Novel natural gas liquefaction system and natural gas liquefaction method

A liquefaction system and natural gas technology, applied in the field of gas liquefaction, to achieve the effect of high liquefaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

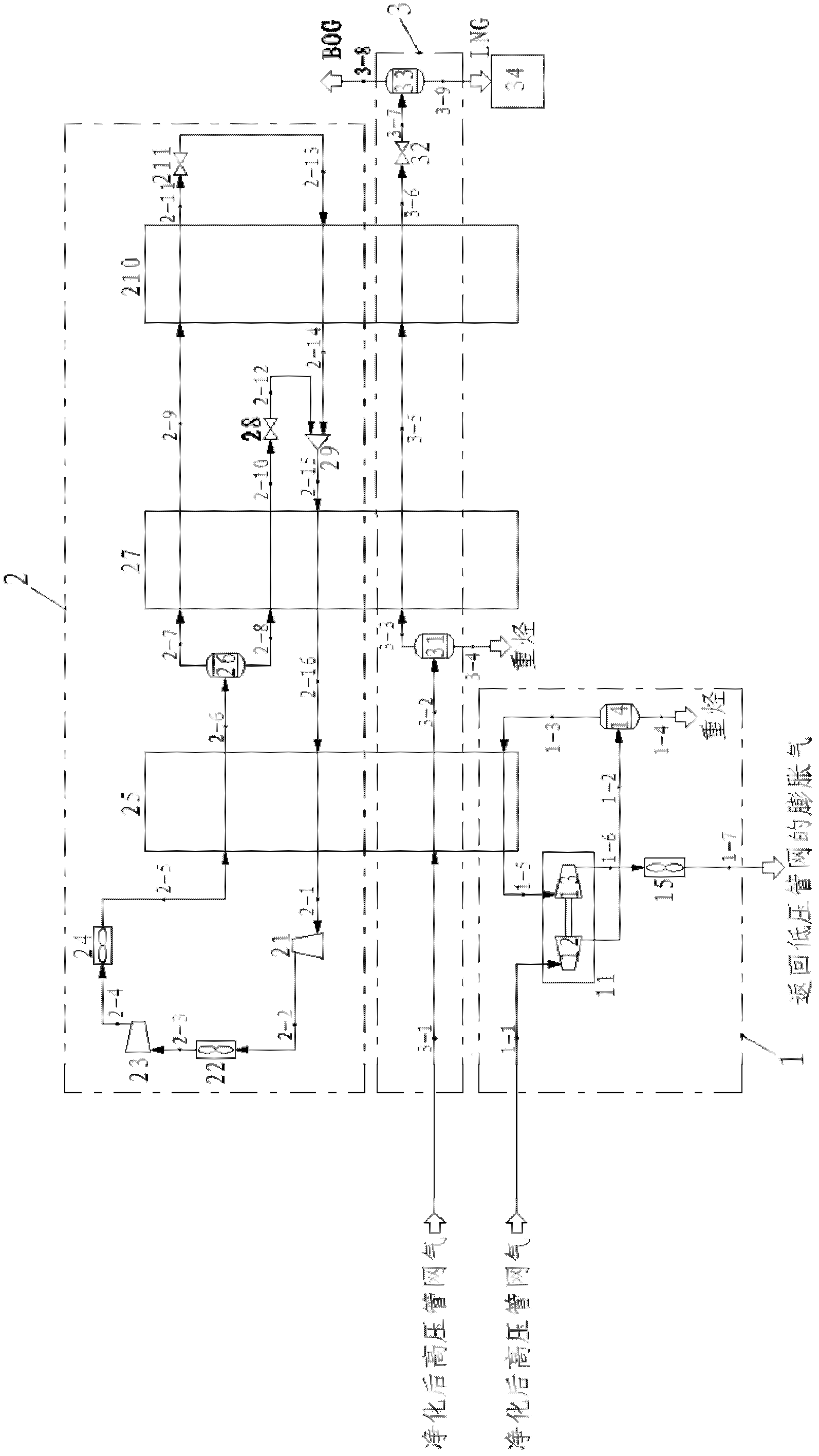

[0048] Such as figure 1 As shown, the natural gas liquefaction process of the present invention includes an expansion precooling system 1 , a mixed refrigerant circulation system 2 and a natural gas liquefaction circuit 3 .

[0049] Expansion pre-cooling system 1, a part of natural gas from the high-pressure pipe network, the pressure and temperature are 3.7MPa and 308.15K respectively, enter the expansion end 12 of the expander 11 for expansion, the pressure drops to about 0.55MPa, the temperature drops to about 221K, and then passes through Expansion gas-liquid separator 14 removes heavy hydrocarbons and other high-boiling point components to condensate, and part of the gas phase flows into the fourth channel of pre-cooling heat exchanger 25 to provide cooling capacity for pre-cooling heat exchanger 25. After sufficient heat exchange The temperature rises to about 290K, then flows into the booster end 13 of the expander 11, pressurizes to about 1.18MPa, the temperature rises...

