Patents

Literature

71results about How to "Avoid serious harm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enzyme microbial organic fertilizer and preparation method thereof

InactiveCN102010241AWell-developed crop rootsImprove qualityBio-organic fraction processingOrganic fertiliser preparationPhosphateInsect pest

The invention discloses an enzyme microbial organic fertilizer and a preparation method thereof. The enzyme microbial organic fertilizer comprises the following components of 40t of fowl manure, 14t of pig manure, 5t of albumen powder, 5t of Chinese wood oil, 10t of peat, 15t of straw powder, 3t of urea, 5t of monoammonium phosphate, 2t of potassium sulfate, 1t of enzyme element expanding agent, 0.2t of rice bran, 0.2t of red sugar and 0.1t of trace elements. The enzyme microbial organic fertilizer can ensure high natural soil building active bacteria, is used for loosening the soil, forms a crumble structure for achieving the effect of remaining water and fertilizing soil, improves the soil, ensures that the root system of crops is developed, can increase the yield and the income, improves the quality of the crops, and is a prophase guarantee of the sustainable development ecological agriculture. Meanwhile, the enzyme microbial organic fertilizer is suitable for a base fertilizer or additional fertilizer of various crops, fruits and vegetables, has remarkable effects of lowering the plant diseases and insect pests and resisting the droop, and is an ecotype environmental-friendly fertilizer for producing organic foods.

Owner:云南益吉生态肥料有限公司

Electrolyte and method for electrolyzing and refining crude lead

InactiveCN104746098AAvoid serious harmAvoid heavy pollutionPhotography auxillary processesHydrometallurgyMethanesulfonic acid

The invention relates to electrolyte and a method for electrolyzing and refining crude lead, and belongs to the technical field of wet-process metallurgy. The electrolyte electrolyzing and refining crude lead is of a methylsulphonic acid solution system comprising methyl lead sulfonate and free methyl sulfonic acid, wherein the concentration of Pb<2+> is 50-200g / L, and the concentration of the free methyl sulfonic acid is 50-160g / L. The method comprises the following steps: placing a solution system electrolyte comprising the methyl lead sulfonate and free methyl sulfonic acid, a to-be-refined crude lead anode plate and a cathode plate into an electrolytic cell, then, applying direct-current power, adding an additive comprising one or a mixture of animal glue, lignosulfonate, aloin and beta-naphthol into the electrolyte to electrolyze for 2-7 days so as to generate cathode lead and anode mud, obtaining national-standard 1# lead ingot after melting and casting cathode lead, performing washing and filter pressing on the anode mud, and then feeding the anode mud to a noble metal extracting process. According to the method, a brand-new methanesulfonic acid solution system is adopted as an electrolyte for electrolysis, so that the method has the characteristic of being remarkable in environment-friendly advantage.

Owner:KUNMING UNIV OF SCI & TECH

Efficient microbial agent for resisting insects, preventing diseases, increasing fertility and promoting growth

The invention discloses an efficient microbial agent for resisting insects, preventing diseases, increasing fertility and promoting growth. In order to solve the technical problem that the existing microbial agent does not have ideal effects of resisting insects, preventing diseases, increasing the fertility and promoting the growth. The technical scheme adopted by the invention is as follows: the microbial agent is obtained by implanting soybean protein, amino acid, fulvic acid and a medium trace element which are used as carriers into a mixture of ferment bacteria, endogenous bacillus and beauveria bassiana and fermenting for 48 to 60 hours at the temperature of between 38 and 46 DEG C; and diseases and insects are prevented and controlled through antibiotics and chitinase generated in the bacteria fermentation process according to the technical principle. The microbial agent has the technical effects that the soil can be improved, and the root system is stimulated to grow, so that crops well absorb required nutrients; the microbial agent has a good effect of resisting the infringement of root-knot nematode and stem eelworms, has quite positive promoting effects of swelling fruits and increasing the sweetness, has obvious promoting effects on crop growth, plant reinforcement, yellowing resistance, lodging resistance and rotting resistance, and integrates insect resistance, disease prevention, fertility increase and growth promotion; and the labor intensity is reduced, manpower and material resources are saved, and the production cost is reduced.

Owner:河北新世纪周天生物科技有限公司

Soft low density halogen free low-smoke flame retardation polyolefin cable material and preparation method thereof

InactiveCN103254492AAvoid serious harmImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a soft low density halogen free low-smoke flame retardation polyolefin cable material and preparation method thereof, and the material comprises the following components: 80-90 parts by weight of ethane-vinyl acetate copolymer, 10-20 parts by weight of linear low density polyethylene, 65-130 parts by weight of inorganic fire retardant after surface treatment, 10-30 parts by weight of synergist, 10-20 parts by weight of high-molecular compatilizer, 0.9-1.5 parts by weight of anti-oxidant, 0.5-4 parts by weight of modified capsaicin, and 1-2 parts by weight of processing auxiliary agent. The invention has the advantages of superior flame retardation performance, excellent toughness and bendability resistance; low-density, low-smoke, low-corrosion, low-toxicity and environment friendly; good processing property and brightened surface of extrudate.

Owner:扬州市交大工业技术研究院有限公司

Harmless management method for diseases, insects and weeds at tea tree seedling stage of organic tea garden

ActiveCN103461038AAchieve the purpose of organic productionProtect environmentPlant protectionCordycepsPesticide residue

The invention discloses a harmless management method for diseases, insects and weeds at a tea tree seedling stage of an organic tea garden and belongs to the technical field of tea leaf ecological production. The method specifically comprises four steps of manually weeding, covering light reflecting weeding films, hanging yellow sticky boards and releasing preying acarus. The method is adopted for production management, chemical herbicides need not to be applied for weeding at the seedling stage of the organic tea garden, chemical pesticides are not used for insect prevention, the labor cost of weeding at the seedling stage can be greatly reduced, no pesticide residue exist, environment pollution does not exist, and the production of organic tea is really realized.

Owner:INST OF PLANT PROTECTION FAAS +2

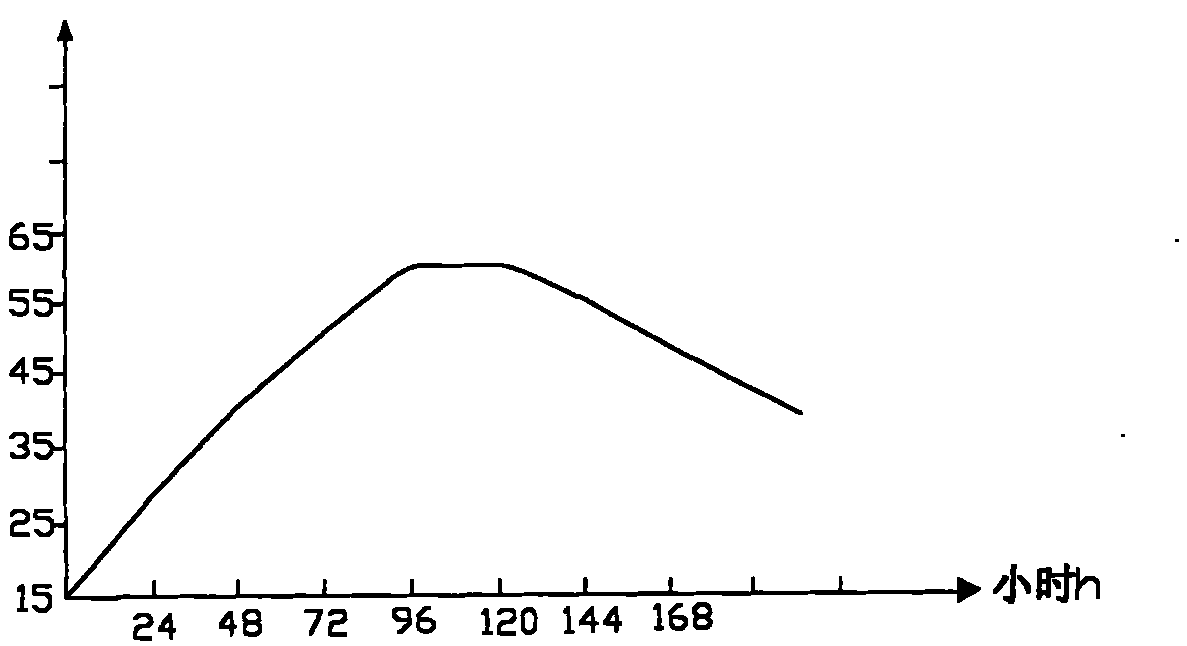

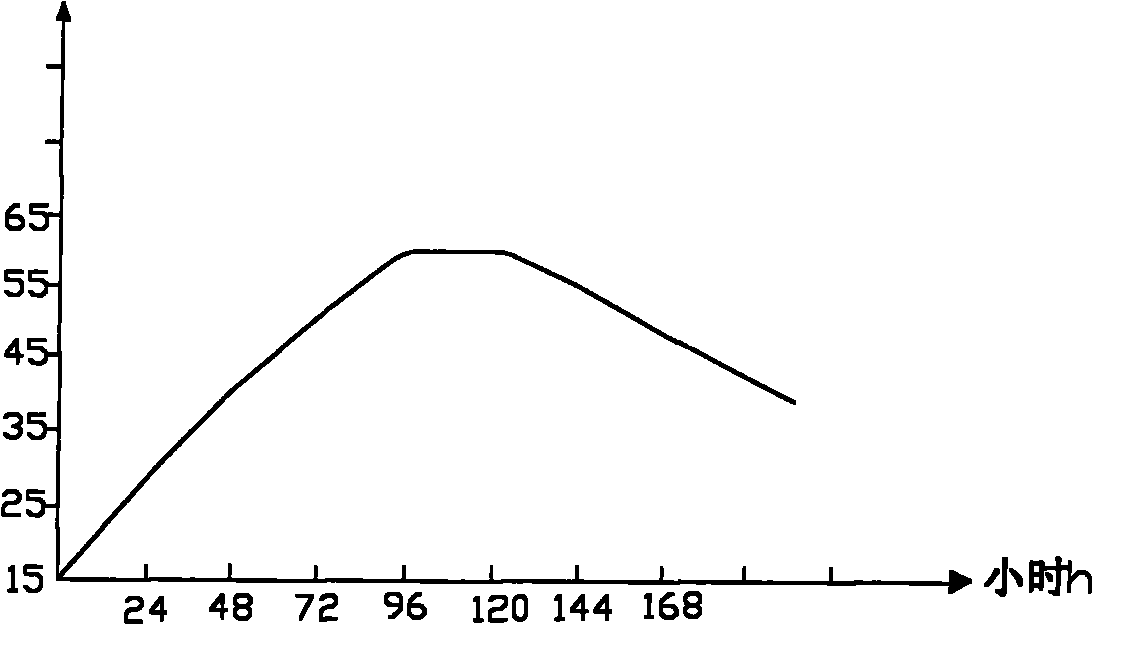

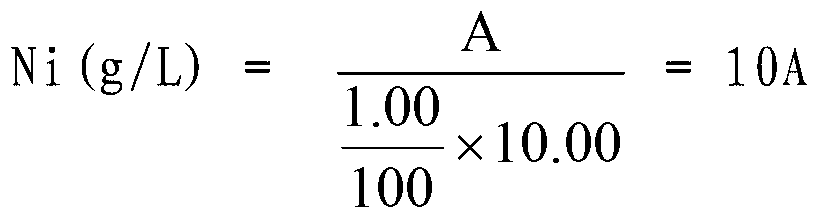

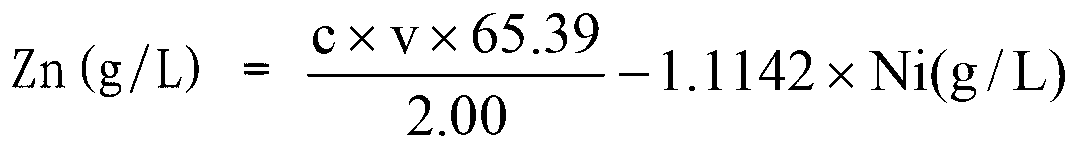

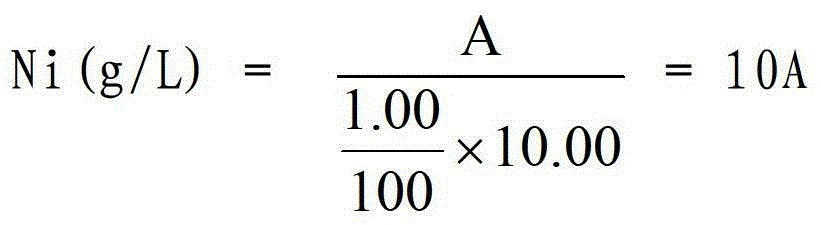

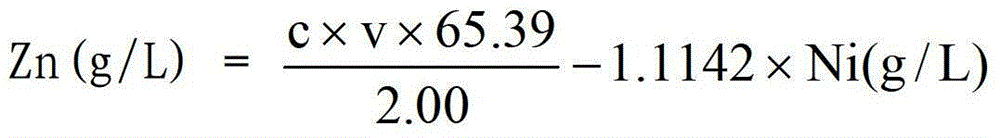

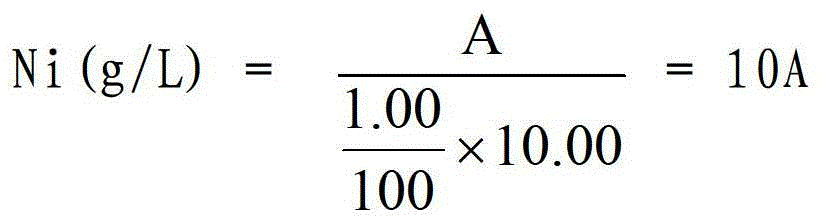

Method for measuring zinc and nickel contents in zinc-nickel alloy electroplating solution

ActiveCN103344641AAvoid serious harmGuaranteed sensitive to color changeMaterial analysis by observing effect on chemical indicatorSodium acetateImpurity

The invention relates to a method for measuring zinc and nickel contents in a zinc-nickel alloy electroplating solution and belongs to the technical field of methods for analyzing the electroplating solution. The method is mainly and technically characterized by comprising the following steps of: reacting dimethylglyoxime and Ni4+ to form a red soluble complex in the presence of an oxidant ammonium persulfate, adding sodium tartrate to eliminate iron and other impurity interference, and measuring the content of nickel in the zinc-nickel alloy electroplating solution by employing a colorimetric method; adding tartaric acid to mask iron and other impurities, with CuY-PAN as an indicator, titrating in an acetic acid-sodium acetate buffer solution with the PH being 5.5 by using an ethylene diamine tetraacetic acid (EDTA) standard titration solution by utilizing a replacement titration principle, calculating the total contents of zinc and nickel in the zinc-nickel alloy electroplating solution, and subtracting the nickel content from the total contents of zinc and nickel to solve the zinc content in the zinc-nickel alloy electroplating solution. The measurement method has the characteristics of simpleness in detection, convenient, rapid and environment-friendly detection process, low cost, accurate and consistent detection result and the like.

Owner:江南工业集团有限公司

Mouse-proof cable material containing modified capsaicin and its preparing method

InactiveCN1971769AAvoid bitesAvoid serious harmBiocidePlastic/resin/waxes insulatorsCapsaicinOrganic matter

This invention discloses one anti-mouse cable materials with improved pepper element, which comprises 0.3 to 2 percentage improved pepper element, wherein, the said improved pepper element uses organic subject as its cover; the cable materials can make mouse mucous membrane of mouth and gustatory nerves for strong stimulation tiring of nibble.

Owner:上海新上化高分子材料有限公司

Method and system for co-processing waste incineration fly ash and zinc-containing dust mud of steel plant

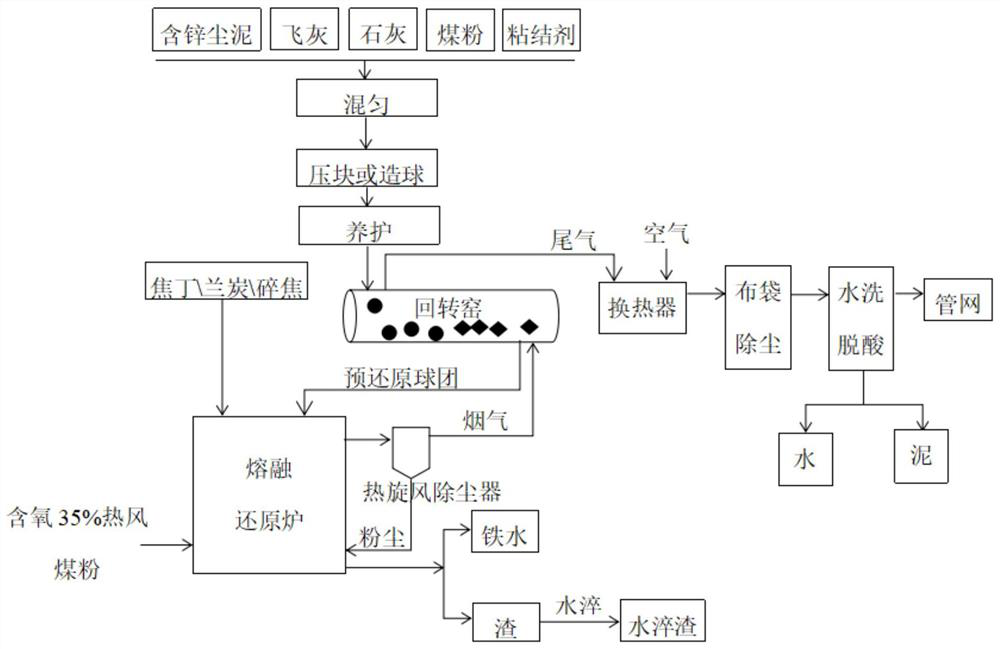

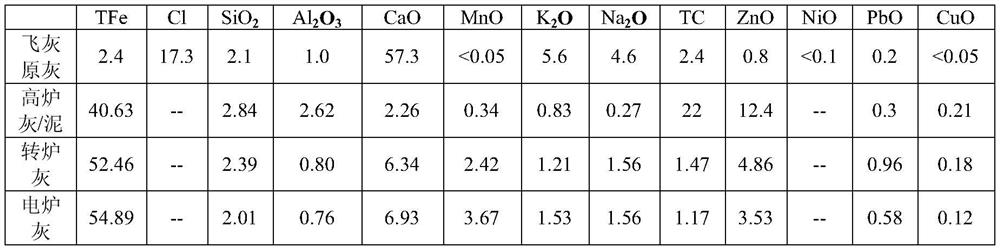

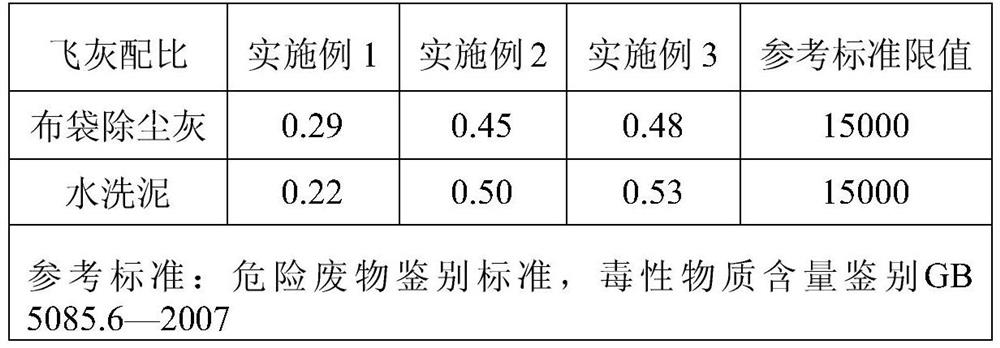

ActiveCN112442589APromote resource utilizationQualified Chemical CompositionRotary drum furnacesSlagCo-processing

The invention discloses a method and a system for co-processing waste incineration fly ash and zinc-containing dust mud of a steel mill. The method comprises the following steps: 1, adding 1.5% of lime and pulverized coal into the fly ash and the dust mud according to the slagging alkalinity of 1.1-1.3, the total carbon content of 2-8% and the binder ratio of 2-5% for proportioning, wherein the fly ash accounts for 5-20% of the dust mud; 2, adding water into the mixture, extruding into blocks or pelletizing, and curing until the strength meets the requirement; 3, adding the agglomerates or pellets into a rotary kiln, and introducing high-temperature coal gas to pre-reduce the agglomerates or pellets in the kiln; 4, continuously adding the pre-reduced agglomerates or pellets into a smeltingreduction furnace, and meanwhile distributing main fuel such as nut coke within the range of the material surface radius of the smelting reduction furnace; blowing hot air with the oxygen concentration of 35% from a tuyere of a reduction furnace, and spraying pulverized coal through the tuyere; and carrying out further indirect reduction, softening melting and FeO-C final reduction on the pre-reduced pellets in a coke bed in the reduction furnace to generate molten iron and furnace slag. According to the main purpose, the fly ash is cooperatively treated and utilized by combining the advantages of a metallurgical furnace for treating zinc-containing dust according to the chemical components of the fly ash.

