Preparation method of liquefied bio-based coated controlled release material

A controlled-release material and bio-based technology, which is applied in the field of preparation of liquefied bio-based coated controlled-release materials, can solve the problems of increased process and energy consumption, inability to separate and remove, and poor liquefaction quality, so as to reduce process and energy consumption, Effect of shortening liquefaction time and reducing liquefaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

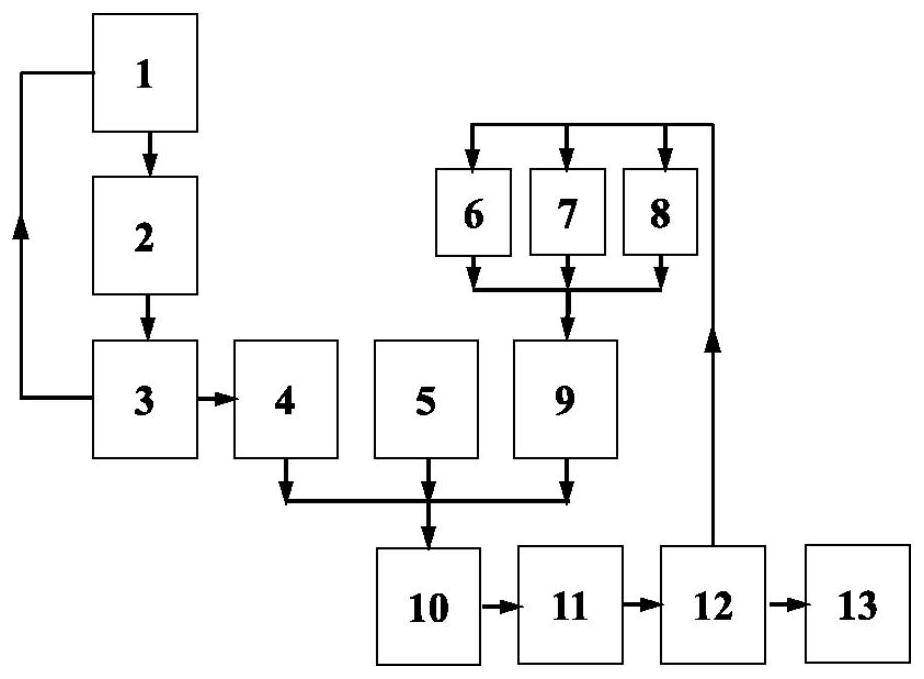

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the microcapsule-wrapped catalyst is as follows: dispersing the ionic substances in the polyvinyl alcohol aqueous solution by ultrasonic waves, as the water phase, the concentration of the ionic substances in the water phase is 100-500 mg / ml; dissolving the polylactic acid In dichloromethane, as the oil phase, the concentration of polylactic acid in the oil phase is 50-100mg / ml; the water phase is added to the oil phase and mixed, and the volume ratio of the water phase and the oil phase is 1:1. A water-in-oil emulsion was prepared under stirring, and the droplets were solidified overnight under mechanical stirring, and then collected by centrifugation, and the obtained microcapsules were freeze-dried using a freeze dryer.

[0051] The technical characteristics of the present invention are: the liquefaction agent adopts small-molecular volatile organic matter, which can be recycled, realizes recycling, and reduces waste of resources; adopts micr...

Embodiment 1

[0055] Disperse potassium persulfate in polyvinyl alcohol aqueous solution by ultrasound, as the water phase, the concentration of potassium persulfate in the water phase is 200mg / ml; dissolve polylactic acid in methylene chloride, as the oil phase, polylactic acid in the oil phase The concentration is 80mg / ml; the water phase is added to the oil phase and mixed, the volume ratio of the water phase and the oil phase is 1:1, and the water-in-oil emulsion is prepared under mechanical stirring, and the droplets are solidified overnight under mechanical stirring. Then it is collected by centrifugation, and the obtained microcapsules are freeze-dried by using a lyophilizer to prepare potassium persulfate wrapped in microcapsules.

