Patents

Literature

43results about How to "Play a solid role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

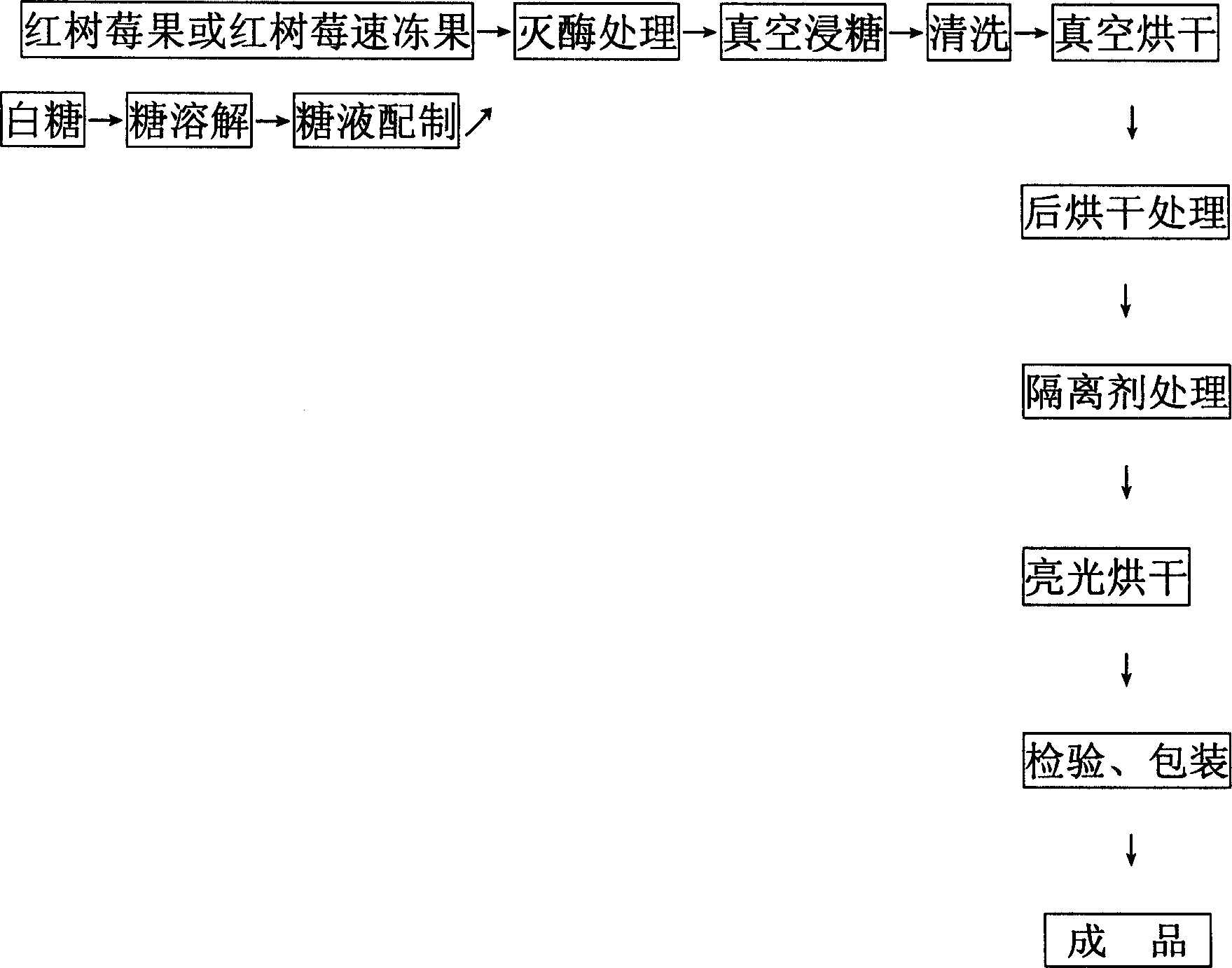

Dried fruit food with red aeterio and production thereof

InactiveCN1817165AComplete fruitBright red uniform colorConfectionerySweetmeatsMangroveAdditive ingredient

A health-care preserved mangrove raspberry fruit for removing free radicals from human body, delaying sanility and preventing and treating cancers is prepared through collecting mangrove raspberry fruits, quick freezing, deactivating enzyme, vacuum preserving in sugar, water washing, vacuum drying, treating with isolating agent, baking, examining and packing.

Owner:LIAONING TODAY AGRI

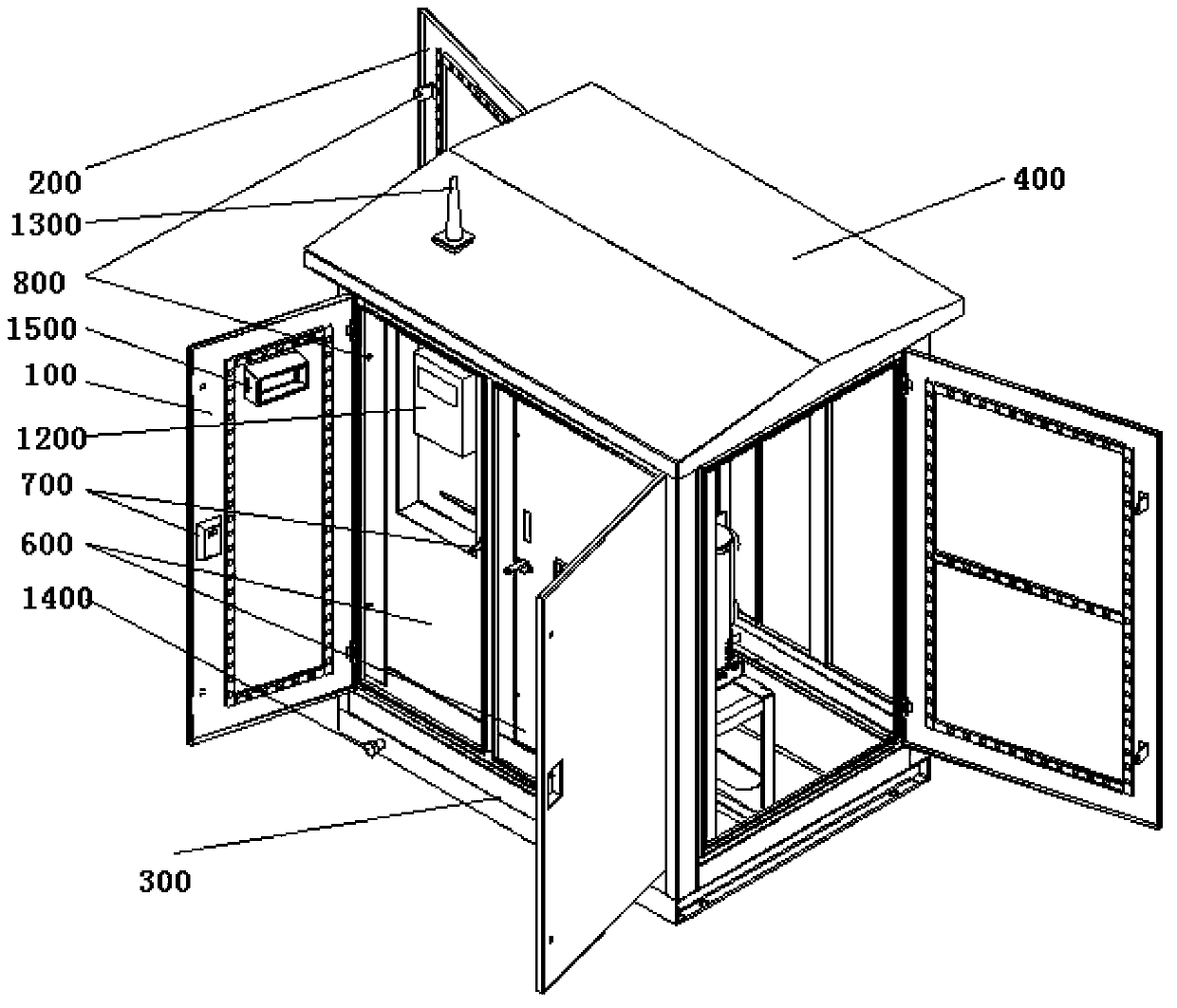

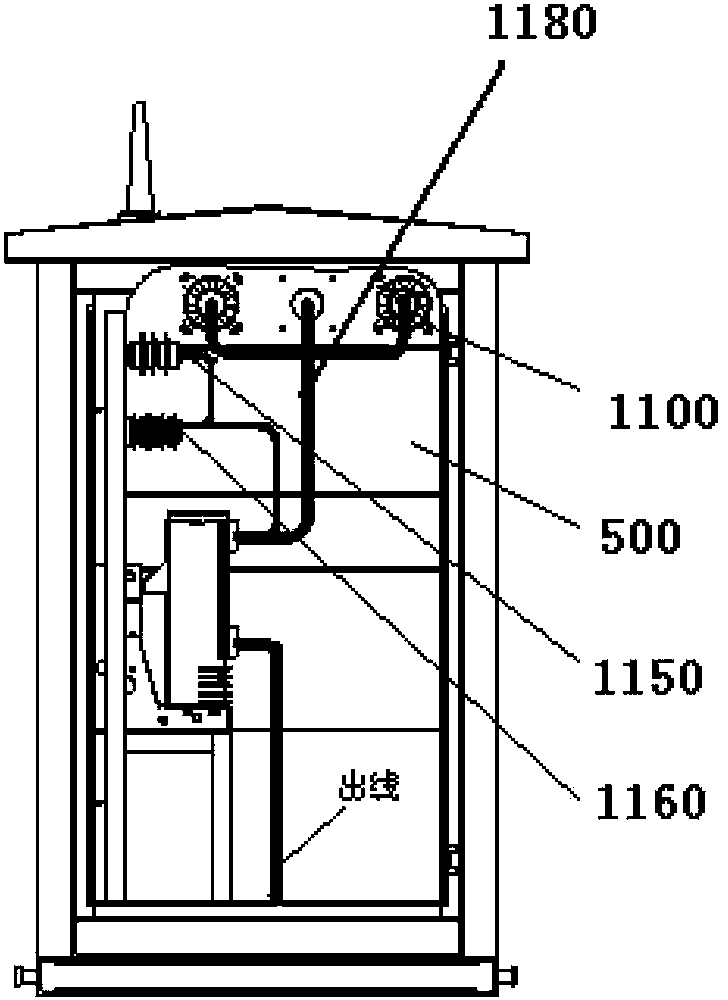

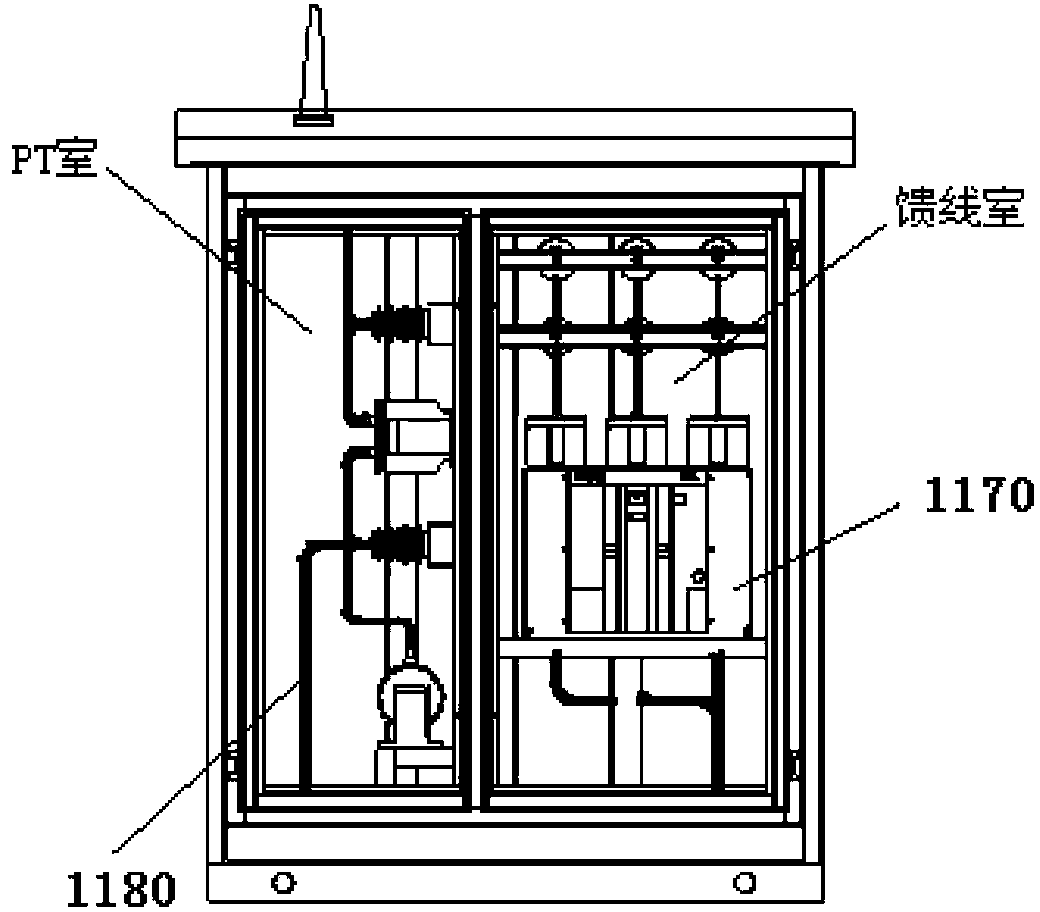

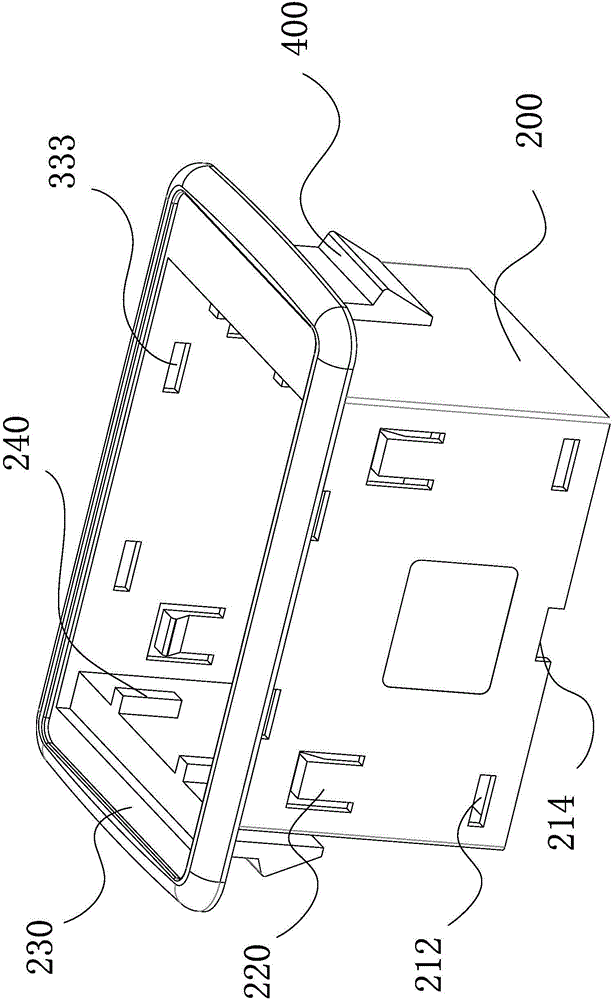

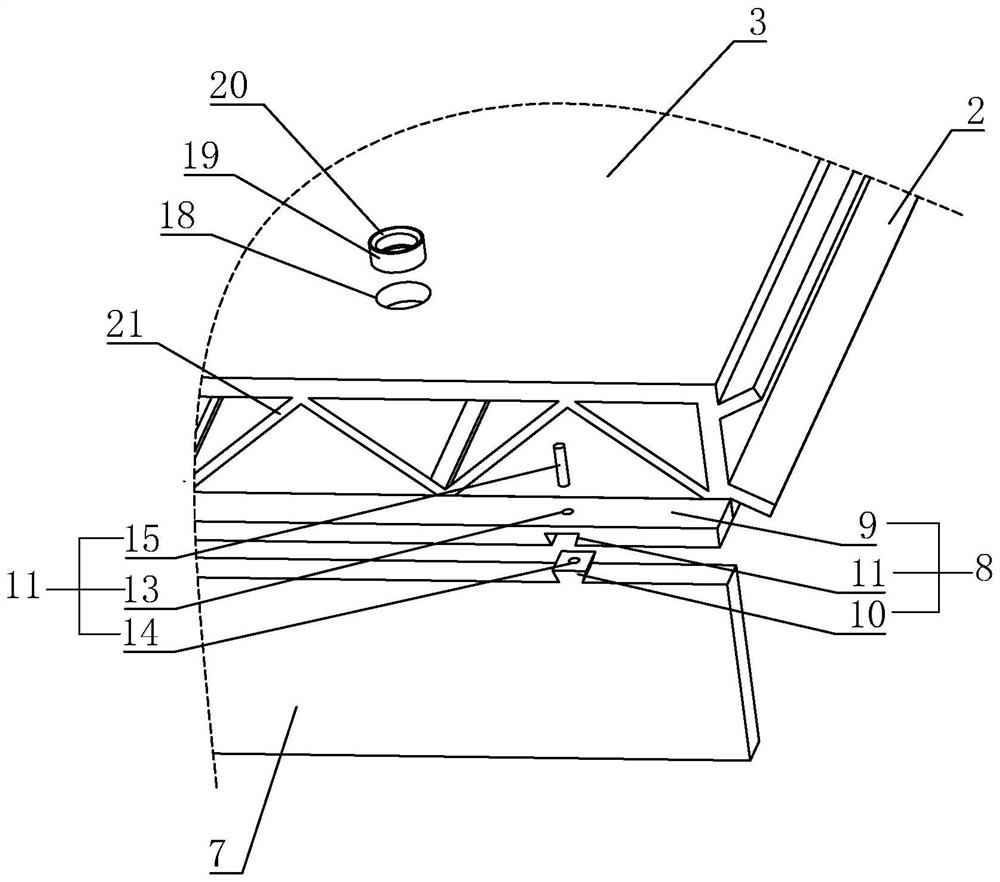

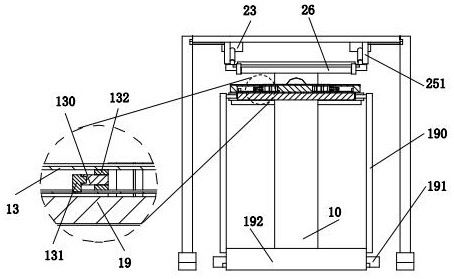

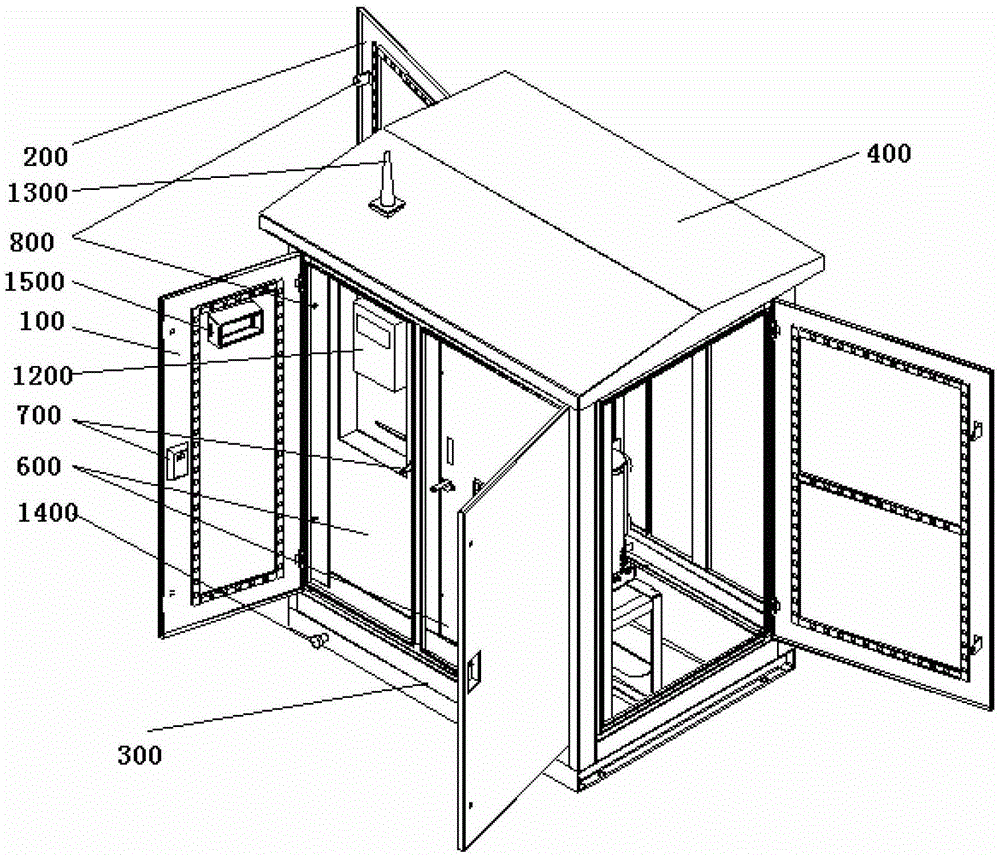

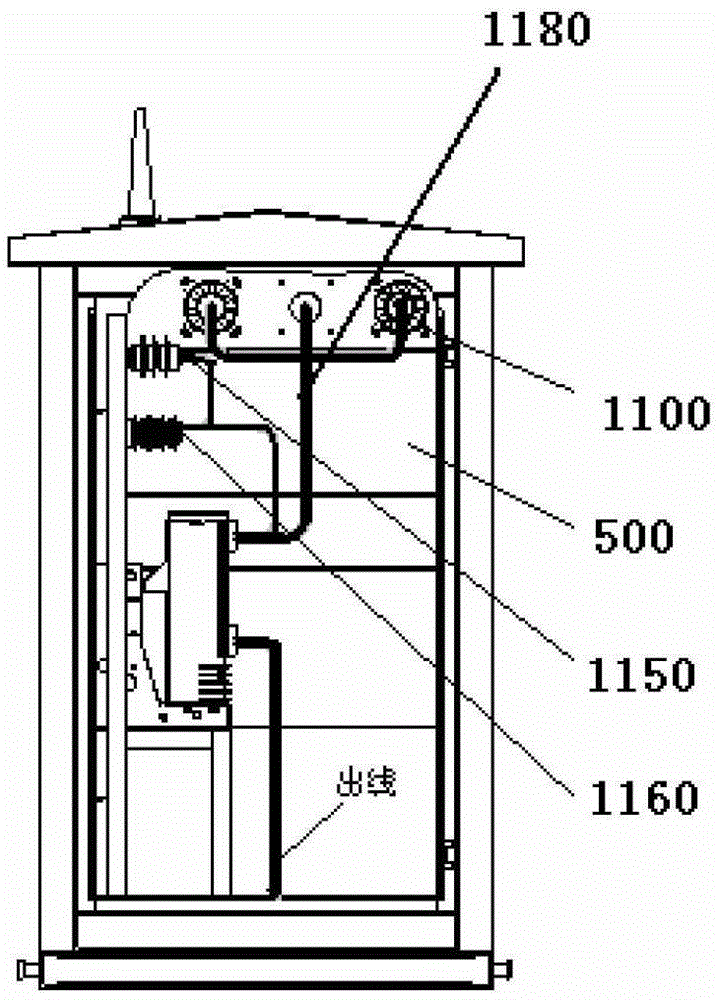

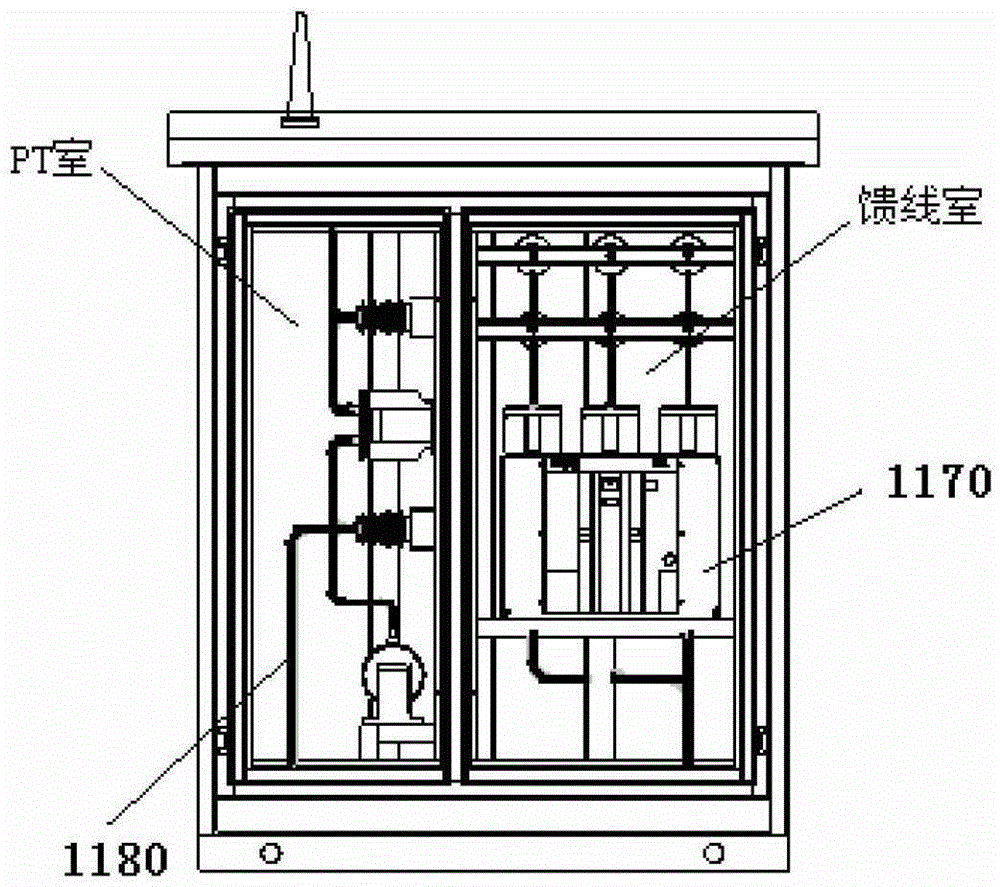

Outdoor intelligent high-voltage metering box

InactiveCN103427348ASimple and reliable structurePlay a solid roleSubstation/switching arrangement detailsLocking mechanismHigh pressure

