Patents

Literature

31results about How to "Lower liquefaction costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Wood liquefier and method for preparing surfactant using liquidated wood

InactiveCN101396838AImprove liquefactionLow costTransportation and packagingWood treatment detailsEpoxyActive agent

The invention provides a preparation method for a wood liquefacient. A discarded PET bottle is crashed into powder, which is mixed with polylol and added with 0.01-0.5wt% of catalyst, and the mixture is stirred uniformly and heated to react, thus obtaining the wood liquefacient. The invention also relates to a method for preparing a surfactant by using the liquefacient to liquefying wood, which includes the steps: 0.5-10wt% of inorganic acid catalyst and glycerin are added into the mixture of the liquefacient and the wood meal of broad leaved forests or coniferous forests, which reacts by heating to obtain a coarse liquefied wood product; the product is cooled to room temperature, diluted in absolute ethyl alcohol or acetone and then filtered in vacuum to form the filtrate, which is subsequently decompressed and distilled so as to obtain refined liquefied wood; the sodium hydroxide solution of the fully dissolved liquefied wood is added with propylene oxide according to the mass morality of total hydroxide radical to propylene oxide being 1:3-10 for reaction, and then epoxy ethane is entered for end capping, after that, the pH value is adjusted to 7, then the liquefied wood polyethenoxy ether of the surfactant is obtained as the final product.

