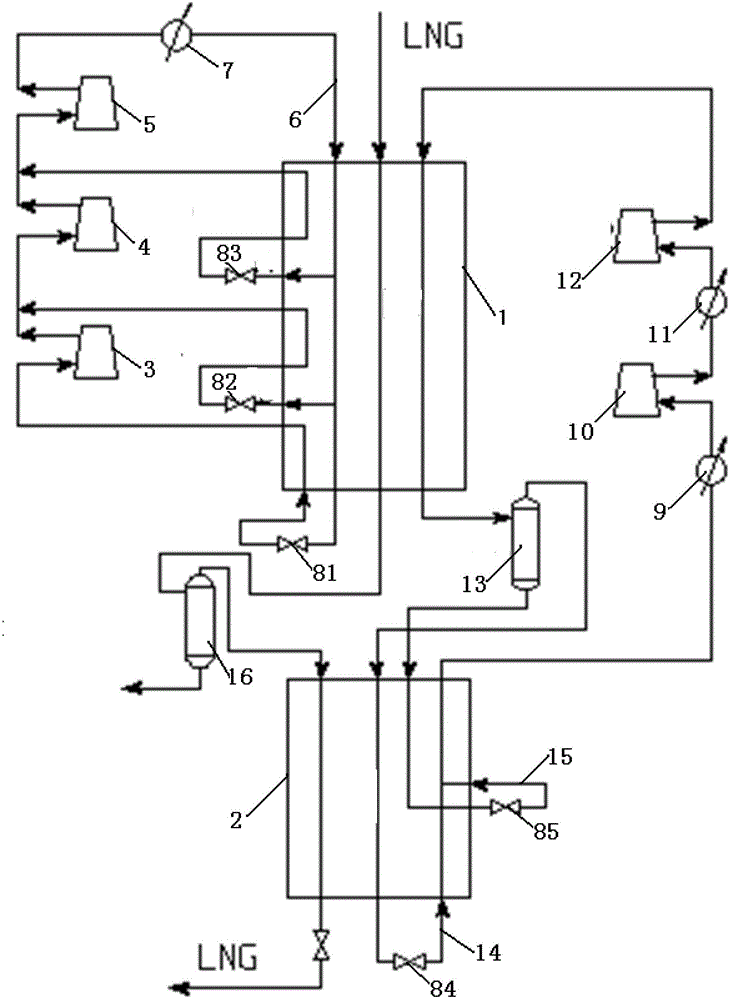

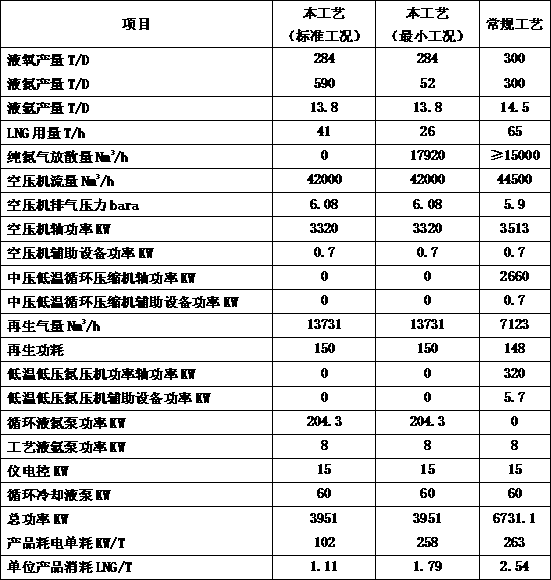

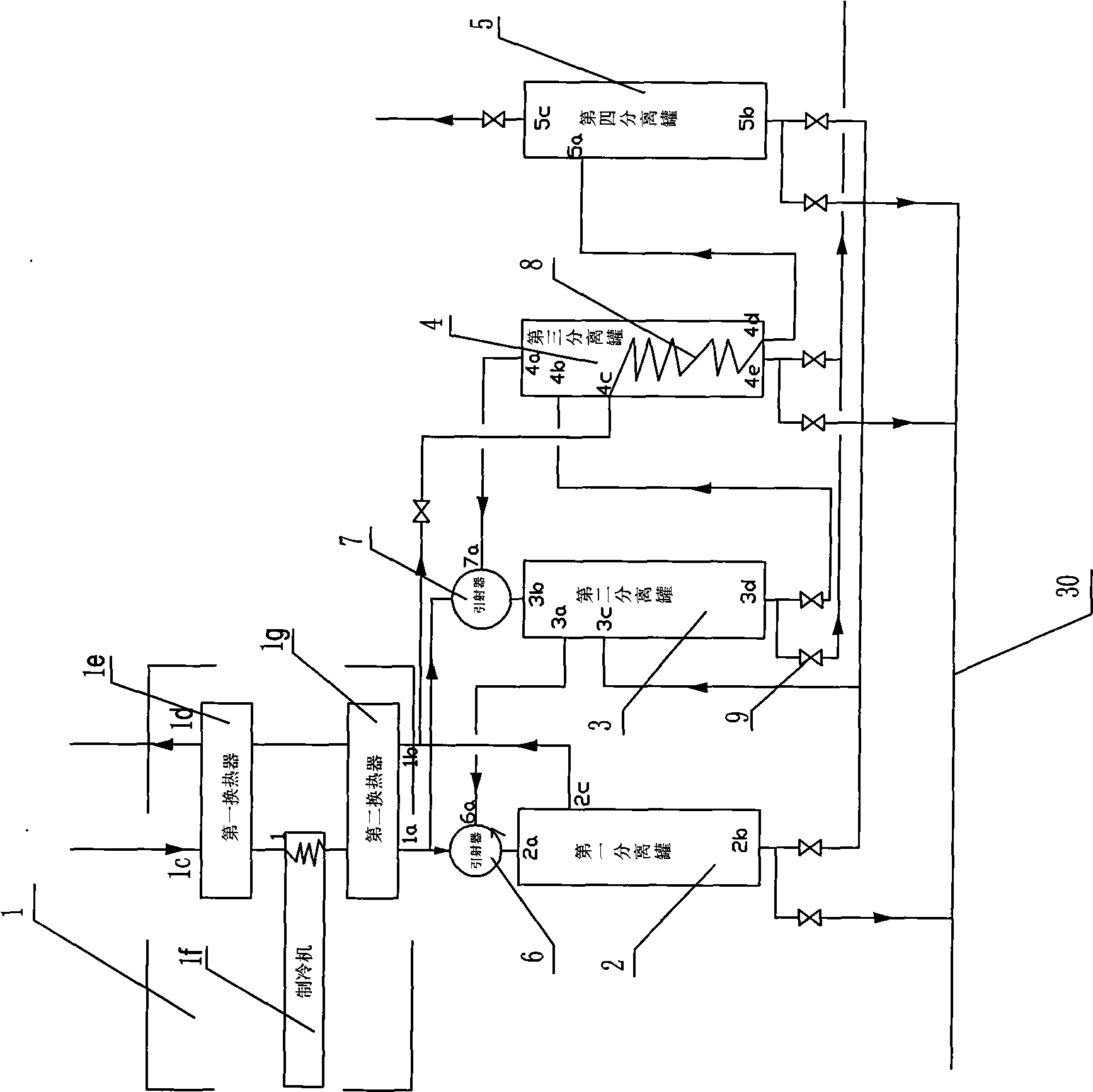

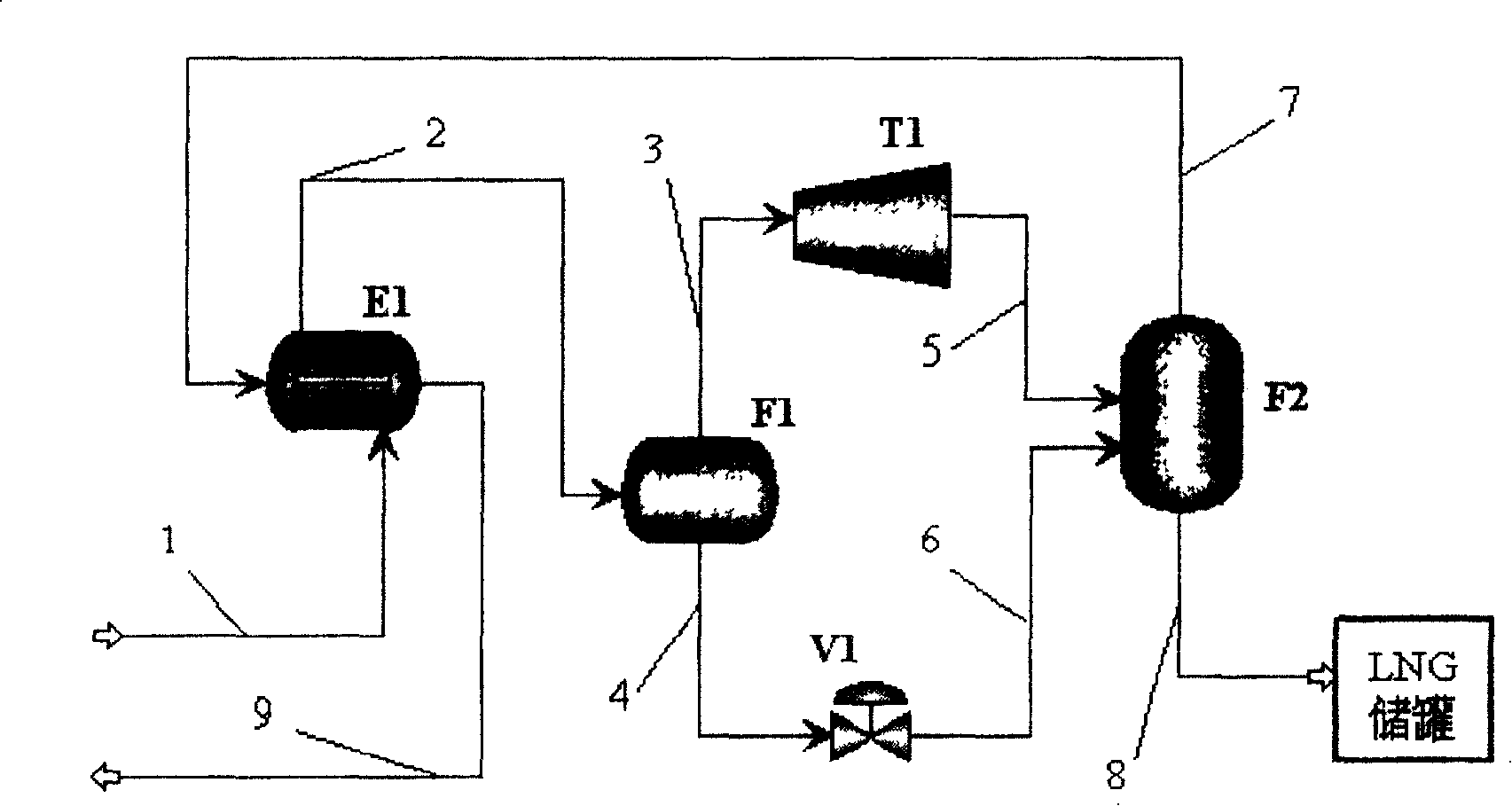

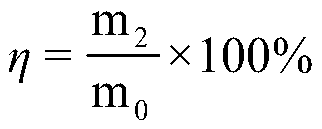

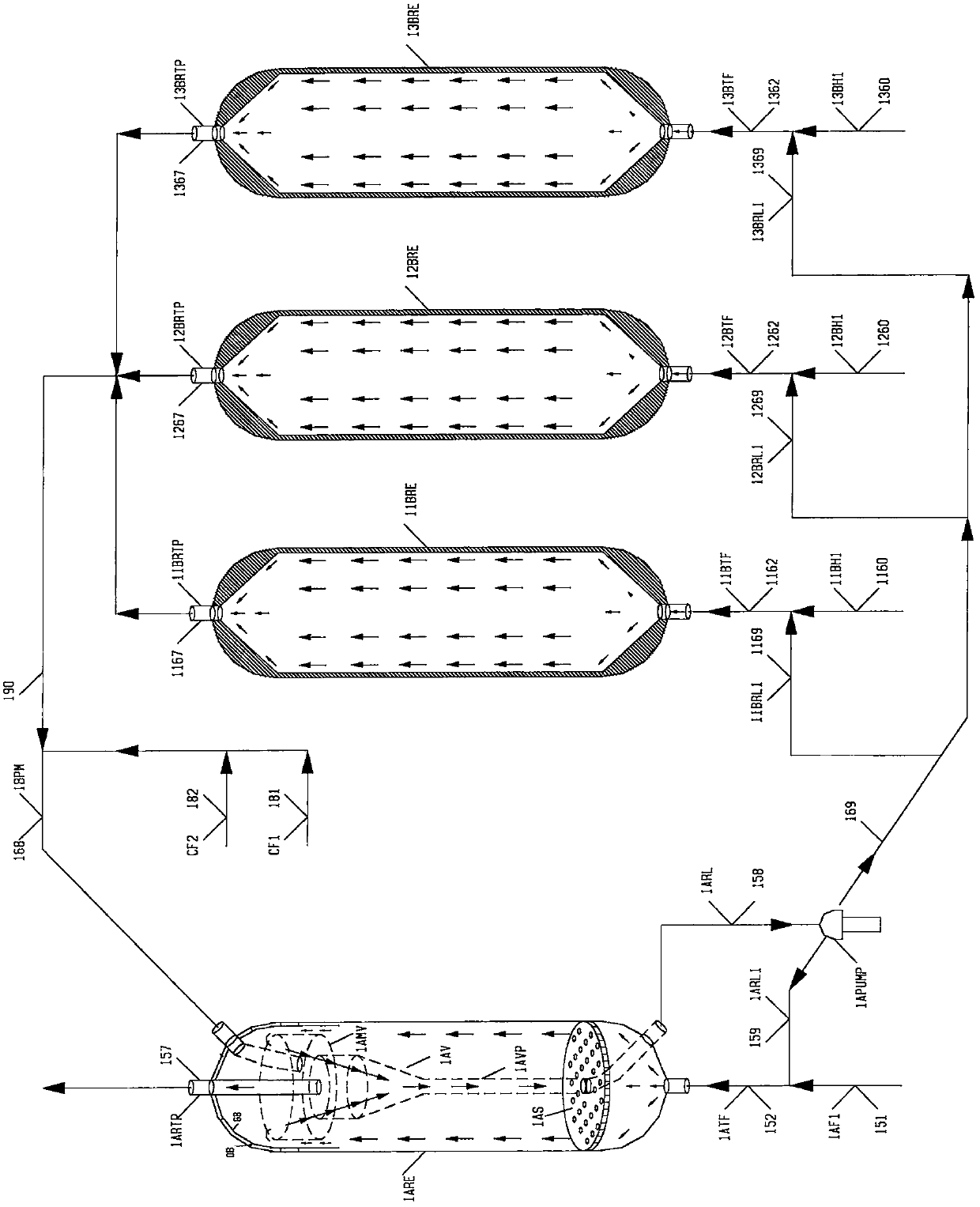

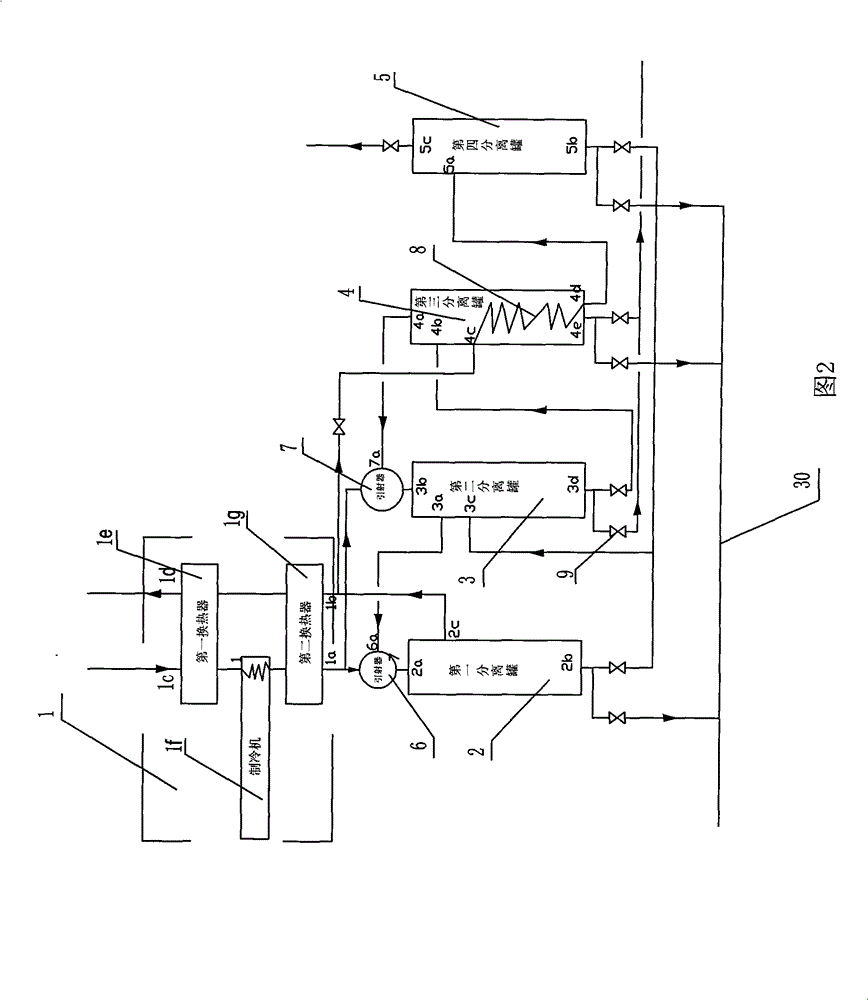

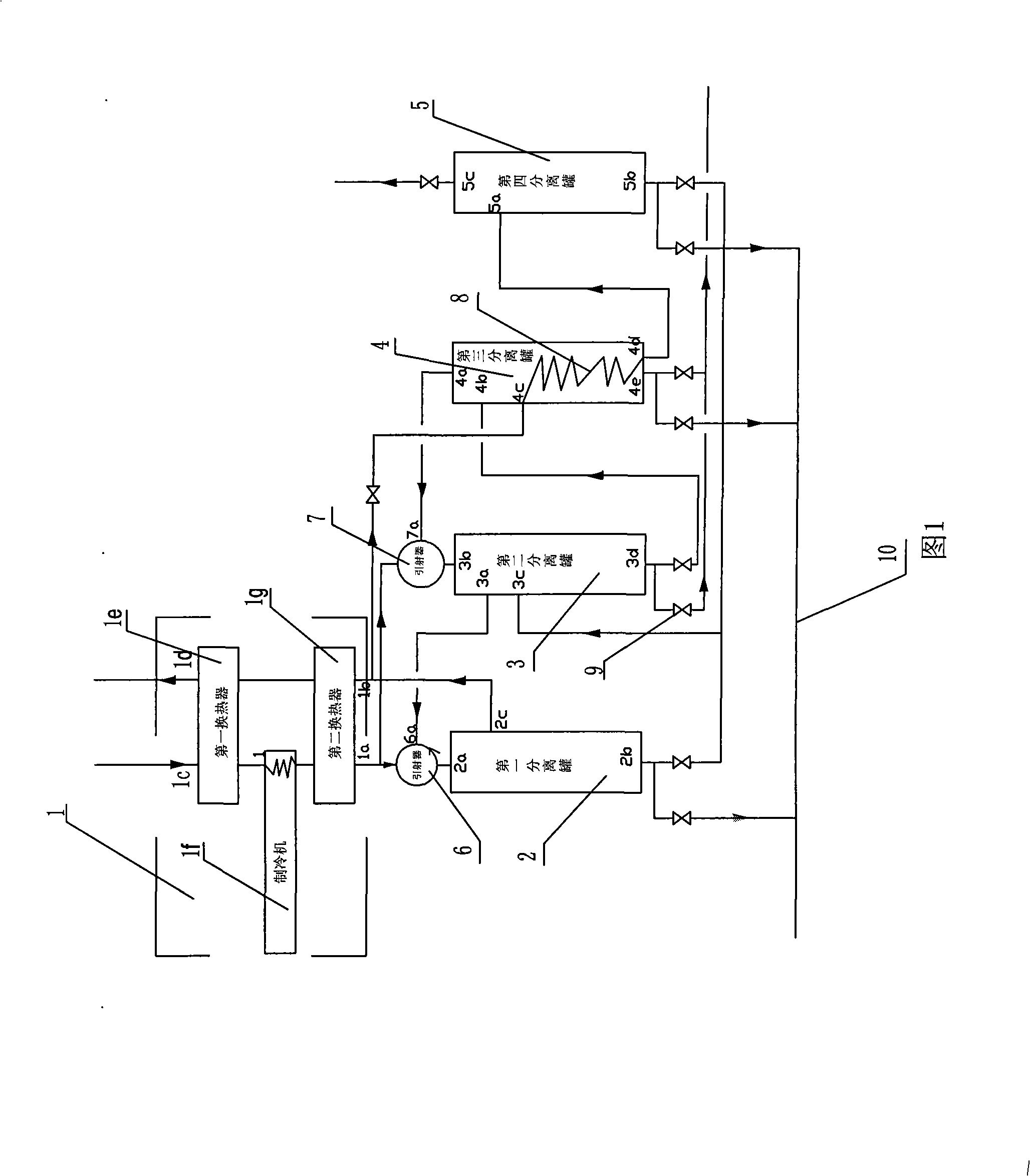

Two-section type single loop mixed refrigerant natural gas liquefaction process and device

InactiveCN102492505ASimple processIncrease liquefaction rateSolidificationLiquefactionLiquid stateGas phase

The invention relates to a two-section type single loop mixed refrigerant natural gas liquefaction process and a device. The process comprises the following steps: conducting two-section compression cooling on mixed refrigerant, enabling the mixed refrigerant to be in gas state after first section compression cooling, conducting first gas-liquid separation after second section compression cooling, obtaining gas state refrigerant and liquid state refrigerant; enabling the liquid state refrigerant to enter an ice chest for cooling and then throttling, cooling and returning to the ice chest for providing cooling amount of a high temperature position; enabling the gas state refrigerant to enter the ice chest for cooling to a low temperature and then throttling, cooling and returning to the ice chest for providing cooling amount of a low temperature position; enabling the gas state refrigerant to be converged with the liquid state refrigerant returning to the ice chest after throttling to improve the cooling amount of the high temperature position; conducting two-section type compression cooling on the mixed refrigerant providing the cooling amount to enter next circulation; enabling natural gas to enter the ice chest for cooling, and then obtaining liquefied natural gas products after throttling. The invention further provides a liquefied natural gas device used in the process. The process is simple in process, and has the advantages of high liquefaction rate, low energy consumption and the like.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

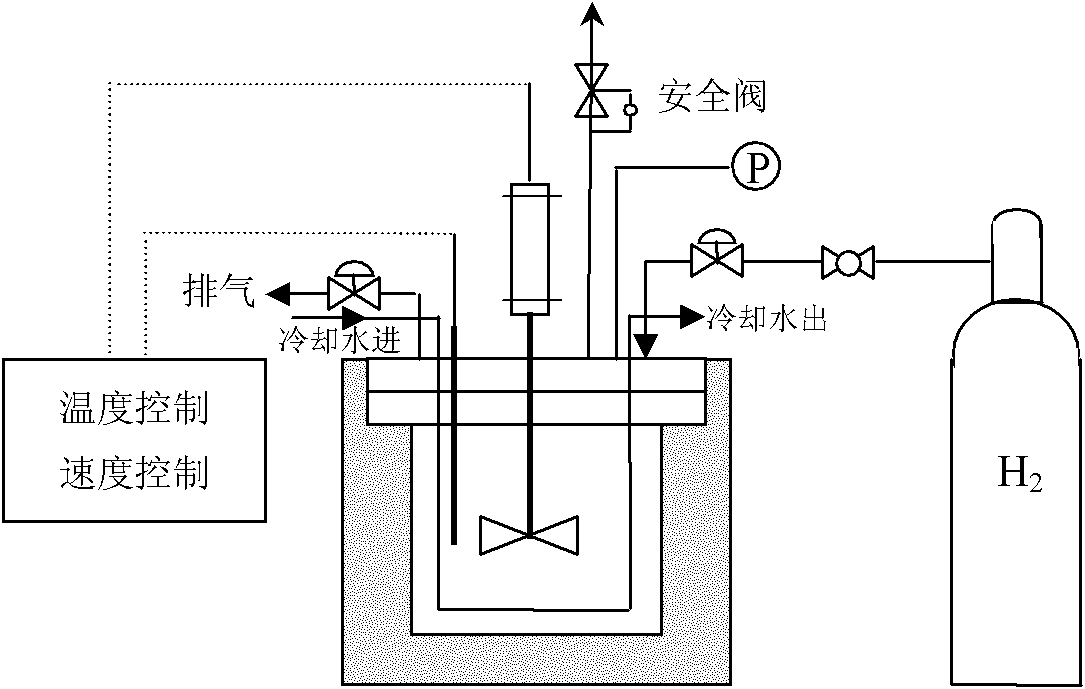

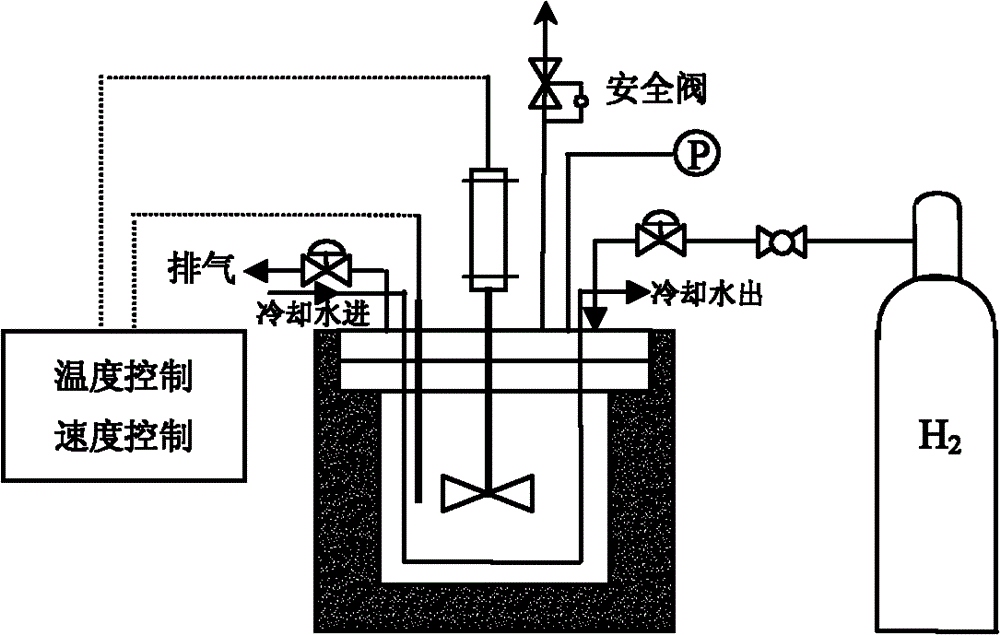

Method for preparing biological oil from algae biomass through direct catalytic liquefaction method