Owner:BAOSHAN IRON & STEEL CO LTD

Biosafety intelligent conveying control method and system based on radio frequency identification and location technology

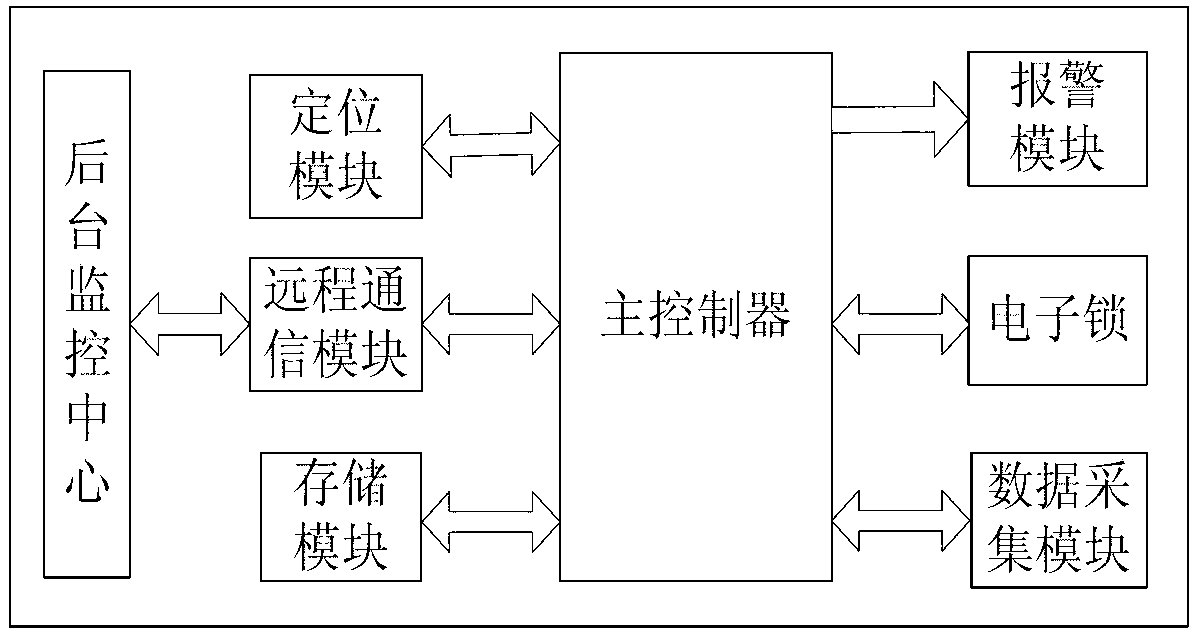

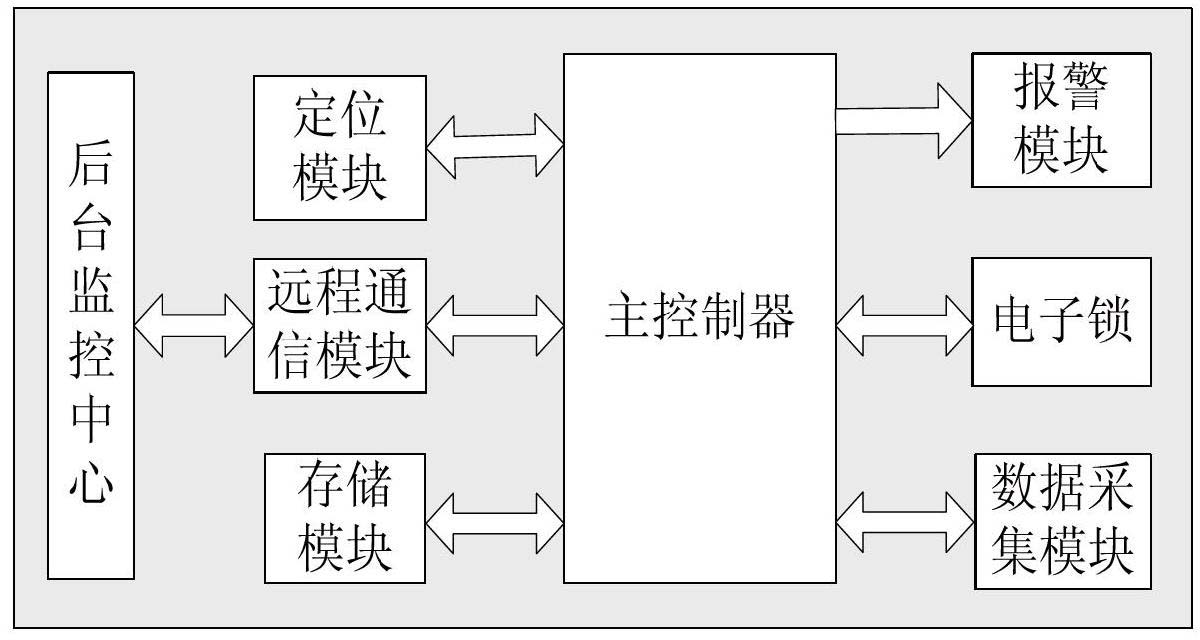

InactiveCN102708531AAdd locking functionAdd mutual authentication functionData processing applicationsAlarmsGeolocationLocation technology

The invention relates to a biosafety intelligent conveying control method and system based on a radio frequency identification and location technology.. The biosafety intelligent conveying control method comprises the following control steps of: 1, storing a biological sample parameter in a storage module, acquiring biological sample information by a data acquiring module, comparing the acquired biological sample information with the biological sample parameter stored in the storage module by a main controller, sending a comparing result to a background monitoring center, and setting an electronic lock action by the background monitoring center according to the biological sample information or abnormal alarm information; and 2, controlling a location module to acquire geographic position information of a conveying device by the main controller, and sending the geographic position information to the background monitoring center by a remote communication module, and setting an electronic lock action by the background monitoring center according to the geographic position information. According to the invention, the geographic position information of the conveying device can be well determined, and the managing personnel conveniently monitor a biological conveying device system in real time.

Owner:CHINA ELECTRONICS CORP 6TH RES INST

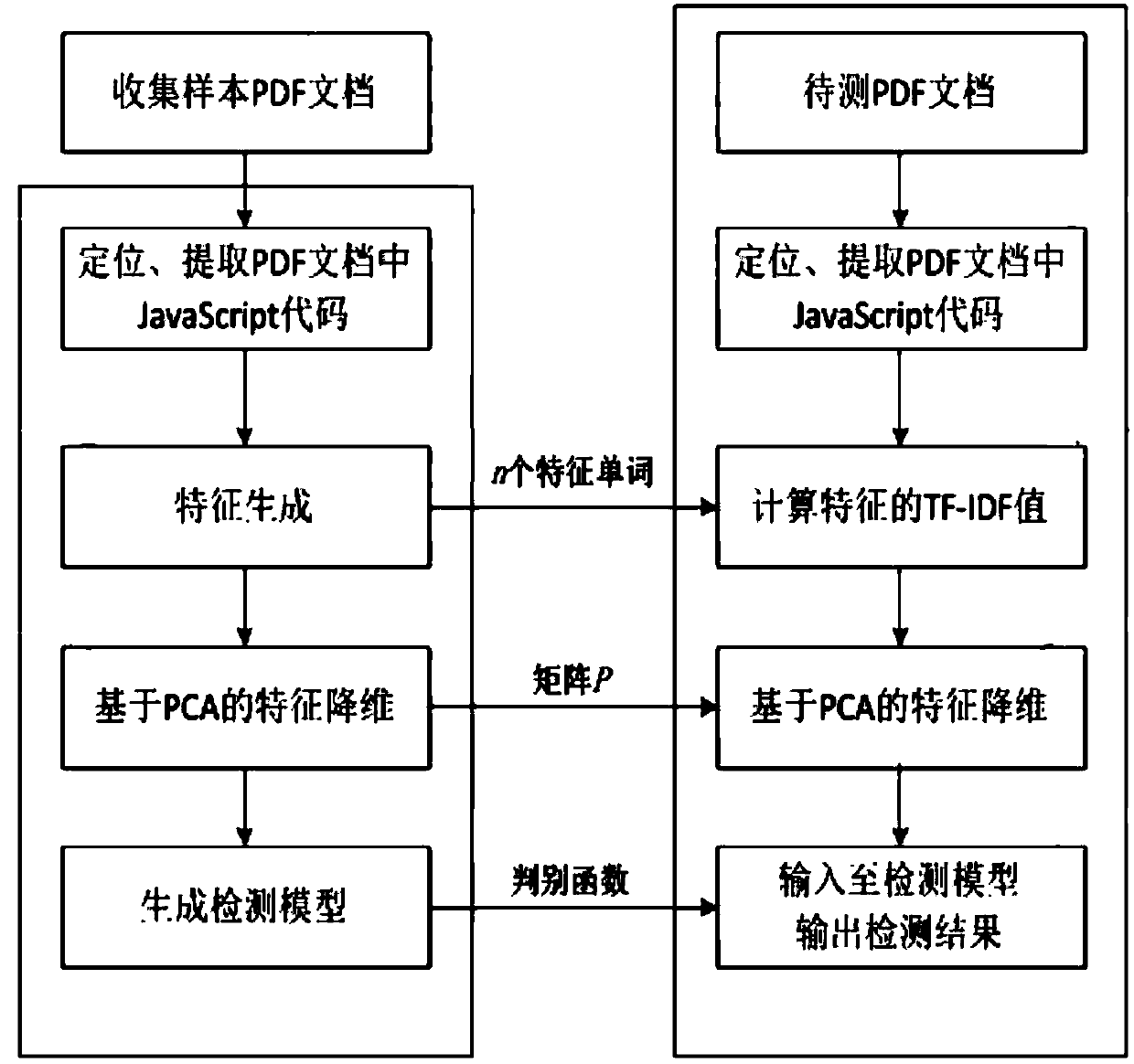

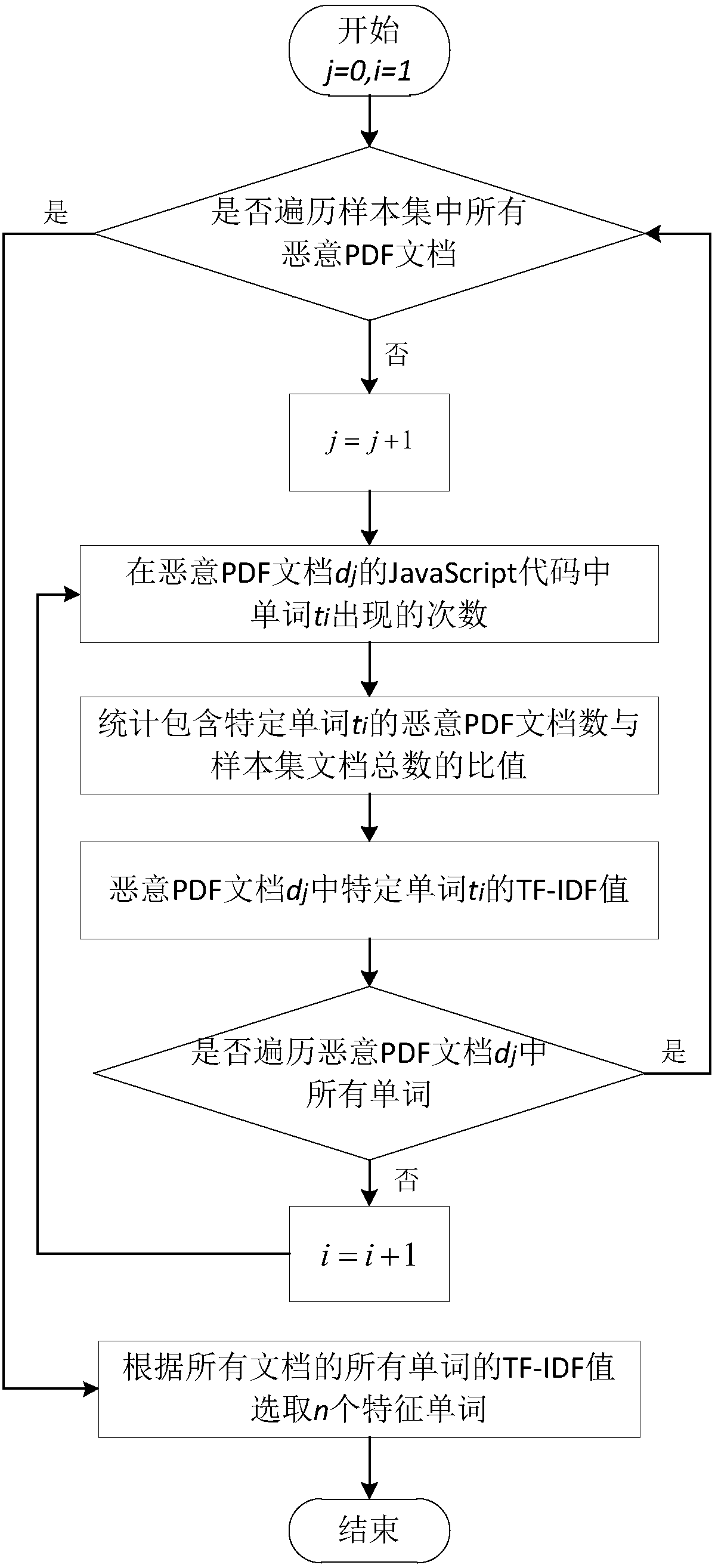

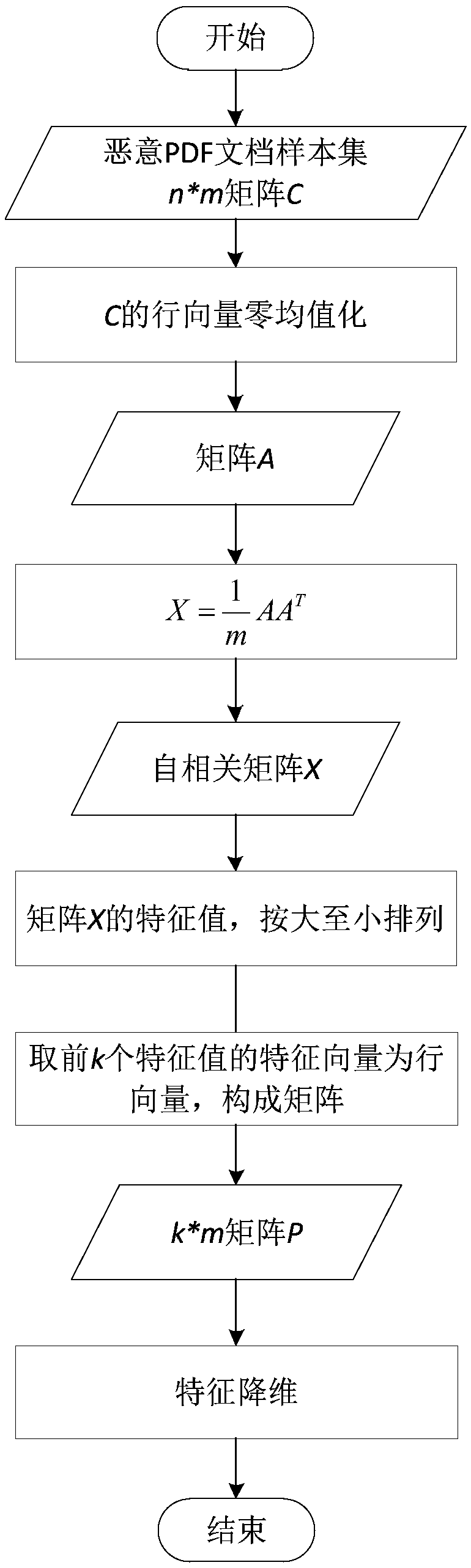

Malicious PDF document detection method based on TF-IDF algorithm and SVDD algorithm

ActiveCN107944273AAccurate and Efficient AnalysisAccurate and Efficient DetectionPlatform integrity maintainanceDocument preparationDocumentation

The invention discloses a malicious PDF document detection method based on a TF-IDF algorithm and an SVDD algorithm. The method includes the following steps: 1) collecting malicious PDF documents andnormal PDF documents as sample sets; 2) generating a detection model capable of detecting the malicious PDF documents; and 3) detecting PDF documents to be detected. The malicious PDF documents and the normal PDF documents are collected as the sample sets in the step 1); suspicious JavaScript codes contained in the malicious PDF documents in the sample sets are positioned and extracted in the step2), the TF-IDF algorithm is adopted to perform malicious PDF document feature generation, and the SVDD algorithm is adopted to generate the PDF malicious document detection model and a discriminationfunction; and in the step 3), the judgment on the PDF documents to be detected through the detection model is achieved. According to the malicious PDF document detection method, the malicious PDF documents can be analyzed and detected accurately and efficiently, and serious hazards posed on personal and company property and privacy security by the malicious PDF documents are avoided.

