Intelligent shaft supersonic spraying surface pore filling device

A technology of supersonic spraying and filling equipment, which is applied in the direction of spraying devices, liquid spraying devices, cleaning methods and utensils, and can solve problems such as inconvenient intelligent filling observation work, inconvenient occlusion work, air pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

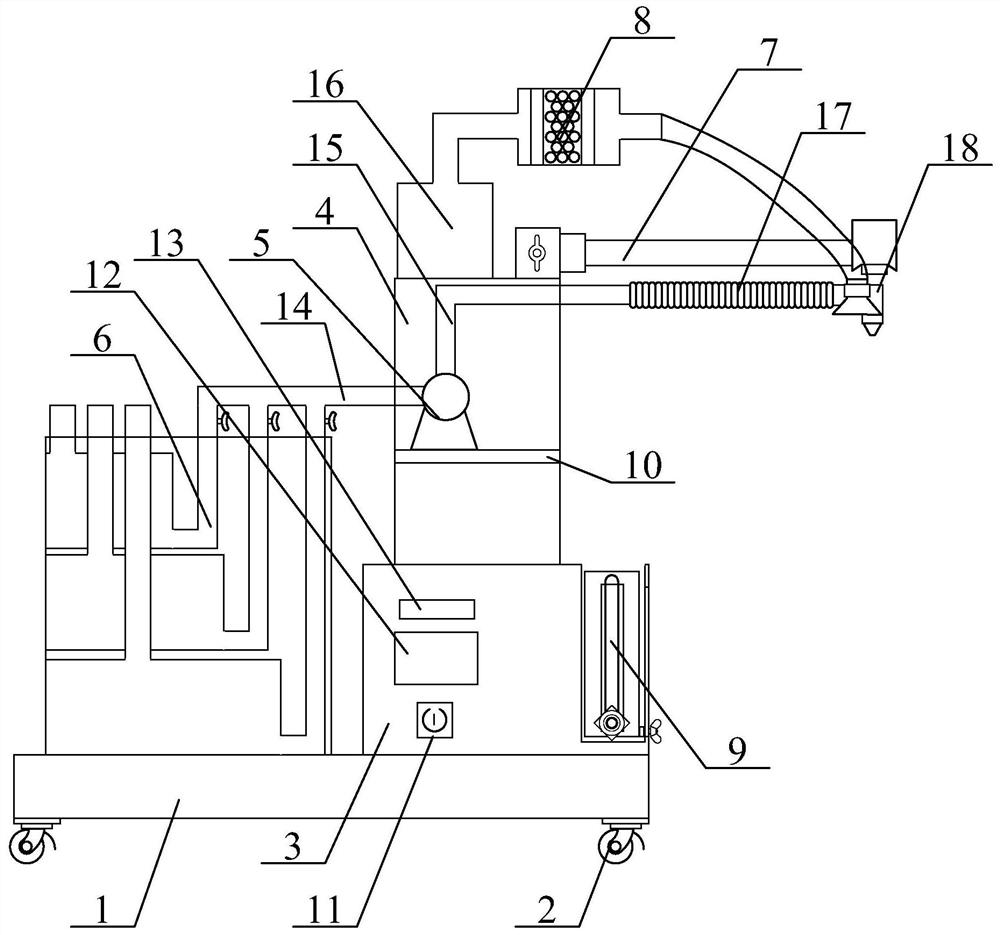

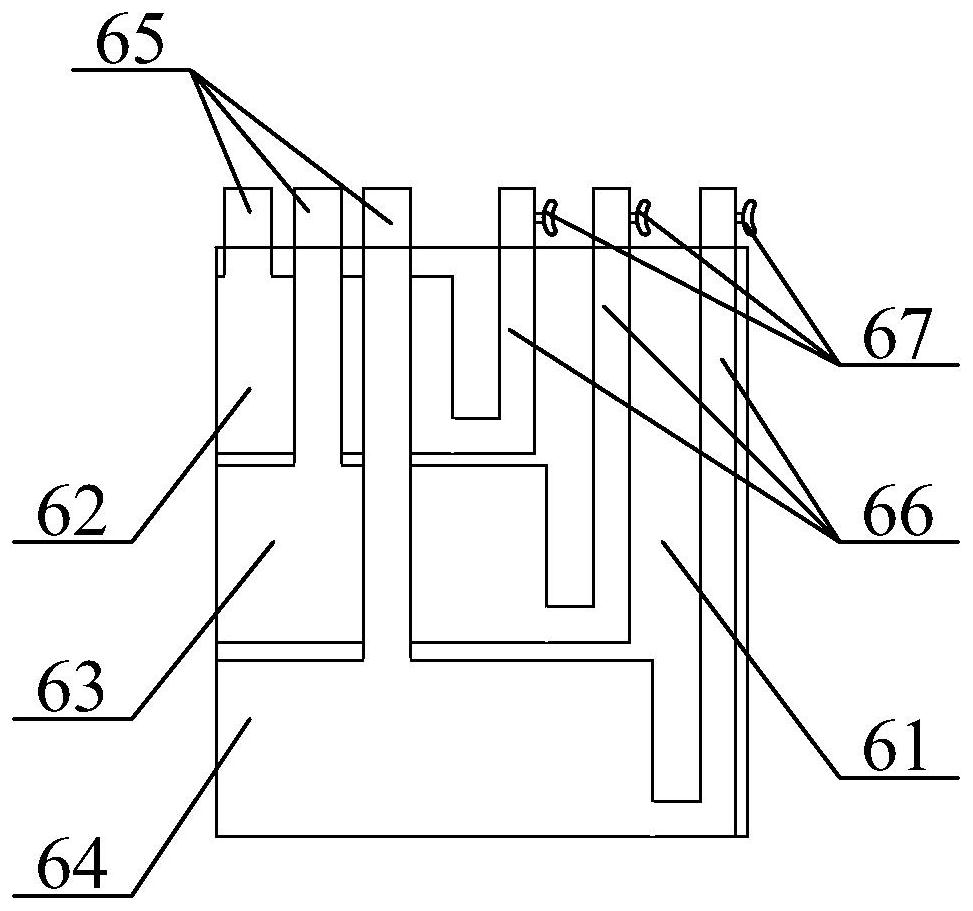

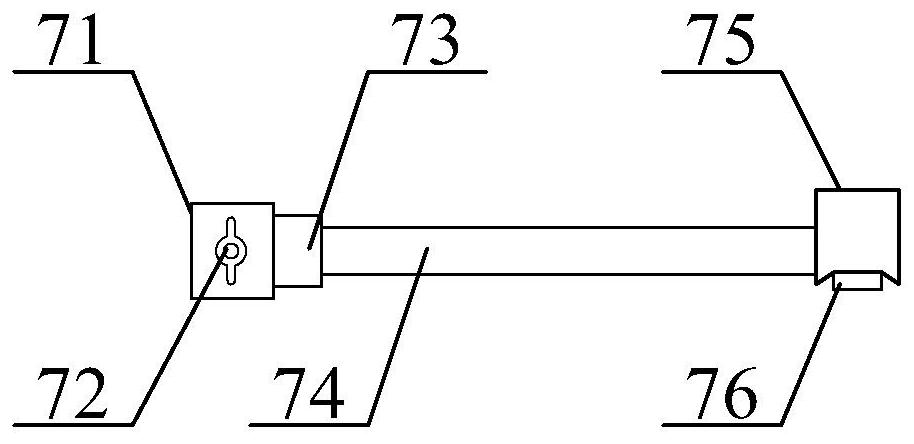

[0039] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2 As shown, an intelligent pore filling equipment for supersonic spraying of shafts, including a moving seat 1, a moving brake wheel 2, a support console 3, a spraying box 4, a spraying pump 5, and a storage and classification supply box structure 6. Rotatable and adjustable image detection seat structure 7, adsorption filter cleaning cover structure 8, accommodating and rotating shielding box structure 9, support plate 10, power switch 11, display screen 12, PLC13, feeding pipe 14, first delivery pipe 15. Vacuum cleaner 16, metal hose 17 and spraying pipe 18. The mobile brake wheels 2 are respectively bolted to the four corners of the lower end of the mobile base 1; the support console 3 is bolted to the upper right side of the mobile base 1 middle position; the spraying box body 4 is bolted to the upper middle position of the support ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com