Method for co-liquefaction of coal and waste plastics under mild condition

A co-liquefaction technology of waste plastics, which is applied in the preparation of liquid hydrocarbon mixtures and the petroleum industry, can solve the problems of obvious aromatization and expensive catalysts, and achieve the effects of low cost, reduced cost and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

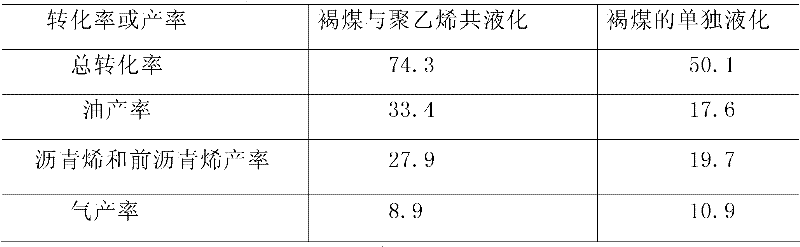

Embodiment 1

[0029] Firstly, the lignite is crushed, divided, and ground to less than 100 meshes according to national standards, and is heated at a temperature of about 90°C and a vacuum degree of 10 -2 Baking under mmHg until the moisture content is less than 1.0% is used as a liquefaction test sample.

[0030] The equipment used in the experiment is the GSHA-1.5L autoclave produced by Shandong Penglai Luwu Chemical Machinery Co., Ltd.

[0031] Add 9.0g of coal, 3.0g of polyethylene, 0.24g of sodium lignosulfonate, 0.12g of boron trifluoride-diethyl ether, and 27.0g of phenol into the autoclave, and replace nitrogen three times and then introduce hydrogen into the autoclave. Pressurize to 1.0Mpa, then raise the temperature to 300°C at a heating rate of about 10°C / min and keep the temperature constant for 30min until the liquefaction reaction is complete.

[0032] After the gas was collected after the autoclave hydrogenation liquefaction test, the gas phase composition was analyzed with ...

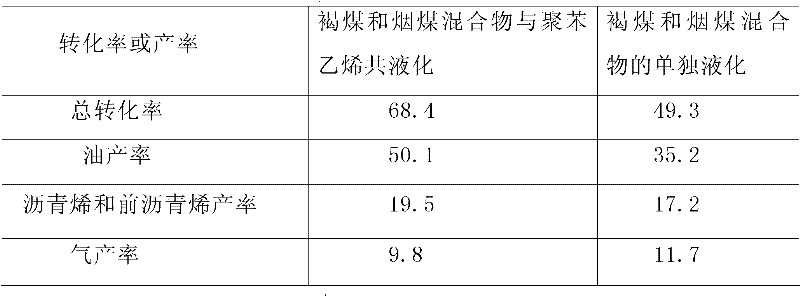

Embodiment 2

[0036] First, the mixture of lignite and bituminous coal is crushed, divided, and ground to less than 100 meshes according to national standards, and the -2 Baking under mmHg until the moisture content is less than 1.0% is used as a liquefaction test sample.

[0037] The equipment used in the experiment is the GSHA-1.5L autoclave produced by Shandong Penglai Luwu Chemical Machinery Co., Ltd.

[0038]Add 20.0g of lignite and bituminous coal mixture, 10.0g of polystyrene, 1.2g of magnesium lignosulfonate, 0.9g of boron trifluoride-phenol, and 60.0g of phenol into the autoclave, and replace nitrogen three times. Introduce hydrogen and pressurize to 5.0Mpa. Then the temperature was raised to 400°C at a heating rate of about 10°C / min and kept at a constant temperature for 30 minutes until the liquefaction reaction was completed. The weight ratio of lignite and bituminous coal in the test does not need to be strictly limited.

[0039] After the gas was collected after the autocla...

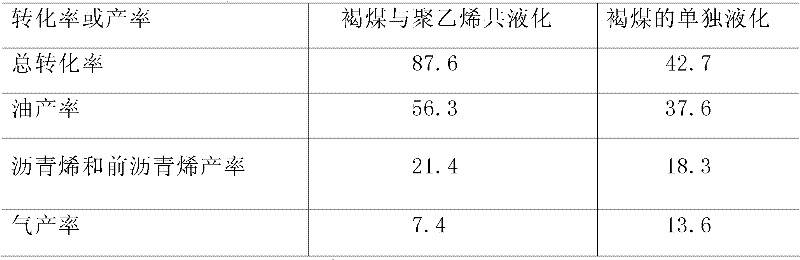

Embodiment 3

[0043] First, the bituminous coal is crushed, shrunk, and ground to less than 100 mesh according to national standards, and the temperature is about 90°C and the vacuum degree is 10 -2 Baking under mmHg until the moisture content is less than 1.0% is used as a liquefaction test sample.

[0044] The equipment used in the experiment is the GSHA-1.5L autoclave produced by Shandong Penglai Luwu Chemical Machinery Co., Ltd.

[0045] Add 12.0 g of bituminous coal, 4.0 g of polyethylene, 0.48 g of ammonium lignosulfonate, 0.16 g of boron trifluoride-ether, and 36.0 g of phenol into the autoclave, and replace the nitrogen three times with hydrogen. Pressurize to 3.0Mpa. Then the temperature was raised to 400°C at a heating rate of about 10°C / min and kept at a constant temperature for 30 minutes until the liquefaction reaction was completed.

[0046] After the gas was collected after the autoclave hydrogenation liquefaction test, the gas phase composition was analyzed with a gas chro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com