The invention discloses an outdoor intelligent high-voltage metering box comprising a box body and electrical elements disposed in the box body. The box body comprises two side doors, two front doors, a base, a back and a top cover. A partition is disposed inside the box body and divides the box body into a PT chamber and a feeder chamber. Each of the PT chamber and the feeder chamber is provided with a mounting plate. The mounting plates are communicated with both the PT chamber and the feeder chamber. The box body further comprises a door lock mechanism and a linkage lock mechanism, wherein the door lock mechanism controls the front doors to open and close and the linkage lock mechanism synchronously locks and unlocks the side doors. The outdoor intelligent high-voltage metering box has the advantages that the inside of the box body is divided into the PT chamber and the feeder chamber, so that metering is allowed, a feeder circuit can make and break, and users can be controlled effectively by the power supply department; the door lock structure is simple and reliable; an inset padlock is used for compact position locking, the fixation function of the padlock is given to play, and burgling is difficult; the linkage lock mechanism allows the side doors to be synchronously locked and unlocked when the front doors are opened and closed.

Owner:SHANGHAI FIRST ELECTRICAL GROUP

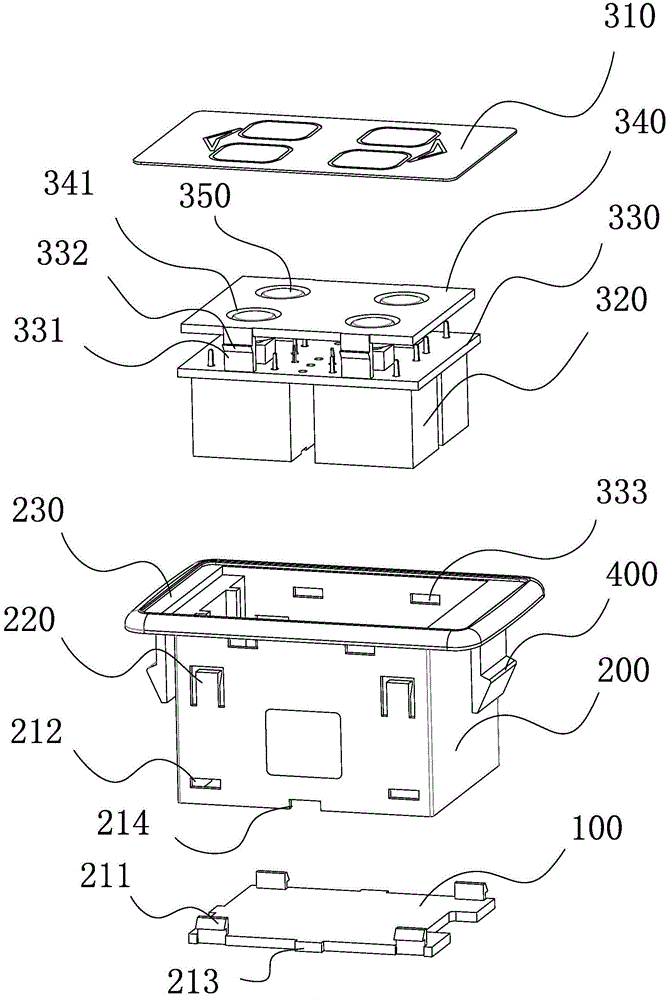

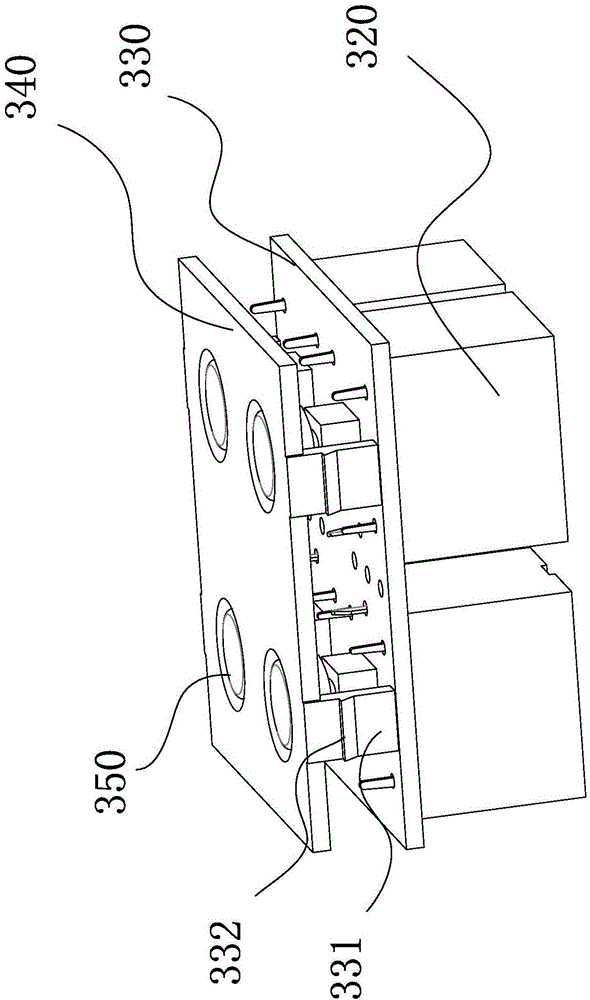

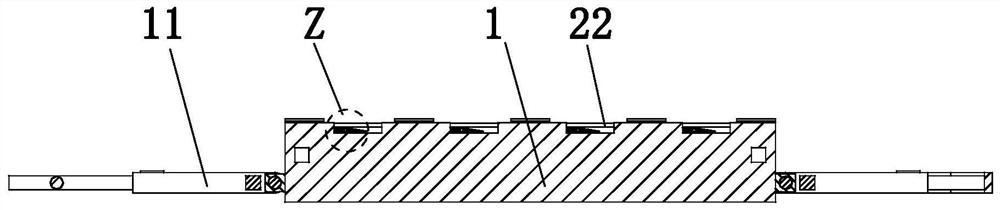

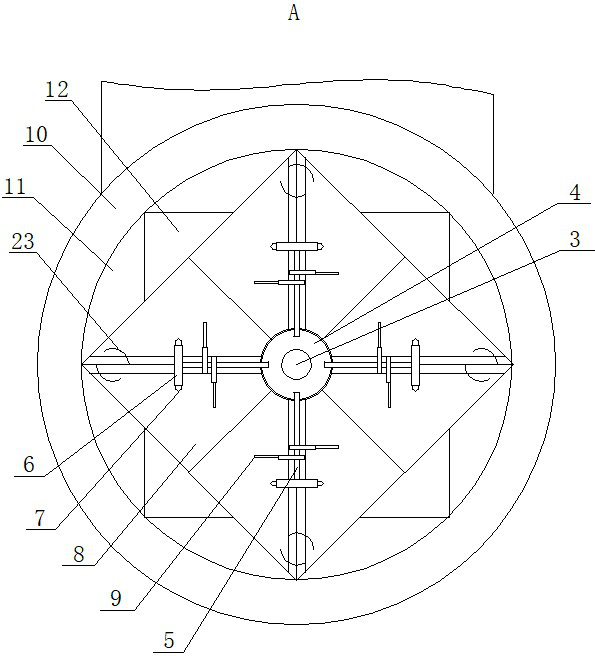

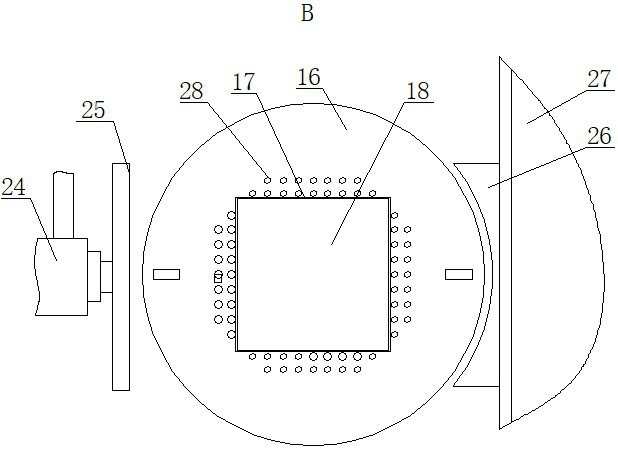

Clamping fixation type relay

ActiveCN104409282AImprove performanceExtended service lifeElectromagnetic relay detailsCarbon fibersResin-Based Composite

The invention provides a clamping fixation type relay, and belongs to the technical field of electrical equipment. The clamping fixation type relay solves the problem that connection of an existing relay is unstable. The clamping fixation type relay comprises a base plate, an outer shell and a control assembly. The control assembly comprises a control panel and a plurality of control coils, wherein the control panel is arranged on the top of the outer shell in a clamping mode, and the control coils are installed in the outer shell. The base plate is arranged at the bottom of the outer shell in a buckling mode through a buckling structure; the outer shell is made of composite resin which is formed by reasonable combination of PC, PET, carbon fibers, titanium dioxide, nano calcium carbonate, flexibilizer, compatibilizer and processing agents; the buckling structure comprises a locking part and a locating part; the locking part comprises a plurality of clamping hooks and a plurality of clamping grooves, wherein the clamping hooks are fixedly connected to the base plate, and the clamping grooves and the clamping hooks are in one-to-one correspondence, and the clamping hooks are clamped in the clamping grooves; the locating part comprises a plurality of locating protruding blocks and a plurality of locating grooves, wherein the locating protruding blocks are arranged on the base plate, and the locating grooves and the locating protruding blocks are in one-to-one correspondence, and the locating protruding blocks are matched with the locating grooves. The clamping fixation type relay is simple in structure, good in connection stability and long in service life and convenient to disassemble.

Owner:NINGBO YINZHOU YONGLIN ELECTRON ELECTRICAL EQUIP

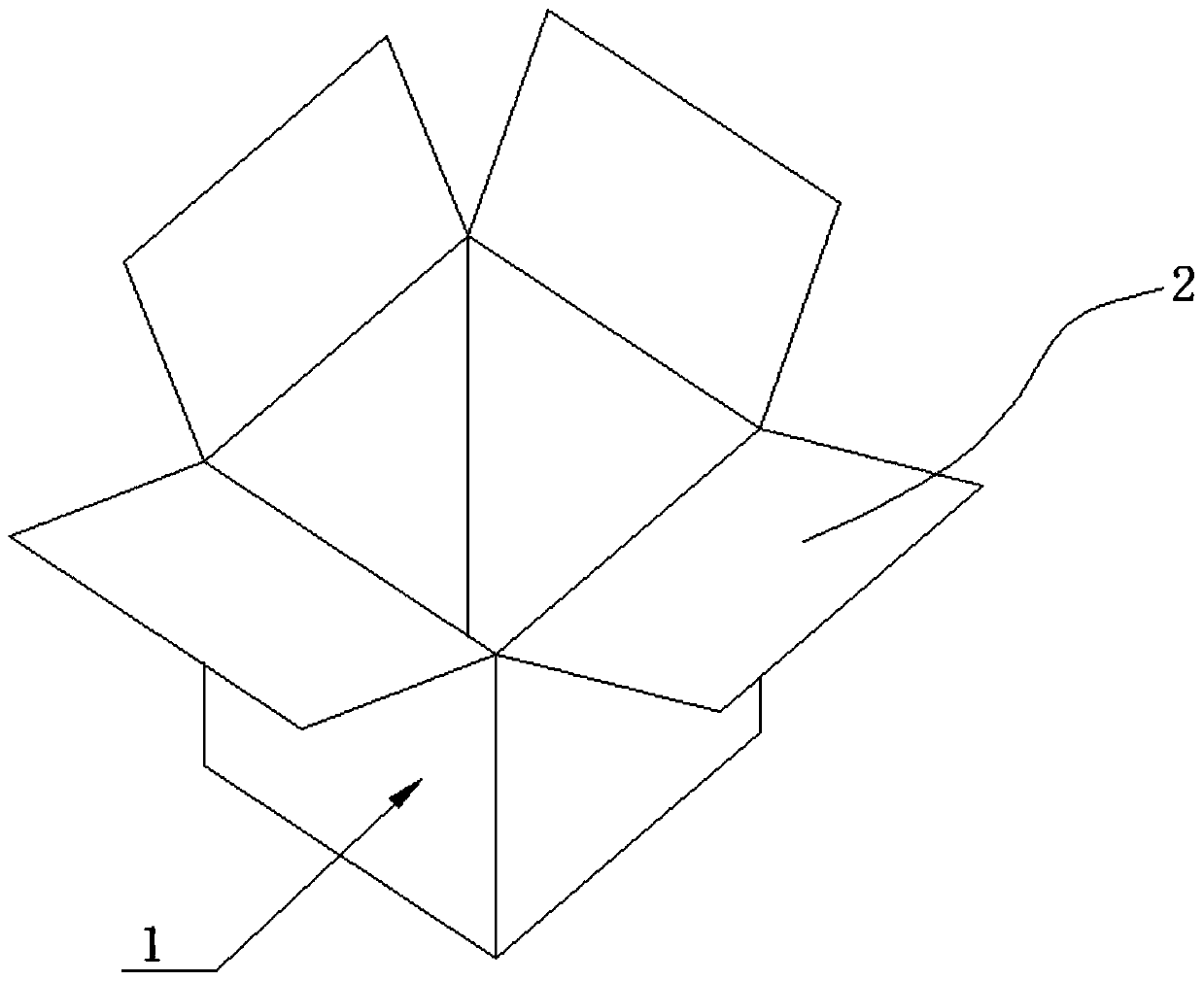

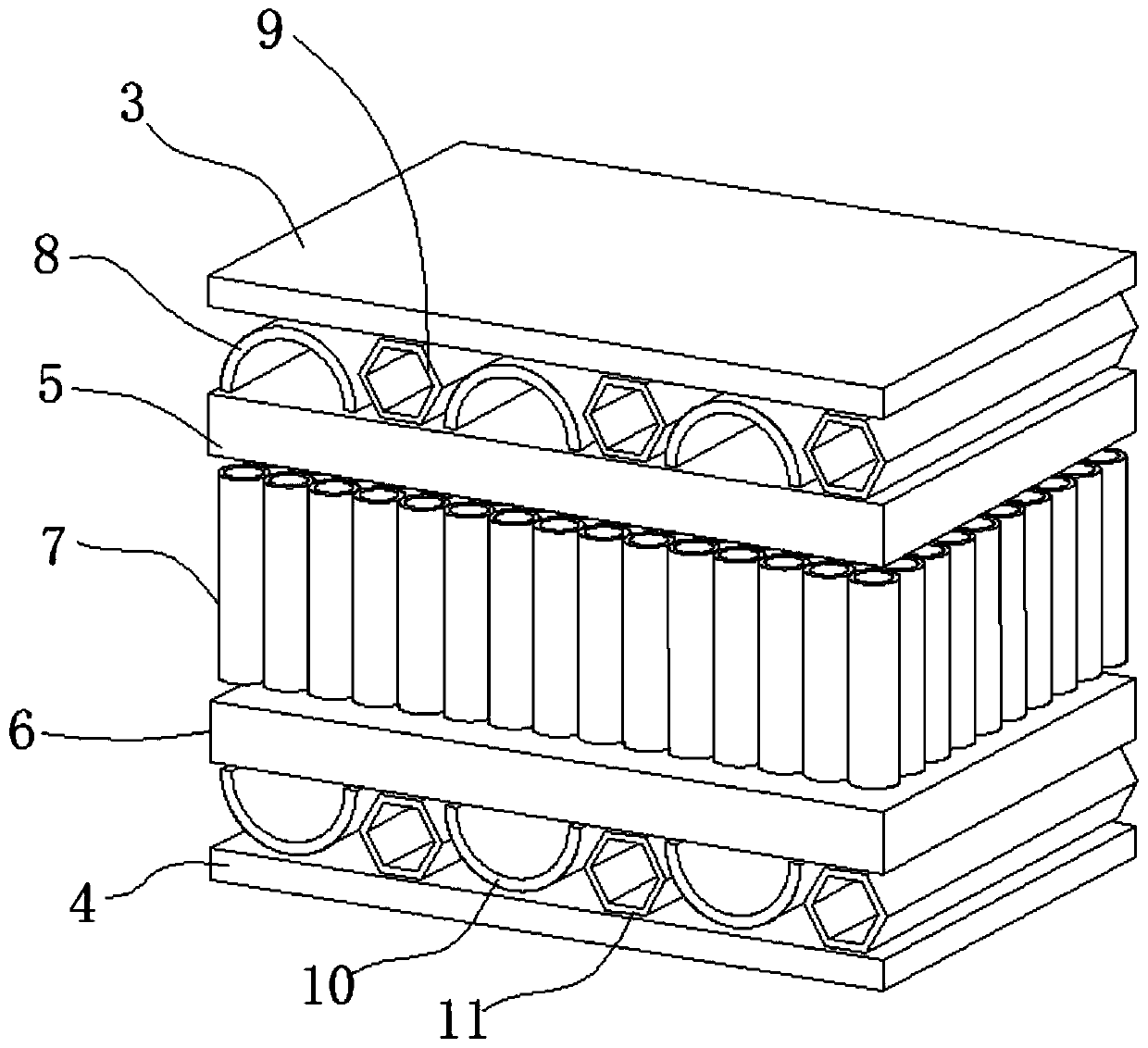

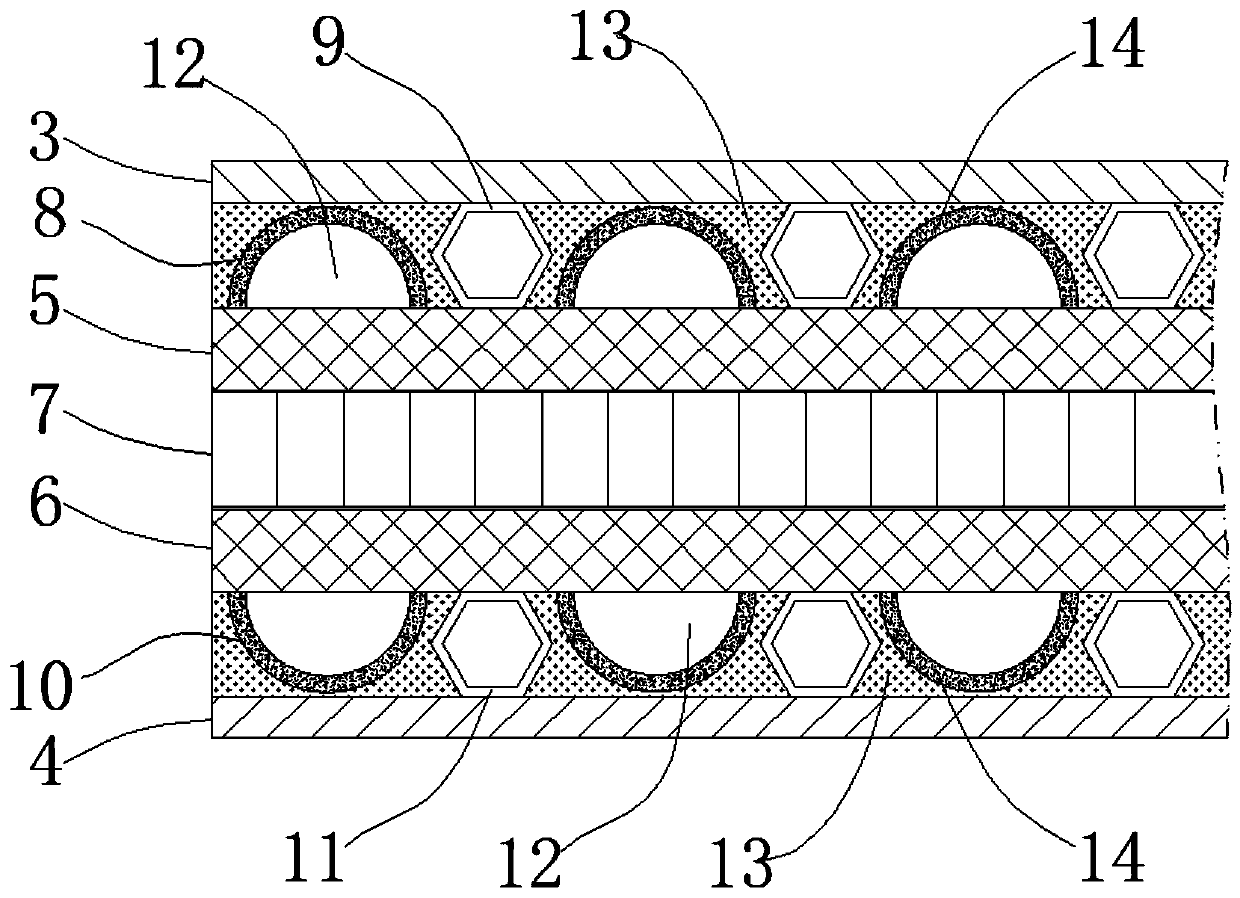

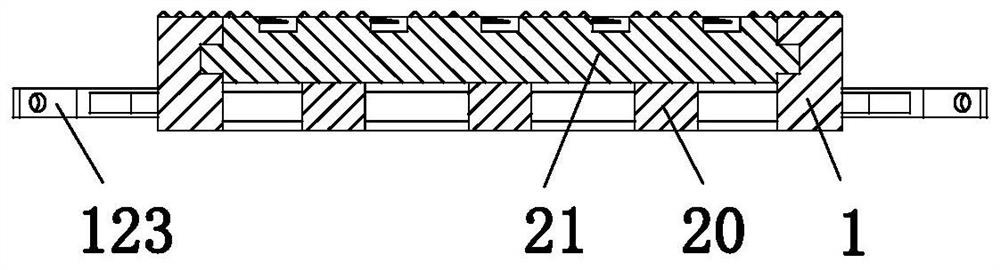

Corrugated paper box with high compressive strength and preparation process thereof

InactiveCN110561827AImprove stress resistanceStable supportBox making operationsPulp beating methodsCardboardPulp and paper industry

The invention provides a corrugated paper box with high compressive strength and a preparation process thereof. The corrugated paper box comprises a box body composed of corrugated paper boards, wherein the corrugated paper boards comprise an upper paper board and a lower paper board; a first partition plate and a second partition plate are arranged between the upper paper board and the lower paper board; a plurality of closely-arranged paper tubes are vertically arranged between the first partition plate and the second partition plate; first corrugated paper and a first pressure-resistant tube which are arranged in a staggered mode are arranged between the first partition plate and the upper paper board; second corrugated paper and a second pressure-resistant tube which are arranged in astaggered mode are arranged between the second partition board and the lower paper board; the first corrugated paper and the second corrugated paper are both of semi-circular arc structures; and hemispherical hollow buffer cavities are respectively formed between the first corrugated paper and the first partition board and between the second corrugated paper and the second partition board. According to the corrugated paper box with high compressive strength, compared with the prior art, the pressure-resistant structures are arranged inside the corrugated paper boards, so that the corrugated paper box has high-strength pressure-resistant capability.