Owner:JIANGSU QIANGLIN BIO ENERGY

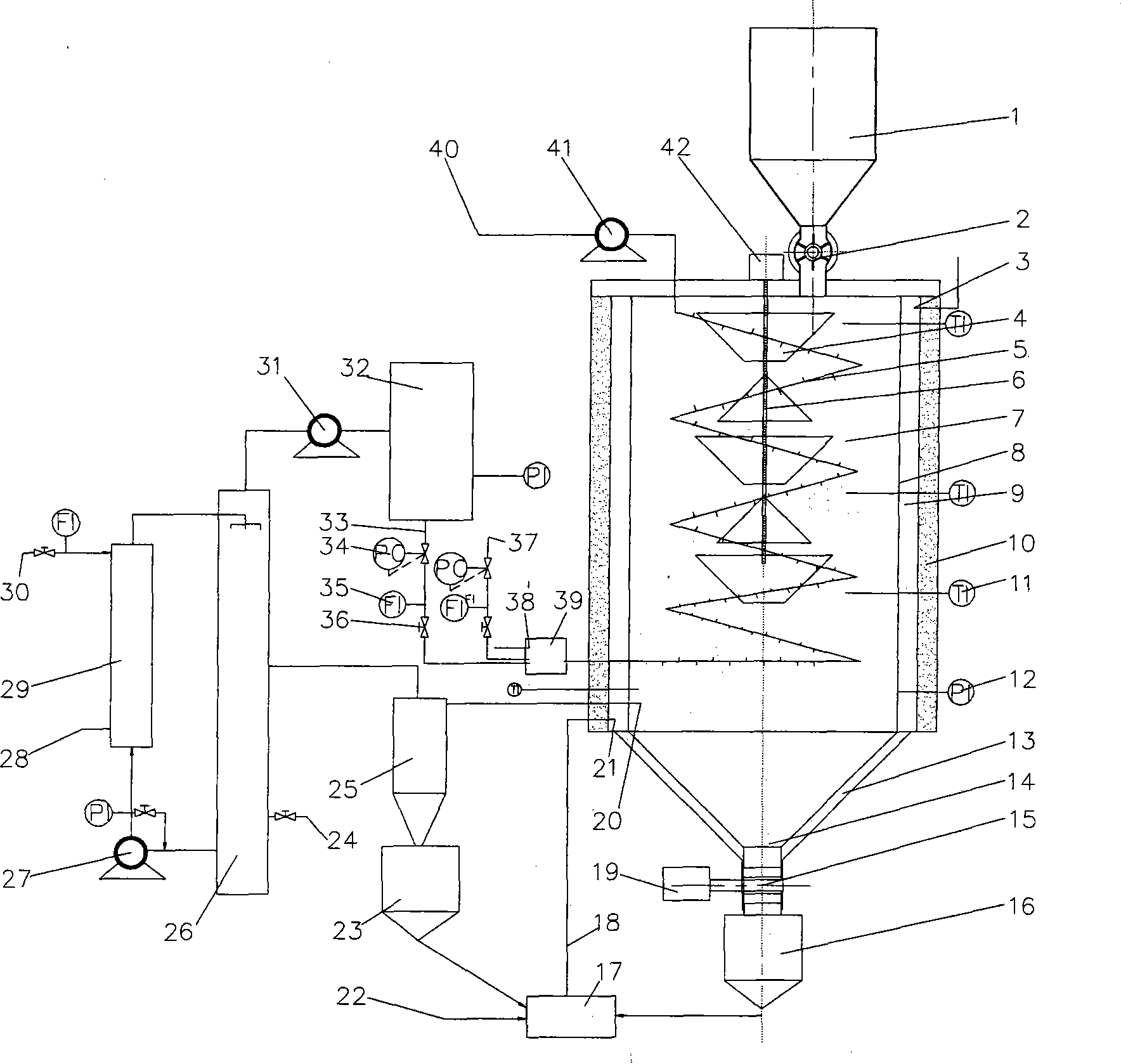

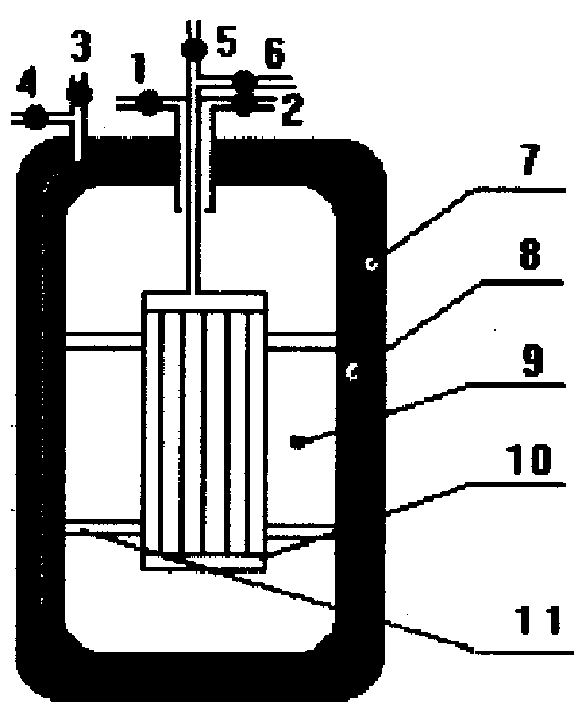

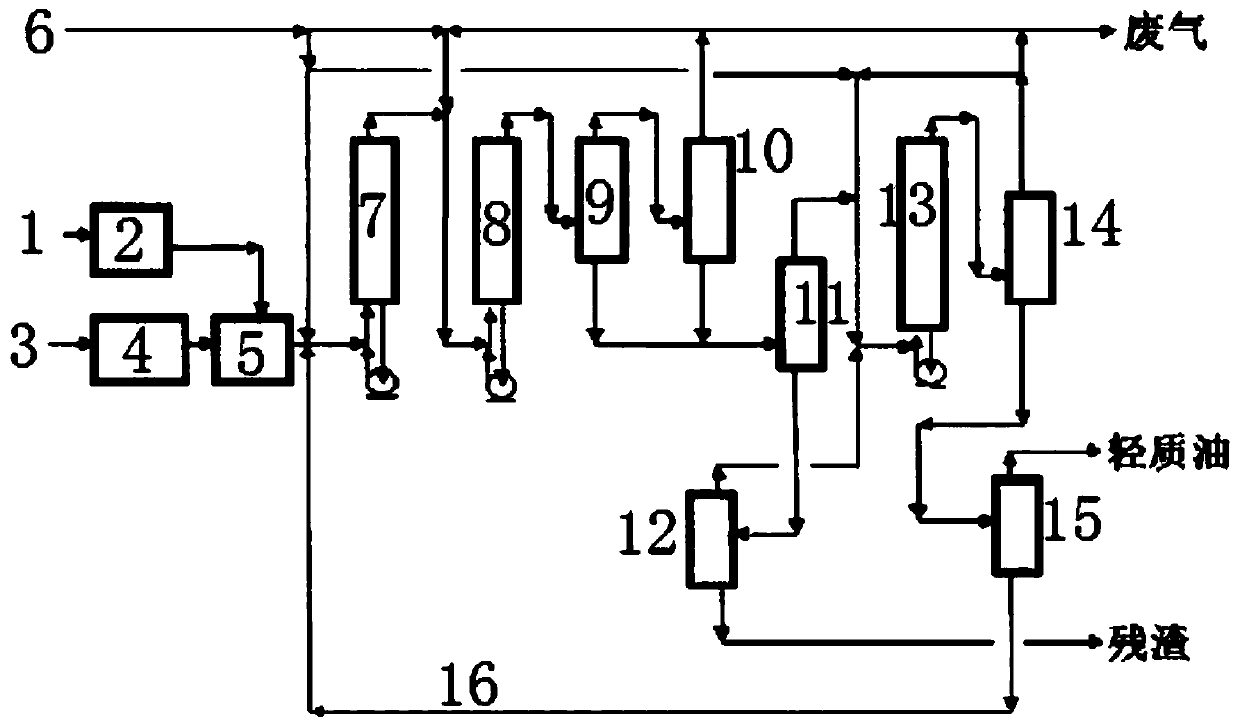

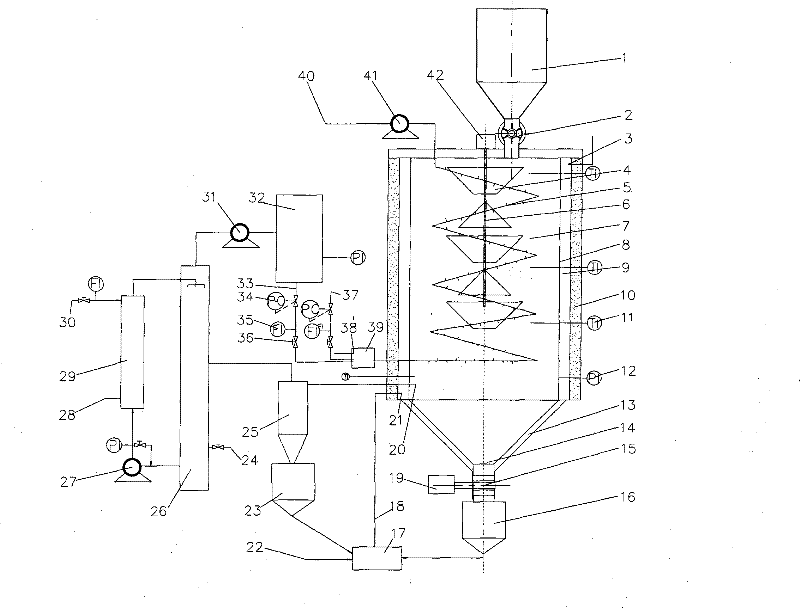

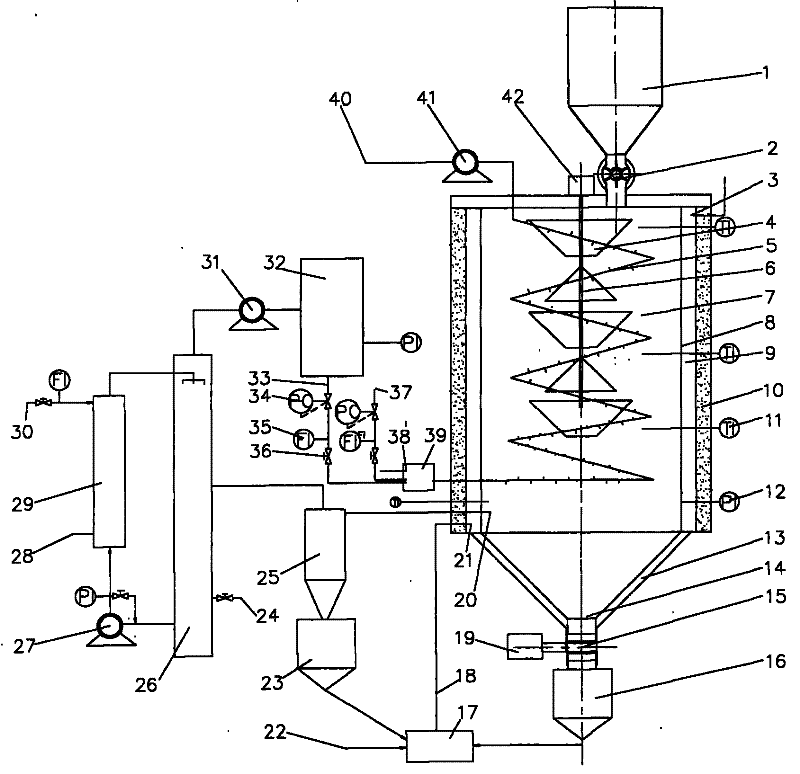

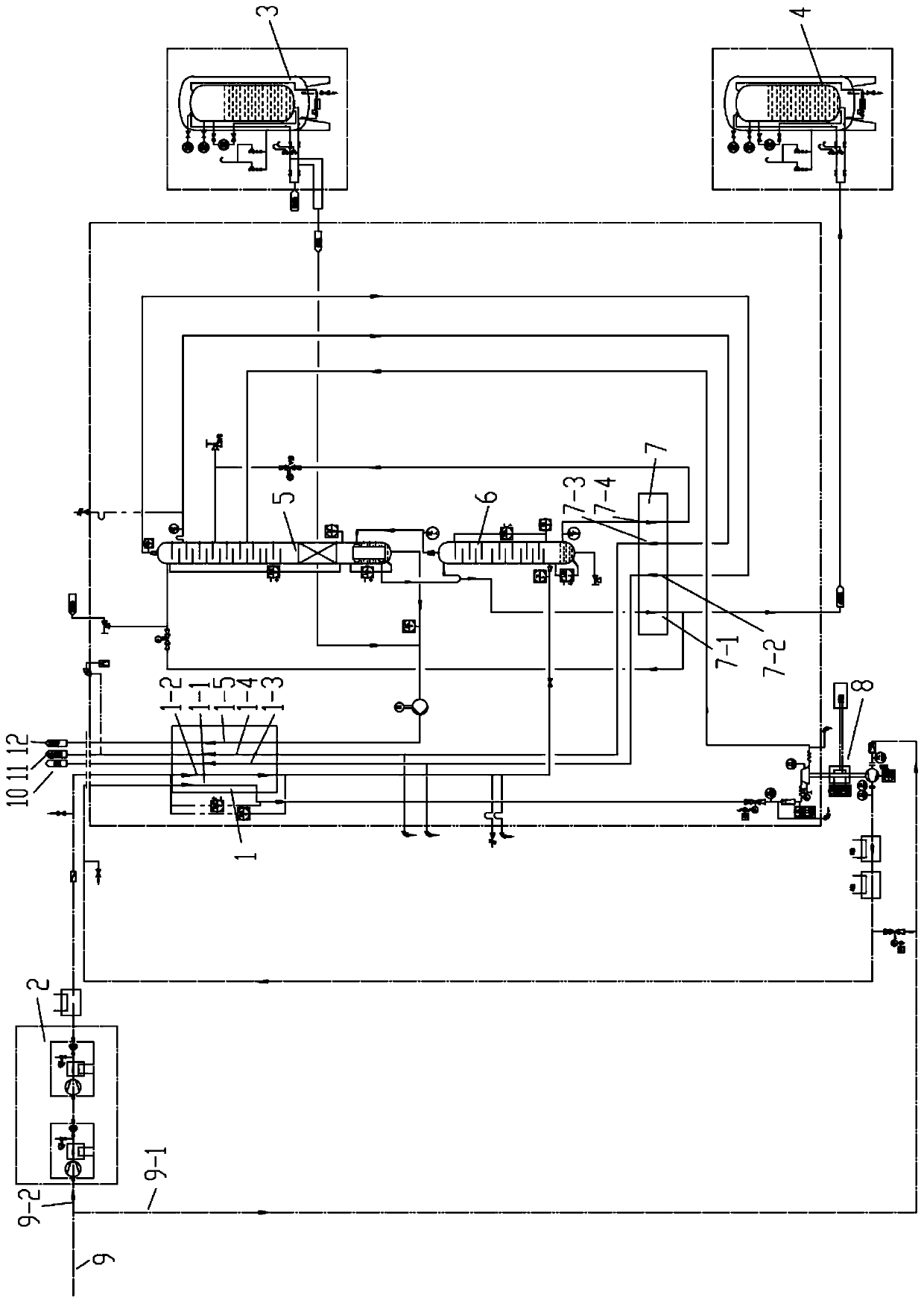

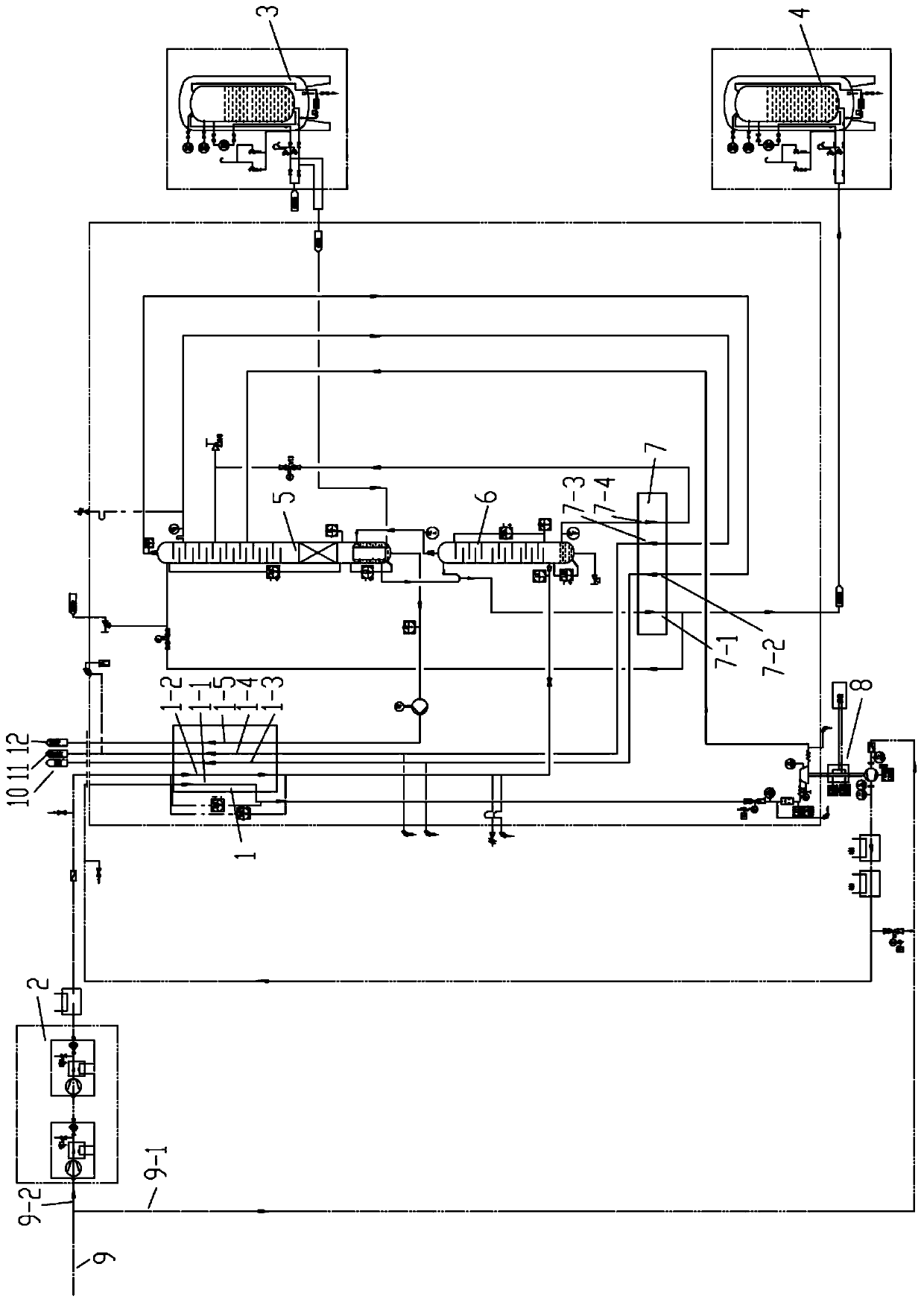

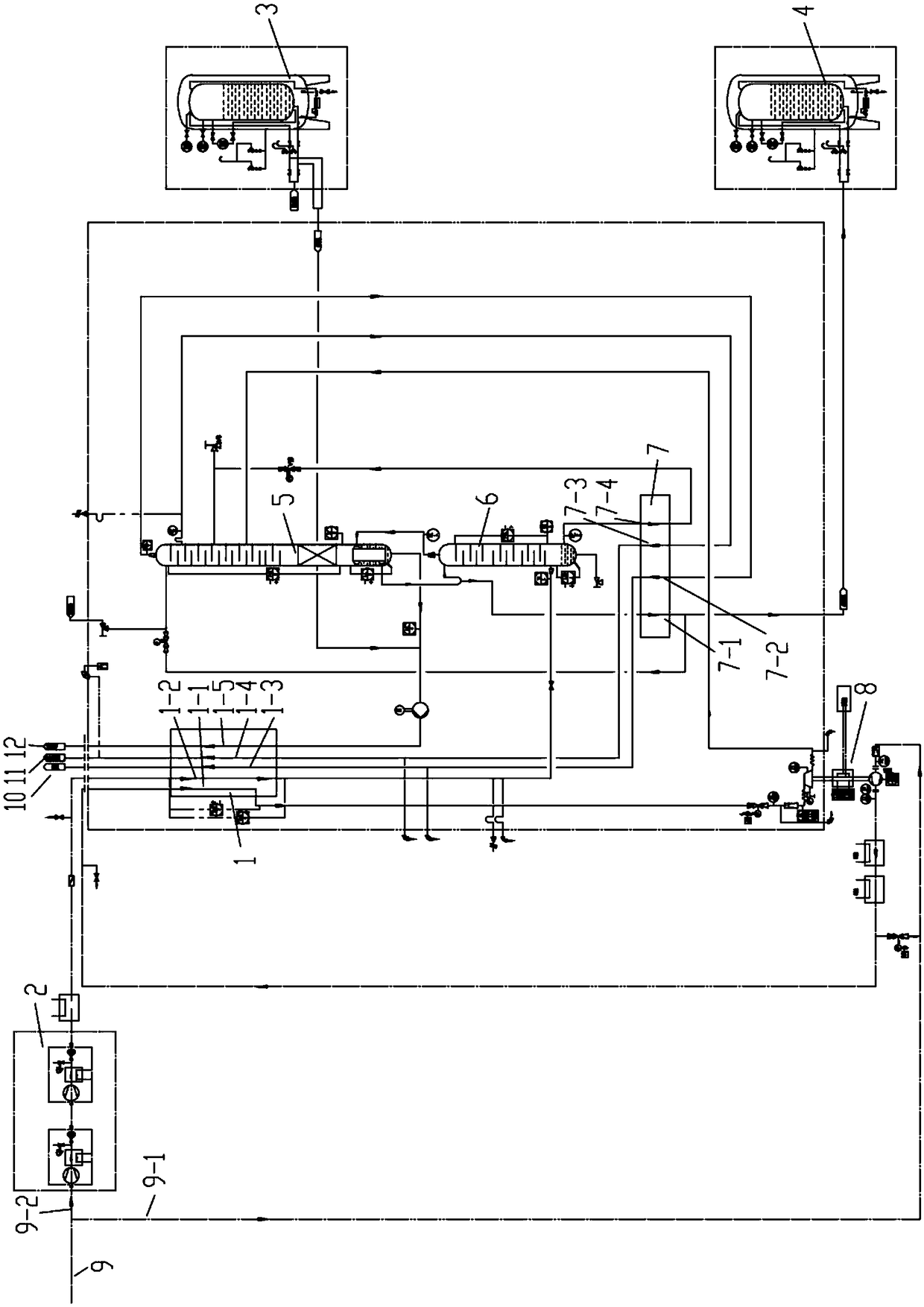

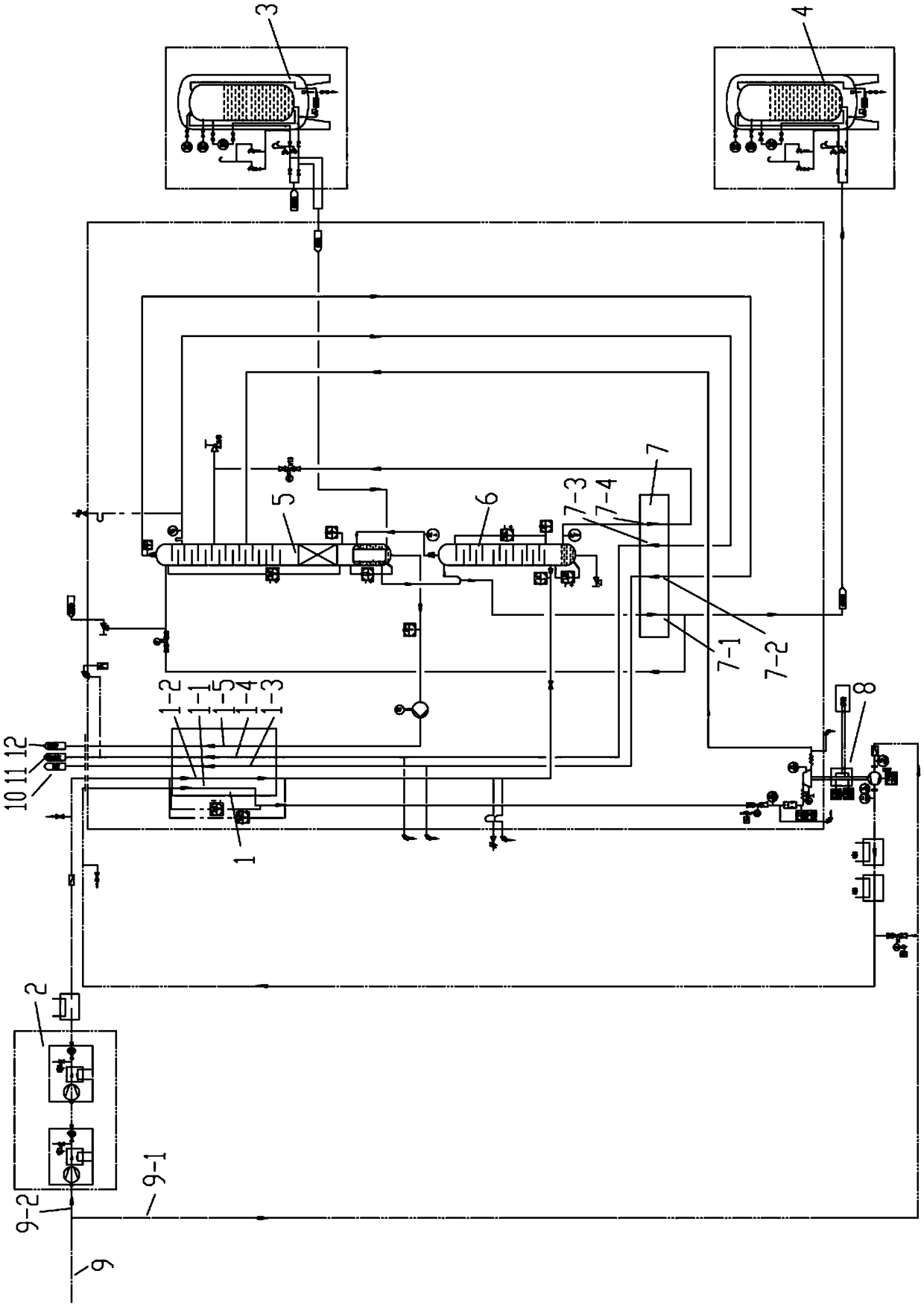

Internal combustion heating moving-bed type biomass pyrolysis liquefying apparatus

InactiveCN101376814AIncrease profitReduce manufacturing costBiofuelsLiquid hydrocarbon mixture productionBiomassPyrolysis

The invention discloses an internal combustion heating movable-bed biomass-pyrolysis liquefaction device which includes a reactor (7); the inside of the reactor is provided with an internal combustion pipeline (5); both the inlet and the outlet of the internal combustion pipeline (5) are arranged outside the reactor (7); a hopper (1) is arranged above the reactor (7); a blanking control valve (2) is arranged on the hopper (1); a rotary shaft (6) is arranged in the center of the reactor (7); conical hoppers (4) are arranged on the rotary shaft (6); conical material dividing umbrellas are arranged between the conical hoppers (4); the material inlet of the hopper (1) is arranged above the conical hoppers (4); a pyrolysis gas outlet (20) is arranged on the reactor (7); the bottom part of the reactor (7) is provided with a slag discharge opening (14); a cyclone separator (23) is connected on the gas pipeline of the pyrolysis gas outlet (20); the flue gas outlet of the cyclone separator (23) is connected into a condenser (26); an oil outlet and an outlet for non-condensable gas are arranged on the condenser (26); the outlet for non-condensable gas is connected to a gas buffer tank (28) through a draught fan. The biomass-pyrolysis liquefaction device reduces the liquefaction cost of bio-oil, has a simple structure and a low processing and manufacture cost as well as is simply and conveniently operated, managed and maintained.