Embodiment 2

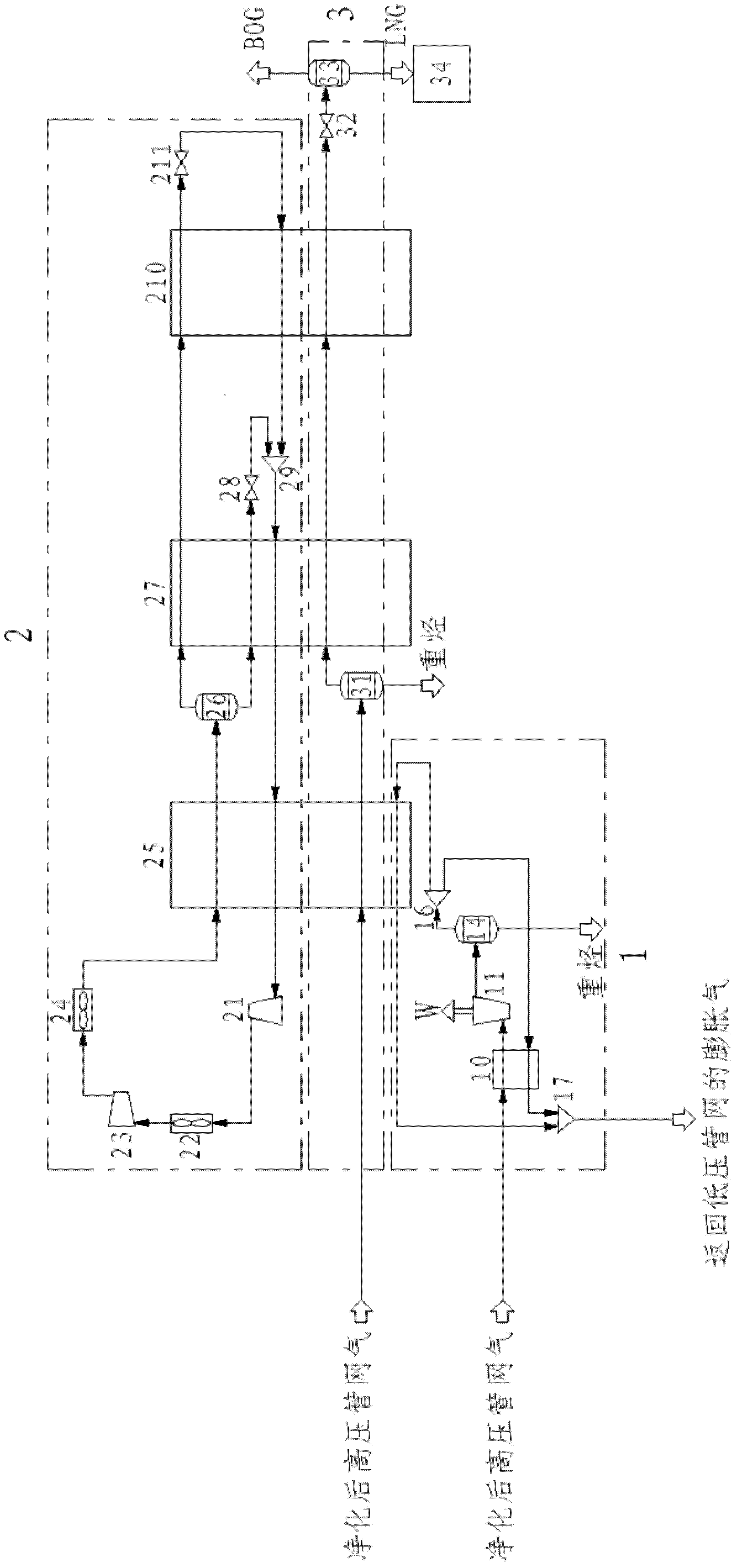

[0054] figure 2 is a schematic diagram of Embodiment 2 of the present invention, which is similar to figure 1 Said embodiment 1, figure 2 The process shown is the same as figure 1 The differences in the flow shown are: (1), figure 2The expansion gas from the high-pressure pipe network enters the expander 11 for expansion and first enters the expansion gas regenerator 10 for cooling, and the cooling capacity of the expansion gas regenerator 10 is provided by a part of the expanded expansion gas; (2), the expander 11 No pressurization end is set, the expansion gas is directly expanded to the pressure of the low-pressure pipe network in the expander 11, and the resulting expansion work can be recovered for power generation or used for other purposes; (3), installed after the expansion gas-liquid separator 14 The expanded gas separator 16 is used to adjust the ratio of the two streams flowing into the pre-cooling heat exchanger 25 and the returned expanded gas recuperator 10...

