Patents

Literature

36results about How to "Easy filling work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

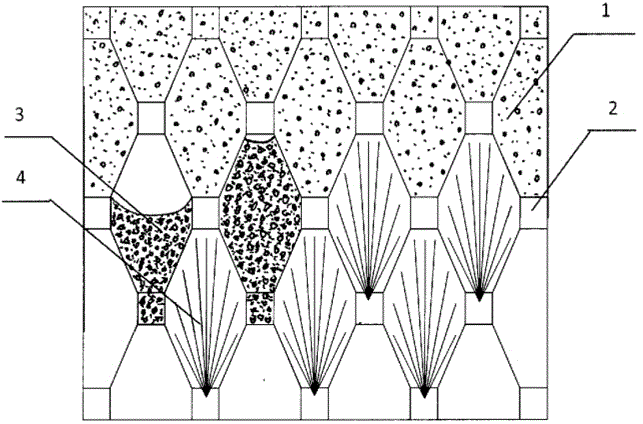

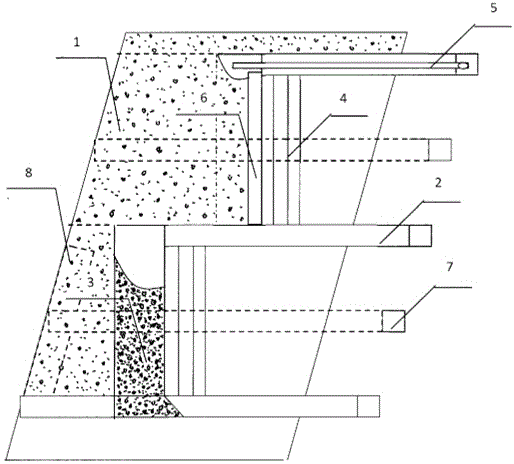

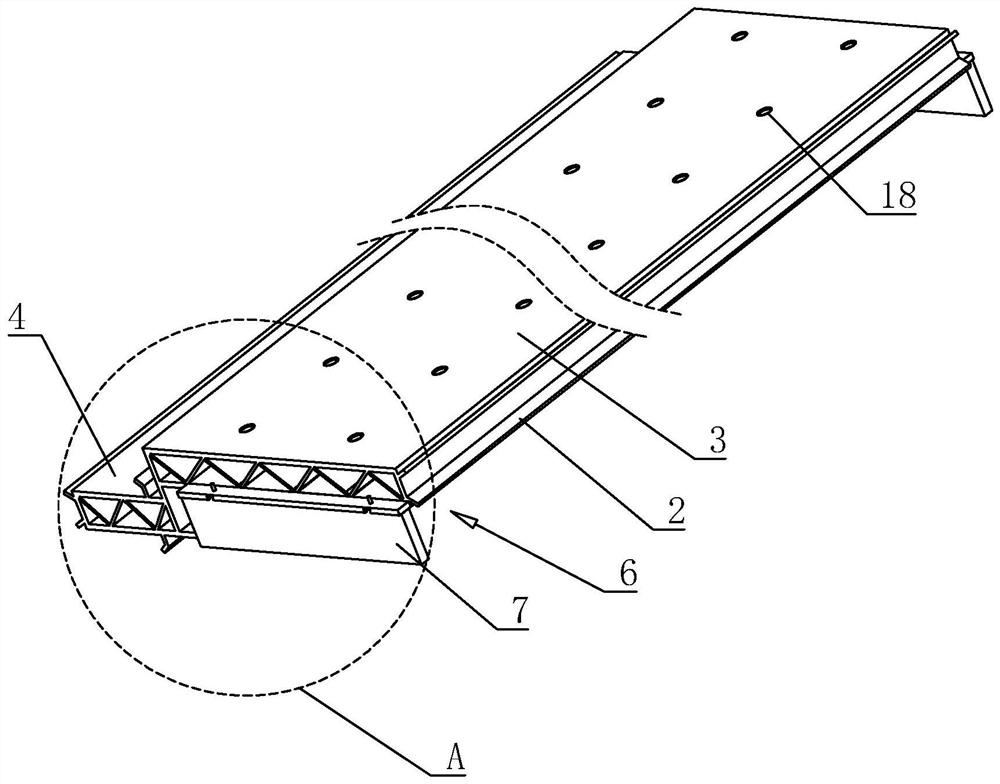

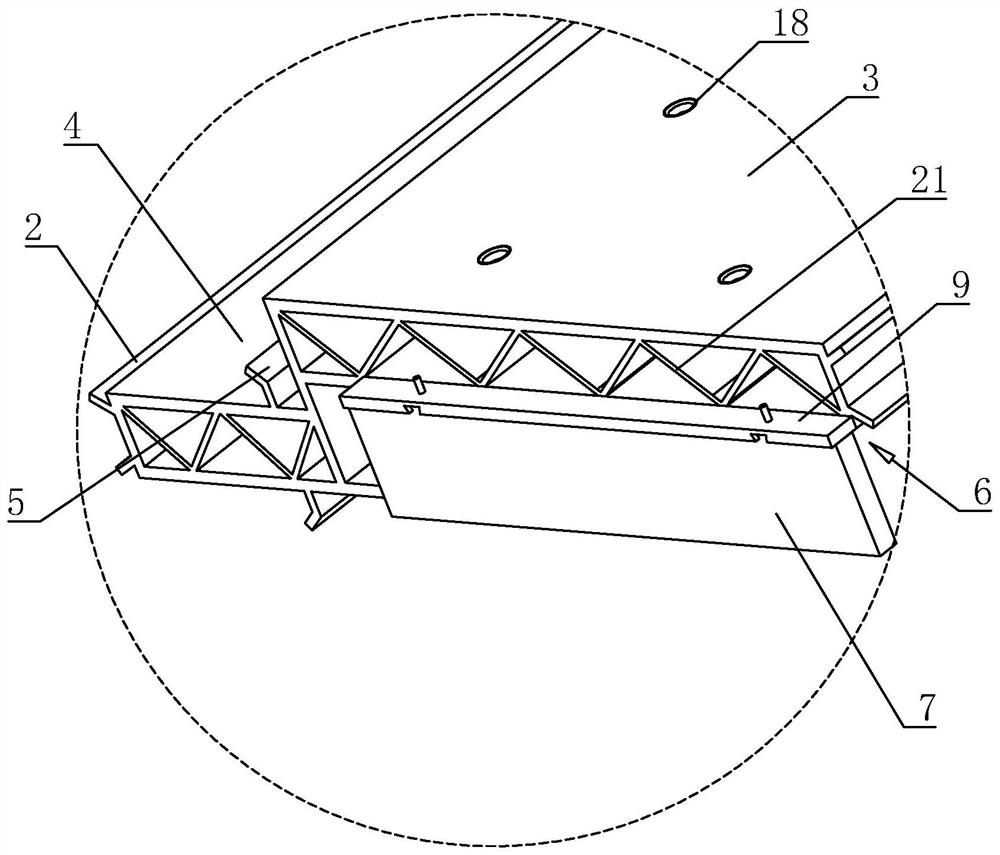

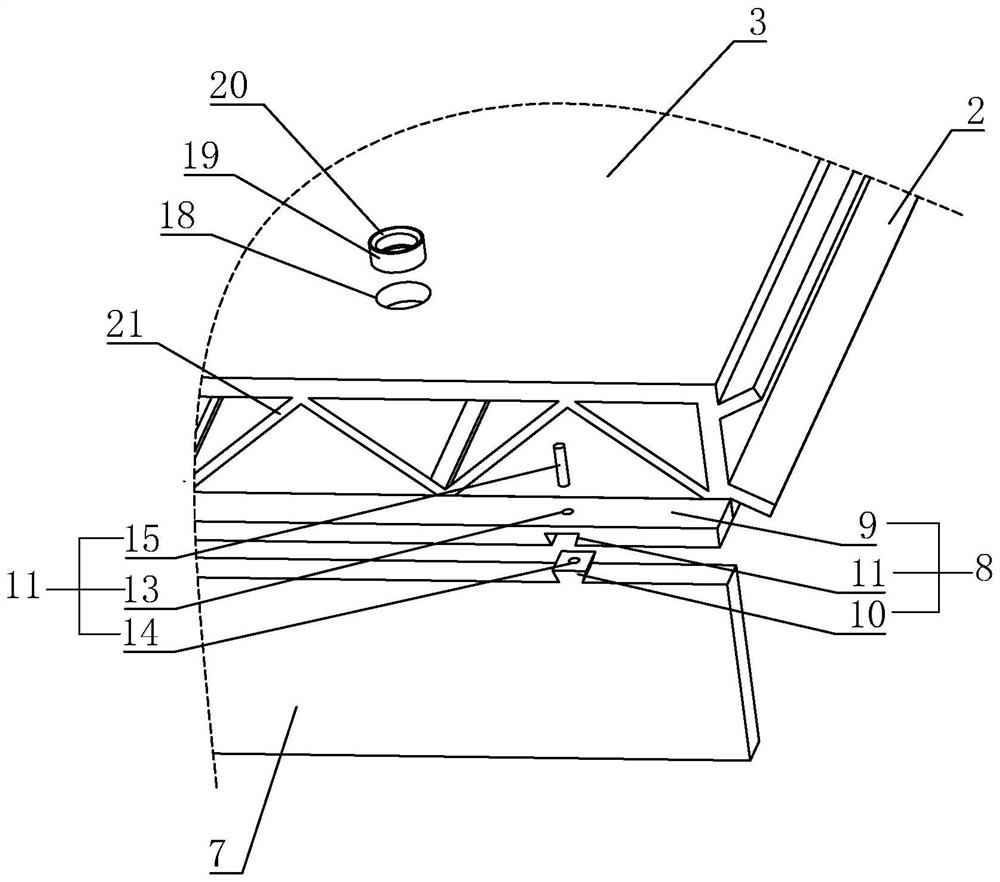

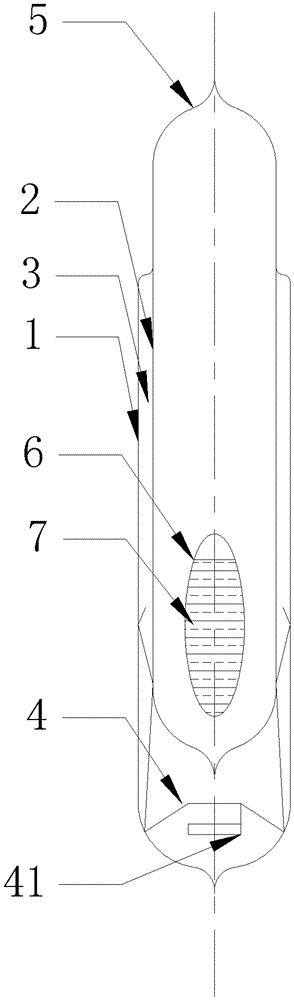

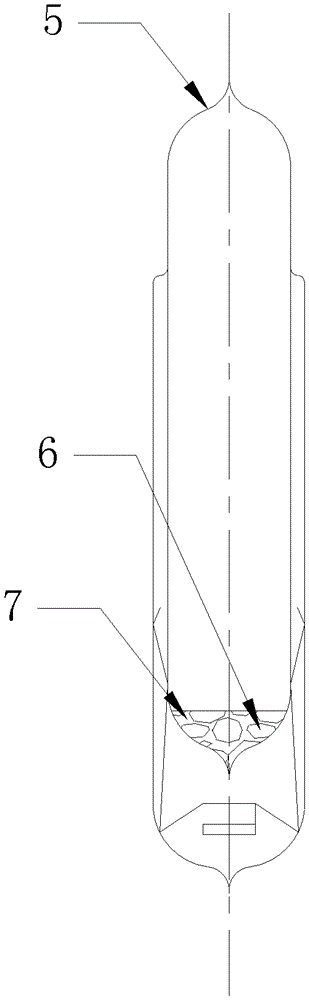

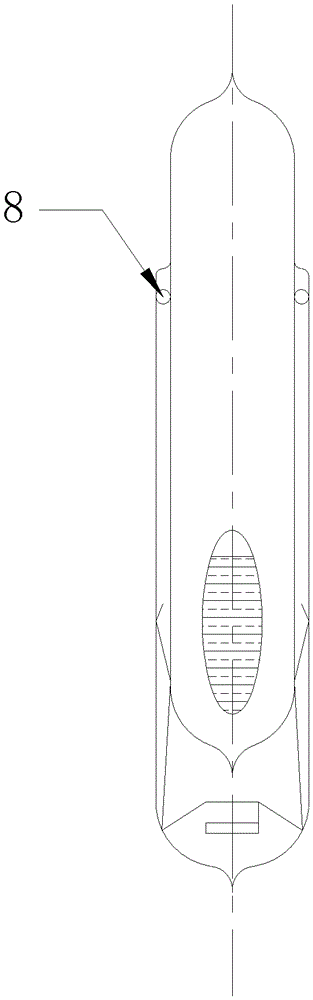

Non-pillar sublevel mining cemented filling mining method

InactiveCN105909247AImprove mining efficiency and mining equipment efficiencyReduce mining costsUnderground miningSurface miningCushionMineralogy

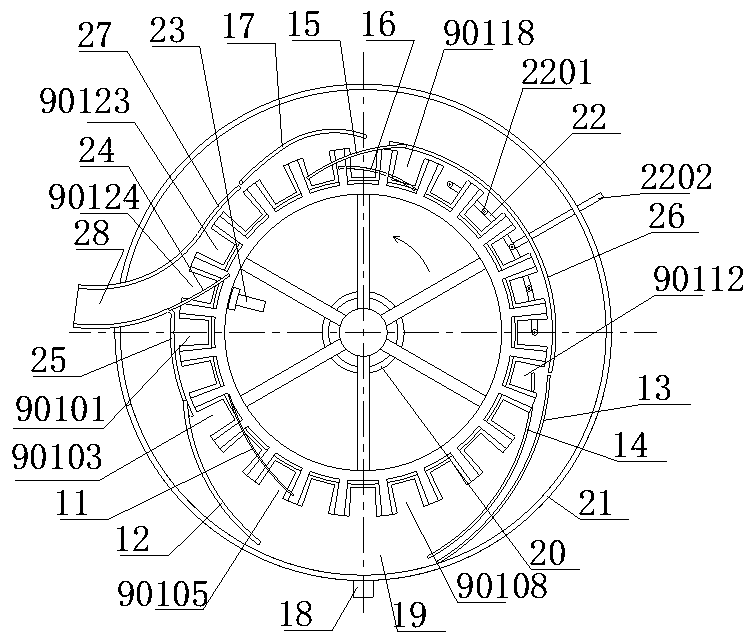

The invention discloses a non-pillar sublevel mining cemented filling mining method. The method is characterized in that sublevels are used as stoping units; stoping drifts are arranged in a staggered way in upper and lower sublevels; rhombic components are stoped in a sublevel mining way; the paces are the basic stoping units; deep hole breakdown is performed in upward fan shapes; multi-row hole short-delay blasting is performed; ore removal is performed under the barnyard condition; after the mining, the cemented filling is performed in time; and rhombic cushions capable of being cyclically used for filling partition wall reserved blasting compensation spaces, blasting free surfaces and the like of the partition wall are used, so that a series of problems of complicated and expatiatory production process, low mining efficiency, high mining cost and the like of the existing top slicing horizontal stoping drift cemented filling mining method can be solved under the condition of steeply-inclined large and thick ore bodies.