Owner:云南瑞升纸业有限公司

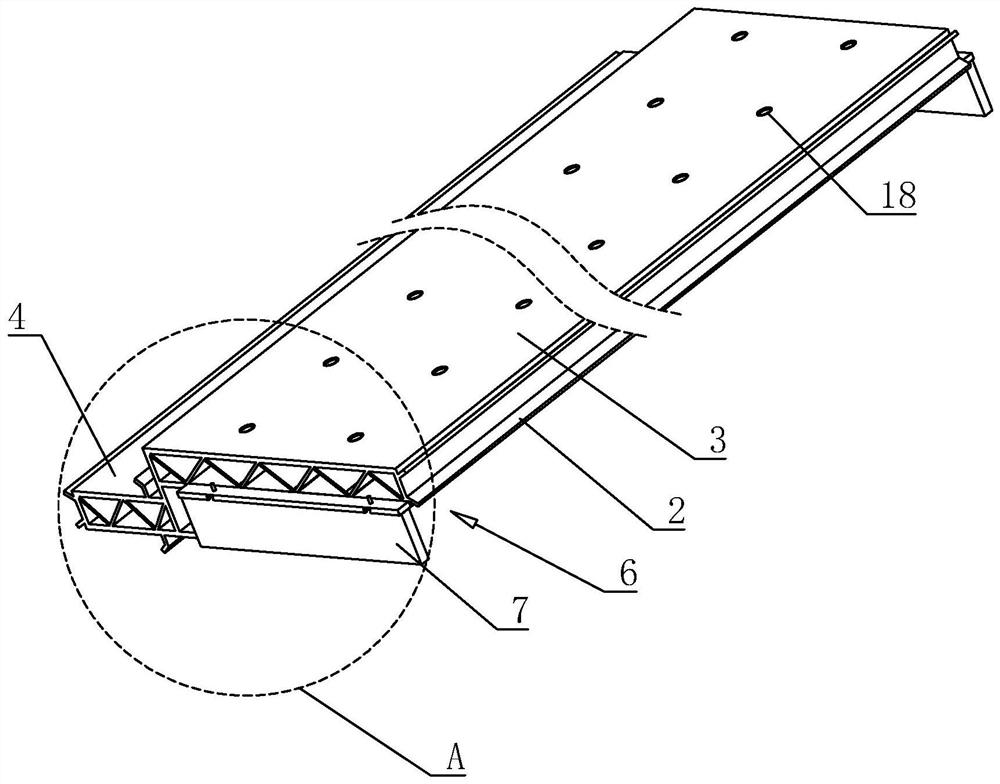

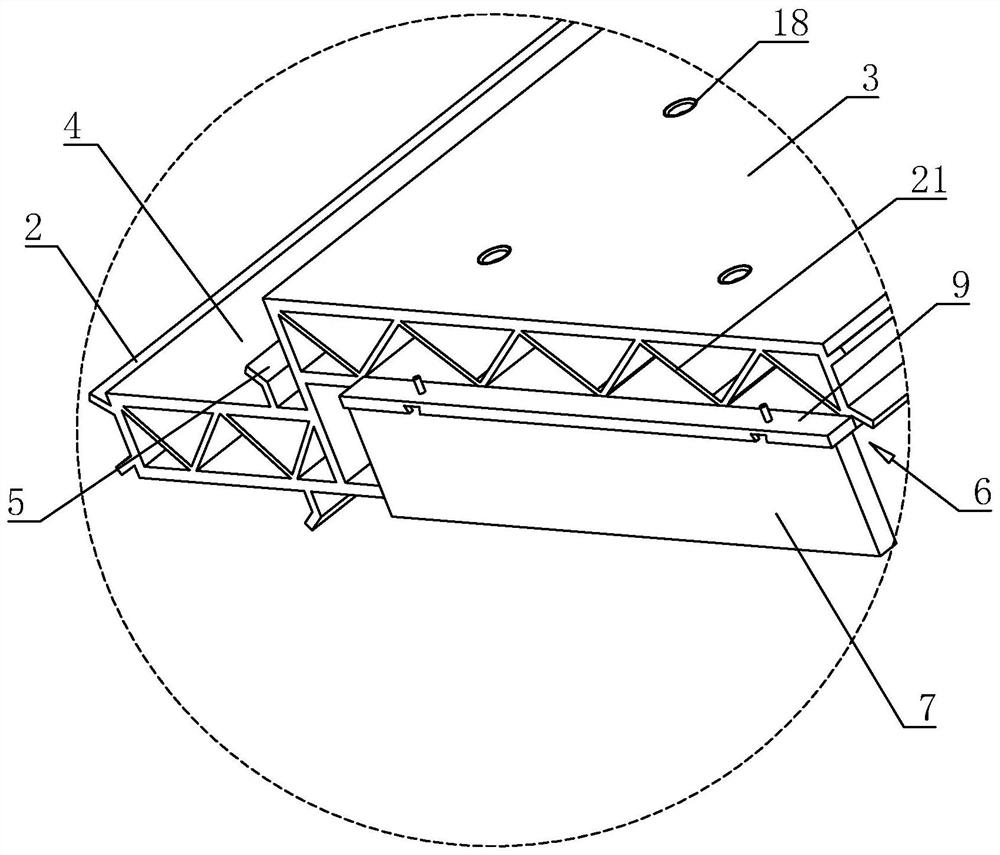

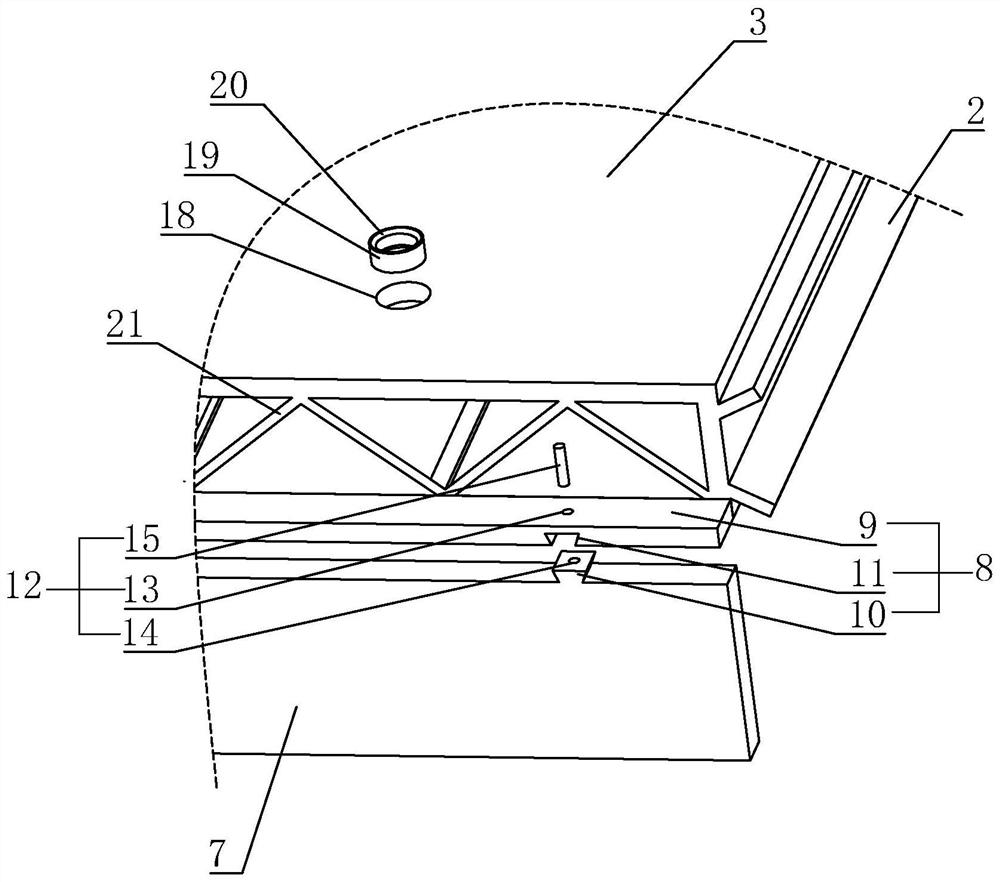

Structural separation seam applied to aluminum form and construction process thereof

ActiveCN111827671AEasy filling workPlay a solid roleForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksStructural engineeringMechanical engineering

