Natural gas liquefaction process

A natural gas and liquefied natural gas technology, applied in liquefaction, refrigeration, liquefaction, solidification, etc., can solve the problems of complex structure of refrigeration equipment, high energy consumption of full liquefaction, poor system reliability, etc., and achieve less equipment maintenance and less operation and maintenance personnel , Simple start and stop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

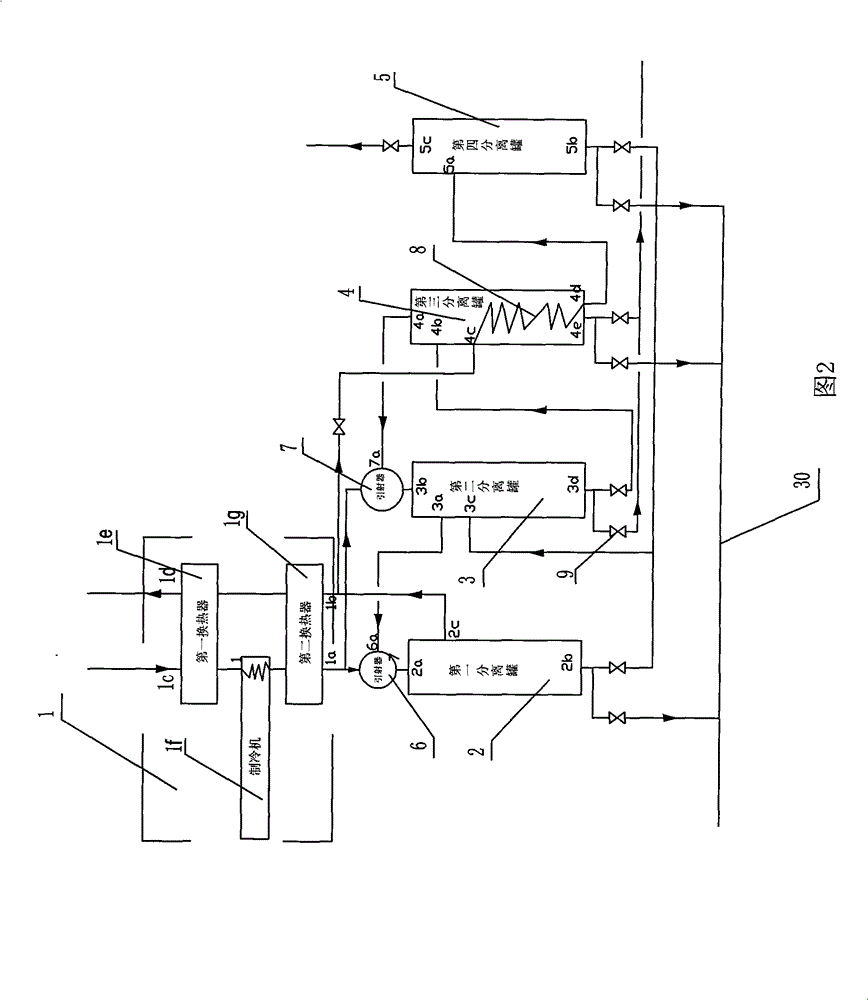

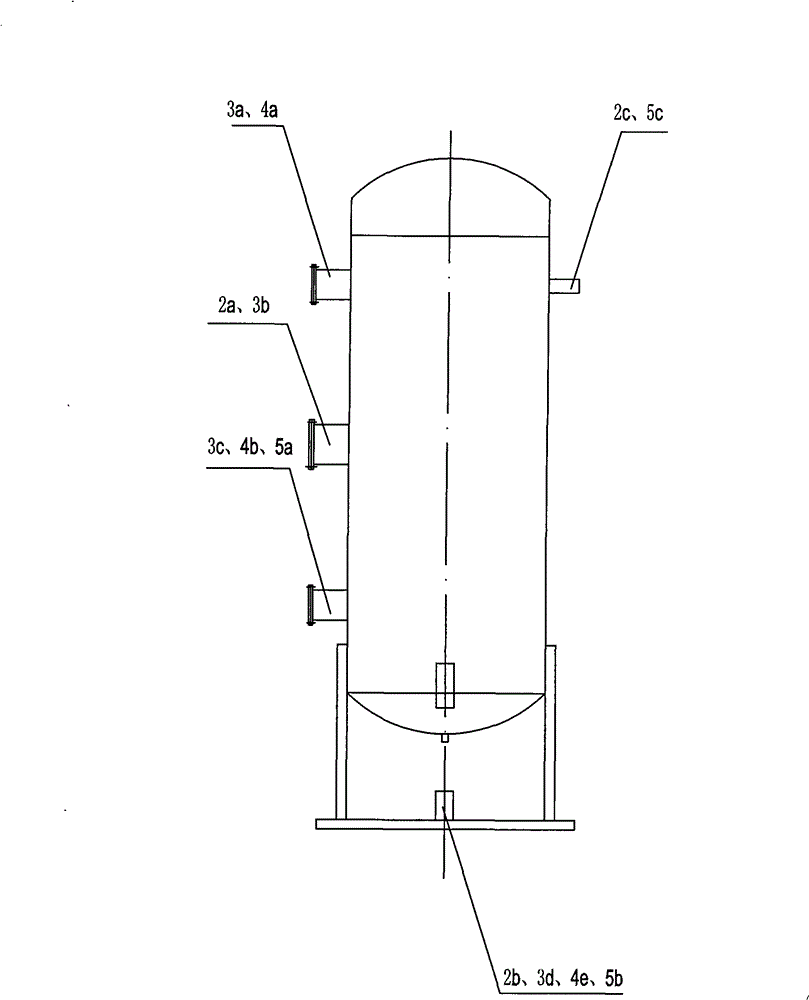

[0049] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0050] Examples such as figure 1 , 2 , 3, 4, 5, 6, and 7:

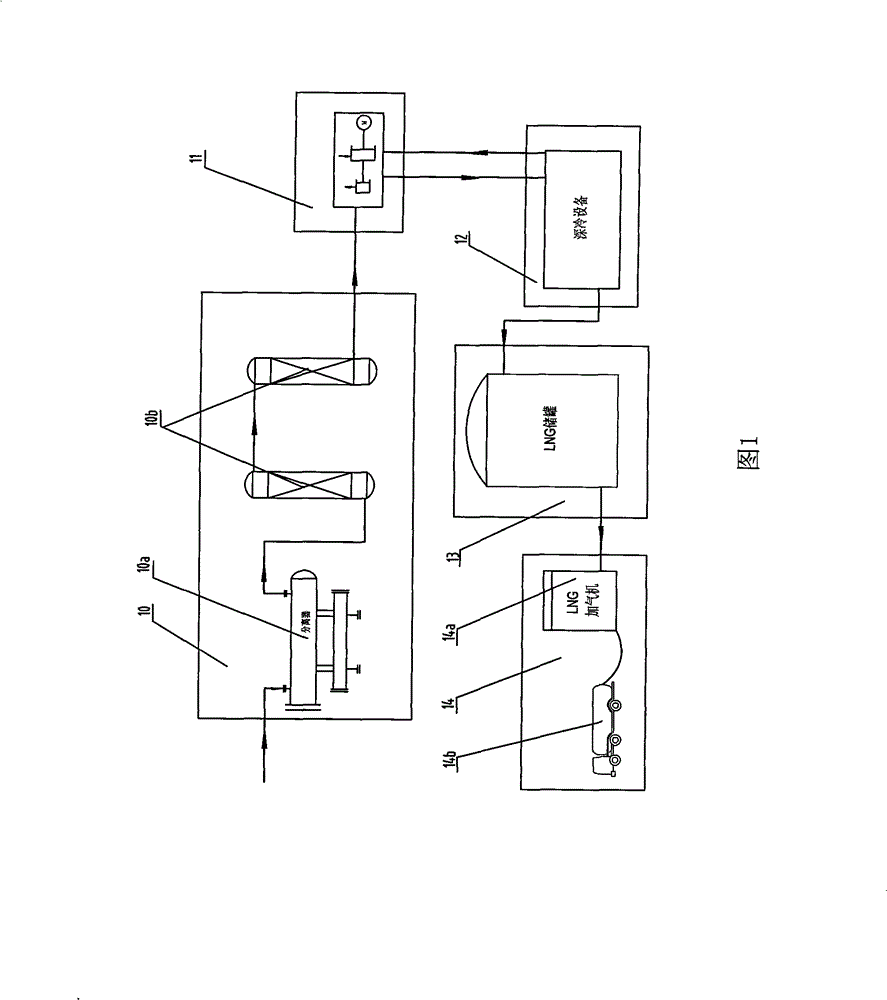

[0051] 1. A natural gas liquefaction process, the liquefaction process comprises a pretreatment unit 10, a compression unit 11, a liquefaction unit 12, a storage unit 13 and a loading unit 14, and its main steps are:

[0052] 1), the raw natural gas first passes through the pretreatment unit 10 to separate the large particles of impurities contained in it and remove the moisture;

[0053] 2), the natural gas processed by the pretreatment unit 10 enters the compression unit 11 to be compressed to 10-25MPa;

[0054] 3), the pressurized natural gas enters the liquefaction unit 12 to be converted into liquid natural gas LNG;

[0055] 4), liquefied natural gas LNG input storage unit 13 preserves;

[0056]5), the liquefied natural gas LNG in the storage unit 13 is loaded through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com