Method for hoisting low-clearance super-long reinforcement cage into hole section by section under high-voltage line

A technology of super-long steel cages and steel cages, which is applied in excavation, underwater structures, buildings, etc. It can solve the problems of insufficient rigidity of steel bars connected by hooks, long time-consuming installation of alignment, and high requirements for hoisting technology, so as to achieve convenient and fast Arrangement, avoid lifting instability, high material utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

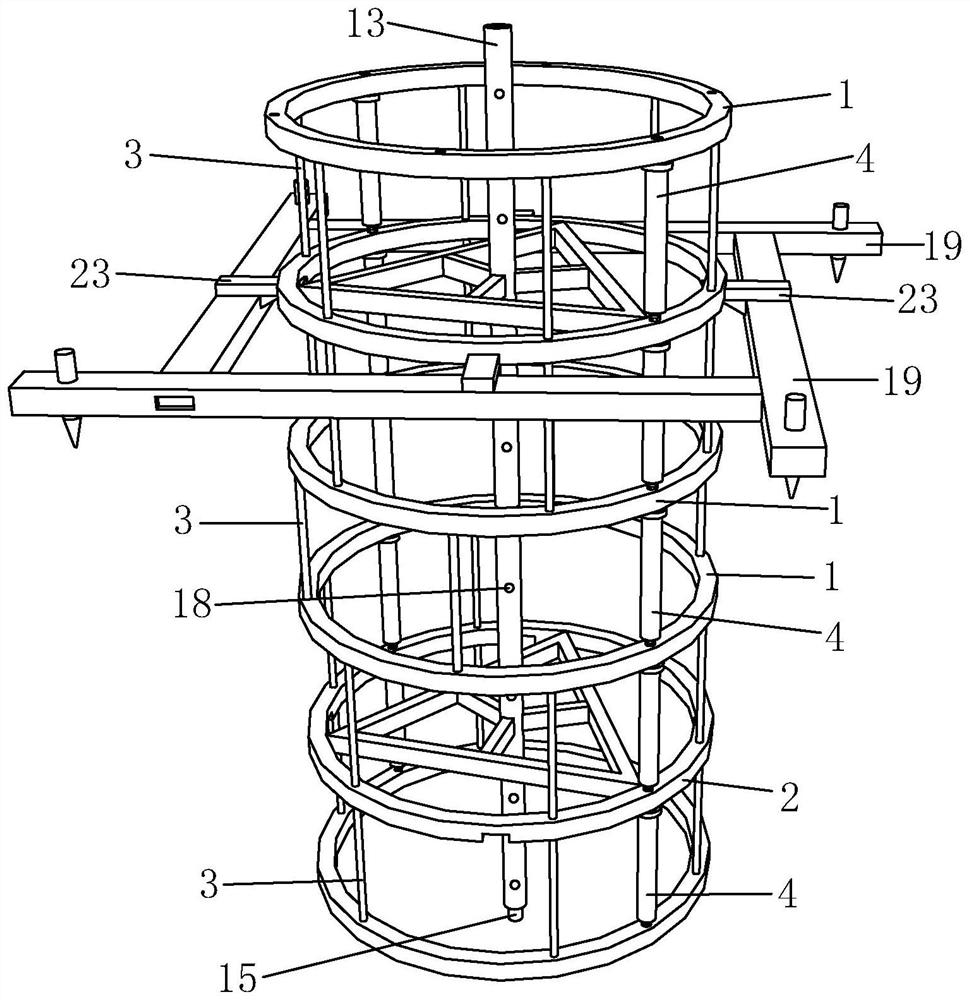

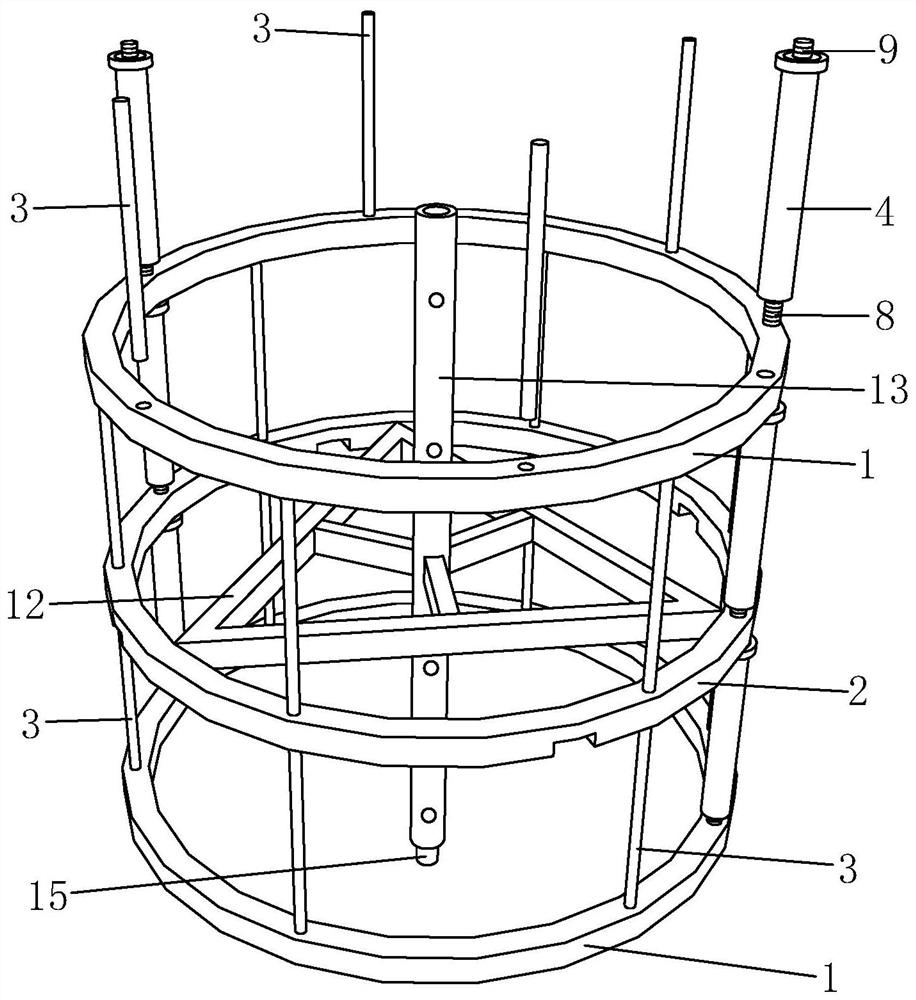

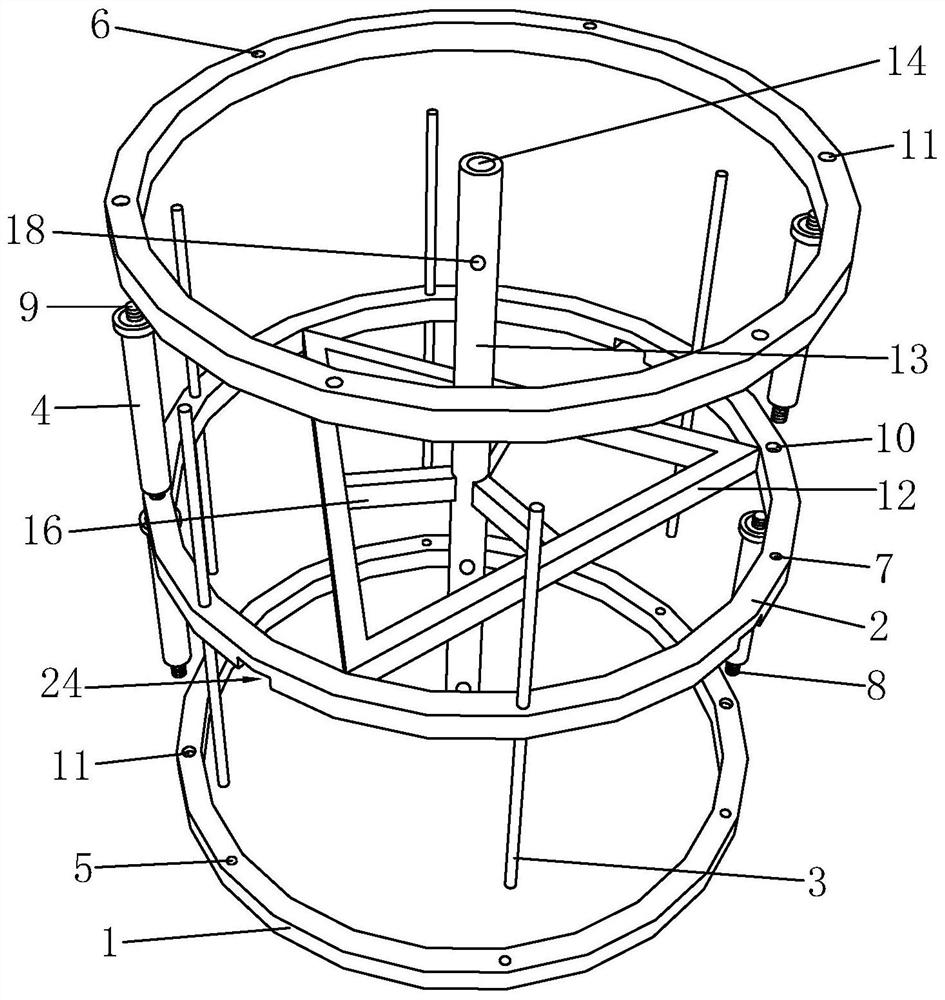

[0043] like Figure 1 to Figure 5 As shown, it is a method for segmentally hoisting a low-clearance super-long reinforcement cage into a hole under a high-voltage line of the present invention, including the following steps:

[0044] (a) Site cleaning: Clean up the garbage around the steel casing, level the ground around the casing, and tamp the soil to provide a good construction environment for the subsequent support brackets and ensure the construction quality of the support brackets.

[0045] (b) Assembling the reinforcement cage: the reinforcement cage consists of a side ring 1, a middle ring 2, a straight steel bar 3 and a connecting rod 4, the middle ring 2 is set between two side rings 1, and the top surface of the side ring 1 is set There is a first positioning concave hole 5 corresponding to the straight steel bar 3, a second positioning concave hole 6 corresponding to the straight steel bar 3 is provided on the bottom surface of the side ring 1, and a second positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com