Owner:HEFEI UNIV OF TECH

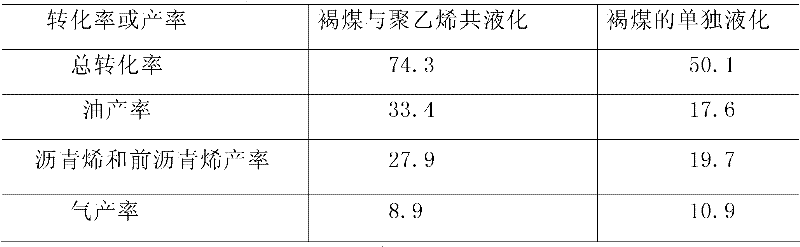

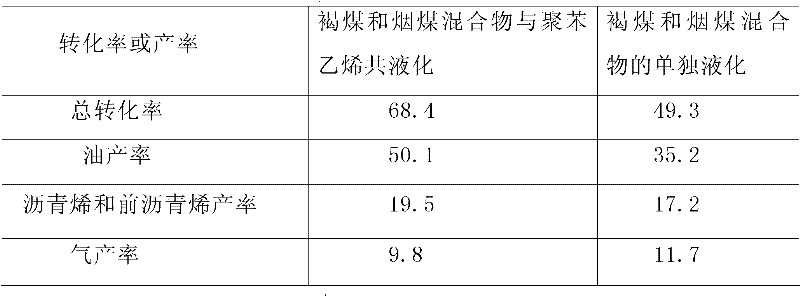

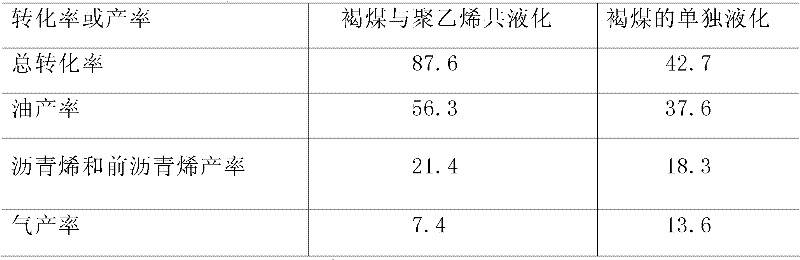

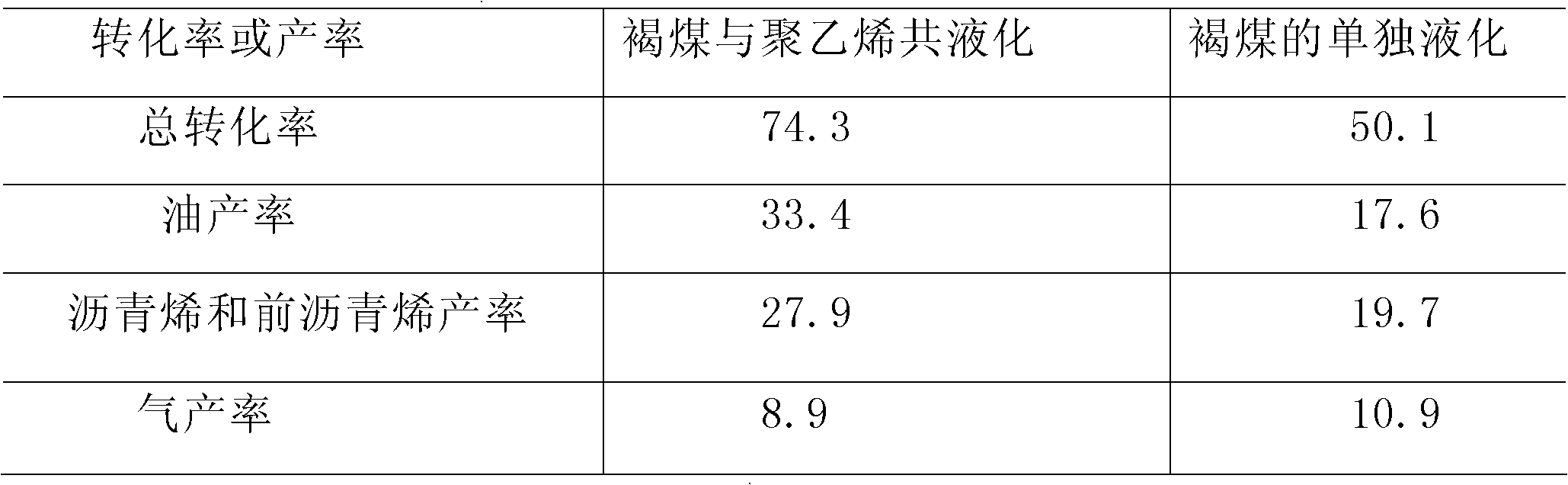

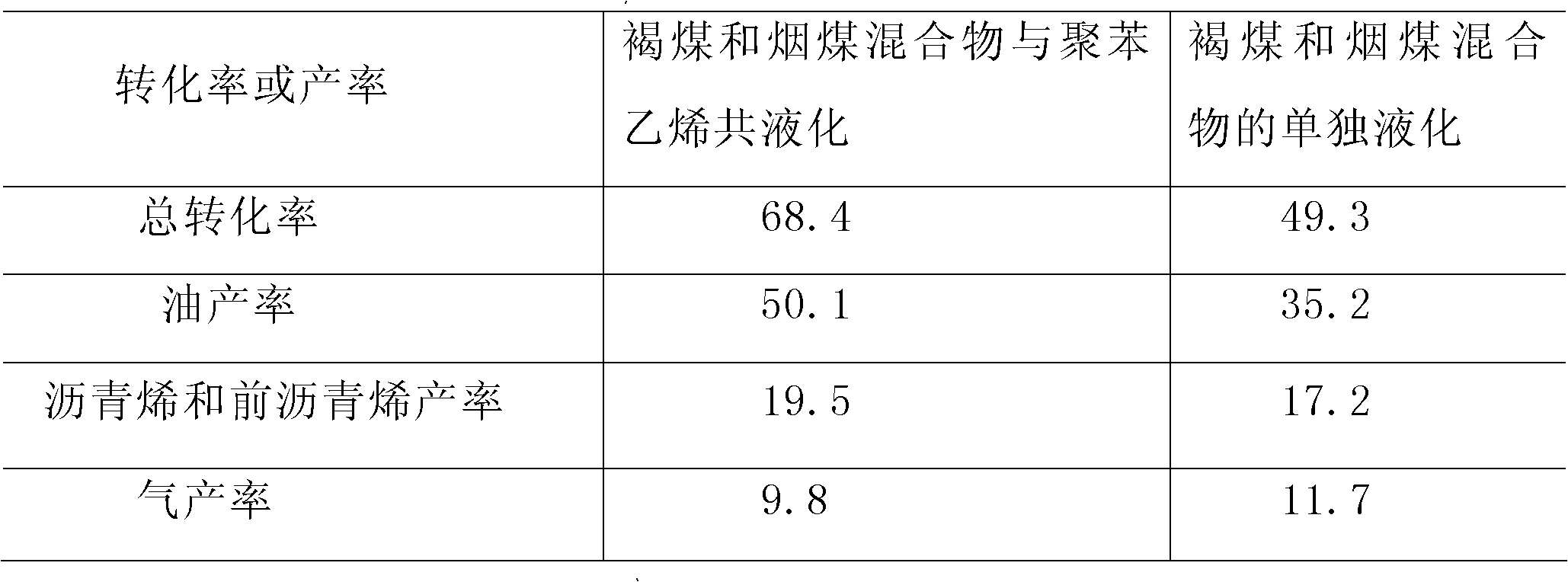

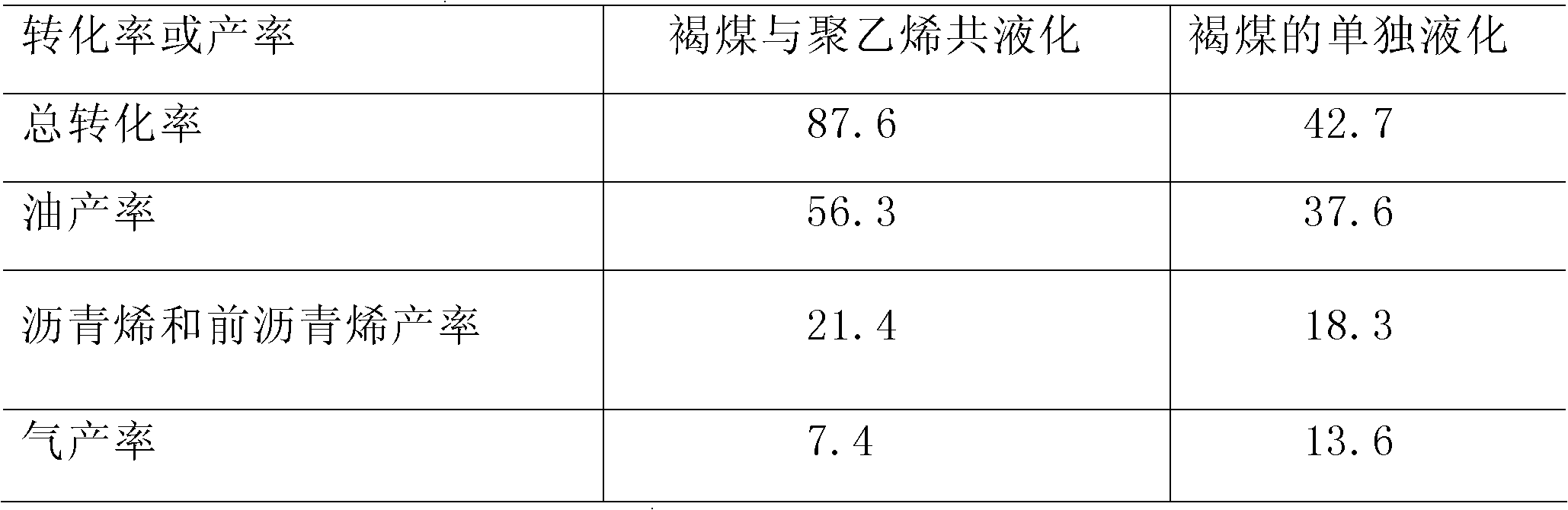

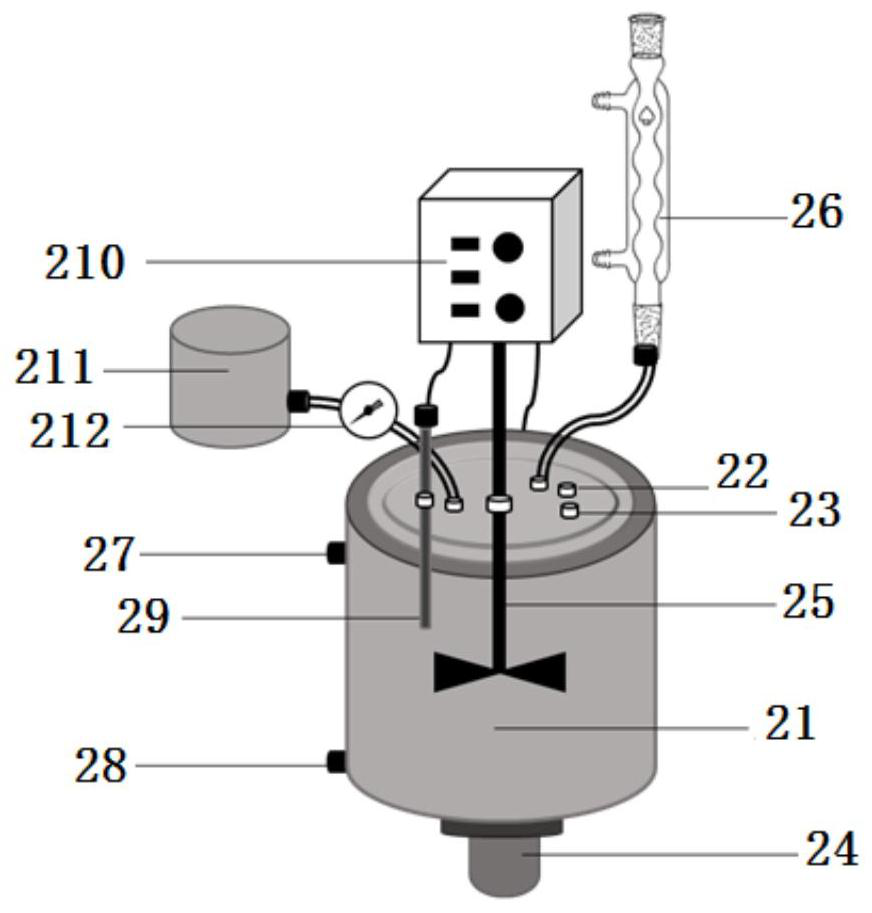

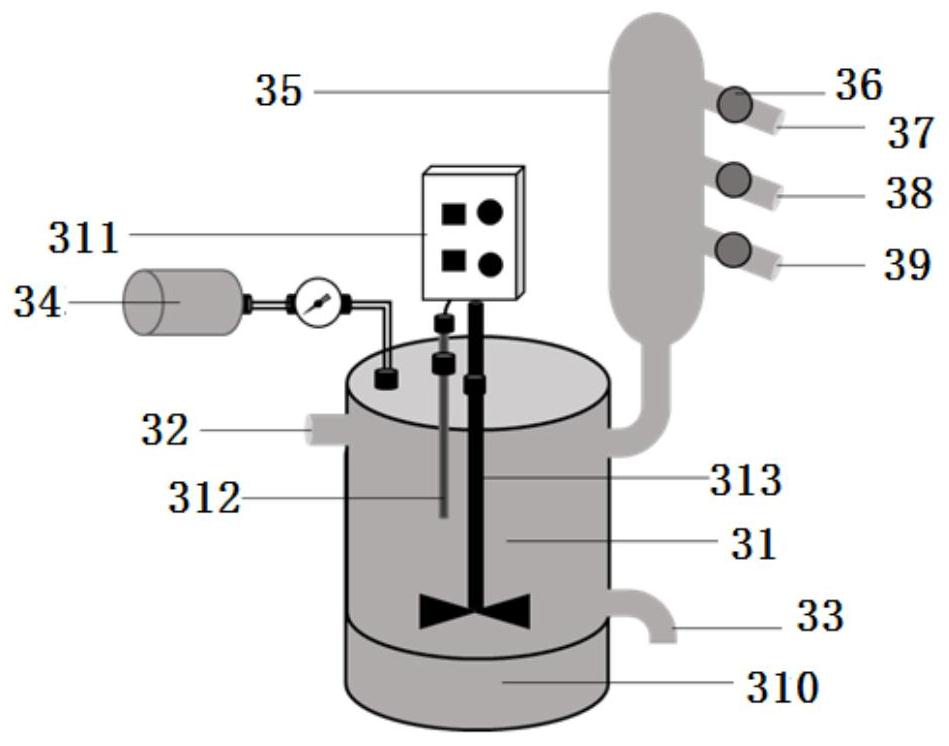

Method for co-liquefaction of coal and waste plastics under mild condition

InactiveCN102344823AHigh yieldIncrease profitLiquid hydrocarbon mixture productionDepolymerizationGas phase

The invention is a method for co-liquefaction of coal and waste plastics under a mild condition, which comprises the following steps: adding coal, waste plastics, lignosulfonate, a catalyst, and a solvent into an autoclave, introducing hydrogen to increase the pressure to 1.0-10.0 Mpa, heating to 300-450 DEG C for a liquefaction reaction, collecting the gas after the hydrogenation liquefaction test in the autoclave, analyzing the gas phase composition by a gas chromatography, collecting all the other liquefaction products in a filter paper cylinder, performing hexane and tetrahydrofuran solvent extraction in order by a soxhlet extraction device, wherein the substance soluble in hexane is oil, and the substances soluble in tetrahydrofuran but insoluble in hexane are asphaltene and preasphaltene, and calculating the total conversion rate of the liquefaction by using the amount of the insoluble substances in tetrahydrofuran. The invention allows the coal to perform a depolymerization reaction at a low temperature, and to be co-liquefied with waste plastics; the extraction rate of coal by solvents such as pyridine and the like is increased, and the coal liquefaction process is accelerated; not only the hydrogen consumption and production cost for coal liquefaction are greatly reduced, but also white pollution caused by waste plastics is solved.

Owner:LIUPANSHUI NORMAL UNIV

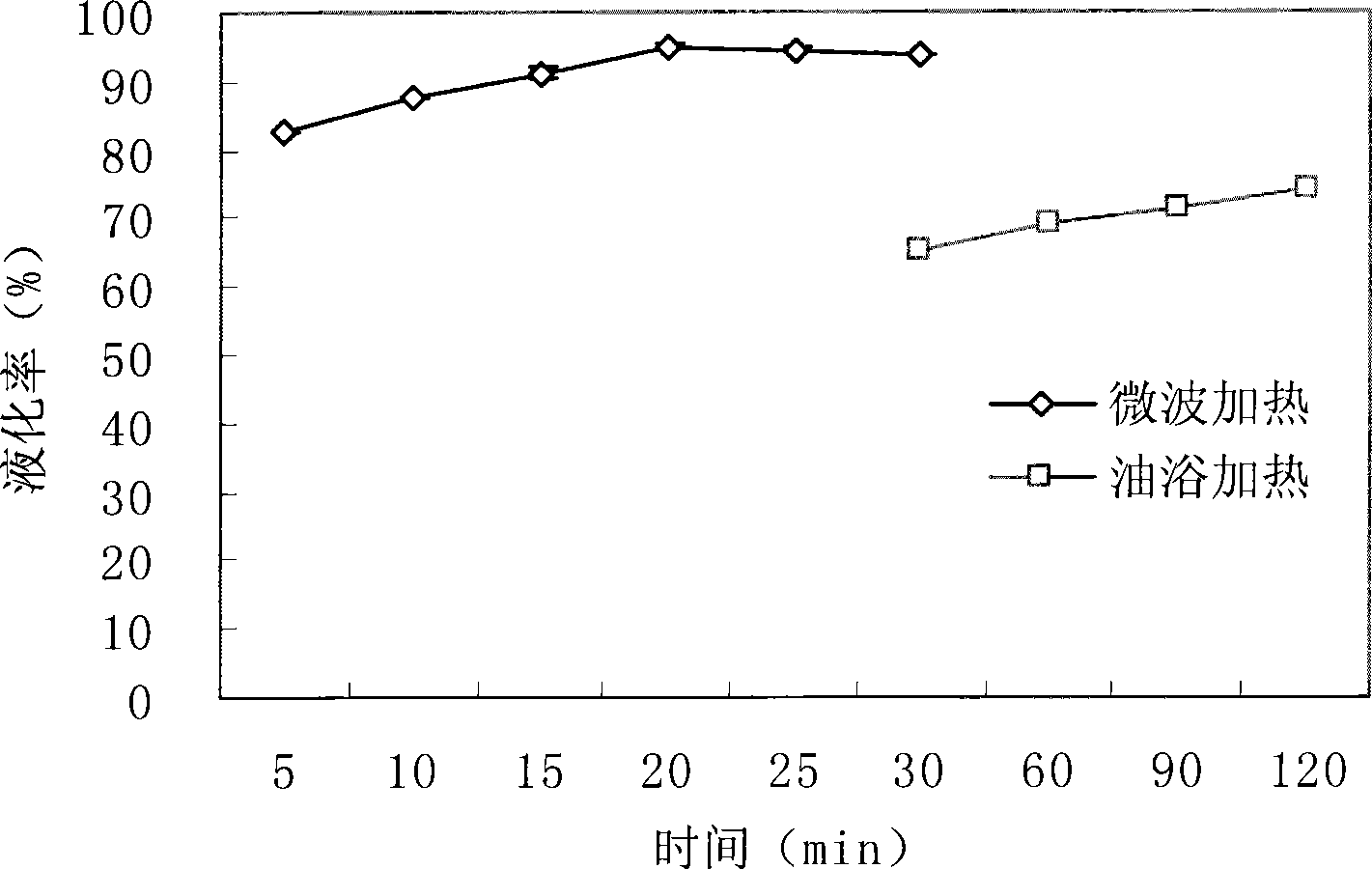

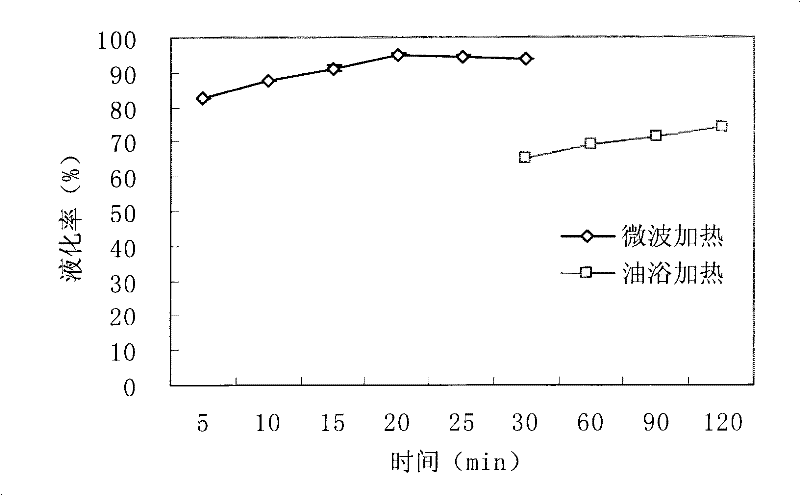

Rapid liquefaction method for corps wastes by microwave heating catalysis

ActiveCN101503338ALower liquefaction costsHeating fastOrganic compound preparationSolid waste disposalMicrowaveCatalytic effect

The invention provides a method for catalyzing waste of crops to be liquefied by microwave heating, which comprises: the waste of crops is added into polylol and sulphuric acid for microwave heating, the temperature is controlled to be 150-180 DEG C, and the liquification reaction is carried out for 10-30min. The method utilizes microwave auxiliary heating and reaction catalytic effect to realize rapid liquification for the waste of crops, thus greatly improving the liquification efficiency of the waste of crops and the liquification effect thereof, and leading the liquification efficiency to reach over 90%; the operation of the method is rapid, simple and convenient as well as efficient, so that the liquification cost of the waste of crops can be greatly reduced.