Owner:GUIZHOU AEROSPACE INST OF MEASURING & TESTING TECH

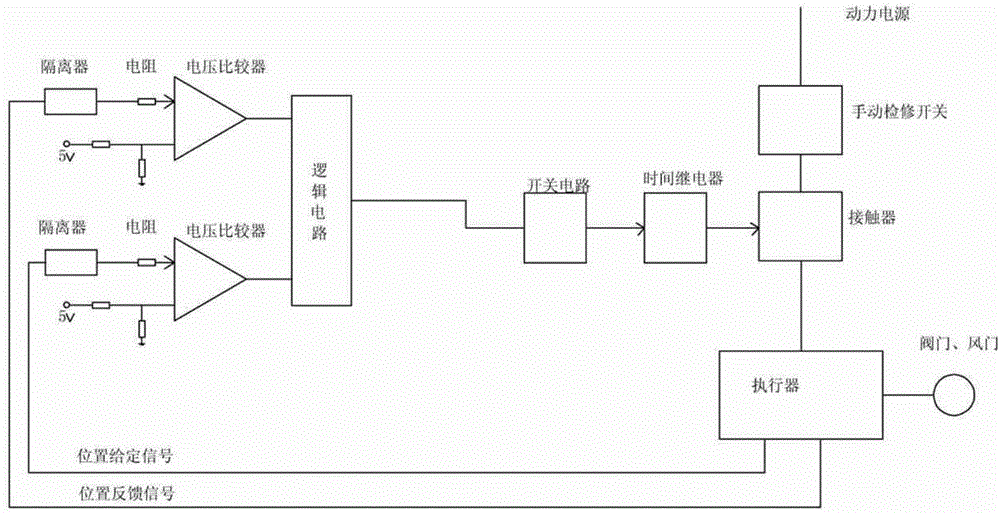

Automatic detecting and power off device of actuator inner failure

ActiveCN103914061AIncrease self-diagnosis functionAvoid serious harmElectric testing/monitoringControl signalVoltage divider

The invention relates to the technical field of actuators, in particular to an automatic detecting and power off device of actuator inner failure. The device is composed of a detecting circuit, a logic judging circuit, a power off control circuit and a contact device which are connected to an actuator through a signal line in sequence, the contact device is connected between a manual detecting switch and the actuator, the detecting circuit is composed of a control signal detecting circuit and a position feedback signal detecting circuit, the control signal detecting circuit is composed of a separating device, a sampling resistor, a voltage divider, and a comparator which are connected to the actuator through a control signal line, and the power off control circuit is composed of a switch circuit and a time relay. The automatic detecting and power off device of actuator inner failure has the advantages that an actuator power source can be powered off automatically, so that the failed actuator is separated from production. When the power source is powered off, opening of various valves and dampers arranged on the actuator can be controlled manually. Serious harm to production caused by actuator failure can be avoided.

Owner:ANSTEEL GRP MINING CO LTD

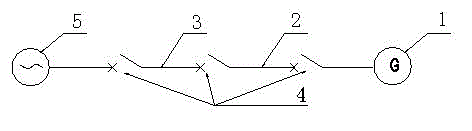

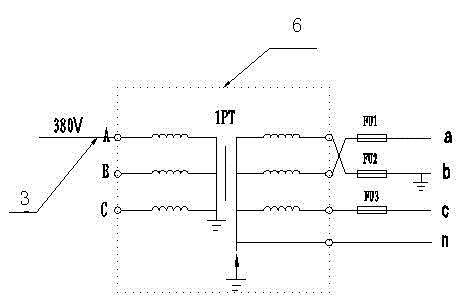

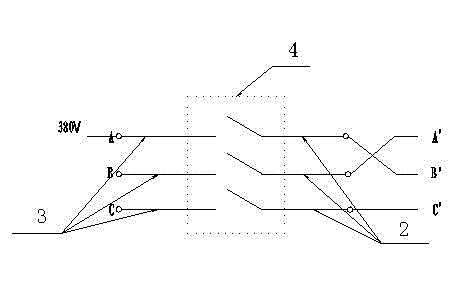

Debugging method of phase sequences of loops at two sides of synchronization point before commissioning of generator set

ActiveCN102944762AGuaranteed accuracyGuaranteed reliabilityPhase sequence/synchronism indicationLow voltagePower grid

The invention discloses a debugging method of phase sequences of loops at two sides of a synchronization point before commissioning of a generator set. Before first synchronization grid connection of the generator set, the corresponding relation between primary phase sequences and secondary phase sequences at the two sides of the synchronization point, the primary phase sequence at the two sides of the synchronization point and the secondary phase sequences at the two sides of the synchronization point are detected and debugged by a protector debugging instrument, a phase sequence meter and a universal meter under a 380-V low-voltage power supply, a power-grid-side high-voltage power supply or a generator self-generating electricity accessing state. According to the debugging method of the phase sequences of the loops at the two sides of the synchronization point before the commissioning of the generator set, the phase sequences on a synchronization voltage miniature bus can be guaranteed to be real reflection of primary loops, the phase sequences of the primary loops at the two sides of the synchronization point and secondary voltage comparison loops are adjusted to be coincident in an unmistakable manner, the serious injury brought by non-synchronization grid connection caused by different phase sequences is avoided; and the condition that the grid connection cannot be carried out because the phase sequences are detected to be inconsistent after the impulse starting of the generator is avoided, and the accuracy, reliability and safety of the grid connection of the generator set are guaranteed.

Owner:XINYU IRON & STEEL CO LTD

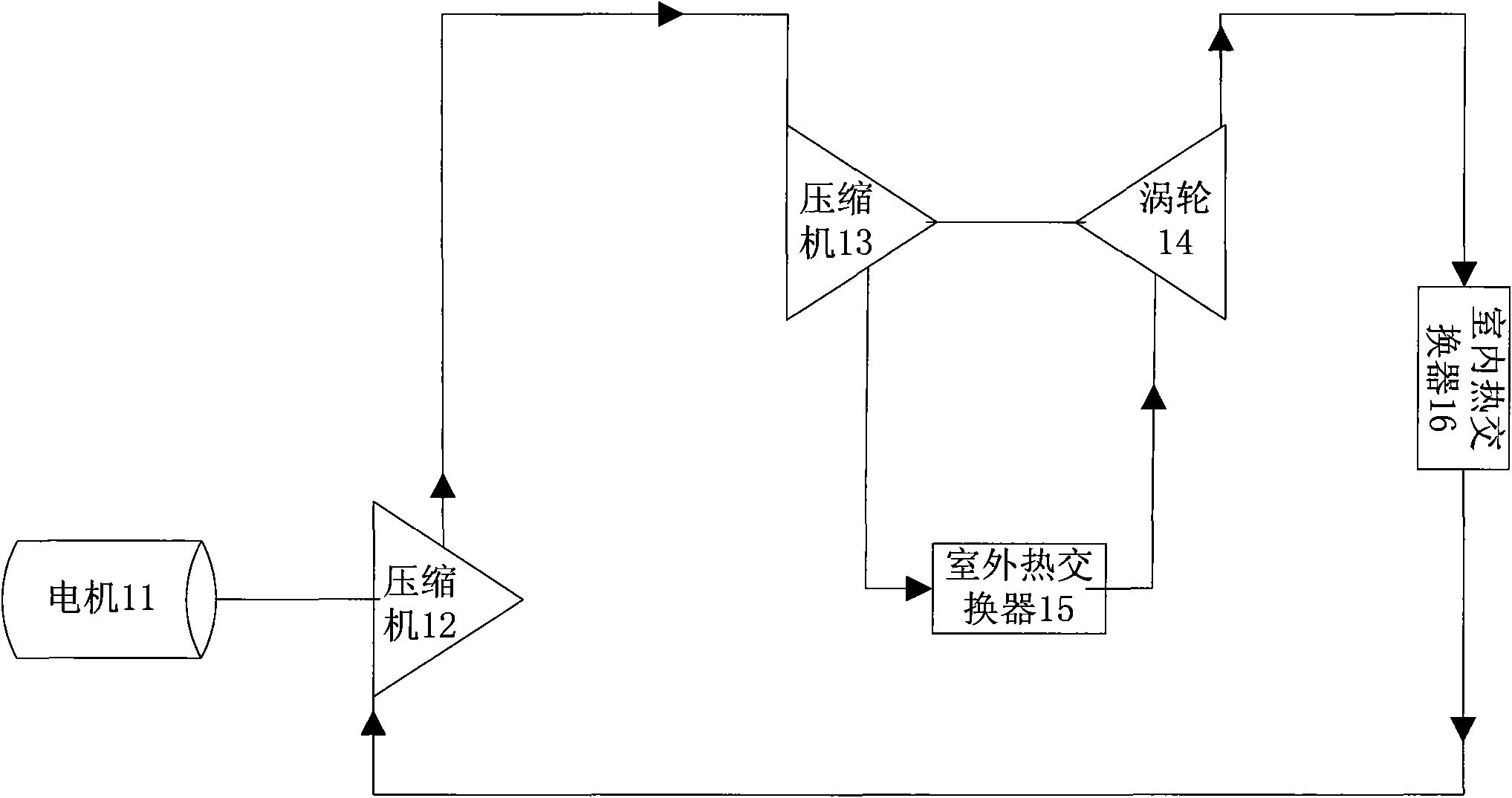

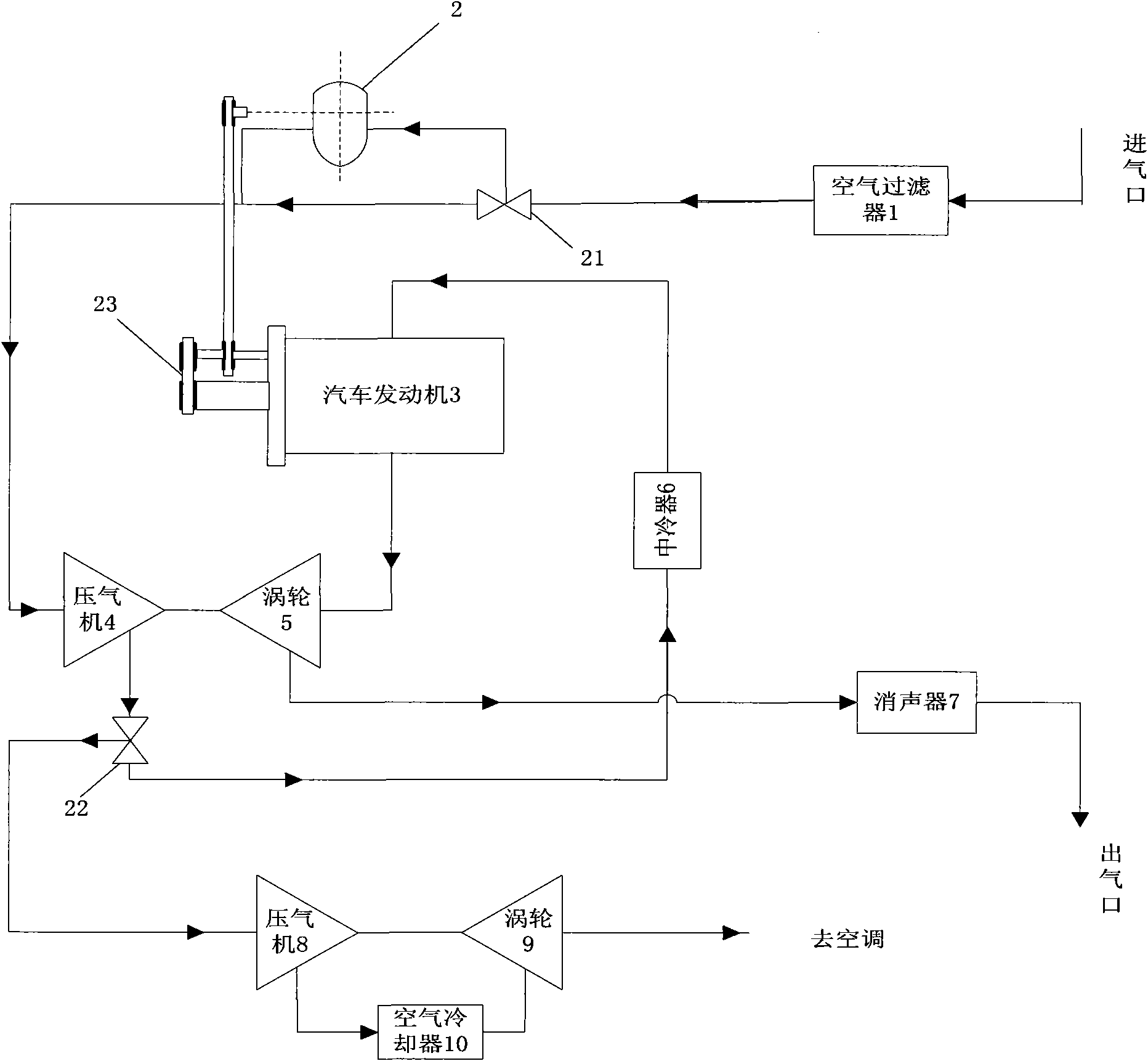

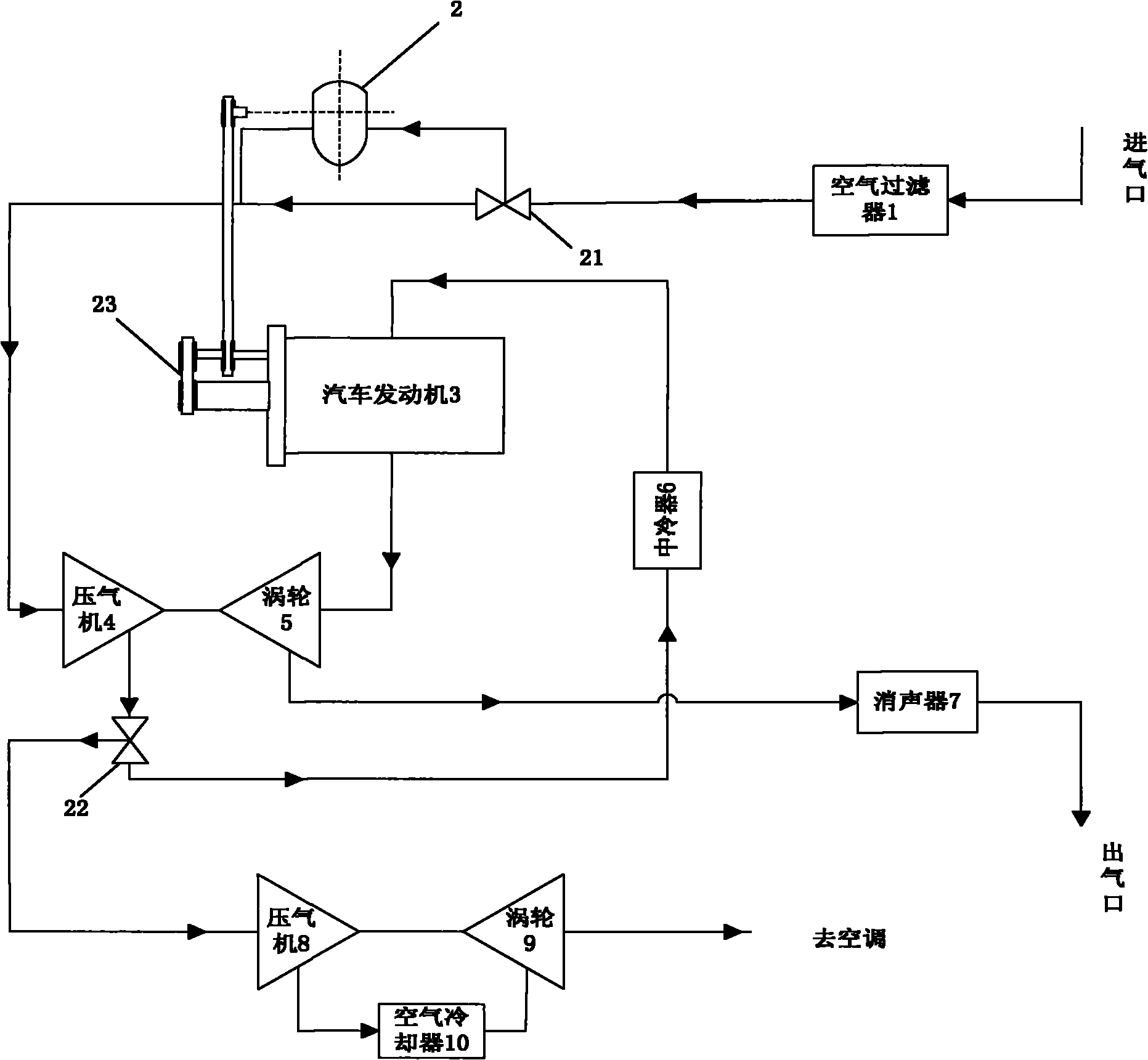

Vehicle-mounted air refrigeration cycle system and method suitable for large vehicles

InactiveCN102398495AImprove low work efficiencySolve bottlenecksAir-treating devicesInternal combustion piston enginesEngineeringAir conditioning

The invention discloses a refrigeration system related to an engine. Partial high pressure air is led out of a turbocharged engine to serve as a high pressure air source of an air refrigeration cycle system to drive an air-conditioning system to perform refrigeration cycle. The air refrigeration cycle system consists of a three-way valve connected to an air supply pipeline of the turbocharged engine, a centrifugal-flow compressor, a radial axial turbine and an air cooler. The compressor and the turbine work coaxially, and the three-way valve is used for regulating the flow rate of turbocharged high pressure air entering the air refrigeration system. By the method, the air supercharging function and the refrigeration function of the traditional air refrigerant can be realized simultaneously, and a bottleneck of the traditional air refrigeration cycle is overcome. The invention is simple and feasible, and convenient to install and operate, and can improve the energy utilization rate of the engine.

