Low temperature hydrogen adsorption for storage and hydrogen storing tank

A hydrogen storage tank and hydrogen storage technology, applied in fixed-capacity gas storage tanks, gas/liquid distribution and storage, mechanical equipment, etc., can solve problems such as practicality that has yet to be proven, and achieve liquefaction cost savings, weight reduction and manufacturing The effect of constant cost and hydrogen release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

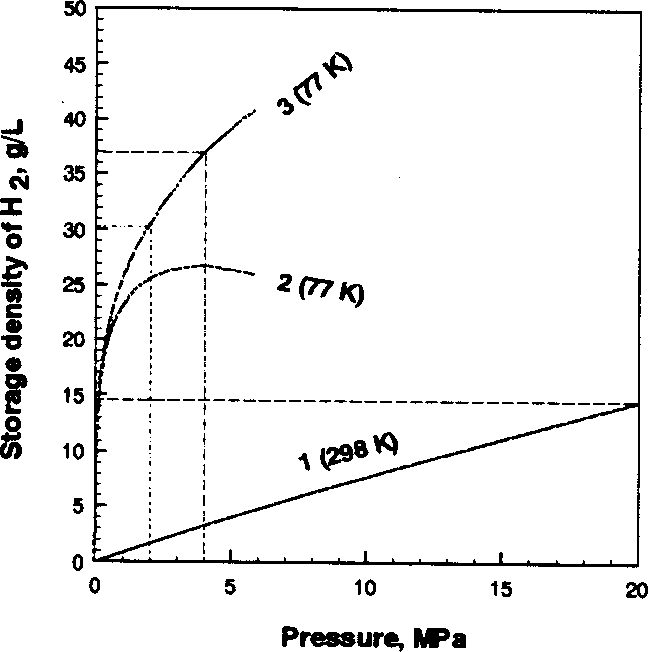

[0013] Embodiment: fill a kind of high surface activated carbon in the hydrogen storage tank of 100 liters, its adsorption storage performance to hydrogen when 77K is as attached figure 2 shown. The figure shows that the compressed hydrogen storage at room temperature can only store 14.5 grams of hydrogen per liter under the pressure of 20 MPa; if liquid nitrogen is used as the cold source for adsorption and storage of hydrogen, it can store 30.5 grams under the pressure of 2 MPa. The pressure is reduced to one-tenth, but the hydrogen storage capacity is more than doubled. The entire cylinder can store more than 3 kg of hydrogen, which is enough for a 4-seater car driven by a fuel cell to travel 400 kilometers. If it is used in a large hydrogen transport vehicle, 10m 3 The storage tank can store more than 300 kilograms of hydrogen, which is equivalent to about 4000m 3 Atmospheric pressure hydrogen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com