Owner:CHINA AGRI UNIV

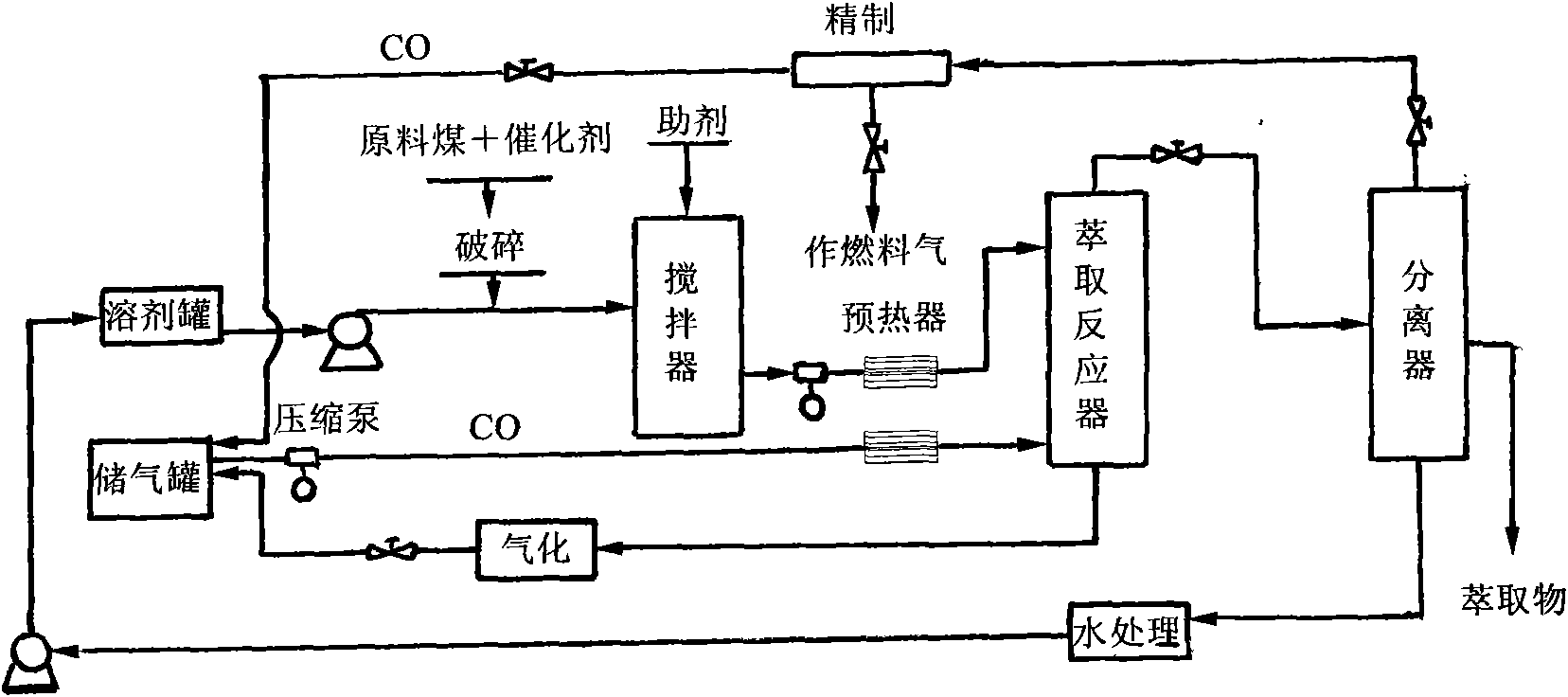

Method for directly liquefying coal in CO and H2O system

InactiveCN101565631AAvoid the disadvantages of complexity and large investmentSimple process equipmentLiquid hydrocarbon mixture productionLiquid productProcess equipment

The invention discloses a method for directly liquefying coal in CO and H2O atmosphere. The method of directly supplying pure hydrogen is replaced by a method of using water-gas shift reaction for supplying hydrogen, water is used for substituting traditionally liquefied circulating solvent oil and the CO / H2O system is used for directly liquefying the coal with hydrogen. Low-rank coal is used as raw material, transition metal oxide or sulfide is used as catalyst, water is used as solvent and hydroxyl compound is added as assistant, and the low-rank coal is directly liquefied with hydrogen in the subcritical or supercritical state of water and CO atmosphere. The liquefying conversion rate thereof can reach 75.4 wt percent (drying ash-free basis coal) and the oil yield reaches 48 percent. The method for directly liquefying the coal in CO and H2O atmosphere avoids the working procedures of complex hydrogen preparation equipment, low-rank coal drying and dehydration and the like in the traditional coal hydroliquefaction process, thereby simplifying the whole processing equipment. As the hydrogen generated in the CO and H2O system has higher activity, the hydrogenolysis of the low-rank coal is promoted, the yield of liquid products is increased, the liquefaction cost of the coal is reduced and the use value of the low-rank cola can be greatly improved.

Owner:EAST CHINA UNIV OF SCI & TECH

Coal direct hydro-liquefaction method

InactiveCN102234520AIncrease the rate of the hydrogenation reactionShort reaction timeLiquid hydrocarbon mixture productionSolventDecomposition

The invention provides a coal direct hydro-liquefaction method. According to the method, under a coal direct hydro-liquefaction reaction condition, a raw material mixture containing coal, a catalyst and a solvent contacts hydrogen in a tubular reactor, such that a liquefied product containing liquid hydrocarbon oil is obtained. According to the method, hydrogen is added into the tubular reactor from at least two positions of the tubular reactor. Compared with prior arts, the method employs a small-diameter tubular reactor which is easy to manufacture and to install. With the method provided by the invention, excess hydrogen amount during a reaction process is reduced, the utilance of hydrogen and the reactor is improved, the reaction time is reduced, secondary decomposition of the target product is reduced, and condensing and coking reactions of macro-molecule organic compounds are reduced.

Owner:杨元一 +2

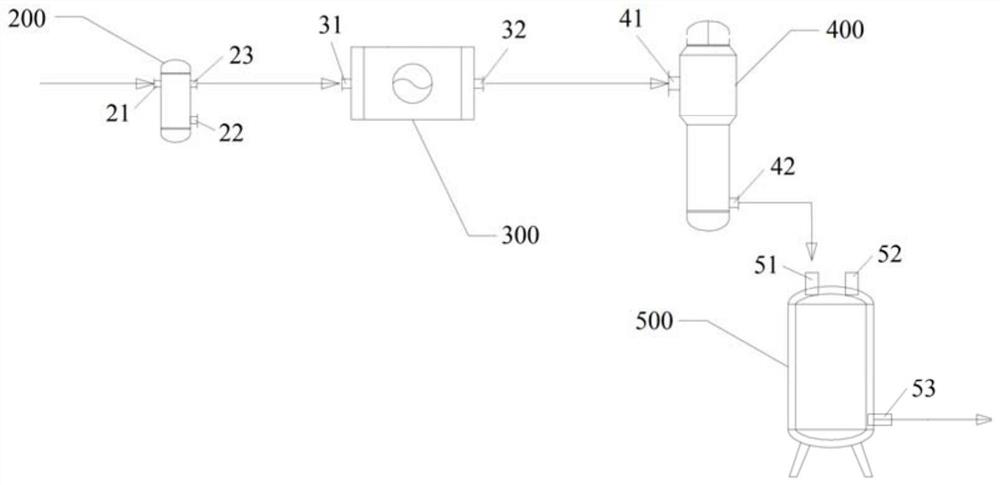

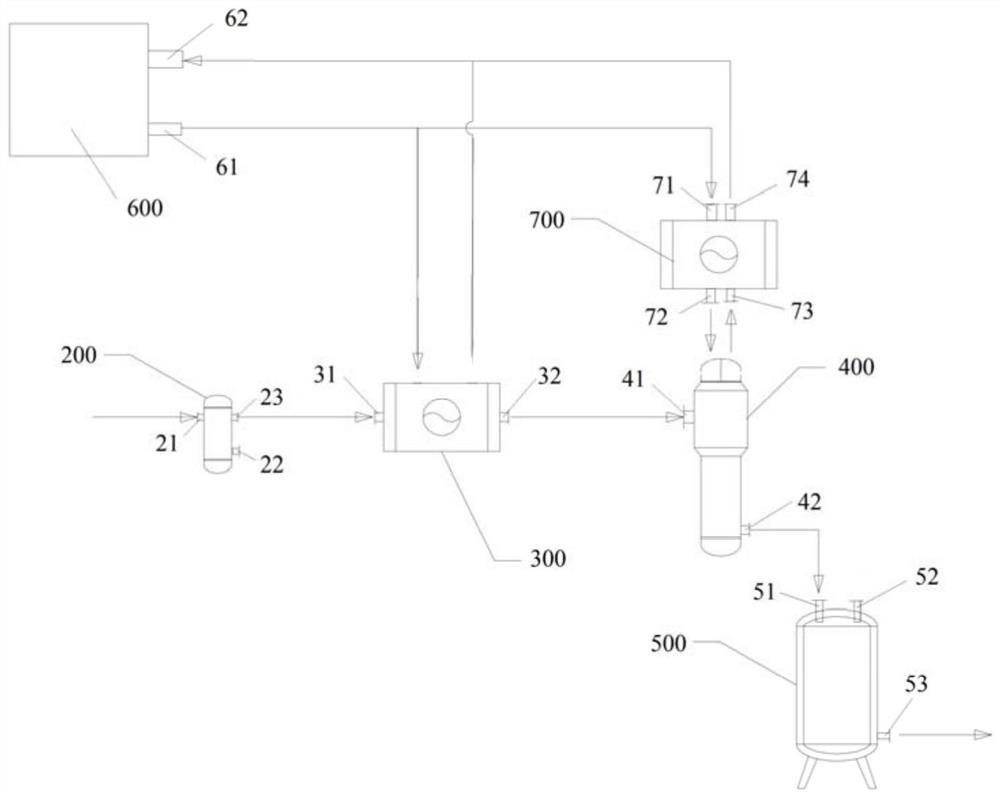

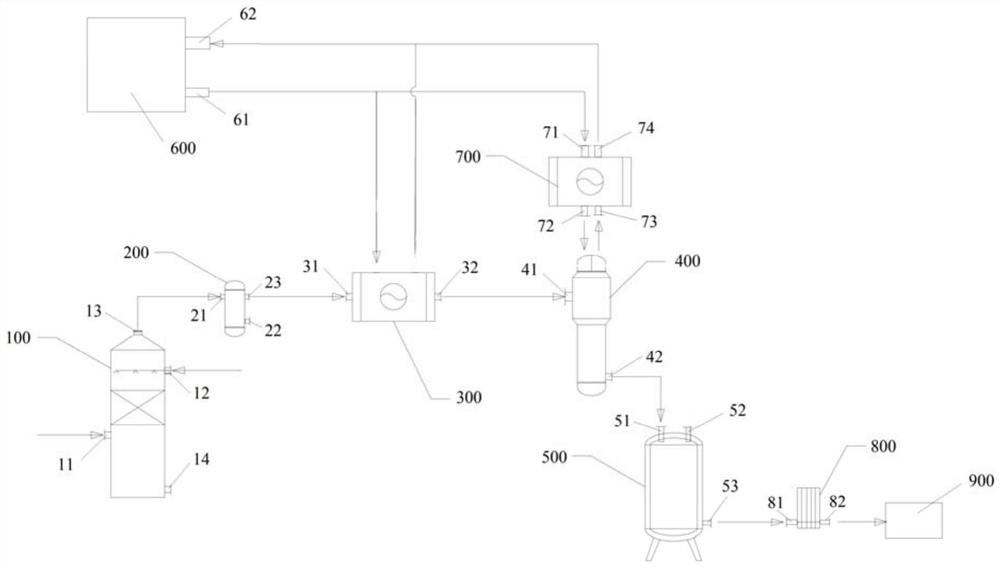

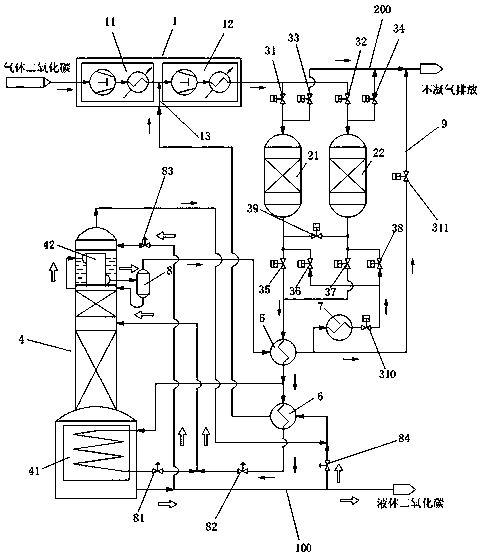

System and method for recycling gas containing carbon dioxide

PendingCN112354351AReduce manufacturing costIncreased compression power consumptionSolidificationProductsProcess engineeringEnvironmental engineering

The invention discloses a system and a method for recycling gas containing carbon dioxide, and the system for recycling the gas containing the carbon dioxide comprises a steam-water separator, a compressor unit, a condenser and a vacuum storage device. Gas containing carbon dioxide is supplied to a steam-water separator, free water in the gas is removed, then the gas enters a compressor unit to besubjected to multi-stage compression cooling, then the gas enters a condenser to be subjected to cooling liquefaction, finally liquefied carbon dioxide is conveyed into a vacuum storage device to bestored, and non-condensable gas is exhausted. The obtained liquid carbon dioxide not only can realize stable use of carbon dioxide, but also can be canned for sale, and has good economic value and environmental emission reduction benefit.

Owner:CHINA NERIN ENG

Method for preparing biodegradable polyurethane rigid foam from bamboo waste liquefaction products

InactiveCN101362818BRealize the purpose of turning waste into treasureReduce dependencePolymer sciencePolyethylene glycol

The invention discloses a method for preparing biodegradable rigid polyurethane foam with liquefaction products of bamboo waste, which comprises the following steps: 1 mass portion of crude glycerin / polyethylene glycol liquefying solvent and 0.02-0.04 mass portion of concentrated sulfuric acid are added into a reaction vessel, heated till the temperature reaches 120-180 DEG C after a reflux condensation tube is connected to the reaction vessel; 0.2-0.5 mass portion of crushed and dried bamboo waste is added, reacted for 90-180min with stirring, taken out and cooled and neutralized by MgO tillbeing neutral; 1 mass portion of liquefaction products of bamboo waste, 0.02-0.08 portion of a dibutyl tin dilaurate / triethylene diamine mixed catalyst, 0.02-0.06 portion of silicone oil, 0.02-0.1 portion of water and 0.1-0.15 portion of fire retardant are added into a container, premixed for 20-30s when stirred at 2,000r / min, added with sufficient PAPI with the molar ratio between isocyanato-NCOin PAPI and hydroxyl group-OH in bamboo waste liquefaction products being 0.6-1.2, stirred for 10s-15s at 1,000r / min, put into a mould, foamed with standing at room temperature, placed for slaking and mould separating at room temperature for 24h-72h after reaction. The method fully utilizes resources, reduces liquefaction cost, and has a mild reaction temperature and stable liquefaction products;the performance of obtained foam meets the national standard and biodegradability.

