Liquefaction method of forest litter

A technology for litter and forest, applied in the field of liquefaction of forest litter, can solve the problems of separation and difficult characterization of liquefied products, and achieve the effects of expanding application scope and functions, low liquefaction cost and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

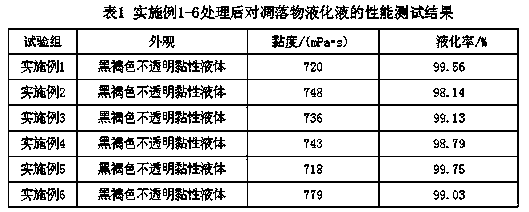

Examples

Embodiment 1

[0018] Leaves that fall naturally in the field are dried in an oven at 42°C, crushed to 400 mesh with a pulverizer after drying, and dried again at the same temperature for 39 minutes to obtain litter powder, and then take 100kg of phenol and heat it in a water bath at 65°C 12min, when it is completely melted into a liquid state, quickly pour it into the reactor, control the temperature of the reactor at 95°C, add 40kg of litter powder, stir and mix evenly, slowly add 2kg of concentrated nitric acid and 2kg of hydrogen peroxide, and stir for 50min until the liquid becomes into a dark red liquid, then add 4 kg of sodium dodecylbenzenesulfonate, stir, mix and dissolve evenly, stop heating until it becomes a clear black liquid, and finally cool to room temperature, seal and store to obtain the litter liquefaction liquid.

Embodiment 2

[0020] Put the naturally littered leaves in the field into an oven at 51°C for drying, crush them to 350 mesh with a pulverizer after drying, and dry them again at the same temperature for 50 minutes to obtain litter powder, then take 100kg of phenol and heat it in a water bath at 75°C 18min, when it is completely melted into a liquid state, quickly pour it into the reactor, control the temperature of the reactor at 93°C, add 40kg of litter powder, stir and mix evenly, slowly add 2kg of concentrated nitric acid and 2kg of hydrogen peroxide, and stir for 75min until the liquid becomes into a dark red liquid, then add 4 kg of sodium dodecylbenzenesulfonate, stir, mix and dissolve evenly, stop heating until it becomes a clear black liquid, and finally cool to room temperature, seal and store to obtain the litter liquefaction liquid.

Embodiment 3

[0022] Leaves that fall naturally in the field are dried in an oven at 44°C, crushed to 300 mesh with a pulverizer after drying, and baked again at the same temperature for 41 minutes to obtain litter powder, and then take 100kg of phenol and heat it in a water bath at 70°C 14min, when it is completely melted into a liquid state, quickly pour it into the reactor, the temperature of the reactor is controlled at 91°C, add 40kg of litter powder, stir and mix evenly, slowly add 2kg of concentrated nitric acid and 2kg of hydrogen peroxide, and stir for 55min until the liquid becomes into a dark red liquid, then add 4 kg of sodium dodecylbenzenesulfonate, stir, mix and dissolve evenly, stop heating until it becomes a clear black liquid, and finally cool to room temperature, seal and store to obtain the litter liquefaction liquid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com