Liquefied natural gas (LNG) cold energy air separation system and air separation method

A technology of liquefied natural gas and air separation system, which is applied in the field of air separation using the cold energy of liquefied natural gas, can solve problems such as increased comprehensive unit energy consumption, large inlet flow, hidden dangers of device safety, etc., to reduce equipment investment and solve energy problems The effect of high consumption and increased dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

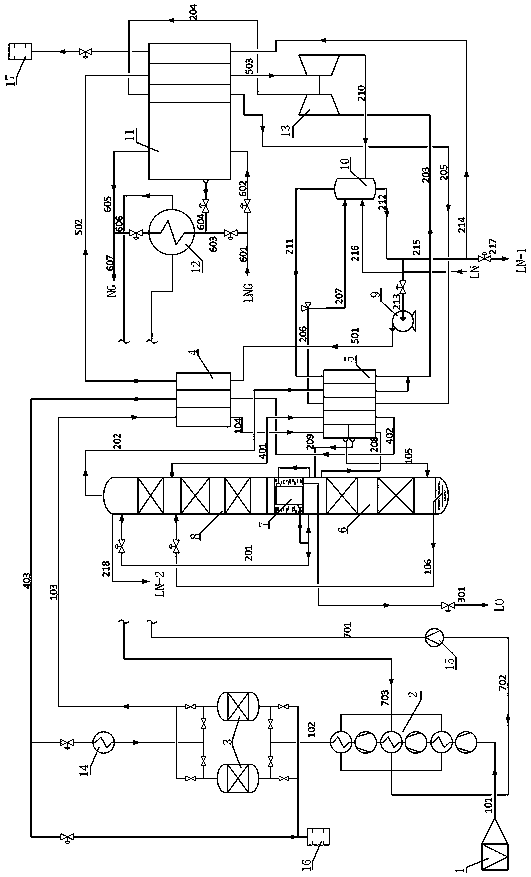

[0054] An air separation system utilizing the cold energy of liquefied natural gas, comprising an air separation unit, an LNG cold energy utilization unit and an ethylene glycol solution circulation cooling unit;

[0055] Described ethylene glycol solution circulation cooling unit comprises LNG-ethylene glycol heat exchanger 12 and ethylene glycol solution circulation pump 15;

[0056] The LNG cold energy utilization unit includes a circulating liquid nitrogen pump 9, an LNG-nitrogen heat exchanger 11, a gas-liquid separator 10, a liquid booster expander 13 and a vent silencer 17;

[0057] The air separation unit comprises a self-cleaning air filter 1, an air compressor 2, a molecular sieve 3, a regeneration gas heater 14, a main heat exchanger 4, a liquefaction heat exchanger 5, a rectifying tower and a vent silencer 16, and the refining Distillation tower comprises lower tower 6, main condensing evaporator 7 and upper tower 8 three parts.

[0058] In the air separation unit...

Embodiment 2

[0078] An air separation system utilizing the cold energy of liquefied natural gas to carry out an air separation method, comprising the following steps:

[0079] a) After the raw air passes through the self-cleaning filter 1 to remove most of the solid impurities, it enters the air compressor 2 for compression, and the purified air 103 is obtained after removing impurities such as water and hydrocarbons through the molecular sieve system 3;

[0080] b) The pure air 103 is cooled in the main heat exchanger 4 by exchanging heat with the dirty nitrogen gas 402 drawn from the upper part of the upper tower 8 and provided with cooling capacity and initially reheated in the liquefaction heat exchanger 5, and the high-pressure circulating liquid nitrogen 501 liquefaction. The dirty nitrogen gas 403 completely reheated in the main heat exchanger is connected to the purification system 3 for regeneration gas and cold blowing gas;

[0081] c) The liquefied air 104 provides cooling capa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com