Owner:NANCHANG UNIV

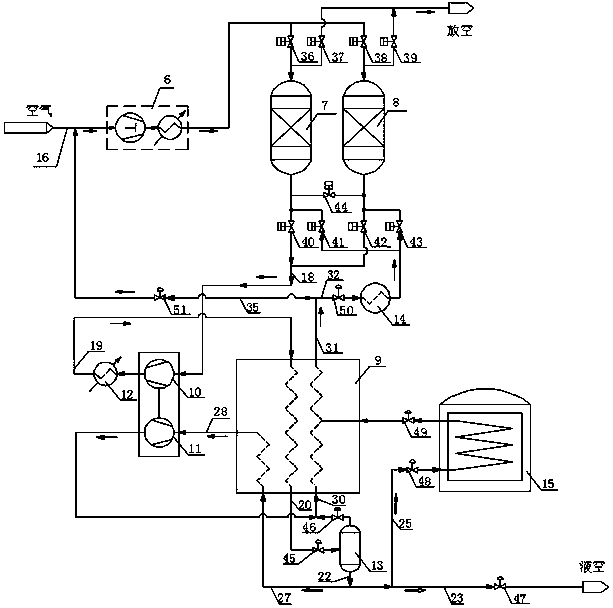

Technological system and technological method for performing cryogenic quick freezing on seafoods by air

PendingCN107736435ALow costReduce manufacturing costFood processingClimate change adaptationAir compressorMoisture

The invention provides a technological system and a technological method for performing cryogenic quick freezing on seafoods by air. The technological system comprises an air compressor, an adsorptionsystem, a switch valve, a throttling valve, an expansion turbine, a cooler, a cryogenic heat exchanger, a gas-liquid separator, a storing tank, a seafood cryogenic quick freezing box and a heater, wherein the technological method comprises the following steps of compressing the air; then removing impurities including moisture, carbon dioxide and the like in the air, and finally compressing and cooling the air to obtain liquid air to perform cryogenic quick freezing on the seafoods. According to the technological system and the technological method disclosed by the invention, air is used to replace liquid nitrogen, so that the cryogenic quick freezing cost of the seafoods is reduced, and the situation that lives are damaged and properties are damaged caused by leakage of the liquid nitrogen is avoided.

Owner:HANGZHOU HONGSHENG ZHONGHONG NEW ENERGY CO LTD

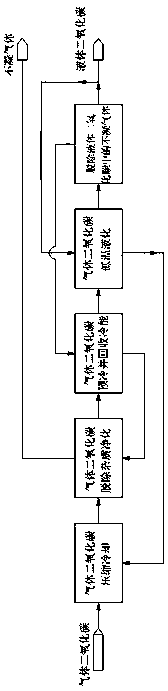

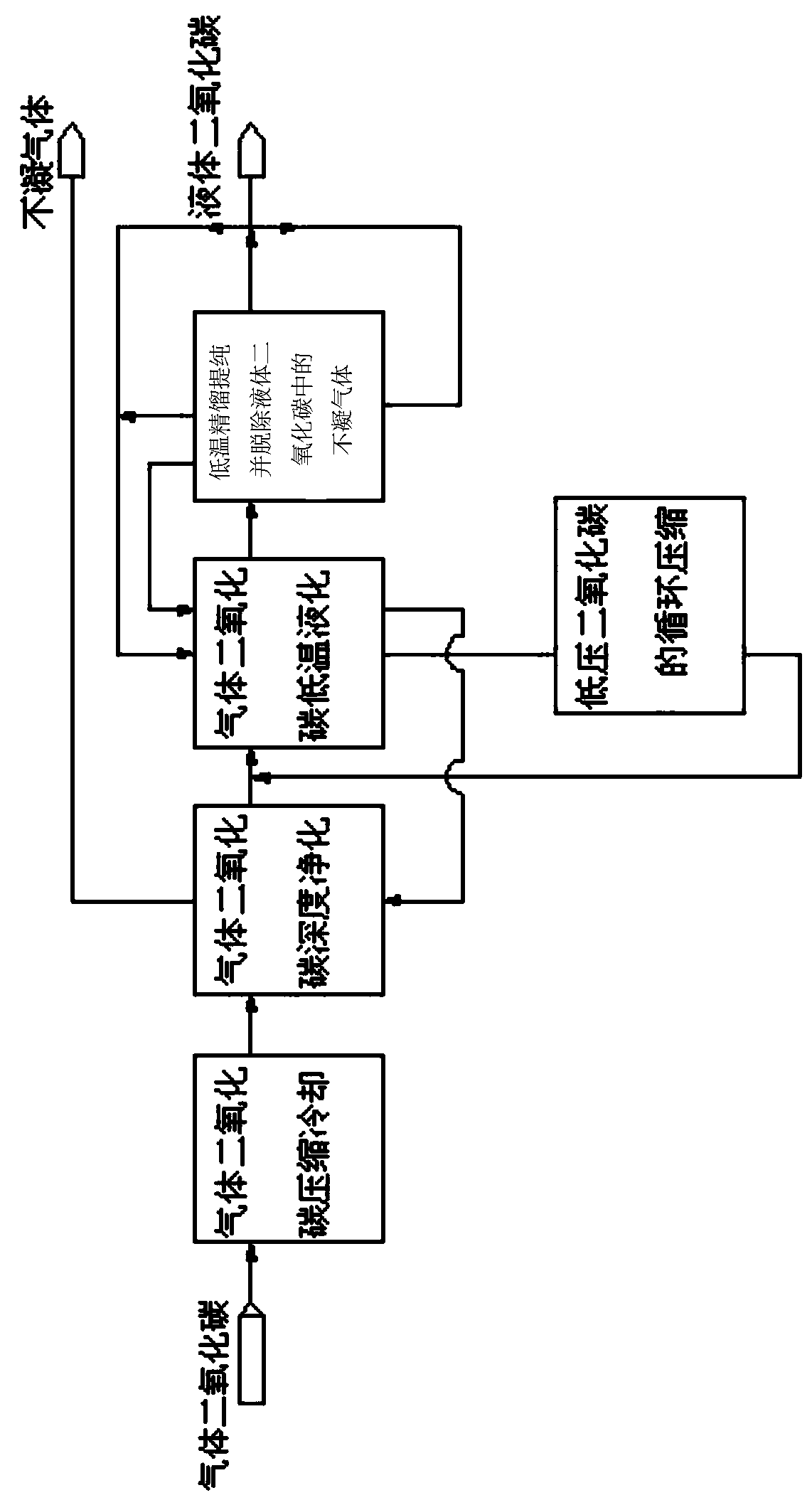

Gas carbon dioxide liquefaction method

The invention discloses a gaseous carbon dioxide liquefaction method, comprising the following steps: 1) compression and cooling of carbon dioxide raw material gas, 2) purification of gaseous carbon dioxide after pressurization, 3) precooling of purified gaseous carbon dioxide and cooling of non-condensable gas 4) Part of the pre-cooled gas carbon dioxide is cooled into liquid carbon dioxide through a low-temperature liquefaction process, and 5) the liquid carbon dioxide is removed from the non-condensable gas in the liquid carbon dioxide through a low-temperature rectification process. The invention does not need to use liquefied ammonia as a refrigerant to cool down and liquefy gaseous carbon dioxide, which improves the safety of the system, and uses low-temperature rectification towers and low-temperature heat exchangers to replace expensive refrigeration equipment, which is more conducive to the liquefaction of gaseous carbon dioxide and greatly reduces gas The cost of carbon dioxide liquefaction realizes the recycling of carbon dioxide gas.