Owner:深圳市旭生骏鹏建筑工程有限公司

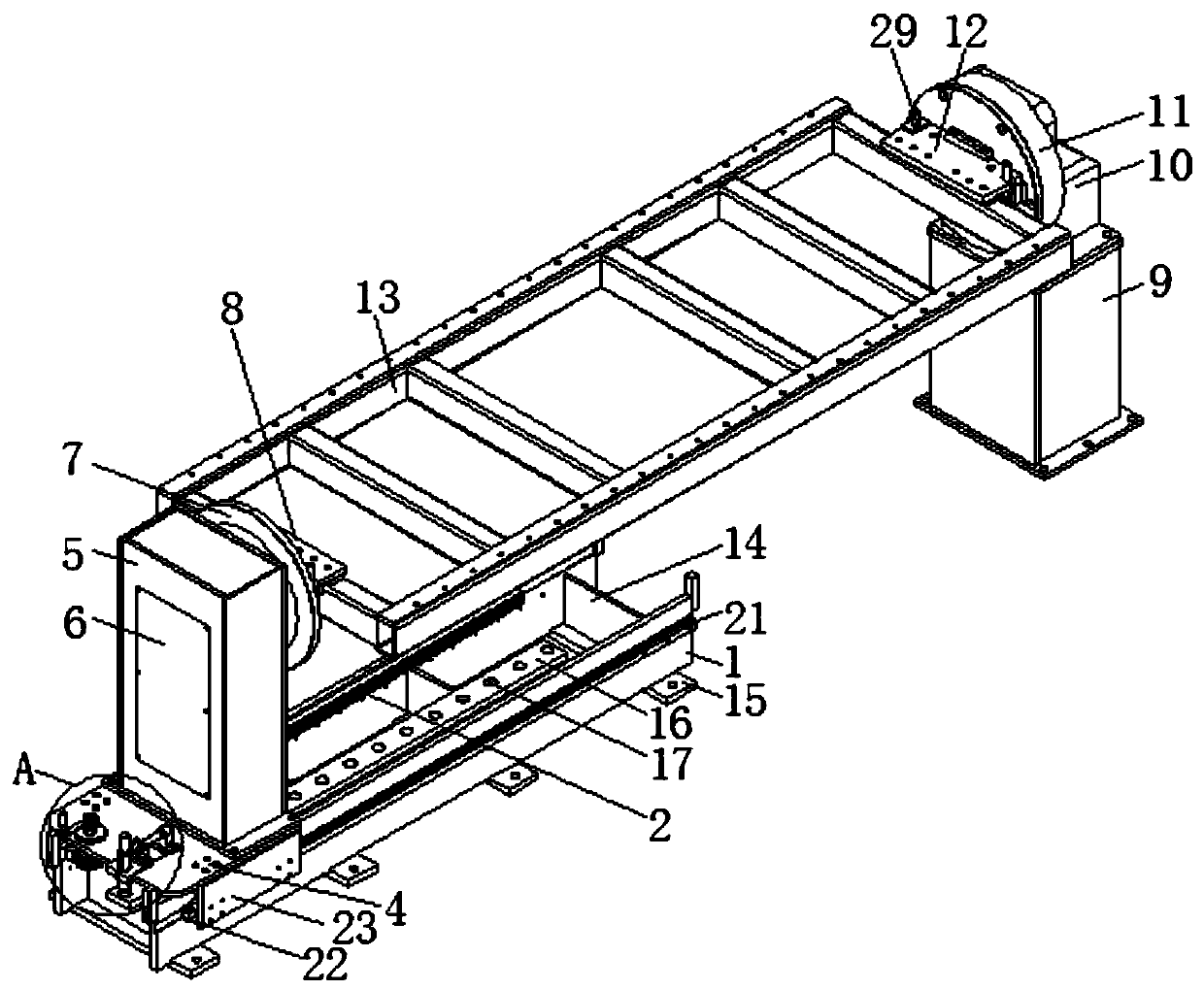

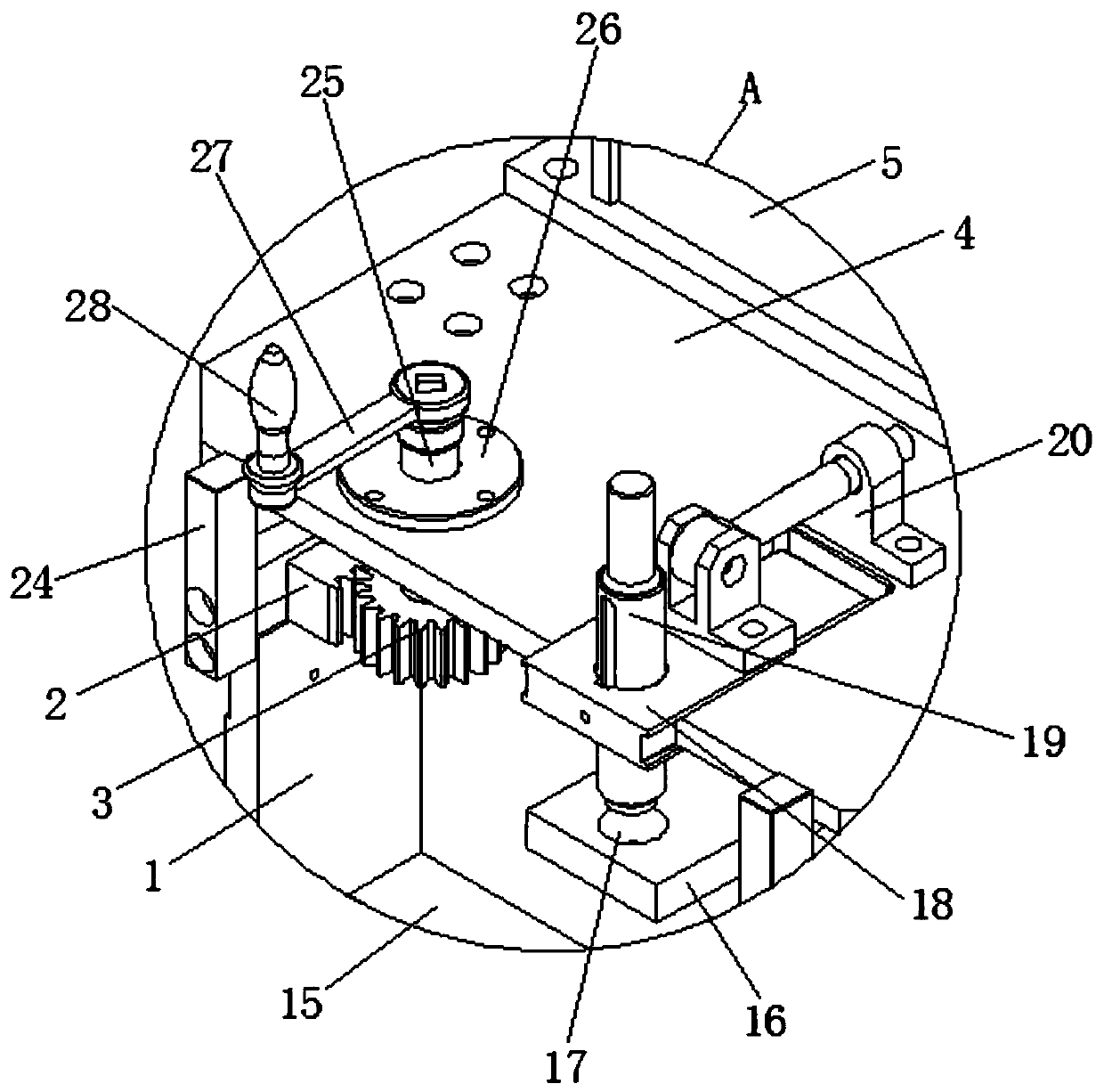

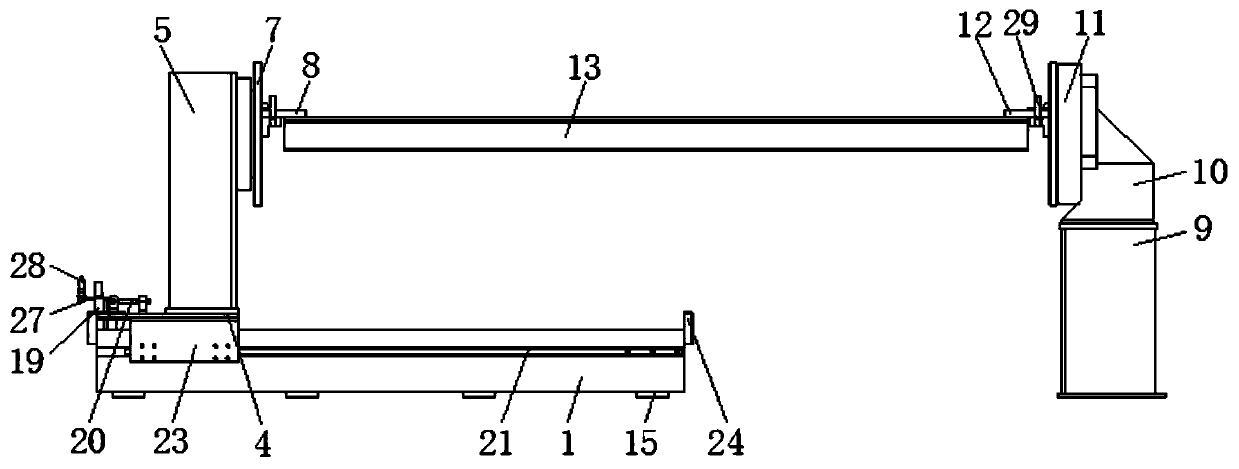

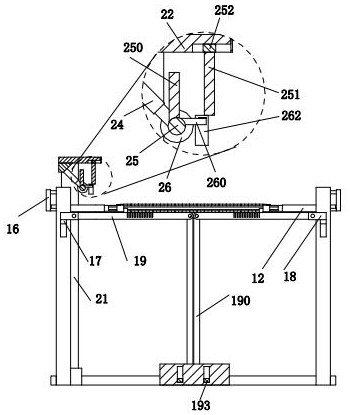

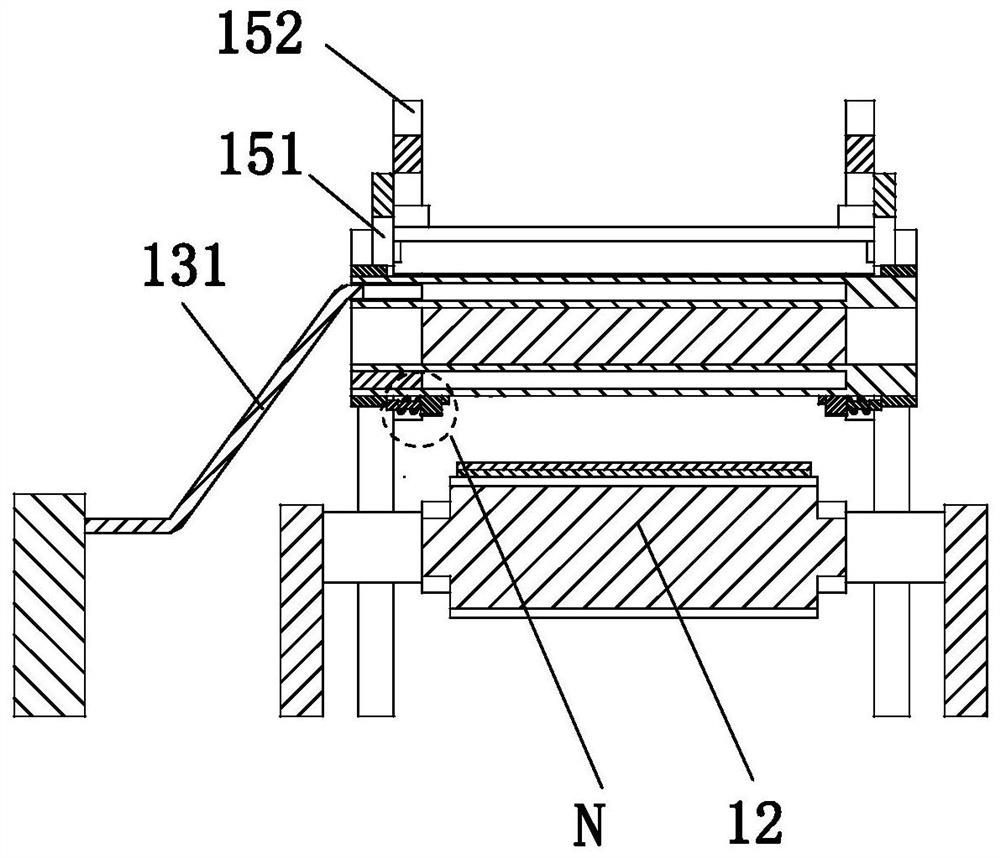

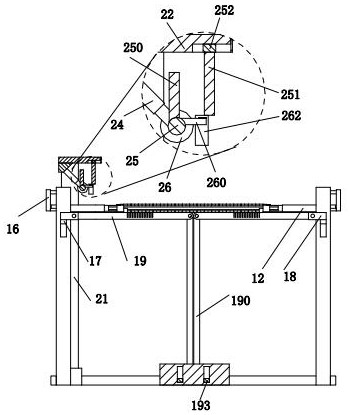

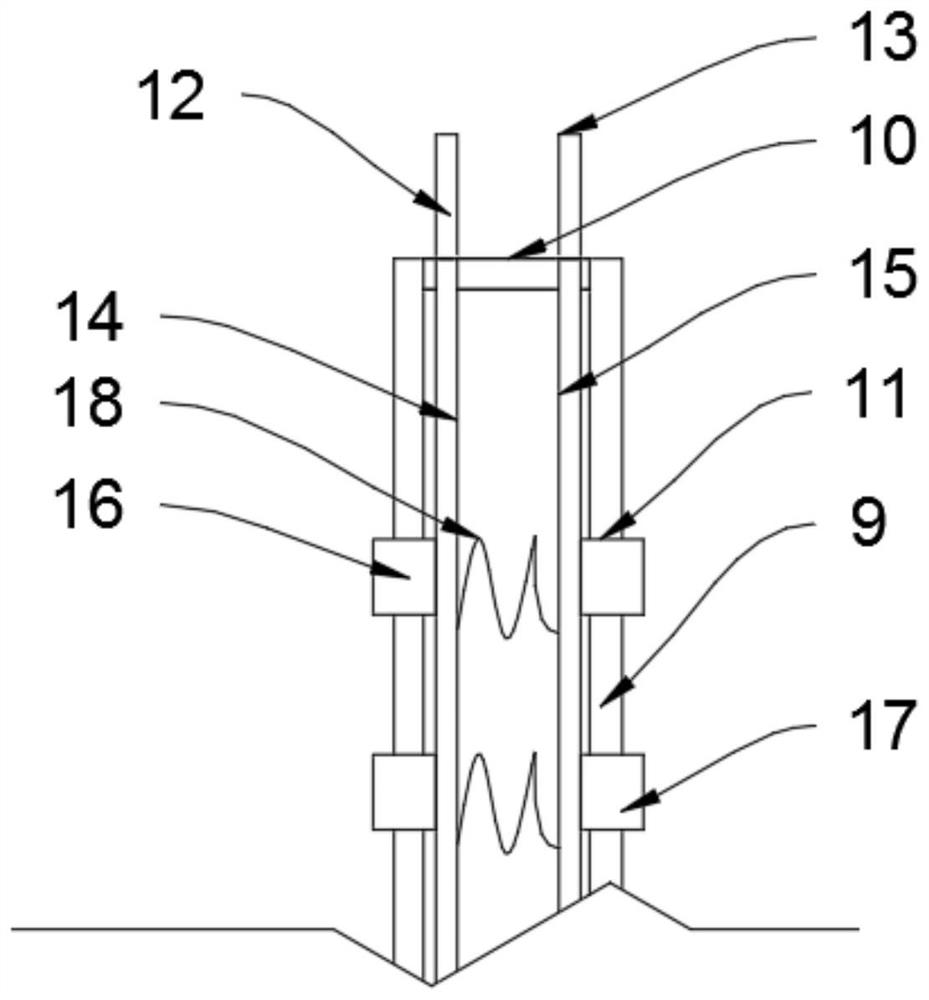

Movable positioner

ActiveCN110170793AEasy to installEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesMachiningEngineering

The invention discloses a movable positioner. The movable positioner comprises supporting plates and a second box. Rack plates are bolted on the inner walls of the supporting plates. The left side ofthe rack plate on the surface of the rear supporting plate is engaged with a gear plate. A fixing plate is arranged above the supporting plates. A box is bolted on the top of the fixing plate. An access door is arranged on the left side of the first box. According to the movable positioner, the supporting plates, the rack plates, the gear plate, the fixing plate, the first box, the access door, afirst rotary table, a first clamping piece, a second box, a fixing base, a second rotary table, a second clamping piece and a working frame are arranged, so that the positioner has the advantages of being convenient to clamp and fix, and capable of reducing the cost and improving the efficiency; the problems that an existing traditional positioner is only suitable for machining panels of fixed sizes and models, and consequentially, the production and machining cost is increased, a large space is occupied, and the working efficiency is affected are solved; and the movable positioner is worthy of popularization.