Owner:BEIHANG UNIV

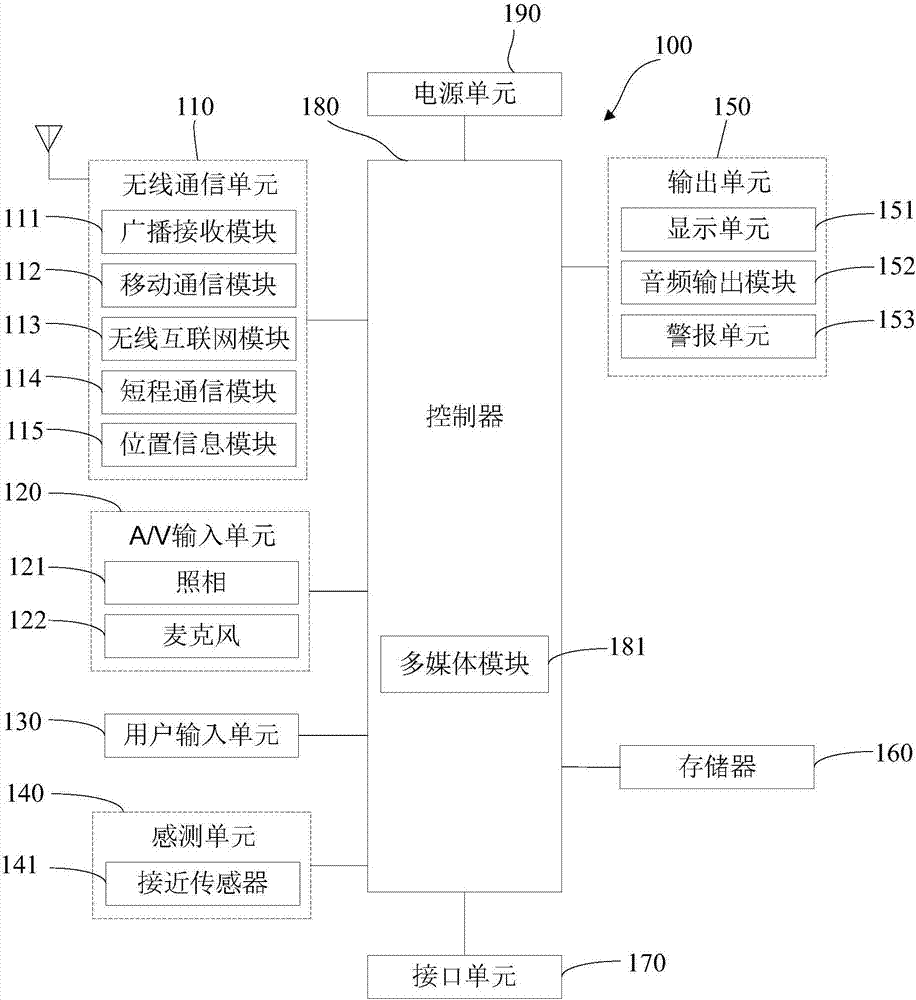

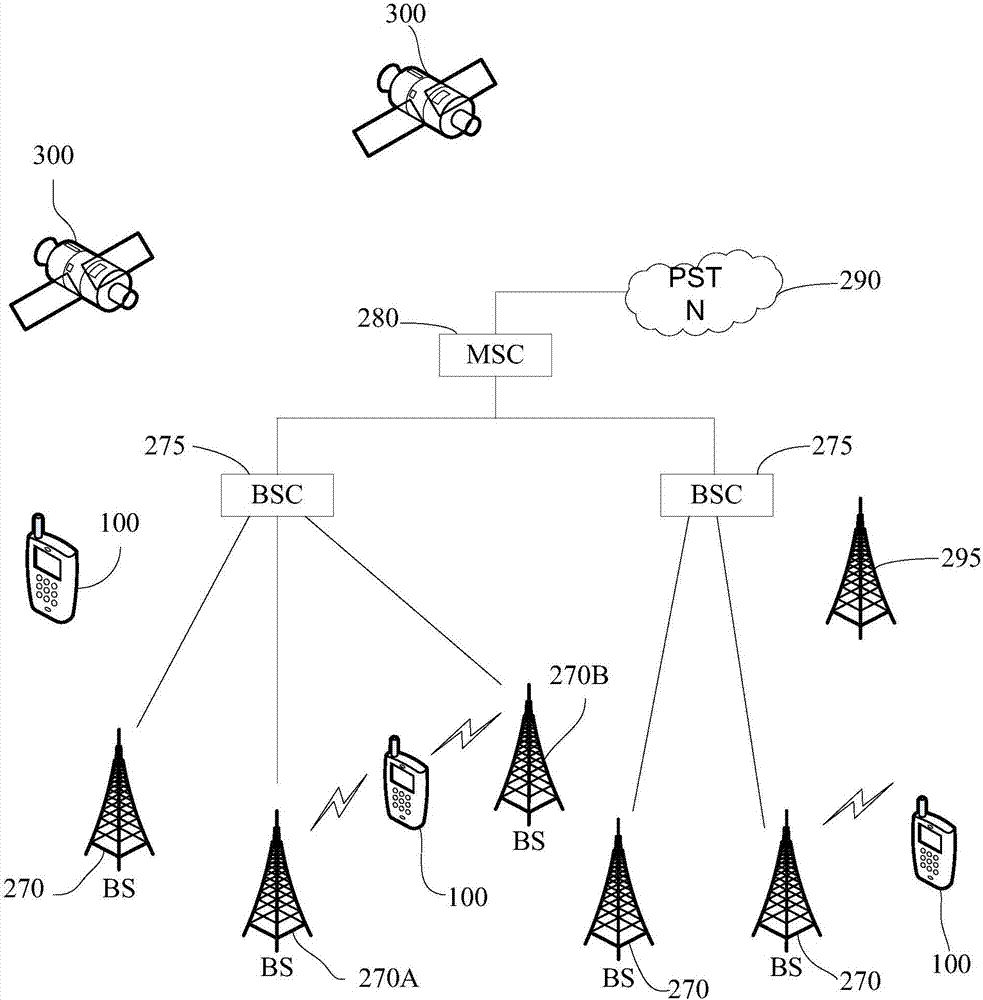

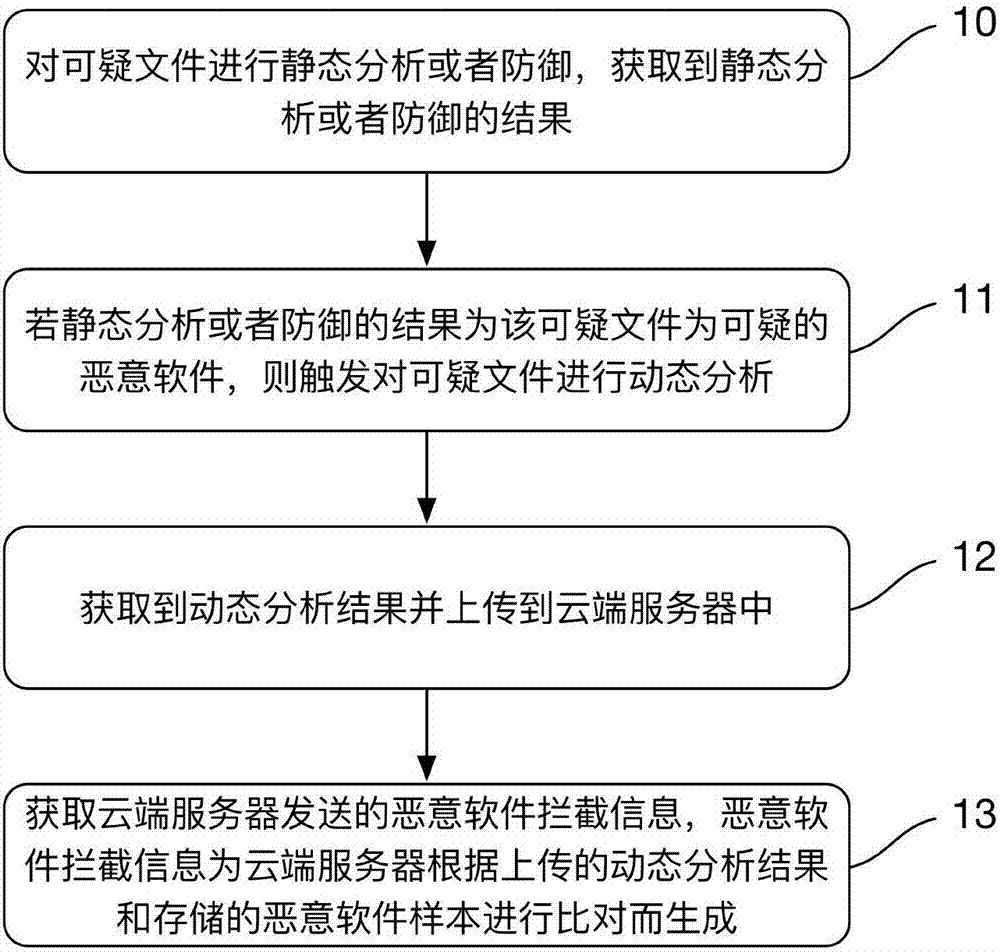

Malicious software interception method and device and terminal

InactiveCN106874765AShort time spentNo human intervention requiredPlatform integrity maintainanceMalwareSoftware

The invention discloses a malicious software interception method and device and a terminal. The method comprises the steps of conducting static analysis or defense on a suspicious file, and obtaining a static analysis or defense result; if the static analysis or defense result is that the suspicious file is suspicious malicious software, triggering dynamic analysis of the suspicious file; obtaining a dynamic analysis result and uploading the dynamic analysis result to a cloud server; obtaining malicious software interception information sent by the cloud server, wherein the malicious software interception information is generated by comparing the uploaded dynamic analysis result with a stored malicious software sample through the cloud server. Through the malicious software interception method and device and the terminal, the malicious software can be intercepted on the terminal in which threat is found, and the malicious software is prevented from further spreading to other systems and causing serious damage to the terminal; a 'patient zero' is prevented from losing all materials in a system; meanwhile, the consumed time in the interception process is very short, and manual intervention is not needed.

Owner:NUBIA TECHNOLOGY CO LTD

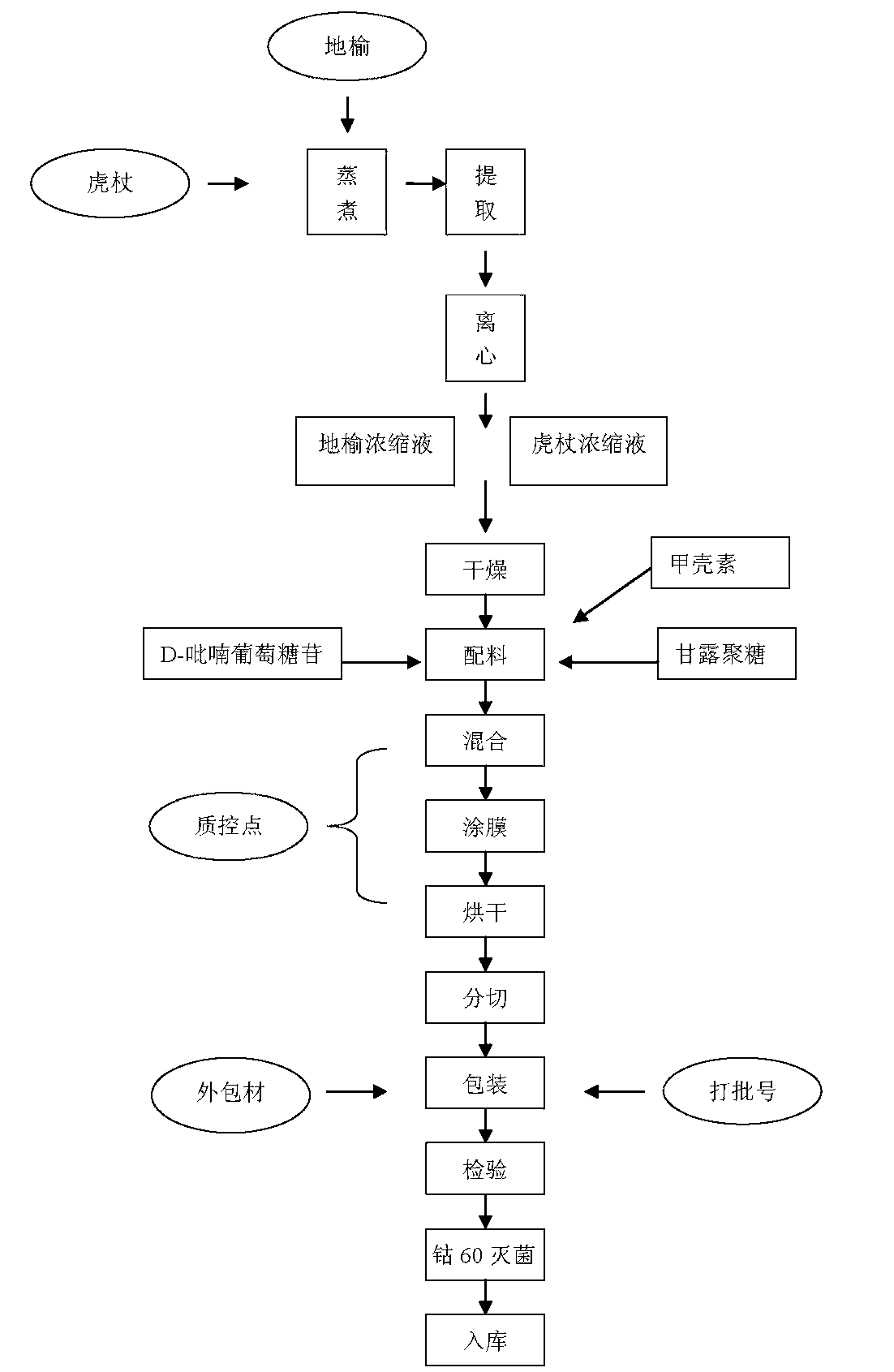

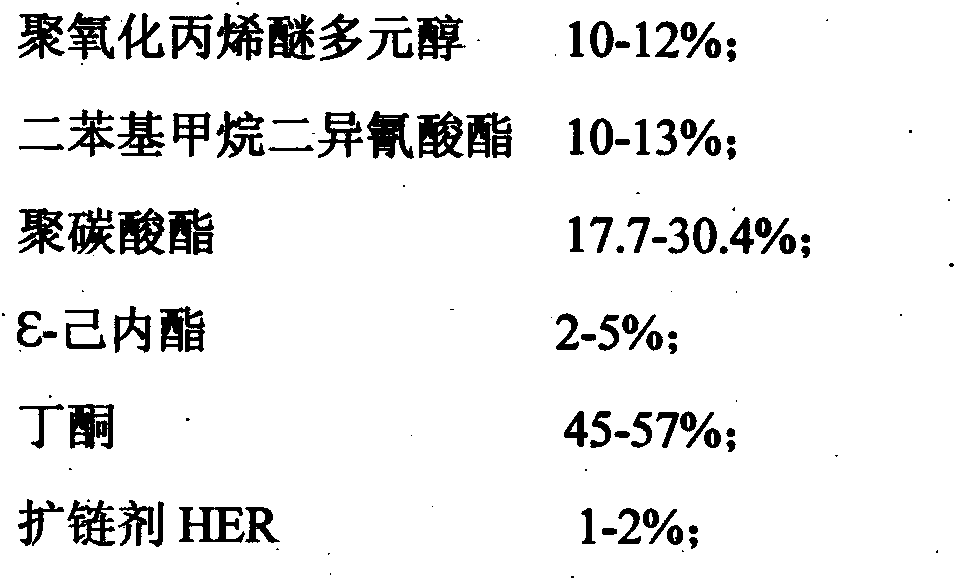

Polymer dressing and dressing patch

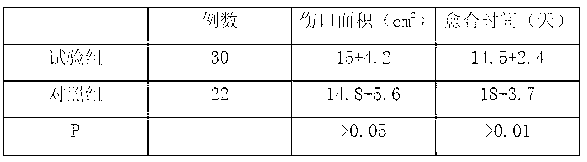

ActiveCN103007337ABlood compatibleHistocompatibilityAbsorbent padsBandagesSanguisorba officinalis RootBULK ACTIVE INGREDIENT

The invention relates to a polymer dressing and dressing patch. The dressing patch comprises a base cloth on which glue and the dressing are coated and release paper covering the glue and dressing. The dressing is prepared by mixing the following active ingredients by weight percent: 24-30% of sanguisorba officinalis root extracts, 20-27% of polygonum cuspidatum extracts, 18-25% of chitin, 12-18% of D-glucopyranoside and 10-15% of mannan. The dressing and the dressing patch can stop bleeding quickly, prevent infections, promote wound healing, reduce pains of patients, shorten the rehabilitative periods of patients and avoid pathogen harms and nerve fiber lesions.

Owner:JIAHENG MEDICAL SUPPLY JIANGSU

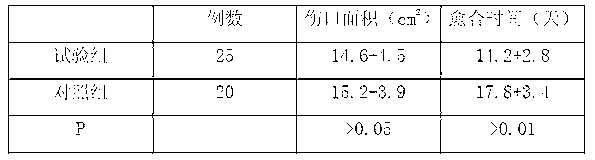

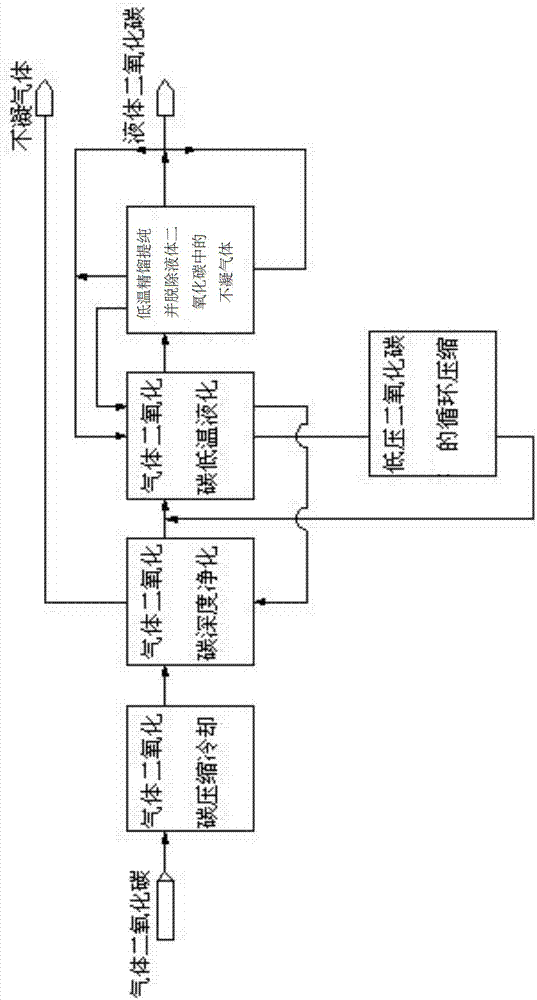

Gas carbon dioxide liquidation system and method

The invention discloses a gas carbon dioxide liquidation system and method. The system comprises a raw material gas compressor, a circulation compressor, a plurality of parallel adsorbers, a resurgent gas heater, a low-temperature heat exchanger, a rectification purification tower, a plurality of switching valves and a plurality of throttle valves. The method includes the steps that (1) carbon dioxide raw material gas is compressed and cooled; (2) gas carbon dioxide deep purification is carried out; (3) gas carbon dioxide low temperature liquidation is carried out; (4) non-condensable gas in liquid carbon dioxide is removed; and (5) low pressure carbon dioxide gas circulated compression is carried out. The gas carbon dioxide liquidation system is compact in structure, high in efficiency, small in equipment investment and running cost and high in reliability; and by means of the method, safety of the system is improved, a low temperature rectifying tower and the low-temperature heat exchanger are used for replacing expensive refrigeration plants, gas carbon dioxide liquidation is facilitated, the cost of gas carbon dioxide liquidation is greatly reduced, and carbon dioxide gas circulated use is achieved.