Owner:毛恒松 +1

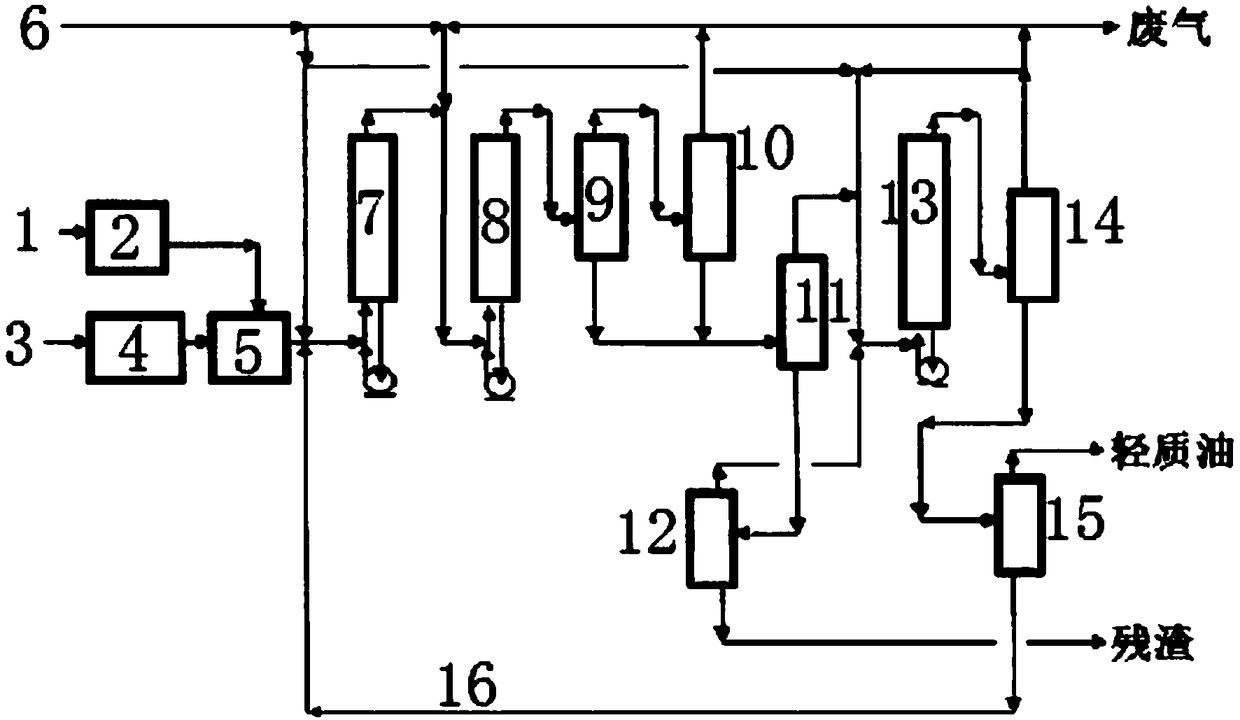

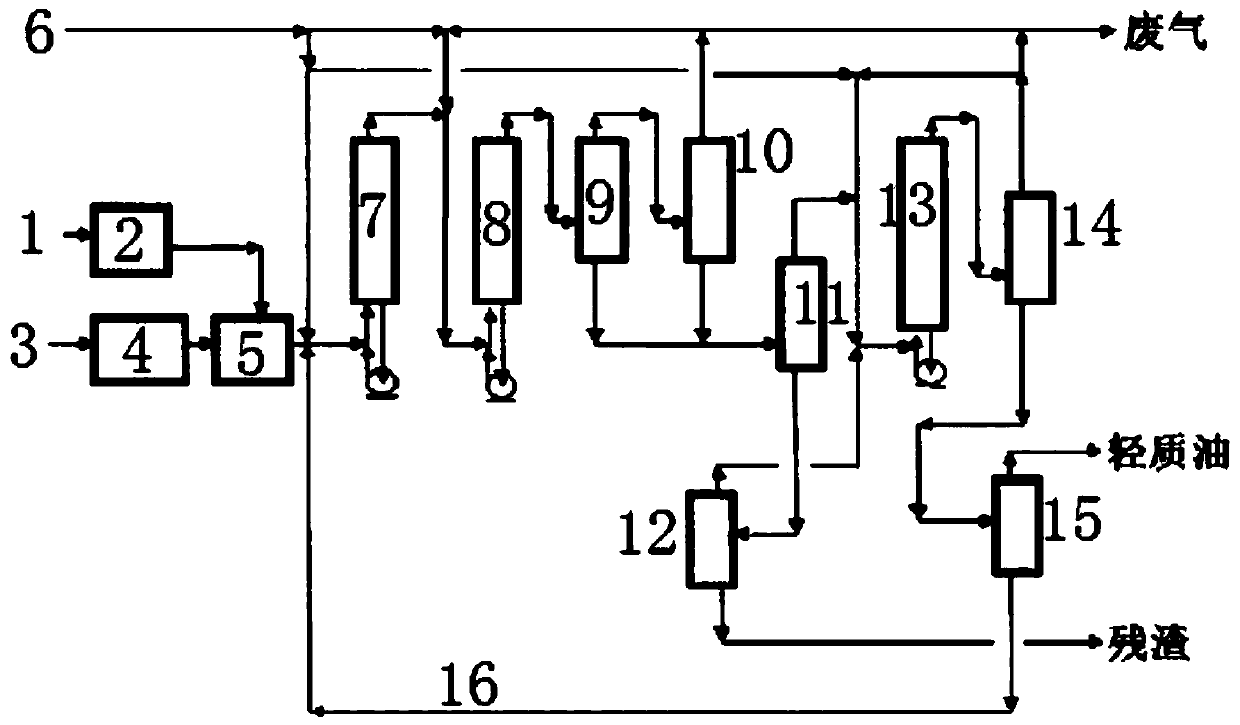

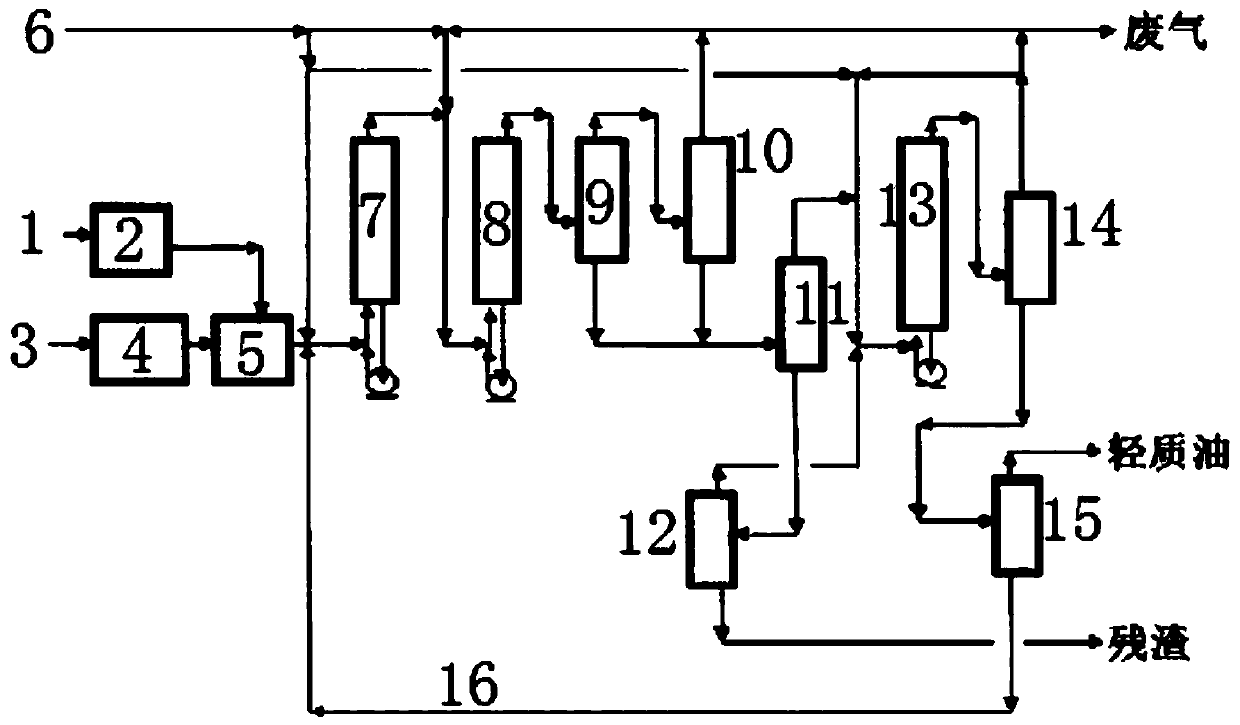

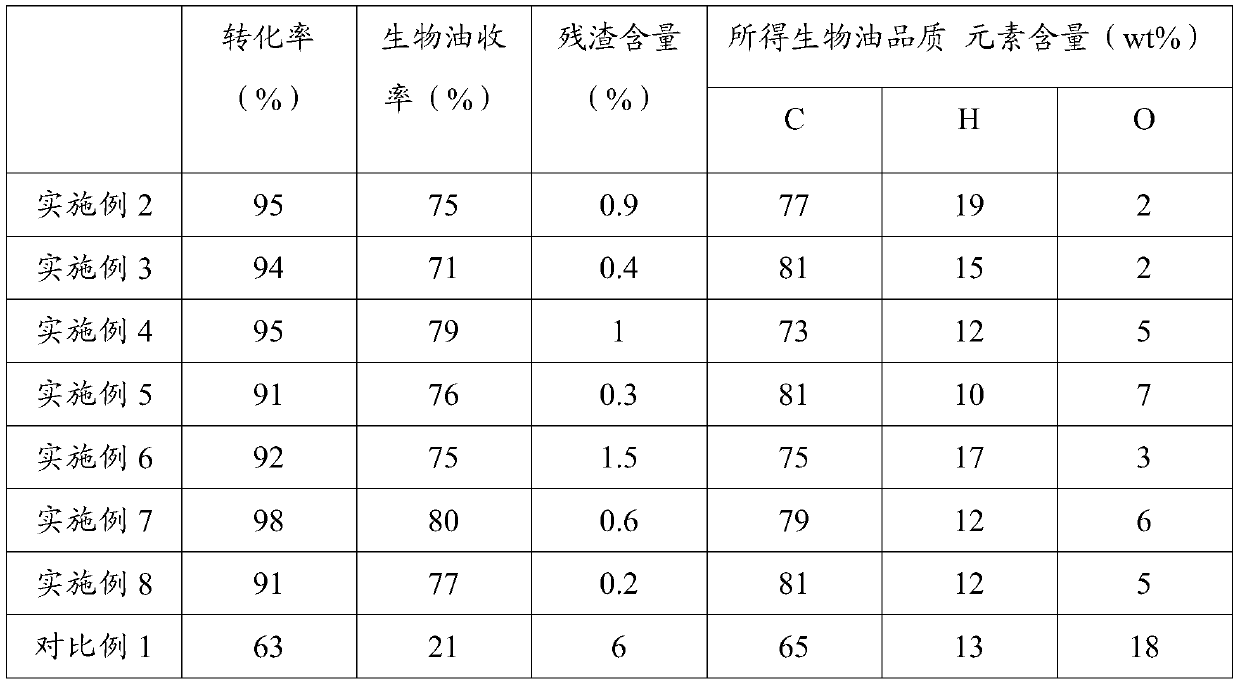

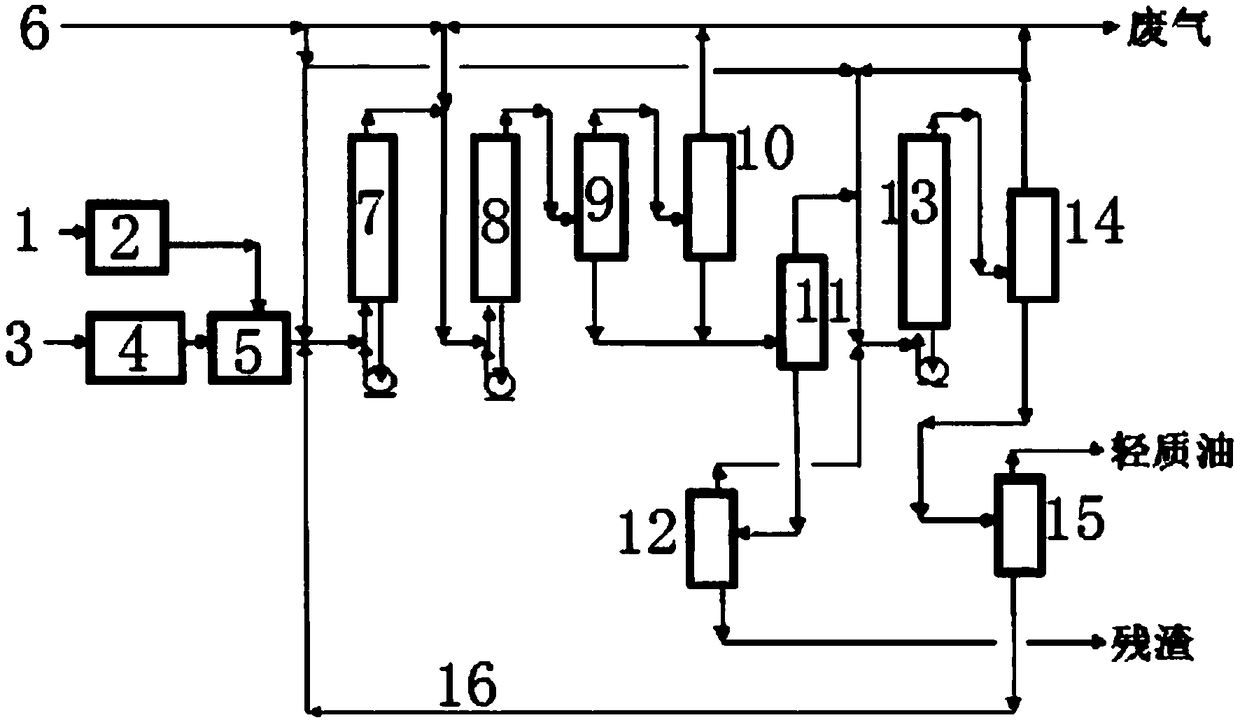

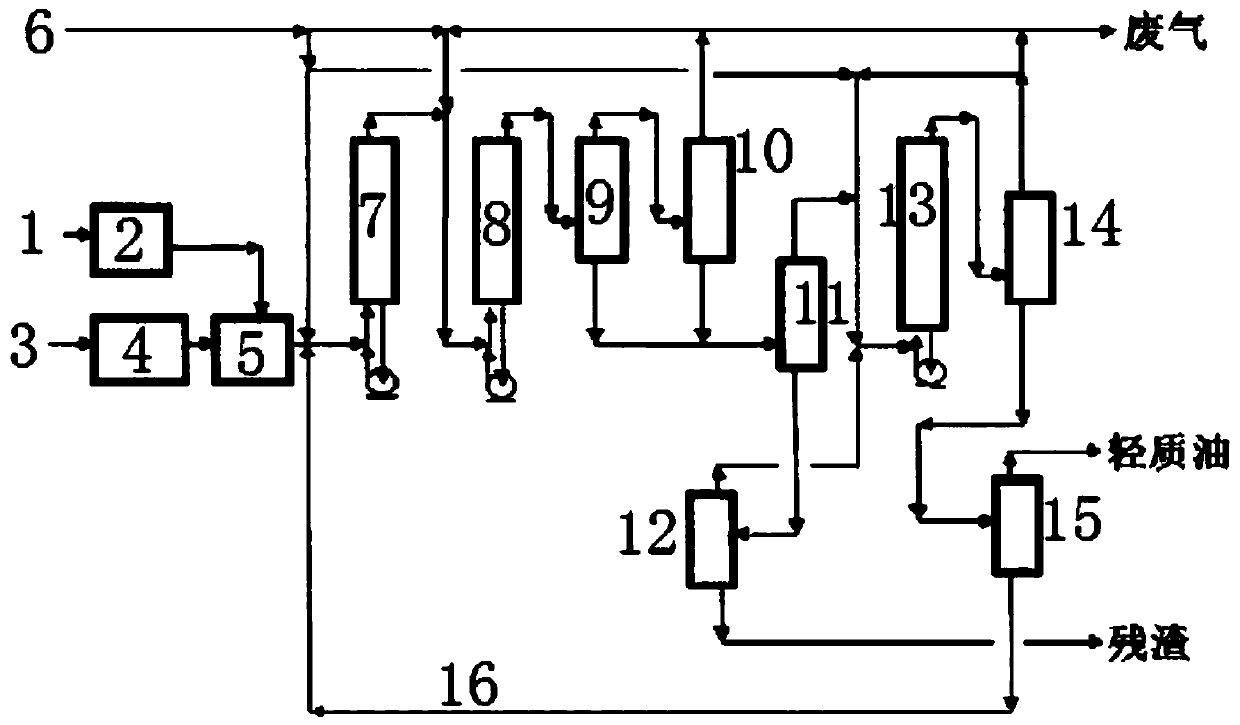

Method for direct liquefaction of biomass

The invention discloses a method for direct liquefaction of biomass. The method includes the following steps: (1) mixing the biomass, a hydrogenation catalyst and a hydrogen donor solvent to obtain abiomass slurry; (2) performing first liquefaction reaction on the biomass slurry and hydrogen to collect a first reaction product; (3) performing second liquefaction reaction on the first reaction product and hydrogen to collect a second reaction product; (4) performing first gas-liquid separation on the second reaction product at 290 to 460DEG C to collect a first liquid phase and a first gas phase; (5) performing second gas-liquid separation on the first gas phase at 30DEG C to 60DEG C to collect a second liquid phase, and mixing the first liquid phase and the second liquid phase to obtain aliquid phase; (6) performing first distillation on the liquid phase to collect a light fraction and a heavy fraction; and (7) performing second distillation on the heavy fraction to separate distillate oil and residue, wherein the light fraction and the distillate oil are liquefied liquids. The liquid yield obtained by the method is high, and the residual solid content in the liquids is low.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

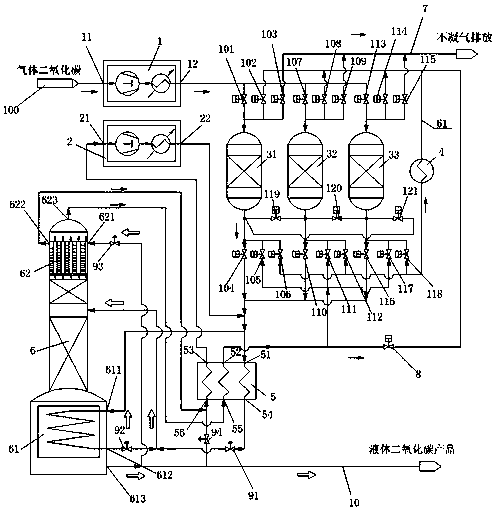

Gas carbon dioxide liquefaction system and method

The invention discloses a gaseous carbon dioxide liquefaction system and method. The system includes a raw gas compressor, a circulation compressor, several parallel adsorption towers, a regeneration gas heater, a low-temperature heat exchanger, a rectification purification tower, and a plurality of on-off valves and several throttling valves, the methods include: 1) compression and cooling of carbon dioxide feed gas, 2) deep purification of gaseous carbon dioxide, 3) low-temperature liquefaction of gaseous carbon dioxide, 4) removal of non-condensable gases in liquid carbon dioxide, 5) Cyclic compression of low pressure carbon dioxide gas. The system of the present invention has the advantages of compact structure, high efficiency, small equipment investment and operating costs, and high reliability. The method of the present invention improves the safety of the system, and adopts a low-temperature rectification tower and a low-temperature heat exchanger to replace expensive refrigeration equipment, which is more efficient. It is beneficial to the liquefaction of gaseous carbon dioxide, greatly reduces the cost of gaseous carbon dioxide liquefaction, and realizes the recycling of carbon dioxide gas.

Owner:上海九宇泰碳科技有限公司

Method for co-liquefaction of coal and waste plastics under mild condition

InactiveCN102344823BMild reaction conditionsHarsh reaction conditionsLiquid hydrocarbon mixture productionDepolymerizationGas phase

The invention is a method for co-liquefaction of coal and waste plastics under a mild condition, which comprises the following steps: adding coal, waste plastics, lignosulfonate, a catalyst, and a solvent into an autoclave, introducing hydrogen to increase the pressure to 1.0-10.0 Mpa, heating to 300-450 DEG C for a liquefaction reaction, collecting the gas after the hydrogenation liquefaction test in the autoclave, analyzing the gas phase composition by a gas chromatography, collecting all the other liquefaction products in a filter paper cylinder, performing hexane and tetrahydrofuran solvent extraction in order by a soxhlet extraction device, wherein the substance soluble in hexane is oil, and the substances soluble in tetrahydrofuran but insoluble in hexane are asphaltene and preasphaltene, and calculating the total conversion rate of the liquefaction by using the amount of the insoluble substances in tetrahydrofuran. The invention allows the coal to perform a depolymerization reaction at a low temperature, and to be co-liquefied with waste plastics; the extraction rate of coal by solvents such as pyridine and the like is increased, and the coal liquefaction process is accelerated; not only the hydrogen consumption and production cost for coal liquefaction are greatly reduced, but also white pollution caused by waste plastics is solved.

Owner:LIUPANSHUI NORMAL UNIV

Preparation method of liquefied bio-based coated controlled release material

ActiveCN113416106AStrong penetrating powerAvoid polycondensationMicroballoon preparationMicrocapsule preparationControlled releasePtru catalyst

The invention discloses a preparation method of a liquefied bio-based coated controlled release material. When the bio-based raw material is subjected to liquefaction treatment, a volatilizable small molecular organic matter is selected as a liquefying agent, an ionic substance is wrapped by a microcapsule technology to serve as a catalyst, and the bio-based material is efficiently liquefied under the condition of lower temperature through ultrasonic treatment, stirring and pressurization; and then the small-molecule liquefying agent is separated out by utilizing an evaporation system to obtain a high-quality liquefied product, thereby preparing the coating material with a good controlled release effect. According to the invention, the liquefaction efficiency and the quality of the liquefied product are greatly improved, the defects in the prior art are effectively overcome, and the method is suitable for industrial popularization and application.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

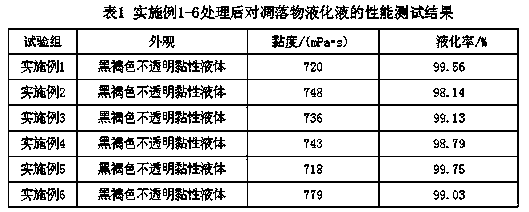

Liquefaction method of forest litter

ActiveCN103721999AConducive to liquefactionSolving the problem of liquefactionSolid waste disposalLitterPhenol

The invention discloses a liquefaction method of forest litter, and belongs to the technical field of bioengineering. The liquefaction method is characterized by comprising the following steps: 1) collecting outdoor naturally withering leaves as materials, baking and then crushing, and baking again at the same temperature so as to obtain litter powder; (2) putting phenol into a water bath at 50-80 DEG C to heat for 10-21 minutes; rapidly pouring into a reaction kettle when the phenol is completely fused into liquid, controlling the temperature of the reaction kettle at 85-110 DEG C, and then adding the litter powder; slowly dropwise adding concentrated nitric acid and hydrogen peroxide after evenly stirring and mixing, stirring for 50-75 minutes until the liquid becomes dark red liquid, adding sodium dodecyl benzene sulfonate, stirring, mixing and dissolving uniformly, and stopping heating until the liquid becomes clear black liquid; 3) cooling the liquid to room temperature, so as to obtain litter liquefied liquid. The liquefaction method of the forest litter is low in liquefaction cost, simple and feasible, accurate and reliable, and the forest litter can be effectively liquefied.

Owner:JIYANG COLLEGE OF ZHEJIANG A & F UNIV

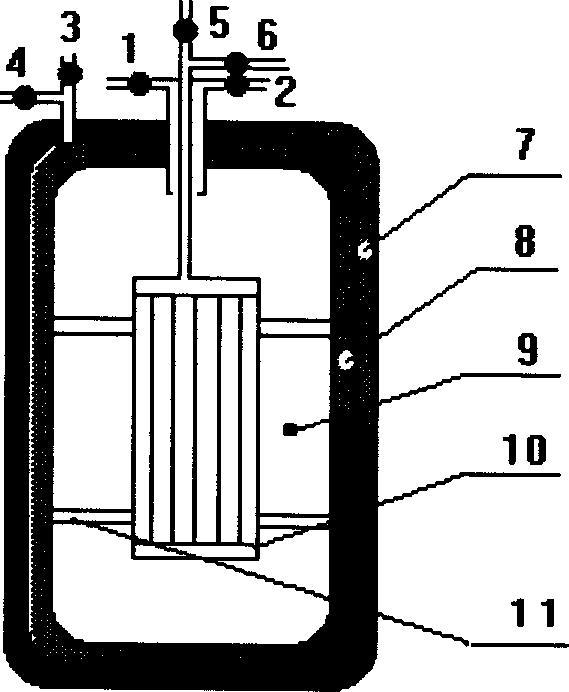

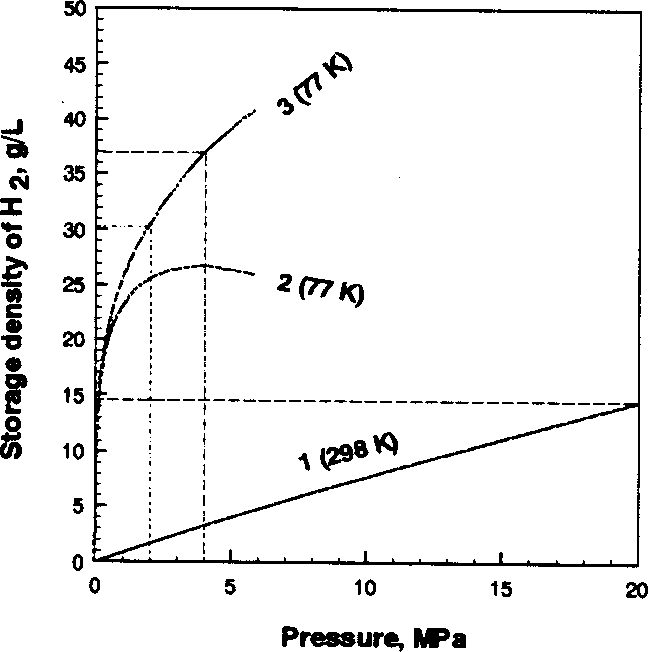

Low temperature hydrogen adsorption for storage and hydrogen storing tank

InactiveCN1123724CUnlimited lifespanImprove adsorption capacityFixed capacity gas holdersActivated carbonAutomatic control

The present invention discloses low-temp adsorption technique for storing hydrogen and its hydrogen storage tank, which can lower the storage pressure of hydrogen and raise the hydrogen storage density based on that the activated carbon or carbon fibres with high specific surface area has high adsorption power to hydrogen at the temp of liquefied nitrogen. The adsorbent bed is cooled to the temp of liquefied nitrogen by the liquefied nitrogen jacket surrounded by insulating layer. In the adsorbent bed there are heat exchanging metal tubes. On aerating hydrogen, liquefied nitrogen is introduced into them and on quick release of hydrogen, it is released into atmosphere. The high-safety decompressing valve is equipped to said jacket and hydrogen storage space. The pressure of stored hydrogen is 2.0 MPa. The stored hydrogen valume is 30 g per litre.