Owner:瀚能机器人自动化(丹阳)有限公司

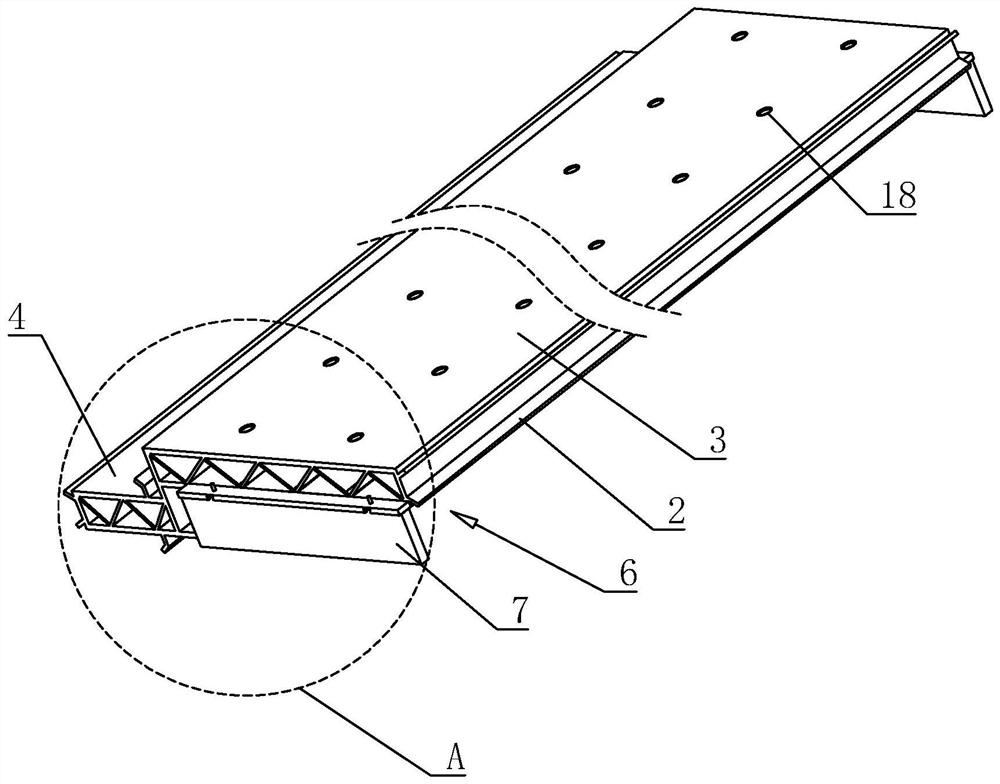

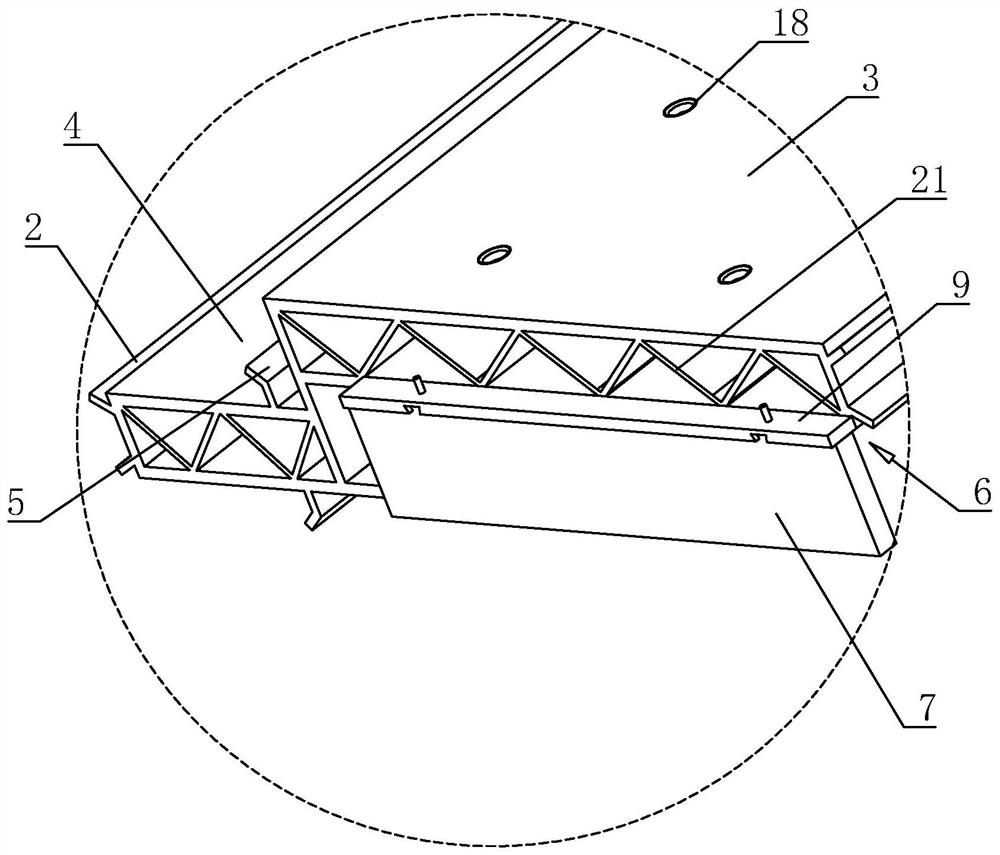

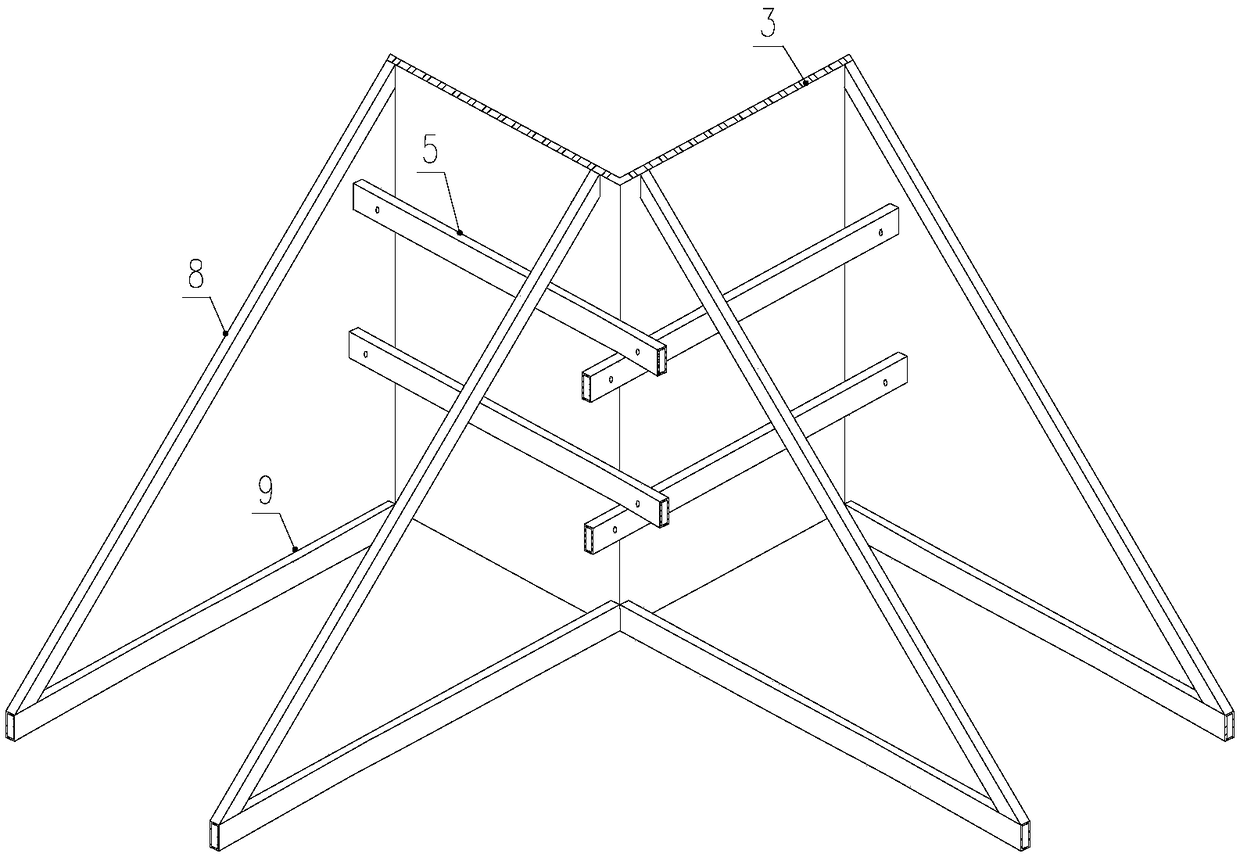

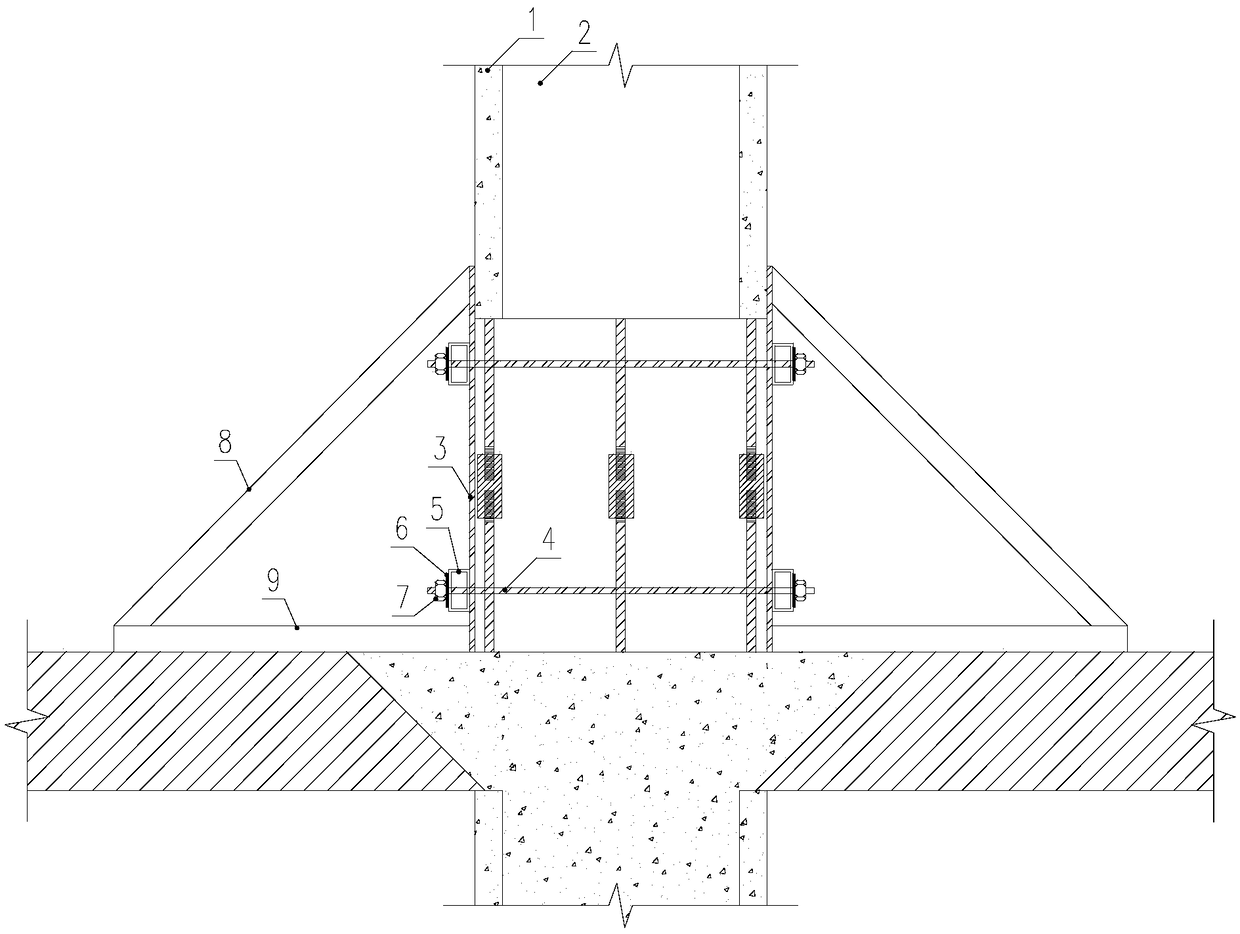

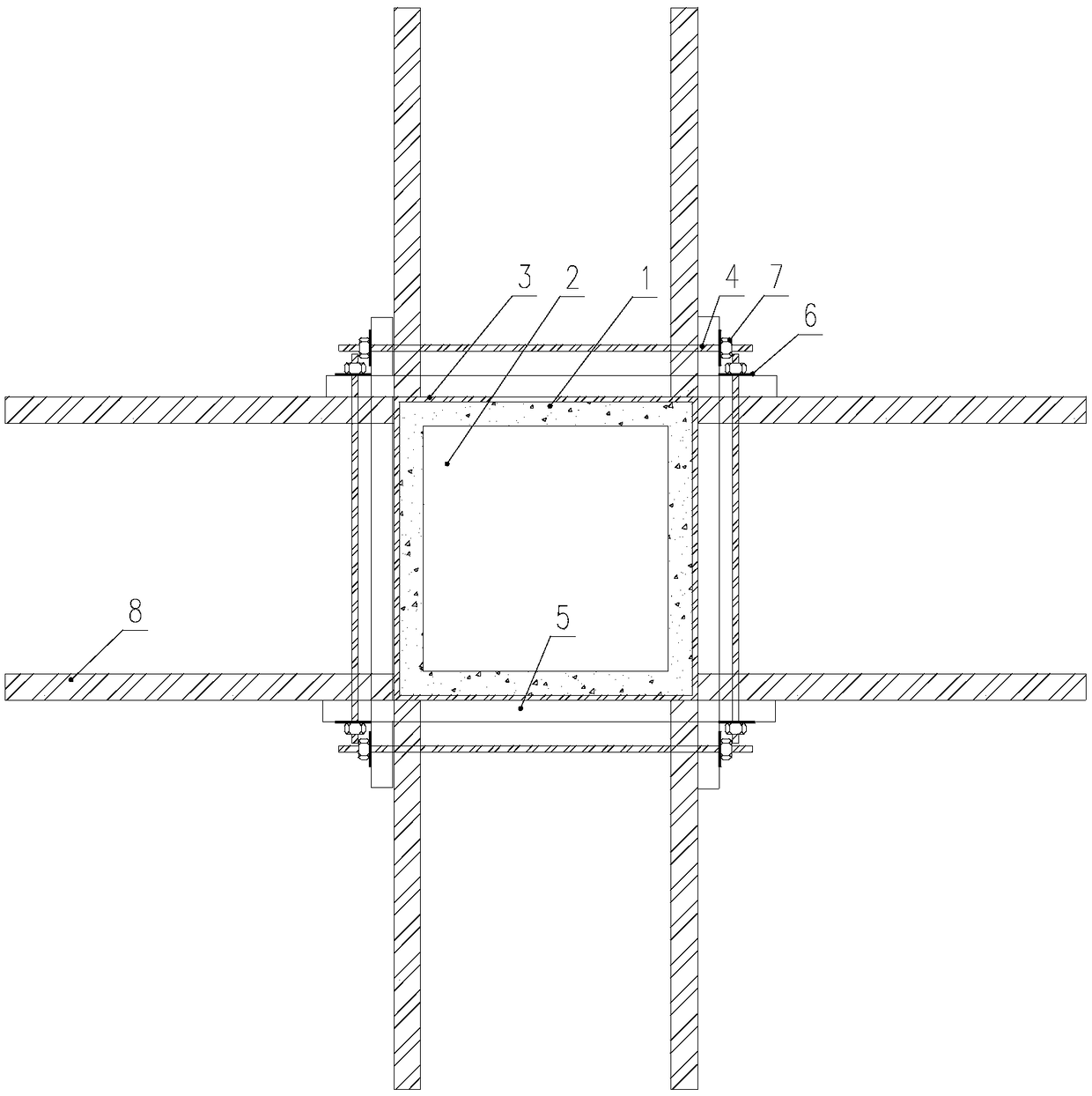

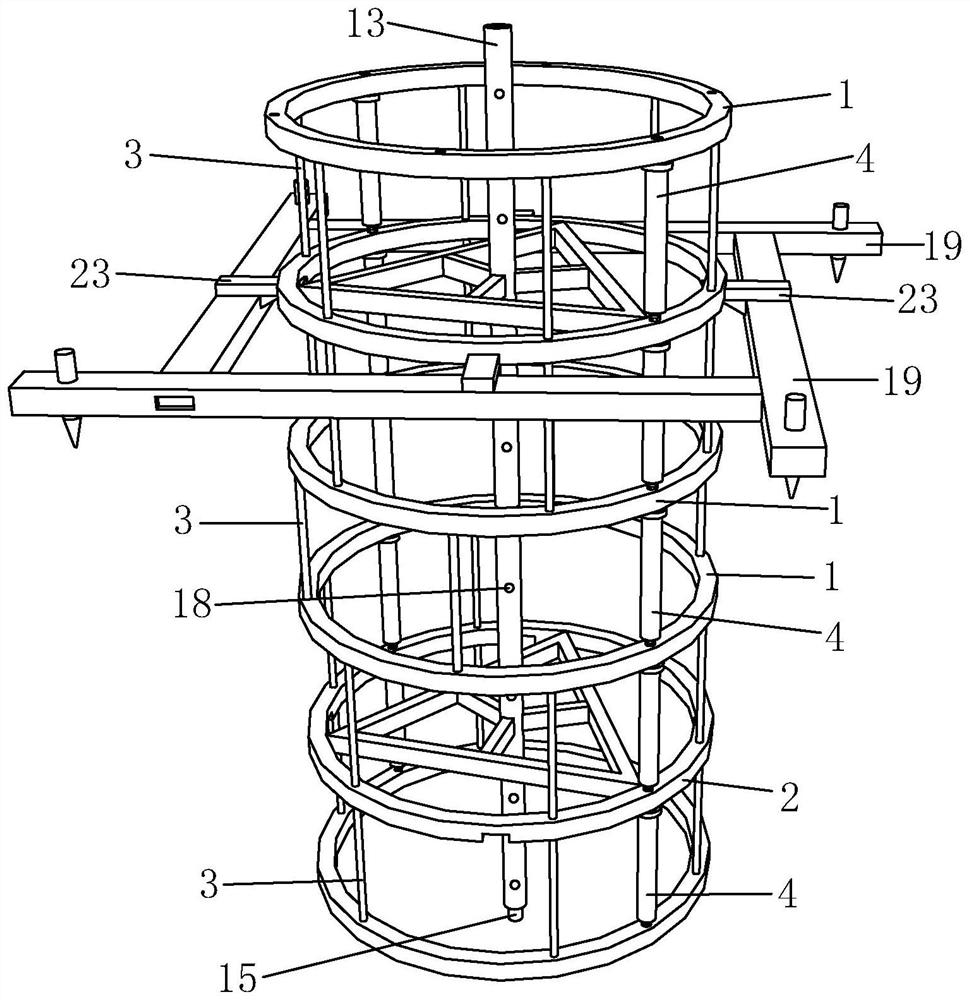

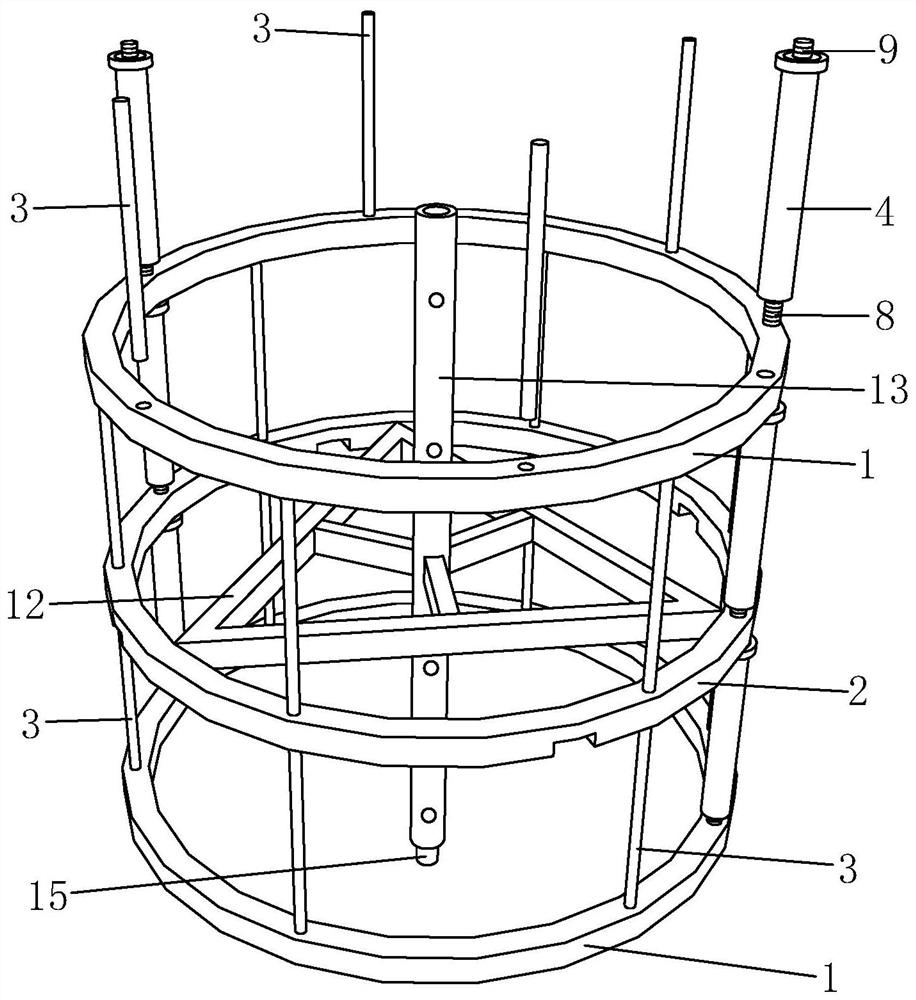

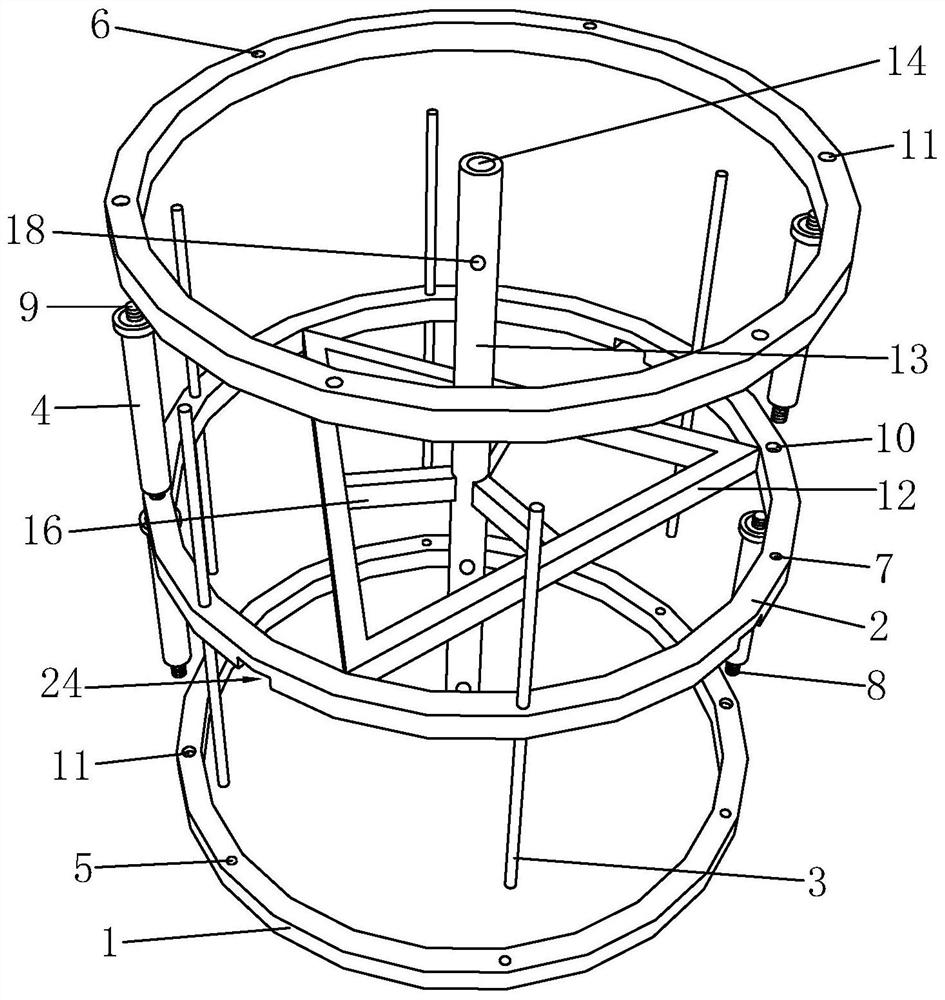

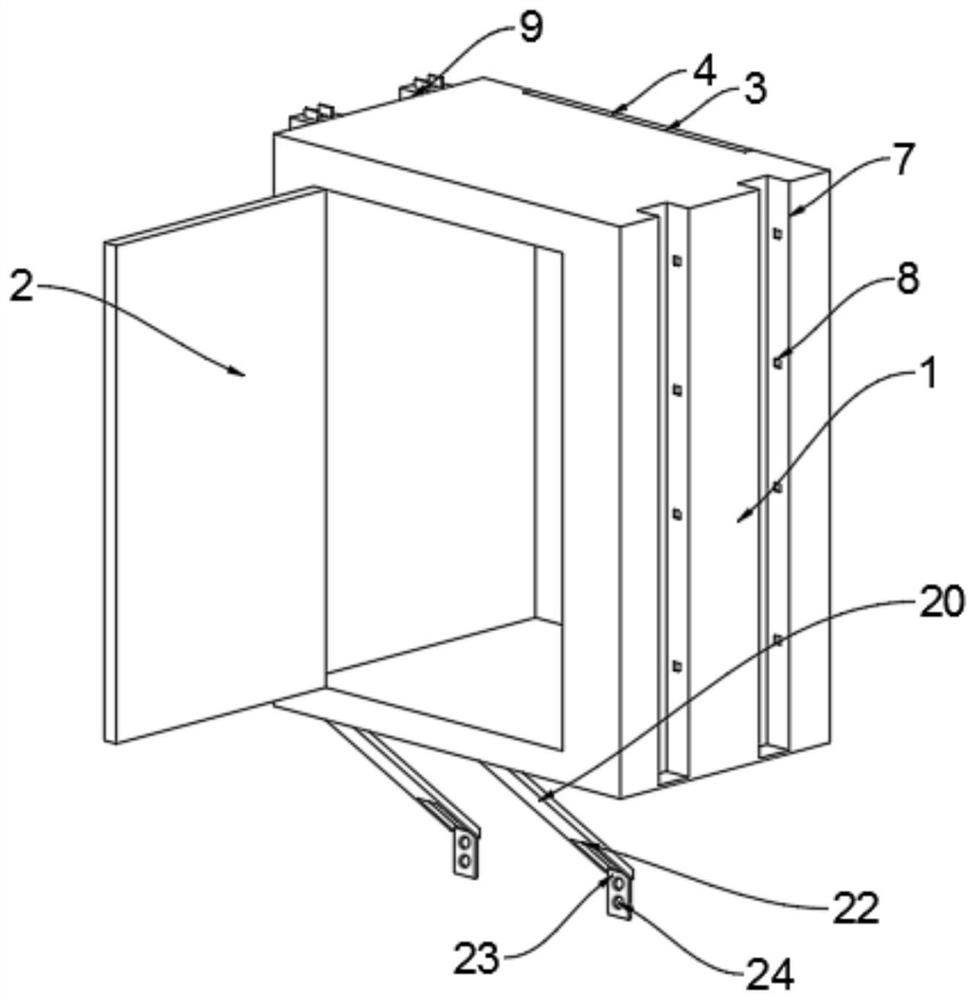

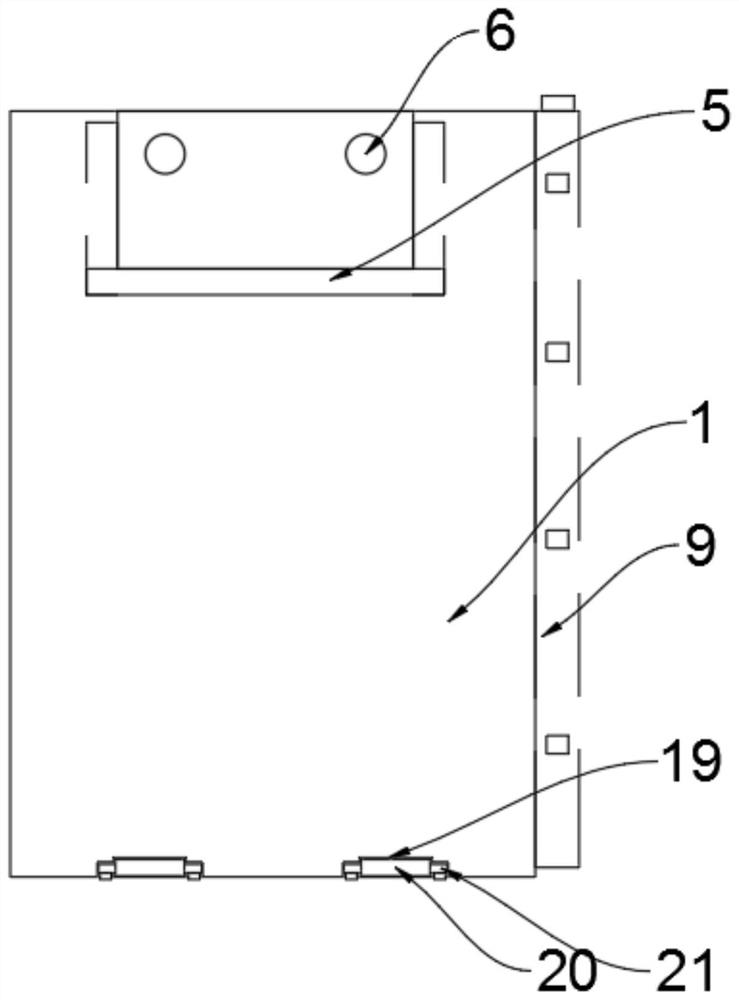

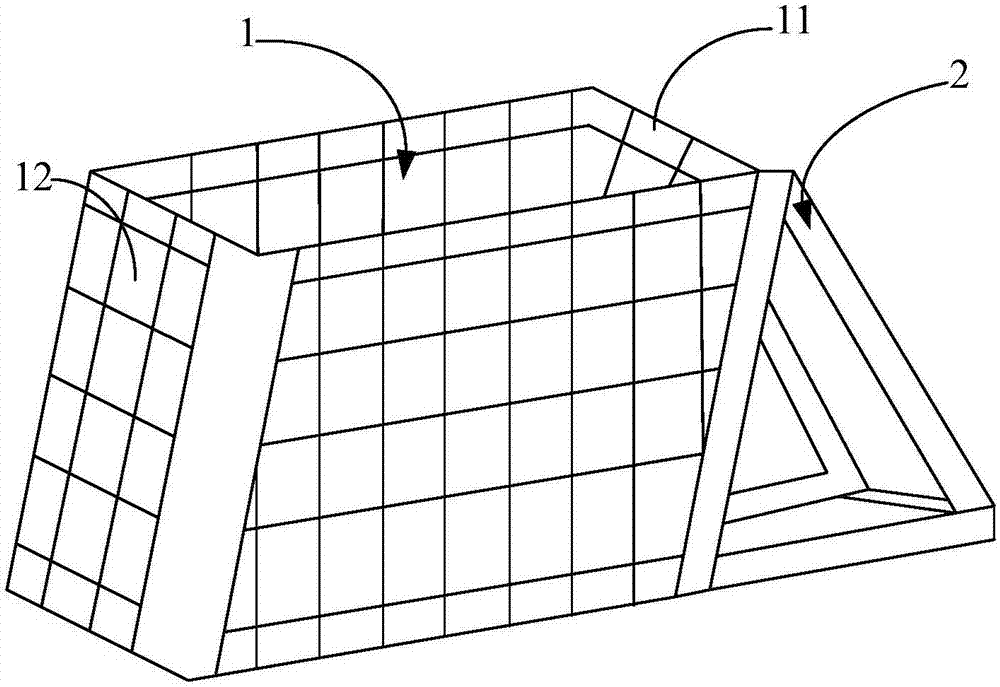

Support system, assembly-type laminated frame column and column bottom module erecting method

PendingCN108979138AImprove structural strengthImprove securityStrutsForms/shuttering/falseworksSteel tubeEngineering

The invention discloses a support system, an assembly-type laminated frame column and a column bottom module erecting method. The support system comprises four support units which surround around fourcorners of a column bottom of the laminated frame column. Each support unit comprises a steel template, a square steel tube horizontal sub-keel and an L-shaped support assembly. Steel templates are arranged in the vertical state. Square steel tube horizontal sub-keels are fixedly connected to surfaces of the steel templates along the horizontal directions. L-shaped support assemblies are in the shapes of L. The assembly-type laminated frame column and the column bottom module erecting method relate to the above support system. The support system, the assembly-type laminated frame column and the column bottom module erecting method have stable and reliable erecting effect. Meanwhile, construction cost is markedly reduced. High promotion and application value are acquired.

Owner:SANY CONSTR TECH CO LTD

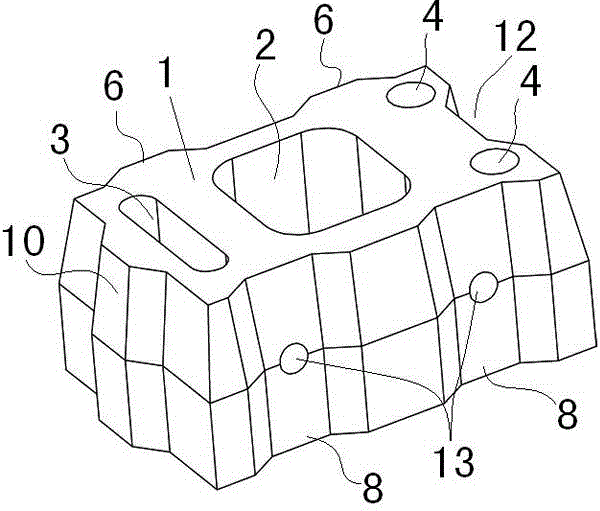

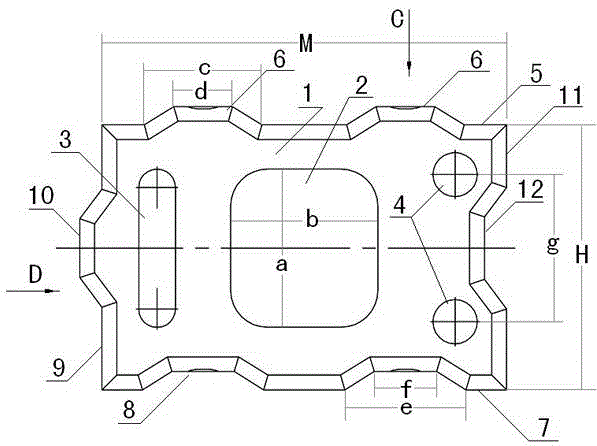

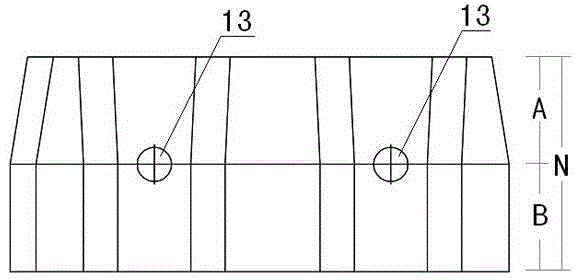

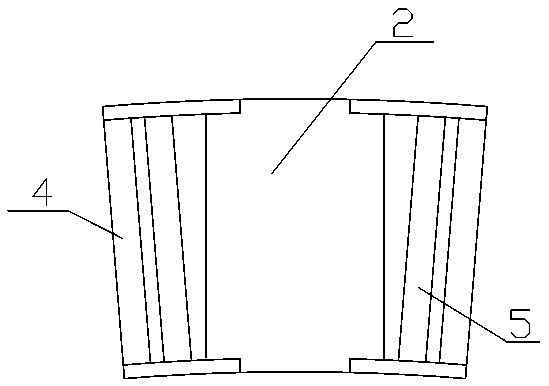

Building block shaped like Chinese character 'qu', sinking mattress system of building blocks shaped like Chinese character 'qu' and construction method of sinking mattress system of building blocks shaped like Chinese character 'qu'

InactiveCN105696521AHigh strengthHigh number of freeze-thaw cyclesCoastlines protectionChinese charactersEngineering

The invention discloses a curved block, a curved block sinking system and a construction method thereof. The block includes a block body, and the block body is divided into upper and lower parts. The cross-section of the upper part A The shape is a trapezoidal structure, and the cross-sectional shape of the lower half B is a rectangular structure. There is a first through hole in the center of the block body, and a second through hole on one side of the first through hole. There are two third through holes on the other side, two first self-locking tenons are symmetrically arranged on the front side of the block main body, and two second self-locking tenons are arranged on the rear side of the block main body corresponding to the first self-locking tenons. A self-locking concave mortise, the left side of the main body of the block is provided with a second self-locking tenon, the right side of the main body of the block is provided with a second self-locking concave mortise, the upper half A of the main body of the block and the lower half There are two transverse reinforcement holes in the self-locking tenon at the intersection of part B. The process steps include making a solid row platform, laying geotextiles, arranging curved blocks, threading reinforcement, overall sinking and rowing, and solid rowing.

Owner:吉林久盛生态环境科技有限公司 +3

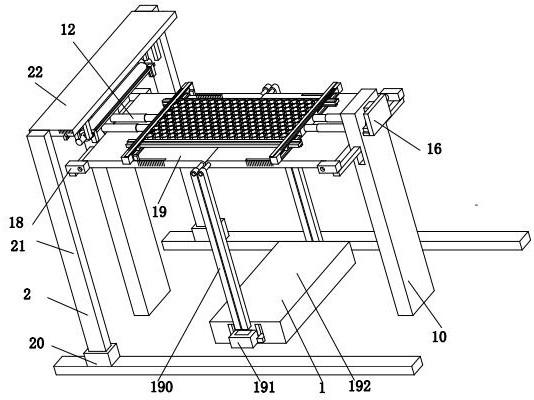

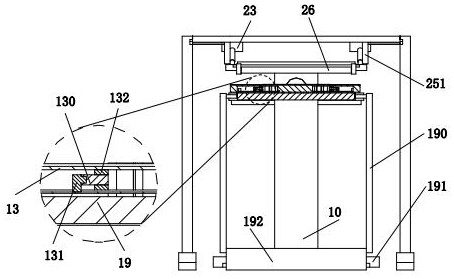

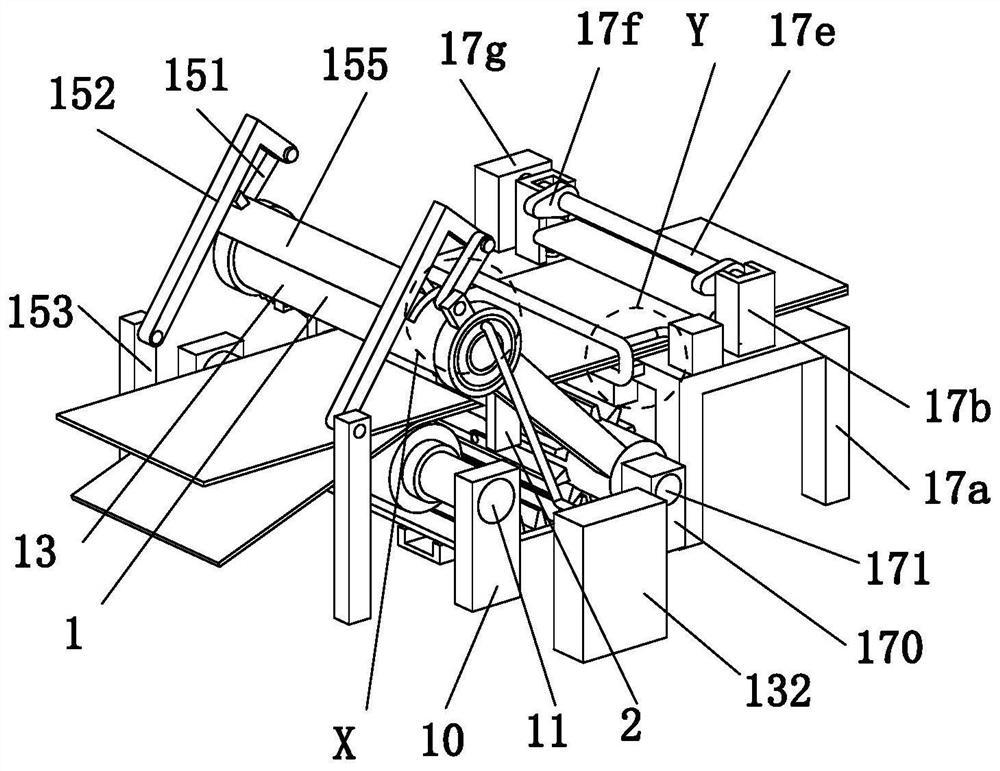

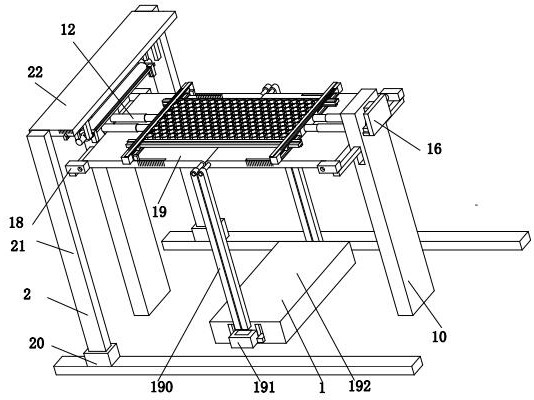

Honeycomb plate production and forming composite processing machine

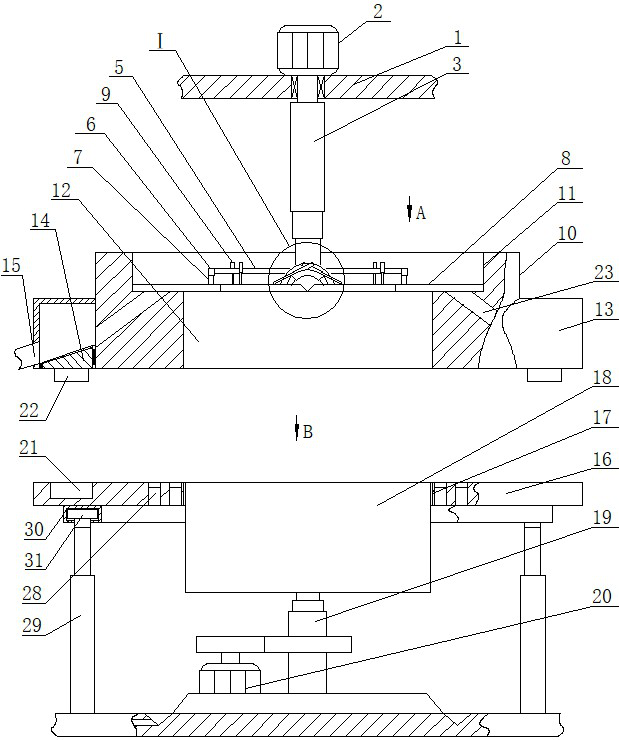

ActiveCN113290945AImprove bonding tightnessImprove composite molding qualityPaper/cardboard articlesHoneycombStructural engineering

The invention relates to the field of honeycomb plate production, in particular to a honeycomb plate production and forming composite processing machine which comprises a clamping and fixing mechanism and a pressing mechanism, the clamping and fixing mechanism is arranged on the ground, and the pressing mechanism is arranged at the left end of the clamping and fixing mechanism. The clamping and fixing mechanism comprises a vertical frame, a disc, a first electric push rod, a clamping plate, a limiting block, a stop block, a connecting plate, a first electric sliding block, a lug plate, a supporting plate, a supporting rod, a connecting plate, a bottom block and a second electric sliding block. By adopting the design concept of multidirectional limiting, the whole processing machine can realize multidirectional clamping and fixing of a honeycomb core, so that the honeycomb core is prevented from shifting or deforming, the function of turning over the honeycomb core so that the honeycomb core can be subjected to double-faced composite panel treatment is also achieved, meanwhile, the arranged pressing mechanism can press a panel and the honeycomb core, then the purpose of improving the bonding compactness between the honeycomb core and the panel is achieved, and the composite forming quality of the honeycomb plate is improved.