Owner:SOUTHWEAT UNIV OF SCI & TECH

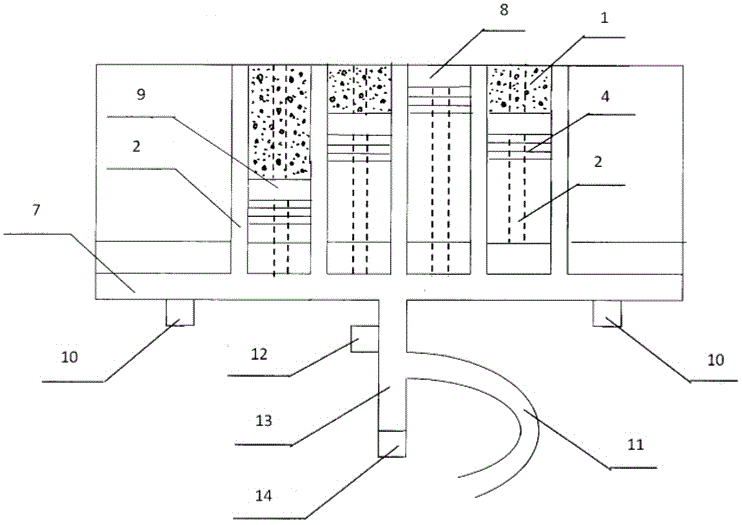

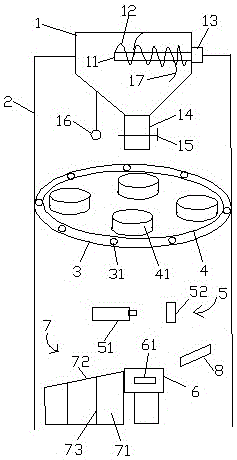

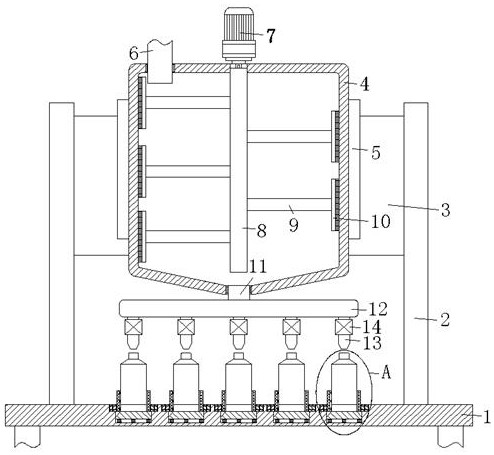

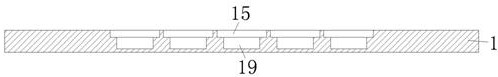

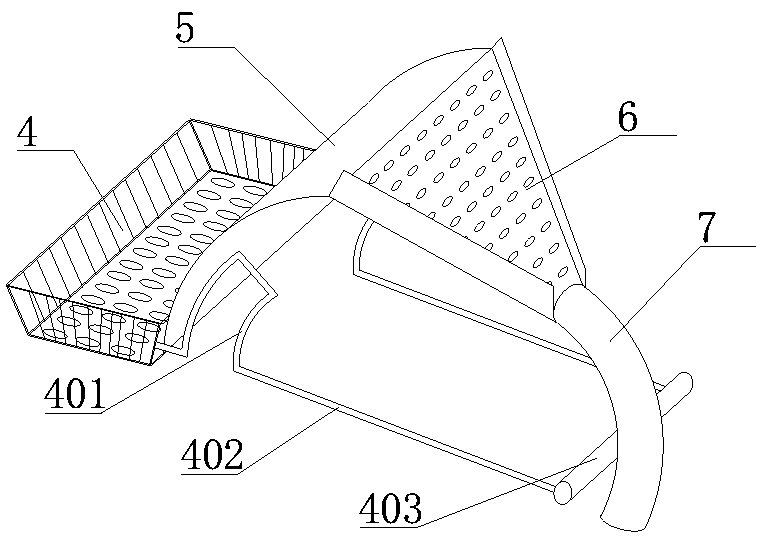

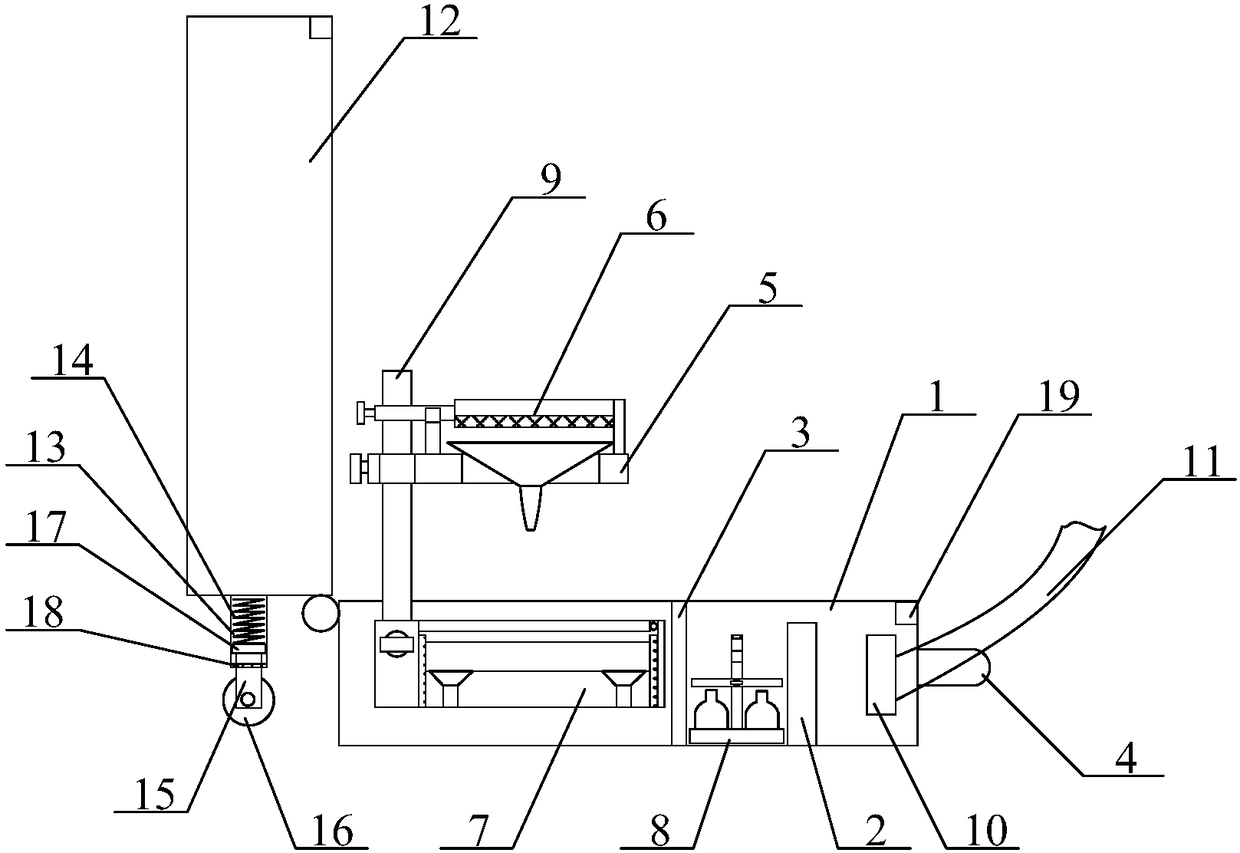

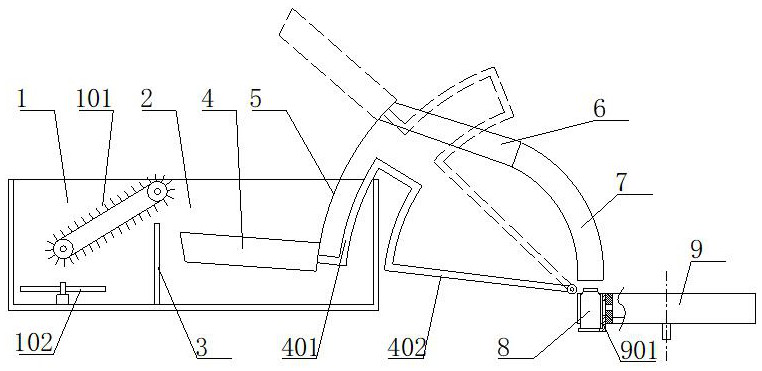

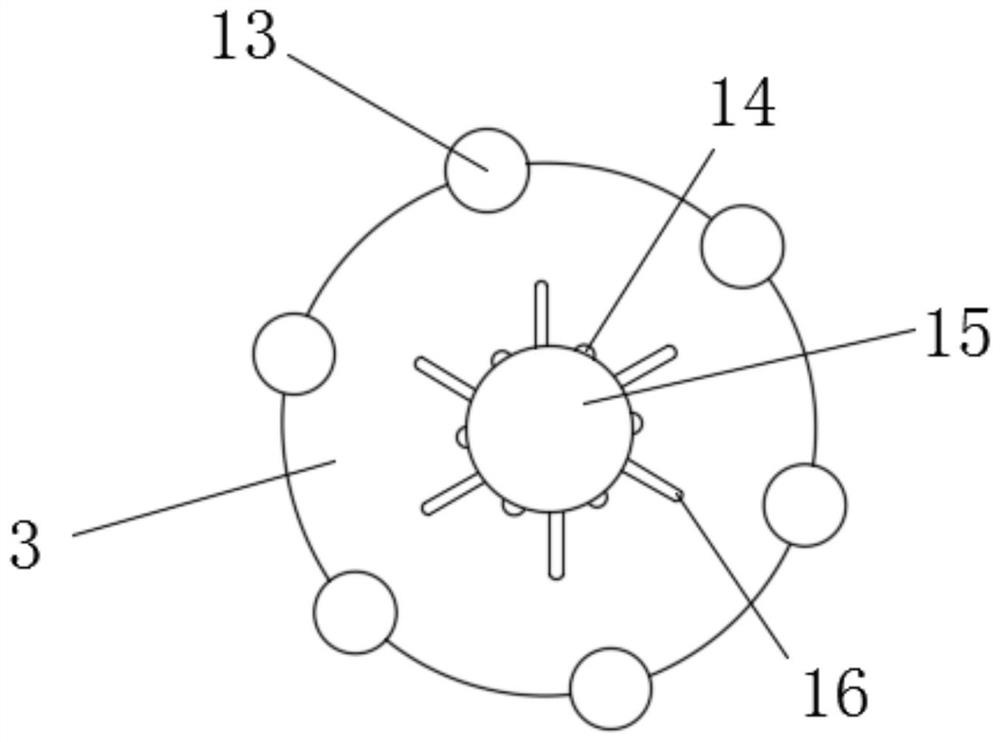

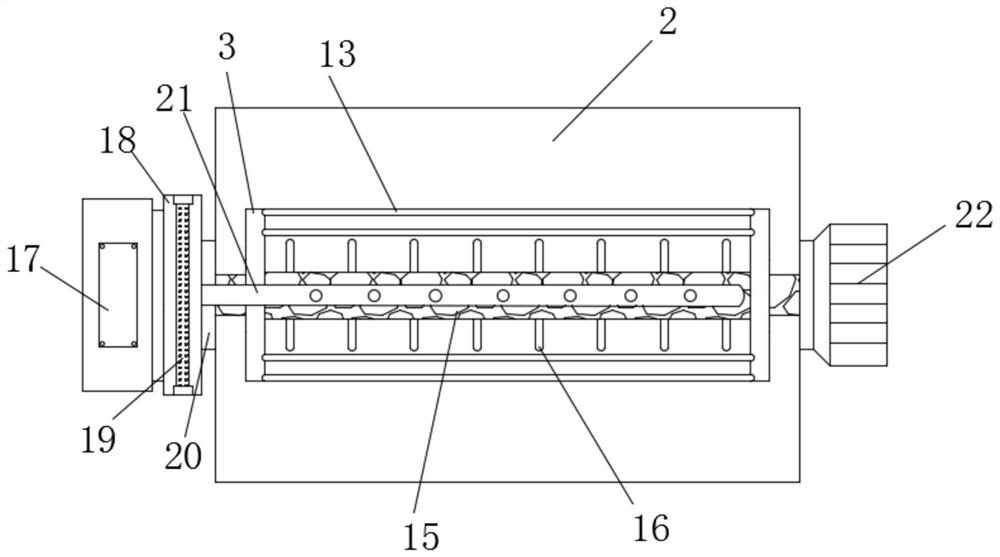

Automatic sand and gravel bagging machine

InactiveCN106167105AImprove bagging efficiencyAccurate measurementLarge containersWrapper twisting/gatheringEngineeringNail plate

The invention discloses an automatic sand and gravel bagging machine which comprises a hopper, a fixed frame, a rotating plate fixing base, a rotating plate, a tying machine and a jacking table. A discharge port is formed in the bottom of the hopper and provided with an electromagnetic valve. A vibration swing hammer is arranged on the side wall of the hopper or the fixed frame. The rotating plate fixing base is coaxially arranged below the hopper. The outer side wall of the rotating plate fixing base is fixedly connected with the fixed frame. A plurality of woven bag fixing bases are arranged on the rotating plate. Each woven bag fixing base comprises a through hole, an electromagnet and a metal pressing block, wherein when the electromagnet is powered on, the metal pressing block can attract the electromagnet. The tying machine is arranged below the rotating plate and coaxial with the discharge port. The tying machine comprises an opening sealing machine head and a nail plate. A weighing sensor connected with the electromagnetic valve is arranged on the jacking table. By means of the machine, material blockage can not easily happen, blocking materials or wall-sticking materials can be automatically removed, the bagging amount can be automatically controlled, and bagging efficiency is high. The automatic opening sealing operation of sand and gravel bags can be achieved, opening sealing efficiency is high, opening sealing quality is good, and material leakage can not easily happen.

Owner:许陈菲

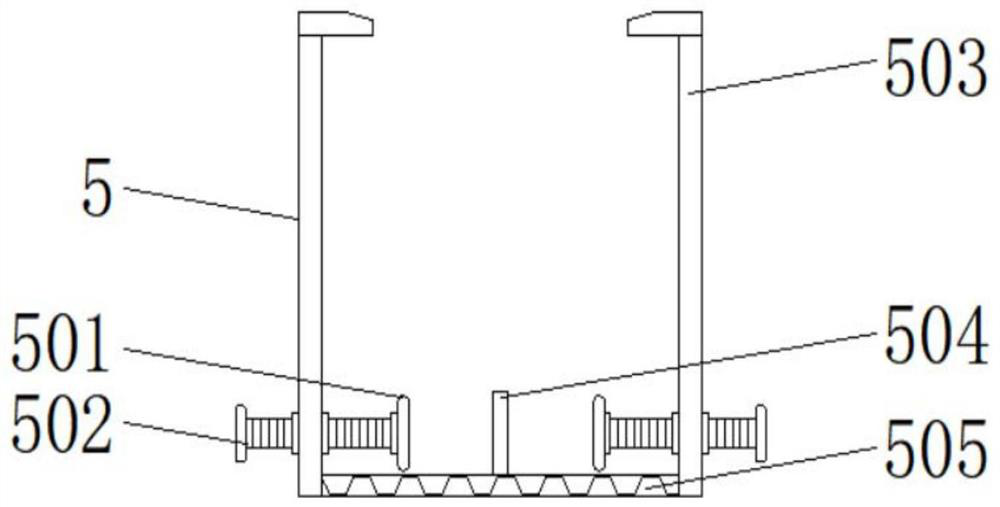

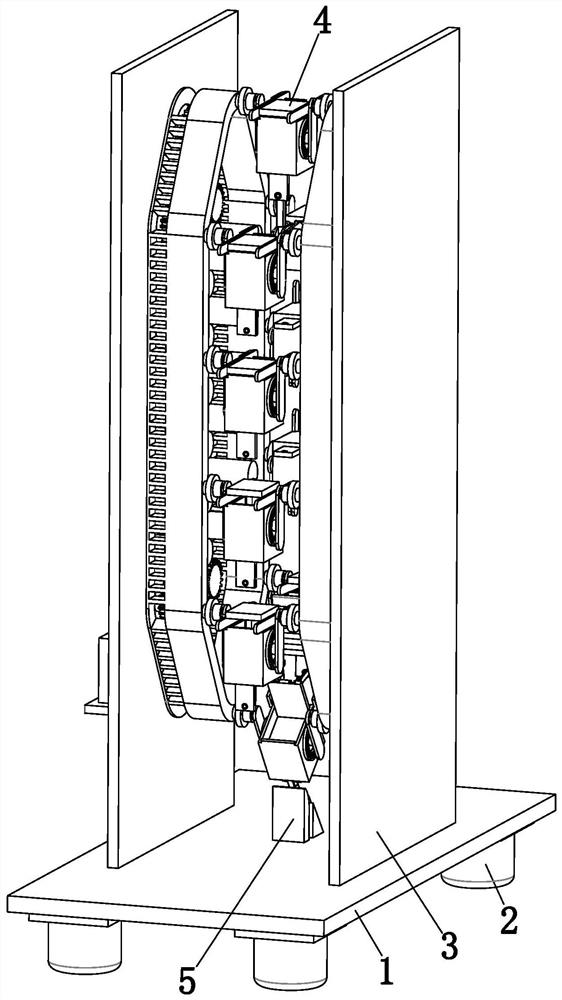

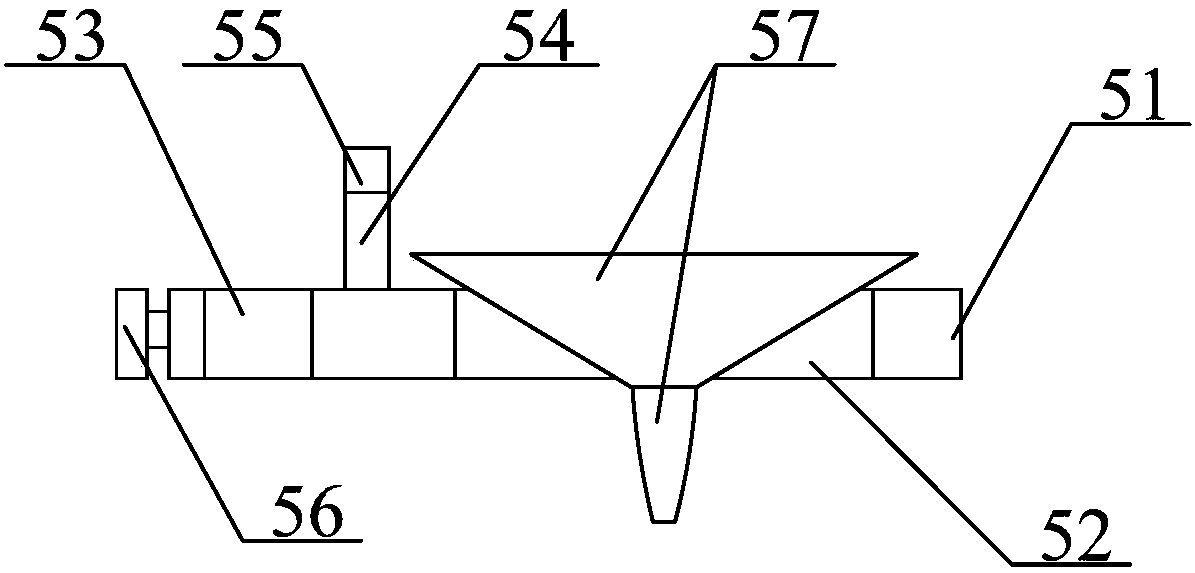

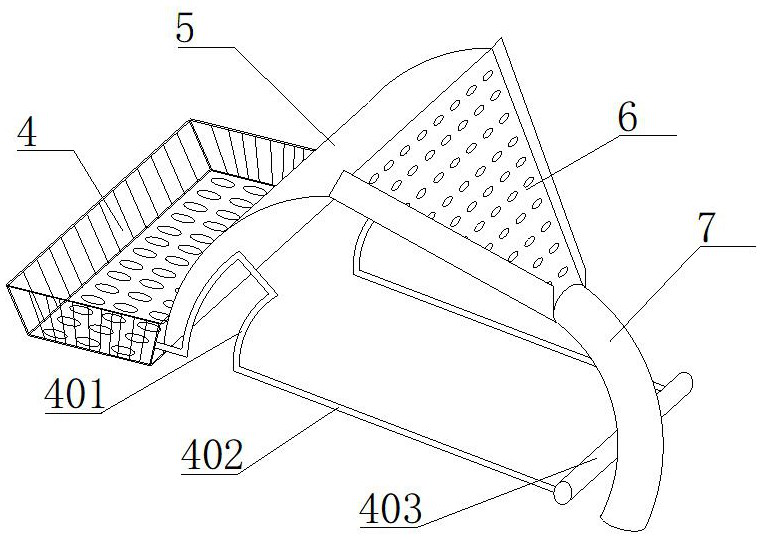

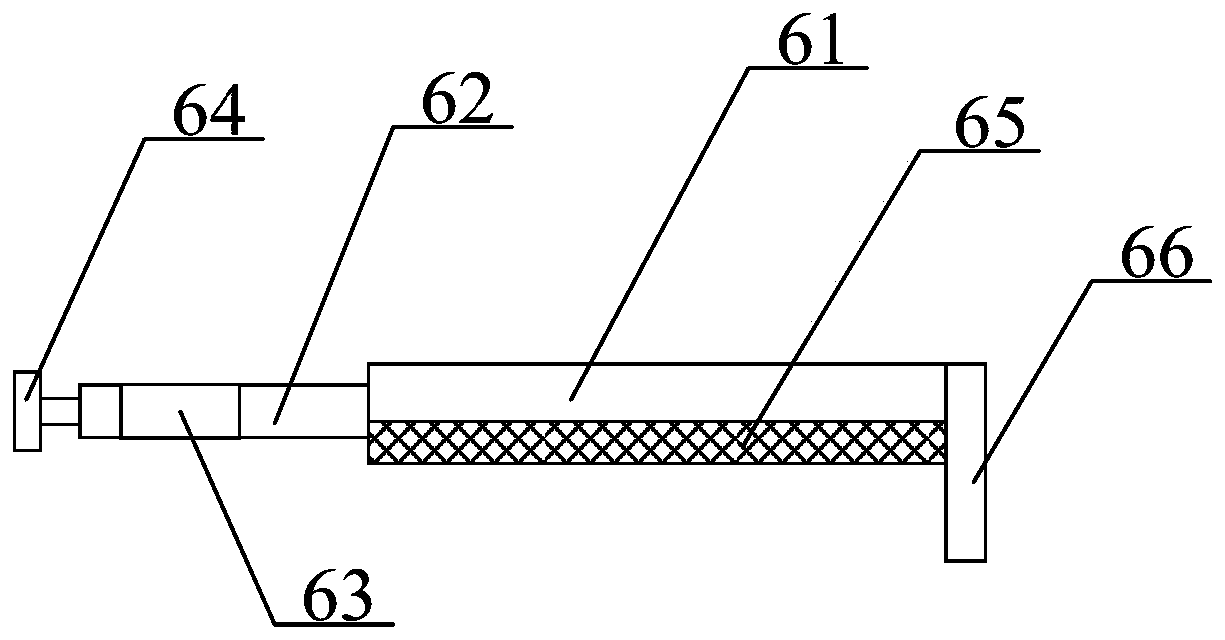

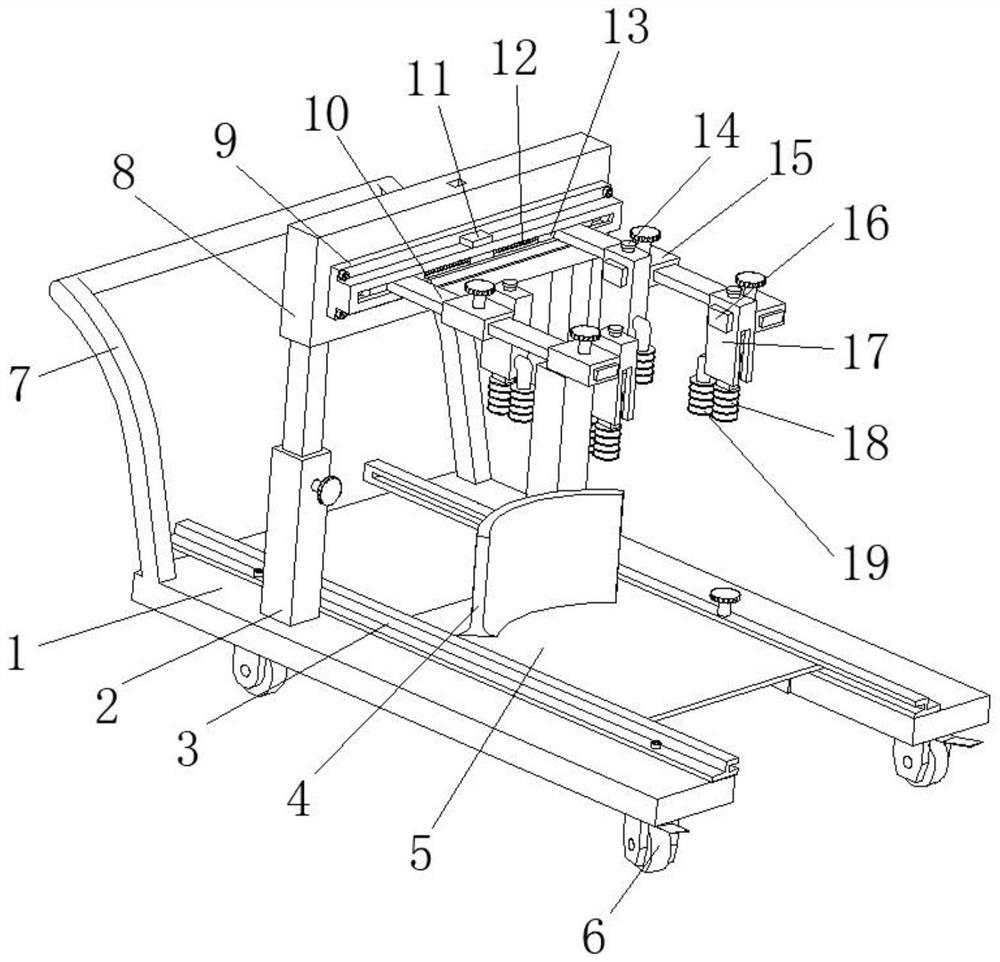

Bag supporting device

The invention discloses a bag supporting device. The device comprises a base, a sliding plate, a moving plate, a fixed base and a bag supporting base. The center of one end of the base is provided with an arc groove, sliding rails are fixed to the positions, on the two sides of the arc groove, of the top of the base, the sliding plate is arranged between sliding grooves of the sliding rails in a sliding manner, an arc baffle is connected to one end of the top of the sliding plate, a handle is connected to one end of the top of the base, stand columns are arranged at the positions, on one end of the handle, of the top of the base, a movable plate is arranged on the stand columns, one side of the movable plate is provided with a fixed base, sliding blocks are in sliding connection into the sliding grooves, one sides of the sliding blocks are connected with bag supporting rods, two mounting bases are in sliding connection to the bag supporting rods, and bag supporting bases are connectedto one ends of the mounting bases. Through mounting of the base, the sliding plate, the movable plate, the fixed base and the bag supporting base, a plastic woven bag can be rapidly and effectively fixed, dismounted and mounted, work of manual bag supporting and manual bag centralizing can be effectively replaced, and work efficiency is improved.