Owner:TIANJIN UNIV

Wood liquefier and method for preparing surfactant using liquidated wood

InactiveCN101396838BImprove liquefactionLow costTransportation and packagingWood treatment detailsEpoxyActive agent

The invention provides a preparation method for a wood liquefacient. A discarded PET bottle is crashed into powder, which is mixed with polylol and added with 0.01-0.5wt% of catalyst, and the mixtureis stirred uniformly and heated to react, thus obtaining the wood liquefacient. The invention also relates to a method for preparing a surfactant by using the liquefacient to liquefying wood, which includes the steps: 0.5-10wt% of inorganic acid catalyst and glycerin are added into the mixture of the liquefacient and the wood meal of broad leaved forests or coniferous forests, which reacts by heating to obtain a coarse liquefied wood product; the product is cooled to room temperature, diluted in absolute ethyl alcohol or acetone and then filtered in vacuum to form the filtrate, which is subsequently decompressed and distilled so as to obtain refined liquefied wood; the sodium hydroxide solution of the fully dissolved liquefied wood is added with propylene oxide according to the mass morality of total hydroxide radical to propylene oxide being 1:3-10 for reaction, and then epoxy ethane is entered for end capping, after that, the pH value is adjusted to 7, then the liquefied wood polyethenoxy ether of the surfactant is obtained as the final product.

Owner:JIANGSU QIANGLIN BIO ENERGY

A method for direct liquefaction of biomass

The invention discloses a method for direct liquefaction of biomass. The method comprises the following steps: (1) mixing biomass, a hydrogenation catalyst and a hydrogen-donating solvent to prepare a biomass slurry; (2) performing a first liquefaction reaction on the biomass slurry and hydrogen, and collecting the first reaction product; (3) carry out the second liquefaction reaction of the first reaction product and hydrogen, and collect the second reaction product; (4) carry out the first gas-liquid separation on the second reaction product at 290-460 ° C, and collect the first liquid phase and the second reaction product A gas phase; (5) performing a second gas-liquid separation on the first gas phase at 30-60°C, collecting the second liquid phase, mixing the first liquid phase and the second liquid phase to obtain a liquid phase; (6) performing a liquid phase on the liquid phase The first distillation collects the light distillate and the heavy distillate; (7) performs the second distillation on the heavy distillate to separate the distillate oil and residue, and the light distillate and distillate oil are liquids obtained from liquefaction. The yield of the liquid obtained by the above method is high, and the residue solid content in the liquid is low.

Owner:BEIJING HUASHI UNITED ENERGY TECH & DEV

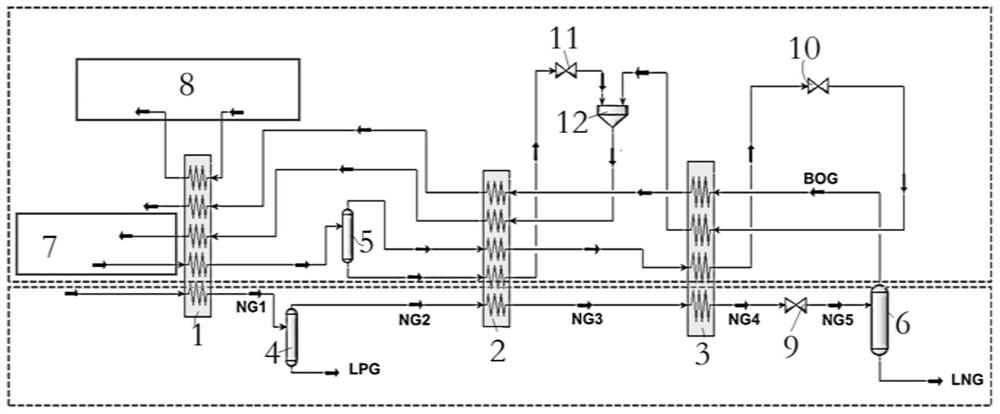

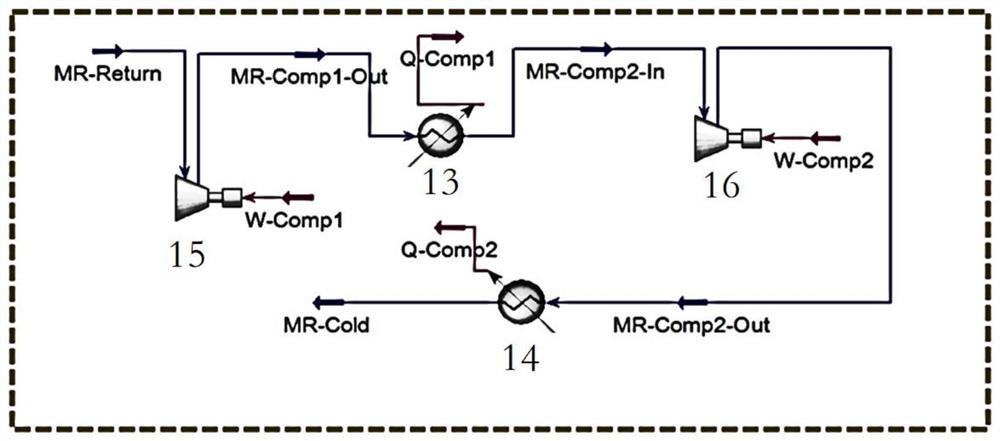

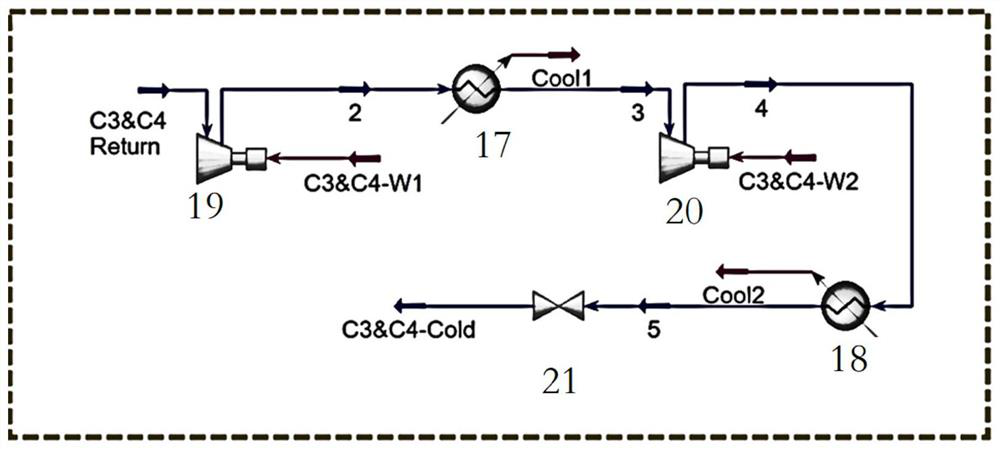

Natural gas liquefaction system based on propane and iso-butane mixed pre-cooling

InactiveCN111854322AImprove energy exchange rateImprove cooling efficiencySolidificationLiquefactionFluid phaseEnergy exchange

The invention discloses a natural gas liquefaction system based on propane and iso-butane mixed pre-cooling. A mixed refrigerant compression skid and a mixed precoolant compression skid are adopted tobe matched with a three-stage heat exchanger; by using the mixed refrigerant compression skid, natural gas to be liquefied is pre-liquefied and separated so that the separating efficiency of the natural gas to be liquefied is enhanced and the separating speed of the natural gas to be liquefied is increased; and then through precoolant cooling circulation of the mixed precoolant compression skid,a first heat exchanger, a second heat exchanger, a third heat exchanger and the mixed refrigerant compression skid, gas phase natural gas which is separated in the first stage is liquefied; by using the mixed precoolant compression skid to perform pre-cooling, the power loss of the mixed precoolant compression skid is reduced; through first-stage separation of liquid phase natural gas and by usinga mixed precoolant and a mixed refrigerant to exchange energy in the first heat exchanger, the second heat exchanger and the third heat exchanger, the structure is simple, the energy loss of the mixed refrigerant is reduced, the liquefaction efficiency is enhanced, and meanwhile, the liquefaction cost is reduced.

Owner:XI AN JIAOTONG UNIV

A method for direct liquefaction of biomass

ActiveCN108085040BImprove the efficiency of the liquefaction processGood suspensionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentPtru catalystProcess engineering

The invention relates to the field of biological energy, in particular to a direct liquefaction method of biomass. Biomass slurry is prepared through steps as follows: straw is subjected to drying, primary smashing, compressing and secondary smashing in sequence and then is mixed with a hydrogenation catalyst and a vulcanizing agent, a mixture is obtained and added to a hydrogen-donor solvent to be ground into slurry, and the biomass slurry with straw concentration being 30wt%-60wt% is prepared. The straw is subjected to first compression and later secondary smashing initiatively with the treatment technology, so that size of the straw is substantially reduced, dispersion of the straw into an oil product is facilitated, content of the straw in the oil product can be increased, concentration of reaction materials is increased, delivery amount of the biomass in unit time by a pump is increased, and stable operation and delivery of the pump are guaranteed.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Internal combustion heating moving-bed type biomass pyrolysis liquefying apparatus

InactiveCN101376814BIncrease profitIncrease temperatureBiofuelsLiquid hydrocarbon mixture productionSlagInternal combustion engine

The invention discloses an internal combustion heating movable-bed biomass-pyrolysis liquefaction device which includes a reactor (7); the inside of the reactor is provided with an internal combustion pipeline (5); both the inlet and the outlet of the internal combustion pipeline (5) are arranged outside the reactor (7); a hopper (1) is arranged above the reactor (7); a blanking control valve (2)is arranged on the hopper (1); a rotary shaft (6) is arranged in the center of the reactor (7); conical hoppers (4) are arranged on the rotary shaft (6); conical material dividing umbrellas are arranged between the conical hoppers (4); the material inlet of the hopper (1) is arranged above the conical hoppers (4); a pyrolysis gas outlet (20) is arranged on the reactor (7); the bottom part of the reactor (7) is provided with a slag discharge opening (14); a cyclone separator (23) is connected on the gas pipeline of the pyrolysis gas outlet (20); the flue gas outlet of the cyclone separator (23) is connected into a condenser (26); an oil outlet and an outlet for non-condensable gas are arranged on the condenser (26); the outlet for non-condensable gas is connected to a gas buffer tank (28) through a draught fan. The biomass-pyrolysis liquefaction device reduces the liquefaction cost of bio-oil, has a simple structure and a low processing and manufacture cost as well as is simply and conveniently operated, managed and maintained.

Owner:HEFEI UNIV OF TECH

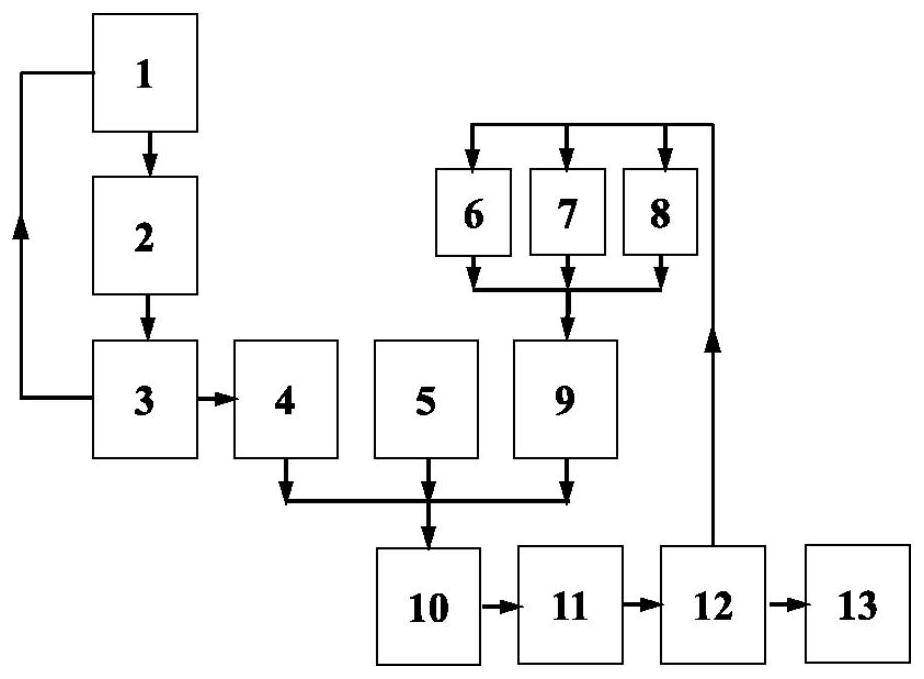

A method for direct liquefaction of coal and biomass

ActiveCN108315041BRealize mixing and liquefactionIncrease contactHydrocarbon oil crackingLiquid hydrocarbon mixture productionDistillationSlurry

The invention relates to the technical field of clean energy, in particular to a process for smelting coal and biomass. The coal and biomass materials are subjected to 'crushing, compression and crushing again' treatment, and biomass coal oil slurry with high solid content and capable of being conveying stably by a pump is successfully obtained. The biomass coal oil slurry is subjected to first liquefaction reaction and second liquefaction reaction sequentially, so that the fact that the biomass is completely liquefied into liquid phase and the yield of the liquid is increased; through twice gas and liquid separation, oil products are enriched and the residues in the oil products are enriched and caked; and through first distillation and second distillation, the yield of the liquid oil isfurther increased, the residues in the liquid oil is further enriched and caked and is discharged to the outside through the bottom of a distillation device, the residues are prevented from entering the subsequent process and the residue solid content of the liquid oil is reduced; and through test, the yield of the liquid oil is above 98 percent by weight and the residue solid content of the liquid oil is less than 0.5 percent by weight.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Rapid liquefaction method for corps wastes by microwave heating catalysis

ActiveCN101503338BLower liquefaction costsHeating fastOrganic compound preparationSolid waste disposalMicrowaveCatalytic effect

The invention provides a method for catalyzing waste of crops to be liquefied by microwave heating, which comprises: the waste of crops is added into polylol and sulphuric acid for microwave heating, the temperature is controlled to be 150-180 DEG C, and the liquification reaction is carried out for 10-30min. The method utilizes microwave auxiliary heating and reaction catalytic effect to realizerapid liquification for the waste of crops, thus greatly improving the liquification efficiency of the waste of crops and the liquification effect thereof, and leading the liquification efficiency toreach over 90%; the operation of the method is rapid, simple and convenient as well as efficient, so that the liquification cost of the waste of crops can be greatly reduced.

Owner:CHINA AGRI UNIV

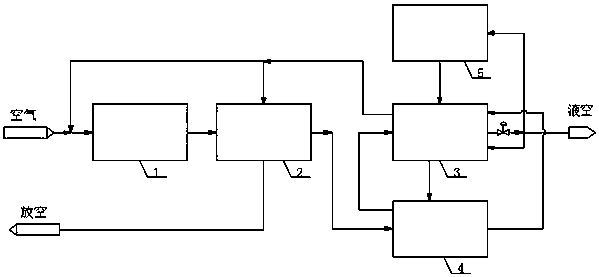

A method and system for stable gas supply with low energy consumption

ActiveCN109297043BLower liquefaction costsReduce energy consumptionSolidificationLiquefactionEngineeringNitrogen gas

The invention relates to a method and system for stably supplying air with low energy consumption. According to the method, at least part of each of first heat exchange airflow, second heat exchange airflow and third heat exchange airflow is treated to obtain first airflow to be supplied and second airflow to be supplied. The system comprises a piston air booster, an efficient postcooler, a booster expansion turbine, a main heat exchanger with five separated fluid loops, an upper rectifying tower body, a lower rectifying tower body, a subcooler with four separated fluid pipes, a low-temperature liquid nitrogen and a low-temperature liquid nitrogen. Originally-wasted nitrogen generated by air separation is liquefied, the liquefaction cost of nitrogen is reduced as the cooling capacity of liquid nitrogen is fully utilized, benefits generated by the liquid nitrogen basically offset the cost increased by use of the liquid nitrogen, and the overall energy consumption is reduced on the whole.