Owner:上海九宇泰碳科技有限公司

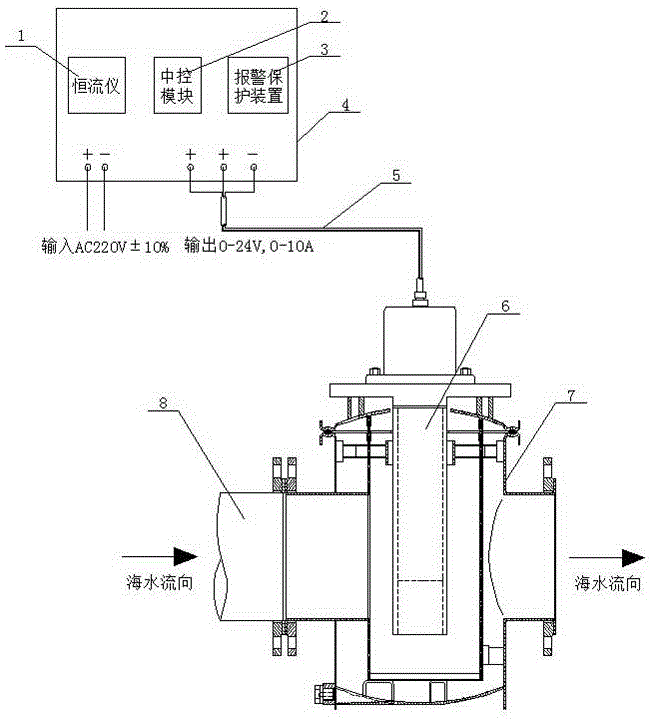

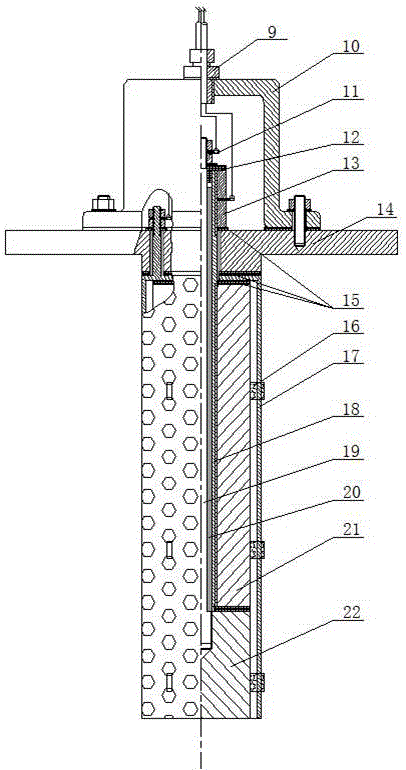

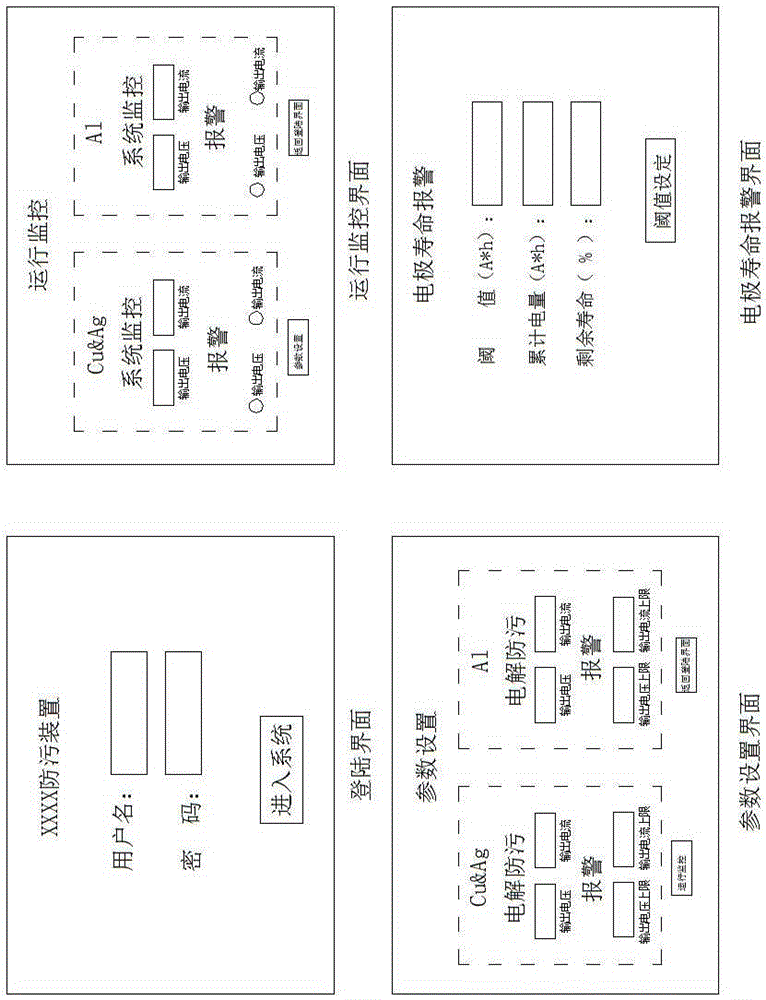

Integrated high-efficiency antifouling electrode and electrolysis antifouling device used for titanium alloy seawater pipeline

The invention provides an integrated high-efficiency antifouling electrode and an electrolysis antifouling device used for a titanium alloy seawater pipeline, and belongs to the field of halobios fouling control for seawater pipelines. The integrated high-efficiency antifouling electrode is designed with an independent cathode body, so that the key problem that hydrogen embrittlement can be easily generated on the titanium alloy seawater pipeline when the titanium alloy seawater pipeline is used as a cathode is solved; the cross section of the cathode body is a closed ring, and defines the outer side of an anode body, and thus, current produced by the anode body is enabled to be basically absorbed by the cathode body, and the problem that stray current corrosion is generated by electrolysis antifouling is avoided; the electrode is designed with an anode conductor, so that space required by installation of the electrode is obviously reduced, and meanwhile, two ways of anode electrolysis current can be controlled independently, and therefore, an antifouling compound is prepared with accurate concentration, and a good antifouling effect is ensured. The electrode is employed by the electrolysis antifouling device, and an alarm device for the service life of the electrode is designed, so that the safety problem possibly caused by anode overelectrolysis is solved, the titanium alloy seawater pipeline is enabled to gain a good halobios fouling control effect, and all related systems are enabled to be stable and safe in operation.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

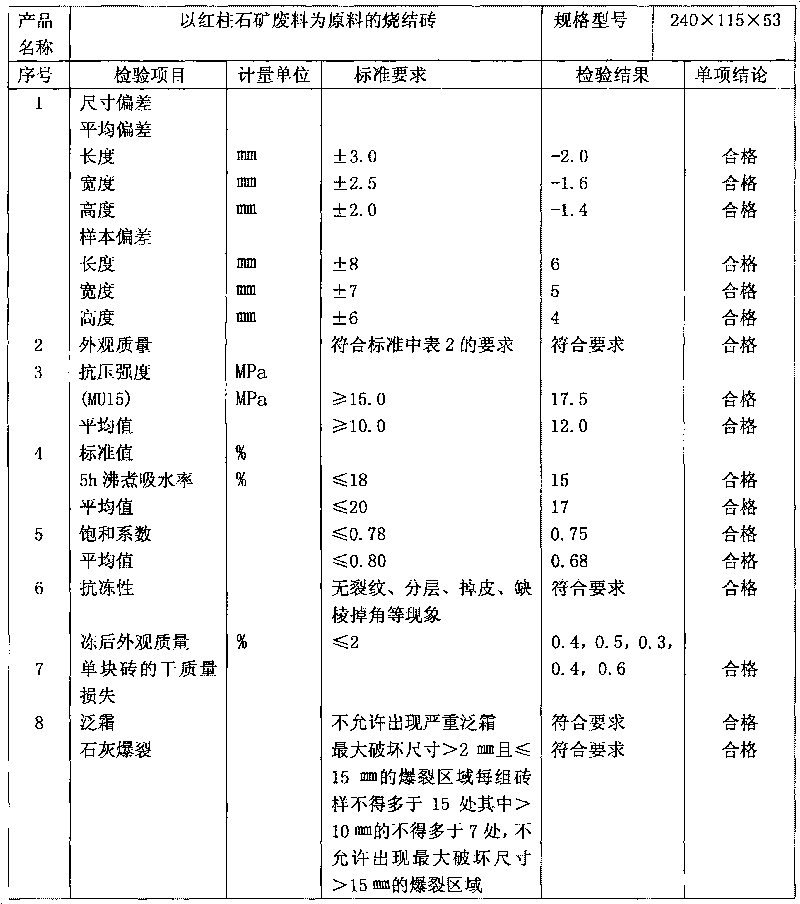

Method for preparing fired bricks by using andalusite, sillimanite and feldspar quarry wastes as raw materials

The invention belongs to the technical field of building materials and relates to fired bricks, in particular to a method for preparing fired bricks by using andalusite, sillimanite and feldspar quarry wastes as raw materials. The method is mainly characterized in that: the andalusite, sillimanite and feldspar quarry wastes, tailing powder and spall in a certain mixing weight ratio are used as the raw materials to prepare the fired bricks; the problem that the andalusite, sillimanite and feldspar quarry wastes cannot be used to prepare fired bricks easily is solved; the andalusite, sillimanite and feldspar quarry wastes are exploited, controlled and used; the occupation of and pollution to land and riverway environments are reduced; the investment in treatment of ore wastes is reduced; a clay raw material is replaced and land sources are saved; and the products can be compared with clay bricks and can be used for building conventional walls and filling frame walls and can be used as outdoor ground bricks such as public square bricks and pavement bricks which are durable to be stepped.

Owner:秦春恒 +4

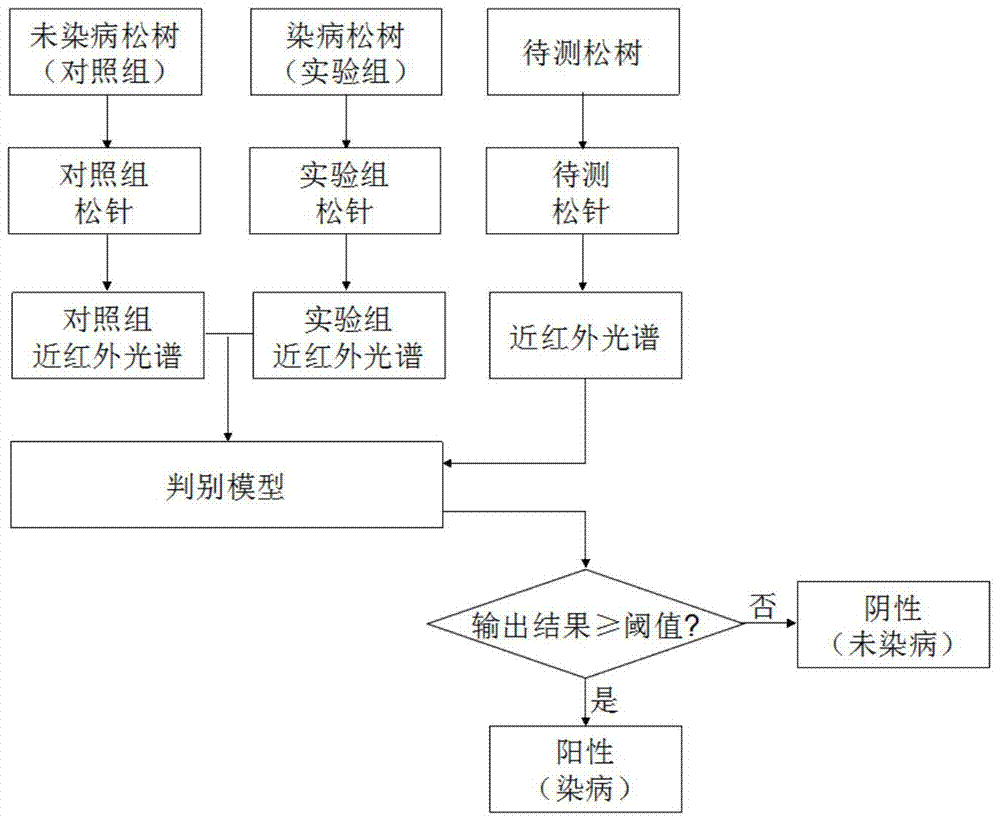

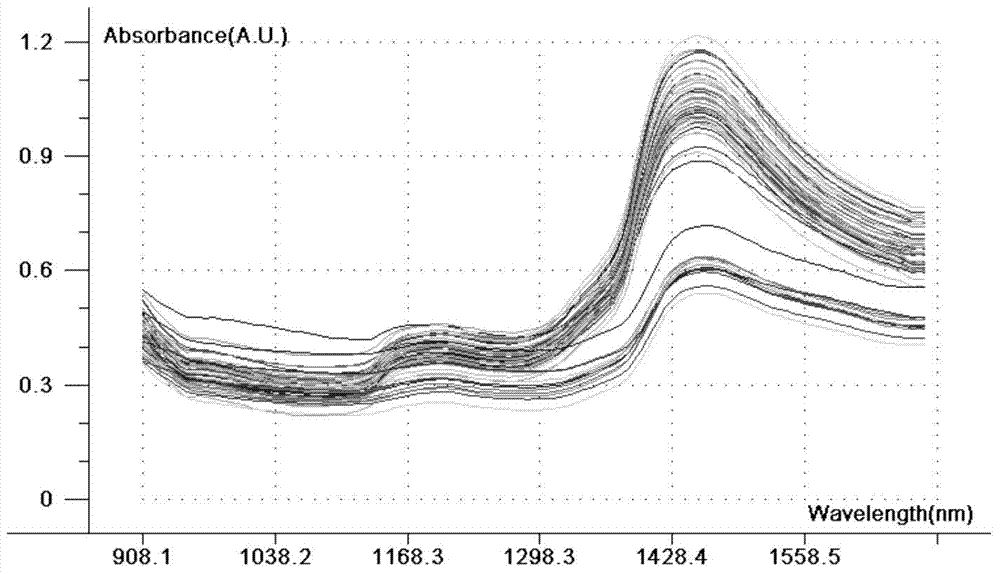

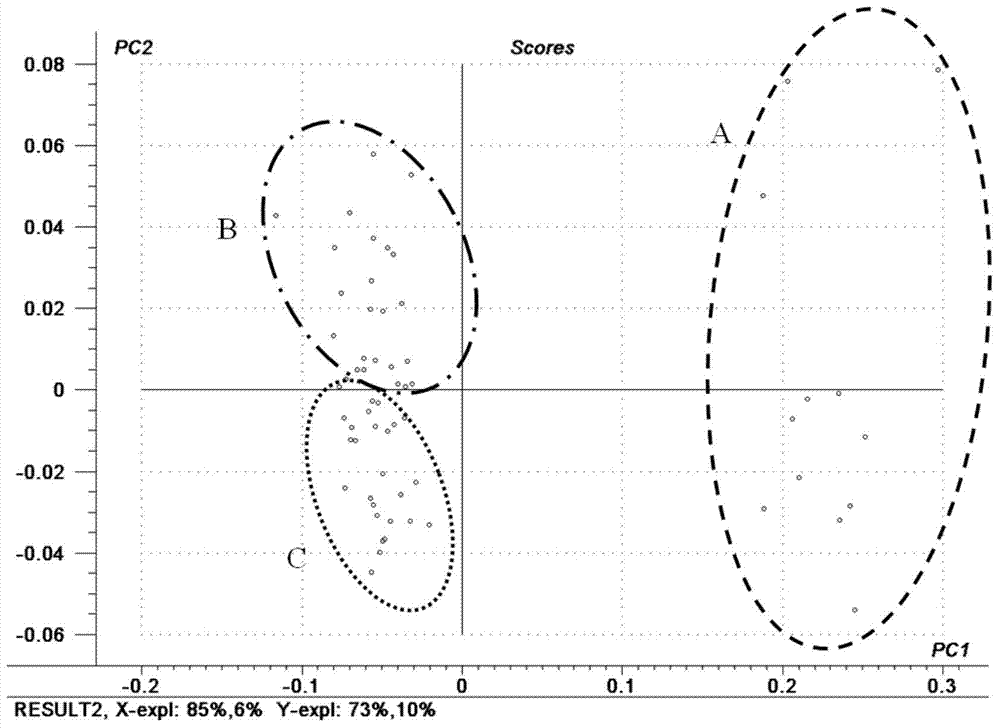

Loose material nematodosis early diagnosis method

ActiveCN103760128AAchieve early diagnosisAvoid serious harmMaterial analysis by optical meansDiagnosis methodsBiology

The invention provides a loose material nematodosis early diagnosis method. The loose material nematodosis early diagnosis method comprises the following steps of collecting a near infrared spectrum of a pine needle of an early stage disease pine tree by using a near infrared spectroscopy, simultaneously collecting a pine needle of a spectrogram of a non-disease pine tree, and establishing a distinguishing model according to two groups of spectrum data; and collecting a spectrogram of the pine needle to be detected, carrying out forecast operation on the spectrogram by using the distinguishing model, and combining a distinguishing threshold value to judge whether the pine tree to be detected gets a disease according to a forecast value. The loose material nematodosis early diagnosis method provided by the invention takes an near infrared spectrum as a core technology, a distinguishing model is rapidly established through a training set sample, the discovery of a pine material nematodiasis of the pine tree is prolonged about ten days, the effective technic instrument is provided for the early diagnosis of the disease, and the abundant time is provided for the treatment of the disease; the loose material nematodosis early diagnosis method provided by the invention has the characteristics that the rapid high efficiency accuracy is high and the like, the early diagnosis of the pine material nematodiasis is realized, and the important technology instrument is provided for the severe damage of the pine tree caused by the early stage discovery, treatment and preventing pine material nematodiasis.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES

