Method for direct liquefaction of biomass

A biomass, direct technology, applied in chemical instruments and methods, biofuels, biological raw materials, etc., can solve the problems of high residual solid content in light oil, waste liquid substances, affect the yield of liquid substances, etc. Yield, improving yield, reducing the effect of residue solid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

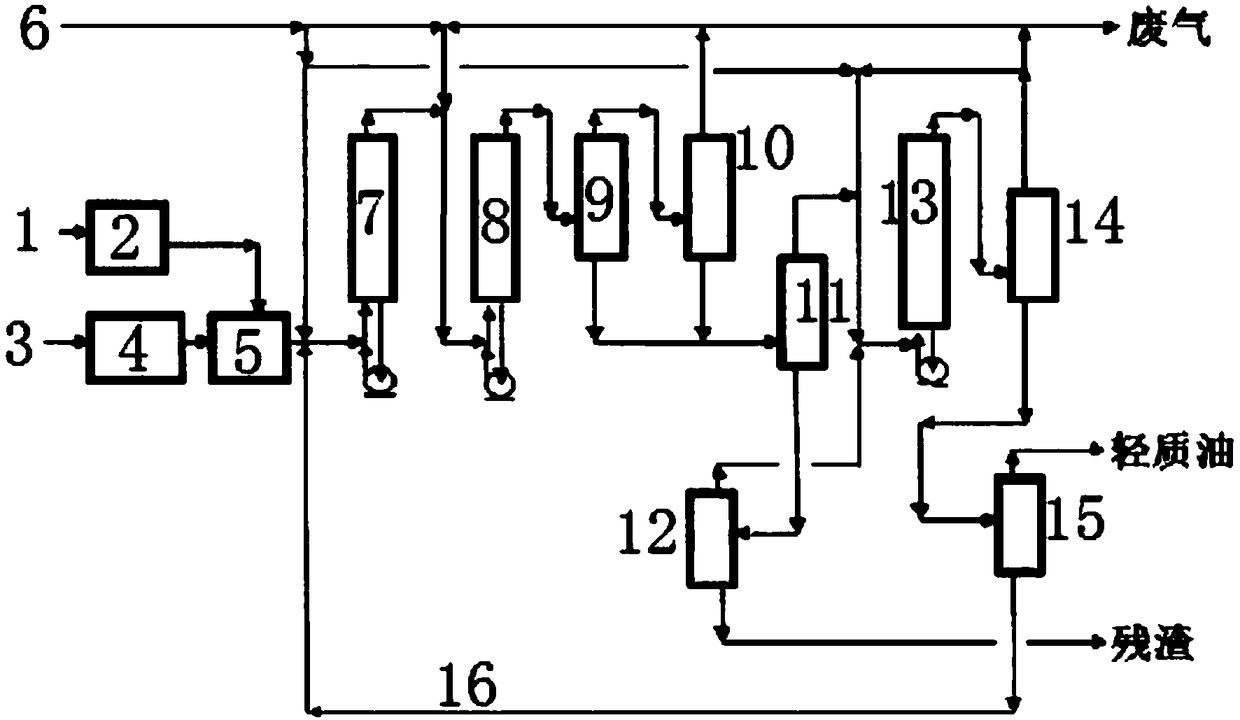

[0073] The method for direct liquefaction of biomass provided by the embodiments of the present invention comprises the following steps:

[0074] (1) The biomass 1 enters the biomass pretreatment device 2 to be dried and pulverized sequentially to obtain pulverized materials with a particle size of 10 μm, wherein the pulverized materials are wheat straw particles;

[0075] (2) The hydrogenation catalyst raw material 3 enters the hydrogenation catalyst preparation device 4 for loading, and obtains a hydrogenation catalyst (its particle size is 20 μm, and the loading capacity is 15 wt %) loaded with Mo oxide and Ni oxide on the amorphous alumina. , mixing the hydrogenation catalyst, the pulverized material and sulfur in the biomass slurry preparation device 5 at a mass ratio of 3:100:0.3 to obtain the mixed material;

[0076] (3) mixing the mixture with a hydrogen-donating solvent to obtain a biomass slurry with a solid content of 25 wt%, wherein the hydrogen-donating solvent is...

Embodiment 2

[0085] The method for direct liquefaction of biomass provided by the embodiments of the present invention comprises the following steps:

[0086] (1) The biomass 1 enters the biomass pretreatment device 2 to be dried and pulverized sequentially to obtain pulverized materials with a particle size of 100 μm, wherein the pulverized materials are reed straw particles;

[0087] (2) Hydrogenation catalyst raw material 3 enters in hydrogenation catalyst preparation device 4 and carries out loading, obtains the hydrogenation catalyst (its particle size is 100 μ m-150 μ m, and loading capacity is 10wt) that is loaded with W oxide and Ni oxide on the amorphous alumina %), mixing the hydrogenation catalyst, the pulverized material and sulfur in the biomass slurry preparation device 5 in a mass ratio of 1:100:0.4 to obtain a mixed material;

[0088] (3) mixing the mixture with a hydrogen-donating solvent to obtain a biomass slurry with a solid content of 10 wt%, wherein the hydrogen-donat...

Embodiment 3

[0097] The method for direct liquefaction of biomass provided by the embodiments of the present invention comprises the following steps:

[0098] (1) The biomass 1 enters the biomass pretreatment device 2 and is sequentially dried and pulverized to obtain pulverized materials with a particle size of 500 μm, wherein the pulverized materials are reed straw particles;

[0099] (2) The hydrogenation catalyst raw material 3 enters the hydrogenation catalyst preparation device 4 for loading, and obtains a hydrogenation catalyst (its particle size is 100 μm-150 μm, and the load capacity is 25wt) that is loaded with Pd oxide and Ni oxide on the amorphous alumina %), mixing the hydrogenation catalyst, amorphous iron oxide, the pulverized material and sulfur in the biomass slurry preparation device 5 in a mass ratio of 2:2:100:0.3 to obtain the mixed material;

[0100] (3) mixing the mixture with a hydrogen-donating solvent to obtain a biomass slurry with a solid content of 50 wt%, wher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com