Owner:JIANGSU HAIDEMAN BUILDING MATERIALS IND

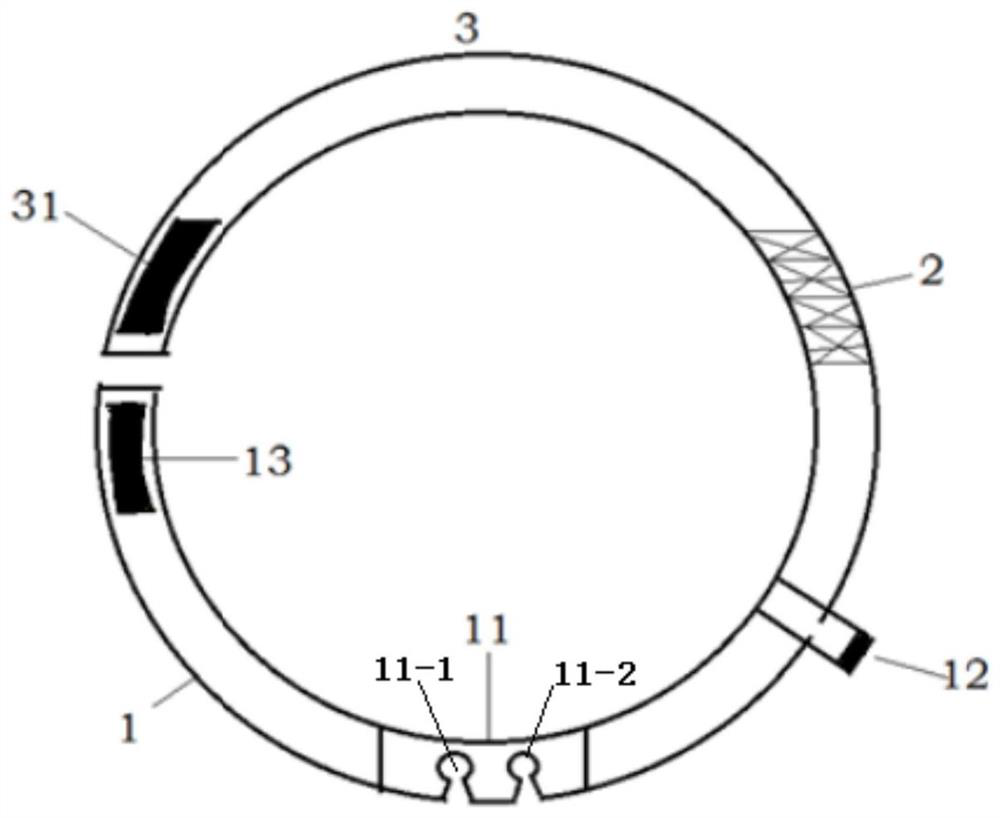

Adjustable nasal oxygen cannula and stomach tube fixing device capable of preventing pressure sores

The invention discloses an adjustable nasal oxygen cannula and stomach tube fixing device capable of preventing pressure sores. The adjustable nasal oxygen cannula and stomach tube fixing device is characterized by comprising a stomach tube fixing belt, wherein the stomach tube fixing belt is of an arc shape; the stomach tube fixing belt is provided with a stomach tube clamping hole structure used for installing a nasogastric tube, and a fixing part used for fixing the stomach tube positioned on the face; and two ends of the stomach tube fixing belt are connected and fixed through connecting parts. The nasogastric tube fixing clamping hole structure can effectively fix a stomach tube and a nasal catheter, a thin rubber ring is arranged on the inner ring of the clamping hole, friction force between the stomach tube and the clamping hole is increased, and the stability of the stomach tube fixing structure is guaranteed. A medical foam dressing on the inner surface of the fixing belt has a high skin-friendly degree and good elasticity, is comfortable and non-sticky, and can quickly absorb parts of fluid, prevent the pressure sores and reduce facial skin allergy.

Owner:ZHONGSHAN HOSPITAL FUDAN UNIV

A non-woven fabric production thermosynthesis equipment

ActiveCN111945297BImprove adhesionHigh speedNon-woven fabricsVibration suppression adjustmentsSpinningProcess engineering

The invention relates to a heat-synthesizing equipment for producing non-woven fabrics, which includes a heat-bonding mechanism and an auxiliary pressure mechanism. The lower end of the heat-bonding mechanism is installed on the existing working ground, and the upper end of the heat-bonding mechanism is provided with an auxiliary pressure mechanism. The present invention adopts the design concept of combining multi-stage pressing structures to carry out thermal synthesis of non-woven fabrics. The auxiliary pressing mechanism and other structures with pressing effects can be used to press the thermally bonded non-woven fabrics multiple times to improve the non-woven fabrics. The purpose of the bonding degree of the woven fabric is to provide an external auxiliary heating structure to improve the bonding speed and quality of the non-woven fabric, and to provide a cooling structure to increase the solidification speed of the non-woven fabric bonding part.

Owner:惠州市新瑞无纺布有限公司

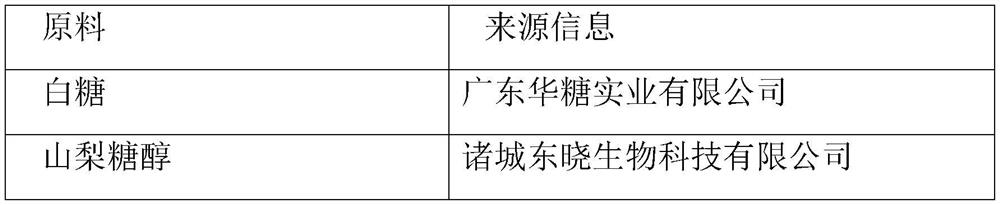

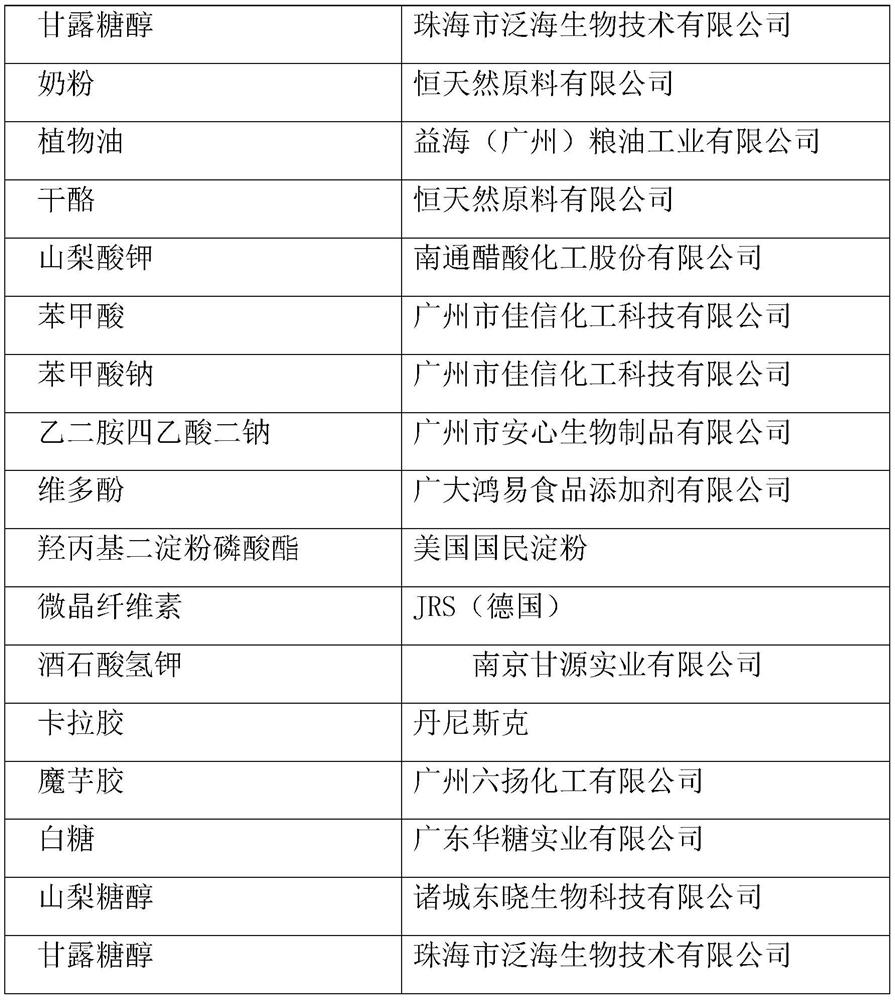

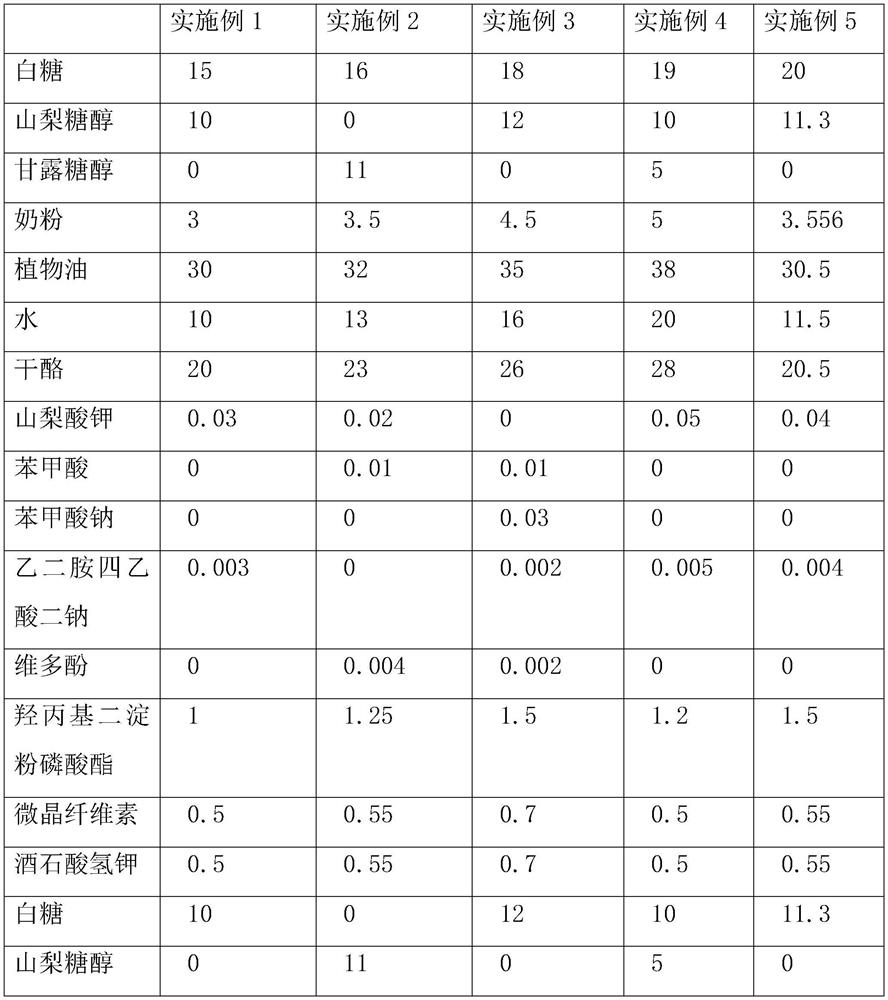

Cheese sauce and preparation method thereof

InactiveCN112841255ANot easy to separateImprove emulsion stabilityBakery productsBiotechnologyVegetable oil

The invention relates to the field of edible sauce, and particularly discloses cheese sauce and a preparation method thereof. The cheese sauce comprises a solid matter, a sweetening agent, a flavoring agent, vegetable oil, water, a flavoring agent, a preservative, an antioxidant, hydroxy propyl distarch phosphate, microcrystalline cellulose and potassium hydrogen tartrate. The preparation method comprises the following steps: step 1, weighing the solid matter, the sweetening agent, the flavoring agent, the flavoring agent, the preservative, the antioxidant, the hydroxy propyl distarch phosphate, the microcrystalline cellulose and the potassium hydrogen tartrate according to a formula, adding the weighed materials into a production pot, weighing water according to a formula, adding the weighed water into the production pot, and uniformly mixing the materials to obtain a powder mixture; step 2, performing homogenizing; step 3, adding vegetable oil and performing emulsifying; step 4, performing heating and preserving heat; step 5, taking out the product of pot; and step 6, performing packaging. The cheese sauce has the advantages that the cheese sauce is compounded by the hydroxy propyl distarch phosphate, the microcrystalline cellulose and the potassium hydrogen tartrate, accordingly, sauce systems can resist high temperatures, and the baking-resistant stability of the sauce systems can be greatly improved.

Owner:广州市倍乐食品有限公司

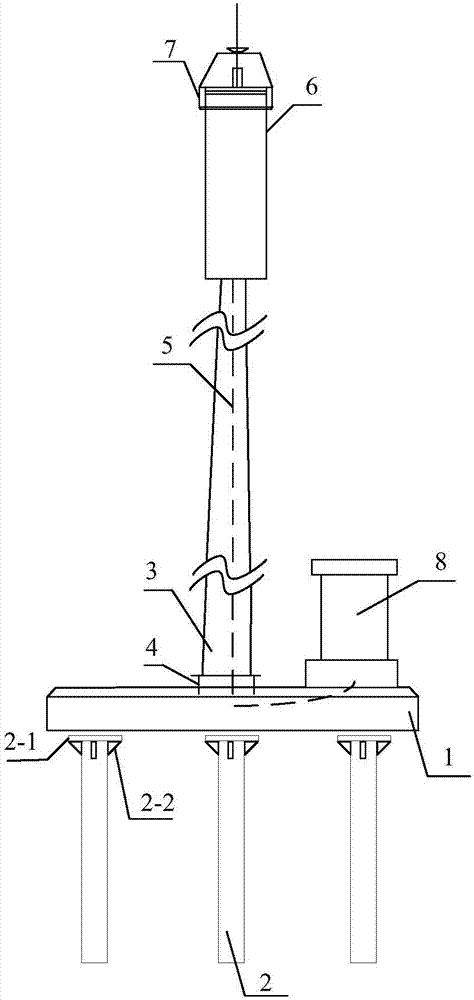

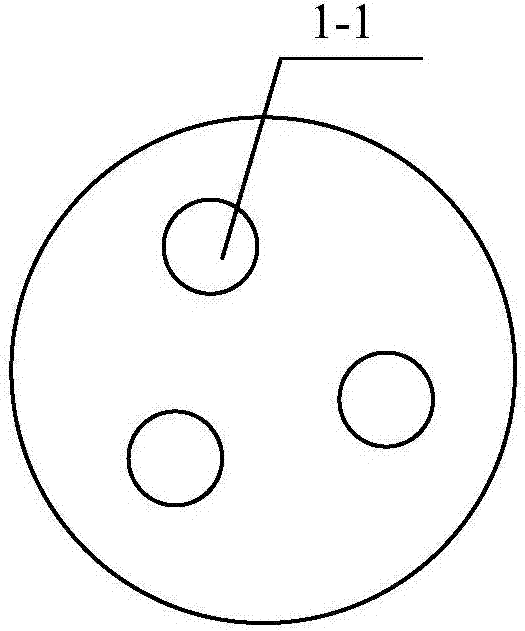

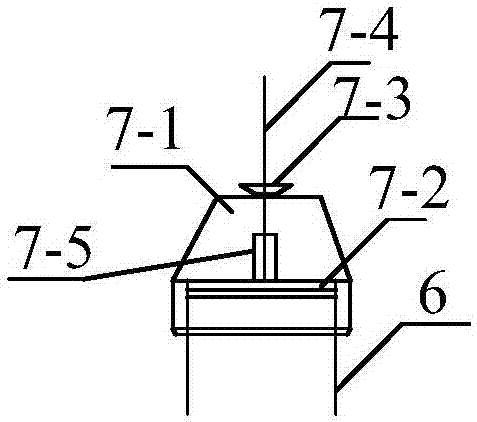

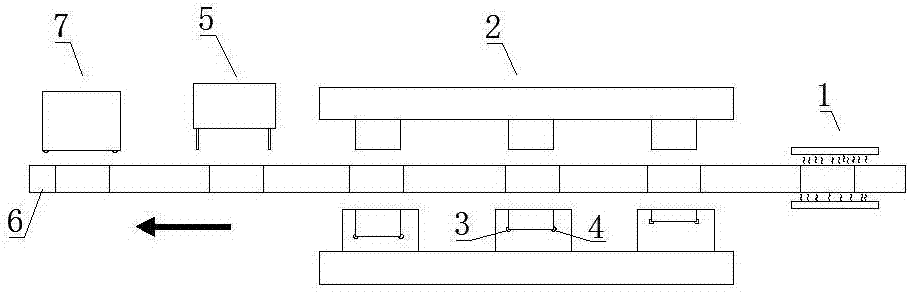

Communication base station

PendingCN107503554APlay a solid roleSmall footprintTowersWireless communicationTowerMechanical engineering

A communication base station relates to the technical field of wireless communication. The problems that an existing communication base station is of an integrated installation structure, the land occupation area is large and an antenna is easily affected by rainwater and thus limited in service life are solved. The communication base station includes a machine room and a communication tower provided with the antenna, the lower portion of the communication tower is provided with a tower footing, the upper portion of the communication tower is provided with the antenna, the antenna is connected with equipment in the machine room through the communication tower, the upper portion of the antenna is provided with a waterproof device, the tower footing includes a bottom plate and a pouring rod, the lower surface of the bottom plate is provided with a concave hole, the top of the pouring rod is provided with a disk surface, and the disk surface is installed in the concave hole and fixed through cement pouring. The lower portion of the communication tower is provided with the tower footing, the communication tower is detachably connected with the tower footing, the pouring rod in the tower footing is embedded underground, the function of vertical fixation is achieved, and the occupation space is reduced.

Owner:CHINA TOWER CO LTD

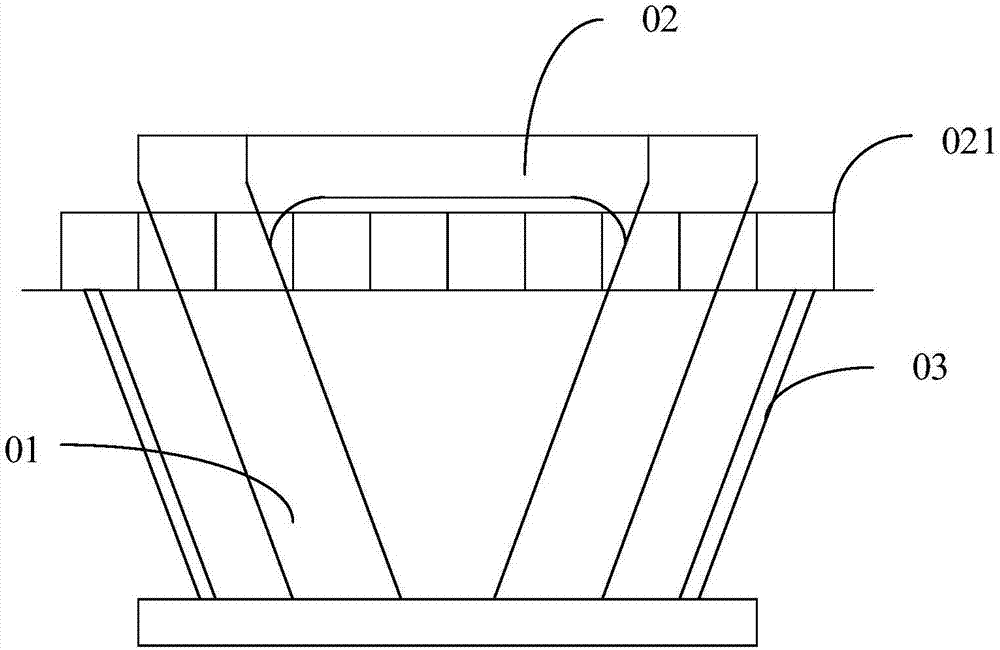

Mess tin forming process

InactiveCN107487000APlay a solid roleGuaranteed temperatureDomestic articlesPressure systemEngineering

The invention discloses a mess tin forming process. The mess tin forming process comprises the steps that S1, preheating is conducted, specifically, a plastic raw material plate is fed into a preheating mechanism at first, the upper face and the lower face of the plastic raw material plate are heated so that the plastic raw material plate can reach the pressing state, and the edges of the plastic raw material plate are not heated and adsorbed through a negative pressure system; S2, pressing forming is conducted, specifically, the preheated material plate is fed into a mold set, the mold set is provided with a plurality of forming molds arranged sequentially, the mold pressing depths are gradually increased, and the preheated material plate is gradually pressed and formed; S3, cutting is conducted, specifically, a mess tin formed through pressing is fed into a cutting mold, and excess materials of the mess tin formed through pressing are cut off; and S4, collection is conducted, specifically, the mess tin of which the excess materials are cut off is sucked away to be collected through a collection mechanism, and another negative pressure system is used for adsorption during collection. The mess tin forming process has the beneficial effects that the yield is high, and cost is reduced.

