Method and device for carrying out liquefaction and heavy hydrocarbon treatment on natural gas

A technology for processing equipment and natural gas, which is applied in the fields of liquefaction, refrigeration and liquefaction, and recovery of liquid hydrocarbon mixtures, etc., and can solve the problems of difficult to control the removal effect of heavy components, poor removal effect, freezing blockage of refrigerators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

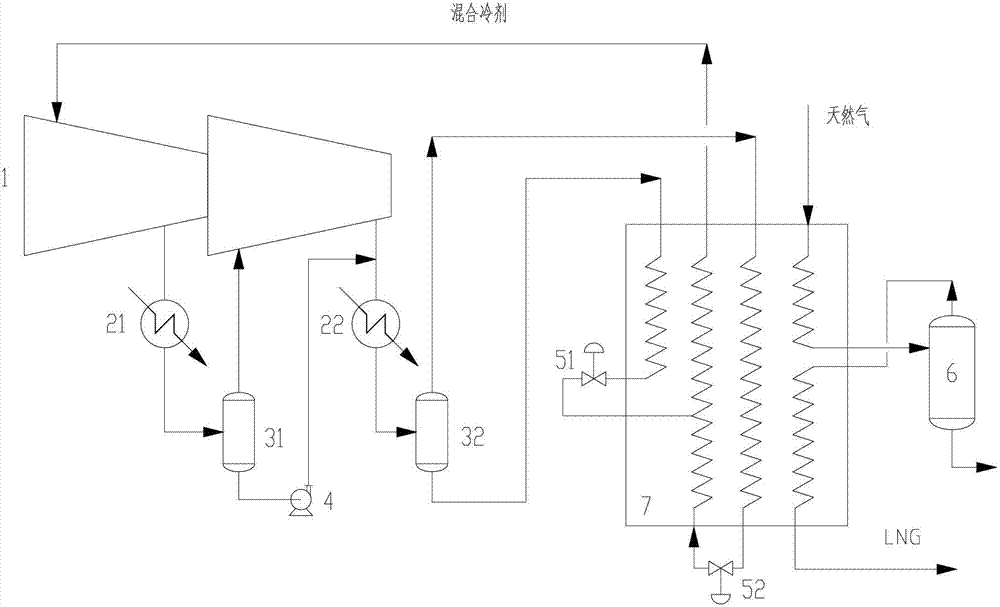

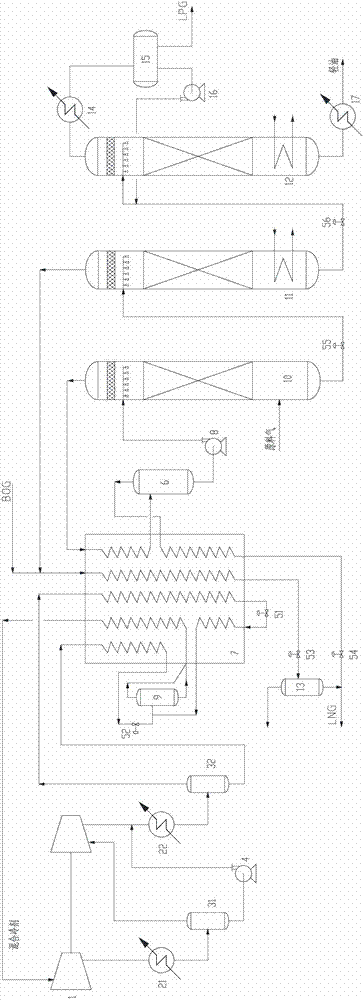

[0060] The process of the present invention includes two parts: a low-temperature liquefaction process and a heavy hydrocarbon treatment process; the low-temperature liquefaction process includes that in the heavy hydrocarbon treatment process, the natural gas after partial heavy hydrocarbon removal is provided by a mixed refrigerant to achieve cooling in a cold box and complete de-weighting Hydrocarbons and liquefaction to obtain LNG; the heavy hydrocarbon treatment process includes the purification of qualified natural gas rich in heavy hydrocarbons to remove part of the heavy hydrocarbons in the heavy hydrocarbon scrubber, and the natural gas with part of the heavy hydrocarbons to go to the low-temperature liquefaction process from the top of the tower, and to be removed The heavy hydrocarbons in the deethanizer are stripped to remove light components (mainly C1, C2 hydrocarbons, etc.) in the deethanizer, and separated into LPG and light oil by-products in the rectification t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com