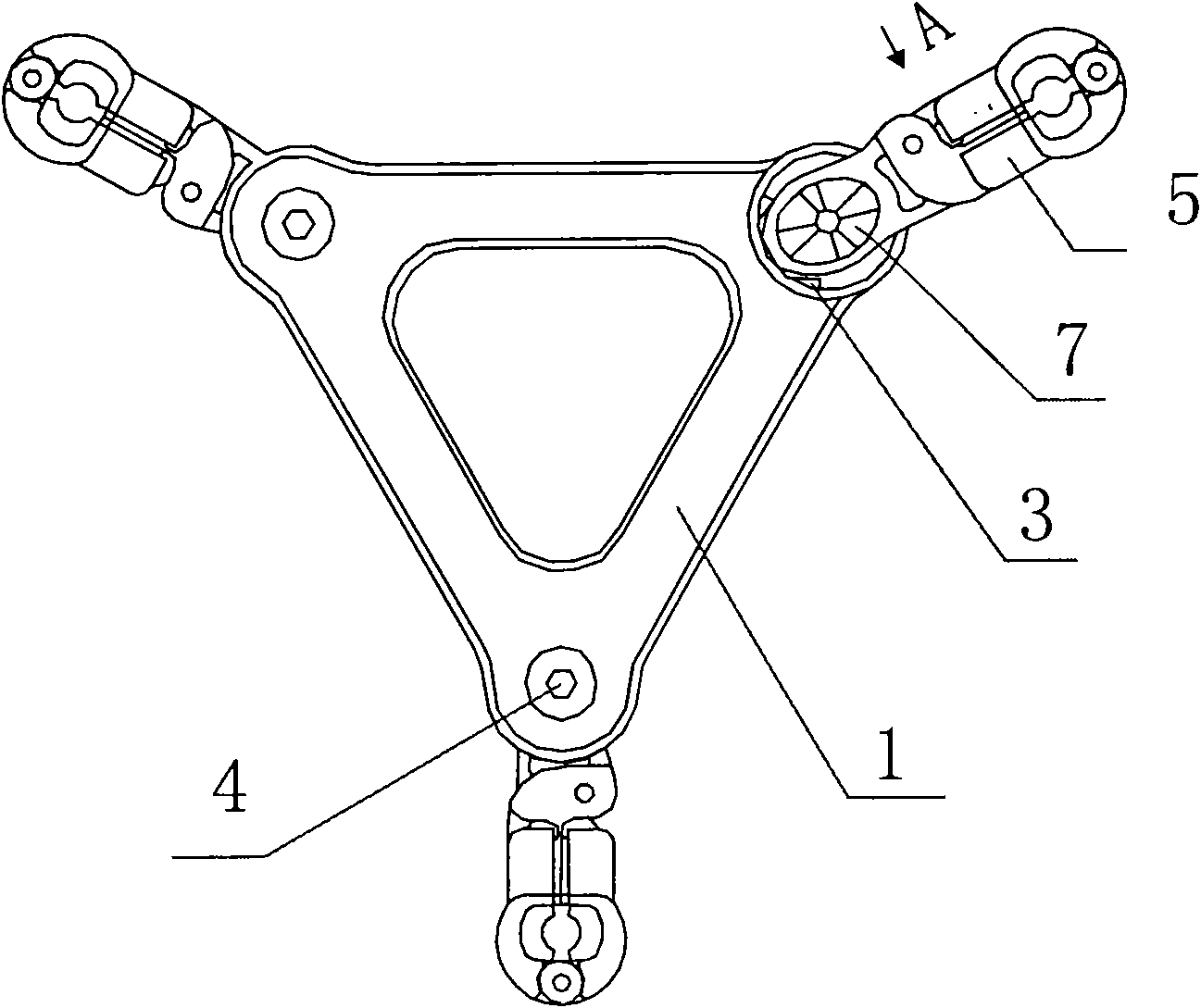

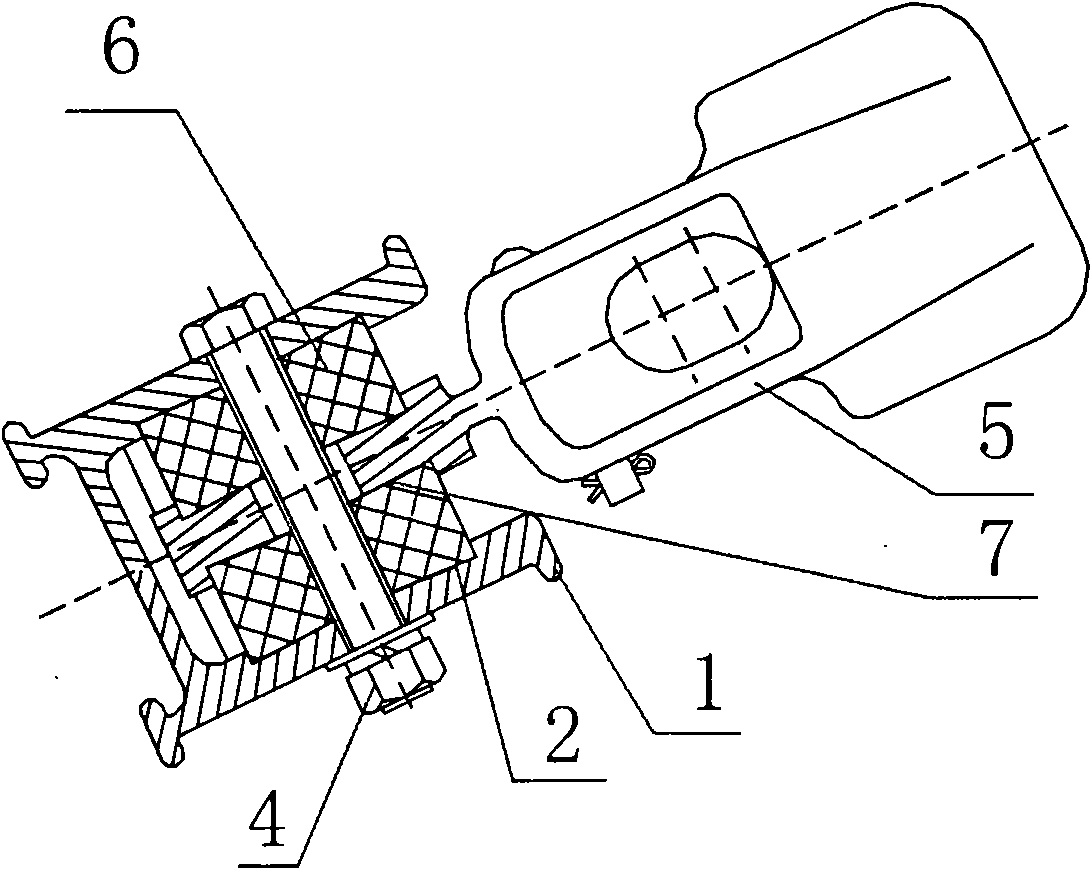

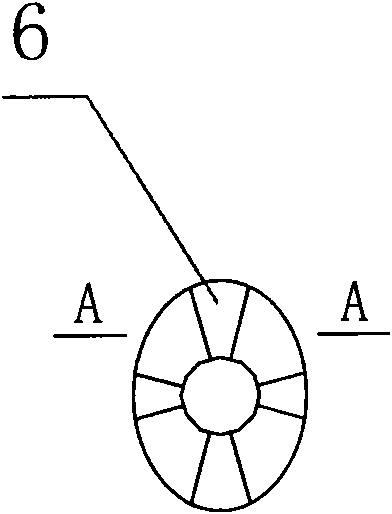

Trifid insulated damping conductor spacer

InactiveCN101593957AReduce and avoid serious harmAvoid serious harmMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsGlass fiberEngineering

The invention discloses a trifid insulated damping conductor spacer matched with a hot-line de-icing scheme of a transmission line, which is realized in by frameworks and a line clamp main body, wherein the frameworks are made of glass fiber reinforced plastics, consist of lug boss type positioning stop blocks and are symmetrically arranged close to the inner side outside each connecting hole on the inner side of a triangular framework, and the line clamp main body consists of a line clamp with a connecting joint. The trifid insulated damping conductor spacer not only can reliably separate and support a trifid conducting line, but also has good insulating effect so as to ensure that three conducting lines are mutually insulated, thereby creating necessary conditions for the hot-line de-icing of the transmission line, avoiding the harm brought by ice and snow disasters and increasing the bearing strength of the conductor spacer. Because of the improvement on a positioning structure, the line clamp main body and a rubber block, the centripetal force of the conductor spacer can be increased at the same time of simplifying the structure so as to ensure that a damping joint is moved along the conducting line all the time and guarantee that the conducting line has damping effect and good positioning when being moved within any possible ranges. The trifid insulated damping conductor spacer has simple structure, easy manufacture, reliable performance, low manufacturing cost, economy, practicality and convenient mounting and is suitable for popularization and ice coating areas.

Owner:中国电建集团四平线路器材有限公司

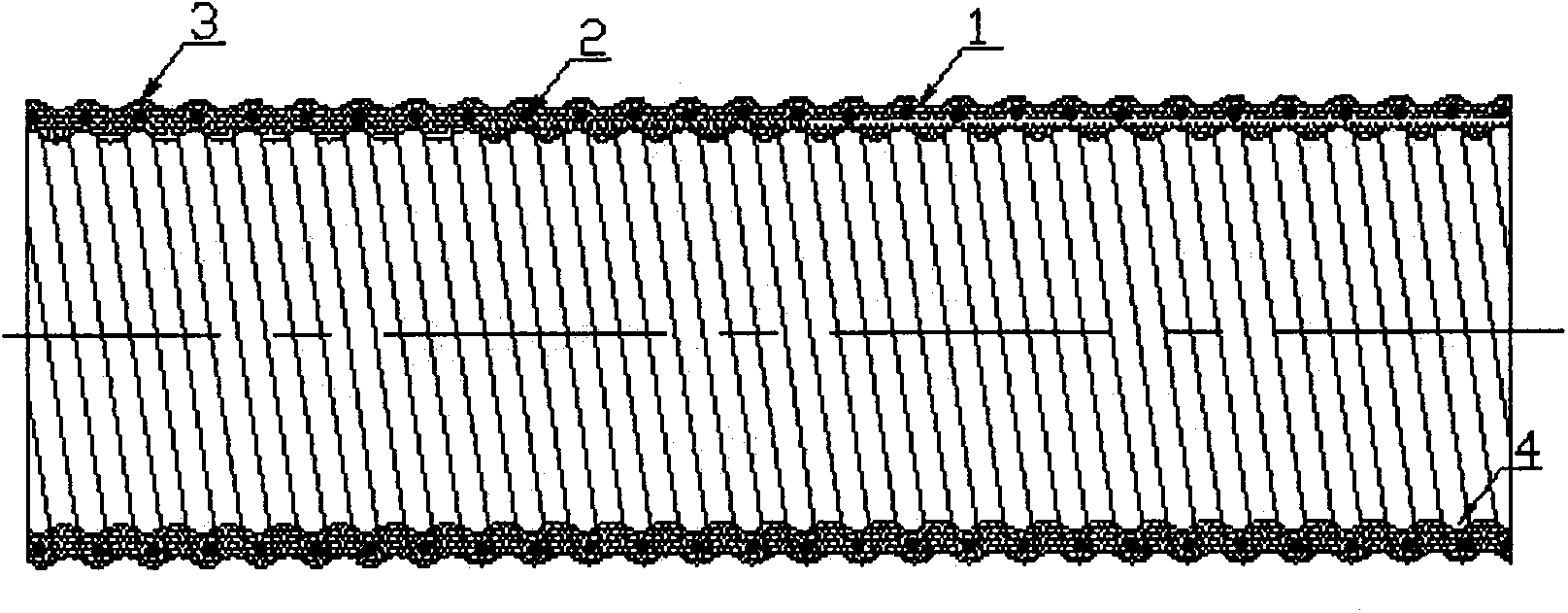

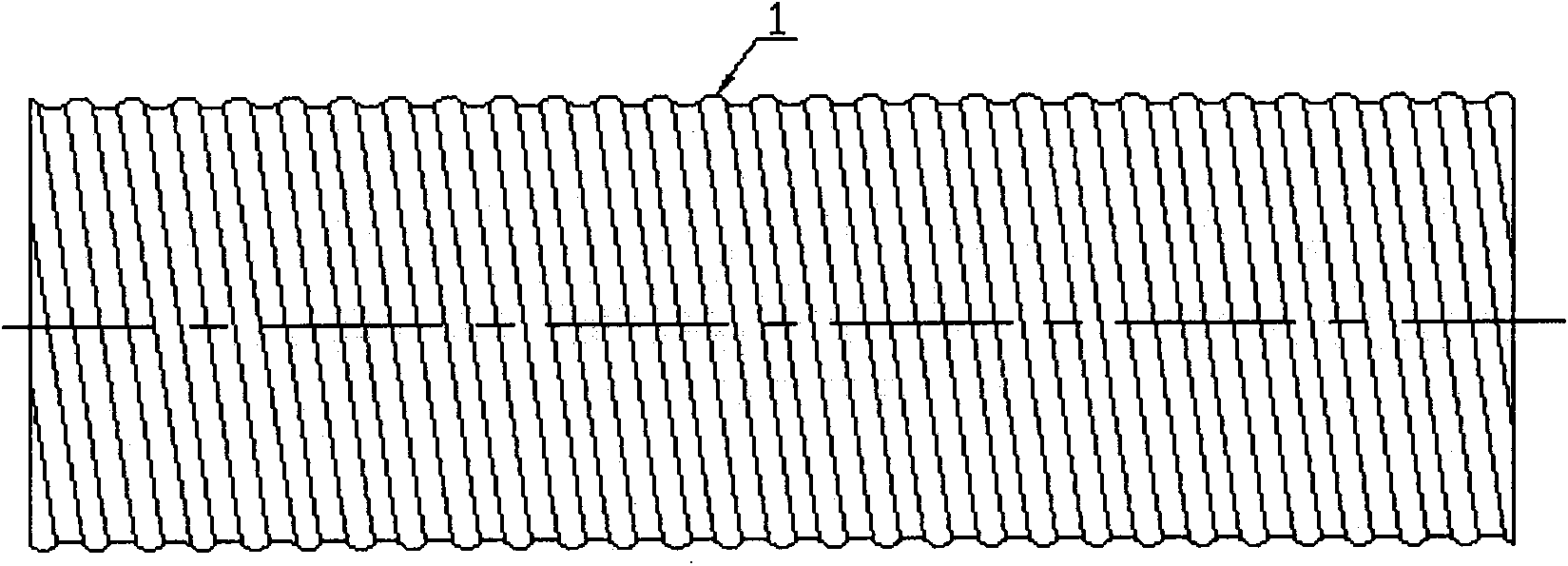

Rubber plastic ventilation (muffling) hose

InactiveCN103353030AAddress serious health hazards prone toAvoid serious harmFlexible pipesSpring steelEngineering

The invention relates to a rubber plastic ventilation (muffling) hose. The rubber plastic ventilation (muffling) hose comprises a rubber plastic (muffling) hose and internal spring steel wires, and is characterized in that the rubber plastic (muffling) hose is internally provided with the internal spring steel wires; a supporting framework formed by the internal steel wires and a rubber plastic tube form a telescopic bending ventilation hose. Since the flexible ventilation hose is made of environment-friendly material, the problems of a VAV (Variable Air Volume) ventilation air-conditioning system in domestic and foreign markets such as hidden pollution of the ventilation hose and serious damage easily generated to the health of a human body are completely solved. The product fills the blank of domestic environment-friendly ventilation hose, and the hose can be set according to environmental conditions; the product has good performances of being environment-friendly, fire-resistant and flame-resistant, flexible to stretch, little in ventilation resistance, heat-insulating and energy-saving, little in heat conductivity coefficient, waterproof and moistureproof, attractive in appearance, convenient to operate, low in using labor cost, good in muffling effect, high in installation efficiency, and the like.