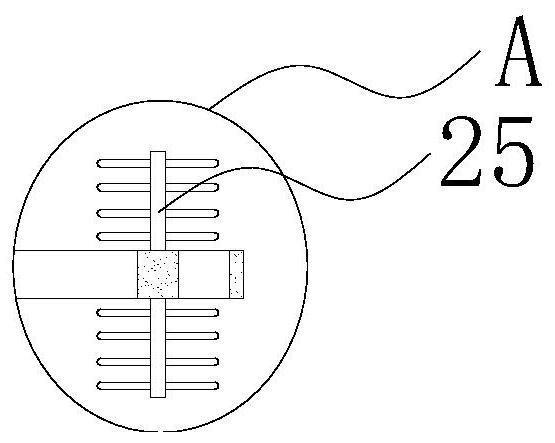

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Emulsion explosive with high power and strong hardness

InactiveCN101531555AImprove filling workLong storage periodExplosive working-up apparatusWater in oilParaffin wax

The invention relates to an emulsion explosive with high power and strong hardness, which is characterized in that the emulsion explosive is prepared by the steps of crushing ammonium nitrate according to proportion by a crusher, adding the crushed ammonium nitrate and sodium nitrate into a melting tank filled with water according to proportion by a inclined spiral machine, stirring and heating to 115-125DEG C to prepare aqueous solution; stirring and heating semi-refined paraffin, Vaseline, crystallite wax, stearic acid and emulsifier according to proportion to 110-120DEG C to prepare oil phase solution; conveying the aqueous solution and the oil phase solution according to ratio of 94:6 to a emulsifying machine by a screw pump, making the aqueous solution excellently wrapped in the oil phase solution to form a water-in-oil type emulsification matrix, cooling to 43-57DEG C by steel strip, adding a sensitizing agent according to proportion, uniformly mixing, packaging and storing. The invention has advantages of hard state, high explosion power, long storage life, low production cost and high production safety.

Owner:ANHUI JIANGNAN CHEM IND CO LTD

Automatic sand-gravel aggregate bagging and conveying device

InactiveCN106184844AUniform loadEasy dischargeSolid materialPackaging automatic controlSolenoid valveFixed frame

Owner:许陈菲

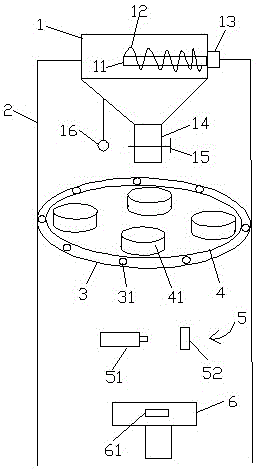

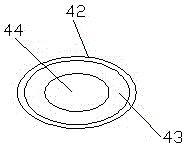

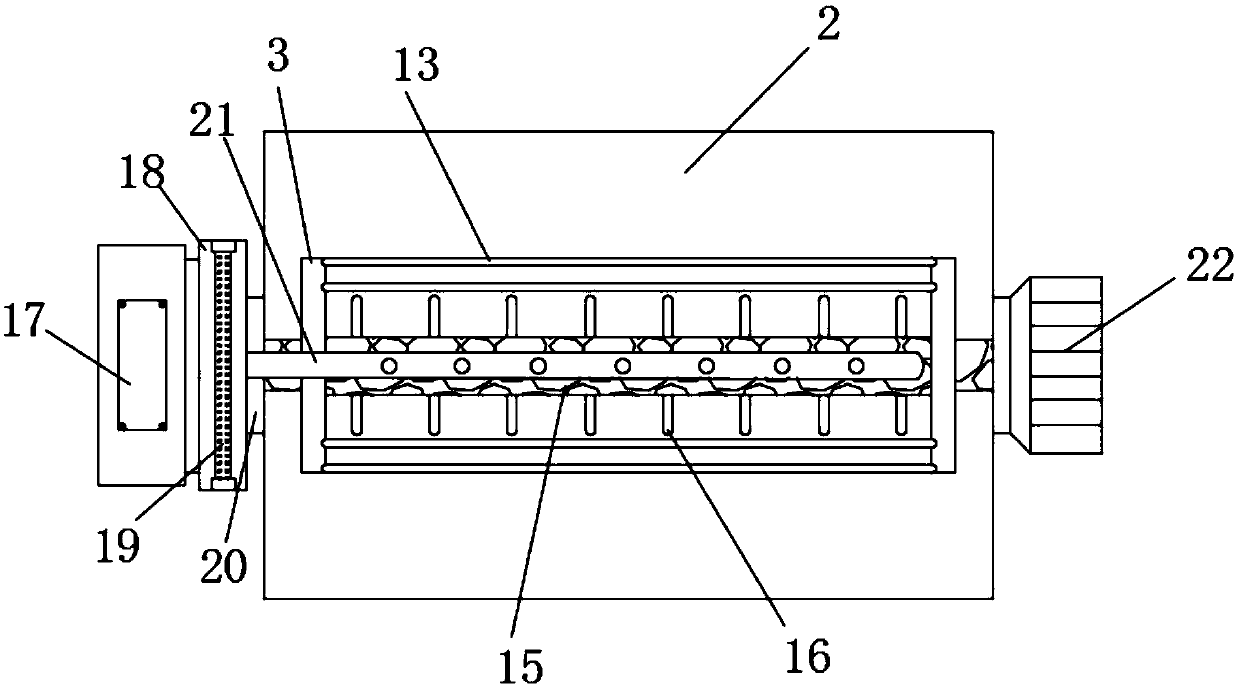

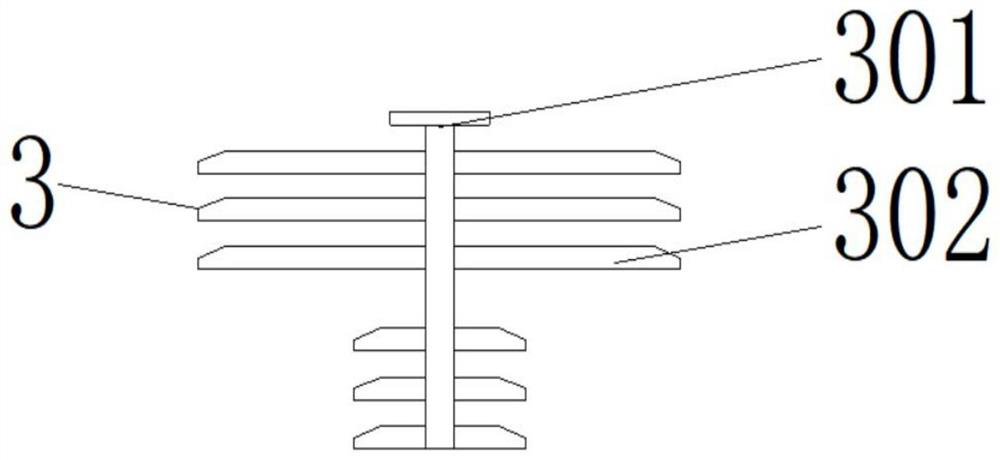

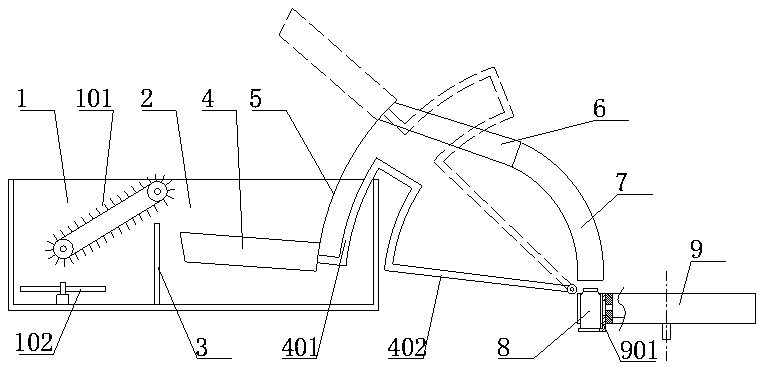

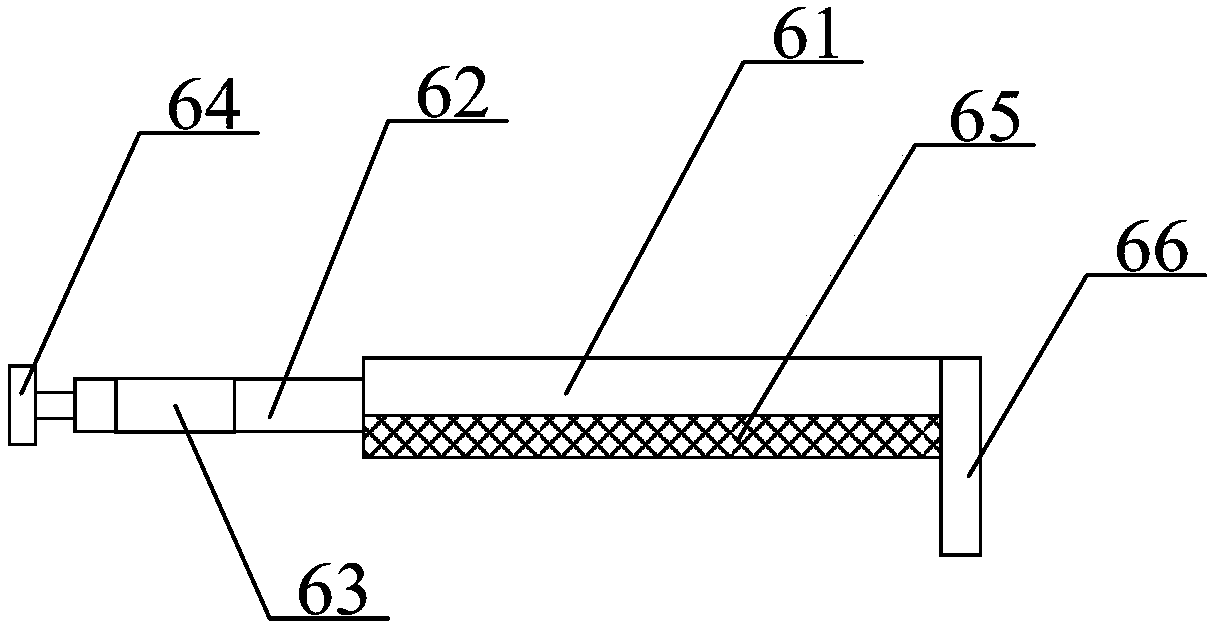

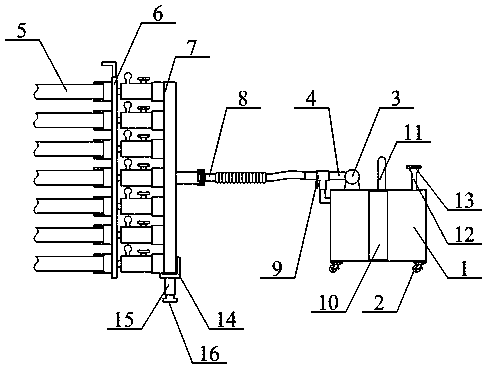

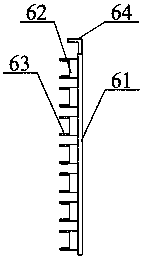

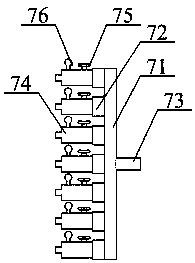

Efficient down filling machine

ActiveCN109607466AAvoid cakingImprove down filling efficiencyUpholstery manufactureClothes making applicancesEngineeringAir blower

The invention discloses an efficient down filling machine which comprises a down filling machine main body, wherein a pipeline is mounted on one side of the down filling machine main body; a down filling port is formed in the other side of the down filling machine main body; a box body is mounted at one end of the pipeline; a down inlet is embedded into the upper part of the box body; a connectionround plate is arranged inside the box body; a rubber band is circumferentially arranged on the connection round plate; a connection pipe is embedded into the connection round plate. According to theefficient down filling machine, when the connection pipe rotates, the connection round plate is driven to rotate, so as to drive the rubber band and a short rod to rotate, and downs entering the boxbody can be flicked to avoid the hardening of the downs, scatter the downs and improve the down filling efficiency; when an air blower works, heat in a heating pipeline can be blown into the box bodythrough a through hole via an air blow pipe to play a very good air drying role and reduce moisture in the downs; an electric push rod controls a distance between a pressure plate and the down fillingport through a rotating shaft and a connection column so as to fix the down filling port and an object to be subjected to down filling.

Owner:颍上县祥盛建设管理有限公司

Stable glue filling facility

The invention discloses a stable glue filling facility. The stable glue filling facility comprises a base, a shell and glue bottles. A fixing mechanism is fixedly connected with the upper end of the base, and the shell is fixedly connected to the front side wall of the fixing mechanism. Heaters are installed on the side walls of the two ends of the shell. A feeding pipe which communicates with theinterior of the shell is arranged at the upper end of the shell in a penetrating mode. A stirring mechanism which extends to the interior of the shell is arranged at the upper end of the shell. A discharging mechanism is arranged at the bottom of the shell in a penetrating mode, and the glue bottles are placed on the base and located under the discharging mechanism. The stable glue filling facility is reasonable in structural design, the glue bottles can be stably fixed and are prevented from shaking in the filling process, the filling work is conveniently conducted, the glue solidification phenomenon can be avoided in the filling working process, the filling work is independently conducted on one glue bottle or simultaneously conducted on the multiple glue bottles, and different usage demands are met.

Owner:何京东

Structural separation seam applied to aluminum form and construction process thereof

ActiveCN111827671AEasy filling workPlay a solid roleForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineeringMechanical engineering

Owner:深圳市旭生骏鹏建筑工程有限公司

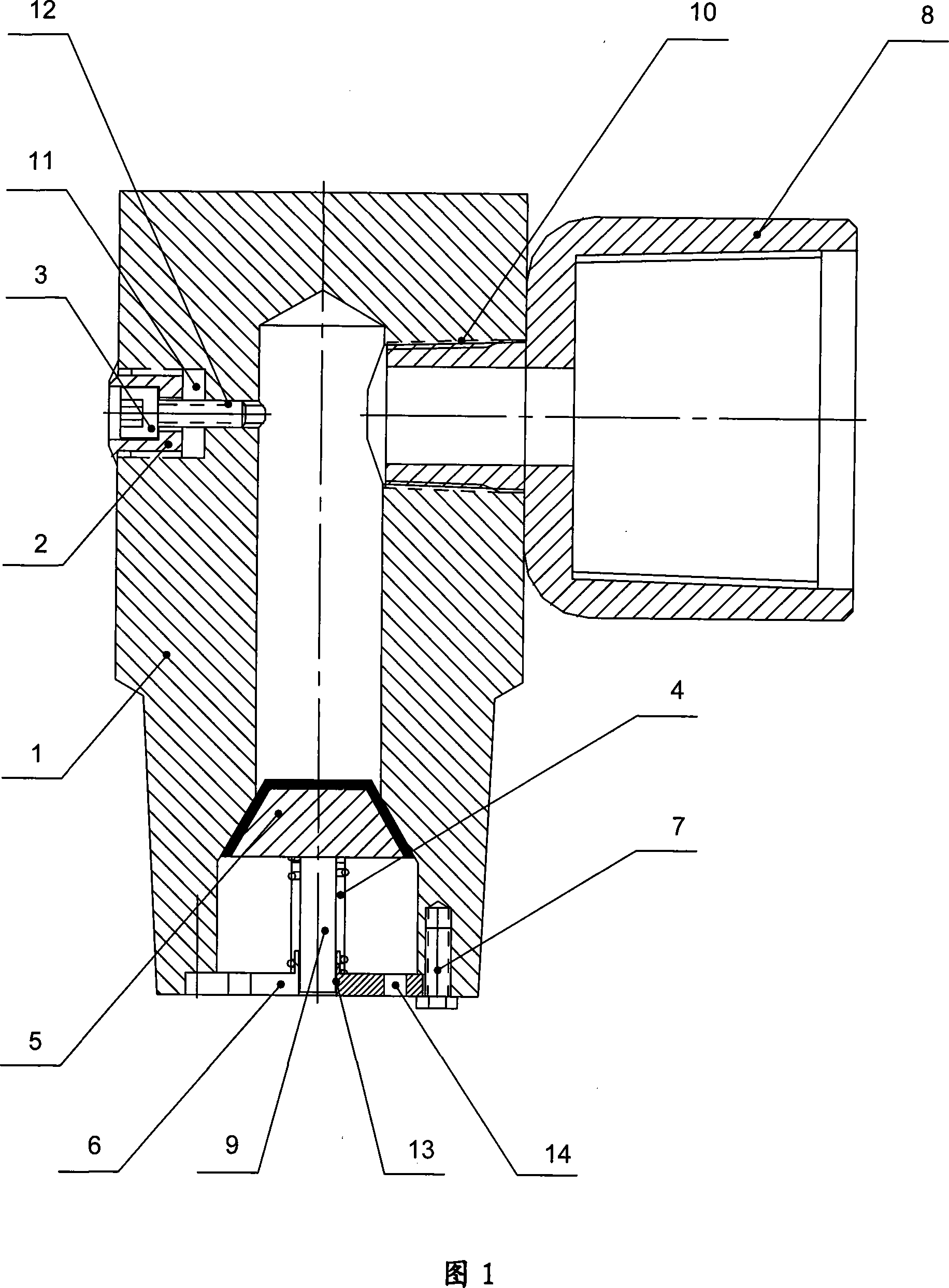

Liquid fill adapter for gas well

InactiveCN101131071AEasy to produceStable productionFluid removalSealing/packingEngineeringMechanical engineering

The present invention provides one kind of natural gas well liquid filling joint, which includes one joint body with hollow cavity possessing opening in the lower end, one great displacement interface and one small displacement interface communicated to the hollow cavity set radially onto the joint body, one movable valve inside the hollow cavity and with truncated cone surface for fitting the inner surface of the hollow cavity hermetically, one valve cover with valve core leading hole and through hole fixed to the lower end of the joint body, and one valve core in the bottom of the movable valve. The joint is for filling liquid to natural gas well, and has features of smart structure, use convenience and high safety.

Owner:许现西

Chili sauce filling device

InactiveCN112250017AImprove filling efficiencyAffect filling workLiquid bottlingChilli con carneElectric machinery

The invention discloses a chili sauce filling device. The chili sauce filling device comprises a charging assembly, a limiting assembly and a moving assembly, wherein a motor is fixedly installed at the top of the charging assembly; a stirring assembly is fixedly installed at an output end of the motor; and a flow dividing assembly is movably installed at an output end of the charging assembly. According to the invention, the stirring assembly is fixedly installed at the output end of the motor, a sealing cover can be opened to fill chili sauce into the charging box, then the motor is used fordriving a shaft rod to rotate, then the shaft rod is used for driving a stirring paddle to stir the chili sauce, and the situation that the chili sauce is condensed into blocks, and filling working of workers is affected is prevented; and then a connecting disc is movably connected with the charging box through a fastening bolt, then the chili sauce is subjected to flow dividing and guided by virtue of a guide block, then flowing of the chili sauce is controlled by virtue of an electromagnetic valve, the workers can carry out the filling working conveniently, and two guide pipes are used forcarrying out the filling working, so that the chili sauce filling efficiency is increased, and a low production cost is achieved.

