Ice box used for natural gas liquefaction system

A technology of natural gas and liquid natural gas, applied in the field of cold box of natural gas liquefaction system, can solve the problems of low primary liquefaction rate of expander refrigeration cycle, complex structure of refrigeration device, high energy consumption of full liquefaction, and achieve less equipment maintenance and work flexibility. Large, high liquefaction rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with accompanying drawing and embodiment the utility model is further described:

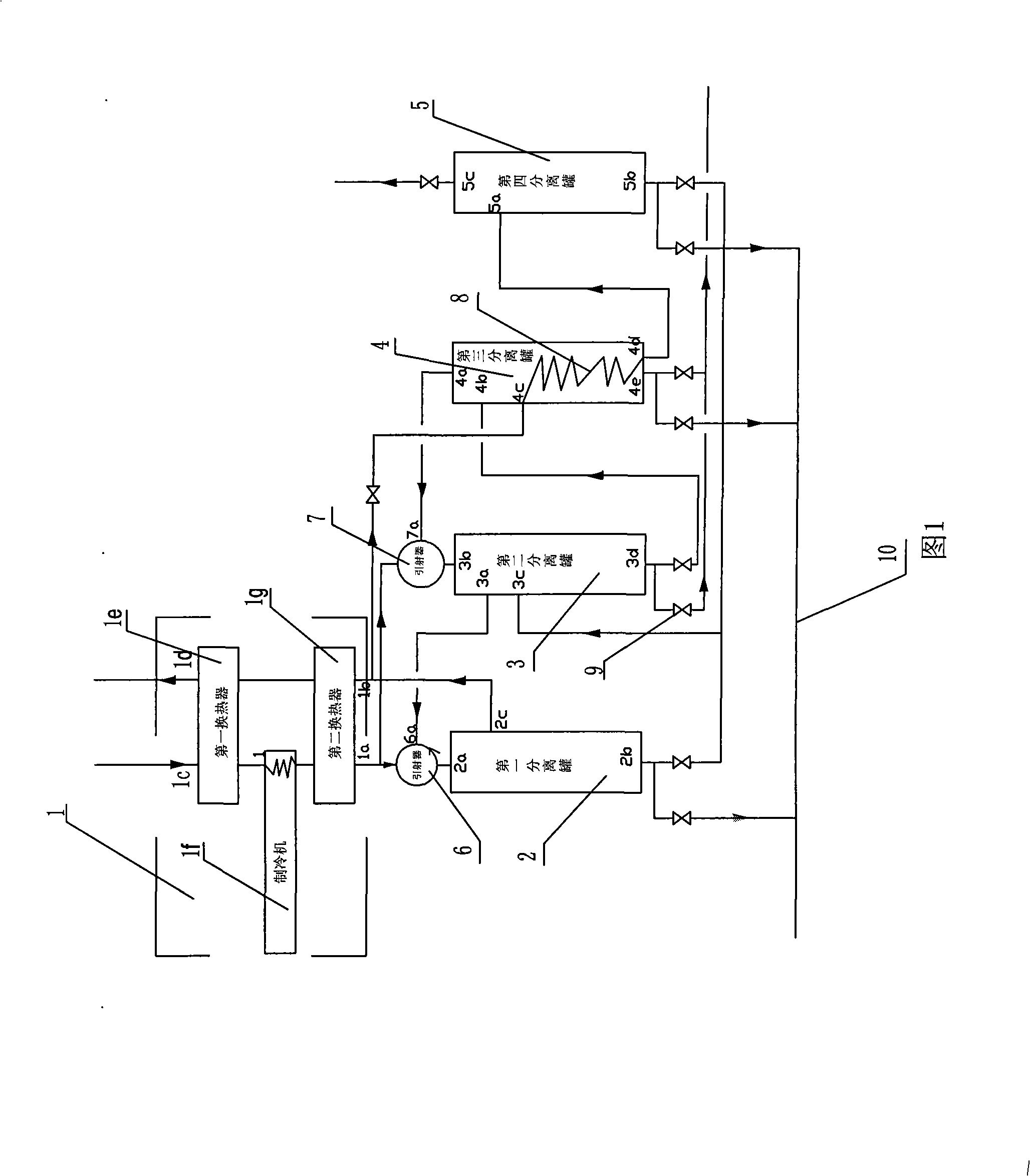

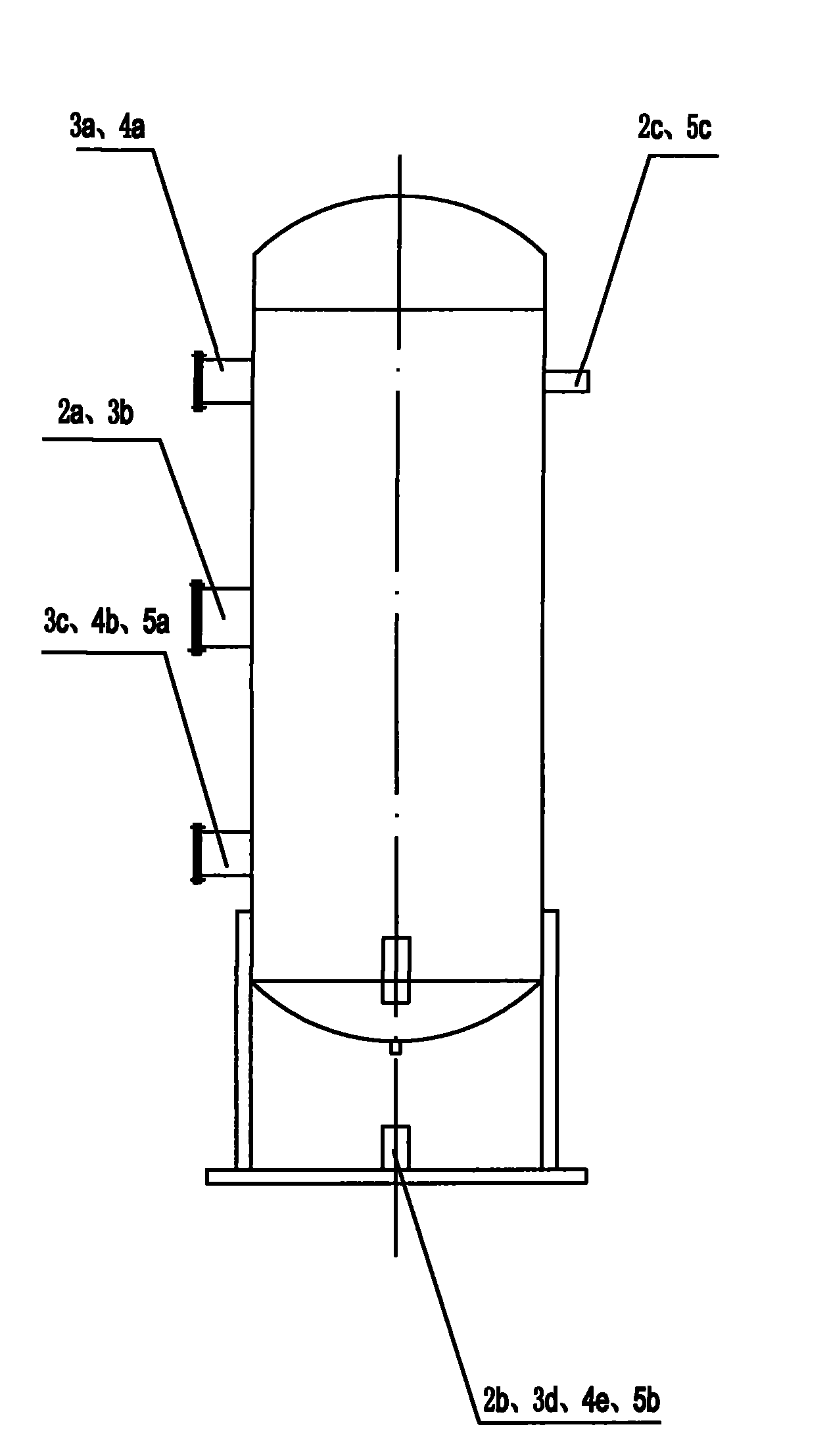

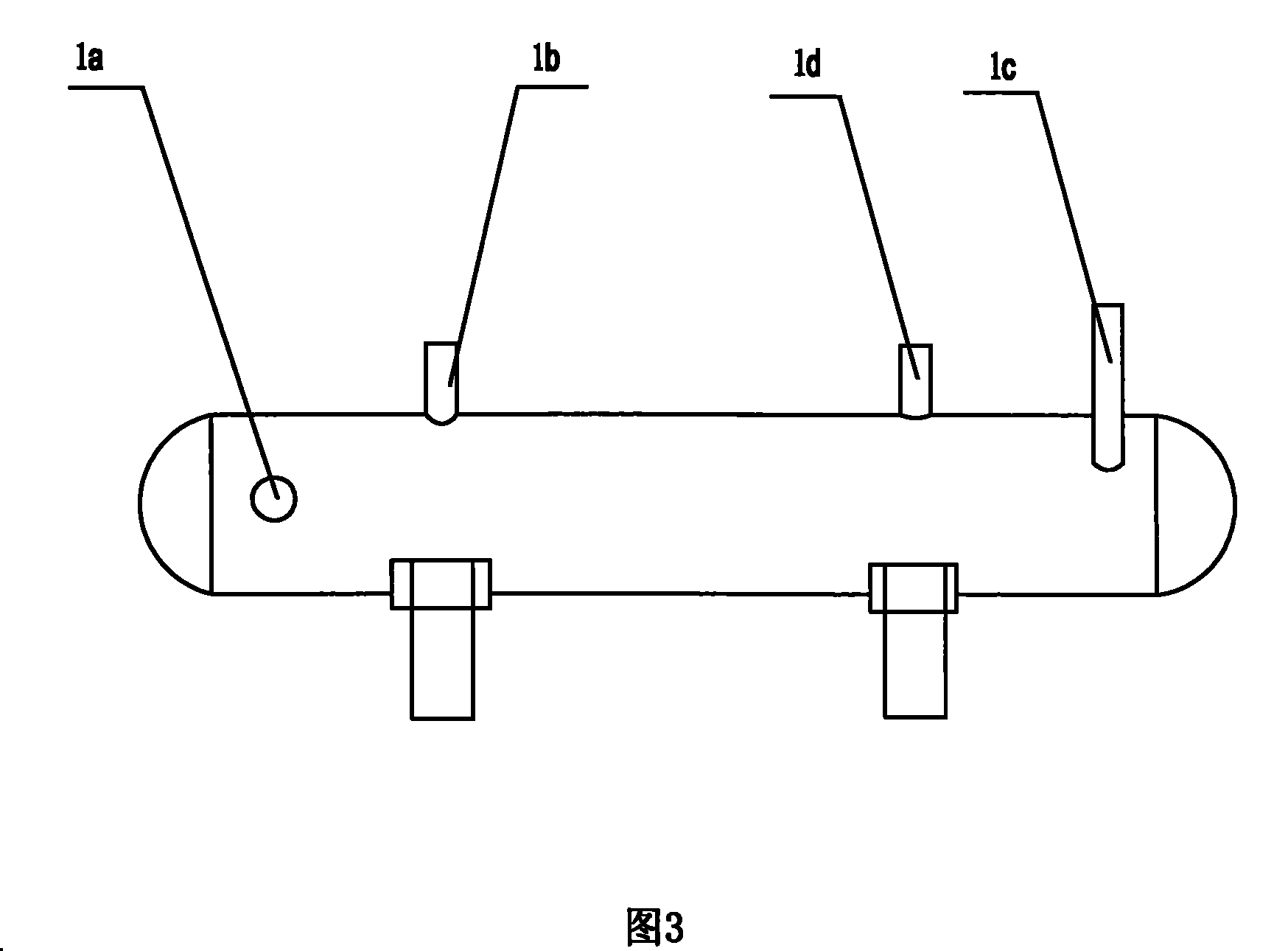

[0030] Examples such as figure 1 , 2 , 3, 4, and 5: a cold box for a natural gas liquefaction system, including a precooling unit 1, a first separation tank 2, a second separation tank 3, a third separation tank 4 and a fourth separation tank 5, The pre-cooling unit 1 has a feed gas inlet 1c, a feed gas outlet 1a, a recycle gas inlet 1b and a recycle gas outlet 1d, and the first separation tank 2 is arranged between the feed gas outlet 1a and the recycle gas inlet 1b. On the passage, a first ejector 6 is connected on the passage between the raw gas outlet 1a and the gas-liquid mixing inlet 2a of the first separation tank, and the inlet 6b of the first ejector is connected to the raw gas inlet 6. The outlet 1a is connected, the gas outlet 6c is connected with the gas-liquid mixing inlet 2a of the first separation tank, and the injection end 6a is connected with the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com