Owner:季星

Textile fiber with conductive ane magnetic conductive function and its preparing method

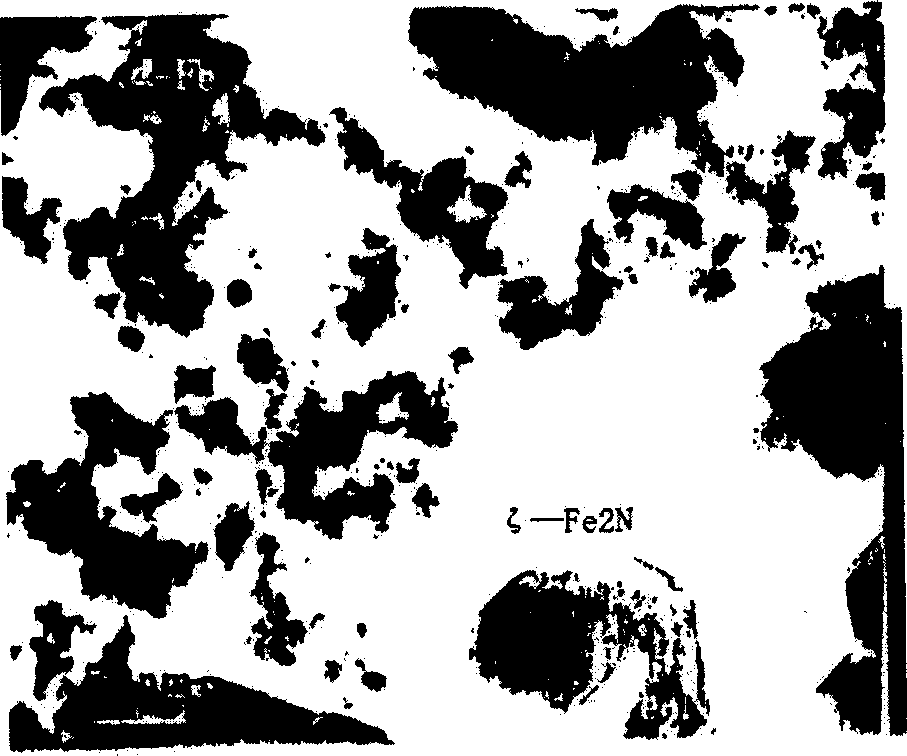

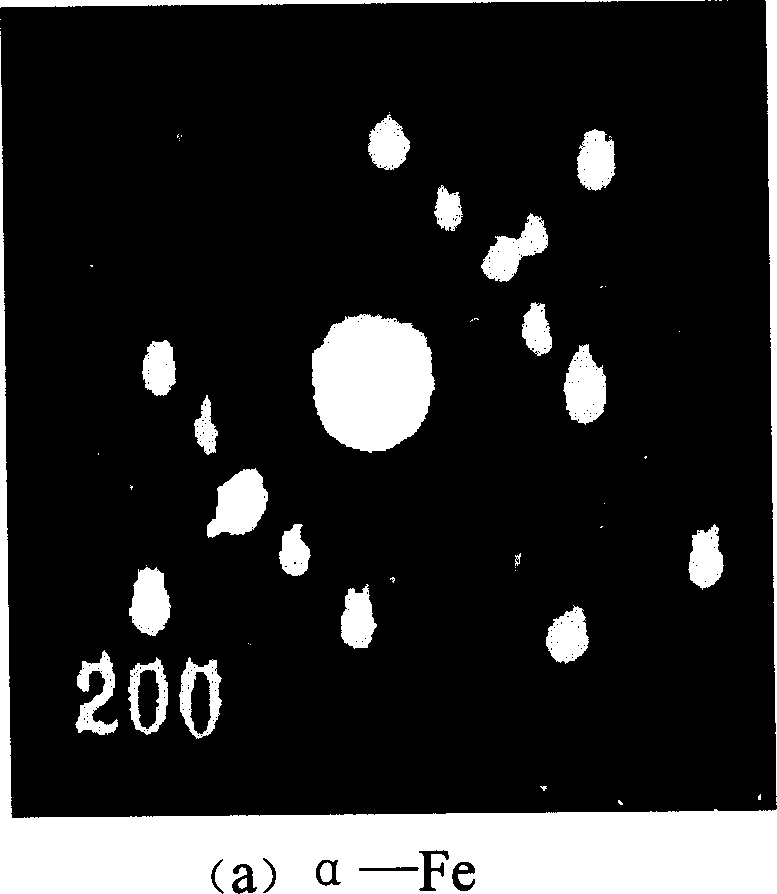

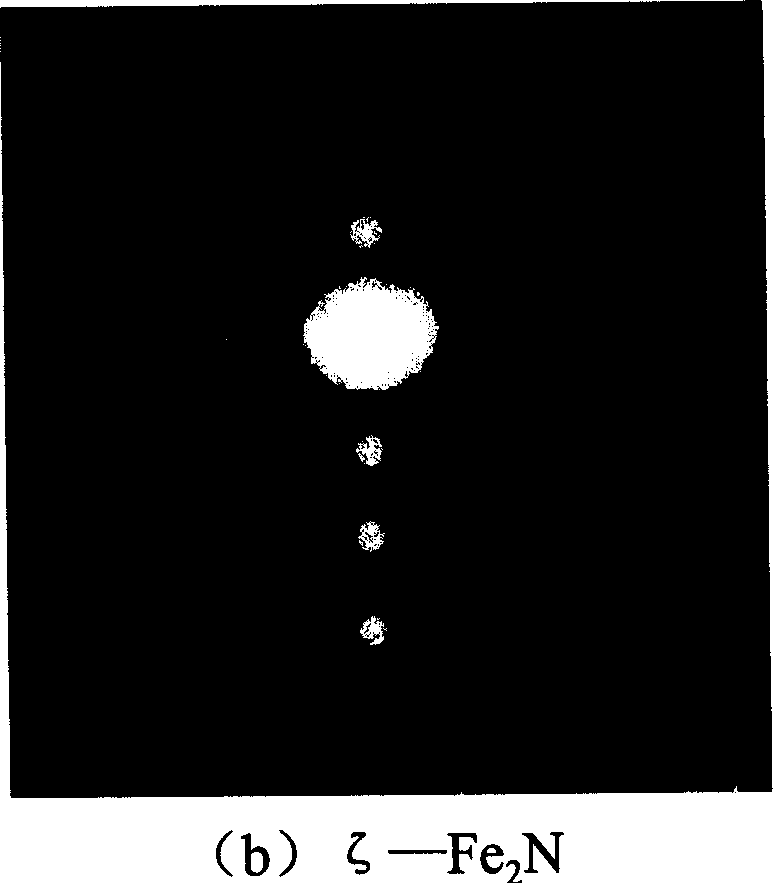

InactiveCN1587456AIt has the function of conduction and magnetic conduction double complexAvoid serious harmArtifical filament manufactureLow frequency magnetic fieldTextile fiber

The dual function electrical conductive and magnetic conductive textile fiber consists of nanometer dual function powder in 2-15 wt% and polymer in 85-98 wt%, and features that the nanometer dual function powder is composite zeta-Fe2N.alpha-Fe powder of size 20-80 nm and coated with Fe3O4 film. Compared with available technology, the dual function electrical conductive and magnetic conductive textile fiber of the present invention has the features of high electrically and magnetically resisting performance, especially capacity of preventing the harm of low frequency magnetic field on human body.

Owner:BEIJING CISRI GAONA TECH

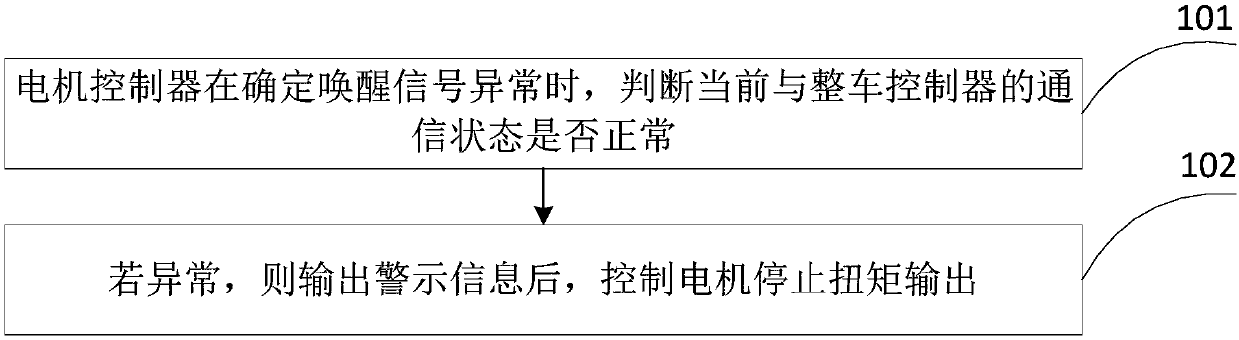

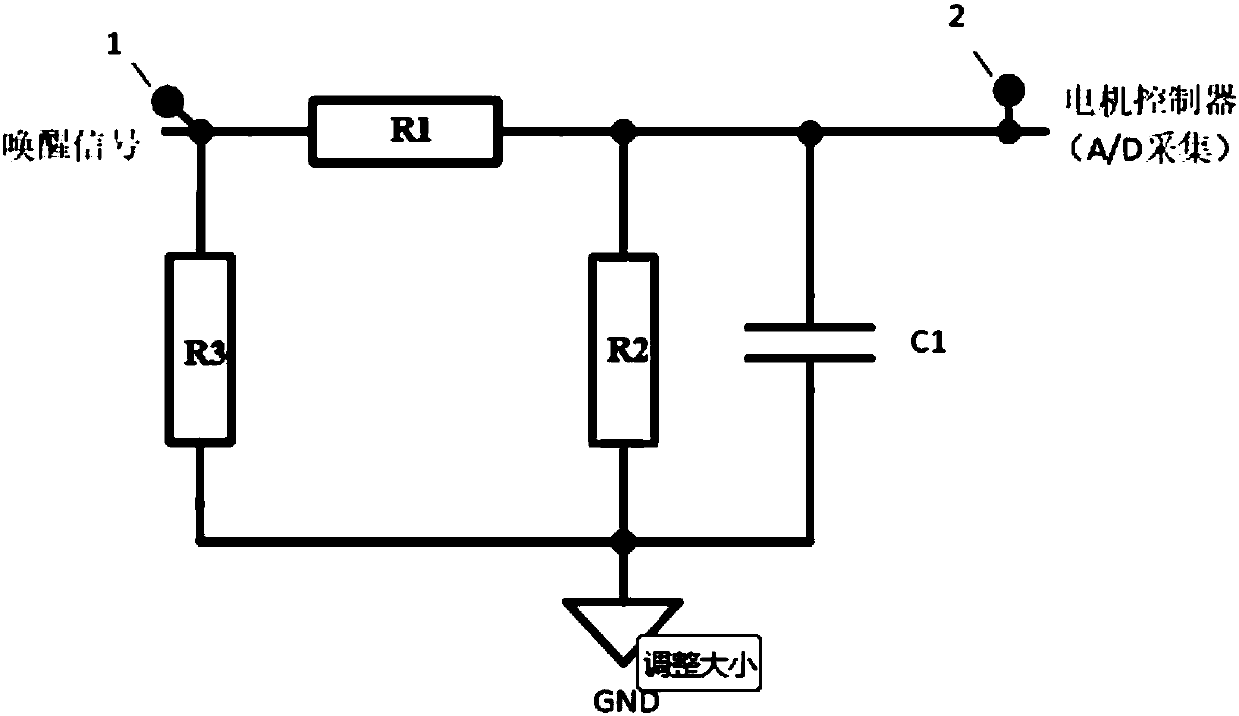

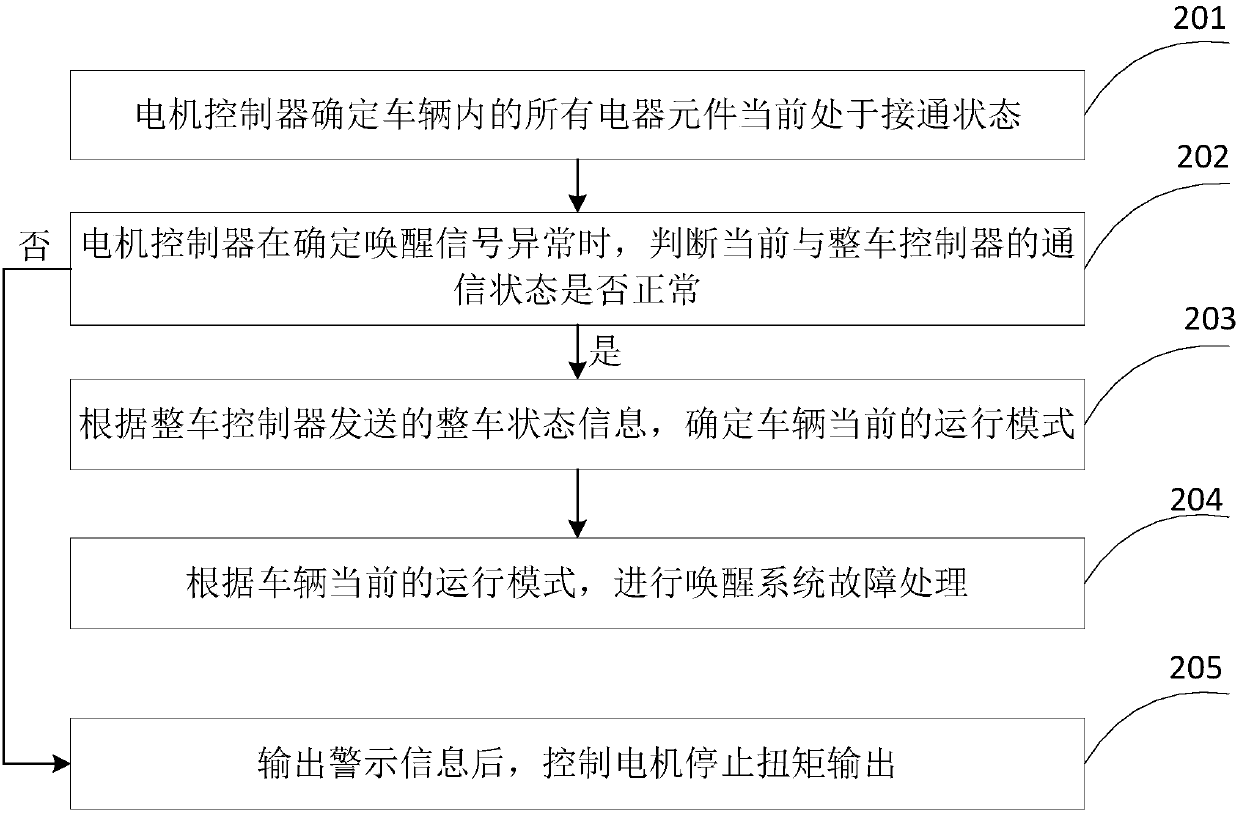

Motor controller arousal system fault handling method and motor controller

ActiveCN107804172AImprove experienceAvoid serious harmSpeed controllerElectric devicesElectricityMotor controller

The invention provides a motor controller arousal system fault handling method and a motor controller. The method comprises the steps that when the motor controller confirms that an arousal signal isabnormal, whether the current communication state with the whole vehicle controller is normal or not is judged; if not, a motor is controlled to stop torque outputting after warning information is output. In this way, fault handling of a motor controller arousal system is achieved when the arousal signal is abnormal, and the phenomenon that when the arousal signal is abnormal, serious damage is caused to the driving safety when power down operation is directly executed by the motor controller is avoided, the driving safety is improved, and the user experience is improved.

Owner:BEIJING ELECTRIC VEHICLE

Method for improving farmland soil

InactiveCN103348797AAvoid heavy pollutionAvoid potentially serious hazardsSoil-working methodsSoil fertilityPollution

The invention relates to a method for improving farmland soil and belongs to the technical field of technical innovation of farmland soil improvement. The method for improving the farmland soil aims to achieving the technical goal that a chemical technology is replaced by a biological technology. The application of the biological technology is the technical key point to achieve the goal. The method for improving the farmland soil has the advantages of avoiding pollution and poisoning of heavy metal and other harmful elements in chemical technological fertilizer, being clean, protecting the environment, maintaining ecological balance, and being capable of effectively improving farmland soil and soil fertility.

Owner:匡仲平

Making method of acid-proof polyamide fabric

The invention discloses a making method of an acid-proof polyamide fabric. The method comprises the following steps: preparing an acid-proof finishing agent; and spraying the right surface of a polyamide fabric with an acid-proof reinforcing adhesive, coating the wrong side of the polyamide fabric with the acid-proof reinforcing adhesive, and carrying out waterproof finishing of the above obtained polyamide fabric. The special acid-proof finishing agent used by the polyamide fabric made through the method is nontoxic, odorless, safe and reliable, has a lasting acid proofing effect, and overcomes the difficult degradation of perfluorooctane sulfonyl compounds in present acid-proof finishing agents and the severe harms of the compounds to the environment and human bodies. The polyamide fabric obtained after the acid-proof finishing is difficult for an acidic liquid to adhere and penetrate, substantially reduces the damages of the acidic liquid to the fabric, improves the use strength, guarantees the effectiveness as a fastener, and provides a safety protection effect for workers contacting with acids.

Owner:DONGHUA UNIV

Field cultivation method of purple-flower bletilla striata tissue culture seedlings

ActiveCN108184589AShorten the cultivation cycleImprove compactionBiocideGrowth substratesBletilla striataPlastic mulch

The invention discloses a field cultivation method of purple-flower bletilla striata tissue culture seedlings. The method includes the following steps of 1, selecting a suitable land parcel for planting bletilla striata; 2, conducting deep ploughing and soil smashing on the selected land parcel; 3, conducting light shielding on the whole planting land parcel and erecting a sprinkling irrigation system; 4, conducting seedling hardening; 5, conducting transplanting; 6, conducting field management. According to a planting technique of the purple-flower bletilla striata tissue culture seedlings, harvesting can be achieved only within two years, and the yield per mu can reach about 2.5 tons. The suitable land parcel is selected according to environmental conditions suitable for survival of bletilla striata, and the great environmental conditions are provided for good growth of bletilla striata after bletilla striata is transplanted into the field; furthermore, by preparing the soil, alleviating soil hardening, carrying out steam sterilization to assist in plastic film mulching, killing pest eggs and weed seeds and the like, elimination of weeds at the early stage of transplanting is achieved, the situation that the growth of the seedlings is influenced since there are too many weeds during a seedling period is avoided, and the adverse impact generated on roots of the seedlings by weeding since the bletilla striata tissue culture seedlings grow slowly and the plants are small is overcome.