Owner:湖南省嘉禾县三味食品有限公司

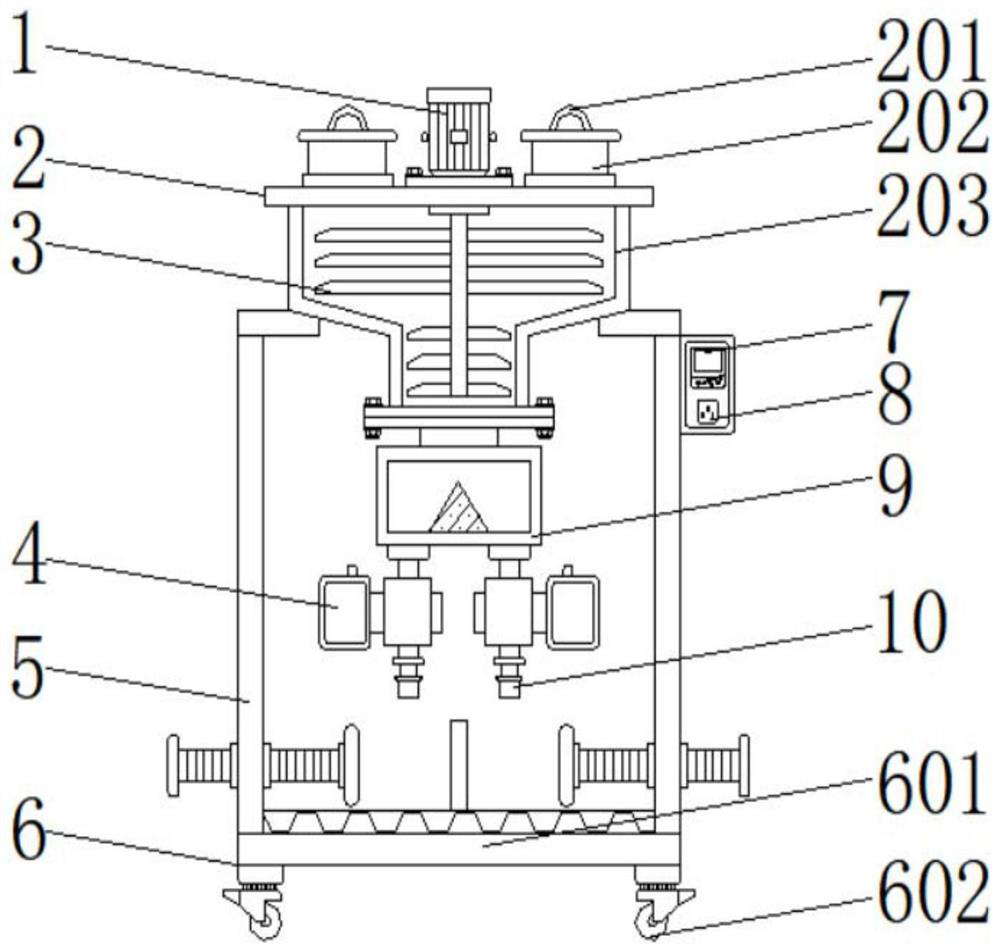

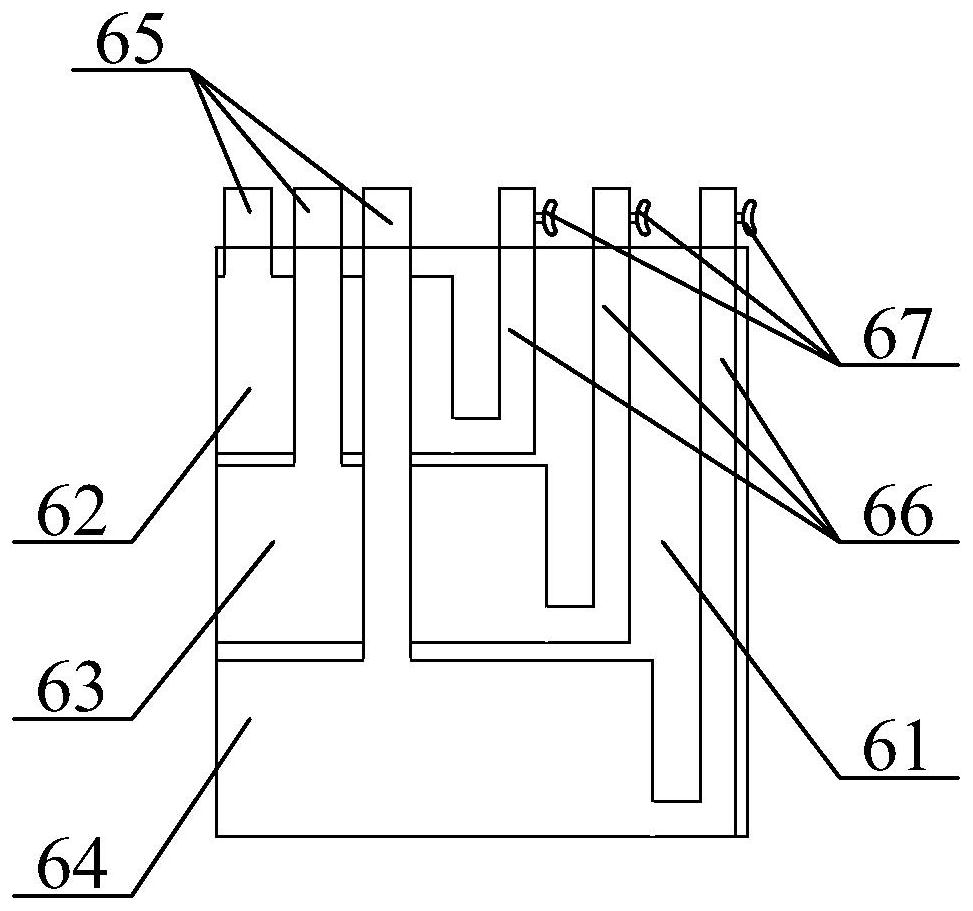

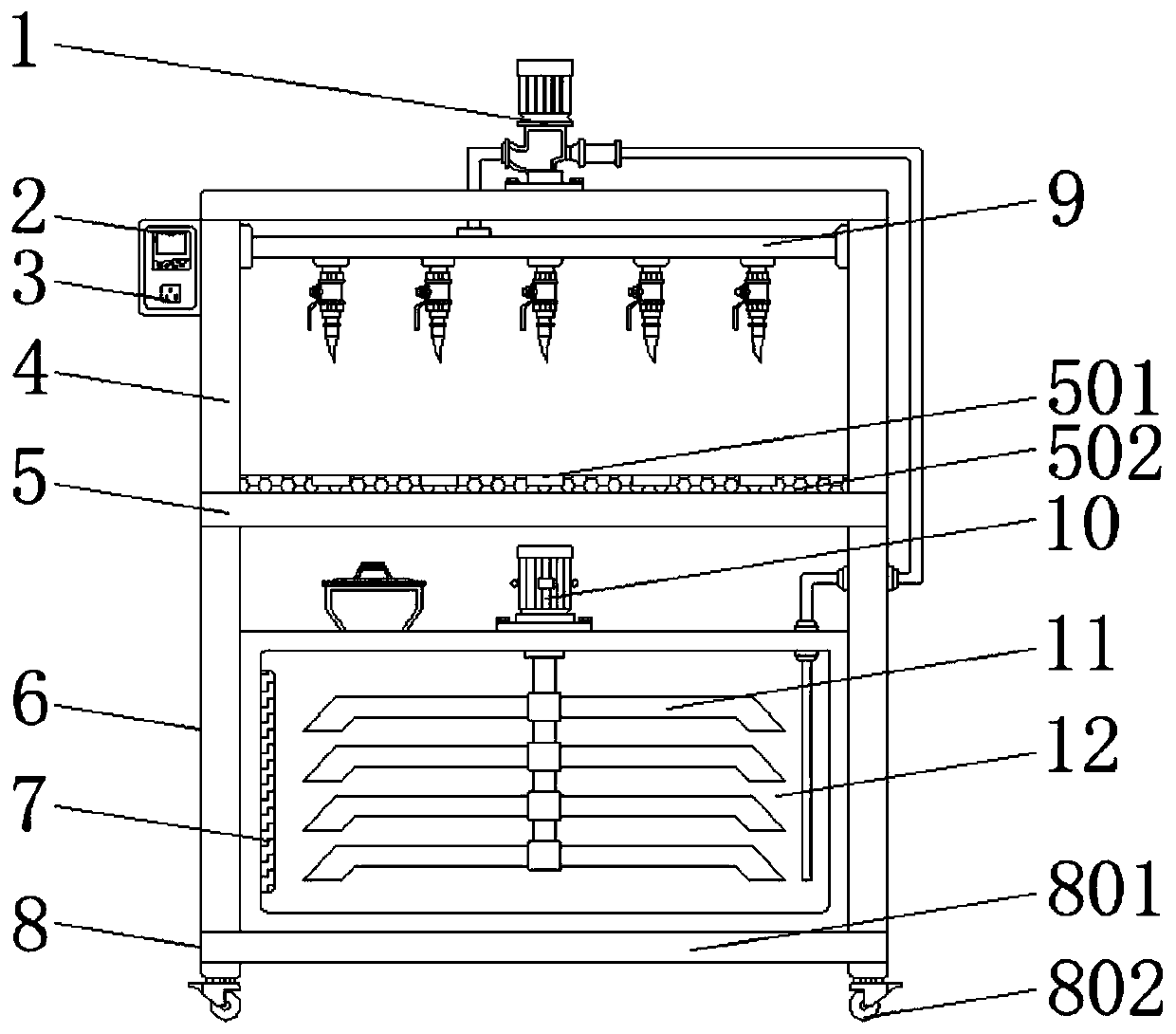

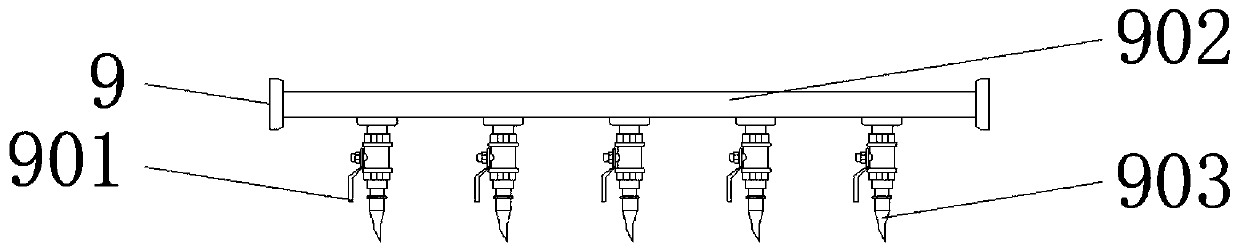

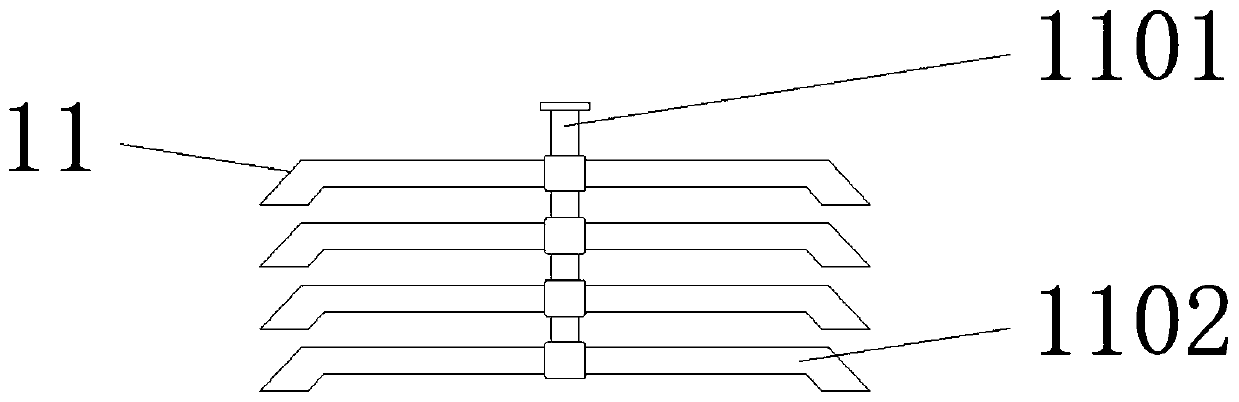

Intelligent shaft supersonic spraying surface pore filling device

InactiveCN111940163AEasy injectionEasy filling workDispersed particle filtrationDirt cleaningImage detectionEngineering

The invention provides an intelligent shaft supersonic spraying surface pore filling device. The device comprises a movable base, movable brake wheels, a supporting control table, a spraying box body,a spraying pump, a storable classified supply box structure, a rotatable adjusting image detection base structure, an adsorbable filtering and cleaning cover structure, a storable rotating shieldingbox structure, a supporting plate, a power switch, a display screen, a PLC, a feeding pipe, a first conveying pipe, a dust collector, a metal hose and a spraying pipe. According to the device, throughthe arrangement of a fixed box, a first-stage storage box, a second-stage storage box, a third-stage storage box, a filling pipe, a second conveying pipe and a manual valve, different materials can be injected into the first-stage storage box, the second-stage storage box and the third-stage storage box through the filling pipe in the working process, and then the materials are conveyed to the spraying pump through the second conveying pipe to be sprayed out; and different materials can be conveyed in the filling process, and the filling work of different materials can be conveniently carriedout in the working process.

Owner:HELI TECH ENERGY CO LTD

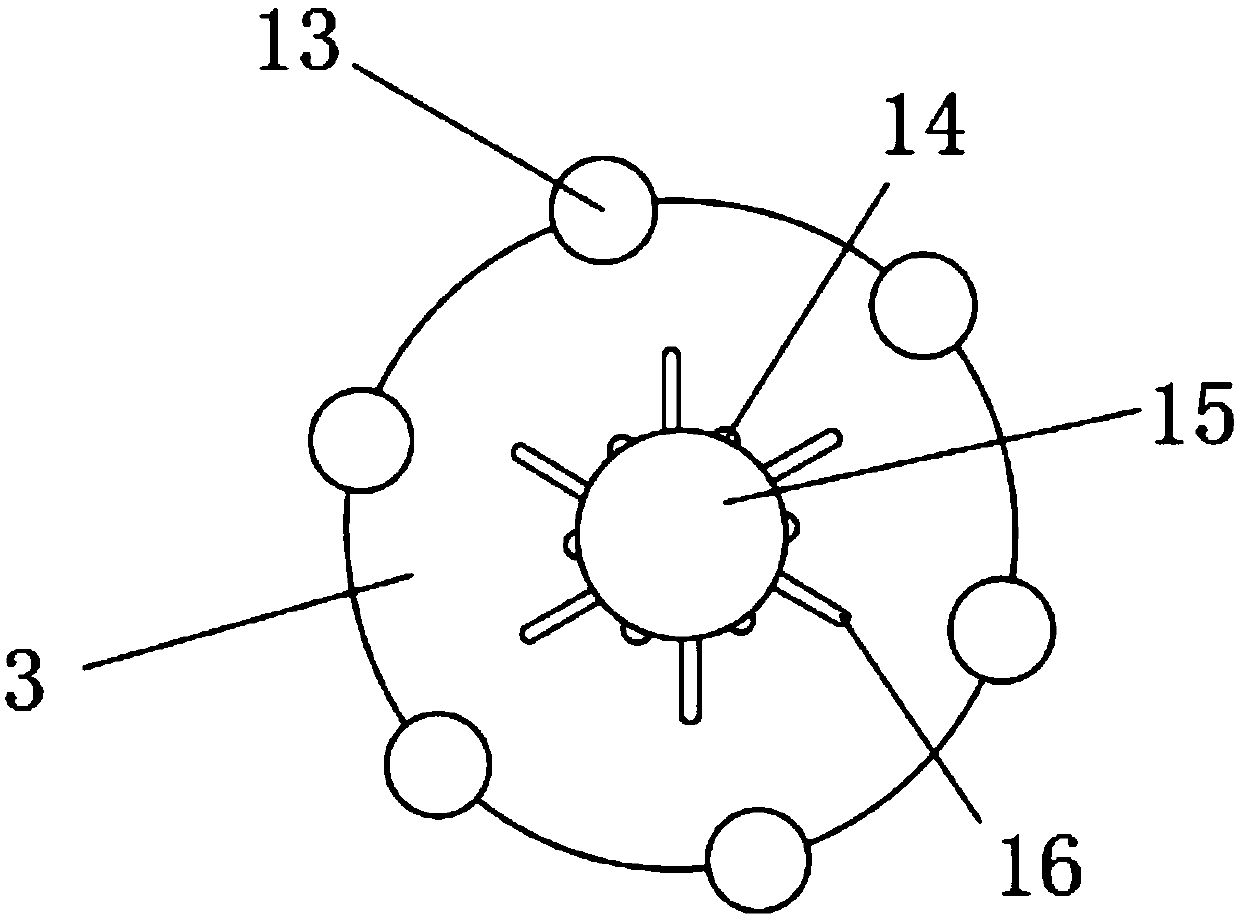

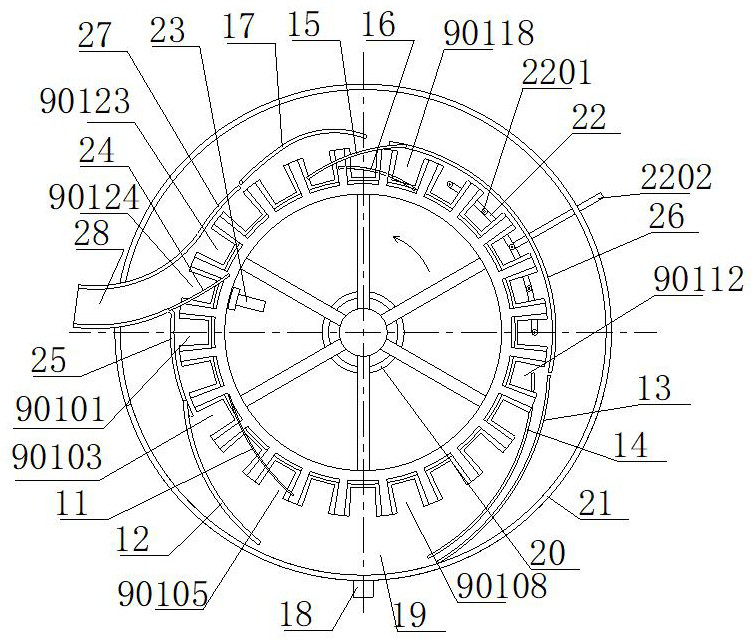

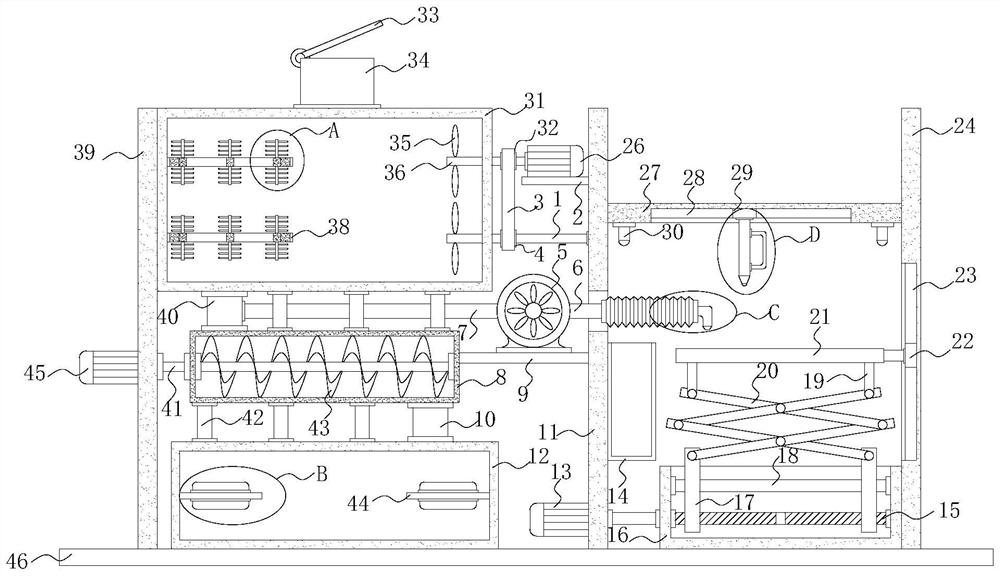

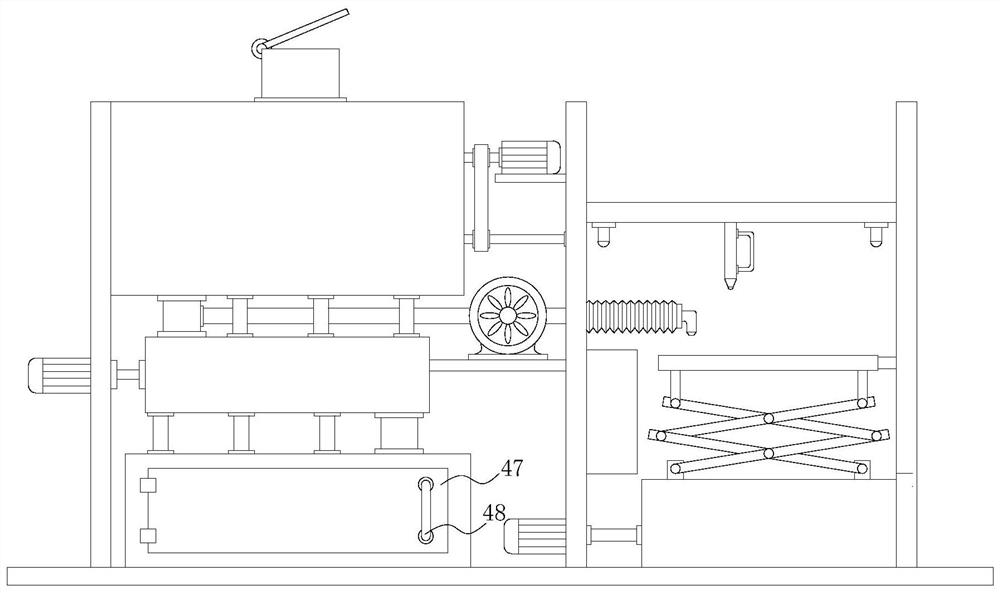

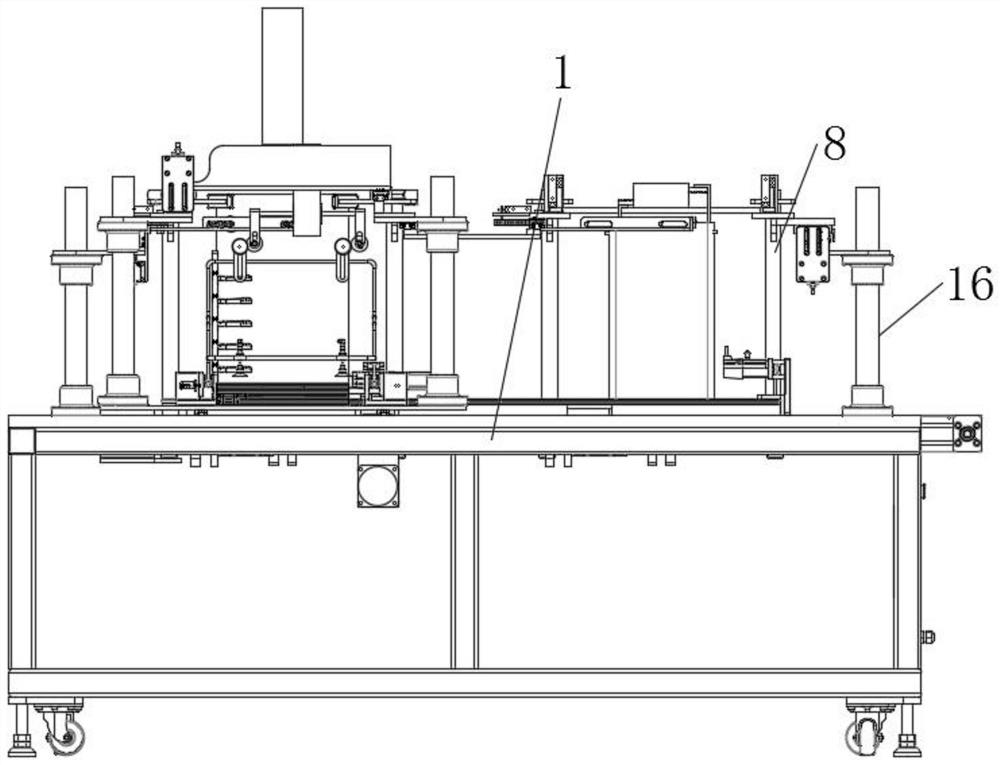

Automatic assembly line for container cleaning and drying

ActiveCN109590299AAutomate operationSave human effortHollow article cleaningDrying gas arrangementsCorrosionAssembly line

The invention relates to an automatic assembly line for container cleaning and drying. Cleaned bottles can be conveniently lifted up from a cleaning pool and poured into a triangular hopper through alifting basket, and the bottles entering the triangular hopper fall into a limiting groove A of a turnover drying rotation disc through a bottle falling pipe; a supporting seat is installed in the limiting groove of the turnover drying rotation disc, U-shaped supporting plates of the supporting seat are provided with openings, according to the characteristic that the bottle bottom and the bottle mouth of each bottle are different in diameter, the bottle mouths can fall into the openings, and accordingly, the upper ends of the bottles which are vertically placed on the supporting seat are higher than the bottles which are placed on the U-shaped supporting plates in an inverted mode; and by means of the characteristic of the bottles, the vertically-placed bottles are pulled down and placed on the U-shaped supporting plates in an inverted mode, accordingly, water in the bottles can be drained, and meanwhile, hot air is blown out by an arc-shaped pipe to dry the bottles. According to the automatic assembly line, the functions of bottle cleaning, drying, placing position turning corrosion and the like are achieved, working before food filling is facilitated, automatic operating is achieved, and manpower and material resources are saved.

