Rigging placing rack for large equipment hoisting

A technology for large-scale equipment and racks, applied in packaging and internal accessories, etc., can solve problems affecting rigging assembly, affecting hoisting time, hidden dangers, etc., to reduce hoisting time, reduce use risks, and prevent hoisting accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

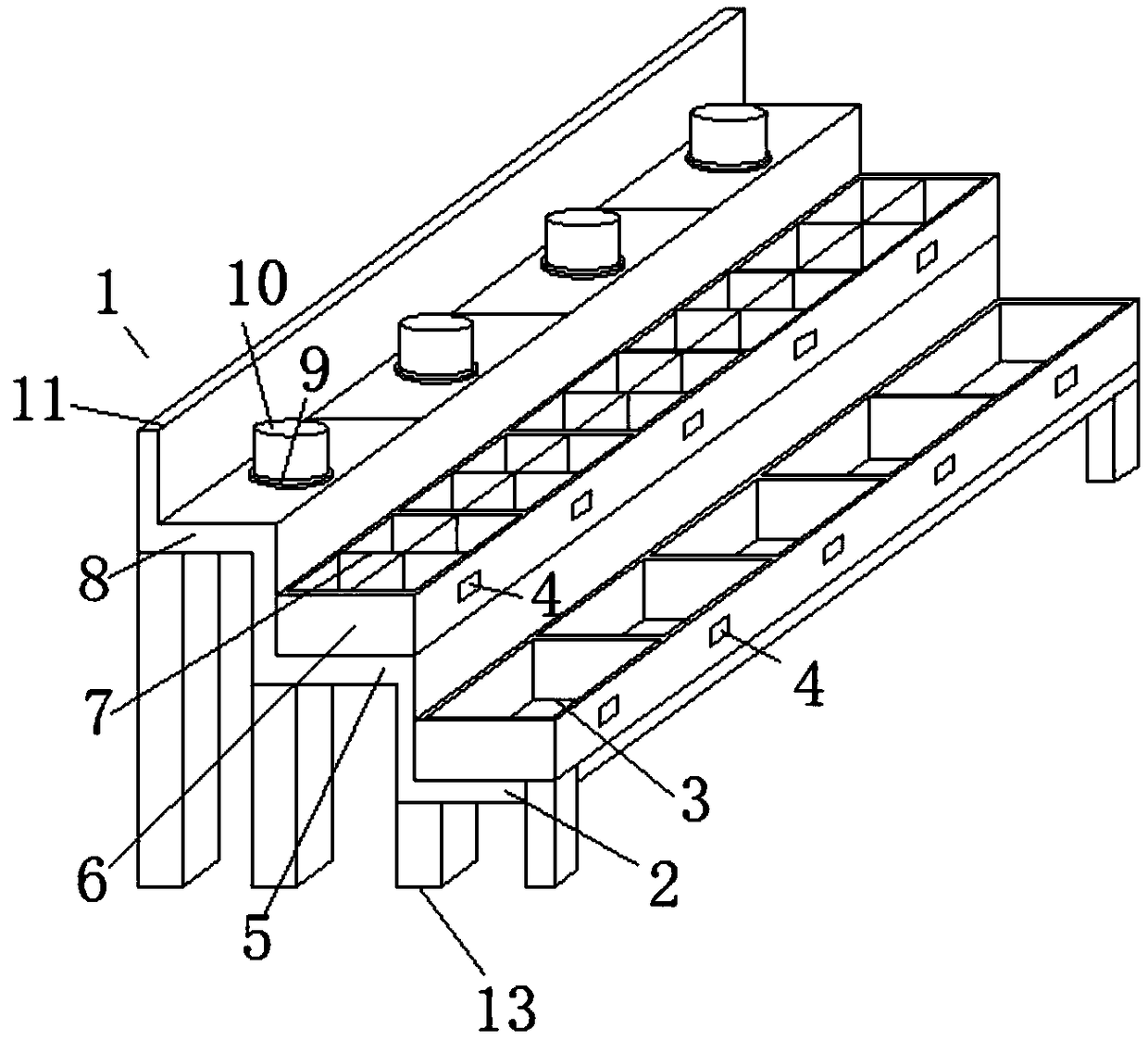

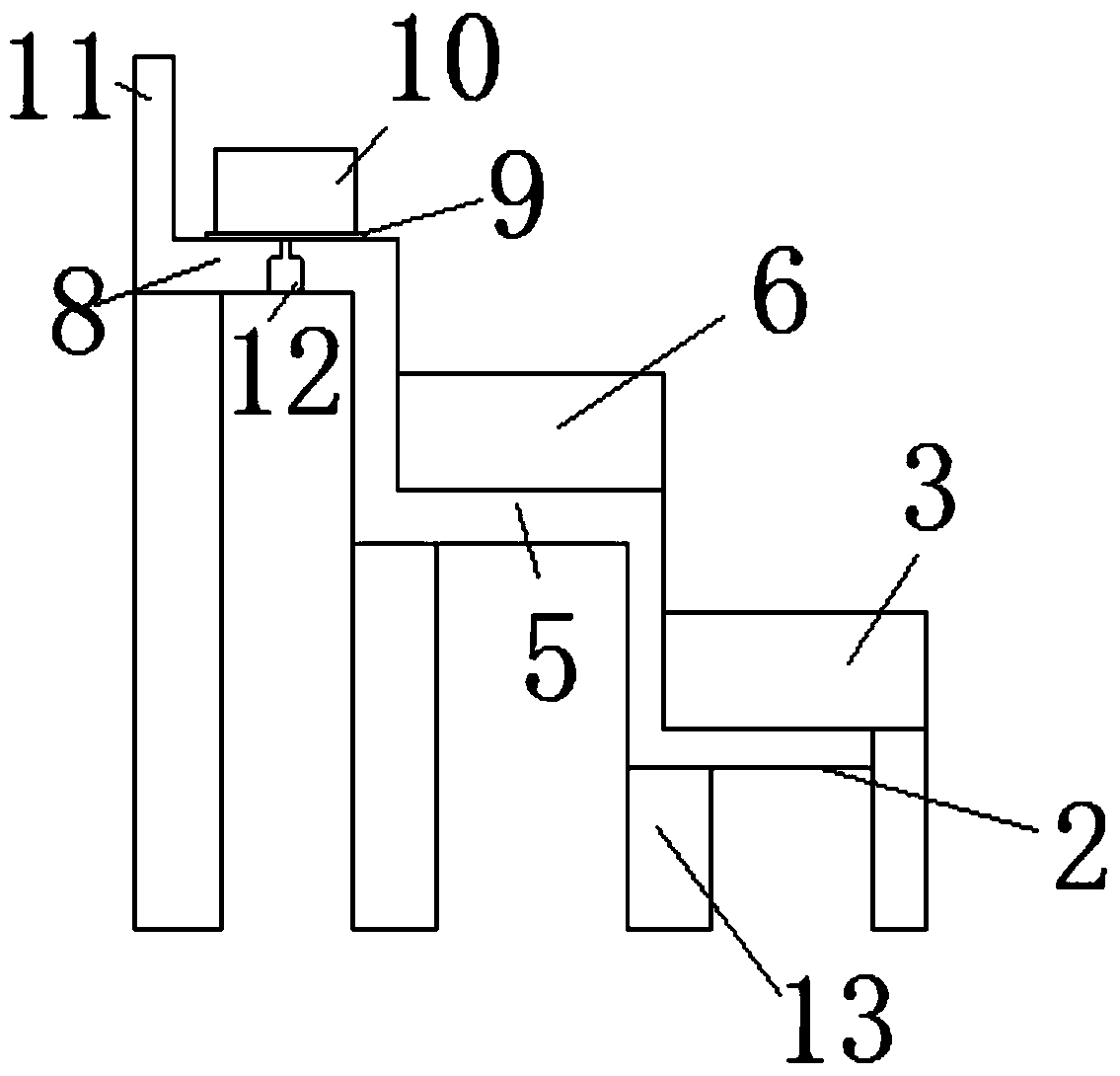

[0018] Such as Figure 1-2 As shown, the rigging rack for large-scale equipment hoisting includes a rack body 1, which includes a first level 2, and a number of storage boxes 3 are connected to the first level 2, and the front side of the storage box 3 is connected There is a nameplate 4, the second level 5 is connected to the upper edge of the first level 2 back plate, the shackle storage box 6 is connected to the second level 5, the shackle storage box 6 is equipped with a partition plate 7, and the second level 5 back A third level 8 is connected to the upper edge of the board and a turntable 9 is connected to the upper side of the turntable 9 is connected to a winding column 10, the rear end of the third level 8 is connected to a rear baffle 11, and a number of motors 12 are provided in the third level 8. The bottom ends of the first tier 2, the second tier 5 and the third tier 8 are all connected with a supporting column 13 and the output end of the motor 12 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com