Owner:剑川禹丰种植发展有限公司

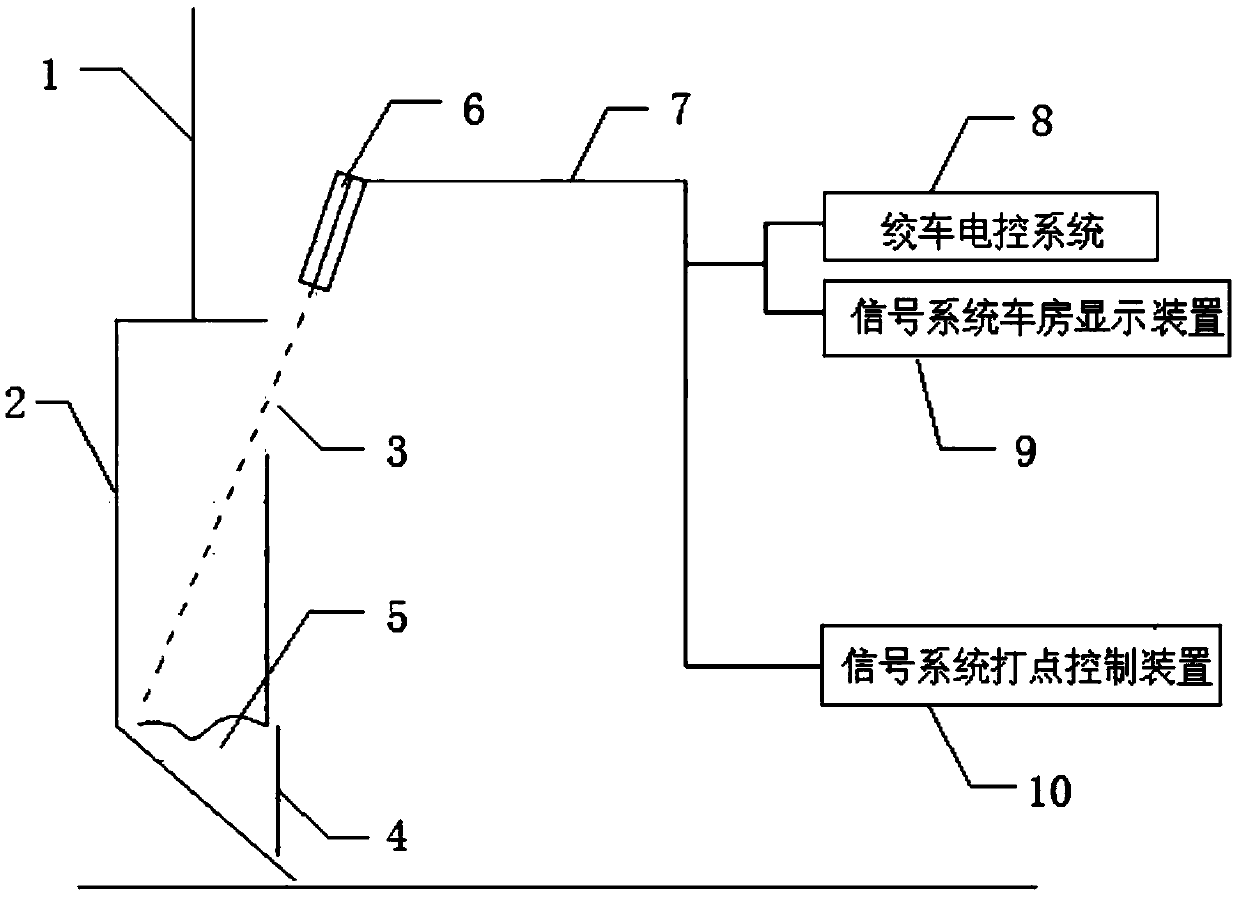

Device for preventing skip bucket from repeatedly coaling

InactiveCN105366472AAlarm monitoring is accuratePrevention of serious harmElevatorsEngineeringSignalling system

The invention discloses a device for preventing a skip bucket from repeatedly coaling. The device comprises a main well winch lifting steel wire rope (1), a lifting skip bucket (2), a winch electric control system (8), a signal system garage display device (9), a signal system management control device (10) and a sensor (6) which is mounted above the lifting skip bucket for measuring coal storage in the skip bucket; the sensor is connected with the winch electric control system, the signal system garage display device and the signal system management control device; the winch electric control system is used for controlling the skip bucket to work according to the coal storage, detected by the sensor, in the lifting skip bucket. The device utilizes the sensor to measure the coal storage in the ship bucket, and is combined with the signal system and the winch electric control system, so that winch operation is stopped when abnormity appears, and alarming and monitoring are accurate, stable and reliable, and therefore, the device is suitable for lifting a vertical shaft gate side-dumping type skip bucket, and effectively prevents serious damages, caused by repeated coaling of the skip bucket, to a mine.

Owner:SHANGHAI DATUN ENERGY

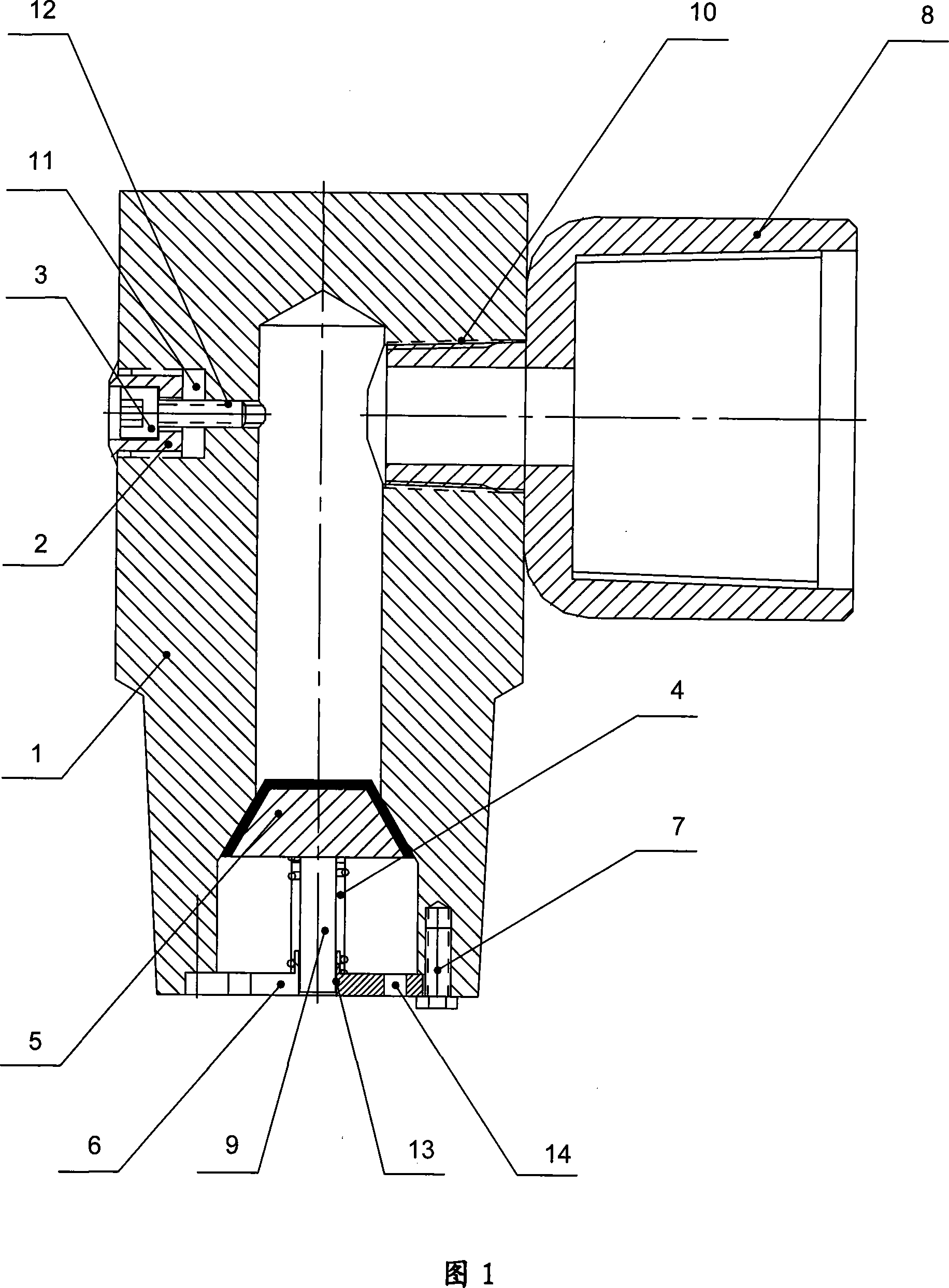

Liquid fill adapter for gas well

InactiveCN101131071AEasy to produceStable productionFluid removalSealing/packingEngineeringMechanical engineering

The present invention provides one kind of natural gas well liquid filling joint, which includes one joint body with hollow cavity possessing opening in the lower end, one great displacement interface and one small displacement interface communicated to the hollow cavity set radially onto the joint body, one movable valve inside the hollow cavity and with truncated cone surface for fitting the inner surface of the hollow cavity hermetically, one valve cover with valve core leading hole and through hole fixed to the lower end of the joint body, and one valve core in the bottom of the movable valve. The joint is for filling liquid to natural gas well, and has features of smart structure, use convenience and high safety.

Owner:许现西

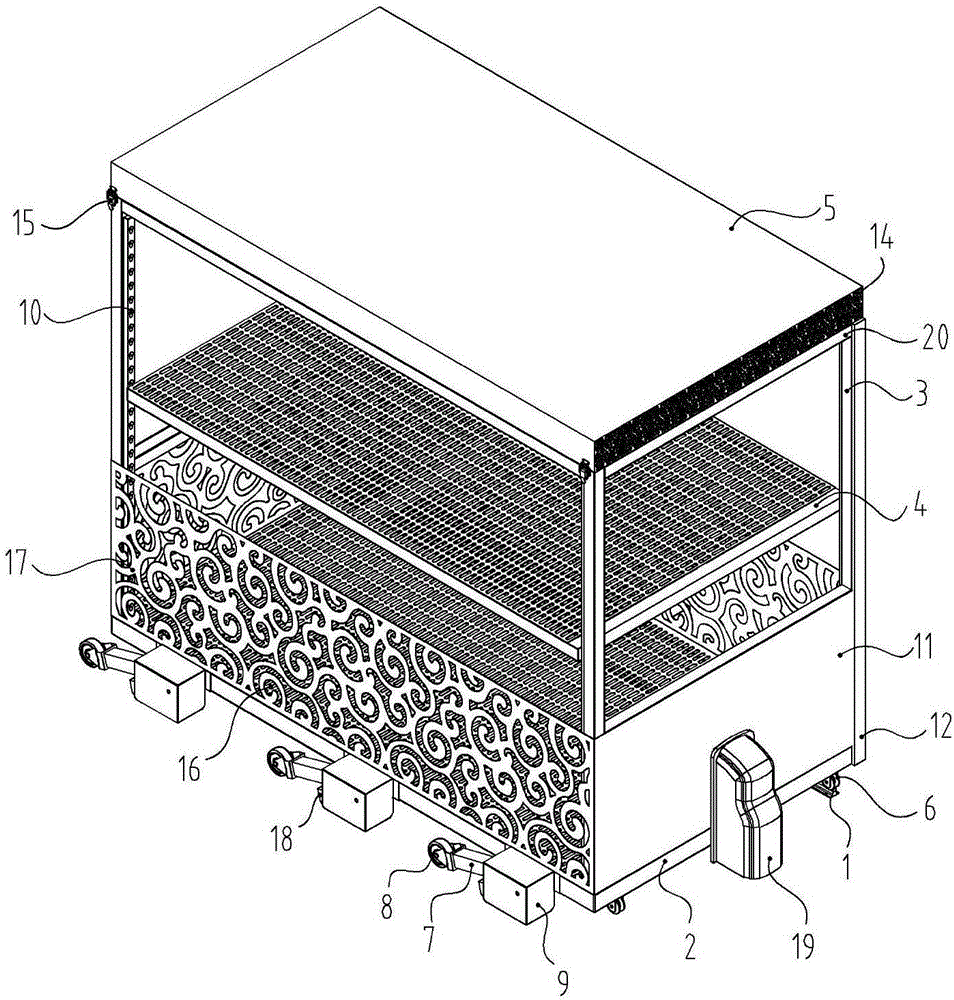

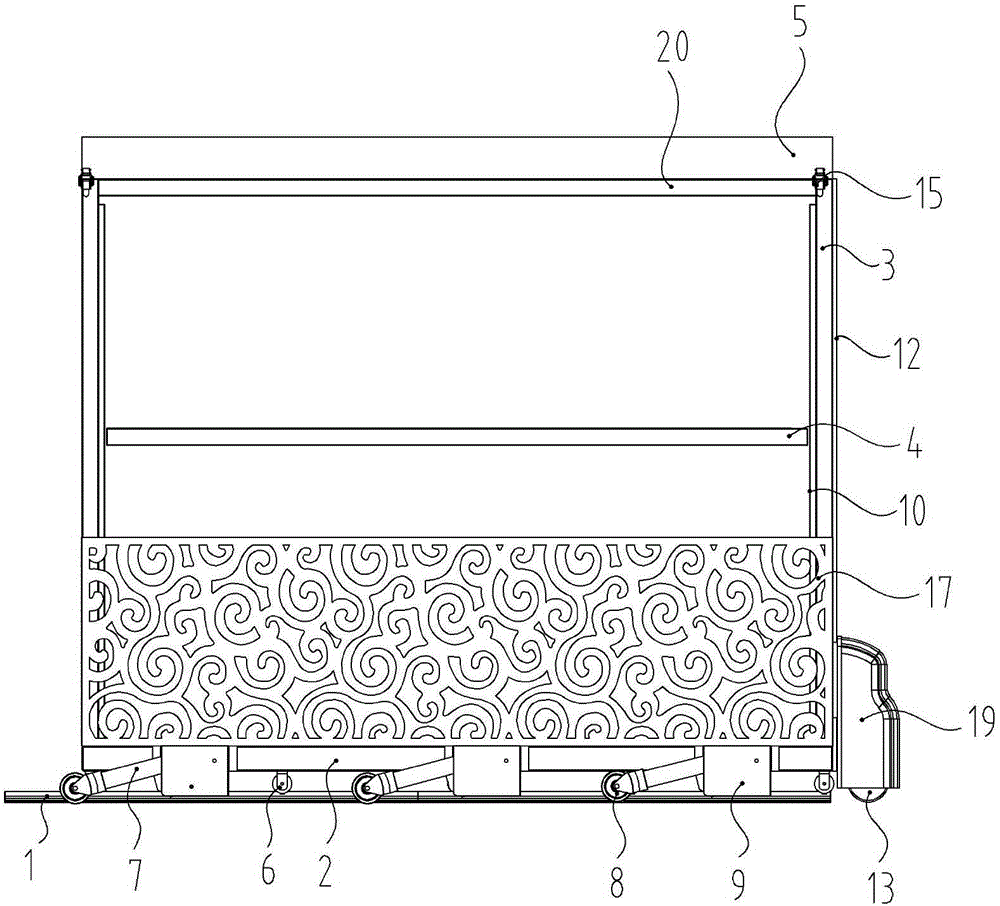

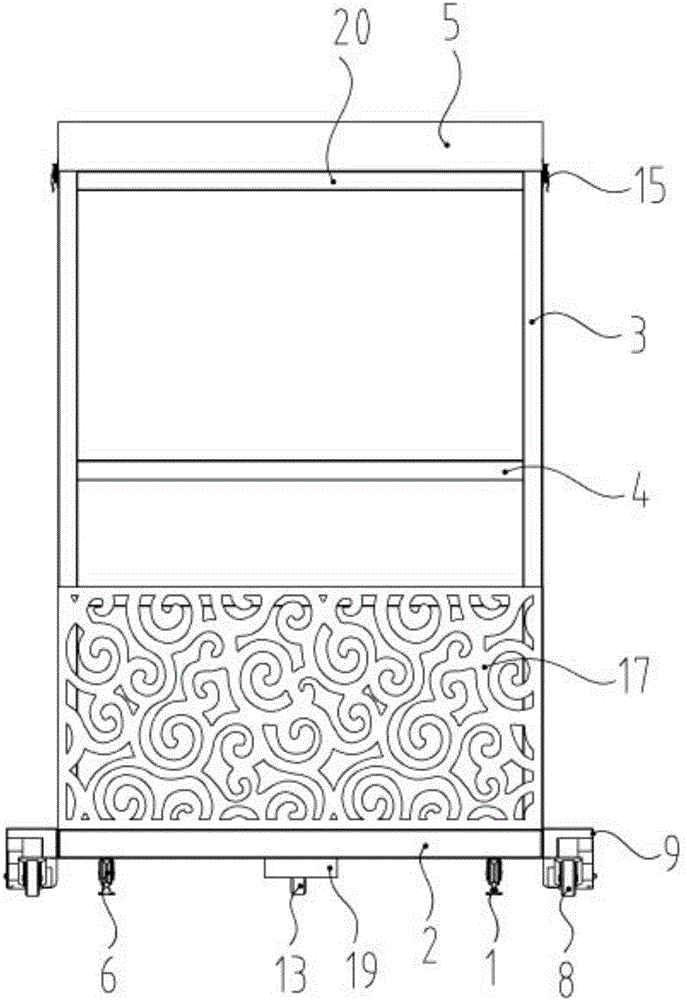

Cultural relic fumigating conveying system

ActiveCN106729855AAvoid loading and unloadingAvoid wear and tearLavatory sanitoryChemicalsDisinfectantEngineering

The invention discloses a cultural relic fumigating conveying system. The cultural relic fumigating conveying system comprises a rectilinear rail and a trolley, wherein the trolley comprises a trolley underframe; a first walking mechanism and a plurality of second walking mechanisms are arranged on the bottom surface of the trolley underframe; the first walking mechanism is matched with the rectilinear rail; upright trolley columns are arranged at the four top corners of the top surface of the trolley underframe respectively; a supporting frame is fixed together to the tops of the four upright trolley columns; a partition board is mounted on the four upright trolley columns; a disinfectant uniformizing box communicated with an air inlet of a disinfector is fixed above the supporting frame. Through the arrangement of the trolley in the disinfector, on one hand, cultural relic fetching and storing operation is more convenient, and damage to cultural relics and serious damage caused by a residual disinfectant to the body of a worker are avoided; on the other hand, through the trolley, uniform distribution of the disinfectant in a disinfecting cabin is achieved so as to ensure a good cultural relic disinfecting effect, the cultural relics can be safely and orderly placed on the trolley, and the space utilization of the disinfecting cabin is maximized while the safety of the cultural relics is ensured.

Owner:CHONGQING SHENGGUANGDIAN ZHILIAN ELECTRONICS CO LTD

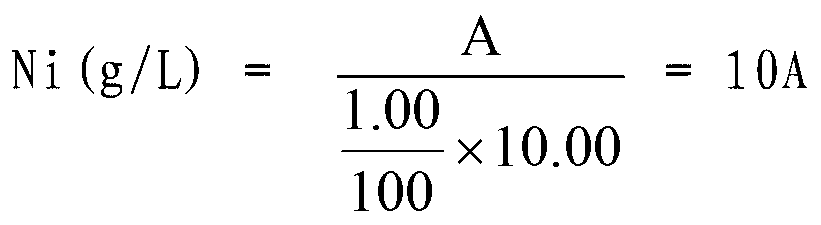

Method for measuring zinc and nickel contents in zinc-nickel alloy electroplating solution

ActiveCN103344641BAvoid serious harmGuaranteed sensitive to color changeMaterial analysis by observing effect on chemical indicatorSodium acetateImpurity

The invention relates to a method for measuring zinc and nickel contents in a zinc-nickel alloy electroplating solution and belongs to the technical field of methods for analyzing the electroplating solution. The method is mainly and technically characterized by comprising the following steps of: reacting dimethylglyoxime and Ni4+ to form a red soluble complex in the presence of an oxidant ammonium persulfate, adding sodium tartrate to eliminate iron and other impurity interference, and measuring the content of nickel in the zinc-nickel alloy electroplating solution by employing a colorimetric method; adding tartaric acid to mask iron and other impurities, with CuY-PAN as an indicator, titrating in an acetic acid-sodium acetate buffer solution with the PH being 5.5 by using an ethylene diamine tetraacetic acid (EDTA) standard titration solution by utilizing a replacement titration principle, calculating the total contents of zinc and nickel in the zinc-nickel alloy electroplating solution, and subtracting the nickel content from the total contents of zinc and nickel to solve the zinc content in the zinc-nickel alloy electroplating solution. The measurement method has the characteristics of simpleness in detection, convenient, rapid and environment-friendly detection process, low cost, accurate and consistent detection result and the like.

Owner:江南工业集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com