Owner:湖北和远气体股份有限公司

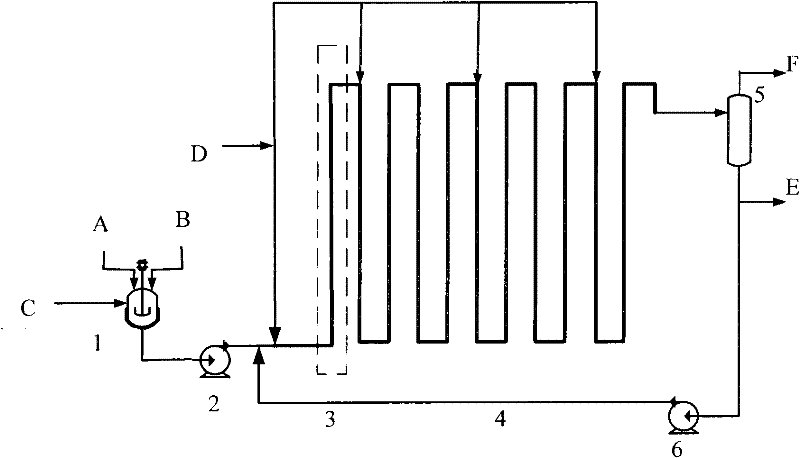

Method for preparing polyurethane rigid foam from microwave liquefaction product of bamboo processing residue

InactiveCN103788327BShorten the liquefaction timeLower liquefaction costsActivated carbonPtru catalyst

The invention relates to a method for preparing rigid polyurethane foam by utilizing microwave liquefaction products of bamboo processing residues, which is characterized in that: polyethylene glycol 400, glycerol and ethylene carbonate mixed liquefaction agent, 98% sulfuric acid and dried and pulverized bamboo The processing residue is put into a three-neck bottle, and placed in a microwave liquefaction reactor with functions of condensation, stirring, and infrared temperature measurement for microwave heating. After the reaction is completed, neutralization reagents are added to neutralize the liquefied product to pH 7-8 , to obtain plant polyols. Then, mix and stir the plant polyol prepared above with polyether polyol, catalyst, curing agent, water, silicone oil, and foaming agent evenly, then add MDI, nano-activated carbon or titanium dioxide, mix and stir for 10s-15s, and put it into the mold. Stand at room temperature for foaming, curing, and demoulding to obtain rigid polyurethane foam. The invention makes full use of bamboo resources, reduces the cost of liquefaction, the liquefaction product can be used in all components, and realizes the goal of converting all components of bamboo processing residues into synthetic polyurethane raw materials. The product has the characteristic of being able to absorb PM2.5, and is a An environmentally friendly bio-based polyurethane rigid foam product.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

Method for liquefying plant biomass and waste polyester mixed supercritical fluid

ActiveCN101693844BImprove utilization efficiencyRealize pollution-free utilizationLiquid hydrocarbon mixture productionPolyesterBüchner funnel

Owner:莱鼎电子材料科技有限公司

Method and system for stably supplying air with low energy consumption

ActiveCN109297043ALower liquefaction costsReduce overall energy consumptionSolidificationLiquefactionLiquid oxygenFluid pipe

The invention relates to a method and system for stably supplying air with low energy consumption. According to the method, at least part of each of first heat exchange airflow, second heat exchange airflow and third heat exchange airflow is treated to obtain first airflow to be supplied and second airflow to be supplied. The system comprises a piston air booster, an efficient postcooler, a booster expansion turbine, a main heat exchanger with five separated fluid loops, an upper rectifying tower body, a lower rectifying tower body, a subcooler with four separated fluid pipes, a low-temperature liquid nitrogen and a low-temperature liquid nitrogen. Originally-wasted nitrogen generated by air separation is liquefied, the liquefaction cost of nitrogen is reduced as the cooling capacity of liquid nitrogen is fully utilized, benefits generated by the liquid nitrogen basically offset the cost increased by use of the liquid nitrogen, and the overall energy consumption is reduced on the whole.

Owner:湖北和远气体股份有限公司

Direct liquefaction method of biomass

ActiveCN108085040AImprove the efficiency of the liquefaction processGood suspensionLiquid hydrocarbon mixture productionHydrocarbon oils treatmentHydrogenSlurry

The invention relates to the field of biological energy, in particular to a direct liquefaction method of biomass. Biomass slurry is prepared through steps as follows: straw is subjected to drying, primary smashing, compressing and secondary smashing in sequence and then is mixed with a hydrogenation catalyst and a vulcanizing agent, a mixture is obtained and added to a hydrogen-donor solvent to be ground into slurry, and the biomass slurry with straw concentration being 30wt%-60wt% is prepared. The straw is subjected to first compression and later secondary smashing initiatively with the treatment technology, so that size of the straw is substantially reduced, dispersion of the straw into an oil product is facilitated, content of the straw in the oil product can be increased, concentration of reaction materials is increased, delivery amount of the biomass in unit time by a pump is increased, and stable operation and delivery of the pump are guaranteed.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

A method for direct liquefaction of biomass

ActiveCN108285806BSpeed up the flowReduce volumeLiquid hydrocarbon mixture productionHydrocarbon oils treatmentVegetable oilPtru catalyst

The invention relates to the field of biological energy sources, in particular to a direct biomass liquefaction method. The preparation method of biomass slurry comprises the steps of sequentially performing drying, primary crushing, compression and secondary crushing on vegetable oil residue, mixing with a hydrogenation catalyst and a vulcanizer to form a mixture, adding the mixture into a hydrogen-donating solvent for grinding and slurrying, and preparing the biomass slurry with a vegetable oil residue concentration of 50-65wt%. According to the method, a treatment technology of the compression and the crushing for twice is performed on the vegetable oil residue initiatively; the volume of the vegetable oil residue is reduced greatly; the dispersion of the vegetable oil residue over an oil product is facilitated; a content of the vegetable oil residue in the oil product can be increased; a concentration of a reaction material is increased; the biomass conveying capacity of a pump inunit time is increased; and the smooth operation and conveying of the pump are ensured.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

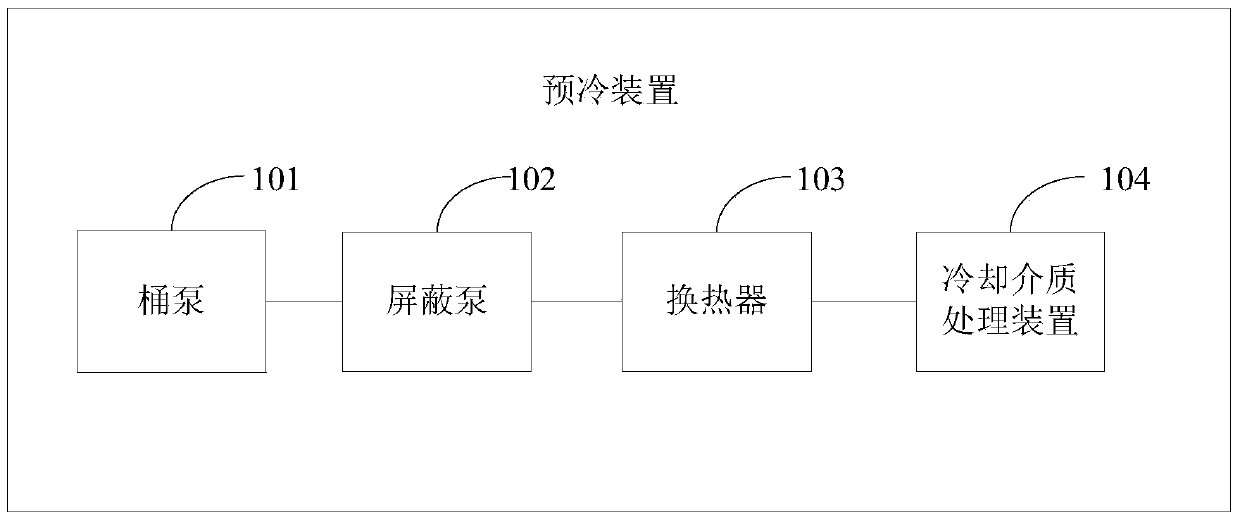

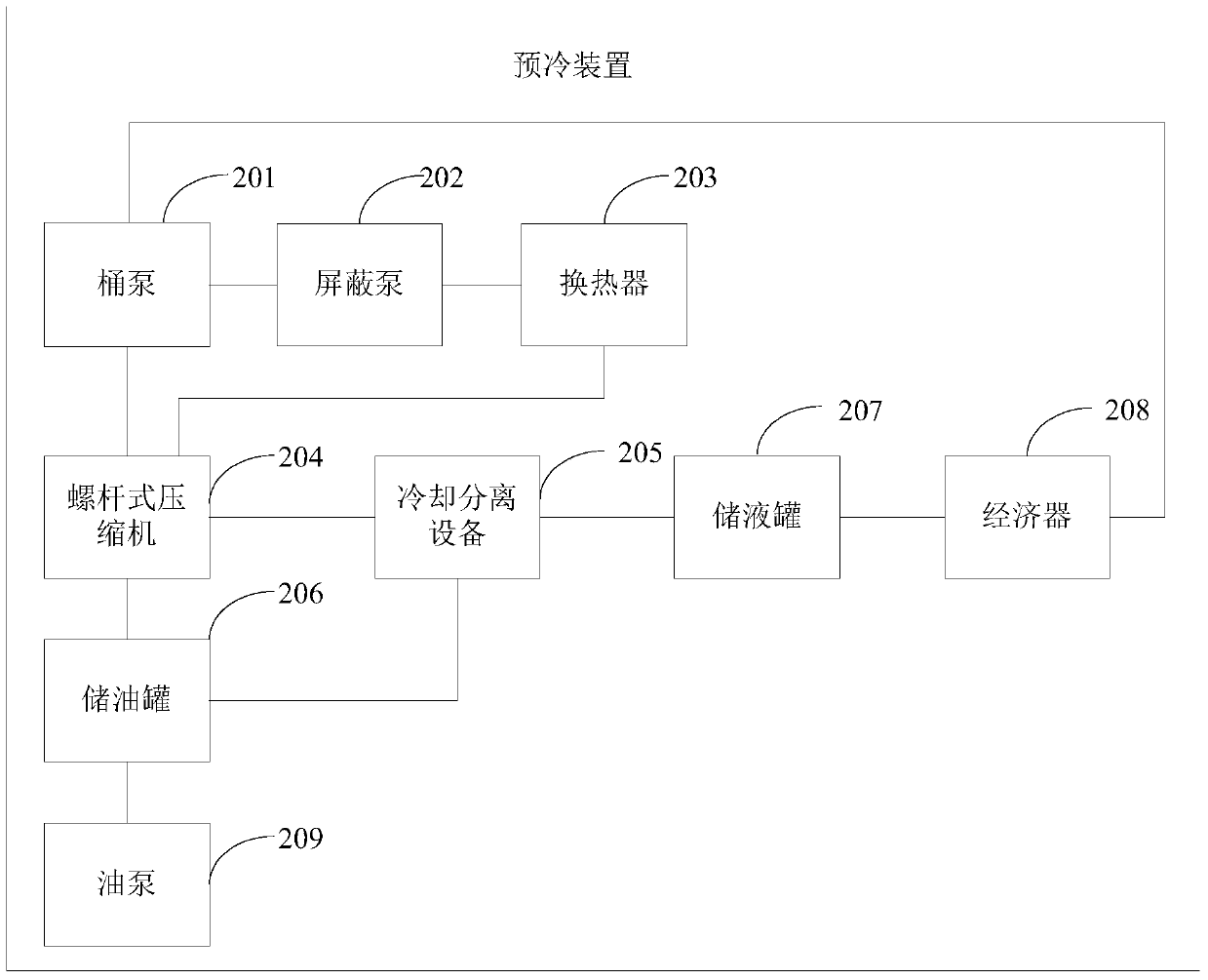

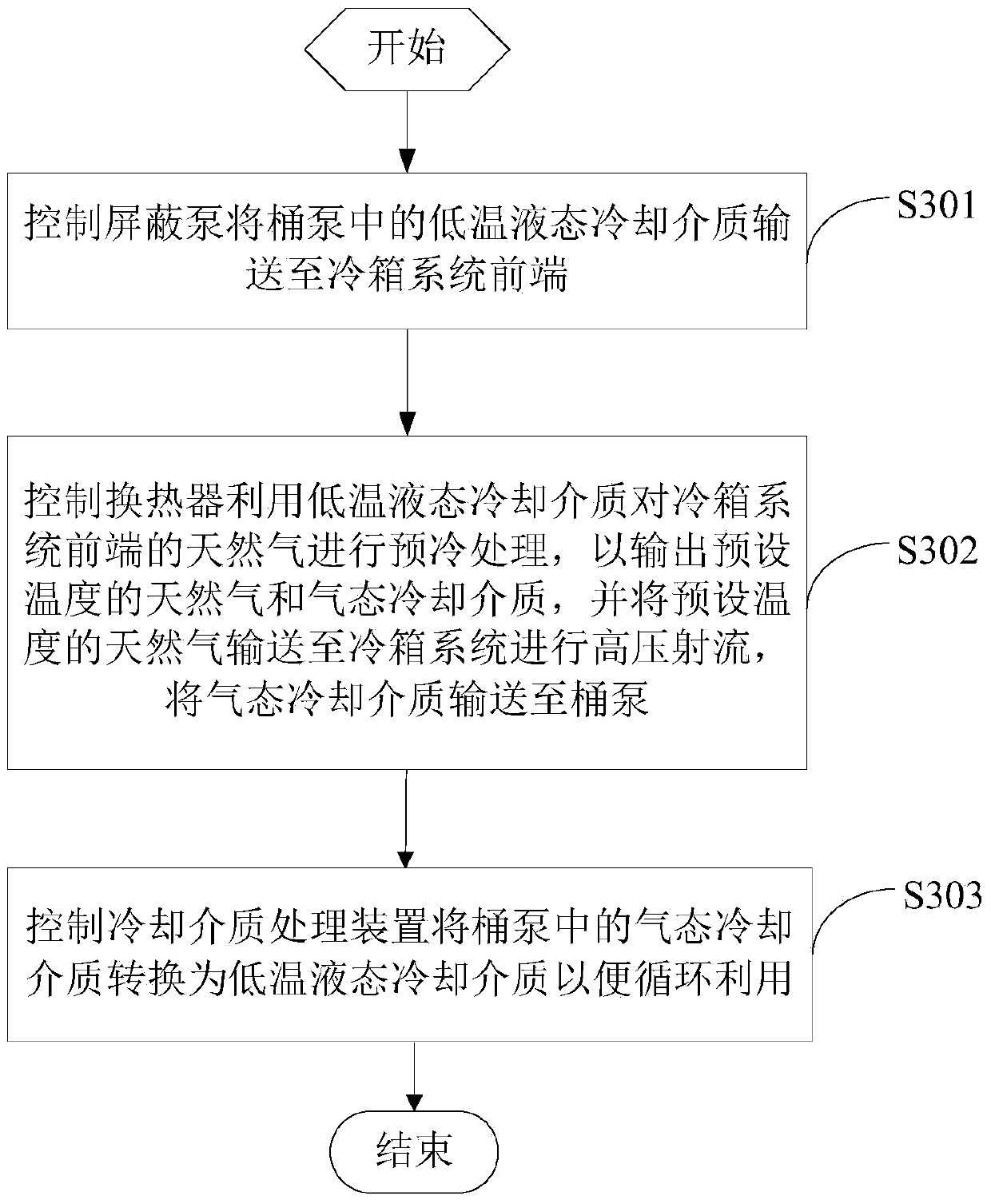

A natural gas precooling device and precooling control method

ActiveCN105783419BIncrease liquefaction rateLower liquefaction costsSolidificationLiquefactionProcess engineeringEngineering

The invention provides a natural gas precooling device and a precooling control method. The precooling device comprises a shield pump, a barrel pump, a heat exchanger and a cooling medium processing device. The precooling control method comprises the steps that pressure in the barrel pump is controlled to stay within a preset pressure range; the shield pump is controlled to transport a low-temperature liquid cooling medium in the barrel pump to the front end of a cold box system; the heat exchanger is controlled to utilize the low-temperature liquid cooling medium to conduct precooling treatment on natural gas at the front end of the cold box system, so that the natural gas of a preset temperature and a gaseous cooling medium of the preset temperature are output; and the cooling medium processing device is controlled to convert the gaseous cooling medium in the barrel pump into the low-temperature liquid cooling medium in order to facilitate reclamation. According to the natural gas precooling device and the precooling method, the natural gas can be precooled, the liquefaction ratio of the natural gas can be improved when precooled natural gas is subjected to liquefaction, recycling gas is reduced, and liquefaction cost of the natural gas is lowered.

Owner:重庆耐德能源装备集成有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com