InactiveCN102002381AConducive to liquefactionIncrease liquefaction rateLiquid hydrocarbon mixture productionHydrogen atmosphereOxygen

The invention relates to a method for preparing biological oil from algae biomass through a direct catalytic liquefaction method, which is a hydrothermal method with algae biomass as a raw material. The method comprises pretreatment, catalytic liquefaction and separation, wherein the pretreatment comprises the steps of: soaking dried and crushed algae in 0.05-0.15mol / L alkali liquor or acid liquor for not less than 20h, pouring the soaking liquid and a modified natural mordenite catalyst into a pressure kettle, catalytically liquefying for not less than half an hour under the condition of agitation in an oxygen free and hydrogen atmosphere at 200-400 DEG C under 3-16MPa, cooling, reducing the temperature, relieving the pressure, separating the solid and the liquid, and dehydrating the liquid under reduced pressure to obtain biological oil. The algae liquefaction rate of the invention is high and reaches more than 82%; the grade of the oil product is high, and the heat value can reachmore than 30 MJ / kg; a water phase system is adopted, so that the invention has the advantages of environmental protection, low preparation cost, relatively mild reaction conditions and good market application prospects, saves energy and is simple and convenient for operation and easy for realization of large-scale production.

Owner:HEFEI UNIV OF TECH

Polyurethane material and its prepn

The present invention provides one kind of polyurethane material and its preparation process. The polyurethane material is prepared through inorganic acid catalyzed liquefacation and foamation on the mixture of natural plant powder material and composite liquefier at 100-150 deg.c under the action of microwave of 2450 MHz frequency. The composite liquefier consists of PEG400 60-80 wt%, glycerin 10-25 wt% and water 10-30 wt%. The polyurethane material may be used in making product with high mechanical strength, low density, high heat insulation, good damping performance, biodegradability advantages, and may be used to replace petrochemical material foaming polyurethane material.