Embodiment 3

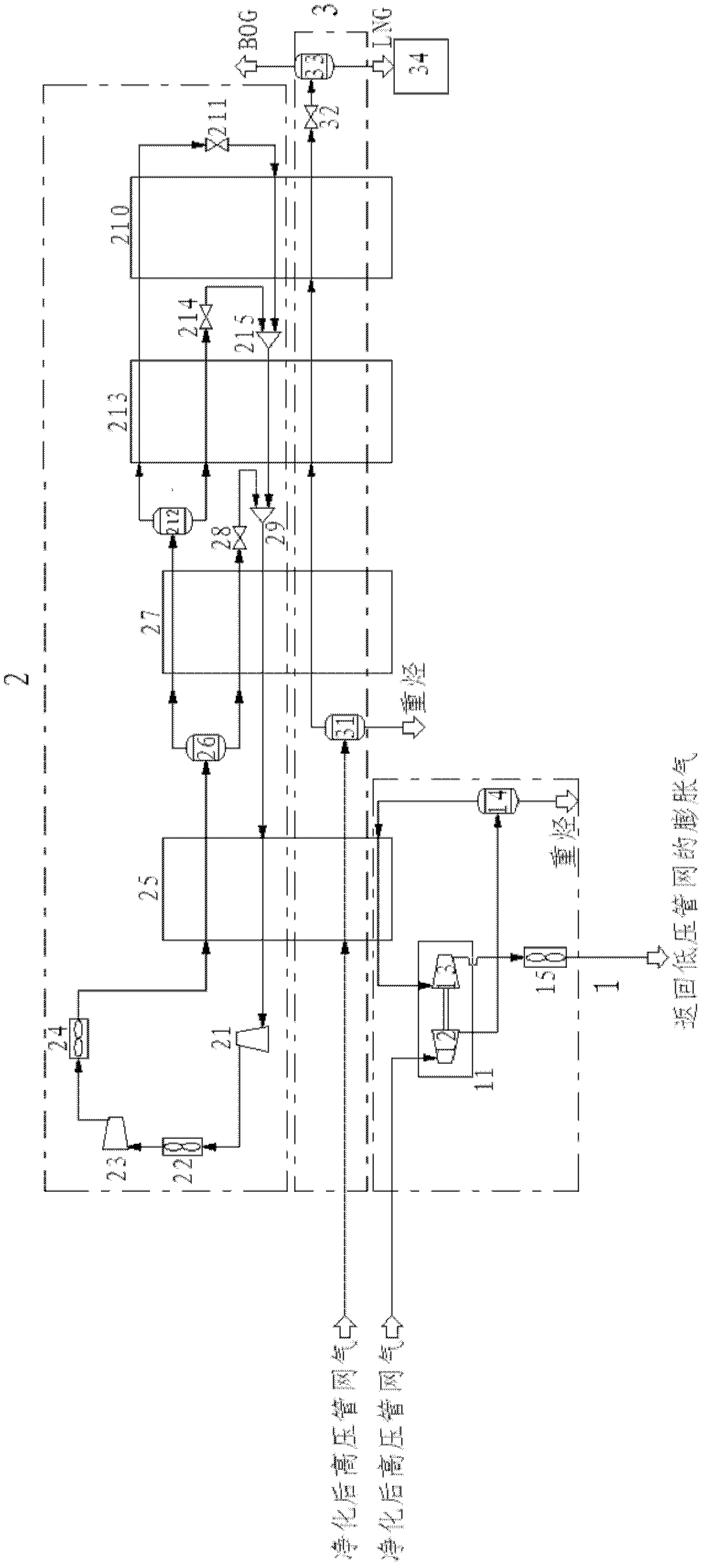

[0056] image 3 is a schematic diagram of embodiment 3 of the present invention, which is similar to figure 1 Said embodiment 1, image 3 The process shown is the same as figure 1 The differences in the flow shown are: (1), image 3 In front of the subcooling heat exchanger 210, a primary heat exchanger is added, which is called the second main heat exchanger 213, forming a precooling heat exchanger 25, two-stage main heat exchangers (27, 213) and supercooling The four-stage heat exchanger mixed refrigeration cycle of the cold heat exchanger 210; (2), the newly added second main heat exchanger 213 and its auxiliary equipment are basically the same as the first main heat exchanger 27, and the second main heat exchanger 213 A second mixed refrigerant gas-liquid separator 212 is arranged at the front end to separate the two-phase refrigerant flowing out of the first flow channel of the first main heat exchanger 27; a third throttling device is arranged at the rear end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com