Owner:四川聚釜有盛新材料有限公司

Method for hoisting low-clearance super-long reinforcement cage into hole section by section under high-voltage line

PendingCN113756320AEnough buried depthAvoid lifting accidentsArtificial islandsExcavationsClassical mechanicsHigh tension line

The invention discloses a method for hoisting a low-clearance super-long reinforcement cage into a hole section by section under a high-voltage line. The method comprises the following steps of (a) cleaning a site; (b) assembling a reinforcement cage; (c) butting two sections of reinforcement cages; (d) positioning; and (e) hoisting section by section. The method for hoisting the reinforcement cage into the hole in a segmented mode is adopted, pile holes of different depths can be flexibly adapted, the enough reinforcement cage burying depth is guaranteed, the problem that construction is not allowed within the vertical distance range of 6 m of the high-voltage line is solved, the construction operation of hoisting the long reinforcement cage into the hole at the limited height is achieved, the hoisting weight of the single-section reinforcement cage is more effectively controlled, the accident of hoisting instability of the whole-section reinforcement cage is avoided, and the safety of constructors and equipment is guaranteed.

Owner:CHINA RAILWAY SHANGHAI ENGINEERING BUREAU GROUP CO LTD

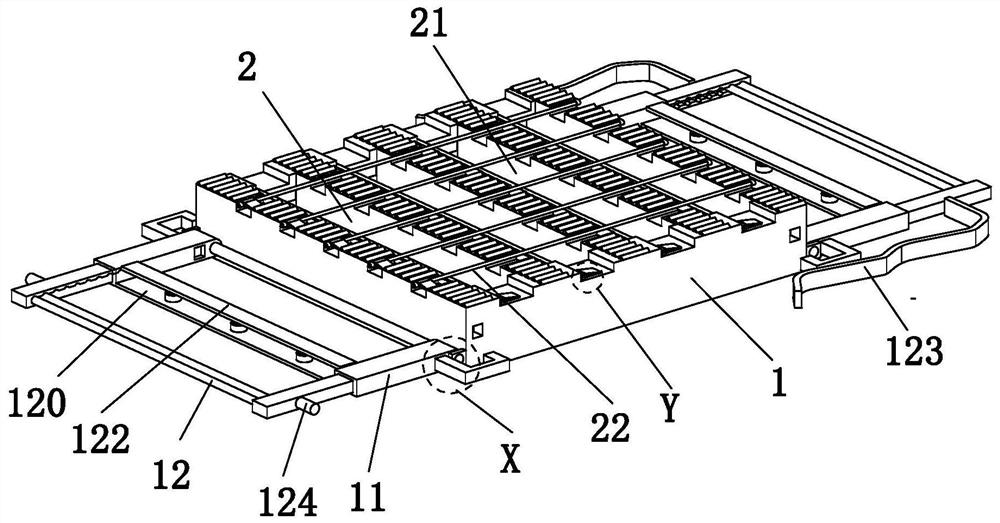

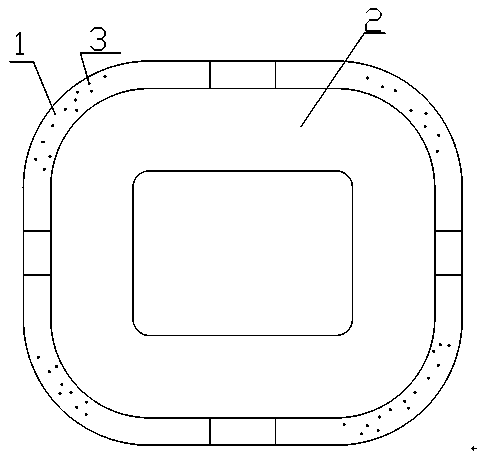

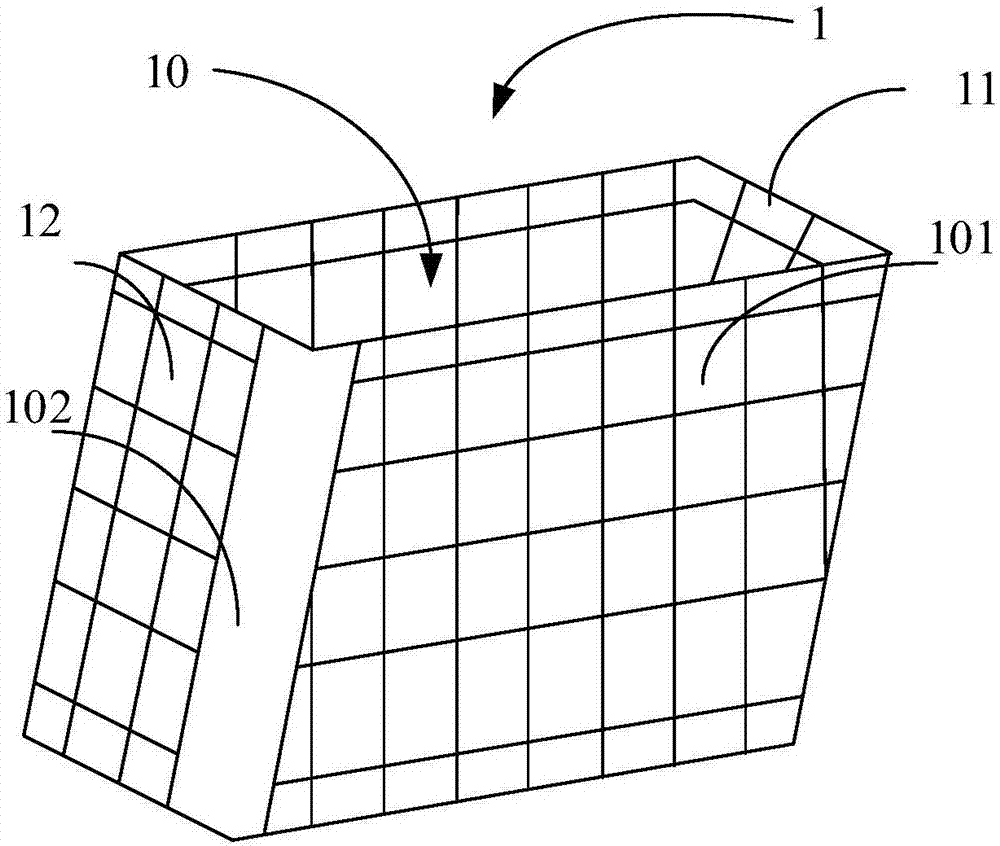

Brick tray-free packaging equipment

ActiveCN111907778AImprove stabilityImprove the stabilityPackage recyclingBuilding material packagingBrickSolid structure

The invention relates to brick tray-free packaging equipment. The brick tray-free packaging equipment comprises a concentric-square-shaped plate and an auxiliary packaging mechanism, the lower end ofthe concentric-square-shaped plate is installed on the existing working ground, and the auxiliary packaging mechanism is arranged in the concentric-square-shaped plate. The brick tray-free packaging equipment adopts the design concept of combining multiple solid structure to perform brick tray-free packaging, the auxiliary packaging mechanism wholly can realize the function of brick stacking piletray-free packaging as a whole so as to avoid the phenomenon of cost increase caused by the unrecyclability of trays after use, and the overall work flow is simplified; and meanwhile, a structure withlimiting and guiding effects is arranged for stacking of bricks so as to improve the stability of different position sections of brick stacking piles, and then the overall stability degree of the brick stacking piles is improved.

Owner:安徽阜阳富龙建筑材料有限责任公司

Frame connecting device

InactiveCN103671393APlay a solid roleSave resourcesFurniture joiningCorner anglePulp and paper industry

Owner:王鑫平

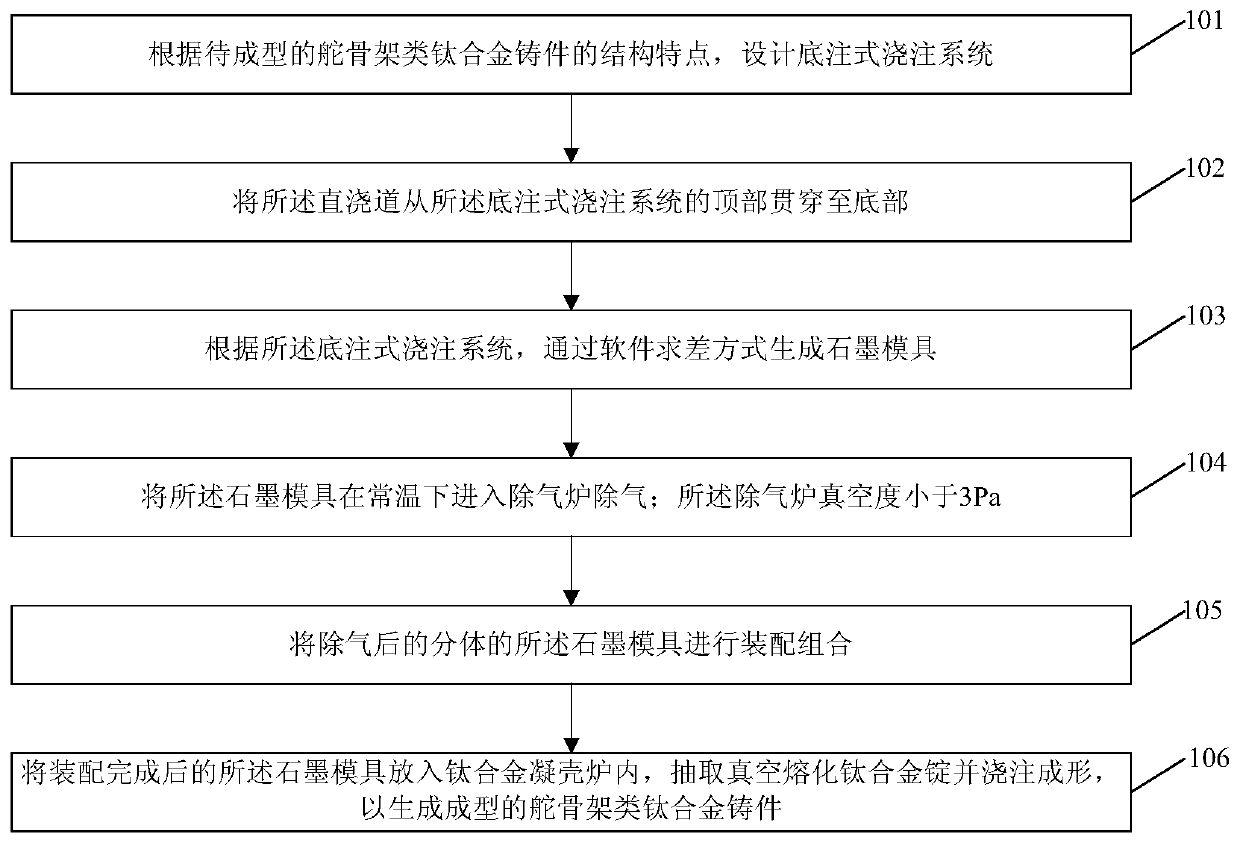

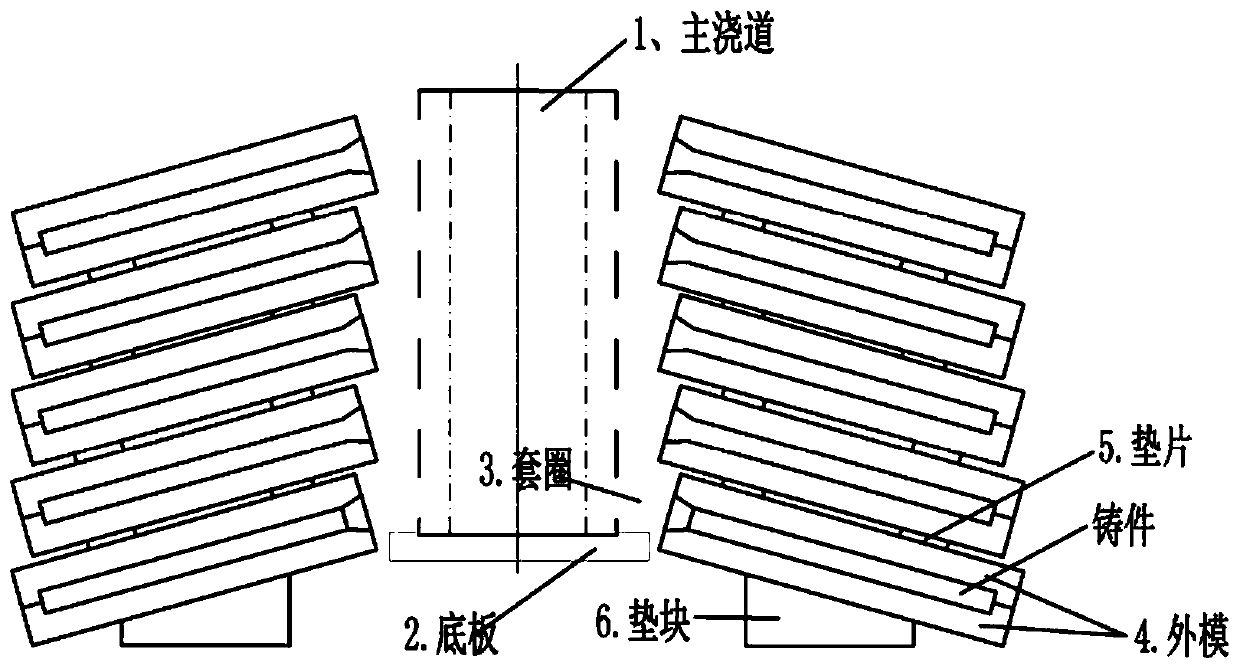

Large complex rudder framework titanium alloy casting method

The invention provides a large complex rudder framework titanium alloy casting method, which comprises the following steps of: designing a bottom pouring type pouring system according to the structural characteristics of a rudder framework titanium alloy casting to be formed, penetrating a sprue from the top of the bottom pouring type pouring system to the bottom of the bottom pouring type pouringsystem, generating a graphite mold in a software differencing mode according to the bottom pouring type pouring system, enabling the graphite mold to enter a degassing furnace for degassing at normaltemperature, the vacuum degree of the degassing furnace being less than 3 Pa, assembling and combining the split graphite mold subjected to degassing, and putting the assembled graphite mold into a titanium alloy skull furnace, conducting vacuum pumping to melt a titanium alloy ingot, conducting casting forming, and generating a formed rudder framework titanium alloy casting. The method can meetthe production requirements of large complex rudder framework titanium alloy castings, and the internal quality and the percent of pass of the large complex rudder framework titanium alloy castings are improved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

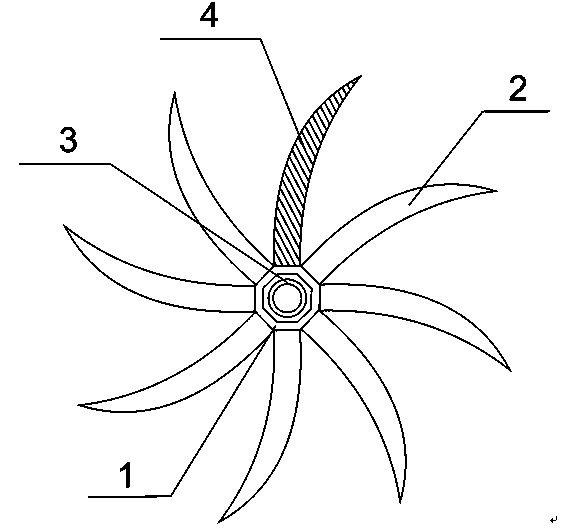

Rustproof heavy harrow blade for agricultural machine

The invention discloses a rustproof heavy harrow blade for an agricultural machine. The rustproof heavy harrow blade comprises a shaft hole and heavy harrow teeth, wherein the shaft hole is regular-octagonal, the heavy harrow teeth are uniformly welded along the circumferential direction of the shaft hole, and the spacing angle between every two of the heavy harrow teeth is the same; a fixing ring is sleeved in the shaft hole; the outer walls of the heavy harrow teeth are coated with a rustproof layer. The rustproof heavy harrow blade disclosed by the invention is simple in structure, novel in design, high in elasticity and fracture resistance, difficult to fracture, long in service life and convenient to maintain; the fixing ring is capable of playing a firm role, and the rustproof layer is capable of preventing the rustproof heavy harrow blade from being corroded by water in soil to rust after being used for a long time.

Owner:徐州睿丰企业管理咨询有限公司

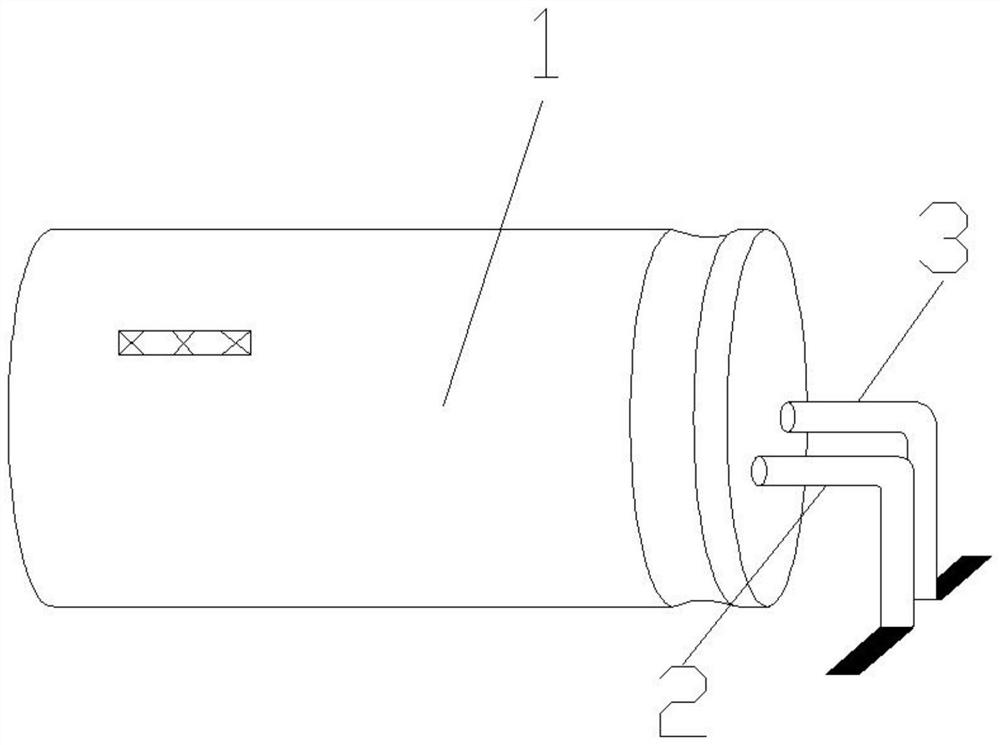

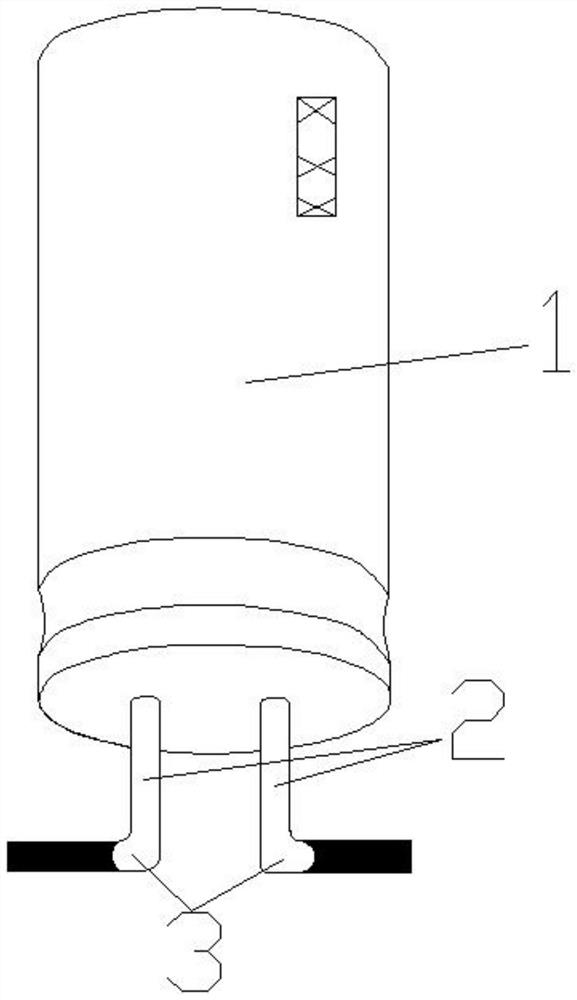

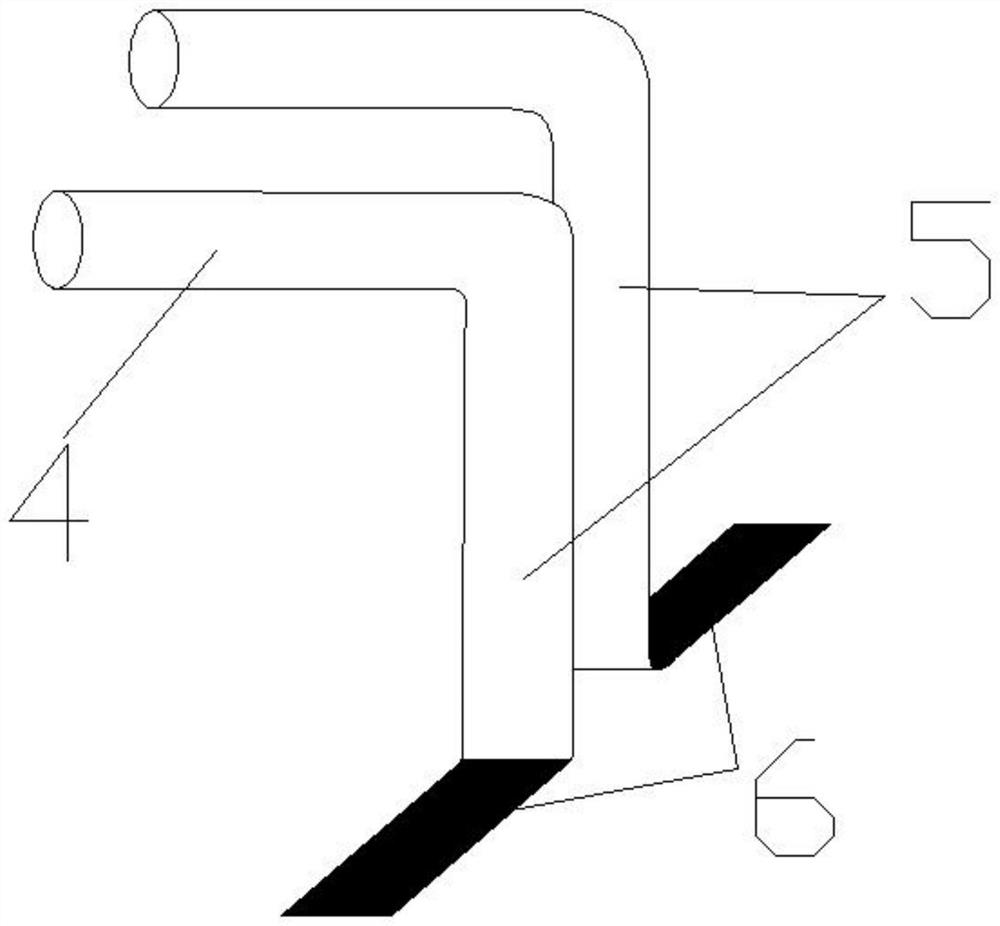

Capacitor and preparation method and installation method thereof

PendingCN114582627AAvoid breakingImprove cooling effectCapacitorsStructural engineeringMechanical engineering

The invention discloses a capacitor and a preparation method and an installation method of the capacitor, the capacitor comprises a capacitor body, a first pin and a second pin extend out of the right side end face of the capacitor body, the first pin and the second pin respectively comprise a protection pin, a heat dissipation pin and a welding pin which are the same, the length of the heat dissipation pin is larger than the radius of the capacitor body, and the length of the welding pin is larger than the radius of the capacitor body. The surface of the upper end of each welding pin is provided with a plurality of uniformly distributed through holes, each through hole is in a quadrangular frustum pyramid shape, the four side faces of each quadrangular frustum pyramid obliquely extend upwards by 30 degrees to form a circular hole channel, and the through holes and the circular hole channels are filled with soldering tin. The whole capacitor is good in heat dissipation effect, space-saving, tighter in welding, material-saving, and capable of reducing occupational diseases of workers. Potential safety hazards are reduced.