Owner:李剑飞

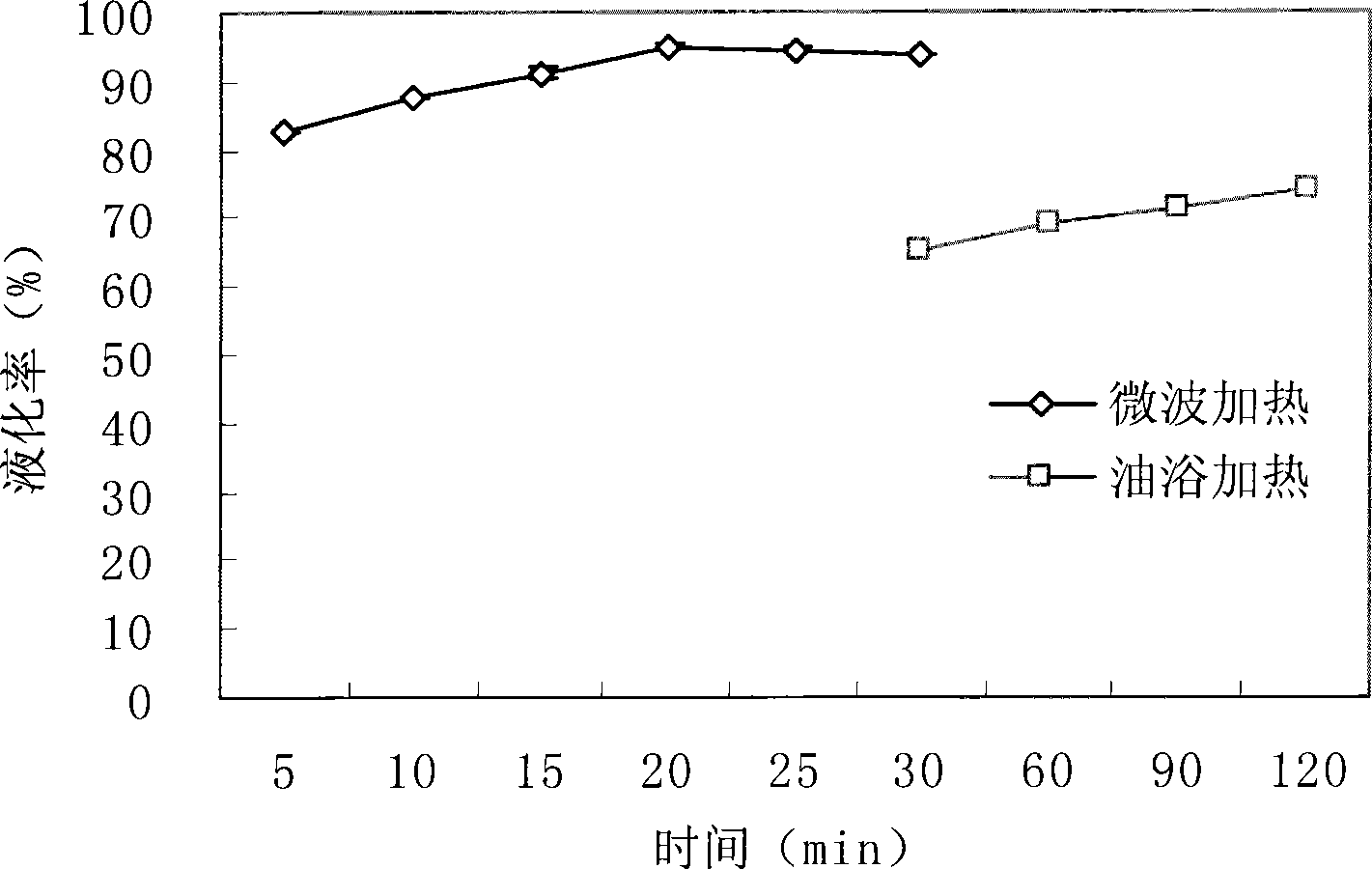

Rapid liquefaction method for corps wastes by microwave heating catalysis

ActiveCN101503338ALower liquefaction costsHeating fastOrganic compound preparationSolid waste disposalMicrowaveCatalytic effect

The invention provides a method for catalyzing waste of crops to be liquefied by microwave heating, which comprises: the waste of crops is added into polylol and sulphuric acid for microwave heating, the temperature is controlled to be 150-180 DEG C, and the liquification reaction is carried out for 10-30min. The method utilizes microwave auxiliary heating and reaction catalytic effect to realize rapid liquification for the waste of crops, thus greatly improving the liquification efficiency of the waste of crops and the liquification effect thereof, and leading the liquification efficiency to reach over 90%; the operation of the method is rapid, simple and convenient as well as efficient, so that the liquification cost of the waste of crops can be greatly reduced.

Owner:CHINA AGRI UNIV

Biomass liquefaction method

ActiveCN105018125AIncrease liquefaction rateLiquid hydrocarbon mixture productionLiquid productSolvent

The invention discloses a solid biomass liquefaction method, which comprises the following steps of adding a solid biomass, a liquefaction solvent and a fat-type compound into a high-pressure container for liquefaction at 200 to 450 DEG C, performing solid-liquid separation on a product after reaction, and collecting a liquid product. According to the method, the fat-type compound is added into the liquefaction solvent to form a mixed solvent, so that the solid biomass liquefaction rate can be greatly increased even without a catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

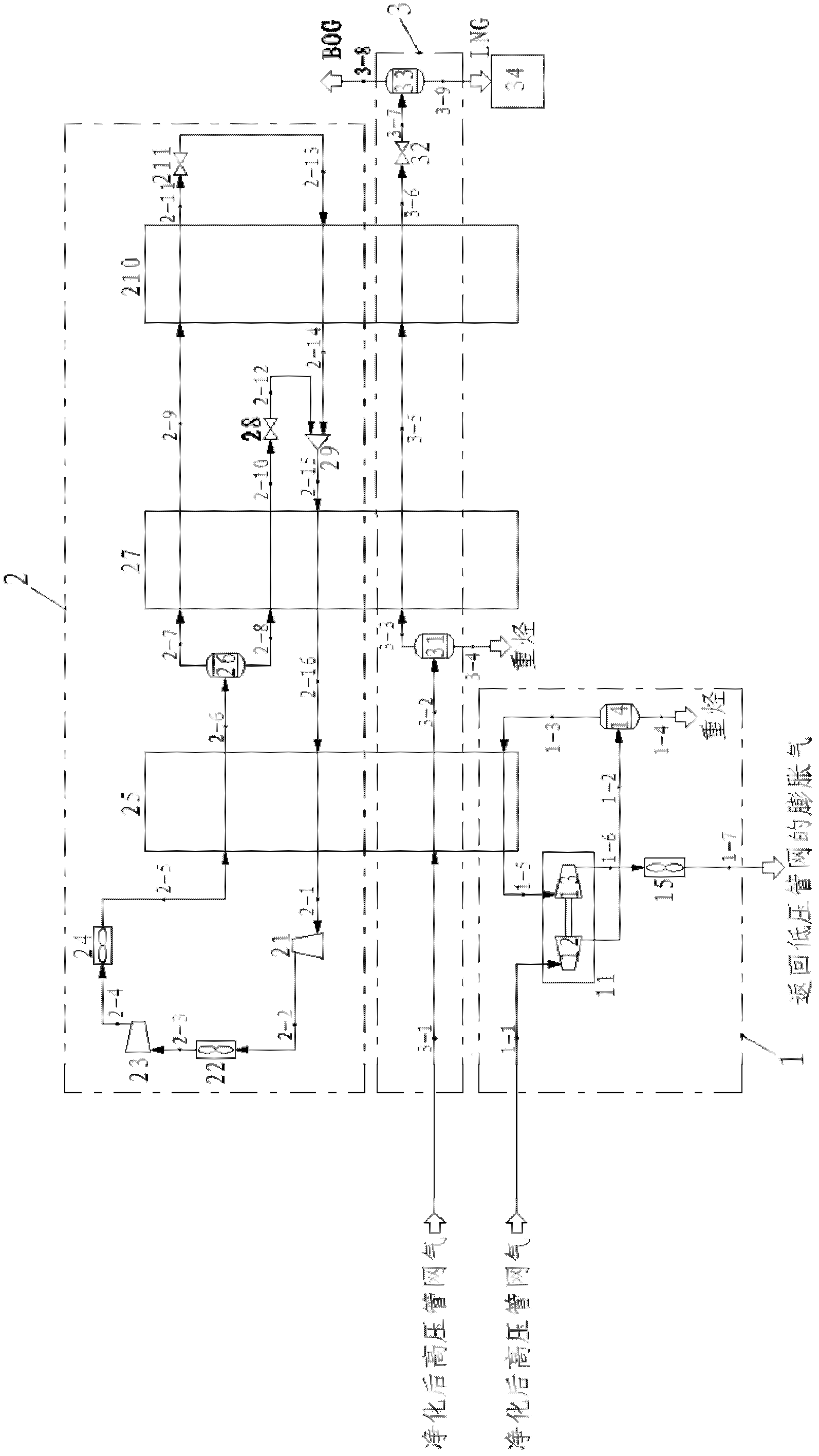

Natural gas liquefying system by vurtue of double-stage mixed-refrigerant circulation

InactiveCN102748918AImprove performanceRaise the ratioSolidificationLiquefactionRefrigeration temperatureProcess engineering

The invention discloses a natural gas liquefying system by virtue of double-stage mixed-refrigerant circulation. The liquefying system comprises a precooling cold box, a deep-cooling cold box, a precooling mixed-refrigerant refrigeration circulating mechanism and a deep-cooling mixed-refrigerant refrigeration circulating mechanism. The natural gas liquefying system has the advantages that deep-cooling circulation adopts two-stage refrigeration, so that the refrigerating efficiency is increased; the double-stage mixed-refrigerant circulation is adopted, so that the adjusting range of components of a precooling refrigerant and a deep-cooling refrigerant is wide, and the refrigerant proportioning is convenient; the refrigerating temperature of the precooling refrigerant circulation can be correspondingly adjusted according to the natural gas components and the ambient temperature, the adaptability is strong; in double-stage mixed-refrigerant circulation, the refrigerating loads in two circulations can be reasonably distributed, and the manufacturing of a precooling heat exchanger and a deep-cooling plate-fin heat exchanger is convenient.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Liquefied air energy storage system

ActiveCN111648833AShort response timeImprove FM capabilityHeat storage plantsEnergy storageLiquid stateProcess engineering

The invention discloses a liquefied air energy storage system. The liquefied air energy storage system comprises an energy storage unit, a liquidation unit, a liquid storage unit storing a liquid-state working medium, a gasification unit and an energy release unit, wherein the energy storage unit comprises a compression device, a first heat exchanger and a cooler which are sequentially connected;the energy release unit comprises an expansion unit and a second heat exchanger which are sequentially connected; the liquidation unit comprises a liquidation device with an inlet end which communicates with an outlet end of the cooler; the gasification unit comprises an evaporation device with an outlet end which communicates with an inlet end of the second heat exchanger; the liquid storage unitcomprises a liquid storage device connected between the liquidation unit and the evaporation device; a gas buffer device is further communicated between the evaporation device and the second heat exchanger; and a gas-state working medium generated in the evaporation device is temporarily stored in the gas buffer device and then enters the second heat exchanger. The gas buffer device is arranged between the evaporation device and the second heat exchanger, so that a response time in a process of adjusting output frequency of the liquefied air energy storage system can be shortened, and the frequency adjustment performance of the liquefied air energy storage system is improved.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

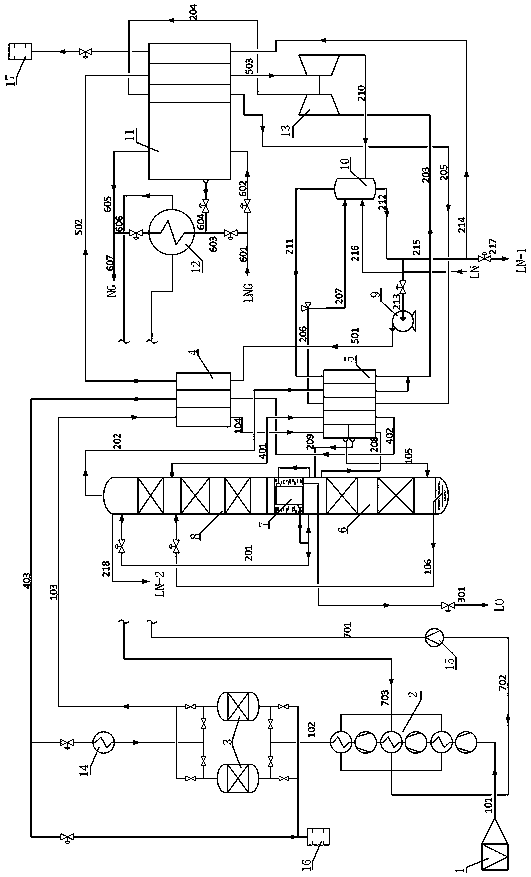

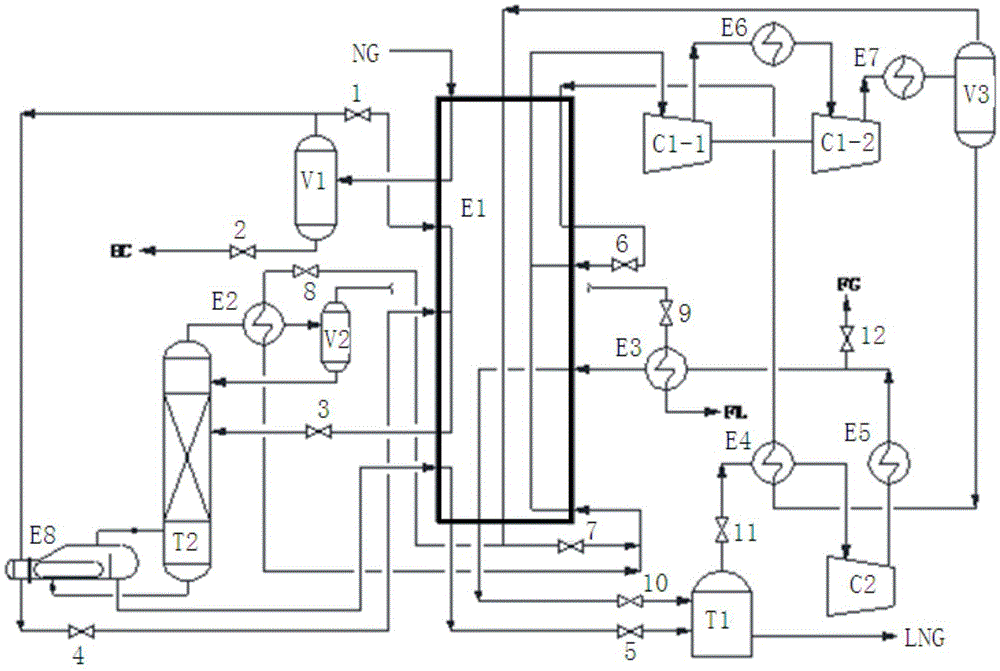

Liquefied natural gas (LNG) cold energy air separation system and air separation method

PendingCN109140903ARaise the dosageReduce energy consumptionSolidificationLiquefactionNitrogen gasLiquefied natural gas

The invention discloses a liquefied natural gas (LNG) cold energy air separation system and air separation method. The air separation system comprises an air separation unit, an LNG cold energy utilization unit and an ethylene glycol solution circulating and cooling unit. Through the new process organization form that a circulating liquid nitrogen pump is used for replacing a low-temperature circulating nitrogen compressor, production energy consumption of the LNG cold energy air separation system is substantially reduced, the extraction rate of oxygen and argon is high, the liquefaction ratioof a nitrogen product reaches up to 100%, and the additional value is high; moreover, a liquid nitrogen reverse current cold supplement mode is matched with LNG cold energy changes, and the LNG coldenergy air separation system has fewer requirements for an LNG receiving station and is high in universality. Compared with an existing LNG cold energy air separation technology, the LNG cold energy air separation system and air separation method have the beneficial effects that the comprehensive energy consumption is reduced by 40% or more, and the unit energy consumption is reduced by 60% or more; moreover, the unit energy consumption is still lower than that in the prior art under extreme production reduction conditions, and the cost advantages are quite obvious.

