A method for direct liquefaction of biomass

一种生物质、直接的技术,应用在化学仪器和方法、分离方法、生物燃料等方向,能够解决轻质油中残渣固含量高、浪费液体物质、影响液体物质收率等问题,达到提高液体收率、提高收率、降低残渣固含量的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

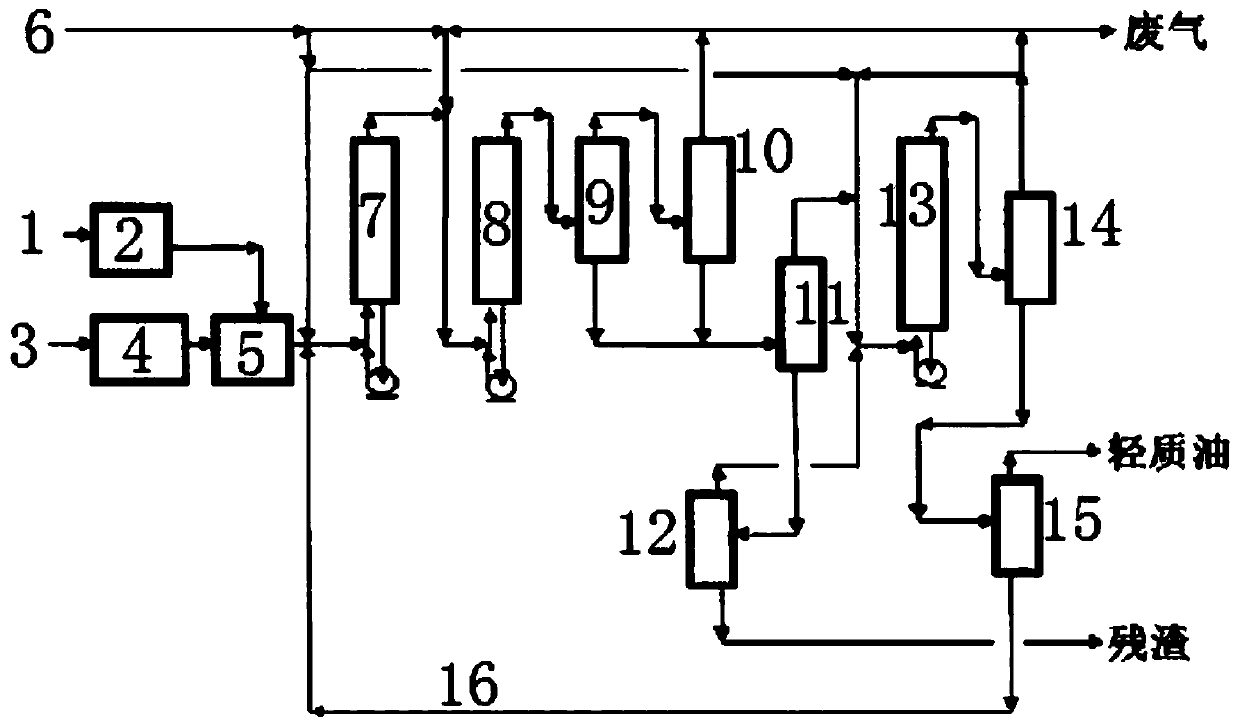

[0073] The method for direct liquefaction of biomass provided by the embodiments of the present invention comprises the following steps:

[0074] (1) The biomass 1 enters the biomass pretreatment device 2 to be dried and pulverized sequentially to obtain pulverized materials with a particle size of 10 μm, wherein the pulverized materials are wheat straw particles;

[0075] (2) The hydrogenation catalyst raw material 3 enters the hydrogenation catalyst preparation device 4 for loading, and obtains a hydrogenation catalyst (its particle size is 20 μm, and the loading capacity is 15 wt %) loaded with Mo oxide and Ni oxide on the amorphous alumina. , mixing the hydrogenation catalyst, the pulverized material and sulfur in the biomass slurry preparation device 5 at a mass ratio of 3:100:0.3 to obtain the mixed material;

[0076] (3) mixing the mixture with a hydrogen-donating solvent to obtain a biomass slurry with a solid content of 25 wt%, wherein the hydrogen-donating solvent is...

Embodiment 2

[0085] The method for direct liquefaction of biomass provided by the embodiments of the present invention comprises the following steps:

[0086] (1) The biomass 1 enters the biomass pretreatment device 2 to be dried and pulverized sequentially to obtain pulverized materials with a particle size of 100 μm, wherein the pulverized materials are reed straw particles;

[0087] (2) Hydrogenation catalyst raw material 3 enters in hydrogenation catalyst preparation device 4 and carries out loading, obtains the hydrogenation catalyst (its particle size is 100 μ m-150 μ m, and loading capacity is 10wt) that is loaded with W oxide and Ni oxide on the amorphous alumina %), mixing the hydrogenation catalyst, the pulverized material and sulfur in the biomass slurry preparation device 5 in a mass ratio of 1:100:0.4 to obtain a mixed material;

[0088] (3) mixing the mixture with a hydrogen-donating solvent to obtain a biomass slurry with a solid content of 10 wt%, wherein the hydrogen-donat...

Embodiment 3

[0097] The method for direct liquefaction of biomass provided by the embodiments of the present invention comprises the following steps:

[0098] (1) The biomass 1 enters the biomass pretreatment device 2 and is sequentially dried and pulverized to obtain pulverized materials with a particle size of 500 μm, wherein the pulverized materials are reed straw particles;

[0099] (2) The hydrogenation catalyst raw material 3 enters the hydrogenation catalyst preparation device 4 for loading, and obtains a hydrogenation catalyst (its particle size is 100 μm-150 μm, and the load capacity is 25wt) that is loaded with Pd oxide and Ni oxide on the amorphous alumina %), mixing the hydrogenation catalyst, amorphous iron oxide, the pulverized material and sulfur in the biomass slurry preparation device 5 in a mass ratio of 2:2:100:0.3 to obtain the mixed material;

[0100] (3) mixing the mixture with a hydrogen-donating solvent to obtain a biomass slurry with a solid content of 50 wt%, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com