Owner:湖州新江浩电子有限公司

A compound processing machine for producing and forming honeycomb panels

ActiveCN113290945BImprove composite molding qualityRealize multi-directional clampingPaper/cardboard articlesCircular discHoneycomb

The present invention relates to the field of honeycomb panel production, in particular to a compound processing machine for producing and forming honeycomb panels, including a clamping mechanism and a pressing mechanism. The clamping mechanism is placed on the ground, and a pressing mechanism is arranged at the left end of the clamping mechanism. The fixing mechanism includes the vertical frame, the disc, the No. 1 electric push rod, the splint, the limit block, the stopper, the connecting plate, the No. 1 electric slider, the ear plate, the support plate, the support rod, the connecting plate, the bottom block and the No. 2 Electric slider, the invention adopts the design concept of multi-directional limit, the processing machine as a whole can not only realize the multi-directional clamping of the honeycomb core to avoid offset or deformation of the honeycomb core, but also has the ability to flip the honeycomb core to accept double The function of surface composite panel processing, and the pressing mechanism set at the same time can suppress the relationship between the panel and the honeycomb core, thereby achieving the purpose of improving the bonding tightness between the honeycomb core and the panel, and improving the composite molding quality of the honeycomb panel.

Owner:JIANGSU HAIDEMAN BUILDING MATERIALS IND

Flaky inorganic filler heavy-duty anti-corrosion epoxy composite coating with multi-layer structure

InactiveCN113637390AImprove surface reactivityIncrease elasticityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceCrazing

The invention discloses a flaky inorganic filler heavy-duty anti-corrosion epoxy composite coating with a multi-layer structure, and relates to the technical field of anti-corrosion coatings. The heavy-duty anti-corrosion epoxy composite coating is prepared from a component A and a component B according to a mass ratio of 3:(1.0-1.4). The component A is prepared from the following raw materials in parts by weight: 55 to 68 parts of bisphenol A type epoxy resin E44, 23 to 29 parts of butyl glycidyl ether, 0.5 to 0.8 part of graphene, 6 to 15 parts of flaky inorganic filler, 2 to 6 parts of aerogel nano powder and 0.35 to 0.55 part of a de-foaming agent. The component B is a T31 curing agent. According to the invention, the sheet-shaped inorganic filler and the aerogel nanopowder are added into the epoxy resin, and the flaky inorganic filler and the aerogel nanopowder can coexist in the epoxy resin and can be laid layer by layer in the epoxy resin to form a compact elastic barrier, thus the external stress resistance of the epoxy composite coating is improved, and the coating does not easily generate gaps or cracks, so that the structural integrity of the coating can be maintained, and the epoxy resin has excellent corrosion resistance.

Owner:ANHUI XINDALU SPECIAL PAINT CO LTD

Aluminum decorative cabinet convenient to install

Owner:宁波米高家具有限公司

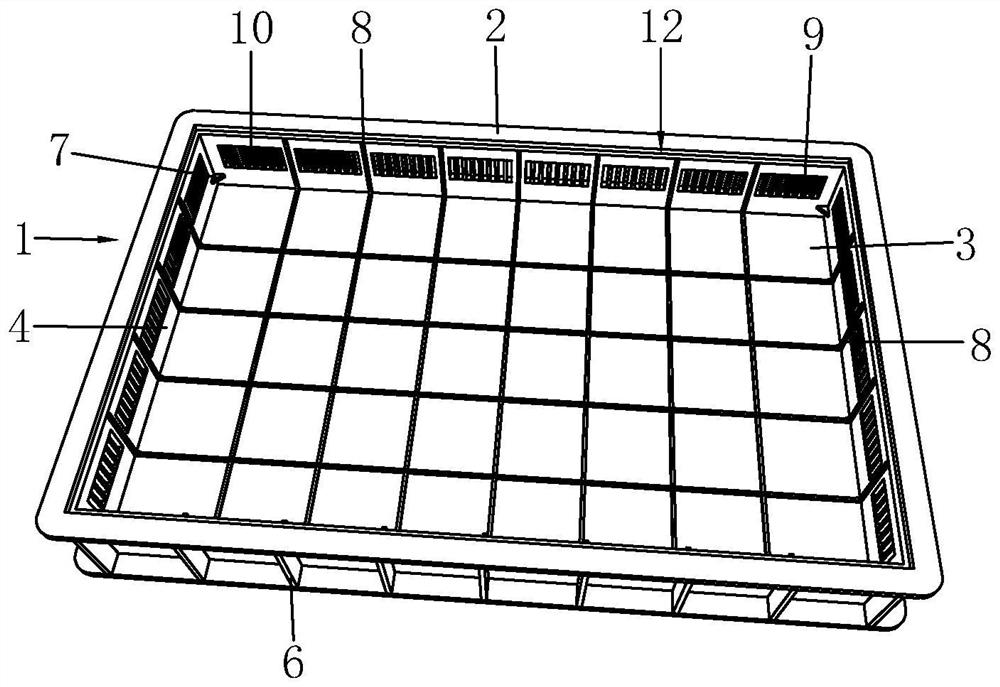

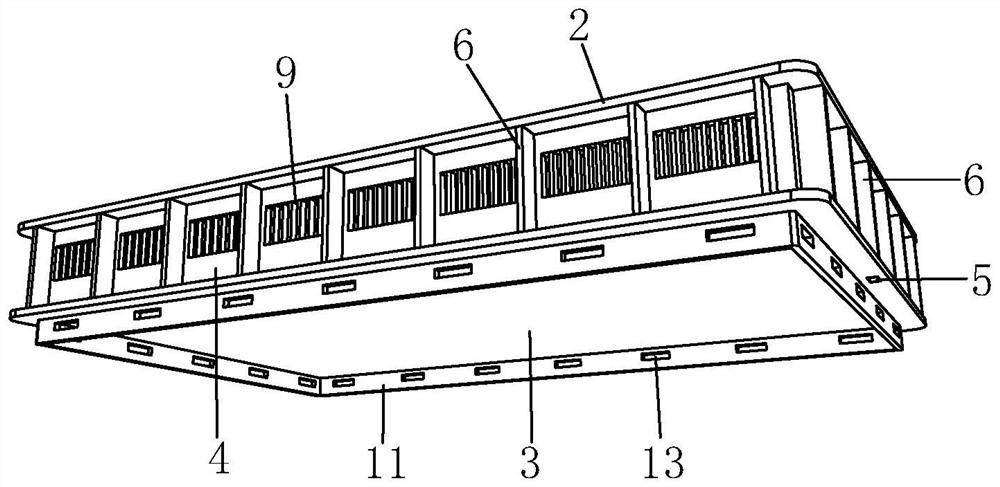

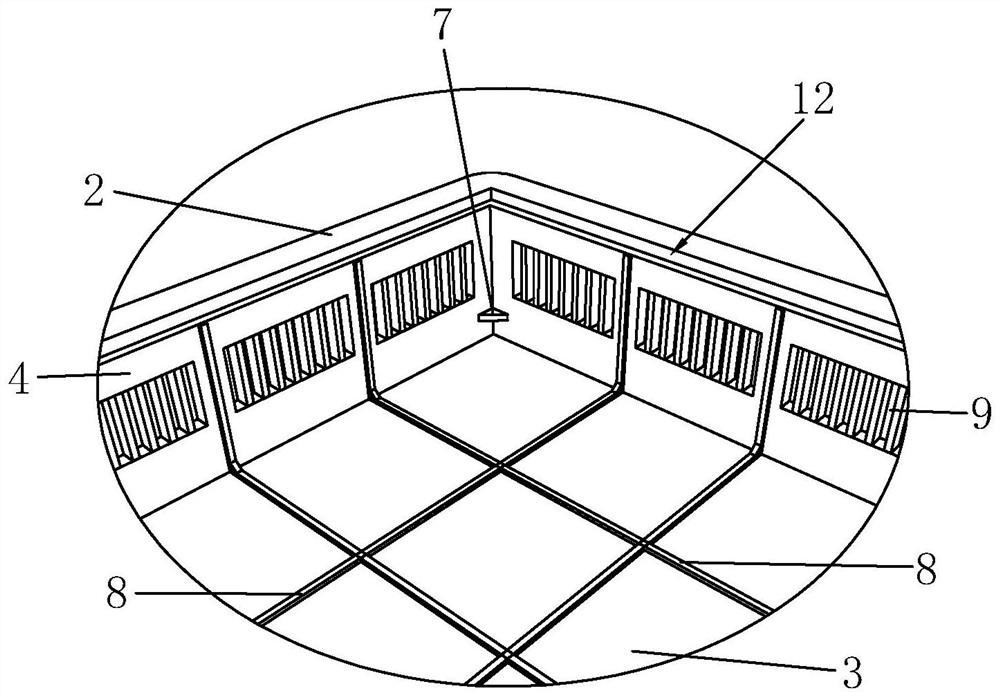

Silkworm frame for industrial silkworm breeding and storage method thereof

ActiveCN114403103AImprove structural strengthImprove bearing strengthRigid containersExternal fittingsStructural engineeringMechanical engineering

The silkworm frame comprises a frame body, a ventilation groove is formed in the side face of the frame body, an annular protruding strip is arranged at the bottom of the frame body, a stepped groove corresponding to the annular protruding strip is formed in the inner side of the top of the frame body, the height of the annular protruding strip is larger than the depth of the stepped groove, and ventilation holes are formed in the side face of the annular protruding strip; the storage method comprises the following steps: (a) stacking the frame bodies; (b) an upper arm; (c) stacking the pedestals; and (d) combining. The silkworm frame is novel in structure, reliable in stacking and comprehensive in ventilation, the survival rate of young silkworms is increased, the storage method is easy to operate and low in difficulty, the silkworm frame is divided into independent units, the independent units do not affect one another and are clear, management is convenient, the space utilization rate is high, the storage number is large, the problems of deformation and damage caused by stacking are solved, and the perfectness rate of the silkworm frame is guaranteed.

Owner:SHENGZHOU MOSANG HI TECH CO LTD

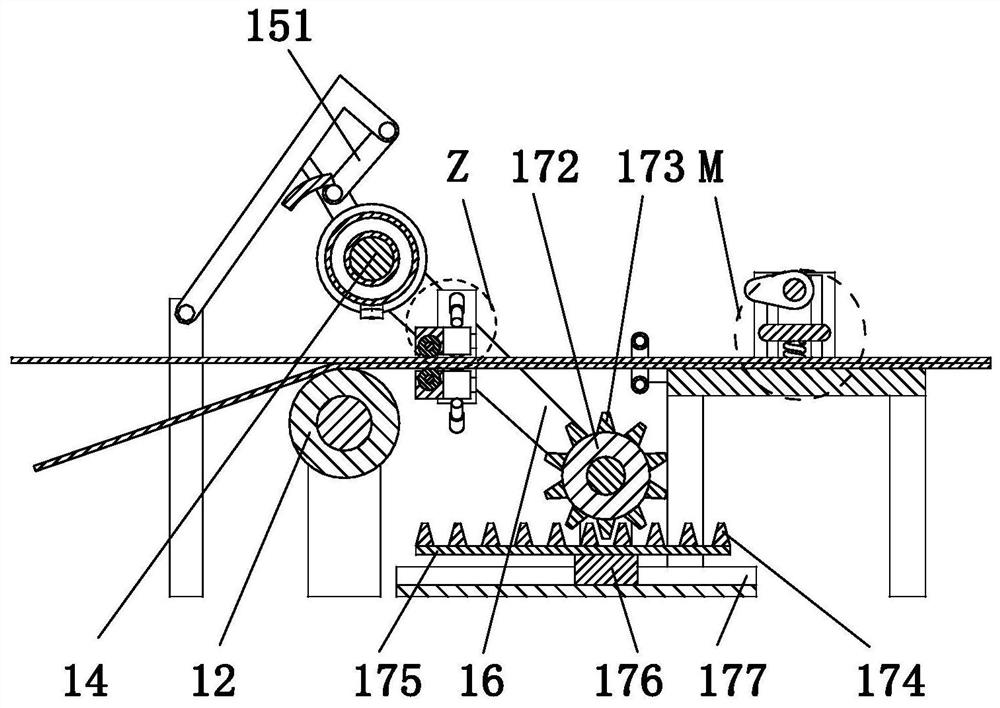

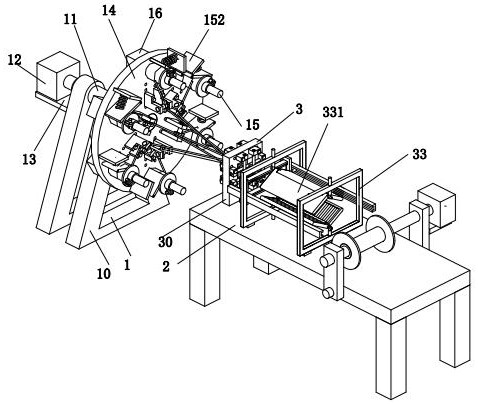

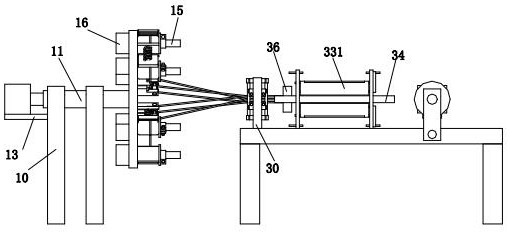

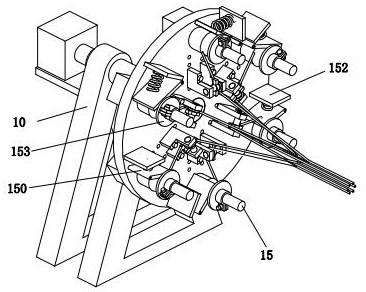

Automatic conducting wire stranding equipment

ActiveCN113963860APlay a limiting roleImprove stranding effectCable/conductor manufactureStructural engineeringMechanical engineering

The invention relates to the field of conducting wire processing, in particular to automatic conducting wire stranding equipment, which comprises a stranding mechanism, a workbench and an auxiliary stranding mechanism, wherein the stranding mechanism is arranged on the ground, the workbench is arranged on the right side of the stranding mechanism, and the auxiliary stranding mechanism is installed on the upper end surface of the workbench. According to the invention, the stranding mechanism can adjust the wiring angle of the conducting wire according to the thickness degree of the conducting wire, and the wiring angle affects the stranding tightness of the conducting wire, so that the overall application range of the equipment is further expanded; the auxiliary stranding mechanism can limit the conducting wire, so that the stranding effect of the conducting wire is further improved, and the abrasion degree of the surface of the conducting wire can be reduced; and the rotating plate, the spring and the extension plate can integrally press the conducting wire coil, so that the probability that the conducting wire coil is loosened is reduced.

Owner:深圳市方泰设备技术有限公司

Adjustable slurry flattening device for coating white board paper

PendingCN113957745APlay a guiding roleAvoid deformationApplied substance rearrangementCircular discWater filter

An adjustable slurry flattening device for coating white board paper comprises a mounting frame, a first motor is arranged on the mounting frame, a first electric push rod is arranged on the first motor, a top face of a triangular plate is arranged at the outer end of an arc-shaped rod, a first disc is arranged in the mounting frame, a second disc is arranged below the first disc, a moving block is arranged in a second through groove, and a second motor is arranged at the bottom of the mounting frame. A push plate device is arranged on one side of the second disc, a conveying device is arranged on the other side of the second disc, water filtering holes are formed in the second disc, gauzes are arranged in the water filtering holes, and a flow guide device is arranged at the bottom of the mounting frame. According to the device, slurry is flattened and extruded through deformation of a triangular plate, the problem of dead angles in the flattening process is avoided, redundant materials can be discharged through a through hole and recycled, when the slurry is extruded, the moving block and the second disc rotate to apply a rotating force to the bottom of the slurry, moisture in the slurry is further removed, the slurry can be solidified through a first channel, and the slurry is prevented from deforming.

Owner:江苏京环隆亨纸业有限公司

An outdoor intelligent high-voltage metering box

InactiveCN103427348BSimple and reliable structurePlay a solid roleSubstation/switching arrangement detailsLocking mechanismEngineering

The invention discloses an outdoor intelligent high-voltage metering box comprising a box body and electrical elements disposed in the box body. The box body comprises two side doors, two front doors, a base, a back and a top cover. A partition is disposed inside the box body and divides the box body into a PT chamber and a feeder chamber. Each of the PT chamber and the feeder chamber is provided with a mounting plate. The mounting plates are communicated with both the PT chamber and the feeder chamber. The box body further comprises a door lock mechanism and a linkage lock mechanism, wherein the door lock mechanism controls the front doors to open and close and the linkage lock mechanism synchronously locks and unlocks the side doors. The outdoor intelligent high-voltage metering box has the advantages that the inside of the box body is divided into the PT chamber and the feeder chamber, so that metering is allowed, a feeder circuit can make and break, and users can be controlled effectively by the power supply department; the door lock structure is simple and reliable; an inset padlock is used for compact position locking, the fixation function of the padlock is given to play, and burgling is difficult; the linkage lock mechanism allows the side doors to be synchronously locked and unlocked when the front doors are opened and closed.

Owner:SHANGHAI FIRST ELECTRICAL GROUP

A structural drawing seam applied to aluminum formwork and its construction technology

ActiveCN111827671BEasy filling workPlay a solid roleForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksClassical mechanicsStructural engineering

Owner:深圳市旭生骏鹏建筑工程有限公司

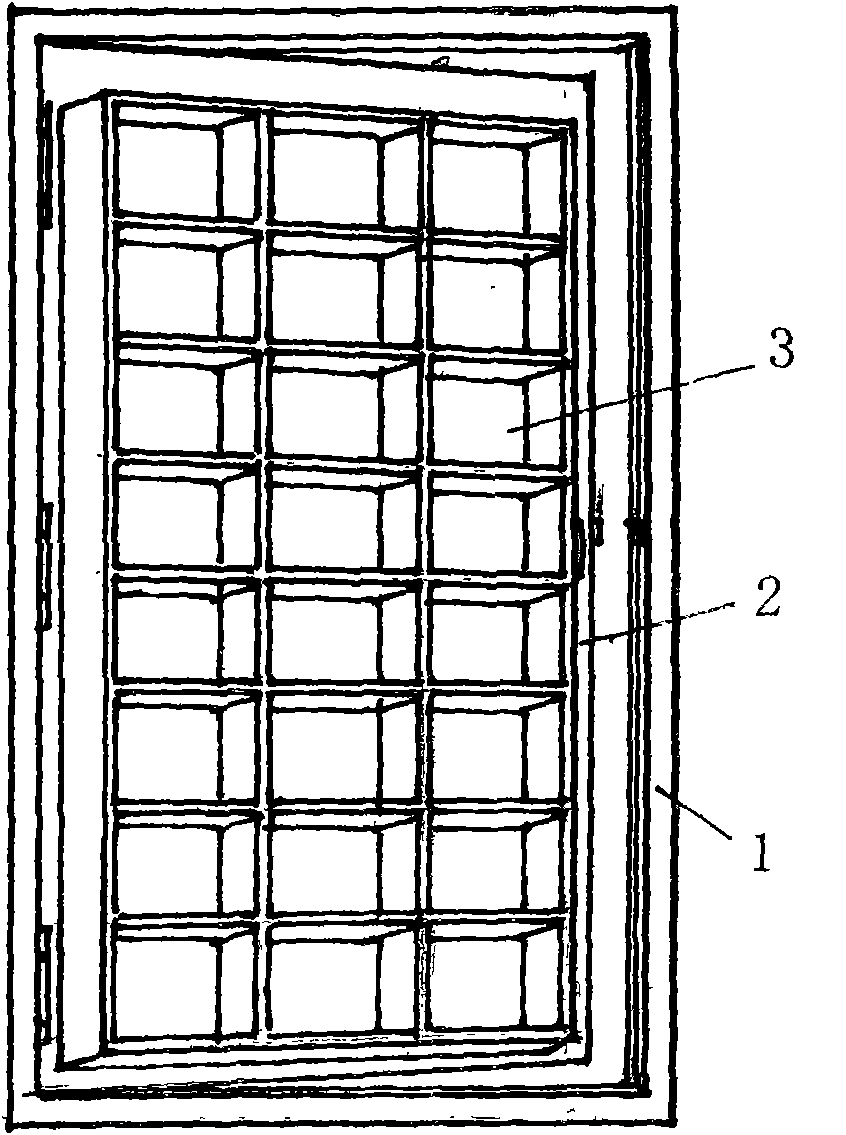

Security door provided with storage locker

The invention provides a security door provided with a storage locker. The storage locker which is also used as a reinforcing rib is arranged on the inner face of an opening-closing door in a door frame of the security door, and the storage locker not only can be used for storing objects or shoes, but also can be used for playing a role of firming the entire opening-closing door, and therefore the door body is more solid and safer.

Owner:李白翎

Inclined type pier body pouring system

PendingCN107386114APlay a solid roleGuaranteed aestheticsBridge structural detailsBridge erection/assemblyEngineeringTower

The invention provides an inclined type pier body pouring system. The inclined type pier body pouring system comprises a concrete formwork, a supporting device and a tensile force device. The concrete formwork comprises a plurality of formwork units which are enclosed to form a pouring cavity, wherein at least one formwork unit which is taken as a pressure side face is subjected to maximum inclined pressure, and a side face opposite to the pressure side face is defined as a tensile force side face; the supporting device abuts against the outside of the pressure side face; and the tensile force device is arranged in the concrete formwork and comprises horizontal pulling rods and diagonal pulling rods, wherein the horizontal pulling rods are horizontally connected to the pressure side face and the tensile force side face, and the diagonal pulling rods are connected with bottom parts of the pressure side face and the tensile force side face. According to the inclined type pier body pouring system, through implementing for the scheme, safety of construction in inclined type pier body or tower column construction can be improved, and construction cost can be reduced.

Owner:ROAD & BRIDGE SOUTH CHINA EINGINEERING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com