Owner:邢仁钊

Method for liquefying bamboo wood

The invention relates to a method for liquefying bamboo wood, which comprises the following steps: a mixed liquefying agent, polymerization inhibitor and acidic catalyst are mixed uniformly, heated to 100 DEG C by heating a reactor, added with bamboo powders, and heated while being stirred to 120-170 DEG C to perform liquefying reaction of bamboo wood. The mixed liquefying agent comprises phenol and a mixture of polyethylene glycol and glycerol. In the liquefying system, the mass ratio of phenol to the mixture of polyethylene glycol and glycerol to the polymerization inhibitor to the acidic catalyst to the bamboo powders is 5-95:95-5:1-4:1-6:20-50. The method for liquefying the bamboo wood has the beneficial effects that the method can be used for liquefying the bamboo wood; the liquefying ratio of the bamboo wood is relatively high; the liquefied product can be widely used, for example for substituting phenol to prepare biobased phenolic resin, for substituting partial polyether or polyester polyol to prepare polyurethane foam, and for preparing a plurality of novel polymer materials such as fiber and carbon fiber, so that the utilization ratio of the bamboo wood is up to 100%.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

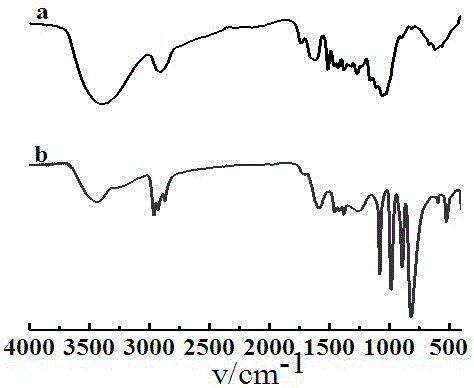

Preparation method for starch-based polyether polyol

The invention provides a preparation method for starch-based polyether polyol, belonging to the technical fields of chemical novel materials and high-quality utilization of biomass. According to the invention, starch and a mixed solution of polyethylene glycol 200 and glycerin are used as raw materials, and a reaction is carried out under a hydro-thermal condition so as to prepare polyether polyol; and the prepared polyether polyol has a hydroxyl value of 274.89 to 426.36 mg KOH / g, and the liquefaction ratio of starch is as high as 90.4% (wherein when the hydroxyl value is 331.0 mg KOH / g, viscosity is 430.5 mPa.s). The preparation method provided by the invention uses biomass as a reaction raw material, and biomass is safe, environment-friendly and good in biodegradability and avoids usage of catalysts used in traditional preparation methods; equipment used in the method and operation carried out in the method are simple; and the prepared starch-based polyether polyol can be used for preparation of hard polyurethane heat-insulation materials.

Owner:CHANGCHUN UNIV OF TECH

Method for liquefying surplus solid residue in fermentation of cellulosic ethanol

ActiveCN103740397ALow liquefaction temperatureReduce energy consumptionLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionLiquid productSulfide

The invention discloses a method for liquefying surplus solid residue in the enzymolysis saccharification and ethanol fermentation by adopting lignocellulose as a raw material. The method is characterized in that the solid residue is liquefied in a high-pressure vessel in the presence of a catalyst and an organic solvent, wherein the organic solvent is absolute ethyl alcohol, anhydrous propyl alcohol or absolute butanol, and the catalyst is aluminum chloride, aluminum sulfide and zinc sulfide. The catalyst which is specially selected by an inventor is added in the method, so that the liquefying temperature is effectively lowered, the liquefying rate of the fermented solid residue and the residue degrading degree can be improved, and more liquid products with smaller molecular weight can be generated. The method can be widely used for liquefying the residue produced by fermenting the biomass fuel ethanol and lignocellulose-rich biomass raw material and has the advantages of low liquefying temperature, simplicity in process, high efficiency and the like, and the raw materials are easily obtained.

Owner:SHANDONG UNIV

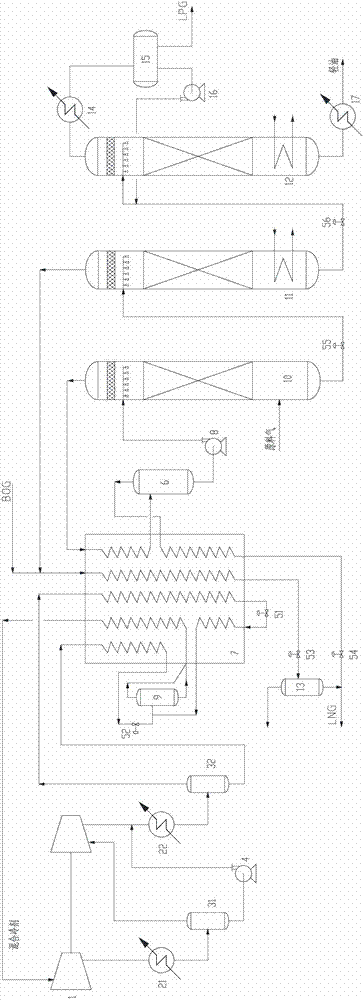

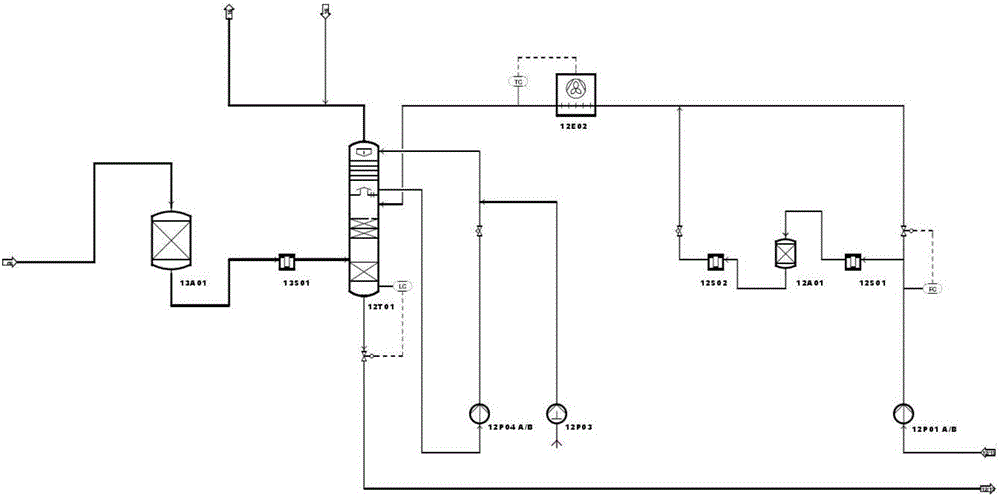

Low-temperature distillation and liquefying separation recovery system and method for coal bed gas high in nitrogen content, oxygen content and hydrogen content

ActiveCN105571269AIncrease productionHigh recovery rateSolidificationLiquefactionRecovery methodDistillation

The invention relates to a low-temperature distillation and liquefying separation recovery system and method for coal bed gas high in nitrogen content, oxygen content and hydrogen content. The low-temperature distillation and liquefying separation recovery system is provided with a cold box, a heavy hydrocarbon separation tank, a rectifying tower, an LCPM storage tank, a refrigerant compressor, a cooler, a final-stage gas-liquid separator, a flash gas compressor and a flash gas cooler. The low-temperature distillation and liquefying separation recovery method of the coal bed gas high in nitrogen content, oxygen content and hydrogen content comprises the steps that heavy hydrocarbon separation and liquefaction are conducted on feedstock gas after the feedstock gas is pre-cooled through a pre-cooling section of the cold box; the liquefied feedstock gas enters the rectifying tower for nitrogen removal, oxygen removal and hydrogen removal, and then the liquefied feedstock gas returns into the cold box to be further cooled and then enters the LCPM storage tank; after the gas mixed with refrigerants is compressed and cooled by two stages, the liquid-phase refrigerant separated by the final-stage gas-liquid separator is used for providing cold energy for the pre-cooling section of the cold box; the gaseous-phase refrigerant obtained after separation is used for providing cold energy for the liquefying section and the supercooling section of the cold box; purge gas is heated and then completely exhausted; and flash gas is pressurized and returns to the liquefying section of the cold box to be liquefied again after heat exchange is conducted between the flash gas and the liquid-phase refrigerant. By the adoption of the low-temperature distillation and liquefying separation recovery system and method, the recovery rate of methane can be increased, so that the processing capacity of a device is improved, the energy consumption of the system is reduced, and the production cost is reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +1

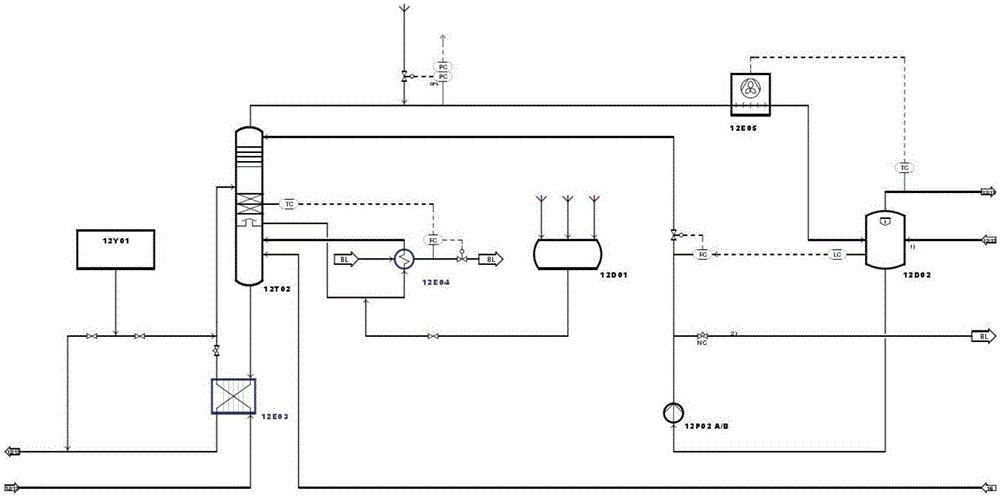

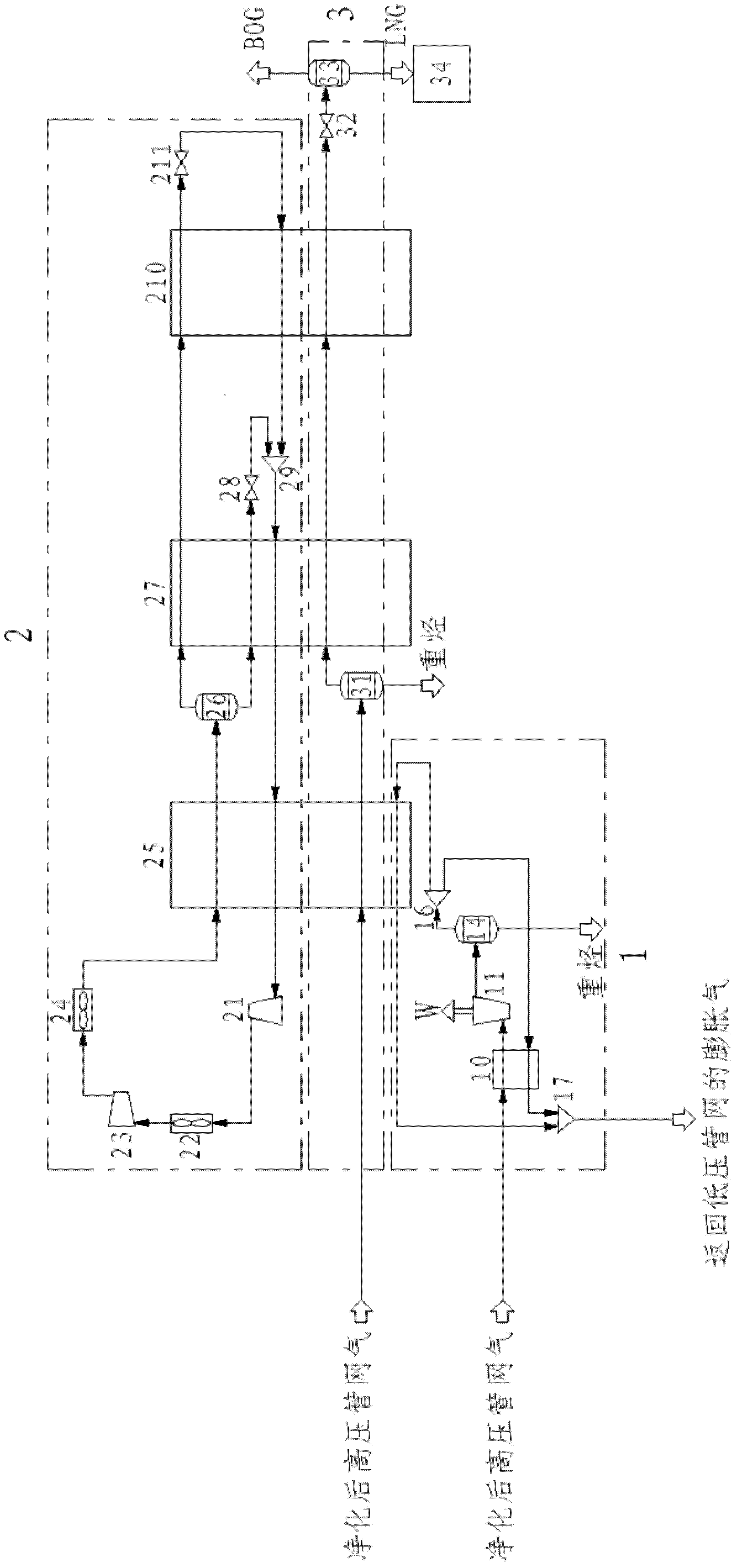

Coalbed methane liquefaction process

ActiveCN105865145AShorten the liquefaction processSimple processSolidificationLiquefactionRefrigerantPre cooling

The invention discloses a coalbed methane liquefaction process. A feeding unit, a mercury removing unit, a CO2 removing unit, a drying unit, a liquefaction unit, a refrigerant circulation unit, a refrigerant supplementing unit, a storage unit, a storage tank return gas compression unit, a hot oil unit and a torch unit are included. The feeding unit is sequentially connected with the mercury removing unit, the CO2 removing unit, the drying unit, the liquefaction unit and the storage unit; the liquefaction unit is pre-cooled, liquefied and supercooled through the refrigerant circulation unit; refrigerants are supplemented to the refrigerant circulation unit through the refrigerant supplementing unit; and the storage tank return gas compression unit is connected with the storage unit.

