Liquid fill adapter for gas well

A natural gas and liquid technology, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc. It can solve the problems of low efficiency of filling liquid, disturbing the stable production of gas wells, and fluctuations in gas production, so as to prevent wellhead piracy Air phenomenon, ingenious structural design, and the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

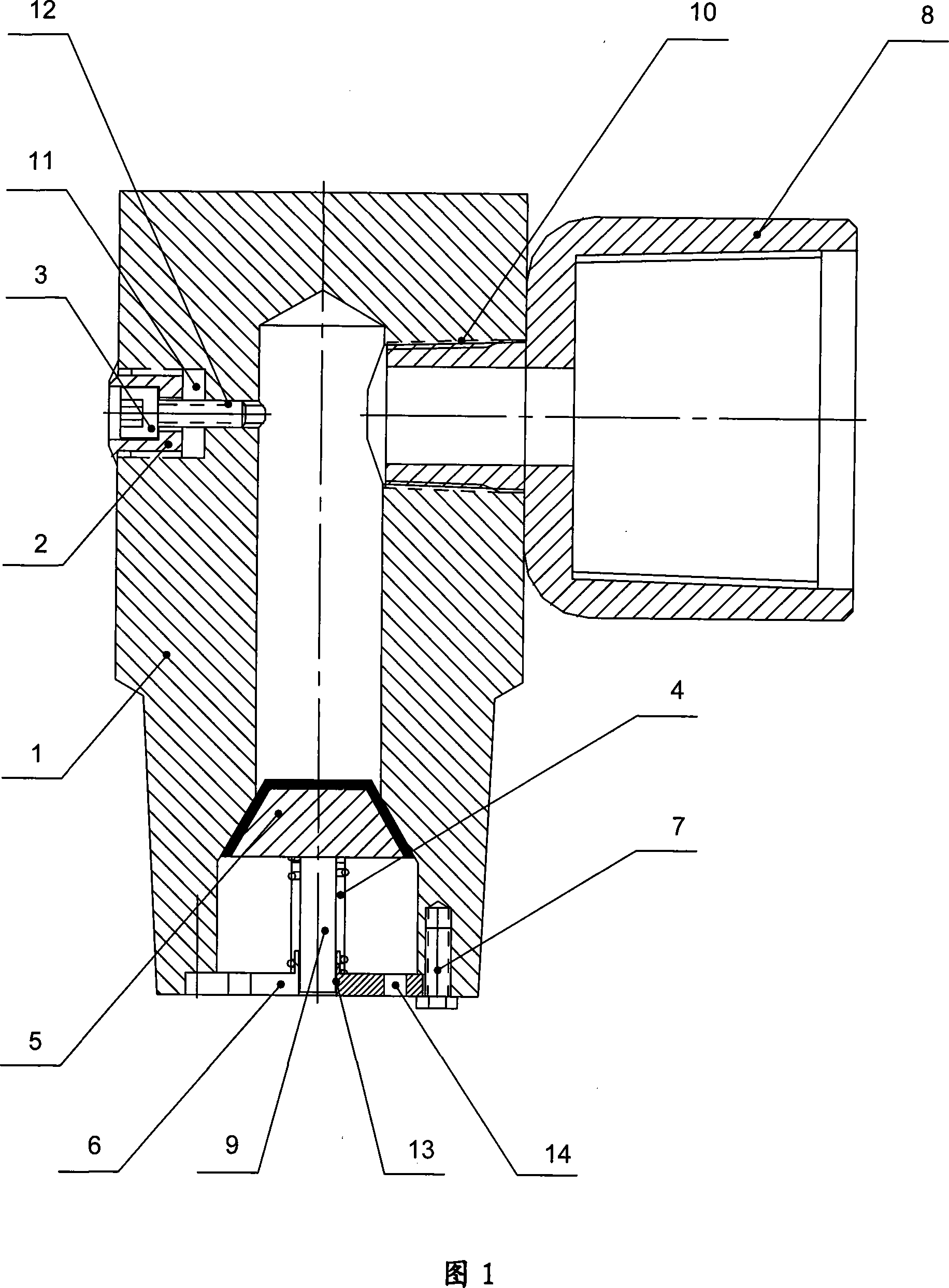

[0017] The technical solution of the present invention will be described in further detail below with reference to the drawings and specific embodiments.

[0018] As shown in Figure 1, a natural gas well liquid filling joint includes a joint body 1, a hollow cavity is arranged inside the joint body 1, and the hollow cavity opens at the lower end of the joint body 1; the joint body The outside of the lower end is provided with threads to cooperate with the flange threads of the natural gas well;

[0019] The upper part of the joint body 1 is radially provided with a large displacement interface 10 and a small displacement interface 11, and the large displacement interface 10 and the small displacement interface 11 communicate with the hollow cavity respectively;

[0020] A movable valve 5 is arranged in the hollow cavity, and an inverted conical sealing inner surface is arranged in the middle of the hollow cavity, and the movable valve 5 has a sealed inverted conical pedestal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com