Owner:TAICANG TAOXIN INFORMATION TECH CO LTD

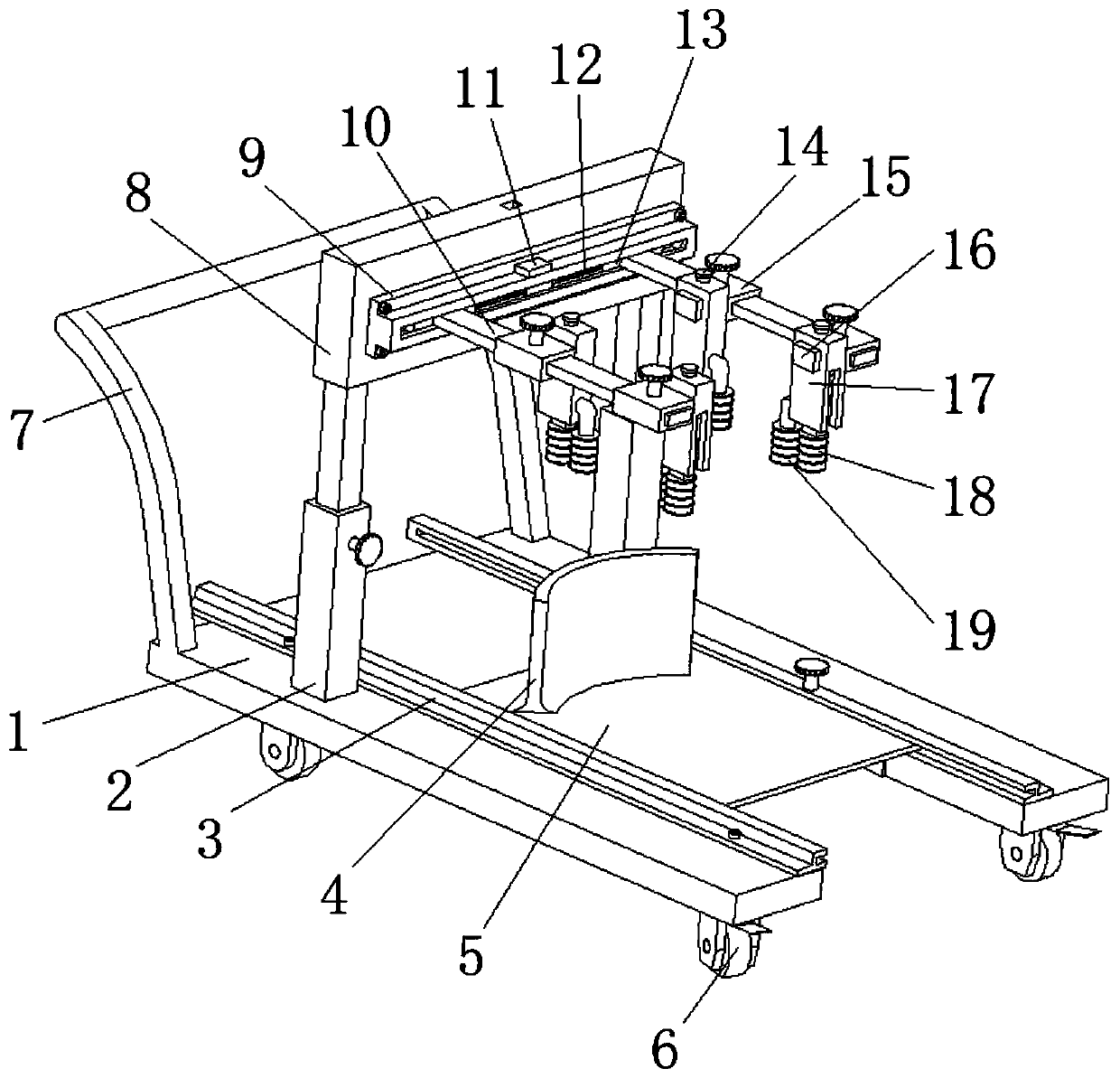

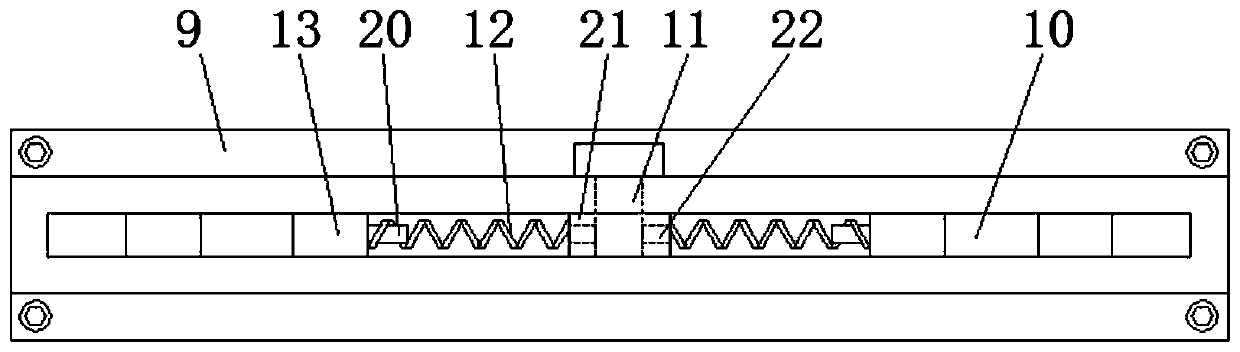

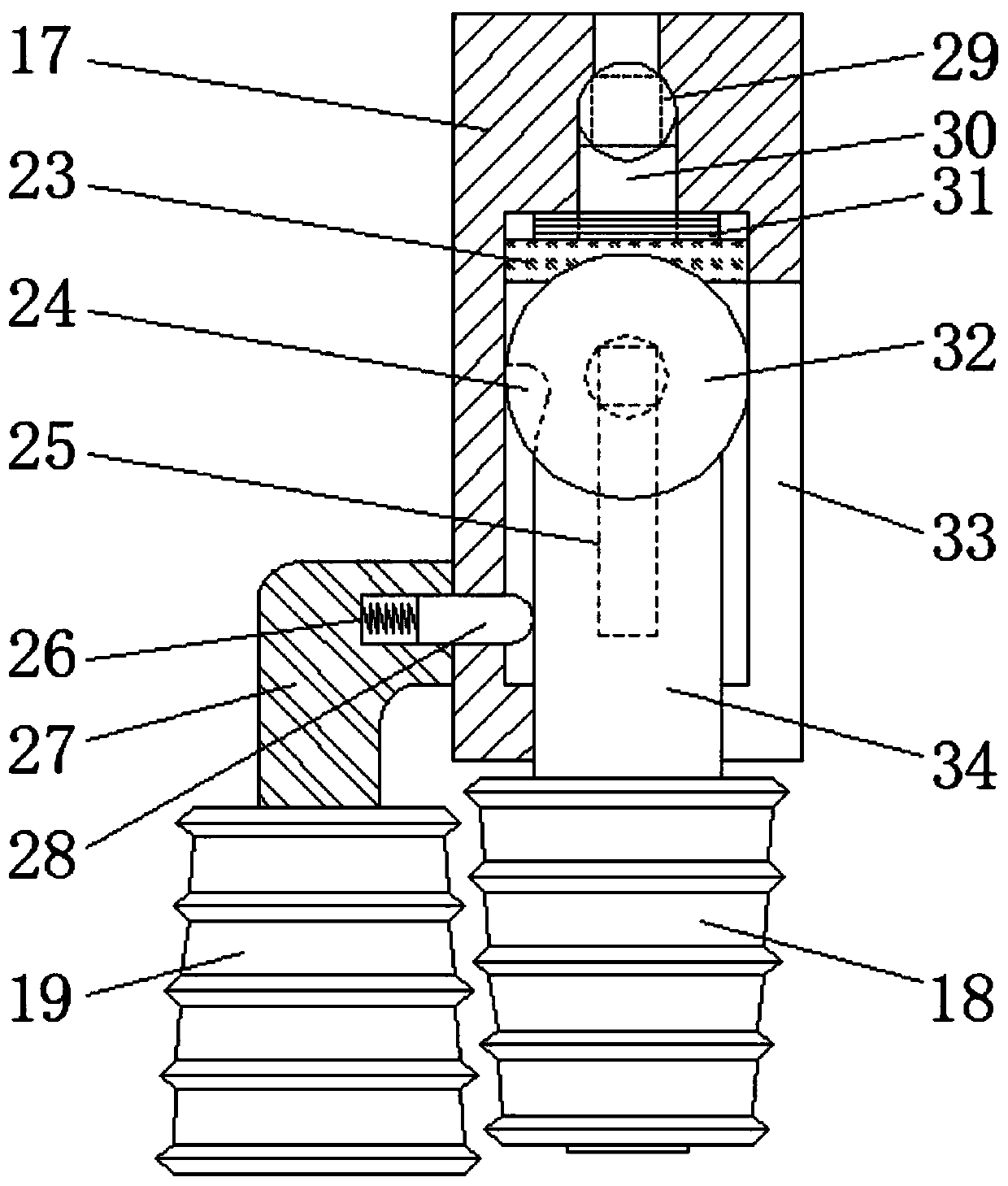

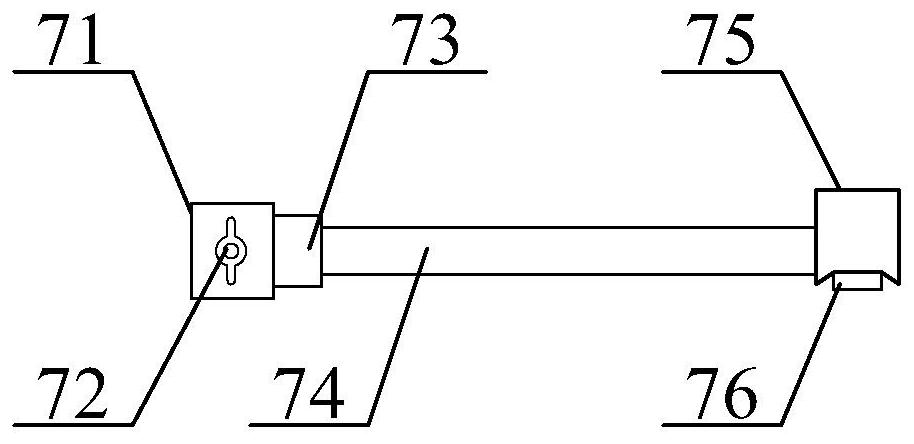

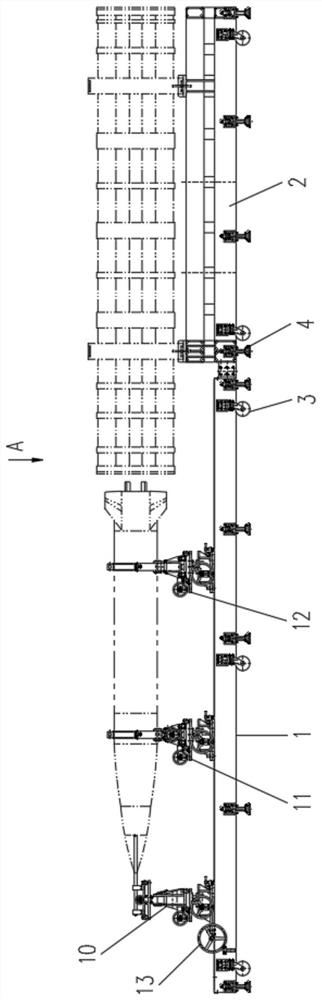

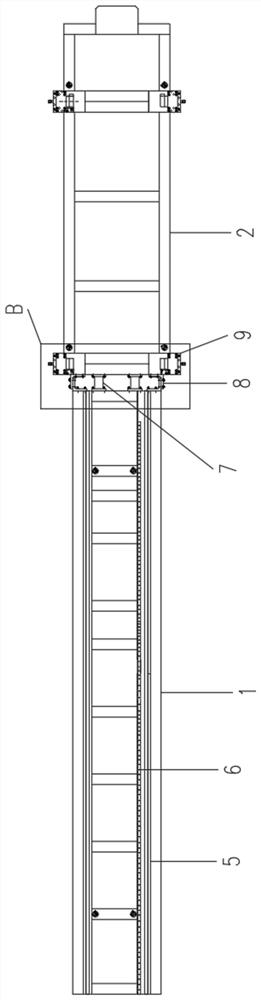

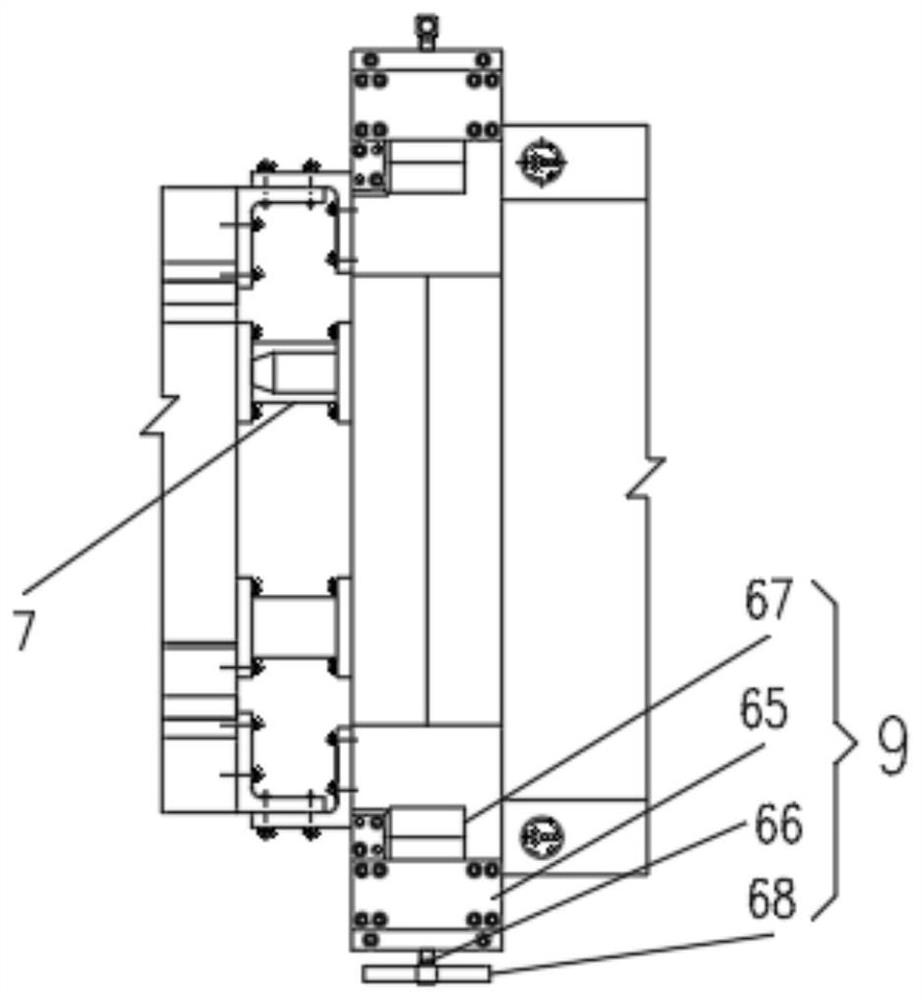

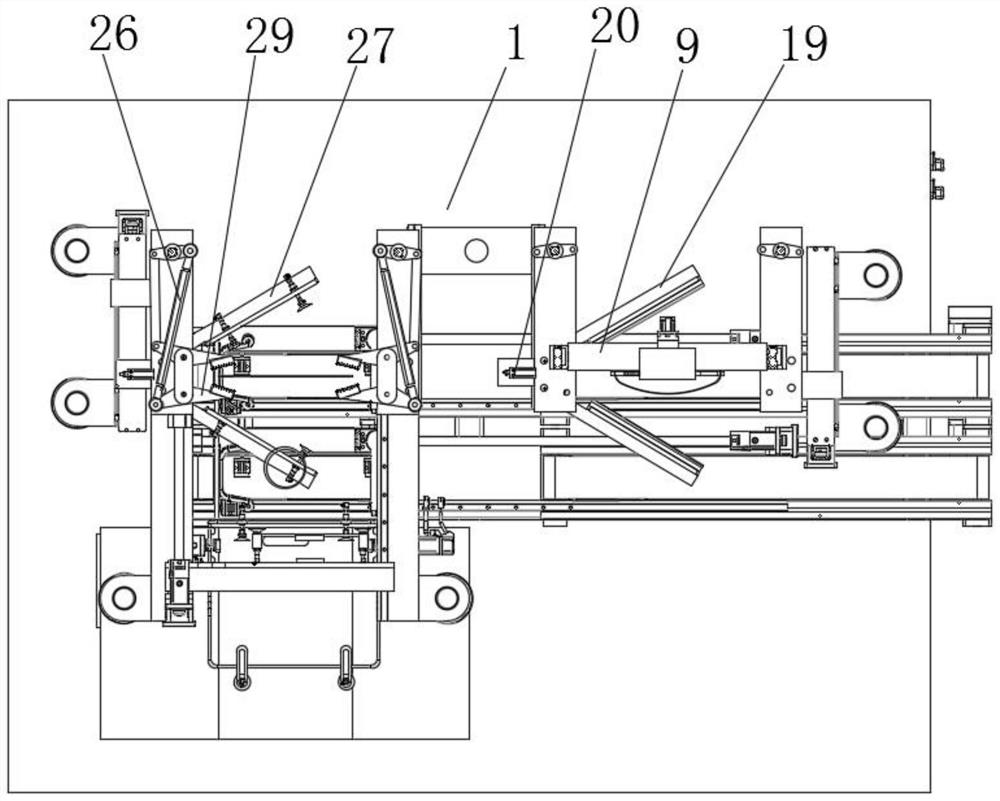

Movable aerospace craft filling device

PendingCN112896564AEasy filling workReduce dependenceCosmonautic ground equipmentsCosmonautic vehiclesVehicle frameFlight vehicle

The invention provides a movable aerospace craft filling device, and the device comprises a missile body frame and a box body frame; the ends, close to each other, of the missile body frame and the box body frame are connected through a guide mechanism and a connecting plate, walking wheels and telescopic supporting legs are arranged on the missile body frame and the box body frame, a clamping mechanism is arranged on the box body frame, a track and a rack are arranged on the missile body frame, a missile body cart, a missile body supporting frame A and a missile body supporting frame B are sequentially arranged on the track close to the box body frame, a driving mechanism is arranged on the lower portion of the missile body cart, and the height of the missile body supporting frame A and the height of the missile body supporting frame B are adjustable. The device is compact in structure and convenient to transport, can be moved through the walking wheels, is convenient to butt, meets the filling requirement of one box and one bullet of an aerospace craft, is convenient to move to a site for filling work, and improves the maneuverability; when a projectile body is filled, manual driving can be adopted, dependence on a power source is reduced, the structure is simple, and potential safety hazards are reduced.

Owner:贵州航天风华精密设备有限公司

Filling equipment for artistic candle production

PendingCN110938494AEasy to operatePrevent solidificationCandle preparation apparatusElectric machineEngineering

The invention discloses filling equipment for artistic candle production. The equipment comprises a workbench, a moving assembly and a filling assembly, fixed plates are fixedly mounted on the two sides of the top of the moving assembly correspondingly, a box body is fixedly arranged between the fixing plates, a heating plate is fixedly mounted on one side of the interior of the box body, a motoris fixedly mounted at the top of the box body, a stirring assembly is fixedly mounted at an output end of the motor, the filling assembly is fixedly arranged in a mounting frame, a PLC is fixedly mounted on one side of the mounting frame, a power jack is fixedly formed in the bottom of the PLC, and a liquid pump is fixedly mounted at the top of the mounting frame. By a series of structures, in theusing process of the device, the output end of the liquid pump passes through the pipeline and the control valve, then wax oil is injected into an outer receiving box through a discharging pipe, thenthe control valve is used for conducting single control over the filling assembly, and operation of workers is facilitated.