Owner:JINCHENG HUAGANG GAS CO LTD

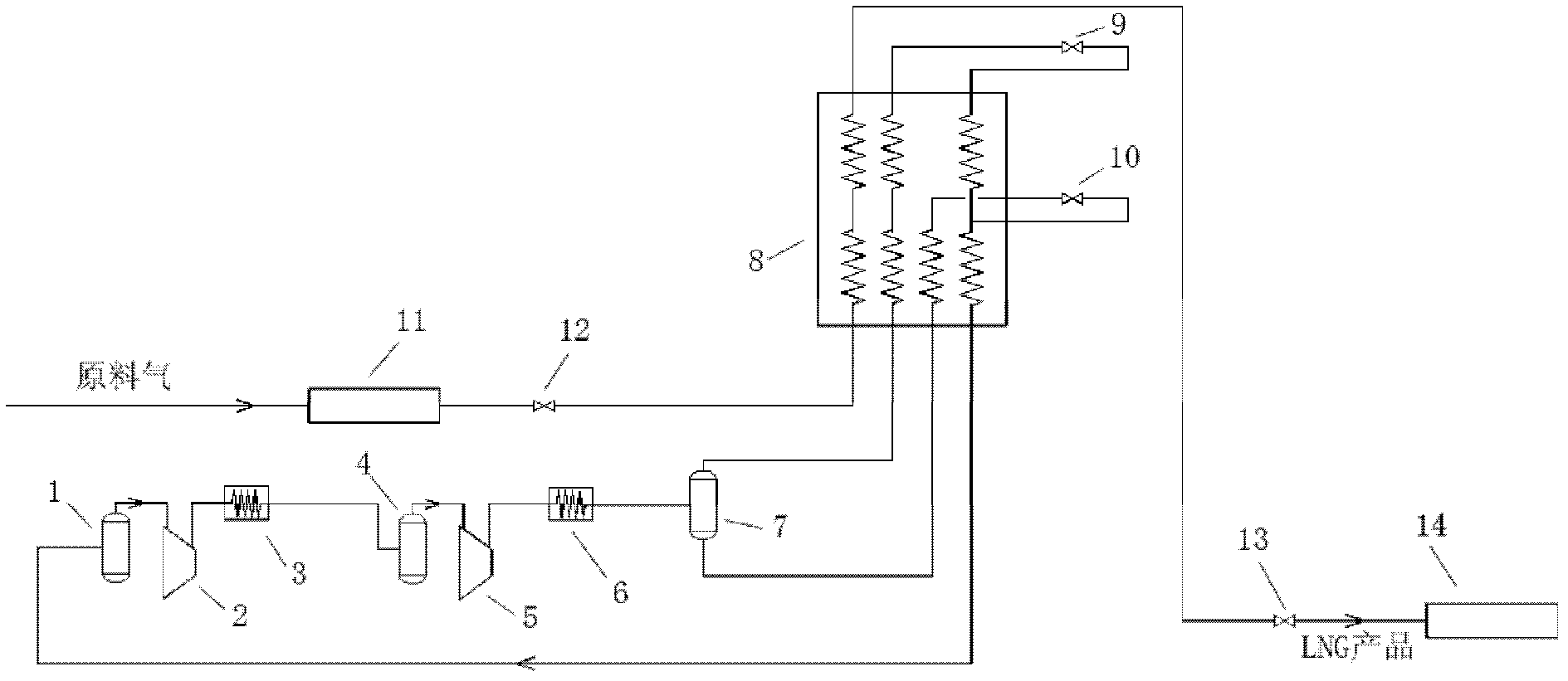

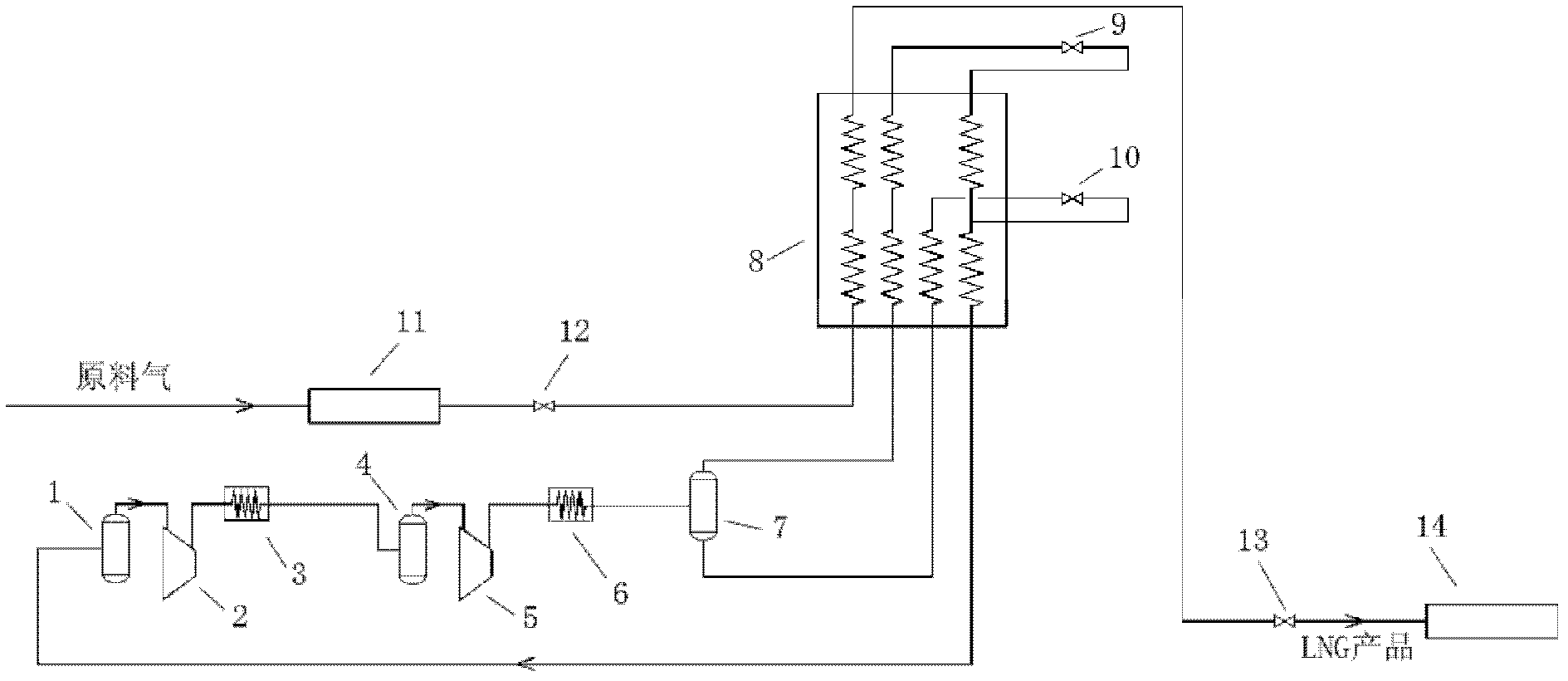

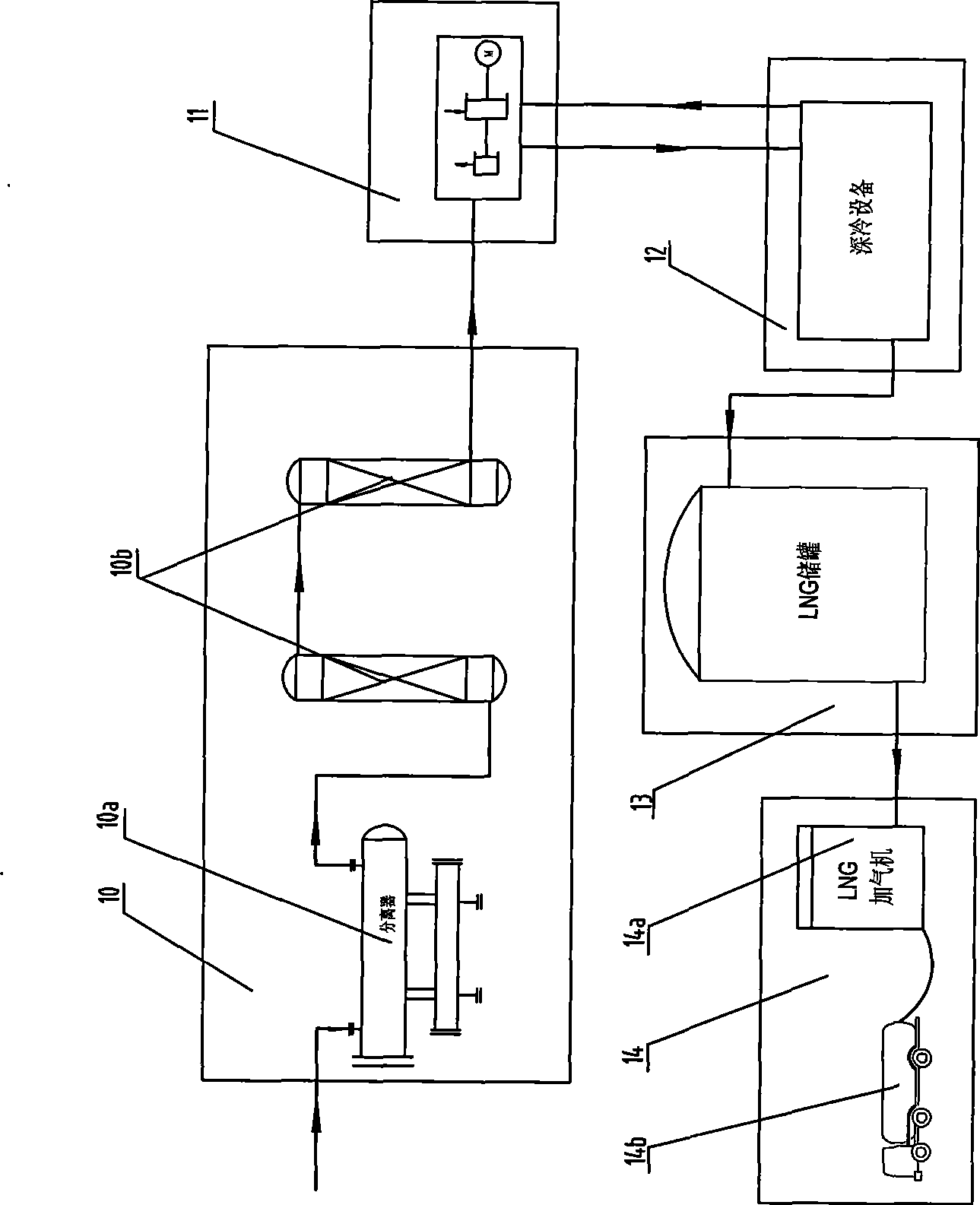

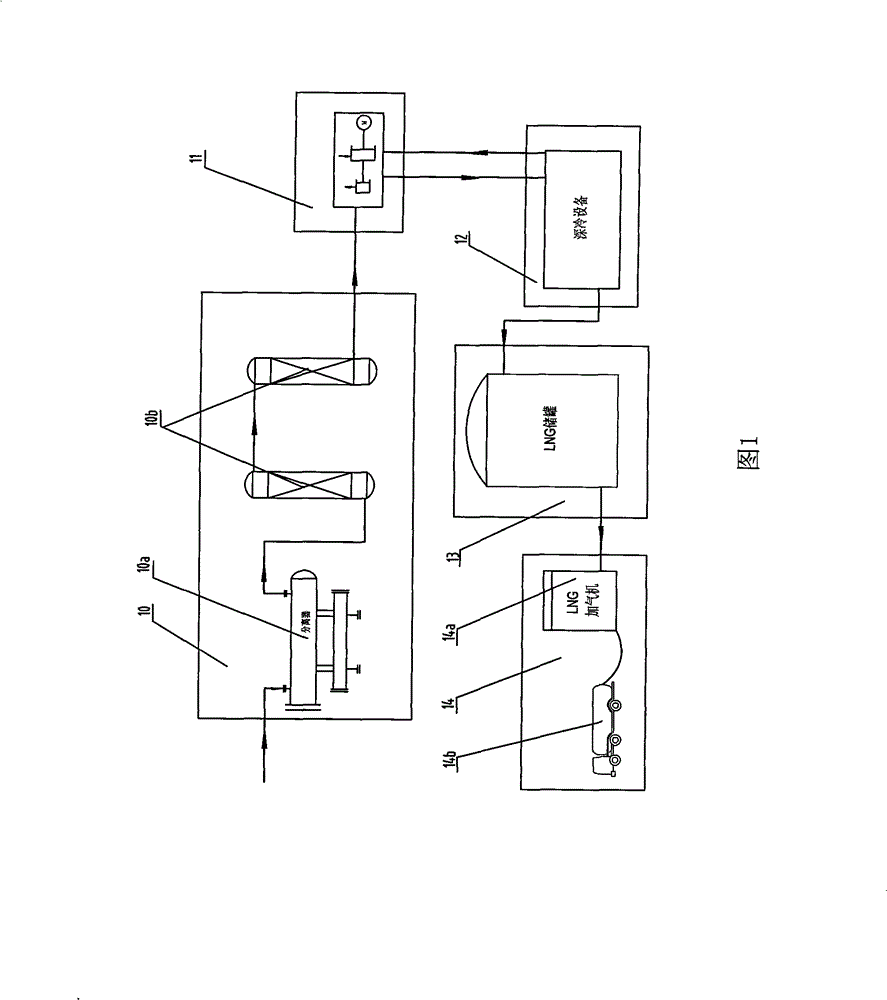

Natural gas liquefaction process

InactiveCN101508925ASmall structureSimple structureSolidificationLiquefactionProcess engineeringPre treatment

The invention discloses a natural gas liquefaction technique which comprises a pretreatment unit (10), a compression unit (11), a liquefaction unit (12), a storage unit (13) and a loading unit (14). The technique mainly comprises the steps: (1) large grained impurities contained by the raw material natural gas can be firstly separated by the pretreatment unit (10), and the moisture is removed; (2) after being processed by the pretreatment unit (10), the natural gas enters the compression unit (11) to be compressed into 10-25MPa; (3) after being pressurized, the natural gas enters the liquefaction unit (12) to be transformed into liquid natural gas LNG; (4) the liquid natural gas LNG is input into the storage unit (13) to be stored; (5) the liquid natural gas LNG in the storage unit (13) is loaded by the loading unit (14). By the improvement of the compression unit and the liquefaction unit of the existing technique, one-off liquefaction rate is effectively improved, and the liquefaction cost can be reduced.

Owner:北京永记鑫经贸有限公司

Technology for achieving catalytic liquefaction of biomass by means of M(salen) catalytic paper in ionic liquid

ActiveCN106190216AThe implementation process is simpleImprove the performance of liquefactionOrganic-compounds/hydrides/coordination-complexes catalystsLiquid hydrocarbon mixture productionIonic liquidBiomass

The invention discloses a technology for achieving catalytic liquefaction of biomass by means of M(salen) catalytic paper in an ionic liquid, and belongs to the technical field of biomass liquefaction. According to the method, on the condition that the ionic liquid and the M(salen) catalytic paper exist, catalytic liquefaction treatment is conducted on the biomass, wherein M in the M(salen) catalytic paper is Cu or Co or Fe or Mn or Zn. According to the technology for achieving catalytic liquefaction of the biomass by means of the M(salen) catalytic paper in the ionic liquid, the dosage of the catalyst is low, no strict requirement needs to be met, various liquefaction properties can be obviously improved, and the liquefaction efficiency can be obviously improved.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing biological oil from algae biomass through direct catalytic liquefaction method

InactiveCN102002381BConducive to liquefactionIncrease liquefaction rateLiquid hydrocarbon mixture productionHydrogen atmospherePre treatment

The invention relates to a method for preparing biological oil from algae biomass through a direct catalytic liquefaction method, which is a hydrothermal method with algae biomass as a raw material. The method comprises pretreatment, catalytic liquefaction and separation, wherein the pretreatment comprises the steps of: soaking dried and crushed algae in 0.05-0.15mol / L alkali liquor or acid liquor for not less than 20h, pouring the soaking liquid and a modified natural mordenite catalyst into a pressure kettle, catalytically liquefying for not less than half an hour under the condition of agitation in an oxygen free and hydrogen atmosphere at 200-400 DEG C under 3-16MPa, cooling, reducing the temperature, relieving the pressure, separating the solid and the liquid, and dehydrating the liquid under reduced pressure to obtain biological oil. The algae liquefaction rate of the invention is high and reaches more than 82%; the grade of the oil product is high, and the heat value can reachmore than 30 MJ / kg; a water phase system is adopted, so that the invention has the advantages of environmental protection, low preparation cost, relatively mild reaction conditions and good market application prospects, saves energy and is simple and convenient for operation and easy for realization of large-scale production.