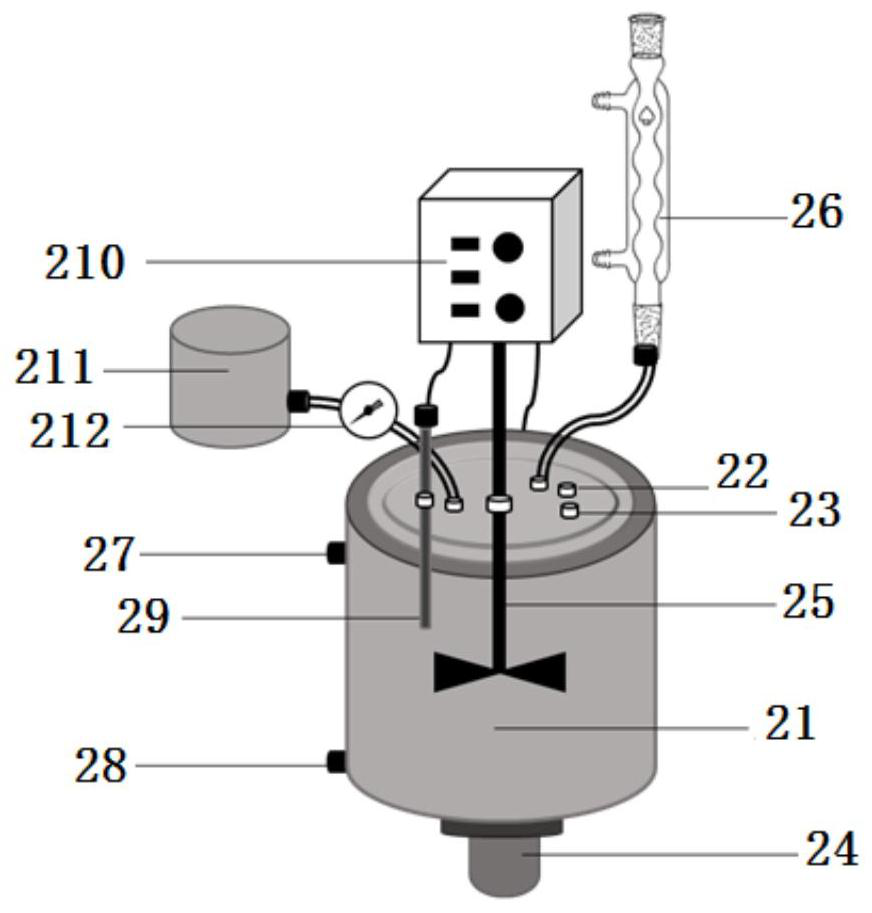

[0056] The wheat straw is pulverized, passed through a 100-mesh sieve, weighed 20g of powder, and added to the liquefaction device ( figure 2 As shown), turn on the ultrasound, stir, and then add 80g of liquefaction agent (methanol and ethanol are unifo...

Embodiment 2

[0060] Disperse sodium persulfate in polyvinyl alcohol aqueous solution by ultrasound, as the water phase, the concentration of sodium persulfate in the water phase is 100mg / ml; dissolve polylactic acid in methylene chloride, as the oil phase, polylactic acid in the oil phase The concentration is 50mg / ml; the water phase is added to the oil phase and mixed, the volume ratio of the water phase and the oil phase is 1:1, and the water-in-oil emulsion is prepared under mechanical stirring, and the droplets are solidified overnight under mechanical stirring. Then it is collected by centrifugation, and the obtained microcapsules are freeze-dried using a lyophilizer to prepare sodium persulfate wrapped in microcapsules.

[0061] The wheat straw is pulverized, passed through a 100-mesh sieve, weighed 20g of powder, and added to the liquefaction device ( figure 2 As shown), turn on the ultrasound, stir, and then add 60g of liquefaction agent (ethyl acetate and ethanol are mixed uniforml...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com