Natural gas liquefying system by vurtue of double-stage mixed-refrigerant circulation

A technology of mixing refrigerant and natural gas, applied in refrigeration and liquefaction, liquefaction, fluid circulation arrangement, etc., can solve the problems of long supply cycle, high refrigerant purity requirements, and large number of equipment, and achieves the improvement of refrigeration efficiency and refrigerant. The effect of convenient proportioning and wide adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The experimental methods used in the following examples are conventional methods unless otherwise specified.

[0016] The materials and reagents used in the following examples can be obtained from commercial sources unless otherwise specified.

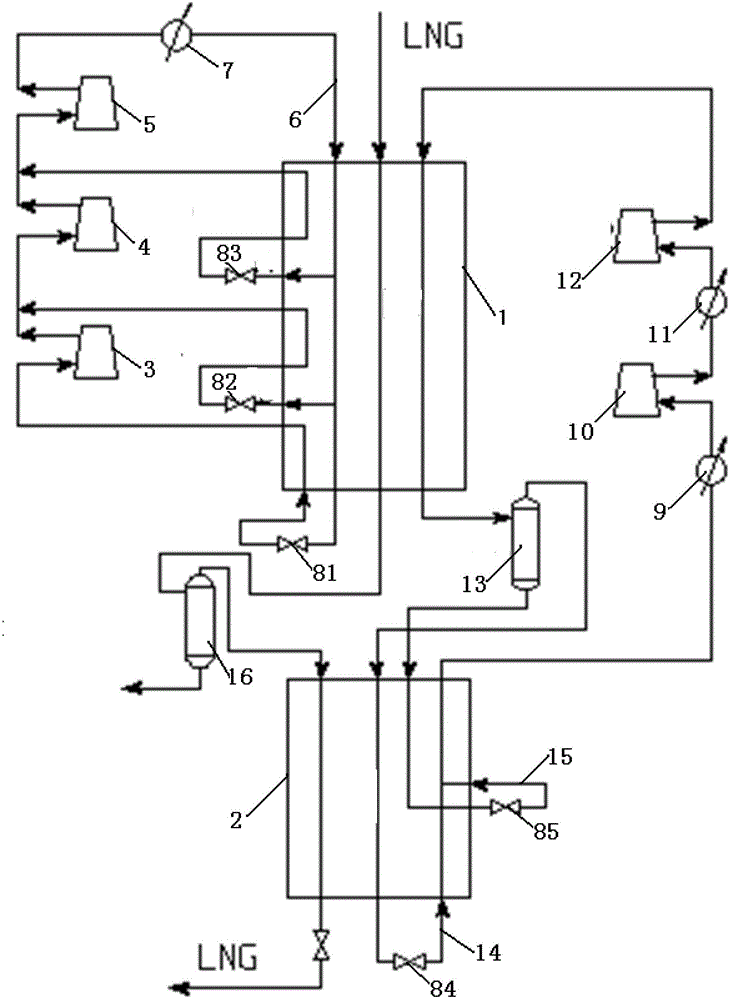

[0017] Such as figure 1 As shown, the liquefaction system provided by the present invention includes a precooling cold box 1, a cryogenic cold box 2, a precooling mixed refrigerant refrigeration cycle mechanism and a cryogenic mixed refrigerant refrigeration cycle mechanism; wherein, the precooling cold box 1 is provided with A plate-fin heat exchanger, and a coiled tube heat exchanger is arranged in the cryogenic cold box 2;

[0018] The pre-cooling mixed refrigerant refrigeration cycle mechanism includes a three-stage compression unit, and the three-stage compression unit includes a first-stage pre-cooling refrigerant compressor 3, a second-stage pre-cooling refrigerant compressor 4, and a third-stage pre-cooling refrigerant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com