Owner:HEFEI UNIV OF TECH

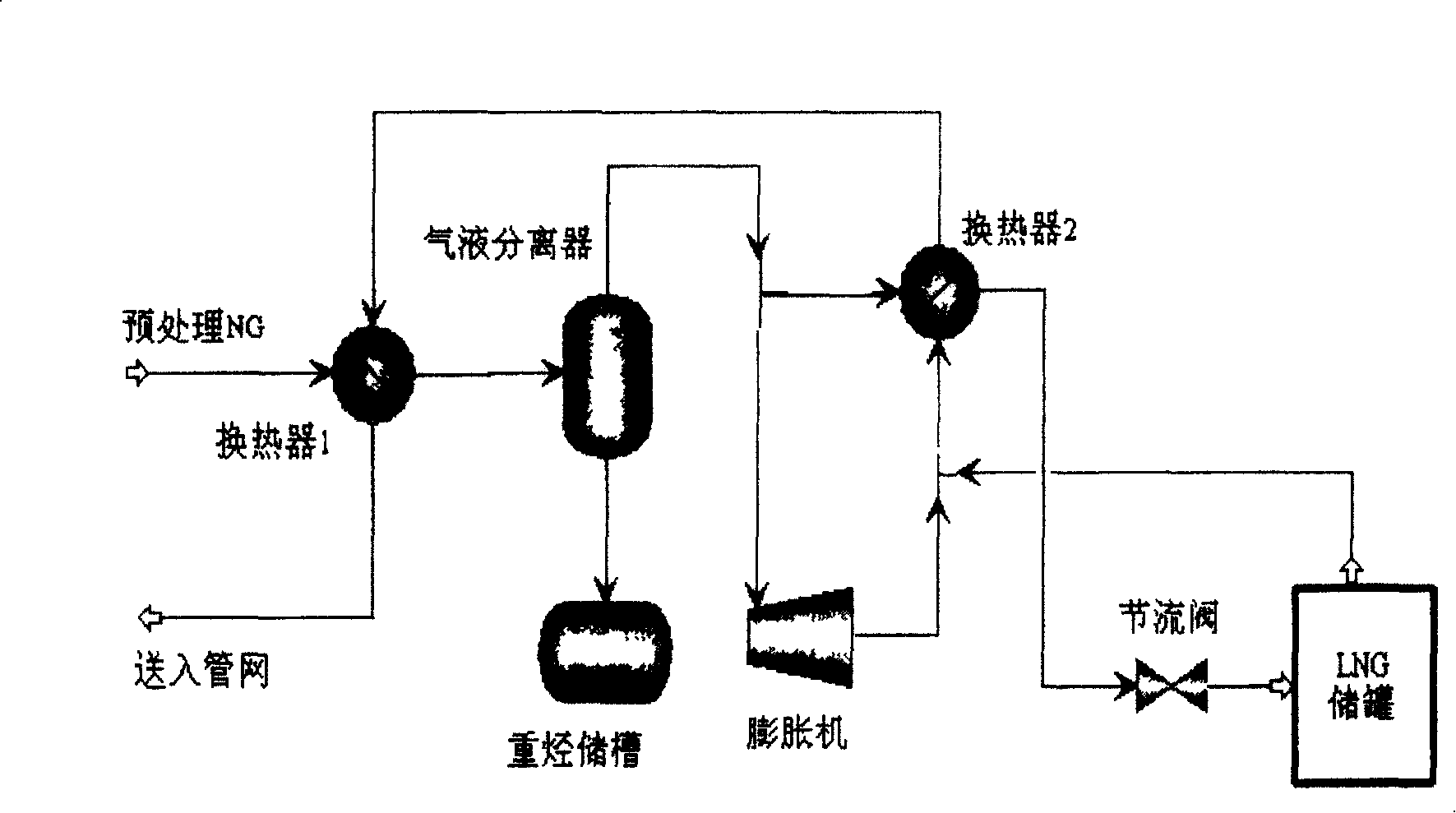

Natural gas liquefying method for gas peak regulation and light hydrocarbon recovery

InactiveCN100392052CIncrease liquefaction rateCold energySolidificationLiquefactionCompressed natural gasHigh pressure

Owner:SOUTH CHINA UNIV OF TECH

A method for supercritical fluid catalyzed liquefaction of plant raw materials

ActiveCN103555353BIncrease liquefaction rateReduce pollutionLiquid hydrocarbon mixture productionPtru catalystHeteropoly acid

The invention discloses a method for supercritical fluid catalyzed liquefaction of plant raw materials, which comprises the following steps: (1) crushing the plant raw materials, passing through a 40-60 mesh sieve, and drying; (2) adding plant raw materials and Alcohol solvent, using solid heteropoly acid as a catalyst, reacting in a supercritical state for 10-50 minutes, washing out the liquefied product with absolute ethanol, and obtaining biomass oil through suction filtration and rotary evaporation. The invention can greatly improve the liquefaction rate of plant raw materials; use solid heteropolyacid as a catalyst to replace traditional liquid strong acid catalysts such as H2SO4, HCl, HNO3, etc., and has the advantages of less environmental pollution, no corrosion of equipment, and easy separation; the obtained The content of esters in biomass oil is high, especially the content of levulinic acid ester is as high as 20.82%. It can be directly used as gasoline additives and biological liquid fuels. It has the advantages of non-toxicity, high lubricity, and high calorific value. It is a kind of clean energy .

Owner:FUJIAN AGRI & FORESTRY UNIV

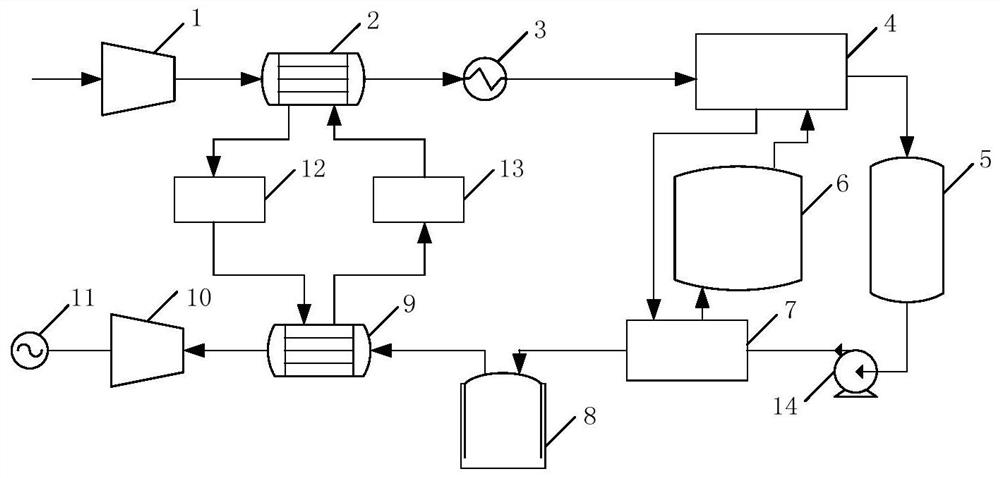

Novel natural gas liquefaction system and natural gas liquefaction method

InactiveCN102538390BIncrease liquefaction rateSolidificationLiquefactionProcess engineeringRefrigeration

The invention discloses a novel natural gas liquefaction system and a natural gas liquefaction method. The natural gas liquefaction system comprises an expansion precooling system, a mixed refrigerant circulating system and a natural gas liquefaction loop. Refrigeration of an expander is combined with mixed refrigerant circulating refrigeration, the expansion precooling system provides energy for precooling natural gas and mixed refrigerant, and the mixed refrigerant circulating refrigeration provides cold energy for liquefying the natural gas. The liquefaction system and the natural gas liquefaction method make full use of pressure energy among high-low pressure pipe networks of urban natural gas stations, and are high in efficiency, energy-saving and high in liquefaction ratio.

Owner:XI AN JIAOTONG UNIV +1

Method for preparing polyurethane foamed plastic from economic forest processing residues

The invention discloses a method for preparing degradable biomass polyurethane foamed plastic from economic forest processing residues, belonging to the technical field of chemical industry of forest products. The method mainly comprises the following steps: uniformly mixing a liquefier and a catalyst in a 1-ton reaction kettle, adding economic forest processing residues, closing the reaction kettle feed port, starting a stirrer and a condensing unit, heating to 140-150 DEG C, liquefying for 60-90 minutes, naturally cooling to 40 DEG C, and adding oxide for neutralization until the pH value is 7-8; heating to 120-130 DEG C, adding a modifier, keeping the temperature for 30-60 minutes, heating to 150-160 DEG C, stirring under reflux for 1-2 hours, and terminating the reaction; cooling to room temperature to obtain the modified liquefying product; and mixing the liquefying product, polyether glycol, water, liquid CO2, silicon oil, an amine catalyst, a tin catalyst and a flame retardant under high pressure, sending into a V-shaped expansion chamber for expansion, and curing by heating to obtain the degradable biomass polyurethane foamed plastic. The method can obviously lower the production cost of the polyurethane foamed plastic and endow the polyurethane foamed plastic with biodegradability; and the detection shows that the polyurethane foamed plastic conforms to the national standard GB / T10802-2006.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

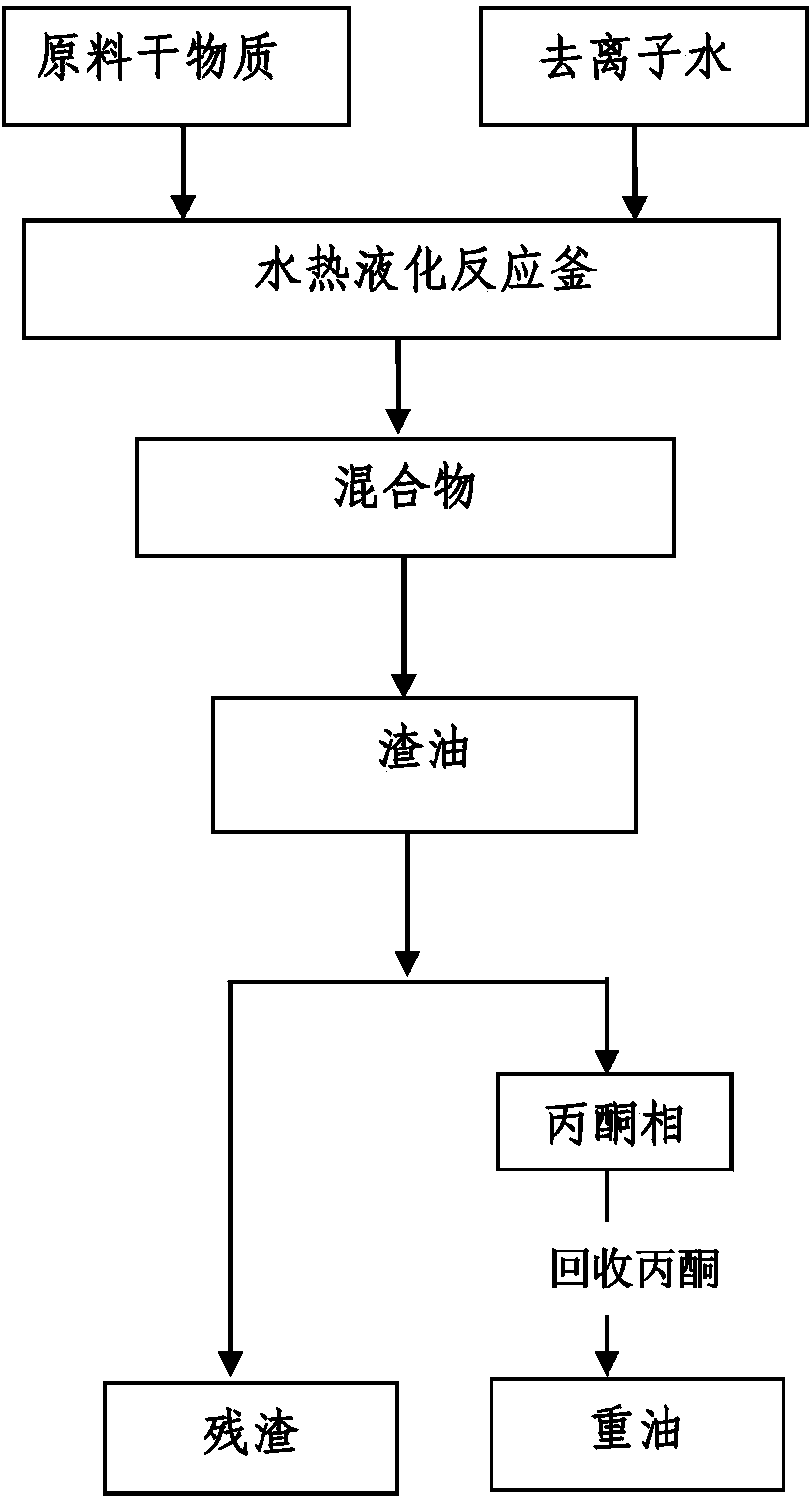

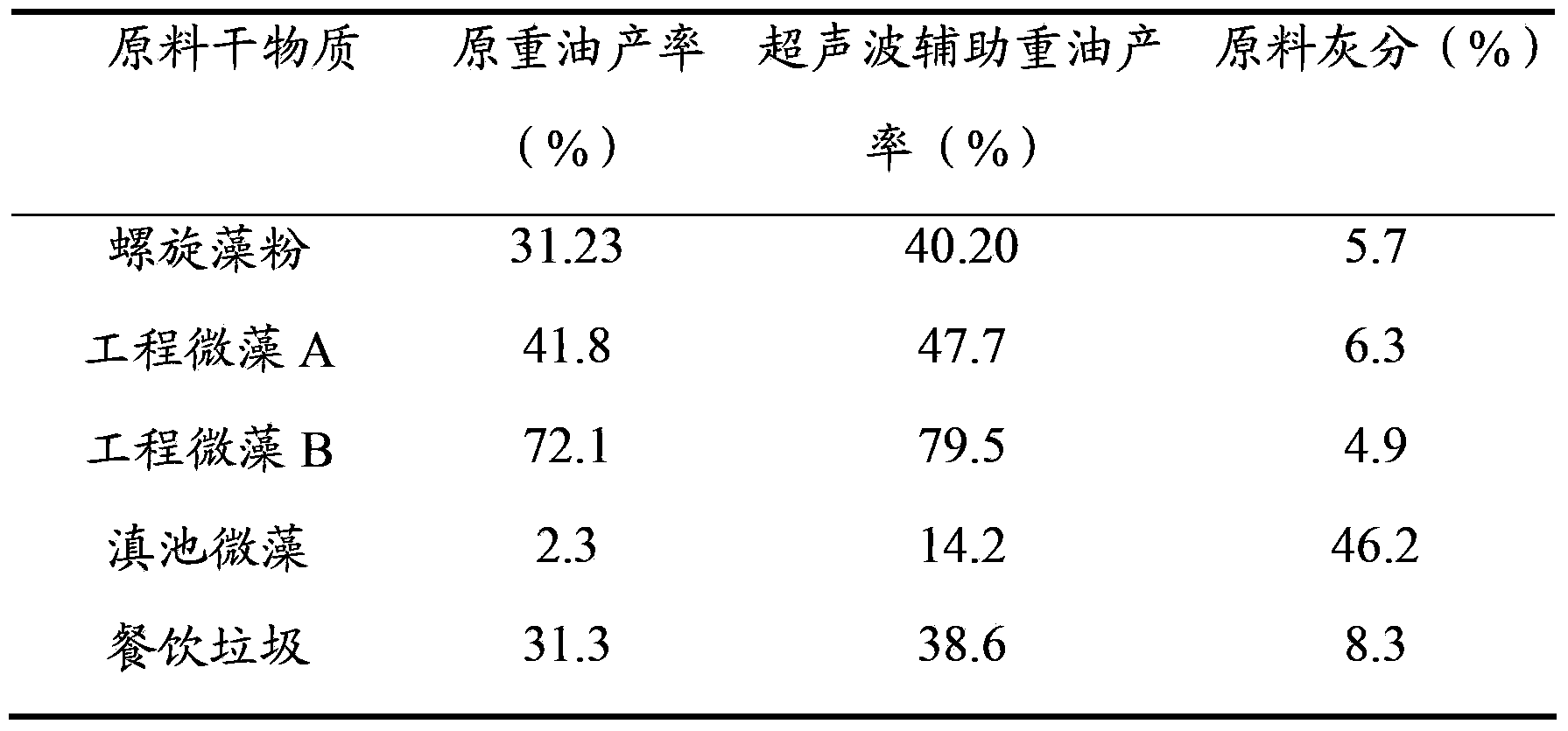

Method for increasing heavy oil yield by treating biological crude oil with ultrasonic wave

