Gas carbon dioxide liquefaction method

A technology of liquid carbon dioxide and carbon dioxide, which is applied in the field of gas processing, can solve problems such as complex process, poor safety, and large investment in equipment, and achieve the effects of facilitating liquefaction, improving safety, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

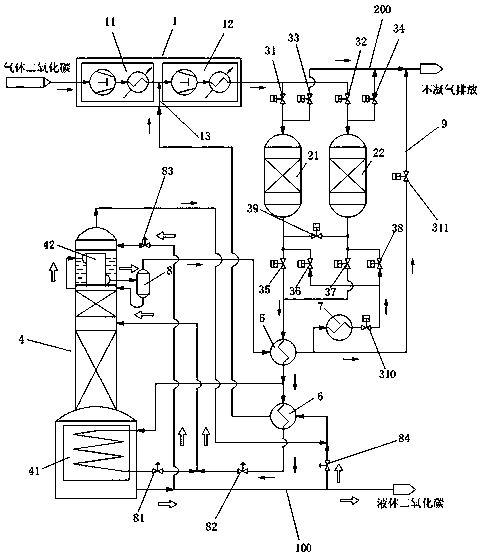

[0026] The present invention will be further described in detail below with reference to the accompanying drawings and examples. In the figure, the single arrow indicates the direction of gaseous carbon dioxide or non-condensable gas, and the hollow arrow indicates the direction of liquid carbon dioxide.

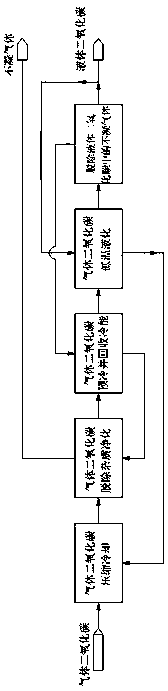

[0027] Such as figure 1 with figure 2 Shown, a kind of gaseous carbon dioxide liquefaction method of the present invention comprises the following steps:

[0028] 1) Compression and cooling of carbon dioxide feed gas

[0029] After the gaseous carbon dioxide containing impurities is continuously compressed and cooled by the first stage compressor 11 and the second stage compressor 12 of the feed gas compressor 1, the pressure of the gaseous carbon dioxide is increased and the temperature of the gaseous carbon dioxide is lowered. Among them, the outlet pressure of the first stage compressor is controlled at 0.8~0.9MPa, and the temperature is controlled at 35°C; an inlet ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com