Owner:桂东县德古文化传播有限公司

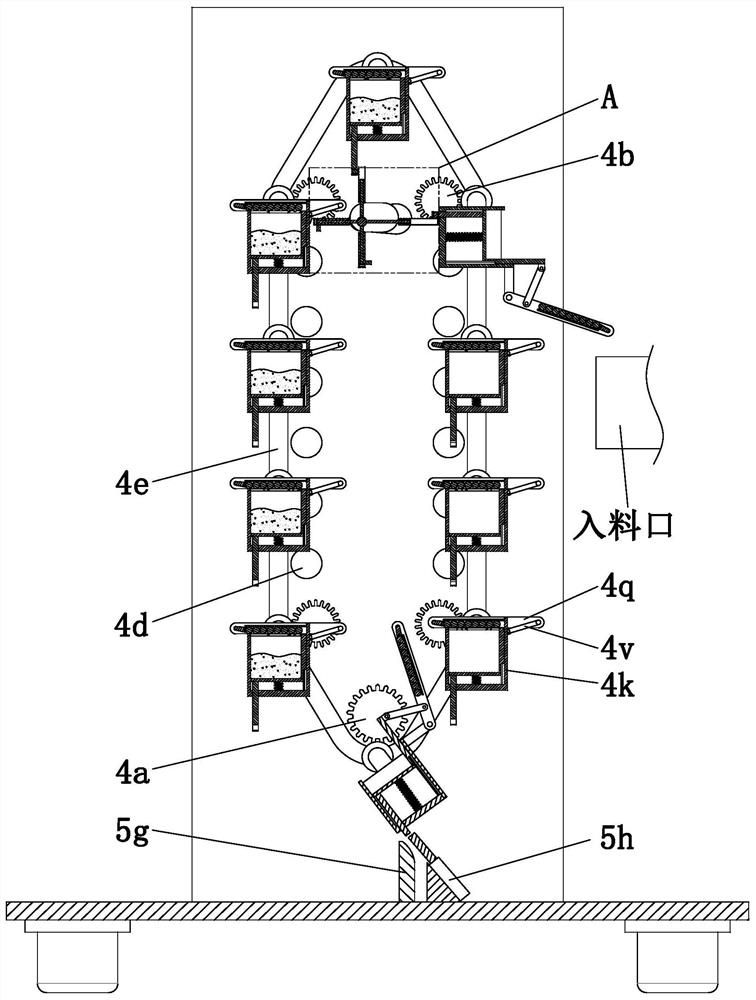

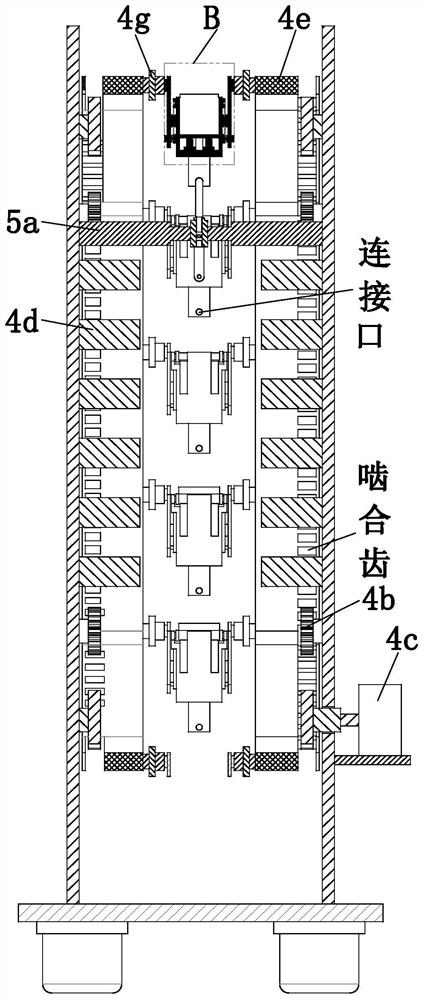

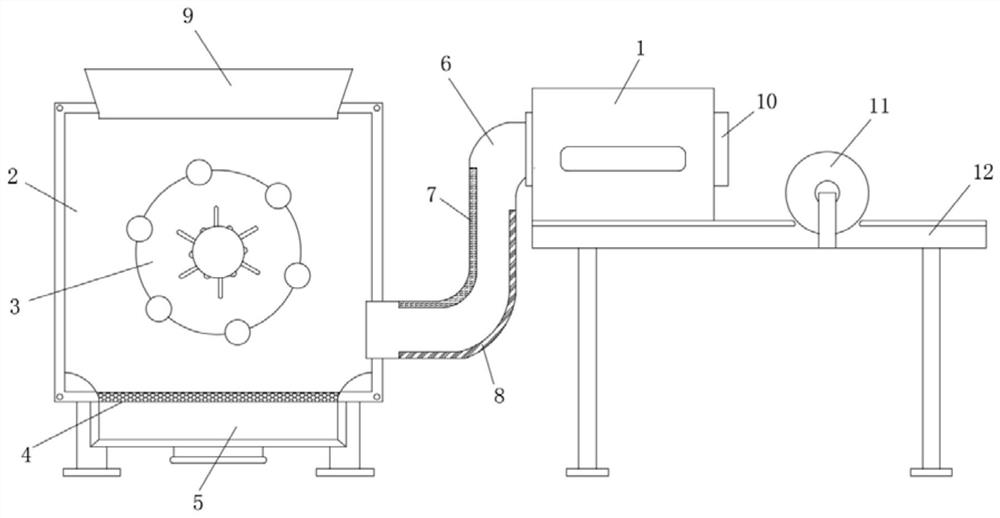

Supply conveying system for activated carbon manufacturing

InactiveCN112320208AAvoid Interfering CollisionsReduce frictionConveyorsConveyor partsActivated carbonProcess engineering

The invention provides supply conveying system for activated carbon manufacturing. The system comprises a mounting bottom plate, supporting legs, a [-shaped frame, a conveying mechanism and a turnovermechanism, and solves the problems that during assembling and fixing work of an electric appliance cabinet, a person needs to use a tool for fill activated carbon materials into a reaction kettle, inthe period, many activated carbon materials needing to be transported exist, due to the operation manner, the labor intensity of workers is increased, the working efficiency of activated carbon transportation operation is reduced, when the activated carbon materials are conveyed through an existing conveying belt, due to the fact that an inlet of the reaction kettle is usually higher, it is difficult to pour all the stored activated carbon materials into an activation furnace manually or through the conveying belt, in the transport process, mechanical vibration easily causes the phenomenon that the activated carbon raw material at a high position fall out of the equipment, so that adverse effects are brought to maintenance of the equipment and body health of workers, and the like.

Owner:宁波锦瑄环保科技有限公司

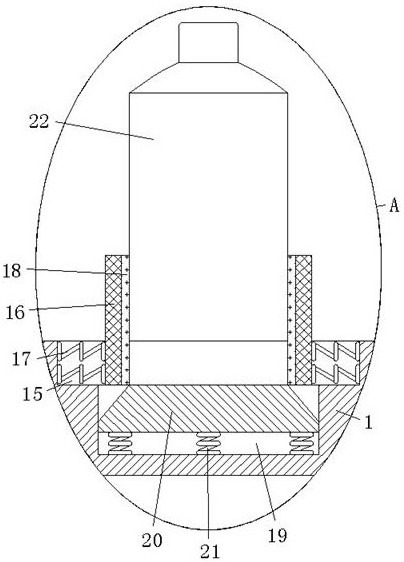

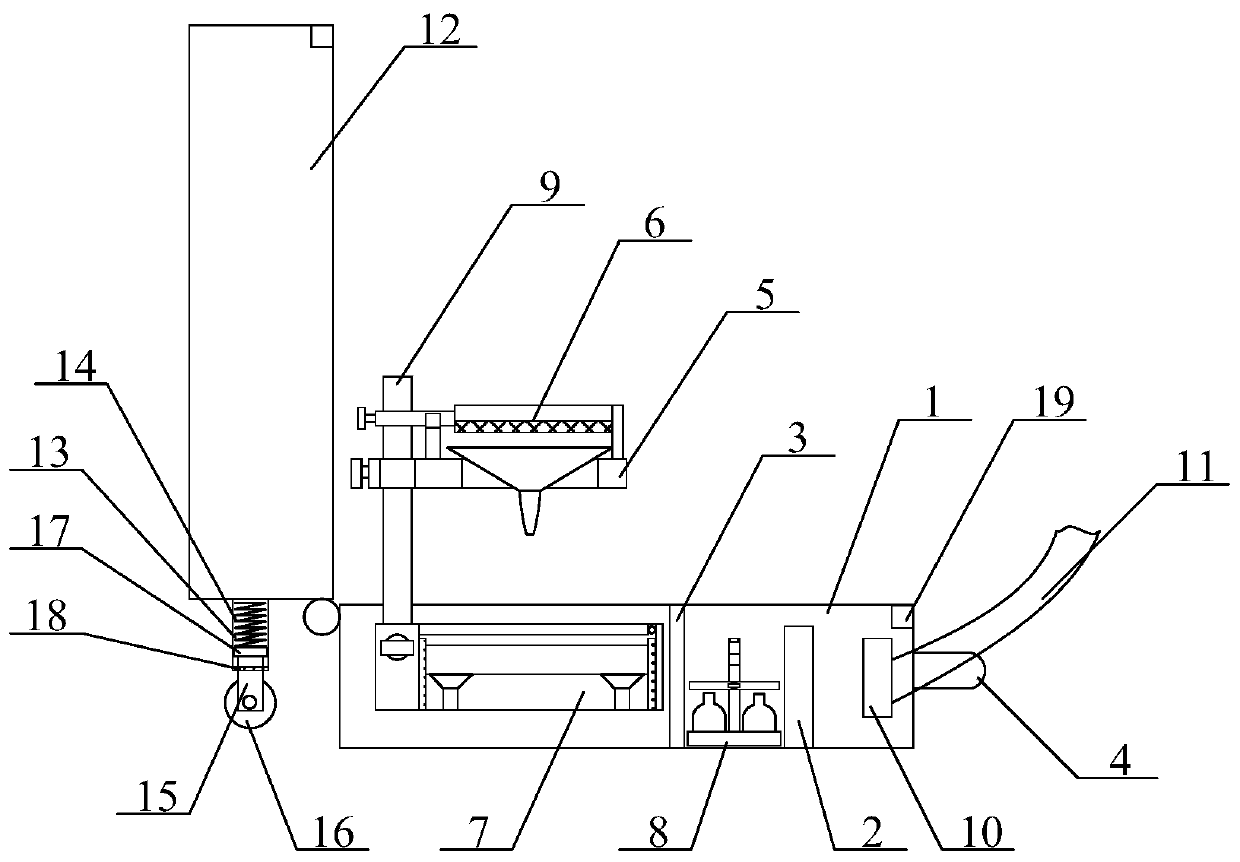

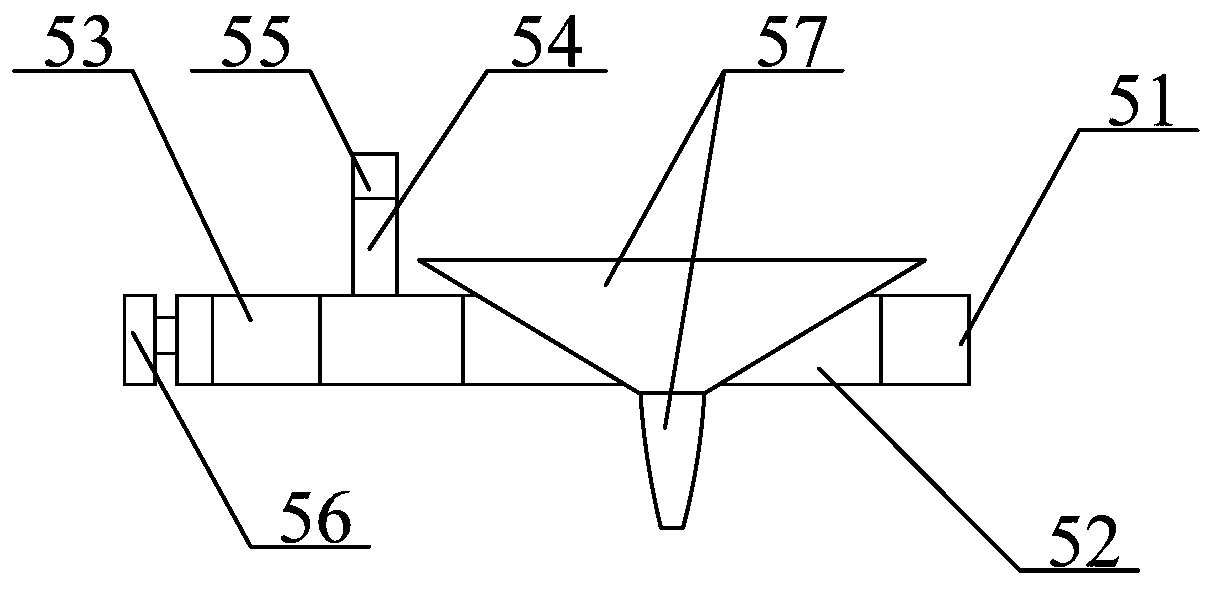

Portable filling device of traditional Chinese medicine

The invention provides a portable filling device of traditional Chinese medicine. The portable filling device of the traditional Chinese medicine comprises a carrying box, a partition plate, an interval plate, a box handle, a filling frame structure, a filtering and collecting frame structure, a weighing frame structure, a classifying frame structure, a filling rod, a fixed base, a back strap, a box cover, a shock absorbing pipe, a shock absorbing spring, a shock absorbing rod, moving wheels, an inserting and connecting base, a sealing strip and a magnet, wherein the partition plate is weldedto the right side position of the bottom end in the carrying box; and the interval plate is welded to the middle position of the bottom end in the carrying box. According to the portable filling device of the traditional Chinese medicine, due to the arrangement of the fixed base and the back strap, it is facilitated that the carrying box and the box cover are conveniently carried; due to the arrangement of the inserting and connecting box, a lifting plate and a storing bottle, classified storing can be performed easily, and the traditional Chinese medicine can be conveniently distinguished; due to the arrangement of a filtering frame and a collecting net, filtering work can be easily performed on the traditional Chinese medicine when filling is performed; and due to the arrangement of theshock absorbing pipe, the shock absorbing spring, the shock absorbing rod and the moving wheels, the carrying box and the box cover can be conveniently moved easily.

Owner:JILIN UNIV FIRST HOSPITAL

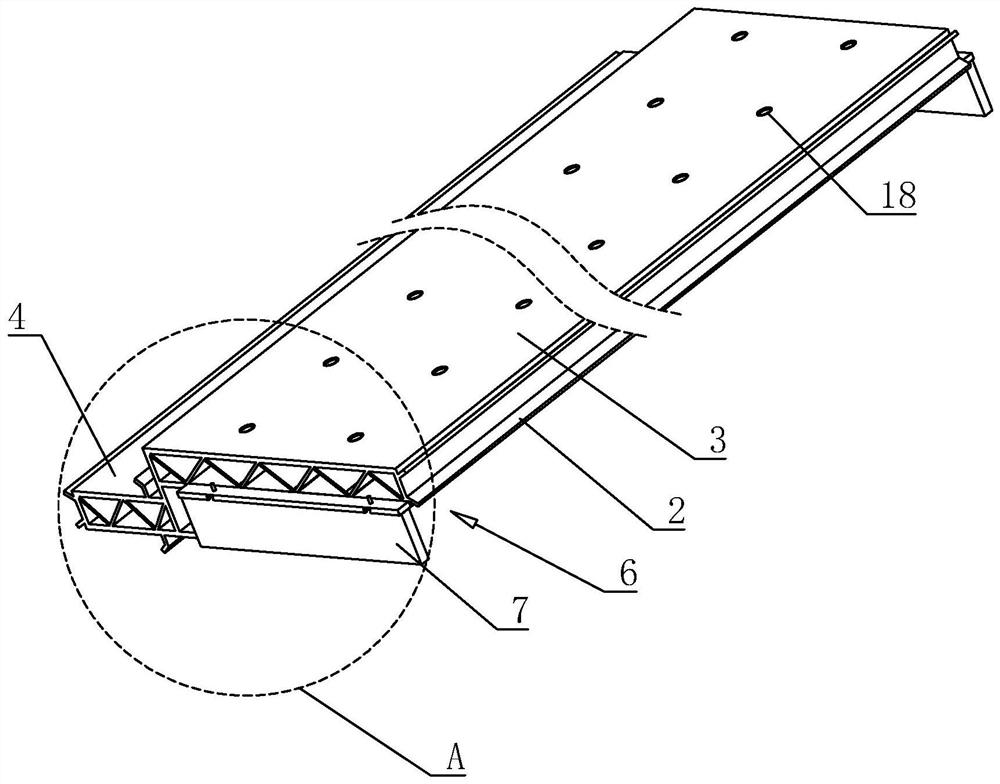

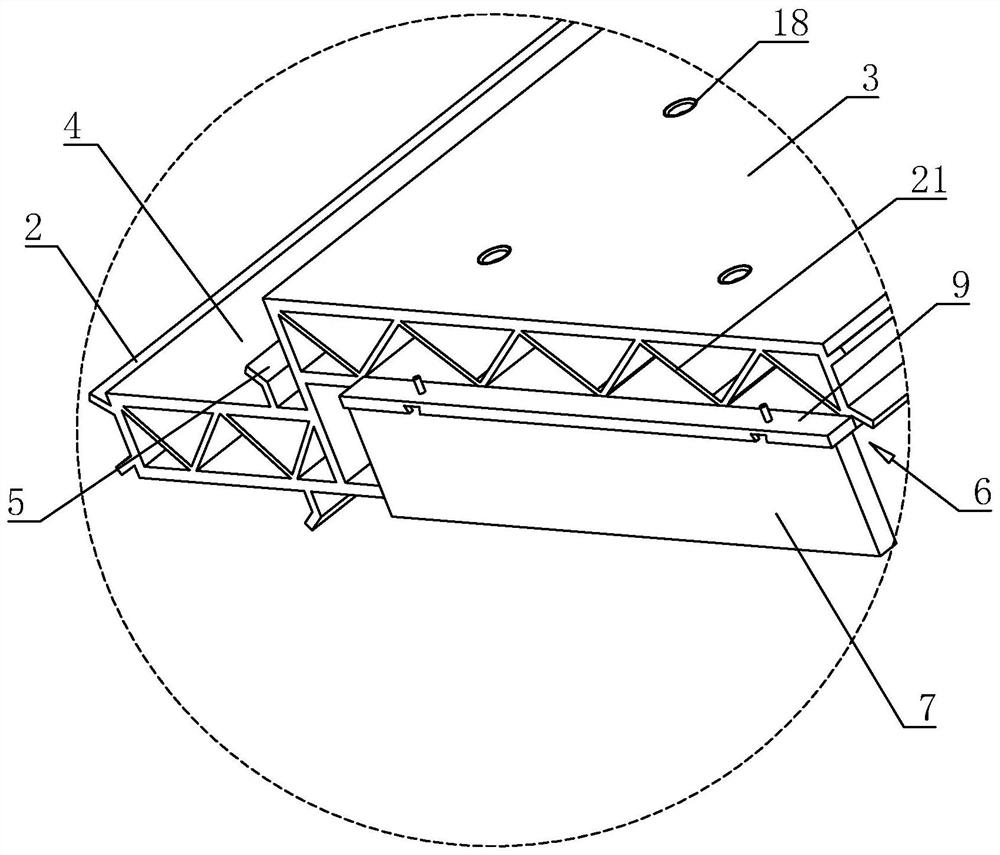

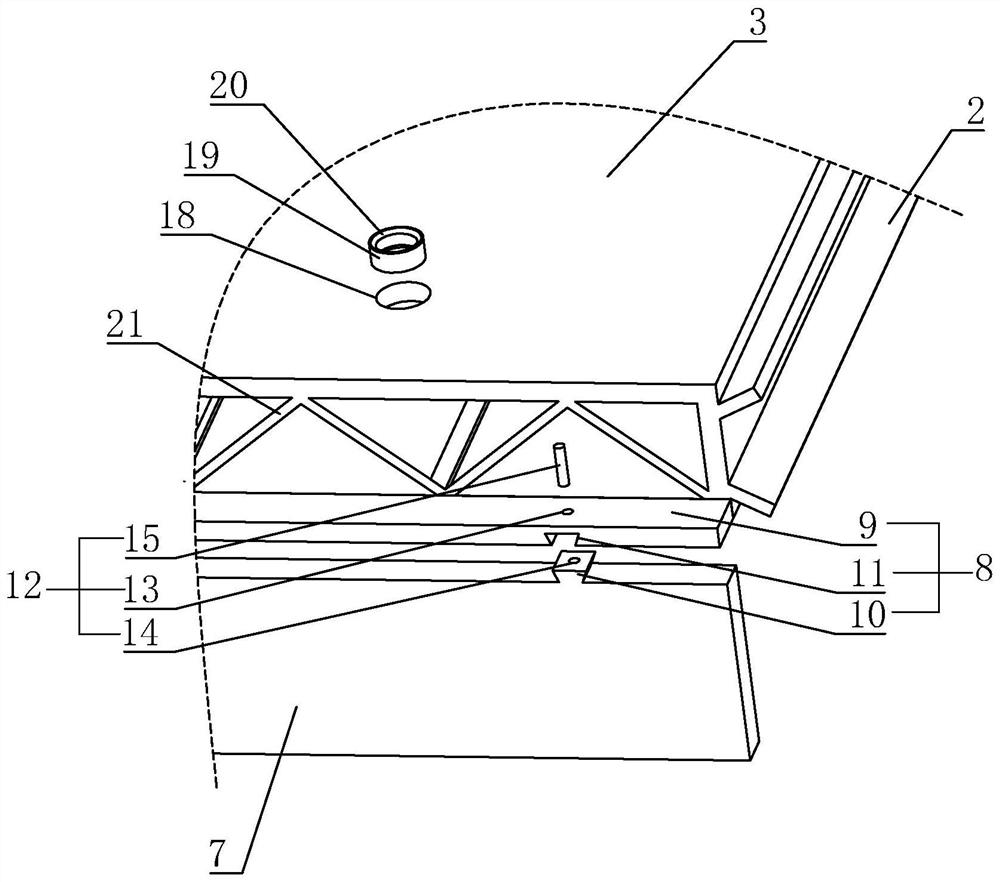

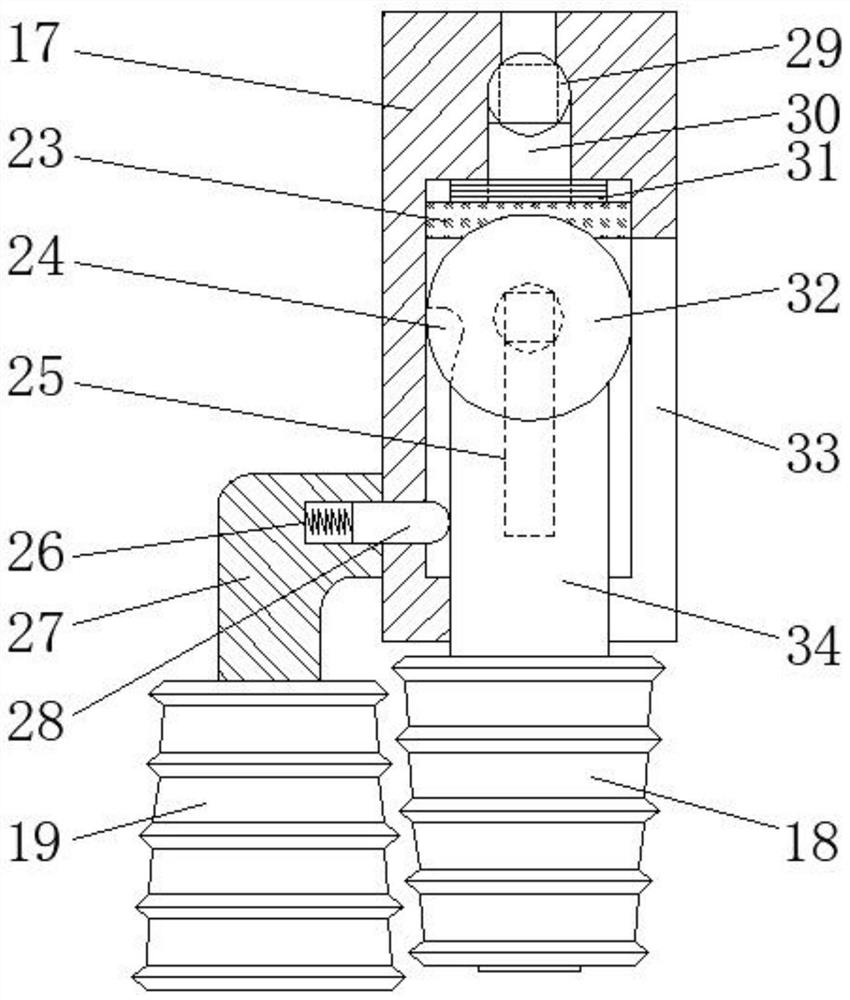

Segmental box girder prefabrication construction structure

PendingCN111319130AEasy filling workFavorable for individual control workAuxillary shaping apparatusBrakeArchitectural engineering

The invention provides a segmental box girder prefabrication construction structure. The structure comprises a hydraulic oil tank, movable brake wheels, a hydraulic pump, an oil outlet pipe, rubber plug shells, a hookable supporting clamping plate structure, an adjustable shunt box structure, a rotatable sealing pipe structure, a backflow conveying pipe structure, an observation piece, a lifting rod, a filling pipe, a rubber cover, a U-shaped clamping seat, a supporting pipe and an inverted T-shaped supporting seat, wherein the movable brake wheels are in bolt connection to four corners of thelower end of the hydraulic oil tank. A shunt box, connecting pipes, an oil inlet pipe, oil filling pipes and the rubber plug shells are arranged, the corresponding number of the rubber plug shells can be selected to be inserted into pipes according to the set number of the pipes in the construction process, and different rubber plug shells are filled with hydraulic oil by mutual cooperation of the shunt box, the connecting pipes and the oil filling pipes, so that a plurality of the rubber plug shells can be conveniently filled in work.