InactiveCN103450920AReduce energy consumptionIncrease polarityTreatment with plural serial refining stagesLiquid hydrocarbon mixture productionUltrasonic assistedNitrogen

The invention relates to recycle of a heavy oil product in a biological crude oil preparation process, namely a method for preparing a heavy oil product from biological crude oil and increasing the yield by means of ultrasonic-assisted extraction. The method comprises the following steps: a, mixing a certain amount of dry raw material with deionized water so as to ensure that the mass percentage of the dry raw material in the obtained mixture is 15%-25%, and putting the mixture into a hydrothermal liquidation reaction kettle; b, regulating the sealed reaction kettle, introducing nitrogen so as to exhaust the air from the reaction kettle and simultaneously enable the pressure in the reaction kettle to be the initial pressure, starting a stirrer, and starting a temperature rise reaction after checking the air tightness; c, filtering and separating the mixture after the reaction is ended; d, mixing the separated residue oil with acetone of which the volume concentration is 98% at a ratio of 1:(10-12) (g:ml), and performing extraction by using an ultrasonic generator; e, filtering a mixed product after the extraction is ended, separating out the acetone phase, and recycling the acetone, thereby obtaining the heavy oil.

Owner:CHINA AGRI UNIV

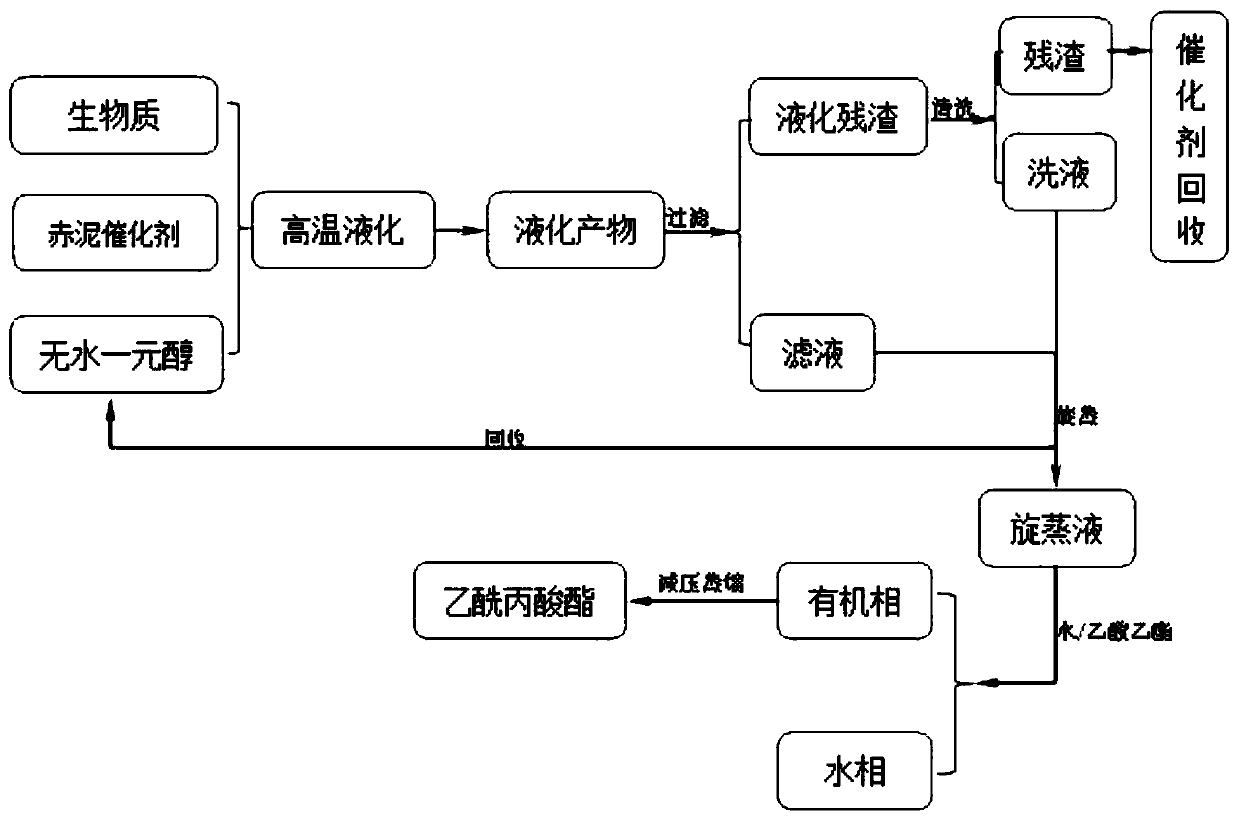

Method for catalyzing biomass to prepare levulinate by red mud-based catalyst

ActiveCN110156595AIncrease liquefaction rateLess corrosiveOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsLevulinic acidRed mud

The invention belongs to the technical field of biomass utilization and in particular relates to a method for catalyzing biomass to prepare levulinate by a red mud-based catalyst. A catalyst taking red mud as a carrier is adopted in the invention. With the adoption of the catalyst and a corresponding method in the invention, compared with an ordinary liquefaction method, the method in the invention is nontoxic and low in corrosivity. The operation is simple, the raw material liquefaction ratio is high, and the product is high in yield and purity.

Owner:ENERGY RES INST CO LTD HENAN ACADEMY OF SCI

Coal liquefaction system with forced circulation hot wall reactor and bubbling bed cold wall reactor

ActiveCN109722266AAvoid interventionIncrease conversion rateLiquid hydrocarbon mixture productionChemical/physical processesManufacturing technologyReaction temperature

The invention discloses a coal liquefaction system with a forced circulation hot wall reactor and a bubbling bed cold wall reactor. In a coal hydrogenation direct liquefaction reaction process, the forced circulation hot wall reactor is adopted in a shallow coal liquefaction reaction process with a low operation temperature, so that advantages of the existing hot wall reactor manufacturing technology is adopted to realize equipment enlargement and improve the space liquid phase fraction of the reaction; and the bubbling bed cold wall reactor is adopted in a deep coal liquefaction reaction process with a relatively high operation temperature, so that the reaction temperature of a deep thermal cracking process is reasonably improved, and the liquefaction rate of coal can be improved. When the product of the rear bubbling bed cold wall reactor returns to the adjacent upstream forced circulation hot wall reactor and a coupled parallel reaction system is formed, an ideal bubbling bed cold wall reactor with liquid material cyclic high-temperature operation is formed, so that the temperature increase amplitude, of the subsequent flow, caused by overtemperature of the product of the bubbling bed cold wall reactor can be favorably inhibited; a circulating pump can be shared, and two or more of the parallel bubbling bed cold wall reactors can form a non-stop on-line switching operation mode, so that the operation period can be prolonged.

Owner:洛阳瑞华新能源技术发展有限公司

Method for producing fermented type rice beverage through adding enzymes, extruding and liquefying

InactiveCN108936148ASimple production processShorten the production cycleFood scienceAlpha-amylaseFood flavor

The invention relates to a method for producing a fermented type rice beverage through adding enzymes, extruding and liquefying, and belongs to the technical field of cereal deep-processing. Accordingto the method, a dual-screw extruder is used as a serialization enzyme reactor, heat-resisting alpha-amylase is added, reasonable parameters of an extruding system, suitable for production of the fermented type rice beverage, are provided, and pasting and liquefying of rice are realized in the extruder; and then through grinding to obtain pulp, saccharifying, homogenizing, sterilizing, inoculation, fermenting, and filling, finished products of the fermented type rice beverage are obtained. Compared with a patent technique for preparing the conventional fermented type rice beverage, the methoddisclosed by the invention has the advantages that the pasting degree and the utilization rate of raw materials are increased, the production cycle is shortened, and the products are unique and richin flavor; and besides, two original working procedures of performing cooking and pasting on rice milk and performing liquefying with alpha-amylase are changed into one working procedure of performingextruding and liquefying, so that the working procedure is simplified, the operating condition is improved, the loss of starch is reduced, and the investments for equipment and construction are reduced.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

A kind of preparation method of starch-based polyether polyol

The invention provides a preparation method for starch-based polyether polyol, belonging to the technical fields of chemical novel materials and high-quality utilization of biomass. According to the invention, starch and a mixed solution of polyethylene glycol 200 and glycerin are used as raw materials, and a reaction is carried out under a hydro-thermal condition so as to prepare polyether polyol; and the prepared polyether polyol has a hydroxyl value of 274.89 to 426.36 mg KOH / g, and the liquefaction ratio of starch is as high as 90.4% (wherein when the hydroxyl value is 331.0 mg KOH / g, viscosity is 430.5 mPa.s). The preparation method provided by the invention uses biomass as a reaction raw material, and biomass is safe, environment-friendly and good in biodegradability and avoids usage of catalysts used in traditional preparation methods; equipment used in the method and operation carried out in the method are simple; and the prepared starch-based polyether polyol can be used for preparation of hard polyurethane heat-insulation materials.

Owner:CHANGCHUN UNIV OF TECH

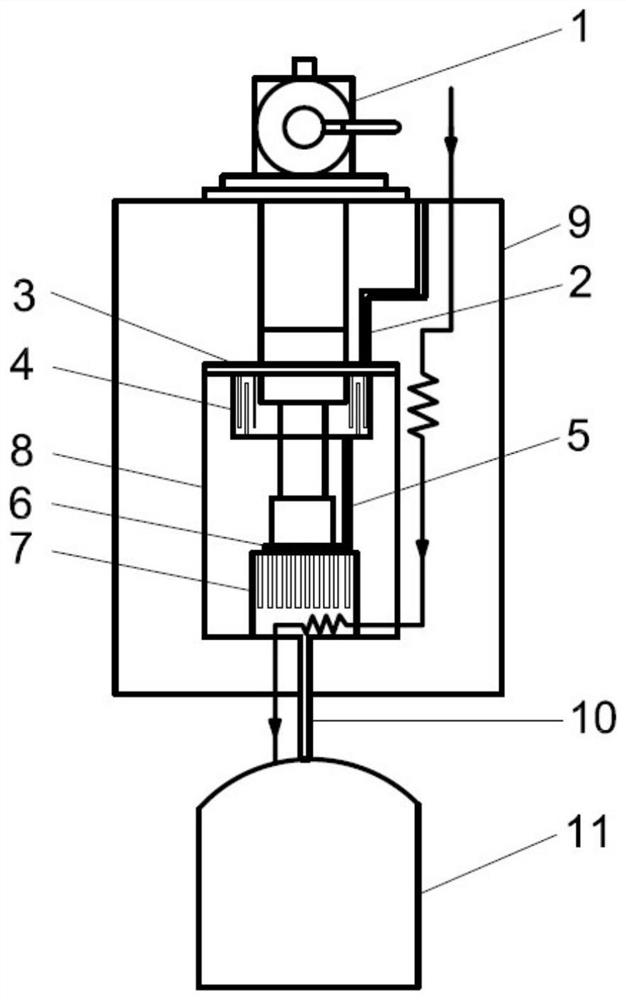

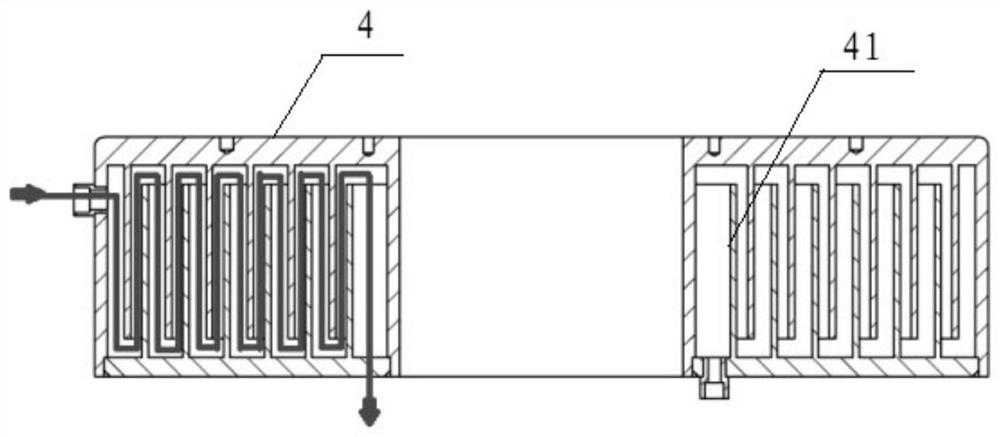

Neon liquefying device

PendingCN113739514ALiquefaction achievedReduce loadSolidificationLiquefactionMechanical engineeringHeat exchanger

The invention relates to the technical field of neon liquefaction, and discloses a neon liquefying device. The neon liquefying device comprises a two-stage refrigerating machine, a first-stage heat exchanger, a gas inlet pipe, a condenser, a gas conveying pipe, a Dewar tank, and a liquid conveying pipe, wherein the two-stage refrigerating machine is provided with a first-stage cold head and a second-stage cold head, the first-stage heat exchanger is connected with the first-stage cold head, the first-stage cold head provides cooling capacity for the first-stage heat exchanger, the gas inlet pipe is used for conveying external neon to the first-stage heat exchanger to be pre-cooled to a set temperature; the condenser is connected with the second-stage cold head, the second-stage cold head provides cooling capacity for the condenser, the gas conveying pipe communicates with the gas inlet pipe and is used for conveying the pre-cooled neon gas to the condenser, the pre-cooled neon gas is cooled to the boiling point temperature through the condenser and liquefied into liquid neon, the Dewar tank is used for storing the liquid neon, and the liquid conveying pipe is connected with the condenser and the Dewar tank and used for conveying the liquid neon to the Dewar tank. According to the neon liquefying device, neon can be effectively cooled, and the liquefaction rate of neon is increased.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Natural gas liquefaction process

InactiveCN101508925BSmall structureSimple structureSolidificationLiquefactionProcess engineeringPre treatment

The invention discloses a natural gas liquefaction technique which comprises a pretreatment unit (10), a compression unit (11), a liquefaction unit (12), a storage unit (13) and a loading unit (14). The technique mainly comprises the steps: (1) large grained impurities contained by the raw material natural gas can be firstly separated by the pretreatment unit (10), and the moisture is removed; (2) after being processed by the pretreatment unit (10), the natural gas enters the compression unit (11) to be compressed into 10-25MPa; (3) after being pressurized, the natural gas enters the liquefaction unit (12) to be transformed into liquid natural gas LNG; (4) the liquid natural gas LNG is input into the storage unit (13) to be stored; (5) the liquid natural gas LNG in the storage unit (13) is loaded by the loading unit (14). By the improvement of the compression unit and the liquefaction unit of the existing technique, one-off liquefaction rate is effectively improved, and the liquefaction cost can be reduced.