Owner:山东博远重工有限公司

An automatic assembly line for cleaning and drying containers

ActiveCN109590299BEasy to pourEasy filling workHollow article cleaningDrying gas arrangementsProcess engineeringMaterial resources

The invention relates to an automatic assembly line for cleaning and drying containers. The lifting basket is convenient for lifting the cleaned bottles from the rinsing pool and pouring them into the triangular bucket, and the bottles entering the triangular bucket fall into the turning and drying turntable from the bottle drop pipe. In the limit groove A of the bottle; a bracket is installed in the limit groove of the flip drying turntable, and an opening is set on the U-shaped pallet of the bracket. Due to the different characteristics of the bottle bottom and the bottle mouth, the bottle mouth can fall In the opening, so that the upper end of the bottle placed on the bracket is higher than the height of the bottle placed upside down on the U-shaped pallet; using this feature of the bottle, the bottle placed upright can be knocked down and placed upside down On the U-shaped pallet, it is convenient to drain the water in the bottle, and at the same time use the arc-shaped tube to blow hot air to dry; the invention realizes the functions of cleaning, drying, positioning and flipping the bottle, and facilitates the food filling before filling. The work is carried out, the automatic operation is realized, and the manpower and material resources are saved.

Owner:TAICANG TAOXIN INFORMATION TECH CO LTD

Short-distance transport method for expanded perlite

InactiveCN106892214AIncrease productivityConvenient filling workDomestic cooling apparatusLighting and heating apparatusPerliteEngineering

The application discloses a short-distance transportation method for expanded perlite. The short-distance transportation method of this expanded perlite, its specific steps are as follows: (1), blanking: introduce the perlite after the expanded perlite of preparation under uncooled situation into cyclone separator with induced draft fan; (2), packing: utilize cyclone The separator directly divides the uncooled expanded perlite into the thermal insulation storage tank and seals it; (3), transportation: transport the storage tank with high temperature expanded perlite as a whole; (4), production of thermal insulation device: directly put the storage tank The high-temperature expanded perlite in the tank is filled to the target position of the insulation device. The short-distance transportation method of expanded perlite described in the present invention can keep the heat of the expanded perlite, and the expanded perlite with high temperature can improve the filling efficiency.

Owner:ZHANGJIAGANG HUAFU IND

A cashmere filling machine

ActiveCN109607466BAvoid cakingImprove down filling efficiencyUpholstery manufactureClothes making applicancesEngineeringAir blower

The invention discloses an efficient down filling machine which comprises a down filling machine main body, wherein a pipeline is mounted on one side of the down filling machine main body; a down filling port is formed in the other side of the down filling machine main body; a box body is mounted at one end of the pipeline; a down inlet is embedded into the upper part of the box body; a connectionround plate is arranged inside the box body; a rubber band is circumferentially arranged on the connection round plate; a connection pipe is embedded into the connection round plate. According to theefficient down filling machine, when the connection pipe rotates, the connection round plate is driven to rotate, so as to drive the rubber band and a short rod to rotate, and downs entering the boxbody can be flicked to avoid the hardening of the downs, scatter the downs and improve the down filling efficiency; when an air blower works, heat in a heating pipeline can be blown into the box bodythrough a through hole via an air blow pipe to play a very good air drying role and reduce moisture in the downs; an electric push rod controls a distance between a pressure plate and the down fillingport through a rotating shaft and a connection column so as to fix the down filling port and an object to be subjected to down filling.

Owner:颍上县祥盛建设管理有限公司

A decorative edge filling device for garment production and processing

ActiveCN111011963BEasy filling workGuaranteed separation efficiencyGarmentsClothes making applicancesElectric machineryEngineering

The invention discloses a decorative edge filling device for garment production and processing, and relates to the technical field of decorative edge filling. The decorative edge filling device for garment production and processing includes a bottom plate, the top outer surface of the bottom plate is welded with a first side frame, a first lint collection box, a second side frame, a fixing seat and a third side frame The outer wall of one side of the first side frame is welded with a second lint collection box, the outer wall of one side of the second side frame is welded with a support plate, the top outer surface of the support plate is welded with a second motor, and the second motor The output shaft of the second rotating rod is welded with a second rotating rod, the free end of the second rotating rod passes through the first side frame, and the first rotating rod is installed on one side of the outer wall of the second side frame to rotate. The invention can air-dry and separate the wet or extruded cotton wadding, so that the wadding becomes silk and can be completely distributed inside the decorative edge, improving the aesthetics of the decorative edge.

Owner:苏州琦谷佳科技有限公司

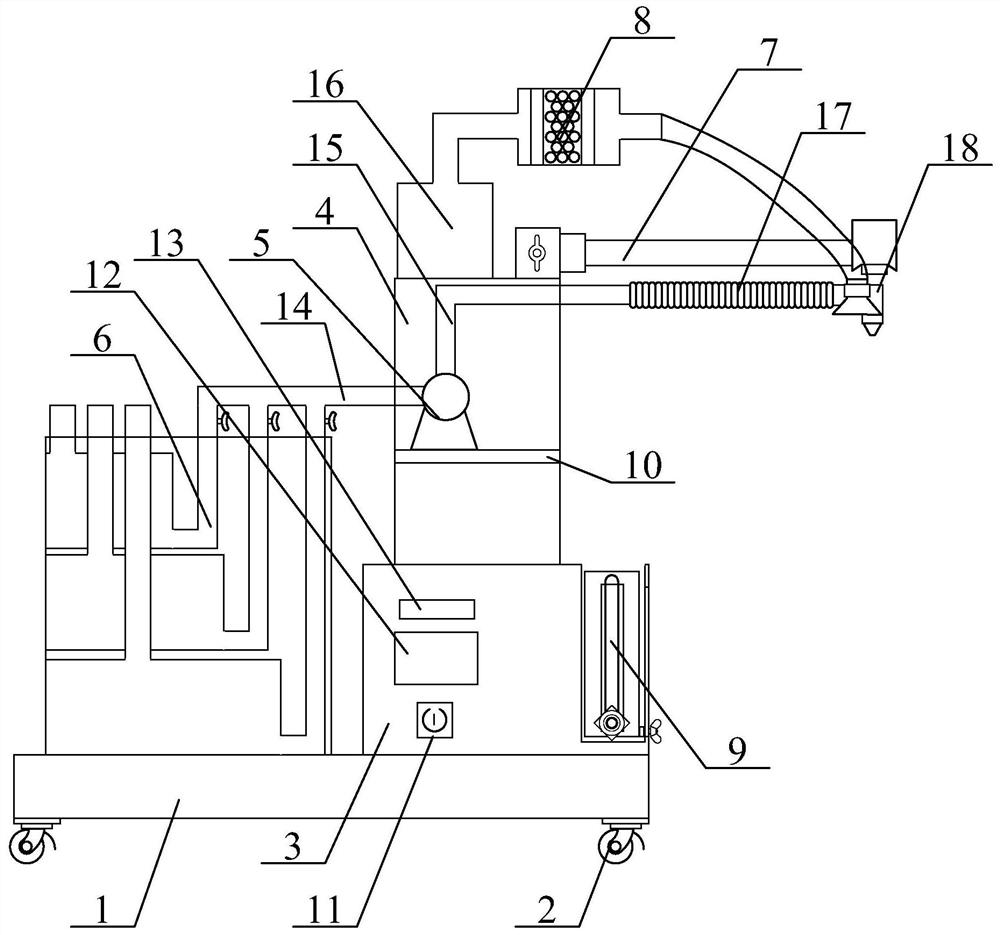

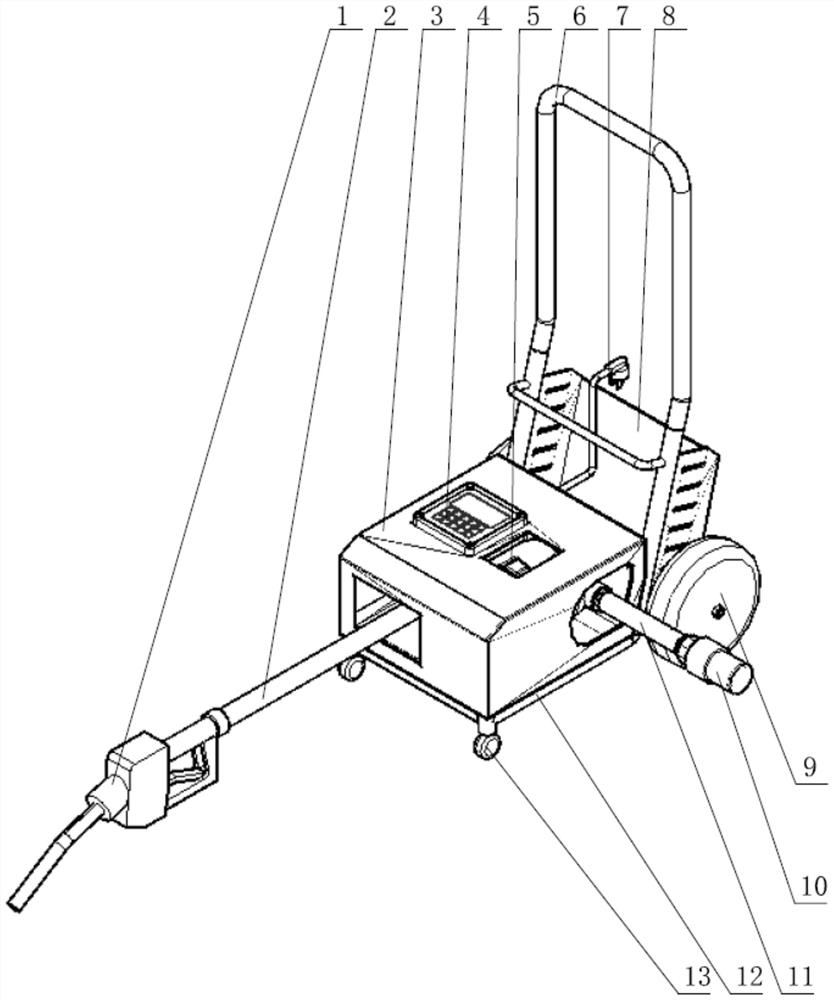

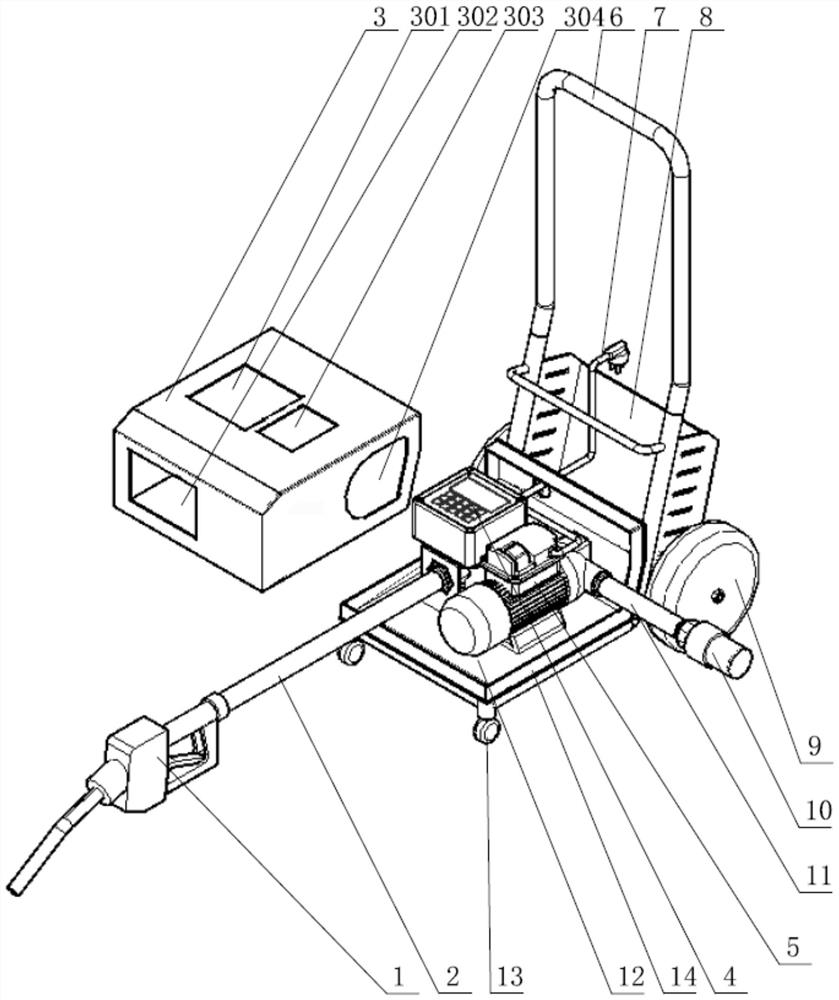

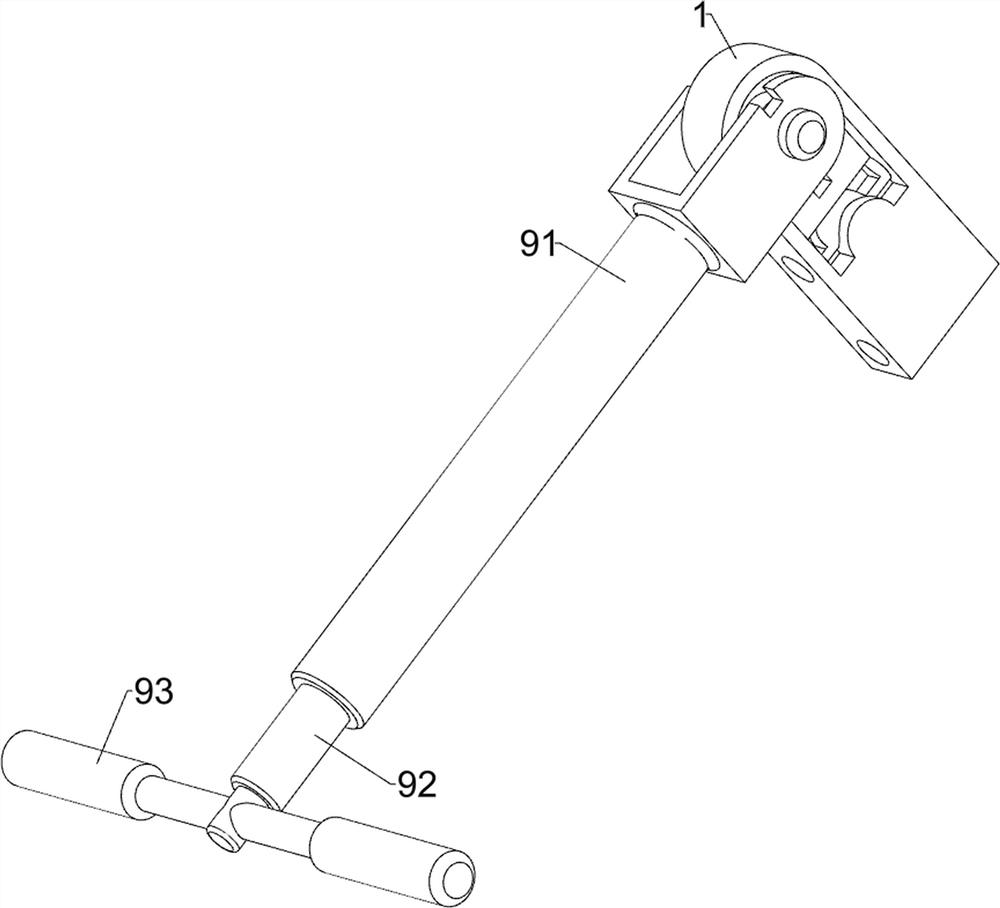

Liquid material filling equipment

InactiveCN112645272AEasy filling workCompact structureLiquid transferring devicesGear wheelHand held

The invention discloses liquid material filling equipment. The liquid material filling equipment comprises a cart body, wherein a pump is fixedly arranged on a base of the cart body; a liquid injection pipe is arranged at an input opening of the pump, and a liquid input filter screen is arranged at a pipe head of the liquid injection pipe; a liquid output pipe is arranged at an output opening of the pump, a directional gear flow meter is arranged on the liquid output pipe, and a handheld liquid filling gun head is arranged at a pipe head of the liquid output pipe; an outer edge is arranged on the periphery of the base of the cart body, a filler shell is arranged on the outer edge in a matched mode, and the pump and the directional gear flow meter are covered with the filler shell; and a handrail is arranged at the rear end of the cart body. Through the cooperative work of the pump, the directional gear flow meter and the handheld liquid filling gun head, the filling work of liquid materials can be conveniently completed, the filling amount is more accurate, and the use and the operation are convenient.