Owner:北京永记鑫经贸有限公司

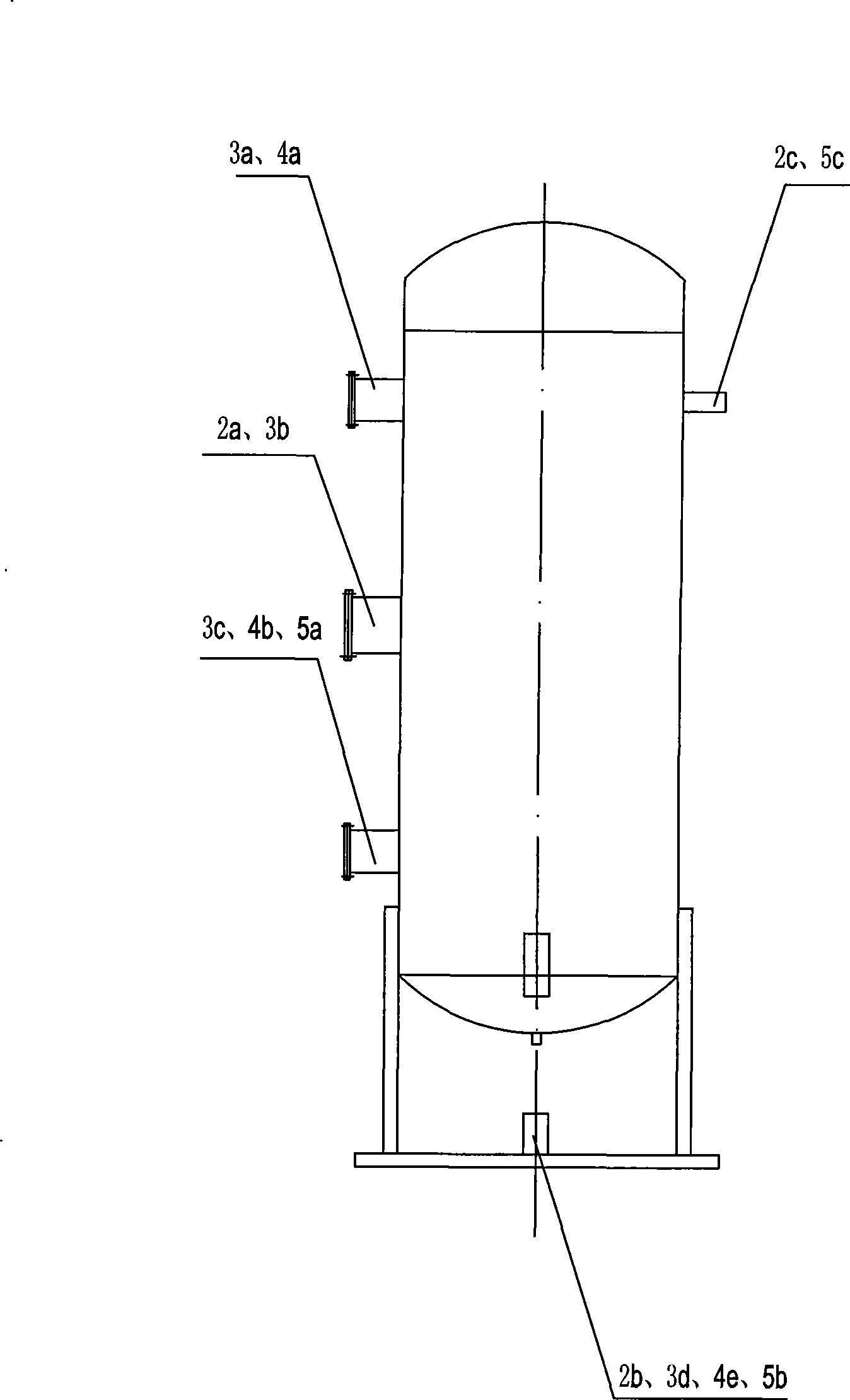

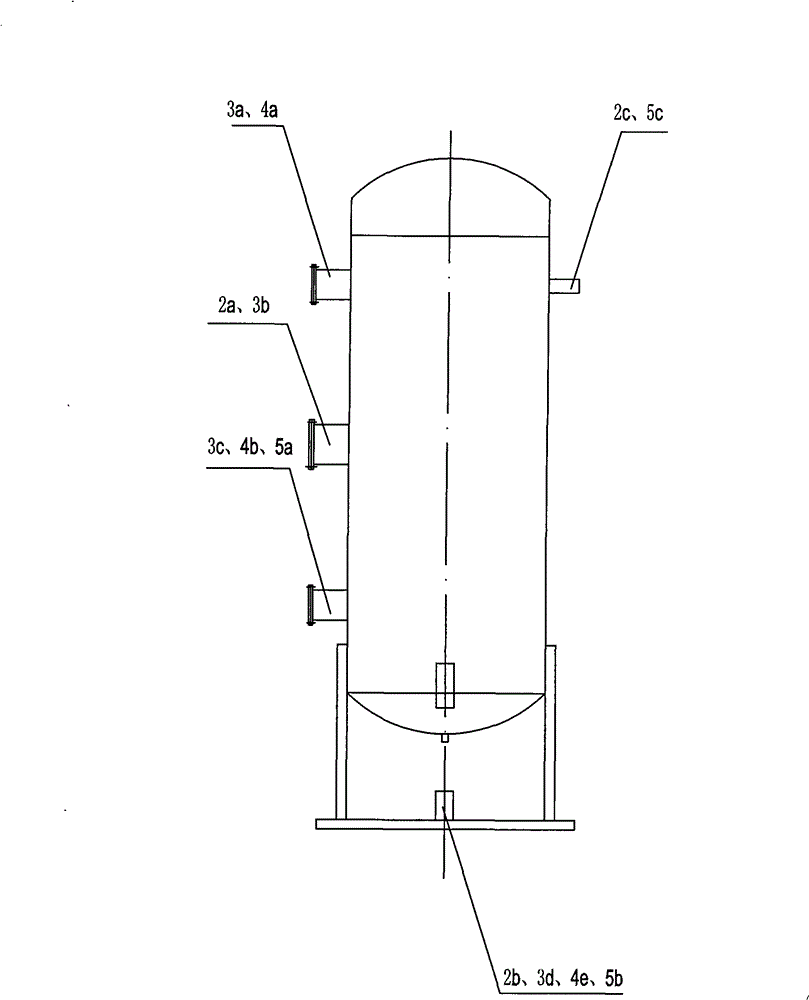

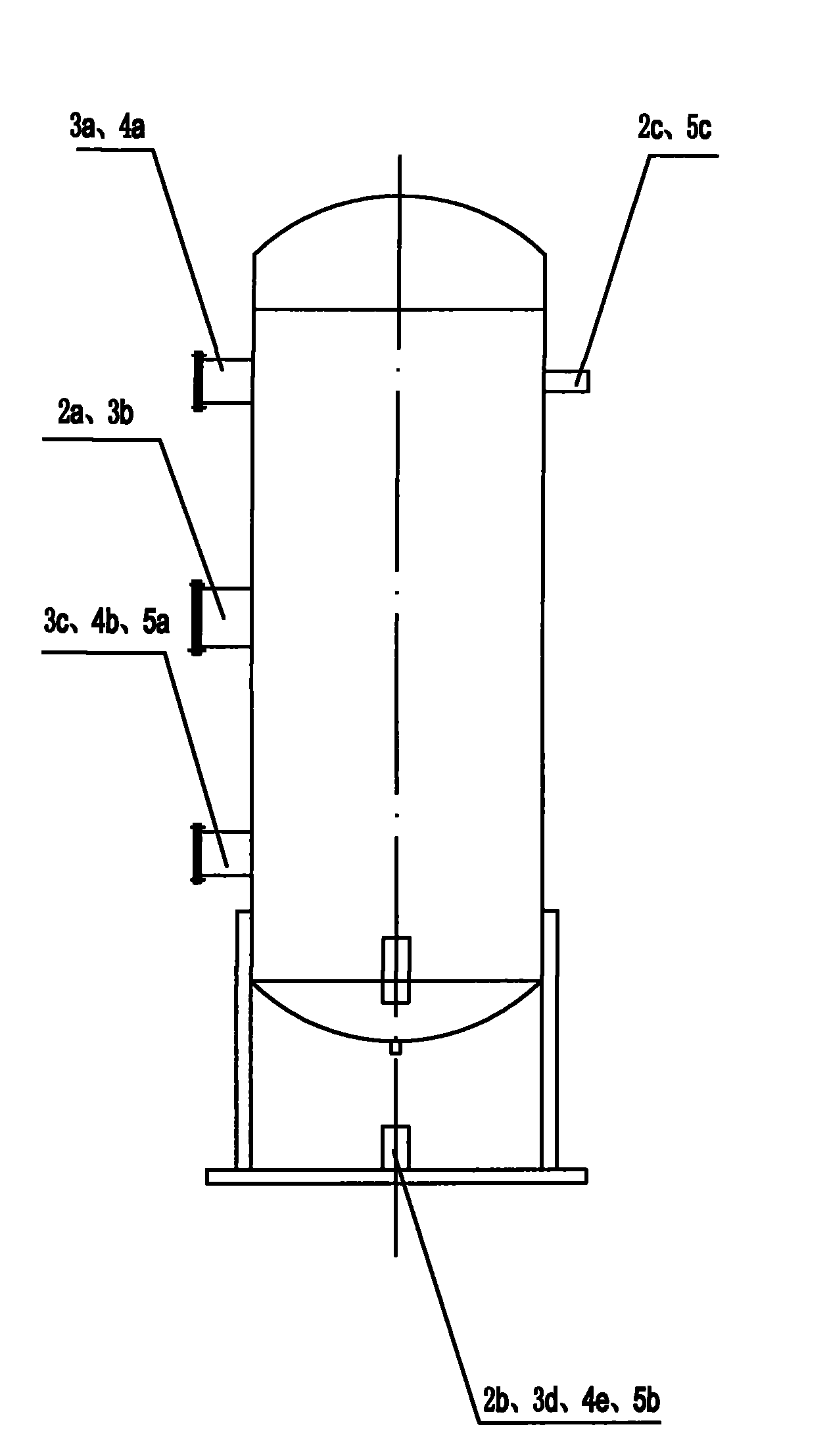

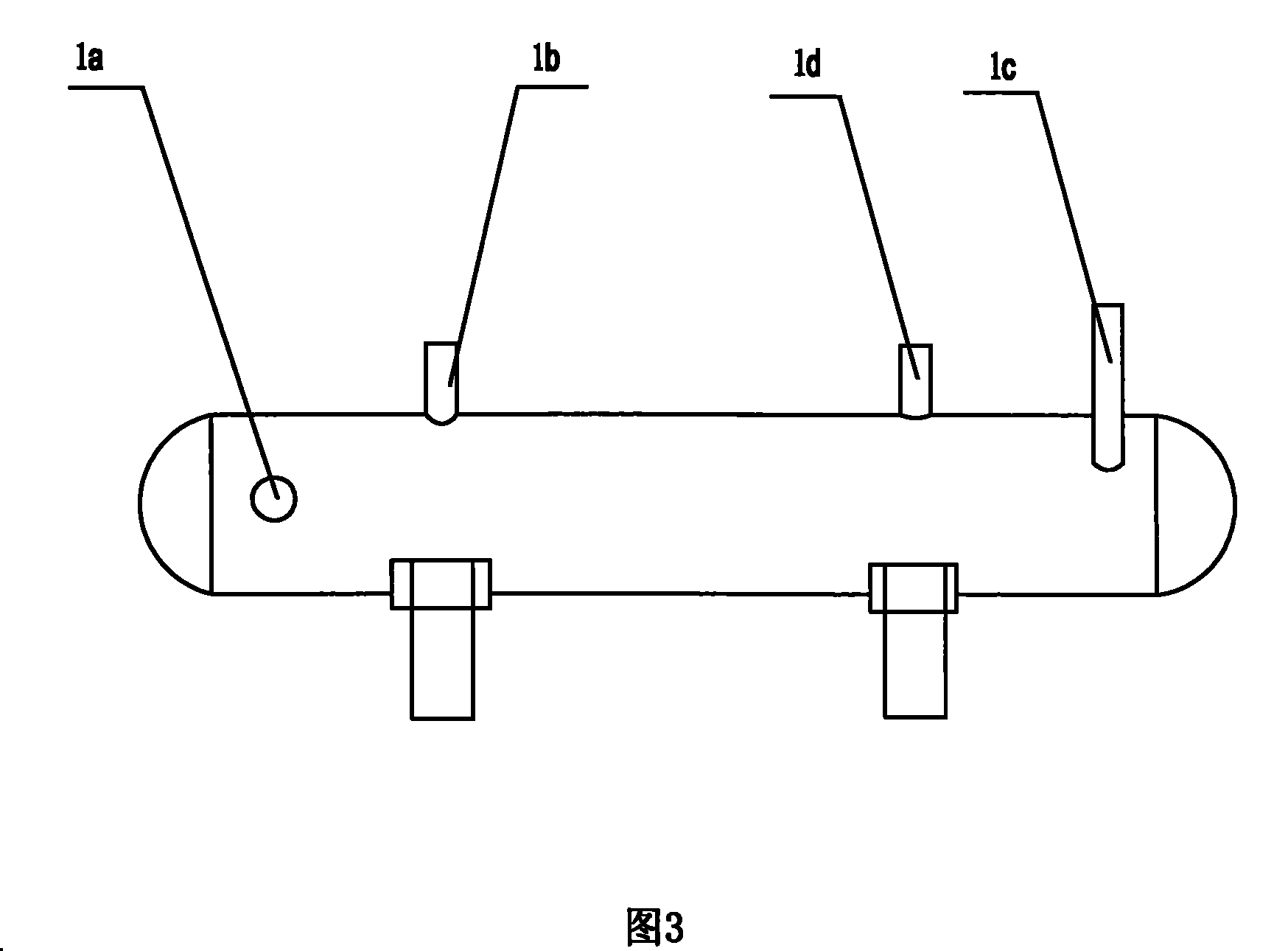

Ice box used for natural gas liquefaction system

InactiveCN101504244BSmall structureSimple structureSolidificationLiquefactionProcess engineeringEnergy consumption

Owner:北京永记鑫经贸有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com