Owner:WUXI TAYLOR PACKAGING ENG CO LTD

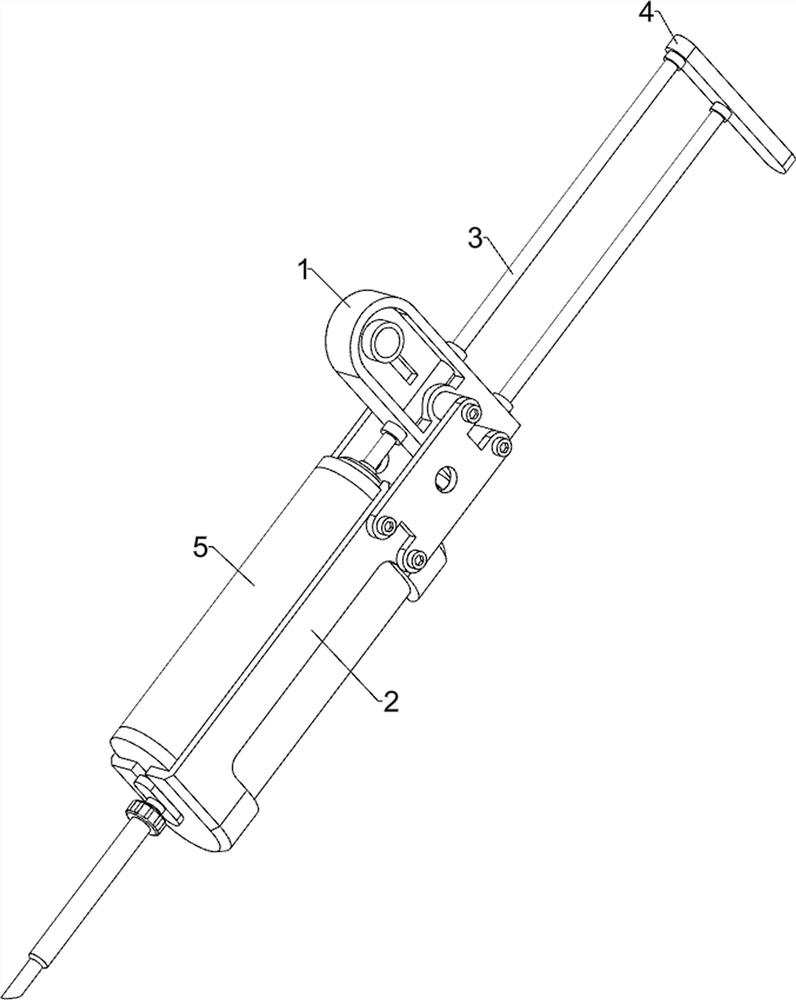

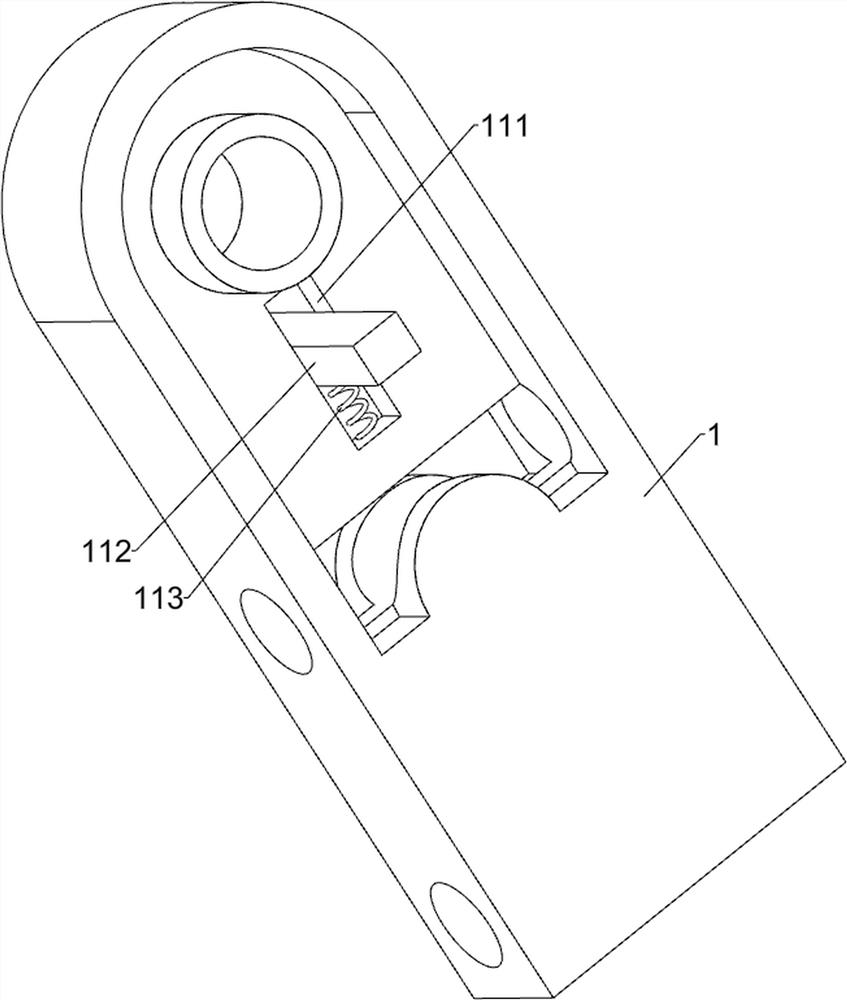

Portable seam beautifying agent filling equipment

PendingCN114525916AFacilitate the filling work of caulking agentEasy to moveBuilding constructionsStructural engineeringMechanical engineering

The invention relates to seam beautifying agent filling equipment, in particular to portable seam beautifying agent filling equipment. The portable seam beautifying agent filling equipment can be operated by people more conveniently, and the workload of people is relieved. The convenient seam beautifying agent filling equipment comprises a mounting block, a placing frame, a push rod, a connecting block, a seam beautifying agent body and the like, two push rods are arranged on the right lower portion of the mounting block in a sliding mode, the left lower portions of the push rods are located in the placing frame, a connecting block is connected between the right upper portions of the two push rods, a seam beautifying agent body is placed in the placing frame, and the left lower portions of the push rods extend into the seam beautifying agent body. The connecting block moves towards the lower left to drive the push rod to slide towards the lower left to extrude the seam beautifying agent in the seam beautifying agent body for filling work, meanwhile, under the action of the fixing plate and the rolling wheels, the device can be supported, the device can be conveniently moved for seam beautifying agent filling work, and a worker does not need to hold the placing frame by hand to move.

Owner:谢莉姣

A portable traditional Chinese medicine filling equipment

InactiveCN108328552BEasy to carryEasy to distinguishLiquid bottlingEngineeringMechanical engineering

The invention provides a portable filling device of traditional Chinese medicine. The portable filling device of the traditional Chinese medicine comprises a carrying box, a partition plate, an interval plate, a box handle, a filling frame structure, a filtering and collecting frame structure, a weighing frame structure, a classifying frame structure, a filling rod, a fixed base, a back strap, a box cover, a shock absorbing pipe, a shock absorbing spring, a shock absorbing rod, moving wheels, an inserting and connecting base, a sealing strip and a magnet, wherein the partition plate is weldedto the right side position of the bottom end in the carrying box; and the interval plate is welded to the middle position of the bottom end in the carrying box. According to the portable filling device of the traditional Chinese medicine, due to the arrangement of the fixed base and the back strap, it is facilitated that the carrying box and the box cover are conveniently carried; due to the arrangement of the inserting and connecting box, a lifting plate and a storing bottle, classified storing can be performed easily, and the traditional Chinese medicine can be conveniently distinguished; due to the arrangement of a filtering frame and a collecting net, filtering work can be easily performed on the traditional Chinese medicine when filling is performed; and due to the arrangement of theshock absorbing pipe, the shock absorbing spring, the shock absorbing rod and the moving wheels, the carrying box and the box cover can be conveniently moved easily.

Owner:JILIN UNIV FIRST HOSPITAL

Glass heat pipe with solid-liquid working medium package and manufacturing method thereof

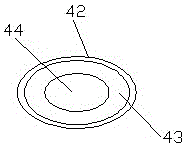

ActiveCN103245105BEasy filling workControl perfusion accuracySolar heat devicesSolar thermal energy generationWorking fluidEngineering

A glass heat tube with a solid-liquid working medium bag comprises a cover glass tube, an inner tube and the solid-liquid working medium bag, wherein the heat collecting end of the inner tube is sleeved in the cover glass tube, the condensation end of the inner tube extends out of the cover glass tube, a vacuum interlayer is arranged between the inner tube and the cover glass tube, a clamp is arranged between the heat collecting end of the cover glass tube and the inner tube to support the inner tube, and the solid-liquid working medium bag is arranged in the inner tube and is formed by a liquid working medium and a solid cavity wrapping the liquid working medium. A manufacture method of the glass heat tube comprises the following steps of (a) confirming the volume proportion of the solid-liquid working medium bag occupying the glass heat tube volume according to the volume of the glass heat tube cavity, a glass material and stress grade; (b) designing the small solid cavity, filling the liquid working medium into the solid cavity and sealing the solid cavity in a fusing mode to form the solid-liquid working medium bag; (c) adding the solid-liquid working medium bag into the inner tube cavity through an exhaust port of the condensation end and vacuumizing the inner tube of the glass heat tube, and sealing the exhaust port of the condensation end in the fusing mode in a vacuum state.

Owner:BEIJING TUS CLEAN ENERGY TECH CO LTD +2

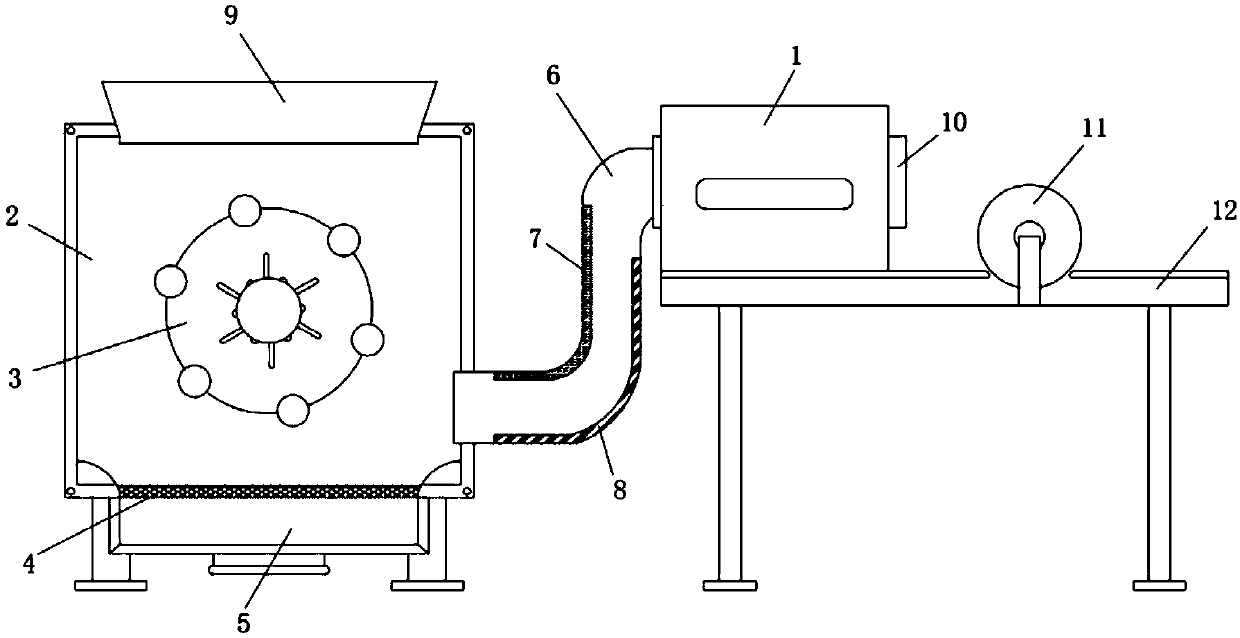

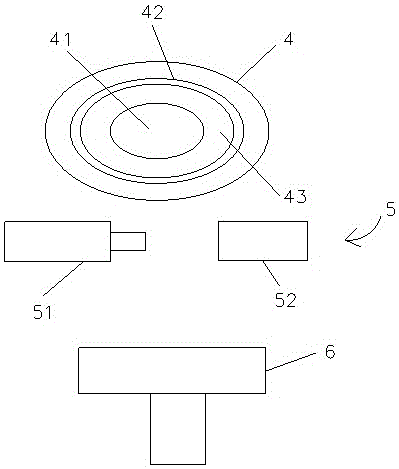

Sand-gravel material bag sealing machine

InactiveCN106184920AEasy filling workImprove efficiencyWrapper twisting/gatheringMechanical engineeringElectromagnet

The invention discloses a sand-gravel material bag sealing machine which comprises a supporting frame, a tying machine and a jacking table. A through hole is formed in the center of the supporting frame. An annular electromagnet is arranged in the edge of the through hole. An annular metal pressing block is placed above the through hole. After the electromagnet is powered on, the metal pressing block and the electromagnet can attract each other. The tying machine is coaxially arranged under the supporting frame and comprises a sealing machine head and a nail plate. A plurality of sealing belts are arranged in the sealing machine head. The sealing machine head can horizontally slide and cooperates with the nail plate. The jacking table is located under the tying machine and is coaxial with the through hole, and the height of the jacking table can be increased and decreased. The sand-gravel material bag sealing machine can achieve automatic sealing operation on a sand-gravel material bag, and is high in sealing efficiency and good in sealing quality, and materials are not prone to being leaked.

Owner:许陈菲

A structural drawing seam applied to aluminum formwork and its construction technology

ActiveCN111827671BEasy filling workPlay a solid roleForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksClassical mechanicsStructural engineering

Owner:深圳市旭生骏鹏建筑工程有限公司

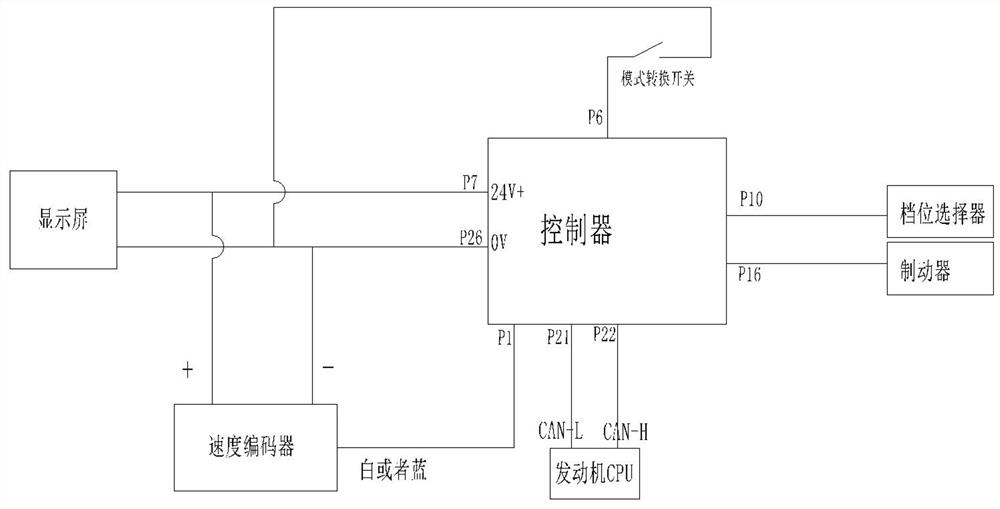

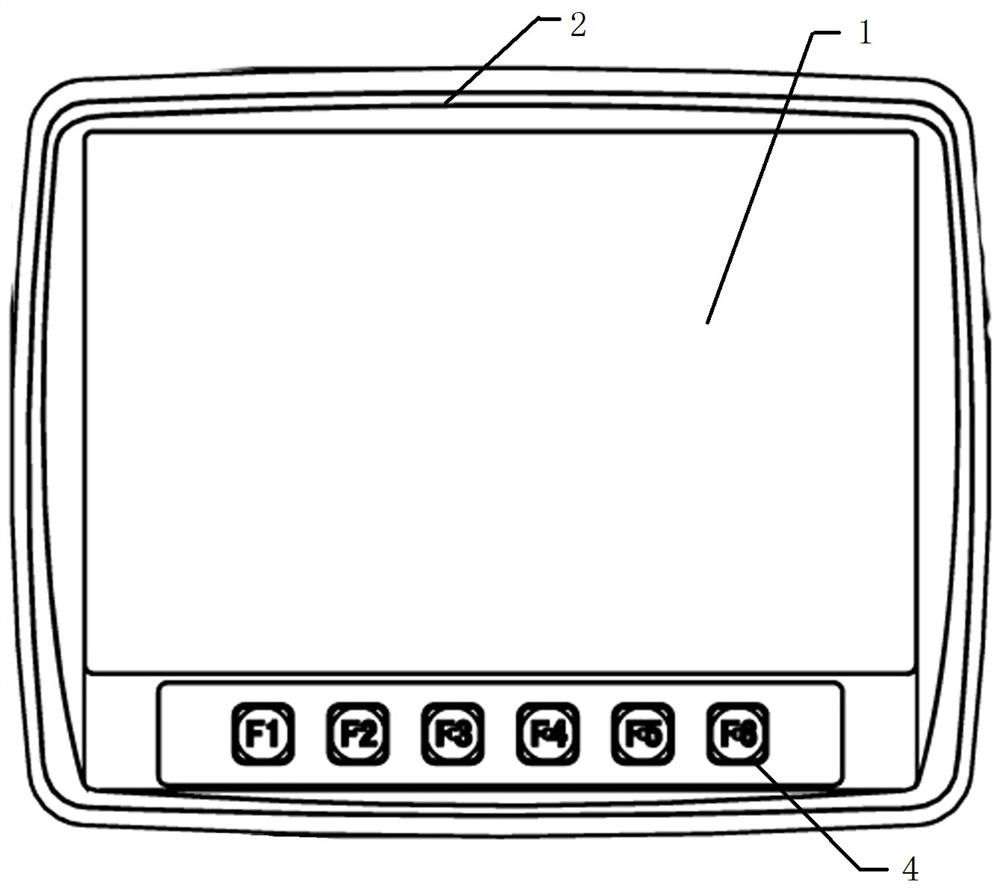

Low constant-speed control device for combined highway and railway tractor

PendingCN111894743AEasy filling workReduce installation costsEngine controllersMachines/enginesControl systemAgricultural engineering

The invention relates to a low constant-speed control device for a combined highway and railway tractor, and belongs to a vehicle control system. According to the technical scheme, the low constant-speed control device for the combined highway and railway tractor comprises a control box composed of a controller, a display screen and a speed encoder arranged on a tractor wheel axle; the speed encoder and a displayer are connected to the controller; and control leads of the controller are connected to an engine CPU, a gear selector, a brake and a mode transfer switch respectively. By adding thecontrol device in the original control system, the device can enable a vehicle to run at a constant speed by setting running speed value, which brings convenience to the loading work requiring a certain speed. The device has low adding cost and is suitable for being directly added to the existing control system for use. The device has the advantages of simple control mode, high integration degreeand convenience in control.

Owner:SHANDONG DONGDA CONSTR MACHINERY

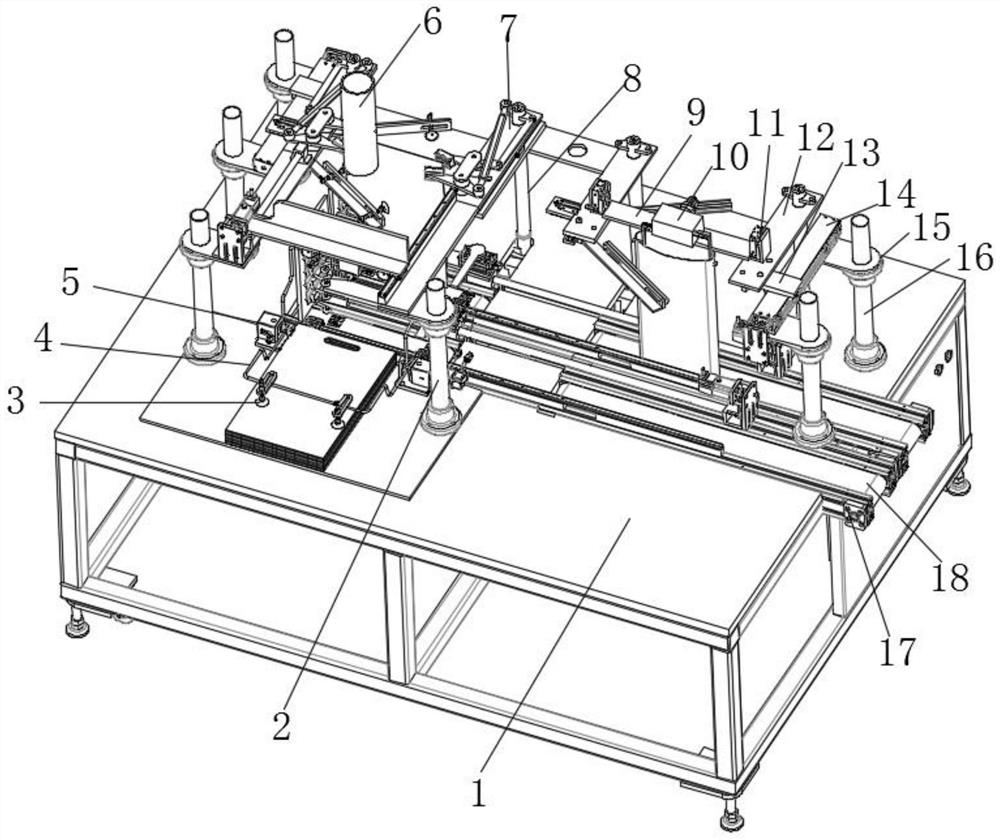

A kind of production process of composite nursing pad for newborn

InactiveCN111714287BEasy filling workSave human effortAbsorbent padsBaby linensSuction forceGear wheel

The invention discloses a composite nursing pad for newborns. The composite nursing pad includes a pad body and a filler. When the two intermediate gears rotate, the two expansion rods also rotate, and the two suction cups suck the pad respectively. The feed port of the body is driven by the output end of the adjusting motor to rotate the screw. Since the screw passes through the inside of the nut seat and is connected with the nut seat by threads, the moving plate moves along the top of the moving frame, so that the pad body to be filled moves to the conveyor belt Control the reverse rotation of the adjusting motor to expand the expansion rod. Due to the suction of the suction cup, the feeding port of the pad body is opened, and there is no need to manually open the feeding port, which is convenient for filling the water-absorbing material, saving manpower and saving energy. The space occupied by the device and the number of conveyors are two. When one conveyor belt is damaged, the processing work can be completed by the other conveyor belt, which provides an alternative solution to ensure the continuous progress of the processing work.

Owner:韩敏敏

A bag holding device

The invention discloses a bag supporting device, which comprises a base, a sliding plate, a movable plate, a fixed seat and a bag supporting seat. The center of one end of the base is provided with an arc-shaped groove, and the tops of the bases on both sides of the arc-shaped groove are fixed with slides. There is a sliding plate sliding between the sliding grooves of the sliding rails, the top end of the sliding plate is connected with an arc-shaped baffle, the top end of the base is connected with a handle, and the top of the base at one end of the handle is equipped with a column. A movable plate is arranged above the column, and a fixed seat is installed on one side of the movable plate, and a slider is slidably connected to the inside of the sliding groove, and a bag support rod is connected to one side of the slider, and the bag support rod There are 2 installation bases that are slidingly connected, and one end of the installation bases is connected with a bag support seat. The invention is equipped with a base, a sliding plate, a movable plate, a fixing seat and a bag support seat, can effectively and quickly fix and disassemble the snakeskin bag, can effectively replace the work of manually supporting the bag and manually straightening the bag, and improves work efficiency.

Owner:ANHUI POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com